Adler 745-34 Installation Manual

Manual, complete

745 - 34 - 2

Sewing unit for runstitching of piped flap

and welt pocket openings and pocket corners

Working methods: A, B, D, F

Operating Instructions

Installation Instructions

Service Instructions

Instructions for Programming DAC

1

2

3

4

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon + 49 (0) 5 21 / 9 25-00 • Telefax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 02/2005 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 745181

745 - 34 - 2

Manual, complete

Contents

Operating Instructions

Installation Instructions

Service Instructions

Instructions for Programming DAC

Interconnection-diagram

9870 745154 B

9890 745002 B

Pneumatic circuit plan

9770 745005

Index Page:

Part 2: Installation Instructions 745-34-2

1. Scope of delivery .............................................. 3

2. General notes ................................................ 3

3. Installing the sew ing unit

3.1 Transport.................................................... 4

3.2 Removingthesecuritydevices....................................... 5

3.3 Settingtheworkingheight ......................................... 6

3.4 Adjusting the foot pedals .......................................... 7

4. Attaching the machine parts removed for shipping

4.1 Threadreelholder.............................................. 8

4.2 Cylinder for pick-up folder stroke ..................................... 9

4.3 Workpieceboxes............................................... 10

4.4 Fastening the holder for control panel, bobbin winder and right-hand tray ............. 11

4.5 Table extension (optional equipment) ................................... 12

4.5.1 Table extension for working method with bundle clamp carriage ................... 12

4.5.2 Tableextensionforstackingtotheside ................................. 13

4.6 Throw-over stacker (optional equipment) ................................ 14

2

5. Electrical connection

5.1 Connecting the control panel DAC III ................................... 16

5.2 Connecting the external bobbin winder .................................. 16

5.3 Checking the nominal voltage and connecting to the mains ..................... 17

5.4 Checking the nominal voltage of the vacuum device (optional equipment) ............ 20

5.5 Directionofrotationofthesewingmotorandthevacuumblower ................. 20

6. Pneumatic connection ........................................... 21

7. Connection to the factory-own vacuum unit ............................. 22

8. Oil lubrication ................................................ 23

9. Commissioning ............................................... 24

10. Installing the sew ing s oftware

10.1 General ..................................................... 24

10.2 Loading the program ............................................. 25

10.3 Dongle-Update via the Internet ...................................... 26

1. Scope of delivery

–

Basic sewing unit for runstitching of piped, flap and welt pocket

openings with rectangular and slanted pocket corners, consisting

of:

–

Height-adjustable stand

–

Step motors for sewing drive, material feed, length adjustment

of the corner incision device

–

Twin needle lockstitch machine

–

DAC III control with control panel

–

Laser marking lamps

–

Sewing light

–

Compressed air maintenance unit with compressed air pistol

–

Thread reel holder

–

Workpiece boxes for additional parts to the left of the operator

and underneath the table top

–

Tools and small parts in the accessories

–

Feeding and sewing equipment according to the working

method

–

Optional equipment

2. General notes

2

ATTENTION !

The sewing unit must only be assembled by trained specialist staff.

Any work on the electrical equipment of the sewing unit must

only be c arried out by electricians or correspondingly instructed

persons.

The mains plug must be pulled out.

The enclosed operating instructions of the s tep motor manufacturer

have to be observed in any case.

3

3. Installing the sewing unit

3.1 Transport

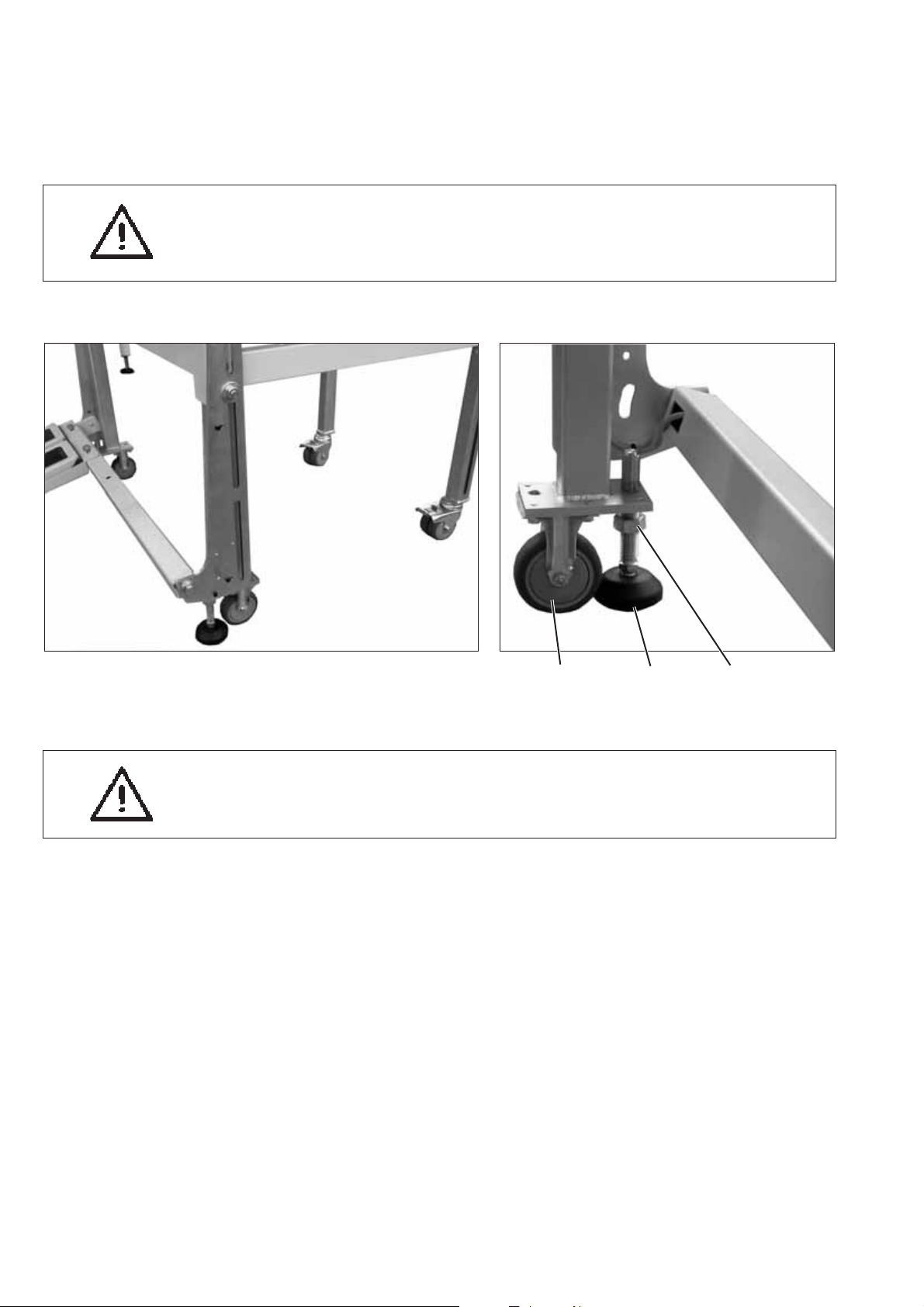

For in-house transport the stand is equipped with four castors.

ATTENTION !

Do not lift the sewing unit at the table tops.

Use an elevating platform truck or a forklift truck.

321

ATTENTION!

Before commissioning the sewing unit screw out the s tand

feet 2 and 3 until a s ecure footing is achieved.

Lifting the sew ing unit

–

Push the elevating platform truck or the forklift forks into the

openings 1 at the back of the sewing unit.

Rolling the sewing unit

–

For transport purpose unfasten the stand feet 2 and 3 by turning

them to the right.

–

After transport secure the sewing unit by turning the stand feet 2

and3totheleft.

4

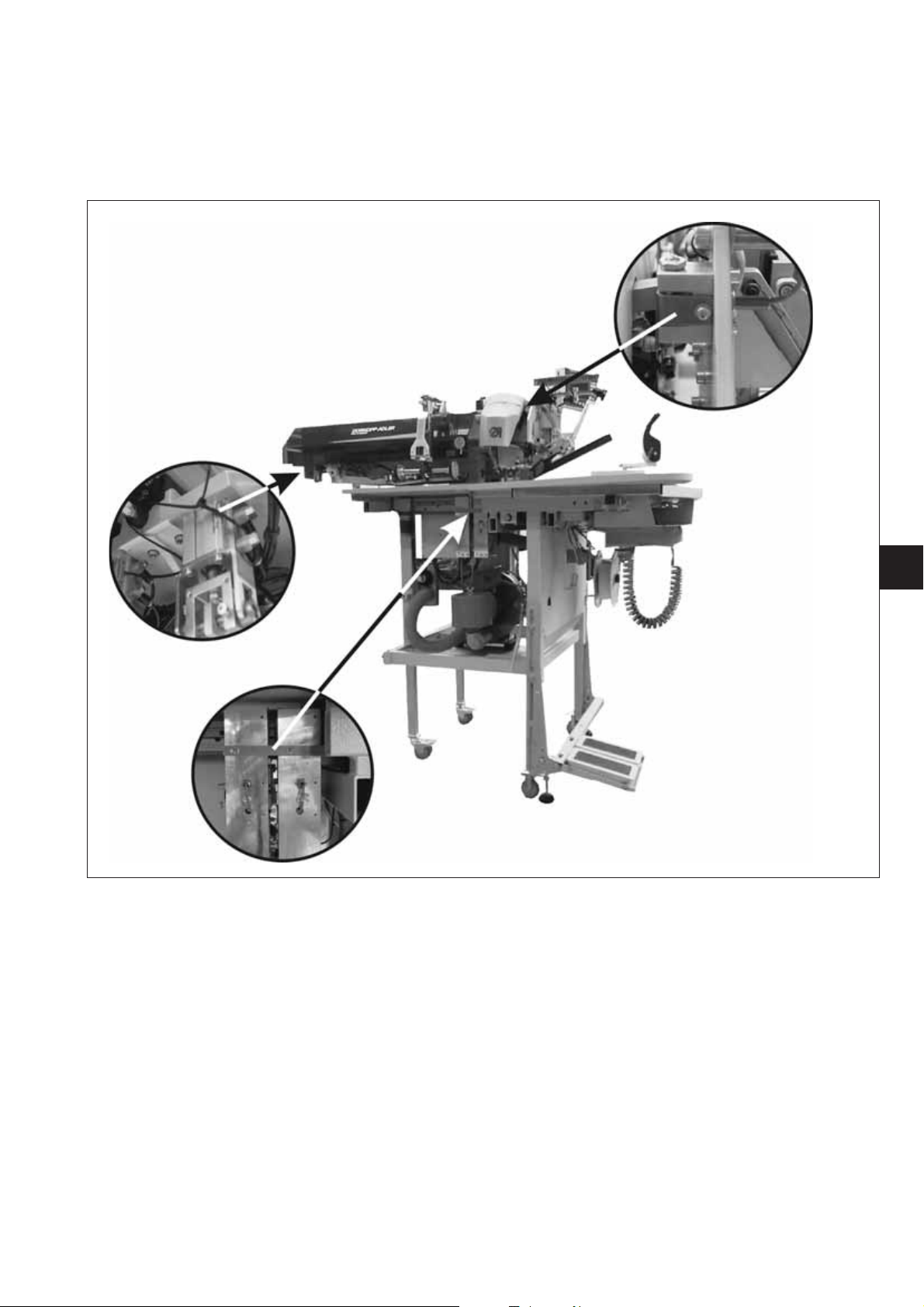

3.2 Removing the securing devices

Before installing the sewing unit all six securing devices have to be

removed.

If the sewing unit has to be transported to another place, please use

the securing devices again.

2

5

3.3 Setting the working height

12

The working height can be set between 79 cm and 110 cm

(measured up to the upper edge of the table top).

The sewing unit is set to the lowest working height of 79 cm by the

manufacturer.

ATTENTION: Danger of breakage !

When loosening the securing screws.

The sewing unit may overturn when the tubular feet of the frame are

pulled out.

Set the height of the sewing unit by pulling equally the tubular feet of

the frame.

–

Loosen the nut 1 ( 4x) and the shoulder bolts 2 (4x) (clamping of the

front tubular foot).

–

Loosen screws 3 (4x) (clamping of the rear tubular foot).

–

Set the table top to the desired height to be flush.

–

To avoid a tilting, pull out / push in the tubular feet uniformly on

both side.

–

Tighten the shoulder bolts 2 and the screws 3.

–

If you want to set the foot pedal afterwards, please do not tighten

the nut 1 yet. Otherwise it can also be tightened.

3

6

3.4 Adjusting the foot pedals

1 243

43 5

The height of the foot pedals can also be set, independently of the

height of the sewing unit.

The angle of slope and the lateral position of the foot pedals are also

adjustable.

Setting the height

–

Loosen nut 1 and shift both guides 2 in the slotted hole.

Loosen the screws 3 additionally, in order to displace them in the

next slotted hole.

Make sure to have the same height in both guides 2.

–

Tighten the nut 1.

Setting the angle of slope

–

Unscrew the screw 4 and swivel the pedal.

–

Adjust the angle of slope of the pedal.

–

Tighten the screws 3 (2x) and screw 4 with the pedal at the desired

position.

Setting the lateral position

–

Loosen the screws 5 and shift the pedal laterally.

–

Tighten screws 5 again.

2

7

Loading...

Loading...