Page 1

Contents: Page:

Home

Preface and General Safety Information

Part 1: Operat ing Instruc tions Cl. 8967

1. Product Description

1.1 Sho rt Description an d Pro per U se . . . . . . . . . . . . . . . . . . . . . 5

1.2 Sub -Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Technic al Specif icat ion . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Operating Elements and Their Function

2.1 Elements at the S ewin g Head . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Elements on the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Operating the Sewing Machine

3.1 T hreadin g the Nee dle Th read . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Winding the Bobbin Thread . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Cha ngin g the Bobbin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Setting the Bobbin Thread Tension . . . . . . . . . . . . . . . . . . . . . 14

3.5 Setting the Thread Regulator . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Operating the Frame

4.1 Fol ding Down the Table Top . . . . . . . . . . . . . . . . . . . . . . . . . 16

GB

5. Maintenance

Contents:Pag e:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page 2

Page 3

1. Product Description

1.1 Short Description and Proper Use

The special sewing machine 8967 is a single needle-double lock stitch free-arm

machine with l ower transpor t without stroke and an upper t ransport with al ternating

pressure feet.

The machine is designed and may only be used for sewing of textile material or leather.

1.2 Sub-Classes

8967-160180 Execution without thread trimm er,

8967-160182 Execution with electromechanical

1.3 T echnical Specif ication

Needle system: System 2134-35

Max. number of stitches:

dependent on pressure foot stroke 2000, 3000 rpm

and stitch length

Maximum stitch length:

forward (F), reverse (R) 6 (F); 6 (R) mm

Pressure foot stroke: 2 - 7 mm

Maximum clearance under

the pressure feet:

When sewing: 10 mm

When raised in needle high posit i on: 17 mm

Maximum thread thickness:

Cotton: 9/3

Synth. endless: 15/3 Nm

Core thread (poly-cotton): 20/3 Nm

Through-feed area: 281 x 135 mm

Free arm diameter 47 mm

Operating pressure: 6

Line pressure: 7 - 10 bar

Air consumpti on per work cycle: 0.15 NL

Pressure foot lift electropneumatic.

thread trimmer for needle and

bobbin thread, electropneumatic,

automatic interlock and pressure foot lift.

+

/- 0.5 bar

5

Page 4

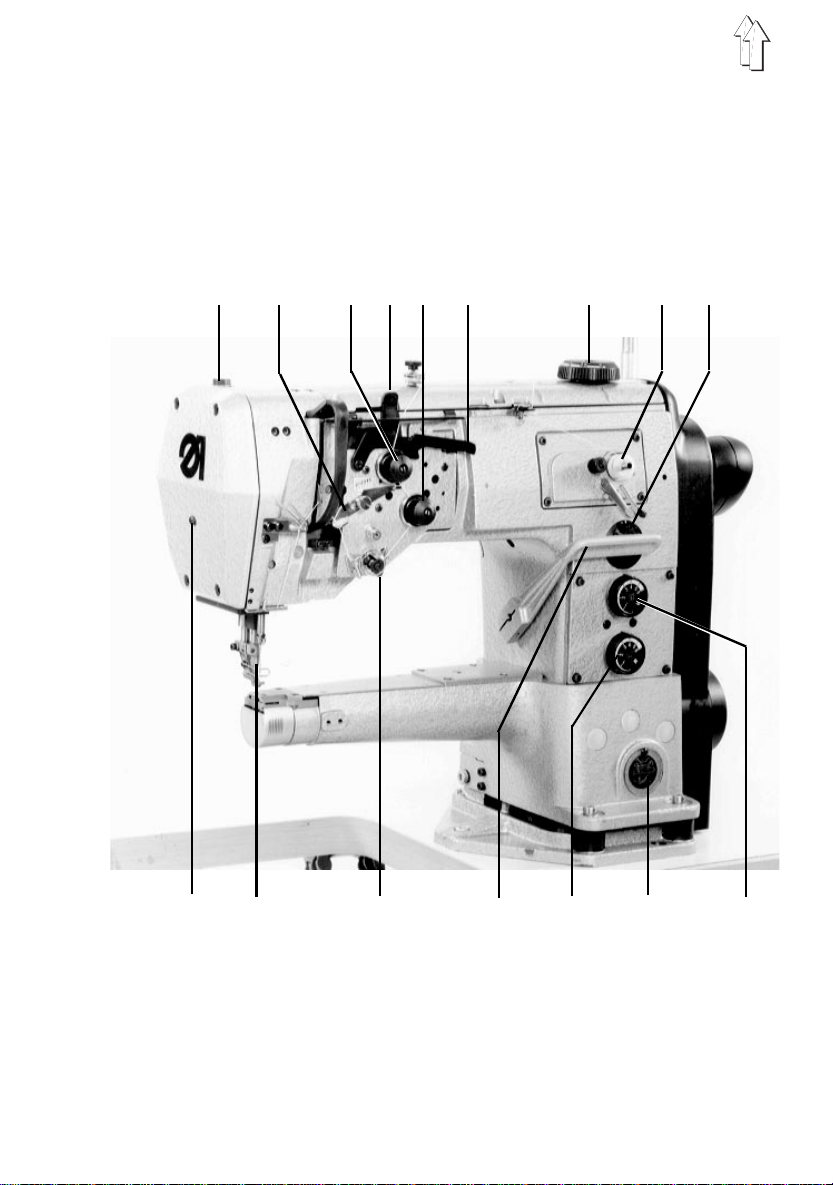

2. Operating Elements and Their Function

2.1 Elements at the Sewing Head

Element Function

1 Pressure foot screw - This screw is screwed in completely at the factory

2 Thread regulator - Setting the correct thread quantity for different

3 Control knob - Setting auxiliary tension for the needle thread.

4 Lever - Opening the main needle thread tension and

5 Control knob - Setting the main tension for the needle thread

6 Lever - Switching the auxiliary tension on and off.

7 Adjustment wheel - Setting the pressure foot stroke.

8 Lever - Bobbin thread winding device

9 Viewing glass with - Show the oil level in the reservoir.

11 fill opening The oil level must be kept above "MIN".

10 Control knob - Setting the stitch length for sewing forwards.

12 Control knob - Setting the stitch length for sewing in reverse.

13 Hand le ver - Continuous ad j ustment of the s titch length between

14 Lever - Determining the status of the main needle thread

15 Needle

and the position may not be changed.

material thicknesses, sewing yarns and stitch lengths.

auxiliary needle thread tension.

Pull the lever to the right before switching over in order to free it from its catch.

If necessary fill Esso "SP NK 10" up to the "MAX"

marking in the reservoir.

the set forward and revers e stitch length s.

tension during pressure foot lift.

Lever up: Tension open.

Lever down: Tension closed.

Caution!

Be sure to turn off the main switch when threading or

replacing the needle.

Risk of Injury.

16 Knob - Arresting the pressure foot in the raised position.

6

Page 5

12

3

56 7

4

9

8

1213141516

11

10

7

Page 6

2.2 Elements on the Frame

Element Function

Frame Type MG 55-3

1 Main switch - Switching the machine on and off

2 Pedal

Rest position - No function

Position forward - Sewing with desired rpm

Position "hal f back" - Raise pressure foot when machine at rest

Position "fu l l back" - Thread trimming and raise pressure foot

3 Screw - Setting the Table Top Height.

Frame Type MG 56-2

4 Main switch - Switching the machine on and off

5 Pedal

Rest position - No function

Position forward - Sewing with desired rpm

Position "hal f back" - Raise pressure foot when machine at rest

Position "fu l l back" - Thread trimming and raise pressure foot

6 Lever - Securing th e raised table top half

7 Brace - For supporting the lowered t able top in the

horizontal position.

8

Page 7

76 5 4

MG 55-3

123

MG 56-2

9

Page 8

Maintenance Unit

8 Air filter and - Bef ore the water level reaches th e filter, screw in

water trap screw 7 far enough to drain water.

9 Pressure regul ator - To set to 6 bar pu l l t he bushing 10 up and turn appropri ately.

not

interrupt t he compressed ai r supply.

Do

89

10

Page 9

3. Operating the S ewing Ma chine

3.1 Threading the Needle Thread.

Caution Risk of Injury !

Turn off the main switch before threading.

–

Thread the needle thread as shown in the illustration.

11

Page 10

3.2 Winding the Bobbin Thread

–

Place the bobbin 4 on the bobbin winder 3.

–

Pull the thread through the guide 1 and the tension 2.

–

Wind the thre ad approx. 5 x clock wise around the

bobbin core a nd tear off at th e t hread clamp 6.

–

Press the bobbinr lever 5 into the bobbin.

–

Sewing

The bobbin wind er lever stops the procedure when

the bobbin is full.

1

2

3

4

5

6

12

Attention !

If the thread is not to be wound during sewing, the

pressure foot must be arrested in the raised position and

the pressur e f oot stroke set at the smallest value.

Page 11

3.3 Changing the Bobbin

3

7

6

1

2

Caution Risk of Injury!

Turn off the main switch before changing the bobbin.

–

Bring the needle into the hi ghest position

–

Pull the covering cap 1 from the free-arm.

–

Remove the bobbin housing 2 with bobbin 3. Hereby

raise the bobbin case flap 4 as far as possible.

–

Remove the bobbin

–

Insert a full bobbin in such a way that, when the

thread is pulled off, it turns in the direction shown in

the illustration.

–

Pull the thread through the slit 7, under the spring 6

to the hole 5.

–

Insert the bobbin case with bobbin as far as possible

into the bobbin case base and release the bobbin

case flap.

For security press in the bobbin case with your index

finger and make sure that the bobbin case flap has

caught.

–

Push on the covering cap 1.

4

5

13

Page 12

3.4 Setting the Bobbin Thread Tension

2

1

Caution Risk of Injury!

Turn off main switch.

–

Bring the needle into the highest position

–

Pull the covering cap from the free-arm

–

Remove the bobbin housing with bobbin. Hereby

raise the bobbin case flap as far as possible.

–

Carefully turn the regulating screw 1.

To the right = Increase thread tension

To the left = Decrease thread tension

14

The initial setting for the tension spring 2 is:

The bobbin housi ng must slowly lower through its

own weight. ( see sketch)

–

Insert the bobbinn case with bobbin as far as

possible into the bobbin case base and release the

bobbin case flap. For security press in the bobbin

case with yo ur index finger and make sure that the

bobbin case fl ap has caught.

Page 13

3.5 Setting the Thread Regulator .

1

With the thread regulator the needle thread quantity

necessary fo r stitch formati on can be regul ated.

The setting is dependent on the stitch length, material

thickness an d the yarn characteristics.

Only a precisely set thread regulator assures an optimal

sewing resu l t.

The needle thread loop should glide over the hook

without excess with little tension.

In the "0" setting the greatest thread quantity is released,

such as is requi red by particularly great stit ch length and

very thick material.

Adjustment:

–

Loosen screw 1 .

–

Change the position of the thread regulator

appropriately.

–

Retighten screw 1.

Note

With a correct setting the thread check spring is pulled

approx. 1 mm down from its upper end position when the

needle thread loop passes the maximum hook

circumference.

The 1 mm dimension is a guideline. Depending on the

thread check spring tension it can be greater or smaller.

15

Page 14

4. Operating the Frame

4.1 Folding Down the Table Top (only F rame MG 56-2)

16

3

1/ 2

Caution Risk of Injury!

Hold the table top with both hands when pulling down.

–

Release the table top fasten ers 1 and 2 under the

table top and f astener 3 on the left frame leg.

–

Pull down the table top with both hands as shown in

the illustration.

–

Lock the diagonal brace 4 into t he mounting.

–

Fold up the table top in the reverse order.

4

Page 15

5. Maintenance

Caution Risk of Injury!

Turn off main switch.

Maintenance work must be co nducted at the latest after

the number o f operating hours listed in the column "

Interval". Shorter maintenance intervals may be required

when working with very linty materials.

Procedure Interval Remarks

Head

Removal of lint 8 Particularly in following areas:

accumulations Underside of t he stitch bed

Check the oil level in both

reservoirs 40 see subject 2.1

Maintenance Unit

Clean insert in the 9

air filter (page 10) 500

Transporter stays

Area around the hook

Bobbin housing top

Element 9 and 11

Caution!

Interrupt the compressed air supply

and vent the system.

17

Loading...

Loading...