Page 1

Manual, complete

745 - 34 - 2

Sewing unit for runstitching of piped flap

and welt pocket openings and pocket corners

Working methods: A, B, D, F

Operating Instructions

Installation Instructions

Service Instructions

Instructions for Programming DAC

1

2

3

4

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon + 49 (0) 5 21 / 9 25-00 • Telefax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 02/2005 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 745181

Page 2

745 - 34 - 2

Manual, complete

Contents

Operating Instructions

Installation Instructions

Service Instructions

Instructions for Programming DAC

Interconnection-diagram

9870 745154 B

9890 745002 B

Pneumatic circuit plan

9770 745005

Page 3

Index Page:

Foreword and general safety instructions

Part 1: Operating Instructions 745-34-2

1. Product Description

1.1 Description of proper use ........................................ 5

1.2 Briefdescription............................................. 5

1.3 Technicaldata .............................................. 7

1.4 Optional equipment ........................................... 8

2. Operation

2.1 Swingingthefoldingstationaside................................... 11

2.2 Pushing the covering hood back and removing the fabric sliding sheet ............ 12

2.3 Tilting the machine head up ...................................... 15

2.4 Needles and threads .......................................... 16

2.5 Threading the needle thread ...................................... 19

2.6 Winding the hook thread ........................................ 20

2.7 Remainingthreadmonitor ....................................... 21

2.8 Changing the bobbins .......................................... 22

2.9 Threadtension.............................................. 24

2.10 Stackingcontrol ............................................. 25

2.11 Slantedpocketcorners......................................... 26

2.11.1 Swingingthecornerknifestationout/in .............................. 27

2.11.2 Setting the corner knives (Manual corner knife station) ...................... 28

2.12 Referenceposition-Startingthesewingcycle-Quickstop................... 30

2.13 Flapandpipingprojection ....................................... 31

2.14 Piping strip length ............................................ 32

2.15 Working methods............................................. 33

2.15.1 Working method A (Production of trousers) ............................. 34

2.15.2 Sewingwithflap ............................................. 37

2.15.2.1 Sewing without light barrier ...................................... 37

2.15.2.2 Sewingwithlightbarrier ........................................ 39

2.15.3 Working method A (Production of jackets)

Piped pockets, manual positioning of piping strip, flaps and other additional parts ..... 40

2.15.4 Working method B

Piped pockets, automatic feed of the piping strip, without/with incision of the

piping ends ................................................ 46

2.15.5 Working method D

Breastweltpockets,automaticfeedandmatchingofthebreastwelt ............. 56

2.15.6 Working method F

Piped pockets, automatic feed of the piping strip,

incision of the piping ends, matching and feed of the flap .................... 62

2.15.7 Foldermonitoring ............................................ 66

2.16 Functions and Operation of the optional equipment ........................ 67

2.16.1 Automatic incision device for piping ends .............................. 67

2.16.2 Downholder, pocket bag and waistband clamp ........................... 70

2.16.3 Feeding devices for flaps, pocket bags etc. ............................. 71

1

Page 4

Index Page:

2.16.4 Throw-overstacker ........................................... 72

2.16.5 Roll-offdevice .............................................. 74

2.16.6 Blow-outdevice ............................................. 75

2.16.7 Bundle clamp and roll-off device ................................... 76

2.16.8 Tapefeedandautomaticcutting.................................... 77

2.16.9 Endless zipper device .......................................... 80

2.16.10 Vacuumdevice.............................................. 82

2.16.11 WorkingmethodBwithsetofparts“Pocketbagonflap” .................... 83

2.16.12 Zipper feeders for method B ...................................... 86

2.16.13 Set of parts “Shaped guide Lining loop triangle” for 745-34-2 methods B and F ....... 87

2.16.14 Smoother for 745-34-2 A and B .................................... 88

3. Maintenance

3.1 Cleaning .................................................. 88

3.2 Weeklylubrication............................................ 91

Page 5

1. Product description

1.1 Description of proper use

The 745-34-2 is a sewing unit which can properly be used for sewing

light to medium-weight material. Such material is, as a rule, material

made of textile fibres or leather. These materials are used in the

garment industry.

In general only dry material should be sewn on this machine. The

material must not contain any hard objects.

The seam is generally made with core thread, polyester fibre

or cotton threads.

The dimensions for needle and hook threads can be taken from the

table in chapter 2.4.

Before using any other threads it is necessary to estimate the

consequential dangers and to take the respective safety measures, if

required.

This sewing unit must only be installed and operated in dry and

well-kept rooms. If the sewing unit is used in other rooms, which are

not dry and well-kept, further measures to be agreed upon may

become necessary (see EN 60204-31 : 1999).

We, as a manufacturer of industrial sewing machines, assume that at

least semi-skilled operating personnel will be working on our products

so that all usual operations and, where applicable, their risks are

presumed to be known.

1

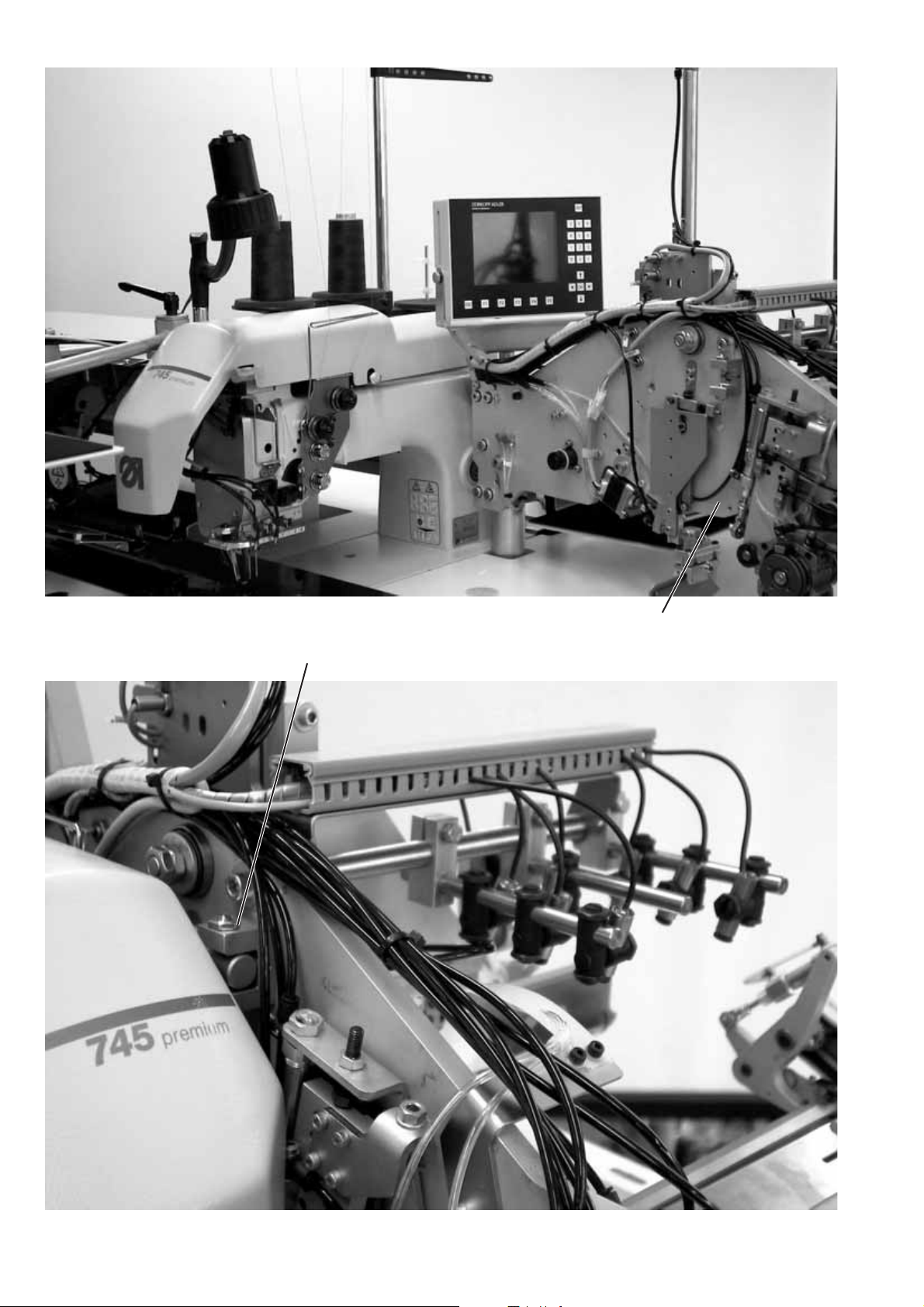

1.2 Brief description

The Dürkopp Adler 745-34-2 is a sewing unit for automatic

runstitching of piped, flap and welt pocket openings with rectangular or

slanted pocket c orners.

The slanted pocket corners result from the seam offset of the two seam

rows. At the seam beginning and seam end it is possible to sew with

different slants.

Dependent on the working method different feeding devices, corner

knife stations and optional equipment are used.

Machine head

–

Twin needle lockstitch version

–

Needle bars can be switched separately or together

–

Large vertical hooks

–

Externally driven center knife, speed and circuit timing

programmable

–

Thread trimming device for needle and hook threads

–

Needle thread monitor

–

Photoelectric remaining thread monitor for the hook threads

–

Sewing drive as DC direct drive

5

Page 6

Step motors for the material feed and the length adjustment of the

corner cutting device

The step motor technology results in short machine times and

guarantees an absolutely precise corner incision.

Thus, it contributes to a pocket quality as yet unequalled and combined

with high productivity.

New generation of “ DAC III” controls (DÜRKOPP ADLER Control)

The graphic user guidance exclusively occurs via internationally

comprehensible symbols and text lines in the corresponding language.

The various symbols are combined in groups within the menu structure

of the s ewing and test programs.

The ease of use makes short training times possible.

The user can combine 99 freely programmable pocket programs with

up to 20 seam patterns.

20 pocket s equences can be called up.

Every pocket sequence can be combined of up to 8 pocket programs in

any order whatever.

All slants suitable for practical application can be programmed by the

operator at the touch of a button.

The time-consuming adjustment of the corner knives and the tiresome

programming of seam offsets are not required.

The comprehensive test and monitoring system MULTITEST is

integrated in the DAC.

A microcomputer does the control tasks, monitors the sewing cycle and

signals operating faults and malfunctions on the display.

Optional equipment

By means of a flexible system o f optional equipment the sewing unit

can be equipped optimally and economically corresponding to the

respective application.

See chapter 1.4 (Equipment of the 745-34-2).

Sewing equipment and folders

Data concerning the sewing equipment and folders for the various

applications can be taken from the Equipment Sheets of c l. 745-34.

Please direct your enquiries to the DÜRKOPP-ADLER sales offices.

6

Page 7

1.3 Technical data

Machine head: Class 0246 992002

Needle system: 2134-85

Needle distance: 10, 12, 14, 16, 20, 24, 26, 30 mm

Needle size: Nm 80 to Nm110

Threads: see table chapter 2.4

Stitch type: Twin needle lockstitch

Speed: min. 2000 rpm

max. 3000 rpm

Stitch length: min. 2.0 to 3.0 mm

Number of stitches/condensed

stitches: 1 - 10 stitches

Number of stitches/bartack

stitch: 0 - 5 stitches

Stitch length condensed

stitches / bartack: 0.5 - 3.0 mm

Pocket length: max. 220 mm

Seam offset: max.

+

/- 13 mm

Operating pressure: 6 bar

Air consumption: approx. 6 NL per work cycle

Rated voltage: 3 x 230 / 400 V / 50/60 Hz

Rated load:

Machine with

vacuum blower 0,8 KW

Machine without

vacuum blower 0,5 KW

Dimensions: 1540 x 925 x 1200 mm (L x W x H)

Working height: 790...1100 mm

(upper edge of table top)

Weight: 280 kg

1

Rated noise level: LC = 81 dB (A)

Workstation-specific emission value

according to DIN 45635-48-B-1

Stitch length: 2.5 mm

Seam length: 180 mm

Speed: 2750 rpm

Material: double fabric

240 g/m

2

Measuring point according to DIN

4895 Part 1

X = 600 mm Y = 0 mm Z = 300 mm

7

Page 8

1.4 Optional equipment

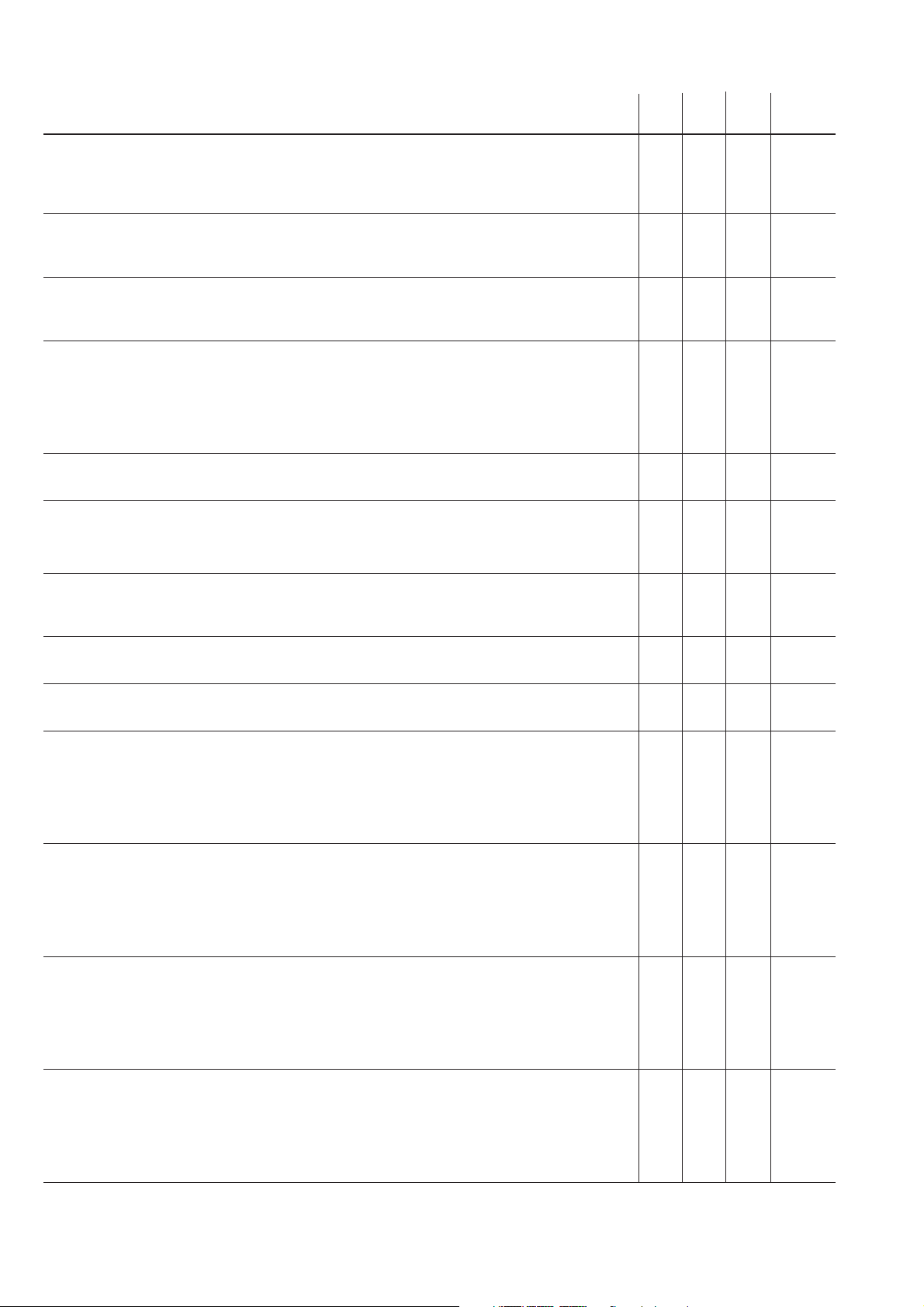

Order No. Optional equipment A B D F

0745 597514 Downholder- pocket bag clamp

Downholder for smoothing the fullness

caused by darts as well as a

clamping device for pocket bags

0745 597524 Waistband clamp

For smoothing the fullness.

Only possible in conjunction with 0745 597514

0745 597544 Endless zipper

Scissors with roll-off device for endless zippers

without slider

0745 597554 Throw-over stacker

To be positioned near the machine for stacking to the

side or to the back.

Furthermore, this throw-over stacker is equipped with

an easy-to-operate height adjustment and

a swivel device.

0745 597604 Blow-out device

For blowing the finished workpieces out

0745 597614 Shaped guide “Lining loop triangle”

In case of inside pockets the lining loop triangle

is fed automatically.

0745 597674 Table extension (large)

The table extension required for the working method

with bundle clamp carriage

XX

XX

X

XXXX

XX

XX

X

0745 597684 Table extension (small)

Tableextensiontobeusedforstackingtotheside

0745 597694 Bundle clamp

This includes the required large table extension

0745 597764 Right zipper feeder

In conjunction with feeding device 0745 517574

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pocket chain

inside.

0745 597774 Left zipper feeder

In conjunction with feeding device 0745 517564

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pocket chain

inside.

0745 597784 Right zipper feeder

In conjunction with feeding device 0745 517574

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pocket chain

inside.

0745 597794 Left zipper feeder

In conjunction with feeding device 0745 517564

For cut-to-length zippers,

without slider, total width 24 mm, chain width

approx. 4 mm, in case of ready-made pockets chain

inside.

XXXX

XX

X

X

X

X

8

Page 9

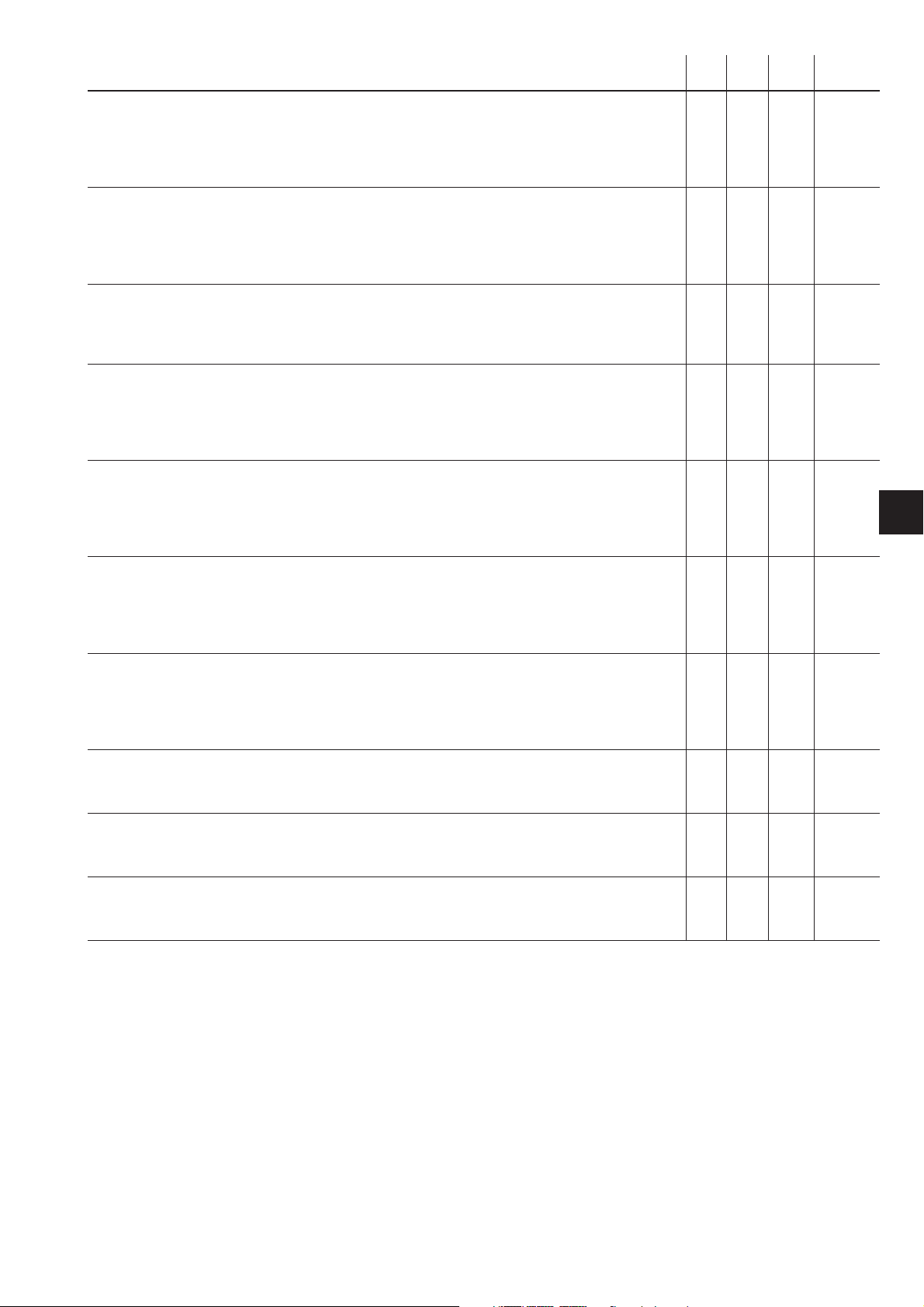

Order No. Optional equipment A B D F

0745 597824 Smoother for the 745-34-2 A/B

The smoother has the purpose to smooth the finished

workpiece held by the bundle clamp. Only in

combination with the table extension 0745 597674

and the roll-off device 0745 597954.

0745 597874 Set of parts “Pocket bag on flap” NA 10 and 12

for the simultaneous attaching of two pocket bag

halves and flap. Combination only in conjunction with

equipment E 3103 or E 3503 for NA 10

as well as E 3107 or E 3507 for NA 12.

0745 597884 Set of parts “Pocket bag / Piped pocket”

for the blowing of the pocket bag or the piping pocket

with equipment E 2604 or E 2606.

Use only in combination w ith the clamp K19.

0745 597934 Three-pack lasers

Add-on kit: for expanding the existing 5 laser marking

lamps to a maximum of 8 laser marking lamps.

(With the working method F, the standard equipment

includes 8 laser marking lamps).

0745 597944 Electromotoric tape feed/Automatic cutting

Automatic feeding and cutting of a

reinforcement strip pulled from a roll. Start time and

cutting time can be programmed

corresponding to the pocket.

XX

X

X

XXXX

XXXX

1

0745 597954 Roll-off device

It is used to for transporting short pieces into the

stacker or to eject the pieces to be processed.

The speed and the working cycle of the roll-off device

can also be programmed.

0745 597964 Vacuum (side channel compressor)

For an accurate positioning of the material when

no in-house vacuum unit is available.

The side channel compressor can be used with the

basic unit.

0797 003031 Pneumatic connection package

Connection hose to the pneumatic supply line

with the appropriate couplings.

0745 517564 Automatic feeding, left 180 - 220 mm

For the automatic feeding of piping strips and

additional parts.

0745 517574 Automatic feeding, right 180 - 220 mm

For the automatic feeding of piping strips and

additional parts.

XXXX

XXXX

XXXX

X

X

9

Page 10

2

1

10

Page 11

2. Operation

2.1 Swinging the folding station aside

For operations at the sewing point (threading the needle threads,

needle change etc.) the whole folding station with folder and light

barriers can be swung to the right.

–

Swingthecompletefoldingstation1withfolder

to the right.

Note:

With the sewing unit switched on, a safety message

appears on the screen of the control panel.

Folding station swung out

1

–

The sewing point is freely accessible.

Swinging the folding station back

–

Swing the folding station back.

ATTENTION!

After being swung back the folding station must lock

in the catch 2.

11

Page 12

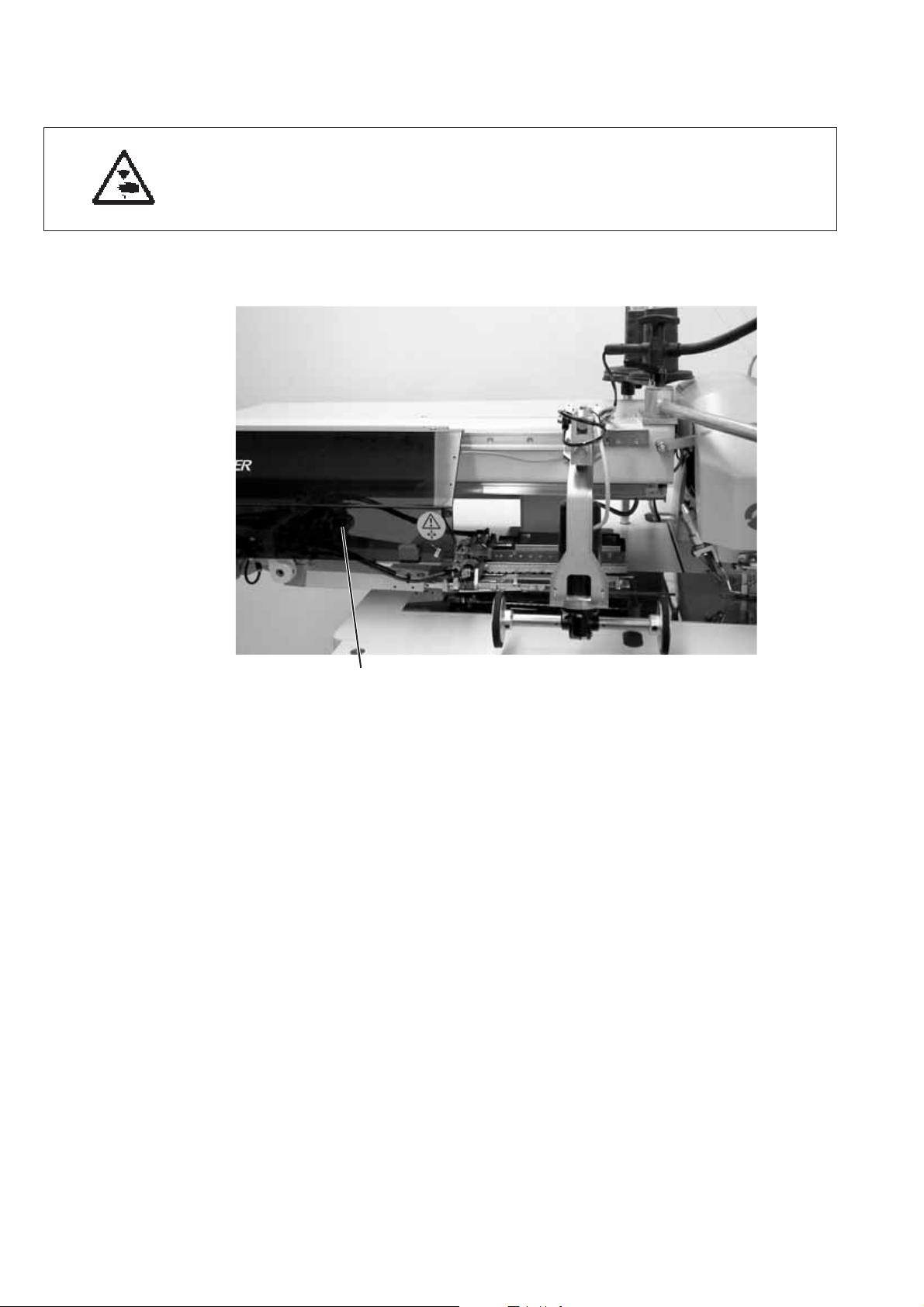

2.2 Pushing the covering hood back and removing the fabric sliding sheets

Caution: Danger of injury!

Switchthemainswitchoff.

Push the covering hood back and remove the fabric sliding sheet only

with the sewing unit switched off.

–

Switchthemainswitchoff

1

For a better accessibility of the feeding clamps the covering hood can

simply be displaced.

Pushing the covering hood back

–

Push the covering hood 1 to the left.

The feeding clamps are accessible.

–

Push the covering hood 1 to the right again until you hear it

snapping in.

12

Page 13

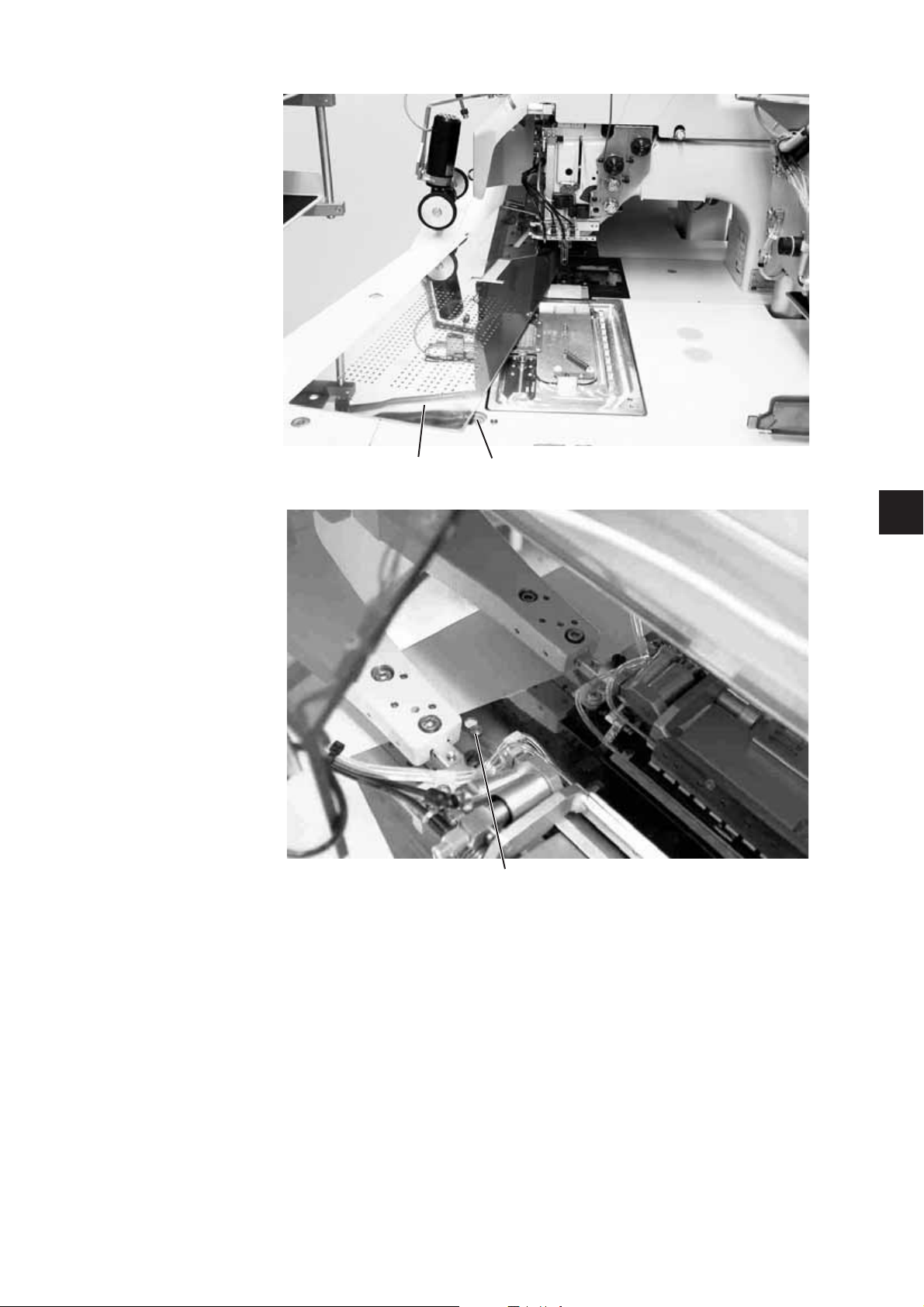

21

3

1

For changing the hook thread bobbins:

–

Lift the fabric sliding sheet 2 in the area of pin 1 and swing it to the

left.

For a complete removal (for maintenance and adjusting operations):

–

Lift off the fabric sliding sheets at the pin 3.

13

Page 14

13

6

45

14

Page 15

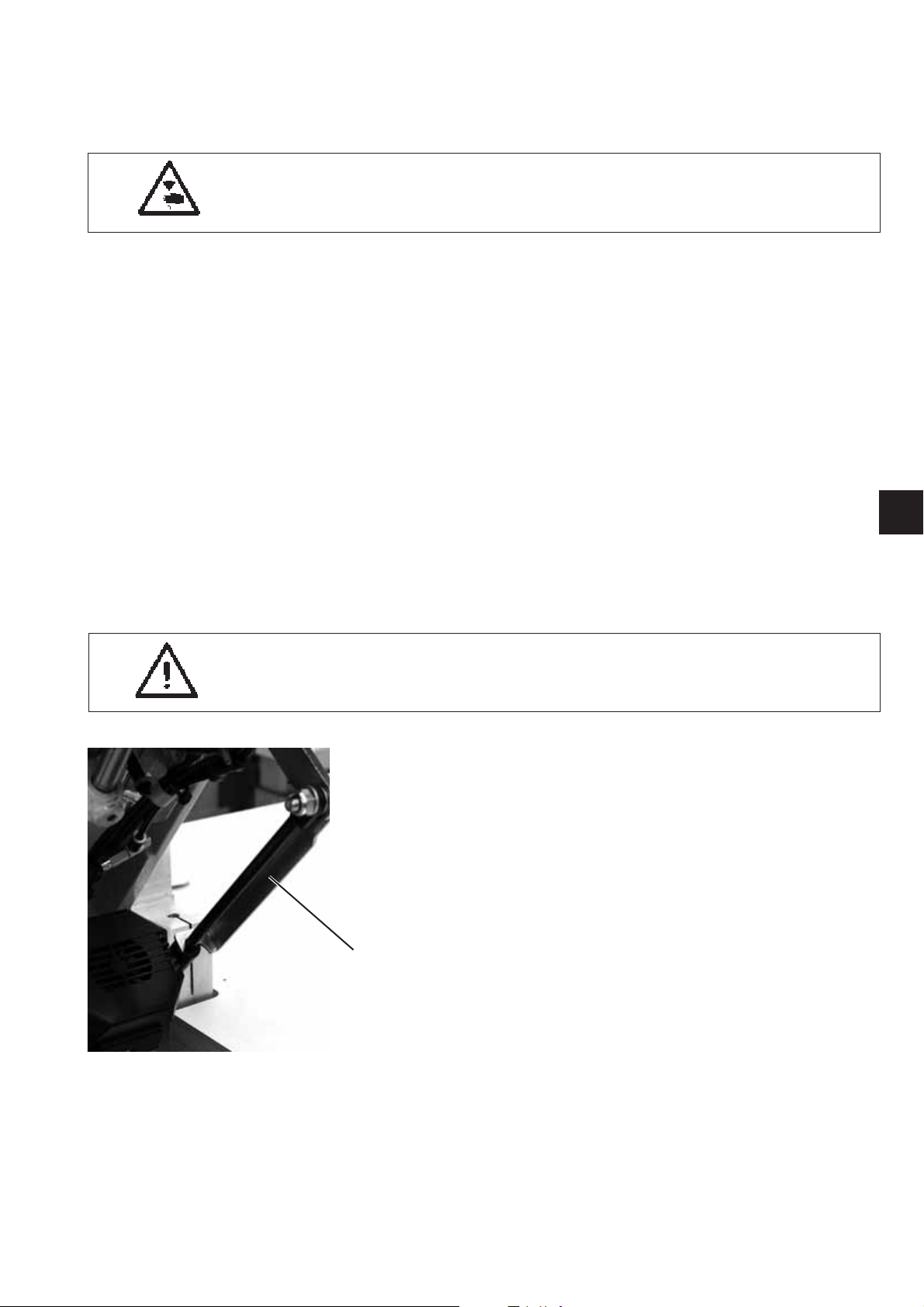

2.3 Tilting the machine head up

For maintenance work the machine head can be tilted up.

For this purpose the transport carriage must be in its rear end position.

Caution: Danger of injury!

Switchthemainswitchoff.

Tilting the machine head up.

–

–

–

–

–

Swinging the machine head back

–

–

–

Remove the covering hood 1.

For this purpose lift the covering hood at the front so that the catch

is released. Carefully lift the covering hood upwards.

Swing the folding station 3 out by 90°.

Swivel the locking lever 4 up.

Lift the left fabric sliding s heet 6 at the front and swing it to the left.

Lift the machine head in the area of head cover 5 and tilt it up

carefully.

Pawl 2 snaps in additionally.

The space under the machine table is accessible for cleaning now.

1

Hold the machine head tight in the area of head cover 5.

Release the pawl 2.

Swing the machine head back carefully.

Caution: Danger of breakage!

Hold the machine head tight until it is at rest completely.

–

Insert the fabric sliding sheets.

–

Swivel the locking lever 4 down.

–

Swing the folding station 3 back and let it catch with the locking

lever.

–

Put on the covering hood 1 and let it catch again.

2

15

Page 16

2.4 Needles and threads

Needle system: 2134-85

Recommended

needle size: Nm 90 for thin material

Nm 100 for medium-weight material

Nm 110 for heavy-weight material

High sewing security and good sewability are achieved with the

following core threads:

–

Two-ply polyester endless polyester core-spun

(e.g. Epic Poly-Poly, Rasant x, Saba C, ...)

–

Two-ply polyester endless cotton core-spun

(e.g. Frikka, Koban, Rasant, ...)

If these threads are not available, the polyester fibre or cotton threads

listed in the table can also be sewn.

Often two-ply core threads are offered by the thread manufacturers

with the same designation as three-ply polyester fibre threads

(3cyl.-spun).This causes uncertainty with regard to twisting and thread

thickness.

When in doubt, unravel the thread and check whether it is twisted 2- or

3-ply.

The label no. 120 on the thread reel of a core thread corresponds e.g.

to the thread size Nm 80/2 (see table values in brackets).

In case of monofilament threads you can use needle threads and hook

threads of the same thickness. The best results are achieved with soft

and elastic threads (software) of the thread thickness 130 Denier.

Recommended thread sizes:

Needle size Core thread Core thread

Nm

Needle thread Hook thread Needle thread Hook thread

Polyester Polyester Polyester Cotton

endless core-spun endless core-spun

Label No. Label No. Label No. Label No.

90 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2)

100 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2)

110 75 (Nm 50/2) 75 (Nm 50/2) 75 (Nm 50/2) 75 (Nm 50/2)

Needle size Polyester fibre thread Cotton thread

Nm (3cyl.-spun)

Needle thread Hook thread Needle thread Hook thread

90 Nm 80/3-120/3 Nm 80/3-120/3 Ne

100 Nm 70/3-100/3 Nm 70/3-100/3 Ne

110 Nm 50/3-80/3 Nm 50/3-80/3 Ne

16

50/3-70/3 NeB50/3-70/3

B

40/3-60/3 NeB40/3-60/3

B

40/4-60/4 NeB40/4-60/4

B

Page 17

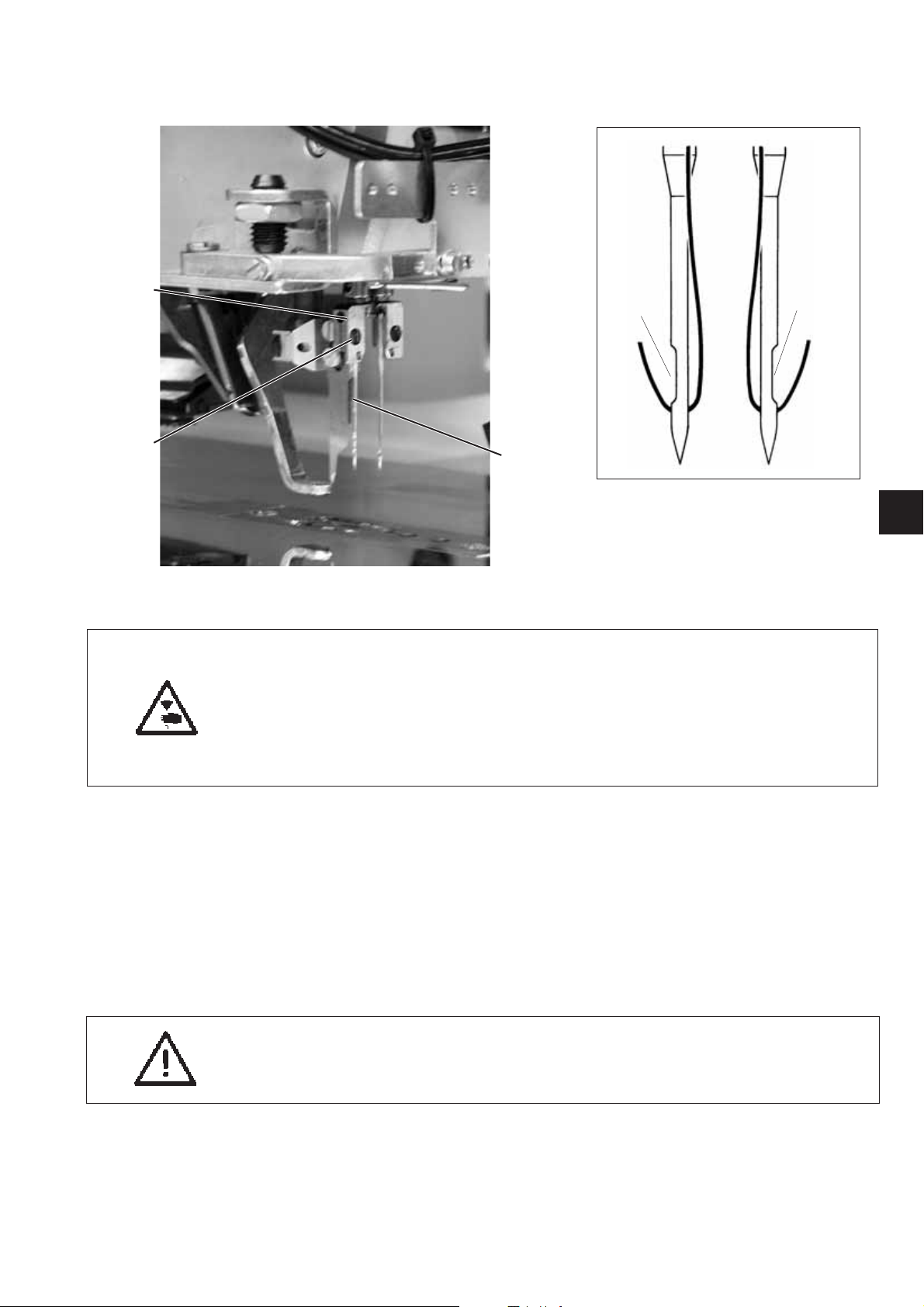

Changing the needles

1

4

5

2

3

1

Caution: Danger of injury!

Switchthemainswitchoff.

Change the needles only with the main switch switched off.

Risk of injuries from cuts!

Do not reach into the area of the center knife 3 when changing the

needles.

–

Swing the folding station aside (see chapter 2.1)

The needles are freely accessible.

–

Loosen screw 2 and remove the needle from the needle holder 1.

–

Push the new needle into the drill-hole of the needle holder 1 as far

as it will go.

ATTENTION!

Seen from the operator ’s side the hollow groove 4 of the left needle

must point to the left and the hollow groove 5 of the right needle

must point to the right (see sketch).

–

Tighten screw 2.

ATTENTION!

After changing to another needle size the needle protection on the

hook has to be readjusted (see Service Instructions).

Note:

The standard needle size of class 745-34-2 is Nm 100.

17

Page 18

2

21

3

4

18

17

16

15

14

5

6

7

8

9

10

12 11

Page 19

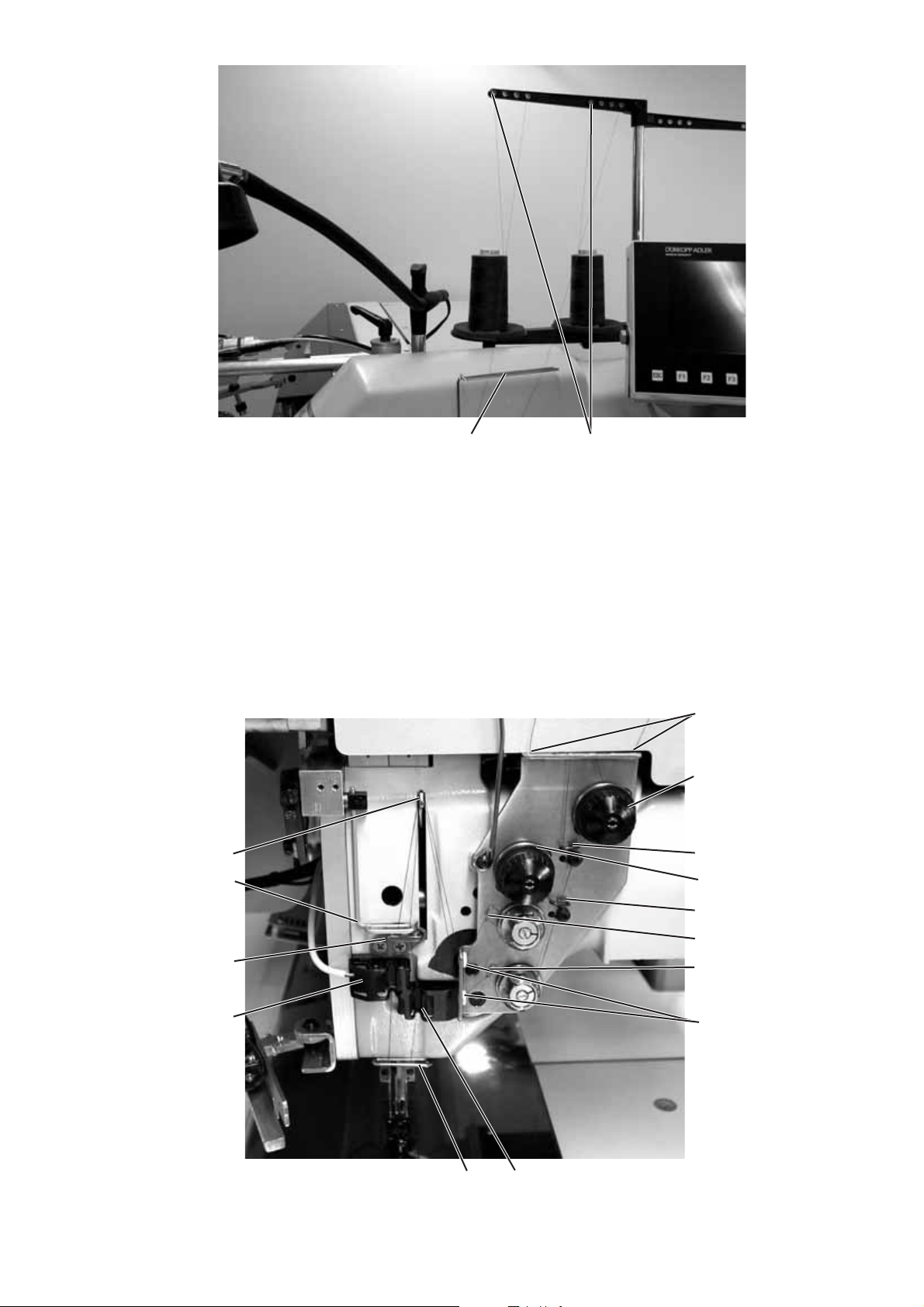

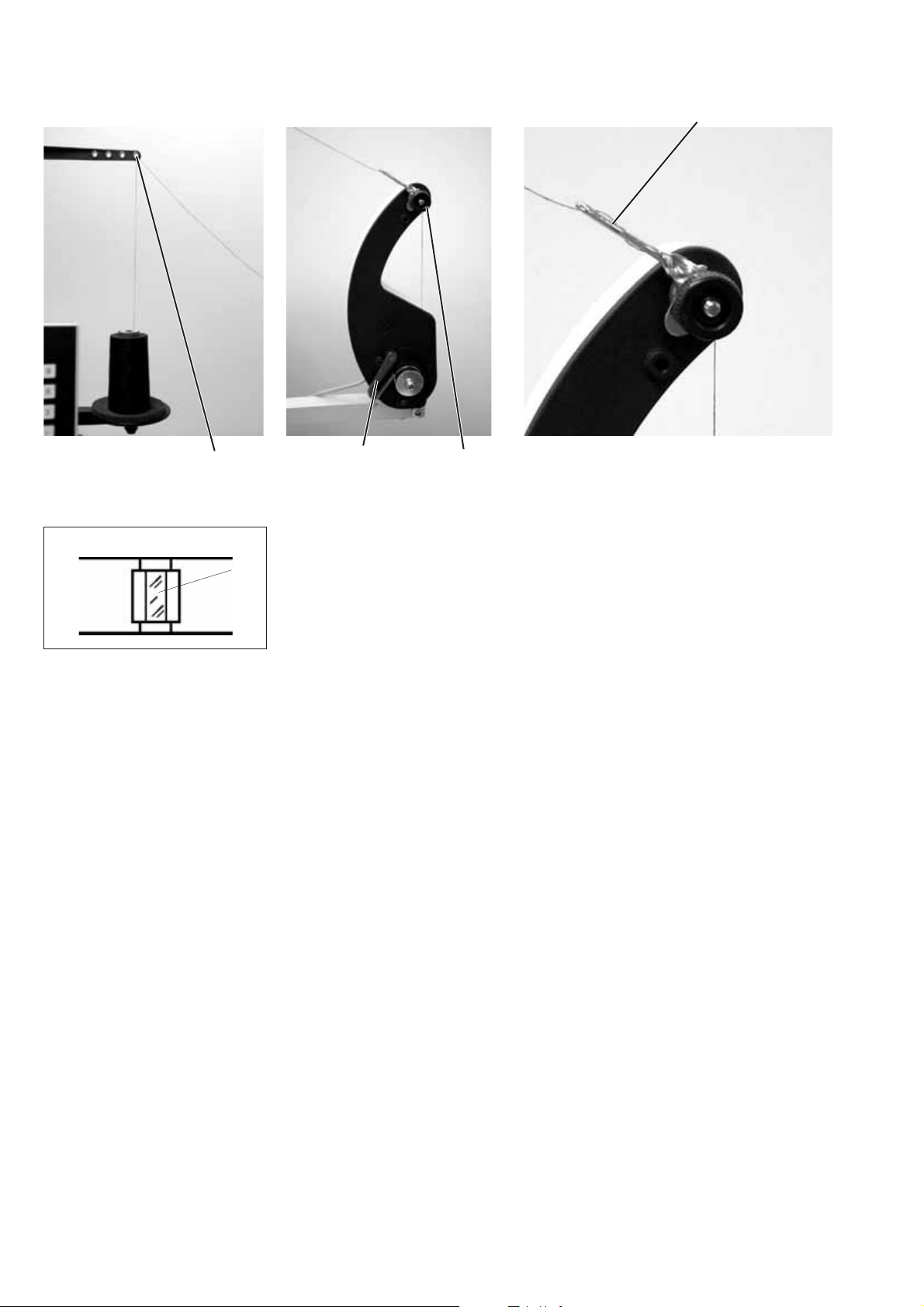

2.5 Threading the needle thread

Caution: Danger of injury!

Switchthemainswitchoff.

Thread the needle threads only with the sewing unit switched off.

The threading of the needle threads is done in ascending numerical

order as shown in the illustrations opposite.

–

Left needle

–

–

–

–

–

–

–

–

–

–

–

–

Swing the folding station aside

Put the thread reel on the thread reel holder.

Thread the thread from the thread reel through the drill-hole 1 of

the thread reel holder.

Guide the thread through guide 2.

Guide the thread through the drill-hole in the support plate 3.

Guide the thread through guide 5.

Guide the thread through the tension discs of the needle thread

tension 6.

Guide the thread through the thread controller spring 8.

Guide the thread through the upper drill-hole in the support plate 10.

Thread the thread through the upper drill-hole in the thread lever 17.

Guide the thread downward through the thread puller 16.

Thread the thread through guide 15 and the needle thread monitor 14.

Thread the thread through guide 12, through the drill-hole in the

needle holder and through the eye of the needle.

1

Right needle

–

Put the thread reel on the thread reel holder.

–

Thread the thread from the thread reel through the drill-hole 1 of the

thread reel holder.

–

Guide the thread through guide 2.

–

Guide the thread through the drill-hole in the support plate 3.

–

Guide the thread through the tension disc of the needle

thread tension 4.

–

Guide the thread through the guides 5 and 7.

–

Guide the thread through the thread controller spring 9.

–

Guide the thread through the lower drill-hole in the support plate 10.

–

Thread the thread through the lower drill-hole in the thread lever 17.

–

Thread the thread downward through the thread puller 16, through

guide 15 and through the needle thread monitor 11.

–

Thread the thread through guide 12, through the drill-hole in the

needle holder and through the eye of the needle.

–

Clamp the thread in the needle thread catcher and cut it off

19

Page 20

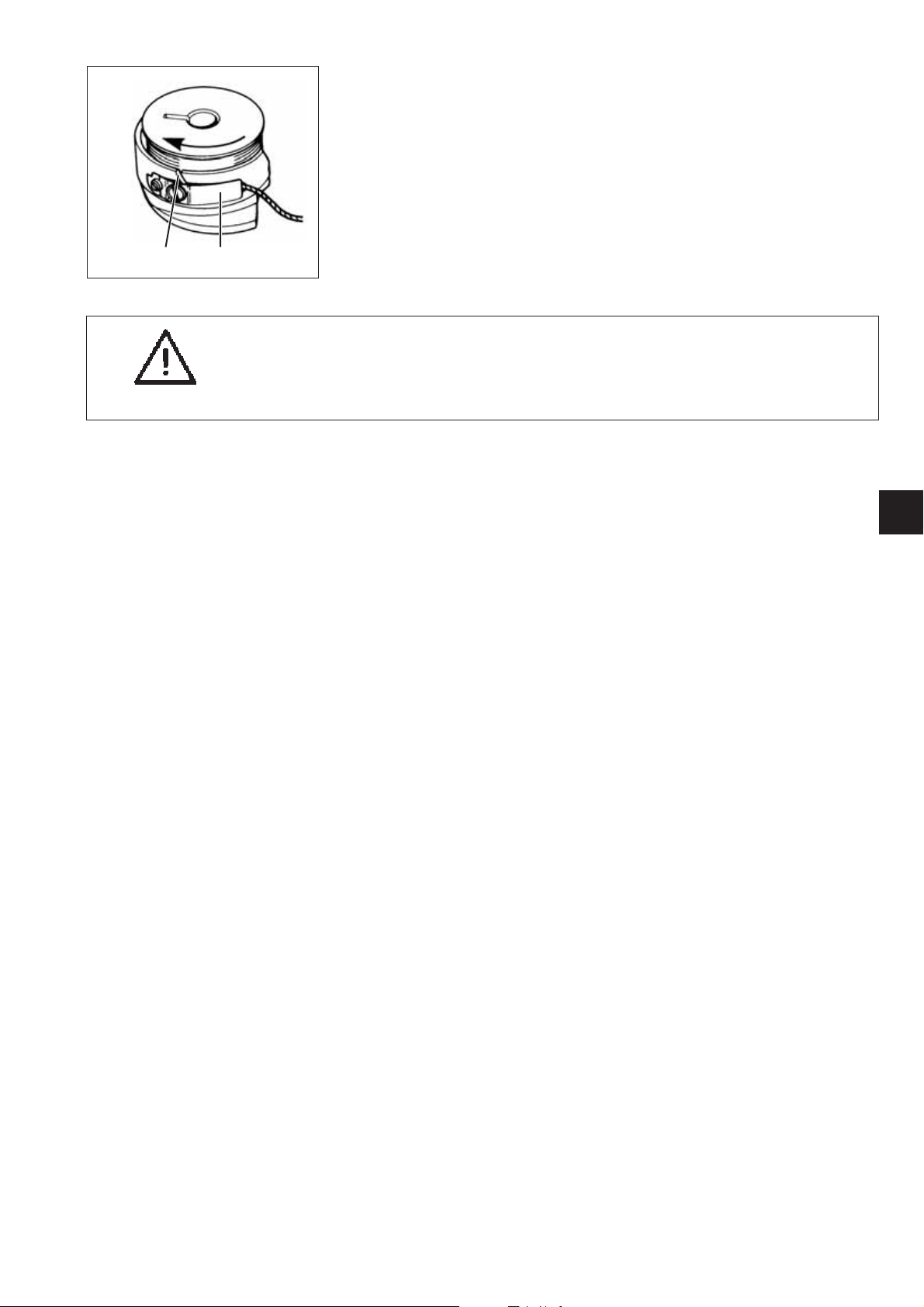

2.6 Winding the hook thread

4

1

5

32

The external winder makes it possible to wind the hook threads

independent of the sewing operation.

–

Remove remaining thread from the bobbin hubs before w inding.

–

Put the thread reel on the thread reel holder.

–

Thread the thread through the drill-hole 1 of the unwinding arm

(see picture on the left).

–

Guide the thread through guide 4.

–

Guide the thread through the bobbin thread tension 2.

–

Prewind the thread to the right in the front and back reserve

grooves of the bobbin hub.

The full r eserve grooves guarantee a secure w inding, even with

monofilament threads.

With the thread reserves in the reserve grooves the pocket opening

can safely be finished after the remaining thread monitor has

indicated that the bobbin is empty.

The reflecting surface 5 of the bobbin hub is to be kept clean.

–

Press the bobbin retainer 3 against the bobbin hub.

The winder starts.

After reaching the set bobbin filling level the winder shuts off

automatically.

See Service Instructions for setting the bobbin filling level.

20

Page 21

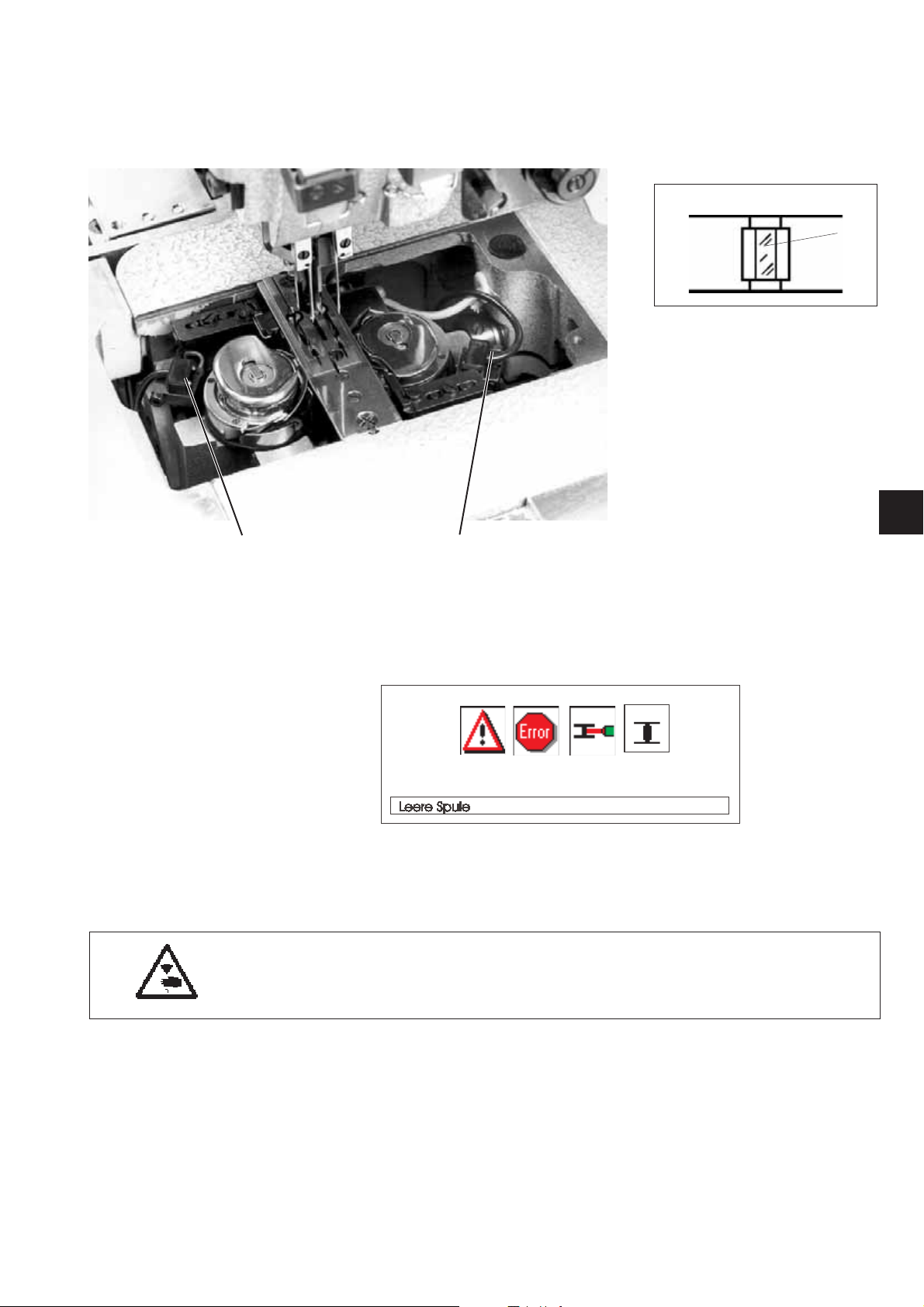

2.7 Remaining thread monitor

The remaining thread monitor monitors the left and right hook thread

bobbin with the infrared reflected light barriers 1 and 2.

3

1

1

–

When the bobbin is empty, the light beam transmitted by the light

barrier 1 or 2 is reflected by the exposed reflecting surface 3 of the

bobbin hub.

–

The display of the control box shows the message

“Empty bobbin”.

–

The pocket opening is safely finished with the thread in the reserve

groove of the bobbin hub.

The transport carriage stops in its rear end position.

Caution: Danger of injury!

Switchthemainswitchoff.

Clean the lenses of the light barriers only with the sewing unit

switched off.

2

–

Switchthemainswitchoff.

–

Clean the lenses of the light barrier with a soft cloth after every

bobbin change.

–

Switchthemainswitchon.

–

Start a new sewing cycle.

21

Page 22

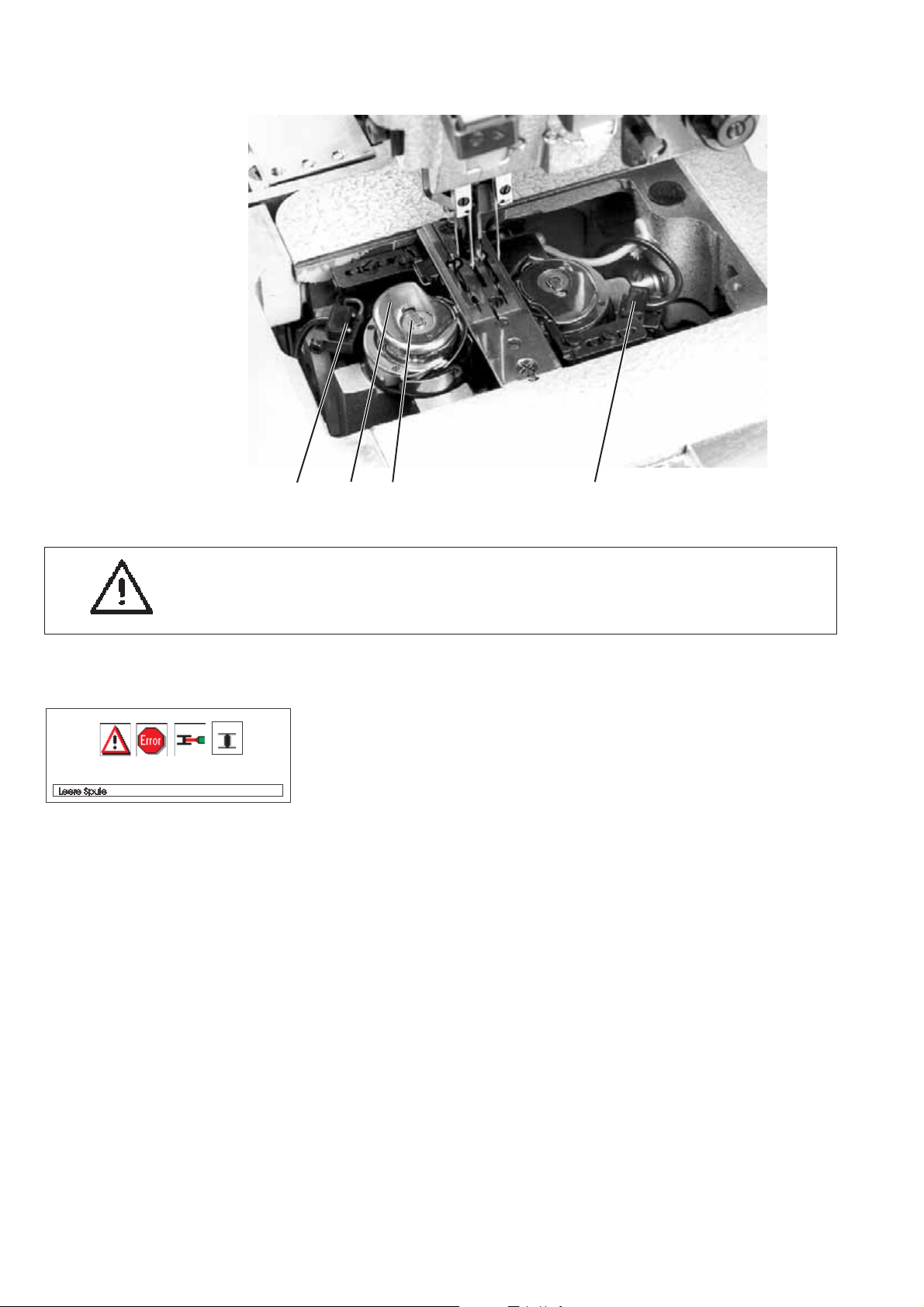

2.8 Changing the bobbins

123 4

ATTENTION!

Switch the main switch off before changing the bobbin.

–

After a certain number of seams the hook thread quantity on the

bobbin is used up.

–

With the remaining thread monitor switched on the message

“Empty bobbin” appears in the display.

–

The pocket opening in progress is finished with the help of the

thread reserve in the reserve grooves of the bobbin hub.

–

After corner incision the workpiece is moved out or stacked.

–

The transport carriages runs to its rear end position.

It can be restarted after the bobbin change only.

Removing the empty bobbin

–

Switchthemainswitchoff.

–

Swing the folding station aside.

–

Lift the fabric sliding sheet and swing it away to the left and to the

right (see chapter 2.2).

–

Lift the upper part of the bobbin c ase in the area 2.

Thereby the bobbin case retainer 3 is lifted, too.

–

Remove the upper part of the bobbin case together with the empty

bobbin.

–

Remove the empty bobbin from the upper part of the bobbin case.

22

Page 23

Inserting a full bobbin

–

Insert a full bobbin in the upper part of the bobbin case 2.

–

Pull the thread through the slit 5 under the tension spring 6.

–

Pull the thread out of the upper part of the bobbin case for a length

of approx. 4 cm.

When the thread is being pulled off, the bobbin must turn in the

direction of the arrow ( counter to the hook rotation).

–

Insert the upper part of the bobbin case 2 with the full bobbin in the

65

lower part of the bobbin case.

–

Close the bobbin case retainer 3.

ATTENTION!

For a trouble-free function of the remaining thread monitor clean

the lenses of the light barriers 1 and 4 with a soft cloth after

every bobbin c hange.

–

Put the fabric sliding s heets on again.

–

Switchthemainswitchon.

–

Start a new sewing cycle.

1

23

Page 24

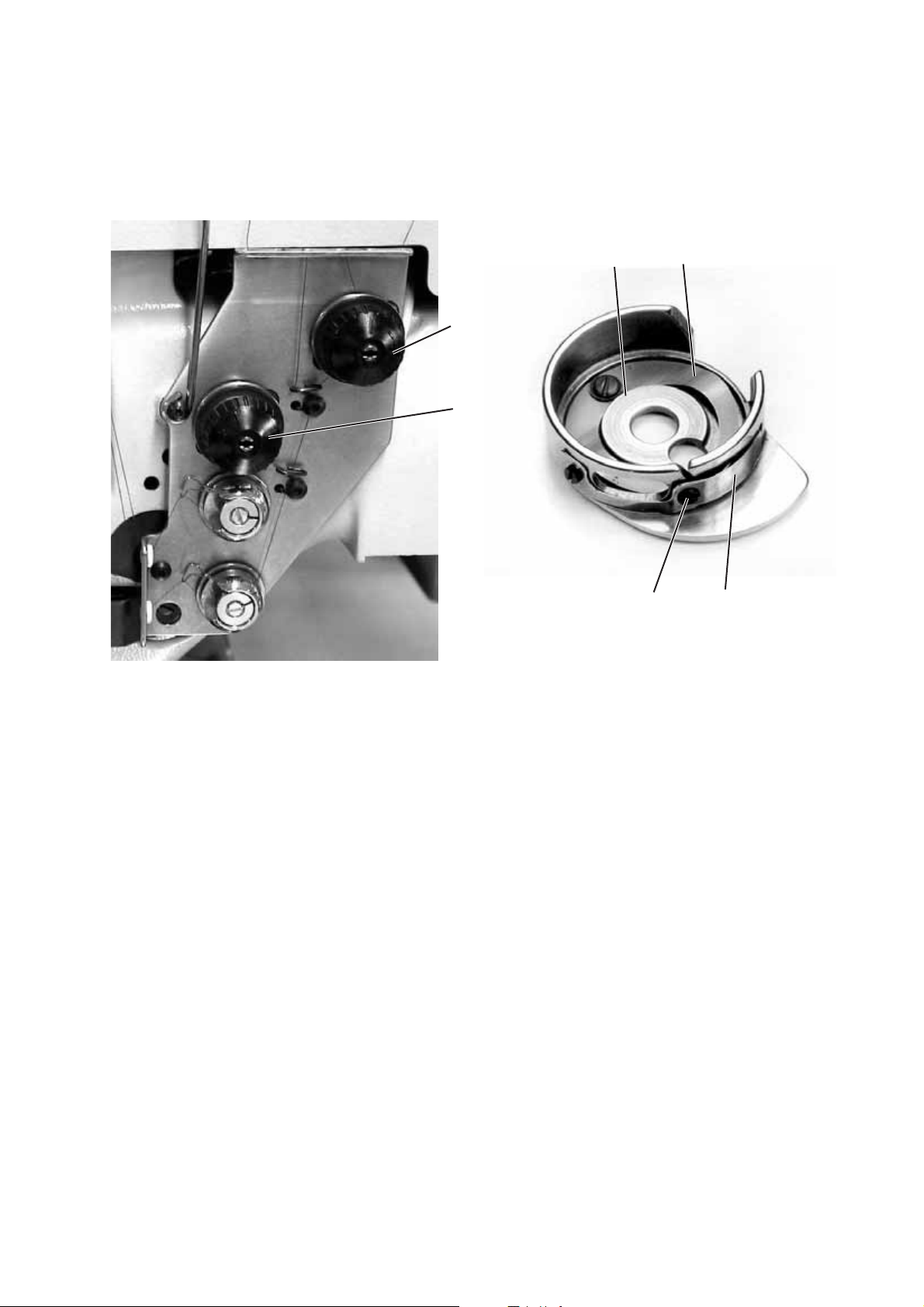

2.9 Thread tension

The interlacing of the threads must lie in the middle of the workpiece.

Thick and hard material requires a tighter thread tension than thin and

soft fabrics.

Too high thread tensions can lead to undesired ruffling and thread

breakage in case of thin material.

3

4

1

2

5

6

Setting the brake spring 4:

At a position stop of the machine head the brake spring 4 avoids an

after-run of the hook thread bobbin.

–

Set the brake spring 4 by alignment.

The brake power is set correctly when the brake spring 4 projects

beyond the surface 3 by approx. 1 mm.

–

When setting the tension s pring 6 the brake power is to be taken

into account.

Setting the tension spring 6:

–

First set only a minimum tension of leaf spring 6 at the adjusting

screw 5.

Increasing the hook thread tension: Turn to the right

Reducing the hook thread tension: Turn to the left

–

With the bobbin inserted and the hook thread threaded through the

throat plate a uniform and easy thread pulling must be guaranteed.

Setting the needle thread tension:

–

Adjust the needle thread tension until a uniform stitch pattern is

achieved.

–

Set the tension of the needle threads at knurled nut 1 (right needle

thread) and knurled nut 2 (left needle thread).

Increasing the needle thread tension: Turn to the right

Reducing the needle thread tension: Turn to the left

24

Page 25

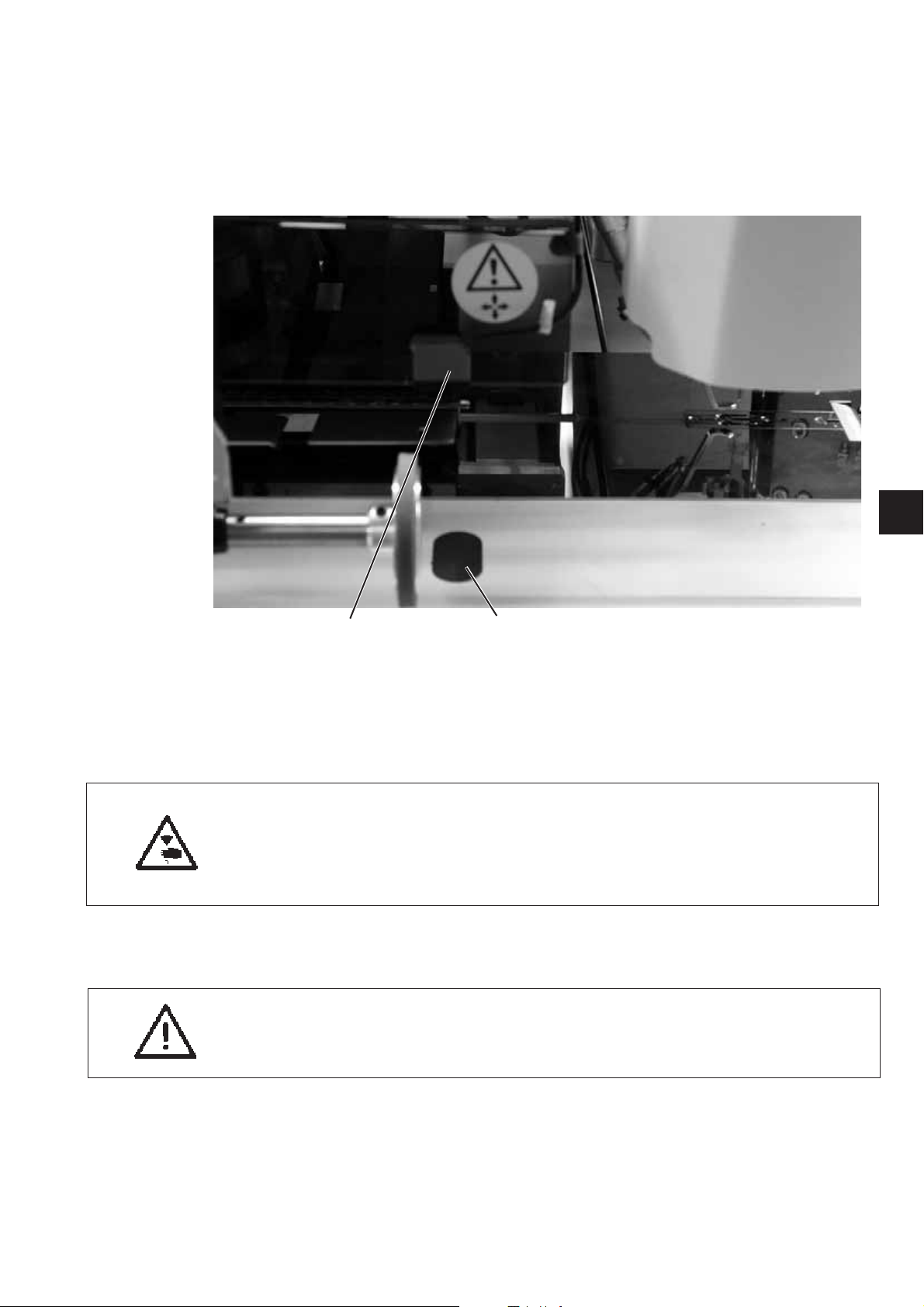

2.10 Stacking control

The reflected light barrier 1 monitors the stacking and blowing-out of

thesewnworkpiece.

The transport carriage does not return before the workpiece has been

correctly moved out.

1

21

–

If the workpiece is not moved out correctly, the light beam between

the reflected light barrier 2 and the reflecting sheet 1 remains

interrupted.

A renewed start is not possible.

Caution: Danger of injury!

Do not reach into the runway of the transport carriage when removing

the workpiece.

In sewing programs with automatic carriage return the transport

carriage moves to the front after the light beam has been released.

–

Remove the workpiece out of the light beam area.

A new sewing cycle can be started.

ATTENTION!

For a trouble-free function of the stacking control clean the lens of the

reflected light barrier once a day with a soft cloth.

25

Page 26

2.11 Slanted pocket corners

Dependent on the working method the 745-34 is equipped with an

automatic or manual corner knife station.

0745 337524 Manual corner knife station

The setting of the corner knives with regard to the pocket length is

programmable and is effected via a step motor.

The slanted pocket corners result from the seam offset of the two seam

rows programmable in steps of 1 mm.

The pocket c orner incision can be manually adjusted by two knurled

screws. For the seam beginning and seam end it amounts to a

maximum of +/- 13 mm relative to the second seam.

The distance of the corner knives to the seam is manually adjustable.

The whole knife block can be tilted out to make setting and service

work possible.

0745 337534 Automatic corner knife station

The setting of the corner knives with regard to the pocket length is

programmable and is effected via a step motor.

The slanted pocket corners result from the seam offset of the two seam

rows programmable in steps of 1 mm.

The programmable pocket corner incision - adjustable via two step

motors - can be freely selected for the seam beginning and seam end

and amounts to a maximum of +/- 13 mm relative to the second seam.

The distance of the corner knives to the seam is manually adjustable.

The whole knife block can be tilted out to make setting and service

work possible.

26

Page 27

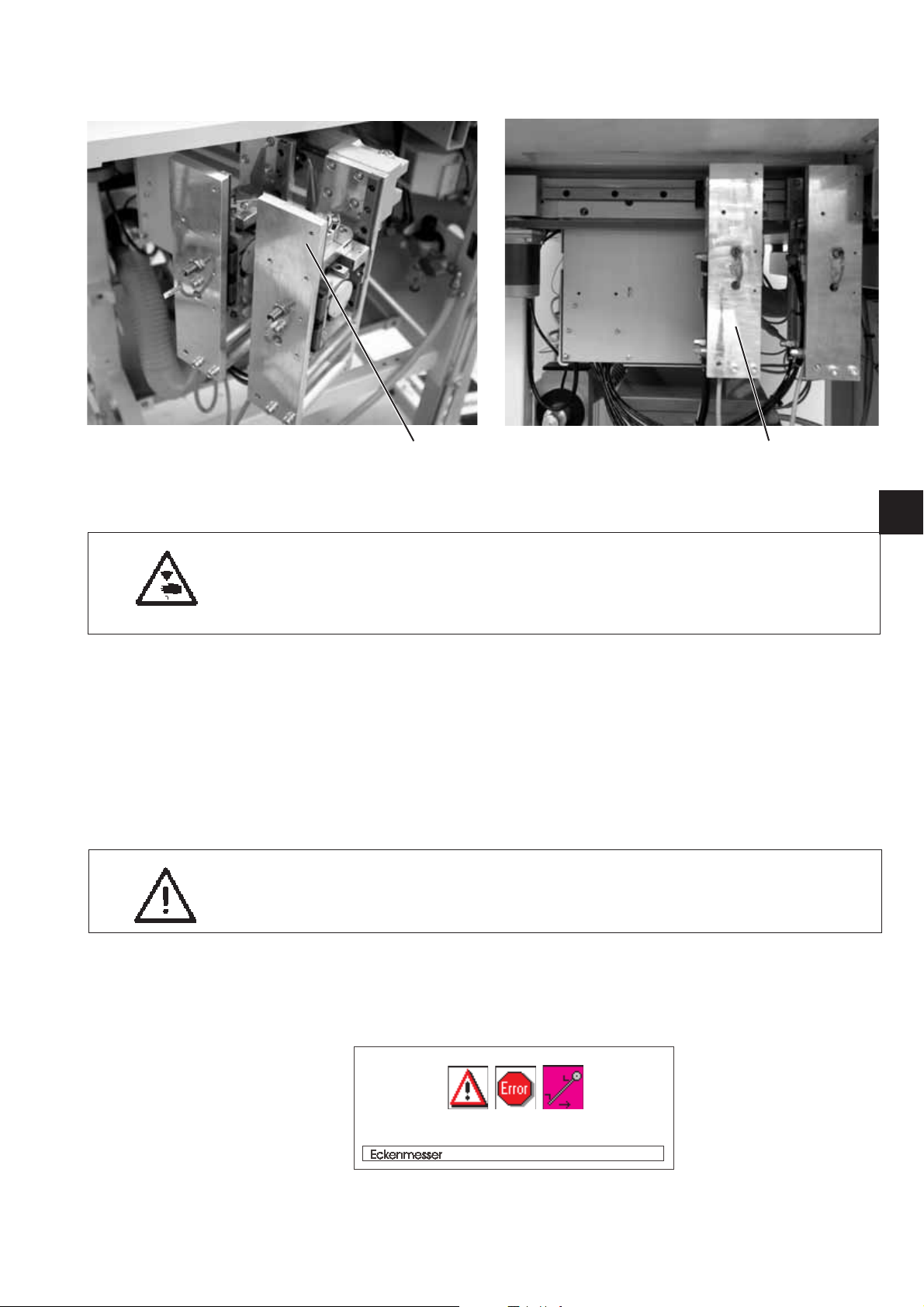

2.11.1 Swinging the corner knife station out / in

1

The corner knife station 1 can be swung out completely.

Caution: Danger of injury!

Switchthemainswitchoff.

Swing the corner knife station out only with the sewing unit switched

off.

Swinging the corner knife station out

–

Swing the corner knife station to the left.

The knives are accessible for setting and service work.

Swinging the corner knife station in

–

Swing the corner knife station back under the sewing unit and let it

catch.

ATTENTION!

The corner knife station must audibly lock when being pushed in.

1

1

Note:

If the corner knife station is swung out with the sewing unit switched

on, the following message appears:

27

Page 28

2.11.2 Setting the corner knives (Manual corner knife station)

With the 745-34 the slanted pockets result from the seam offset

between the two seam rows programmed at the control panel.

Caution: Danger of injury!

Switch off the main switch.

Set the corner knives only with the sewing unit switched off.

–

Swing the corner knife station out (see chapter 2.11.1)

Setting the angle of the corner knives

The angle of the corner knife is set by turning the knife blocks 2 and 4.

–

Loosen the screws 1 and 3.

–

Turn the knife blocks 2 and 4 equally.

–

Tighten the screws 1 and 3.

–

Set the angle at the rear knives correspondingly.

Height of the corner knives

The corner knives are not height-adjustable.

The knives always cut completely through.

Corner knife incision (offset)

The slants of the pockets result from the offset of the left and right

corner knife. The right corner knife is a stationary one, the left knife is

set according to the required offset.

–

Basic position (sewing of straight pocket corners):

The edges 1 and 2 are flush.

Adjustment by dial 5 or 6.

–

Offset (sewing of slanted pocket corners)

The left corner knife is set to the front or to the back by the desired

value by means of dial 5 (front knife) and dial 6 (rear knife).

–

Swing the corner knife station in (see chapter 2.11.1).

28

Page 29

Seam beginning Seam end

Setting example:

Seam offset = 2 stitches

Straight pocket corners

Right and left corner knife

incisions lie parallel

Slanted pocket corners

Right and left corner knife

incisions lie offset

1

4321

stationary knife

1

2

5/6

56

1

2

5/6

29

Page 30

2.12 Reference position - Starting the sewing cycle - Quick stop

Reference position

The reference position is necessary in order to get a defined initial

position.

–

Switchthemainswitchon.

The control is initialized.

–

The DÜRKOPP-ADLER logo briefly appears on the screen.

–

The control checks whether the transport carriage is in its rear end

position.

If this is not the case, the display shows the message “Reference

run”.

Caution: Danger of injury!

Danger of suffering bruising between folder and rest table.

–

Step back on the left pedal.

The reference run starts.

The transport carriage runs in its rear end position.

–

The display changes to the main screen of the sewing unit.

Starting the sewing cycle

–

Step forward on the left pedal.

By repeated stepping on the left pedal the various steps of the

positioning process are started sequentially.

The individual steps are dependent on the working method

(A,D,B,F) and the equipment of the sewing unit

(see chapter 2.15).

–

For positioning corrections:

Step back on the left pedal.

The last s tep of the positioning process is undone.

A new positioning can be made.

–

Step forward on the left pedal.

The sewing cycle is started.

30

Page 31

Quick stop

The safety system of the 745-34-2 offers two possibilities for the

immediate shut-down of the sewing unit in case of faulty operation,

needle breakage, thread breakage etc.:

–

Step back on the left pedal.

The current step of the positioning process or the sewing cycle is

aborted immediately.

The following message appears:

–

Step back on the left pedal.

The carriage runs out of the feeding area.

–

Press the key “RST” on the control panel.

The current sewing cycle is aborted.

2.13 Flap and piping projection

For the unhindered passage of the workpieces at the folder or pick-up

folder the maximum projections of piping, flap and material thickness

(see sketch) must not be exceeded.

The maximum piping strip widths allowed for the individual sewing

equipment (E-No.) can be taken from the Equipment Sheets of the

745-34-2.

1

2

3

1

a

b

4

5

6

NA

1: Folder

2: Flap projection,

max. 20 mm

3:Flap

4: Guide plate at the folder

5: Piping projection,

max. 20 mm / 4 0 mm

6: Piping strip

NA: Seam distance

a, b: Material passage

at the folder

In case of equipment allowing a piping projection of 40 mm and

equipped with blowing tubes at the feeding clamps, the parameter

“Blowing of pocket bag/piping” canbeselectedinorderto

guarantee a trouble-free inlet of piping and/or flap (see Programming

Instructions, chapter 6.4).

31

Page 32

Setting the sew-in depth of the flap

The stop 8 determines the sew-in depth and thus the flap projection.

–

Pull the stop 8 to the front (towards the operator) and lift it.

Place stop 8 in another pair of slotted holes.

–

For fine adjustment adjust the hexagonal bolts 7 underneath the

stop 8.

2.14 Piping strip length

387

The piping strip length must be dimensioned in such a way that it

projects approx. 20 mm beyond the seam beginning and seam end.

This results in the following piping strip length:

Piping strip length = sewing length + 2 x 20 mm

32

Page 33

2.15 Working methods

Working method Remarks

A Piped pockets,

manual positioning of piping strip,

flaps and other additional parts

B Piped pockets,

automatic feed of the piping strip,

with/without incision of the piping ends

optional automatic feed of flap

and additional parts from the right

or from the left or both sides

D Breast welt pockets,

automatic feed and matching

of the breast welt, automatic feed of the

pocket bag

F Piped pockets,

automatic feed of piping strip

and additional parts,

automatic matching and feed

of the flap,

with/without incision of the piping end

1

The individual working methods are described on the following pages.

The description is divided into the following items:

Loading positions

This item indicates which loading positions are used for the various

workpieces (e.g. left and right pieces).

Aligning the positioning aids

This section describes the setting and alignment of the positioning aids

(e.g. positioning marks, marking lamps, stops etc.).

Positioning and starting the sew ing cycle

Under this item the individual positioning steps are listed

with common positioning examples.

ATTENTION!

The steps of the positioning process are dependent on the equipment

of the respective sewing unit.

Thus, the positioning steps described in the examples only apply for

sewing units with equal equipment.

Caution: Danger of injury!

Do not reach under the downholder, the feeding clamp and the folder

during the positioning process.

33

Page 34

2.15.1 Working method A (Production of trousers)

Possible processing variants

–

Front trousers pockets with underlaid pocket bag.

–

Hind trousers pockets with or without flap, with underlaid pocket

bag.

–

Hind trousers pockets with or without flap, with automatically fed

reinforcement strip.

Positioning method

Example: Hind trousers without flap, with underlaid pocket bag

st

step:

1

–

Select the pocket program at the control panel.

–

Push the pocket bag under pocket bag clamp 1 and position at the

markings 2.

As markings you can use e.g. adhesive tape attached to the fabric

sliding plate.

nd

2

step:

–

Position the hind trousers at the “Rear positioning point” 5 and the

marking 6.

–

Touch the left pedal.

The hind trousers is clamped in its position by the fabric

downholder 3 and the waistband clamp 4.

–

Smooth out the clamped hind trousers in the dart area.

–

If additionally equipped with vacuum:

Step the left pedal down as far as it will go and hold it stepped.

The vacuum is switched on.

rd

3

step:

–

Touch the left pedal.

The feeding clamps run to the front and lower onto the workpiece.

–

Position the piping strip 8 on the feeding clamps flush with the front

edges 9.

The alignment of the different types of piping on the feeding clamps

is described more precisely in the following.

See“Positioningthepipingstrip”.

–

Touch the left pedal.

The folder 7 lowers.

–

Touch the left pedal once again.

Thesewingcyclestarts.

34

Page 35

1ststep:

nd

2

step:

2

1

1

3

rd

step:

3

4

6

5

7

8

9

35

Page 36

12

Positioning the piping strip

Double piping:

–

Position the piping strip centered on the feeding clamps and flush

with the front edges.

Single piping (left) with separately positioned facing (right):

–

Position the piping strip on the left feeding clamp flush with the

cutting line.

–

Position the facing on the right feeding clamp.

This positioning method requires the flap clamp “right” (Order

No.0792 011162) available as optional equipment.

–

The edges 1 and 2 must be sufficiently seized by the needle, but

must not be cut by the center knife.

Single piping left with grown-on facing

–

Position the piping strip at stop 3 on the left folding plate.

ATTENTION!

With grown-on facing the right folding plate must not close.

Pull off the hose coupling at the right feeding clamp.

3

36

Page 37

2.15.2 Sewing with flap

Field of application Position Closing order of the flap clamps

Production of trousers right Right flap clamp c loses first

Production of jackets left Left flap clamp closes first

2.15.2.1 Sewing without light barrier

For the simultaneous sewing-in of flaps or other additional parts the

following optional equipment is required according to the field of

application:

Production of trousers: Flap clamp, right (Order No. 0792 011162)

Production of jackets: Flap clamp, left (Order No. 0792 011161)

Selecting the closing order of the flap clamps

–

Set the closing order of the flap clamps 4 at the control panel

under the

menu item “Program Parameters” (Symbol ).

1

12

Shaped guide for flap

The unmachined part 2 is delivered with the flap clamp 1.

It has to be machined as a shaped guide corresponding to the flap

used.

ATTENTION!

The flap length must correspond to the desired length of the pocket

opening.

37

Page 38

Sewing w ith the flap on the right (Production of trousers)

–

When manufacturing trousers always position the flap at the “Rear

positioning point” (light spot 5).

The “Rear positioning point” is a fixed point also for other sewing

units (further flap lengths).

–

Attach the positioning mark 4 for the hind trousers on the fabric

sliding sheet correspondingly.

–

The sketch shows the positioning of a right hind trousers part 3

with flap.

–

Position the left hind trousers parts in reflected image.

The position of the flap remains the same.

3

5

4

4

56

38

Page 39

Page 40

2.15.3 Working method A (Production of jackets)

Piped pockets, manual positioning of piping strip, flaps and other additional parts

Loading positions for left or right jacket front parts

–

Position the left jacket front parts at the rear positioning point (light

spot 3).

Position the right jacket front parts at the front positioning point

(light spot 7).

It is useful to generate a pocket program for left jacket front parts (rear

positioning point selected) and a pocket program for right jacket front

parts (front positioning point selected).

Thus, you only have to alter the pocket program in the main screen

when changing between left and right jacket front parts.

Aligning the positioning aids

Laser markings:

–

When positioning at light spot 9 the distance between breast dart

10 and flap edge 11 will always be the same.

Stops for the manual flap feed:

–

Adjust the stops 8 and 13 on the folder as to the light spots 7 and

12.

ATTENTION!

If the flap 5 is positioned outside the dotted lines of the sewing area,

the function sequence will be interrupted.

The display shows the following message.

Info line

Error of light barrier for flaps

Stop 14 (sew-in depth of the flap):

–

Set the sew-in depth of flap 5 by inserting the stop 14 in the

corresponding pair of slotted holes.

40

Page 41

7654

8

1

9

3

14

10

11

12

13

1

8

5

13

41

Page 42

Caution: Danger of injury!

Do not reach into the working area of the positioning device when

triggering the individual steps of the positioning process.

Positioning and starting the sew ing cycle

1. Position the jacket front part on the fabric sliding sheet.

a) Plain goods:

Left jacket front parts:

Position the jacket front part with breast dart 10 at the light spot 9.

Right jacket front parts:

Position the jacket front part with breast dart 10 at the light spot 6.

b) Patterned goods:

Mark the flap edge 11 on the jacket according to the pattern.

Left jacket front parts:

Position the jacket front part with the marking on light spot 12.

Right jacket front parts:

Position the jacket front part with the marking on light spot 7.

2. Align the pocket incision 15 at the lengthwise lines of the

light spots (center knife incision).

The pocket incision 15 is between breast dart 10 and

side seam 4.

3. If additionally equipped with vacuum:

Step forward on the pedal and release.

The vacuum is switched on.

4. Step forward on the pedal.

The transport carriage moves to the loading position.

The feeding clamps lower onto the jacket front part.

For positioning corrections:

Step back on the pedal.

The feeding clamps lift.

Step back on the pedal again.

The transport carriage runs back to the waiting position.

5. Position the piping strip 16 on the feeding clamps.

Left jacket front parts:

Position the piping strip 16 flush at the front edges 17.

Right jacket front parts:

Position the piping strip approx. 20 mm behind the light spot 7.

42

Page 43

4

6

5

87

9

12

1110

13

1

6

15

9

16

17

1

2

43

Page 44

6. Step forward on the pedal.

The folder 20 lowers.

7. Position the flaps on the left feeding clamp at the stop 14 and

align in sewing direction.

Left jacket front parts:

Position flap 5 at the rear stop 13 of the folder 20.

Right jacket front parts:

Position flap 5 at the front stop 8 of the folder 20.

8. Step forward on the pedal.

Flap clamp 18 closes.

9. Step forward on the pedal.

Flap clamp 19 closes.

Thesewingcyclestarts.

ATTENTION!

The steps 8 and 9 are dependent on the closing order of the flap

clamps set in the pocket parameters.

See Programming Instructions, chapter 6.4.

44

Page 45

8

14

18

13

5

19

2

1

45

Page 46

2.15.4 Working method B

Piped pockets, automatic feed of the piping strip, without/with incision of the piping ends

Example:

Sewing pocket openings w ith or w ithout flap in jacket front parts

Loading positions for left and right jacket front parts

–

Position the left jacket front parts 7 at the rear light spot 6.

Position the right jacket front parts 1 at the front light spot 3.

It is useful to generate a pocket program for left front parts (rear

light spot selected) and a pocket program for right front parts (front

light spot selected).

Thus, you only have to alter the pocket program in the main screen

when changing between left and right jacket front parts.

Caution: Danger of injury !

Do not reach into the working area of the positioning device when

triggering the individual steps of the positioning process.

Positioning and starting the sew ing cycle

Example: Right jacket front part

With piping incision

1. Position the piping strip 8 at the front stop 18.

(For the left jacket front part position the piping strip at the rear

stop 9). Position the piping strip also at the lateral stop 19.

2. Step forward on the right pedal and hold it stepped down.

The left flap clamp 14 opens.

3. Position flap 16 at stop 15.

4. Release the right pedal.

The flap clamp 14 closes.

5. Step the right pedal to the back and hold it stepped down.

The right flap clamp 12 opens.

6. Align pocket bag 11 on the rest table 13 at the positioning mark

(e.g. thin adhesive tape).

46

7. Release the right pedal.

The flap clamp 12 closes.

8. Position the right jacket front part 1 with dart 2 at light spot 4.

9. Align the pocket opening at the lengthwise line of light spot 5

(center knife incision).

Page 47

12 345

1

16

15

14

76

18

11

12

13

19 9

47

Page 48

10. Step forward on the left pedal.

The piping strip is cut and taken up by the pick-up folder.

The transport carriage moves to the loading position.

The feeding clamps lower.

11. Step forward on the left pedal.

The pick-up folder 17 lowers with the piping strip. The folding

sheets close. The piping strip is blown against the folder by air

nozzles fitted in the feeding clamps.

For adjustment see Programming Instructions, chapter 6.4 Modes

“Blowing of pocket bag/flap” .

For positioning corrections step the left pedal back:

st

1

touch of the pedal: The folding sheets open.

The pick-up folder 23 swivels back to the

nd

2

touch of the pedal:The feeding clamps lift.

rd

3

touch of the pedal: The transport carriage moves b ack to the

initial position.

waiting position.

12. Flap feeder 14 with the flap 16 and flap feeder 12 with the pocket

bag 11 swivel in.

13. Step forward on the left pedal.

The flap clamps close.

The flap feeders open, lift and swivel out.

14. Step forward on the left pedal.

Thesewingcyclestarts.

Note

According to the selected pedal mode the sequence of the positions 10

to 14 occurs in inching operation or automatically.

See Programming Instructions, chapter 6.4, for pedal mode selection.

By actuating the “F3” key the piping strip already picked up can be

released again.

48

Page 49

17

11

16

14

12

1

49

Page 50

Example:

Sewing pocket openings w ith or w ithout flap in hind trousers

Loading positions for hind trousers parts

–

Hind trousers can be positioned according to two methods:

a) symmetrical at the central light spot 2 (according to the dart)

b) according to the positioning marks 4 or 8

–

Align the end of pocket opening 7 preferably at the rear light spot

3.

The hind trousers parts should be positioned as close as possible

to the operator. Thus, the hind trousers can - after positioning - be

safely smoothed out when the feeding clamps move forward.

Aligning the positioning aids

Positioning aids 5 and 9:

–

Align the end of the pocket opening at the light spots 1 and 3.

–

Bring the middle of the pocket opening in line with light spot 11.

–

Attach two positioning marks 5 and 9 (e.g. thin adhesive tape) to

the waistband edge of the fabric sliding sheet.

Symmetrical alignment at the light spot 2 (positioning method a)):

–

Align the light spot 2 in such a way that it is exactly above the dart 6.

The front light spot 1 can be shifted towards the operator.

Alignment according to positioning marks 4 and 8 (positioning

method b)):

–

Position the right hind trousers.

Attach a positioning mark 8 (e.g. thin adhesive tape) to the hip bow

of the r ight hind trousers.

The distance between hip bow and pocket opening end 7 must

amount to approx. 30 mm.

–

Position the left hind trousers.

Attach positioning mark 4.

Between the positioning mark 4 and the light spot 3 there must be a

distance of 30 mm + pocket length.

Stop 10 for the automatic feed of flap 12:

–

Adjust the stop 10 of the feeding device as to the pocket opening

end 7.

ATTENTION!

If the flap 12 is positioned outside the dotted line of the sewing area,

the function sequence is interrupted.

The display shows the error number 9720 or 9722.

50

–

When positioning symmetrically at light spot 2 set the stop 10 for

flaps for shorter pocket lengths correspondingly lower within the

sewing area.

–

Adjust the stops for the positioning of piping 13 also in such a way

that the piping is symmetrical to the light spot 2.

Page 51

45

1

2

3

Sewing area

max. 180/220 mm

11 7 8 9 10

½ x pocket length

1

Sewing direction

12

10

13

6

51

Page 52

Caution: Danger of injury!

Do not reach into the working area of the positioning device when

triggering the individual steps of the positioning process.

Positioning and starting the sew ing cycle

With piping incision

1. Position the piping strip at the front stop 21 or at the rear stop 22.

Position the piping strip at the lateral stop 23.

2. Step the right pedal to the back and hold it stepped down.

The feeding device 13 opens.

Position flap 14 at stop 10 of the feeding device.

When sewing pockets with pipings on both sides position loop

and facing on the feeding device, too.

3. Release the right pedal.

The feeding device 13 c loses.

4. Push the pocket bag 16 under the pocket bag clamp 15 and align

according to the positioning marks.

As positioning marks you can use e.g. adhesive tapes attached to

the fabric sliding sheet.

5. Align the hind trousers according to positioning method a) or b) at

the positioning marks 4 and 8 as well as 5 and 9.

6. Step forward on the left pedal.

Downholder 20 and waistband clamp 19 lower and clamp the hind

trousers in its position.

Smooth the clamped hind trousers out to the side and to the front.

7. Step forward on the left pedal.

The vacuum is switched on.

8. Step forward on the left pedal.

The piping is cut and picked up.

The transport carriage moves to the loading position.

The feeding clamps lower.

52

Page 53

45

89 10

23

18

17

16

15

21

13

1

14

10

20

22

19

53

Page 54

9. Step forward on the left pedal.

The pick-up folder 23 lowers with the piping strip onto the hind

trousers.

The folding sheets close.

The piping strip is blown against the folder by air nozzles fitted in

the feeding clamps.

For adjustment see Programming Instructions, chapter 6.4 Modes

“Blowing of pocket bag/flap” .

For positioning corrections step the left pedal back:

st

1

touch of pedal: The folding sheets open.

The pick-up folder 23 swivels back to

nd

2

touch of pedal: The feeding clamps lift.

rd

3

touch of pedal: The transport carriage moves back to the

the initial position.

waiting position.

10. Step forward on the left pedal.

The feeding device 13 swivels in with flap 14.

11. Step forward on the left pedal.

The flap clamp 24 closes.

Thesewingcyclestarts.

Note

According to the selected pedal mode the sequence of the positions 8

to 11 occurs in inching operation or automatically.

See Programming Instructions, chapter 6.4, for pedal mode selection.

By actuating the key “F3” the piping strip already picked up can be

released again.

54

Page 55

14

13

23

24

1

55

Page 56

2.15.5 Working method D

Breast welt pockets, automatic feeding and matching of the breast welt

The maximum sewing length for breast welt pockets is 125 mm.

The positioning device allows an overlapped working method.

Sewing patterned or plain goods

When processing plain goods it is not necessary to align

jacket front part and breast welt 2 as per pattern.

This results in a more rapid working method for plain goods (see page 58)

Aligning the positioning aids

Height of the positioning device:

–

Set the height of the positioning device at the adjusting aid 4.

It must be possible to shift the jacket front part under the

positioning device unhindered.

56

Page 57

1

2

4

3

1

57

Page 58

Caution: Danger of injury!

Do not reach into the working area of the positioning device when

triggering the individual steps of the positioning process.

Positioning and starting the sew ing cycle

1. Align the jacket front part at the positioning marks 12 and 16.

The positioning marks (e.g. thin adhesive tape) serve for the

rough positioning of the jacket front part.

Right pedal: Picking up the “pocket bag”.

2. Position the pocket bag 9 with facing 8 at the stop 13 of plate 15.

Align pocket bag 9 at positioning mark 14 (e.g. thin adhesive tape)

in sewing direction.

3. Step forward on the right pedal.

The gripper 11 lowers onto plate 15.

The needles of the gripper 11 run out and seize the pocket bag 9.

Note

The procedure can be undone by stepping the right pedal backward

once again.

4. Step back on the left pedal and hold it stepped down.

The feeding device 10 opens.

5. Position the upper side of breast welt 2 at the stops 1 and 3.

6. Step forward on the left pedal.

The feeding device 10 c loses and clamps the breast welt 2.

7. Step forward on the left pedal.

The positioning device 10 swivels with breast welt 2 in alignment

position.

8. Align jacket front part to breast welt 2 as per pattern.

9. When equipped with vacuum:

Step forward on the left pedal.

The vacuum is switched on.

Note

The procedure can be undone by stepping the left pedal back once

again.

10. Step forward on the left pedal.

The feeding device 10 turns the breast welt 2.

The gripper 11 runs to the loading area and places the pocket bag

9 on the jacket front part.

11. Step forward on the left pedal.

The transport carriage runs to the loading area.

The feeding clamps lower.

The flap clamp 17 opens.

The positioning device 10 places the turned breast welt 2 on the

left feeding clamp.

The flap clamp 17 closes and clamps the breast welt 2.

The positioning device 10 swivels back to the basic position.

The vacuum is switched off automatically.

58

Page 59

10 2 1 11 8 9

10

1

312131415 16

10

17

2

11

2

9

59

Page 60

For positioning corrections:

Step back on the left pedal.

The flap clamp 17 opens.

Step back on the left pedal once again.

The feeding clamps lift.

The transport carriage runs back to the waiting position.

12. Step forward on the left pedal.

The positioning process starts anew.

More rapid working method for plain goods

For plain goods (no alignment as per pattern) a more rapid working

method can be selected at the control panel (see Programming

Instructions, chapter 6.4).

The steps 1 to 6 of the positioning process remain unchanged.

The steps 7 and 8 are effected as described hereafter:

7. If additionally equipped with vacuum:

Step forward on the left pedal.

The vacuum is switched on.

8. Step forward on the left pedal.

The positioning device 10 turns the breast welt 2.

The gripper 11 moves to the loading area and places

the pocket bag 9 on the jacket front part.

The transport carriage moves to the loading area.

The feeding clamps lower.

The flap clamp 17 opens.

The positioning device 10 places the turned breast welt 2

on the left feeding clamp.

The flap clamp 17 closes and clamps the breast welt 2.

The positioning device 10 swivels back to the basic position.

The vacuum is switched off automatically.

9. Step forward on the left pedal.

Thesewingcyclestarts.

60

Page 61

17

10

11

1

2

9

61

Page 62

2.15.6 Working method F

Piped pockets, automatic feed of the piping strip, incision of piping ends, matching and

feeding of the flap

The working method F allows the matching of the flap as per pattern.

There is no need to sketch the flap manually.

The advantages are a simplified and quick handling as well as a

constantly high quality when processing chequered and striped fabrics.

Loading positions for right and left jacket front parts

–

Position the left jacket front part 10 at the rear light spot 7.

Position the right front part 1 at the front light spot 4.

It is advisable to generate a pocket program for left front parts (rear

light spot selected) and a pocket program for right front parts (front

light spot selected).

Thus, you only have to alter the pocket program on the main

screen when changing between left and right jacket front parts.

Caution: Danger of injury !

Do not reach into the working area of the positioning device when

triggering the individual steps of the positioning process.

Positioning and starting the sew ing cycle

Example: Right jacket front part

With piping incision

1. Position the piping strip 11 at the front stop 12.

(For the left jacket front part position the piping strip at the rear

stop 13). Position the piping strip also at the lateral stop.

2. Step the right pedal back and hold it stepped down.

The right flap clamp 14 for the pocket bag 15 opens.

3. Align the pocket bag 15 on the rest table 16 at the positioning

mark (e.g. thin adhesive tape).

4. Release the right pedal.

The flap clamp 14 closes.

5. Position the right jacket front part 1 with dart 2 on the light spot 4.

6. Align the pocket incision at the light spot 5 (corner knife incision).

62

7. If additionally equipped with vacuum:

Step forward on the left pedal.

The vacuum is switched on.

Page 63

12 345

1

10 9 8 7 6

11 12 14

16

4

15

13

5

63

Page 64

8. Step forward on the left pedal.

The matching device 17 swivels in.

9. For a better positioning and alignment of flap 18:

Switch the vacuum on and off by stepping back on the right pedal

in inching operation.

10. Position the flap 18 at the laser marking 19.

11. Align flap 18 to the jacket front part as per pattern in sewing

direction.

If the patterns of flap and jacket front part do not match exactly:

- Step the right pedal back.

The vacuum is switched off.

- Align the jacket front part as per the pattern of flap 18 by slightly

shifting it to the right or to the left.

- Step forward on the right pedal.

The vacuum is switched on again.

Note !

Do not shift the jacket front part too far so that the pocket opening

will not tear at the pocket incision.

ATTENTION!

After the alignment as per pattern the flap edge 23 must not project

beyond the light spot 3.

If the sewing range is exceeded, the function sequence is interrupted.

Error number 9720 or 9722 appears in the display.

12. Step forward on the left pedal.

Clamp 17 of the matching device closes.

13. Step forward on the left pedal.

The matching device swivels up and turns the flap 18.

The flap feeder 20 seizes the flap 18 and holds it clamped.

14. The piping strip is cut and taken up by the pick-up folder. The

transport carriage moves to the loading position.

The feeding clamps lower.

15. Step forward on the left pedal.

The pick-up folder 21 lowers with the piping strip.

The folding sheets close. The piping strip is blown against the

folder by air nozzles fitted in the feeding clamps. For the

adjustment see Programming Instructions, chapter 6.4 Modes

“Blowing of pocket bag/flap” .

64

For positioning corrections step the left pedal back:

st

1

touch of pedal: The folding sheets open.

The pick-up folder 23 swivels back to the

nd

2

touch of pedal: The feeding clamps lift.

rd

3

touch of pedal: The transport carriage moves back to the

initial position.

waiting position.

16. Step forward on the left pedal.

The flap feeder 20 swivels in w ith flap 18.

The flap feeder with the pocket bag swivels in.

The flap clamps on the feeding clamps close.

Page 65

17. Step forward on the left pedal.

Thesewingcyclestarts.

Note

According to the selected pedal mode the sequence of the positions 12

to 18 is effected in inching operation or automatically.

See Programming Instructions, chapter 6.4, for pedal mode selection.

By actuating the key “F3” the piping strip already picked up can be

released again.

3

1

20

18

23

17

18

19

21

65

Page 66

2.15.7 Folder monitoring

S8

S7

The folder in use is monitored by the sensors S 7 and S 8. The sensors

are actuated by a hexagonal bolt screwed in the pick-up folder.

If a sewing program with incorrect clamp position settings is started,

the following message appears:

Info 9014

Correction

–

Step back on the left pedal.

The error message is cancelled.

–

Select another program or alter the setting in the program.

Setting

Single piping, left

The upper sensor S 8 is active. The outer position of the left clamp

must be set.

Single piping, right

The lower sensor S 7 is active. The outer position of the right clamp

must be set.

Double piping

None of the sensors is active.

66

Page 67

2.16 Functions and operation of the optional equipment

In this chapter the function and the operation of the most important

optional equipment is described.

2.16.1 Automatic incision device for piping ends

With the automatic incision device for piping ends the piping strip end

is cut open from the center knife incision to the piping ends. The

cutting areas are automatically adapted to the respective seam length

as well as to the positioning point.

The piping strip ends can be notched up to 30 mm (with a pocket

length of 180 mm) or 20 mm (with a pocket length of 200 mm). The

incision device for piping ends is already a c omponent of the

E-equipments E 3503, E 3504, E 3507 and E 3508.

The total length L of a piping incision always amounts to

approx. 45-50 mm (dependent on the fabric) and cannot be altered.

The programmable value S indicates the length of the cut within the

pocket length T.ThevalueS is set to 15 mm as a standard. With this

adjustment the piping strip is notched 30 mm from the seam. When

increasing the value S the cut is shifted to the middle of the pocket;

when the value S is reduced, the cut is shifted outwards (see sketch on

page 67).

1

Note

At the front or the rear positioning point with sewing lengths of 200 mm

the cutting length can only be altered inwards to the middle of the

pocket.

Activating and sw itching the piping incision device on

–

Select the parameter “Piping incision device” and the icon “Piping

incision device on/off” under the menu item “Pocket parameters”

(key F1) - see Programming Instructions, chapter 5.4.

Correcting the position of the cut

–

Select the parameters “Piping incision device on/off -

Correcting the piping incision at the seam beginning” or

“Piping incision device on/off - Correcting t he piping incision

at the seam end” under the menu item “Pocket parameters” (key

F1)

(See Programming Instructions, chapter 6.4)

The entered correcting value corresponds to the value S.

(see sketch on page 69)

67

Page 68

21

3

Function and operation

Positioning when processing double piping

–

Position the piping strip at the front or rear stop 1 for the respective

positioning point. Position the piping strip also at the lateral stop 2.

–

Carry out the loading process as described in chapter 2.15.4

(method B) or chapter 2.15.6 (method F) and start the sewing

cycle.

Positioning when processing single piping

–

Position the piping strip at the front or rear stop 1. Position the

piping strip also at the center stop 3.

68

Page 69

View of the cutting areas

Seam beginning

Piping strip

T = Pocket length

L = fixed cutting length of the

piping knife

S = cutting length within

the pocket length

Ü = Cut-open

piping projection

30 mm with sewing length 180

20 mm with sewing length 200

1

seam end

Example:

Cutting length: S = 15mm

Fixed cutting length: L = 45 mm

Cut-open piping projection: Ü = 30mm

69

Page 70

2.16.2 Downholder, pocket bag and waistband clamp

With these equipment hind trousers and pocket bags are safely held

when smoothing out the fullness caused by the dart.

The devices consist of the following components:

Order No. 0745 597514

–

Downholder 1

–

Pocket bag clamp 3

Order No. 0745 597524

–

Waistband clamp 2

312

Caution: Danger of injury!

Do not reach under downholder 1 and waistband clamp 2 during the

positioning process.

Function

–

Push the pocket bag under the pocket bag clamp 3 and align.

–

Push the hind trousers under the open waistband clamp 2 and

align.

–

Step forward on the left pedal

Downholder 1 and waistband clamp 2 lower and clamp the hind

trousers in its position.

–

Smooth out the clamped hind trousers laterally and to the front.

70

Page 71

2.16.3 Feeding devices for flaps, pocket bags etc.

When using these feeding aids the total duration of a working cycle is

reduced.

Flap, pocket bag etc. are manually positioned during the machine time

already.

All feeding devices can also be used in c ombination with the device for

cutting open the piping ends.

The feeding devices are equipped with a blower for a flat pocket bag.

Two different feeding devices are available for an optimum adaptation

to the respective field of application:

0745 517564 Left feeding devices, sewing length 180-220 mm

0745 517574 Right feeding devices, sewing length 180-220 mm

1

1

Switching t he transfer device on

–

Switch the transfer device on in the menu item “Pocket parameters

(F1)”.

Function

–

Step the right pedal back and hold it stepped down.

The right clamp 2 of the feeding device opens.

–

Insert flap or additional part in the feeding device.

–

Release the right pedal.

Theflapclamp2closes.

–

Step forward on the right pedal and hold it stepped down.

The left flap clamp 1 opens.

–

Position the flap at the stops of the feeding device.

–

Release the right pedal.

Theflapclamp1closes.

2

After the folding process

–

Step forward on the left pedal.

The flap clamps 1 & 2 swivel in the loading area and feeds the flap

automatically.

71

Page 72

2.16.4 Throw-over stacker

The finished workpieces are stacked on the throw-over stacker

(Order No. 0745 597554).

The stacked and clamped workpieces can be removed when actuating

the foot switch 7.

The triggering of the stacker is effected via a control impulse from the

solenoid valve YC 111.

The pneumatic functions can be taken from the enclosed pneumatic

connection diagram.

Activating the stacker

–

Activate the stacker at the control panel in the menu “Machine

parameters”.

(See Programming Instructions, chapter 7.2)

The parameter signals the control that the sewing unit is equipped

withastacker.

Switching t he stacker on

–

Switch the stacker on in the menu “Pocket parameters”.

(See Programming Instructions, chapter 6.4)

Function sequence

Caution: Danger of injury!

Do not reach into the working area of the throw-over stacker

during the stacking process.

–

During the sewing cycle the material runs into the opening between

the stacked goods stand 1 and the clamping pipe 4.

–

After notching the corners and lifting of the feeding clamps the

stacking process is triggered by the control impulse from the

solenoid valve YC 111 .

Clamping pipe 4 and smoother 3 swing against the stacked goods stand 1.

The material is clamped.

–

A pneumatic cylinder holds the clamping pipe 4 at the stacked goods stand 1.

–

Clamping pipe 2 and counter-holder 6 open.

For this purpose they swing away from the stacked goods stand 1.

–

The smoother 3 lifts and smoothes the material out above the stacked

goods stand 1 and the rest sheet 5.

–

Before the smoother 3 reaches its front end position, it swings back

to its initial position.

–

Clamping pipe 2 and counter-holder 6 close.

For this purpose they swing back against the stacked goods stand 1 and

clamp the stacked material.

–

The clamping pipe 3 swings back behind the clamping pipe 4.

–

In this position the motion sequence is briefly interrupted.

The material is safely clamped.

–

The clamping pipes 4 and 3 swing back to the basic position

and the clamping pipe 2 is held at the stacked goods stand 1.

72