Page 1

Manual, complete

745 - 34 Speedpocket

Sewing unit for runstitching

of rectangular piped pockets

Operating Instructions

Installation Instructions

Service Instructions

Instructions for programming DAC

1

2

3

4

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon + 49 (0) 5 21 / 9 25-00 • Telefax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 08/2005 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 745171

Page 2

745 - 34 Speedpocket

Manual, complete

Summary

Operating Instructions

Installation Instructions

Service Instructions

Instructions for programming DAC

Interconnection diagram

9870 745131 B

9890 745001 B

Pneumatic circuit plan

9770 745002

Page 3

Index Page:

Part 4: Programming Instructions DAC Cl. 745-34 Speedpocket

Program version A 01.0

1. Structure of menu ............................................ 3

2. Operation

2.1 Editingthepocketprogram ....................................... 5

2.2 Editing the sequence ........................................... 6

3. Setting programs of the machine

3.1 Indicating / Deleting the counter for the bobbin thread quantity .................. 7

3.2 Setting the counter for the bobbin thread quantity .......................... 7

3.3 Testing the feeding process ....................................... 7

3.4 Step-by-stepmode ............................................ 8

3.5 Dongle menu ................................................ 9

4. Multitest

4.1 Testingtheoutputelements....................................... 12

4.2 Testing the input elements manually .................................. 12

4.3 Testing the input elements automatically ............................... 12

4.4 TestingtheROM ............................................. 13

4.5 TestingtheRAM.............................................. 13

4.6 Testingthesewingmotor......................................... 13

4.7 Testingthecornerknives......................................... 14

4.8 Testingthecenterknifeactivation ................................... 14

4.9 Settingthelight-barrierfortheflap................................... 14

5. Table Seam Parameters ......................................... 16

6. Machine parameters ........................................... 18

7. Error messages/ Functional indications .............................. 19

8. Input elements .............................................. 24

9. Output elements ............................................. 24

Page 4

Page 5

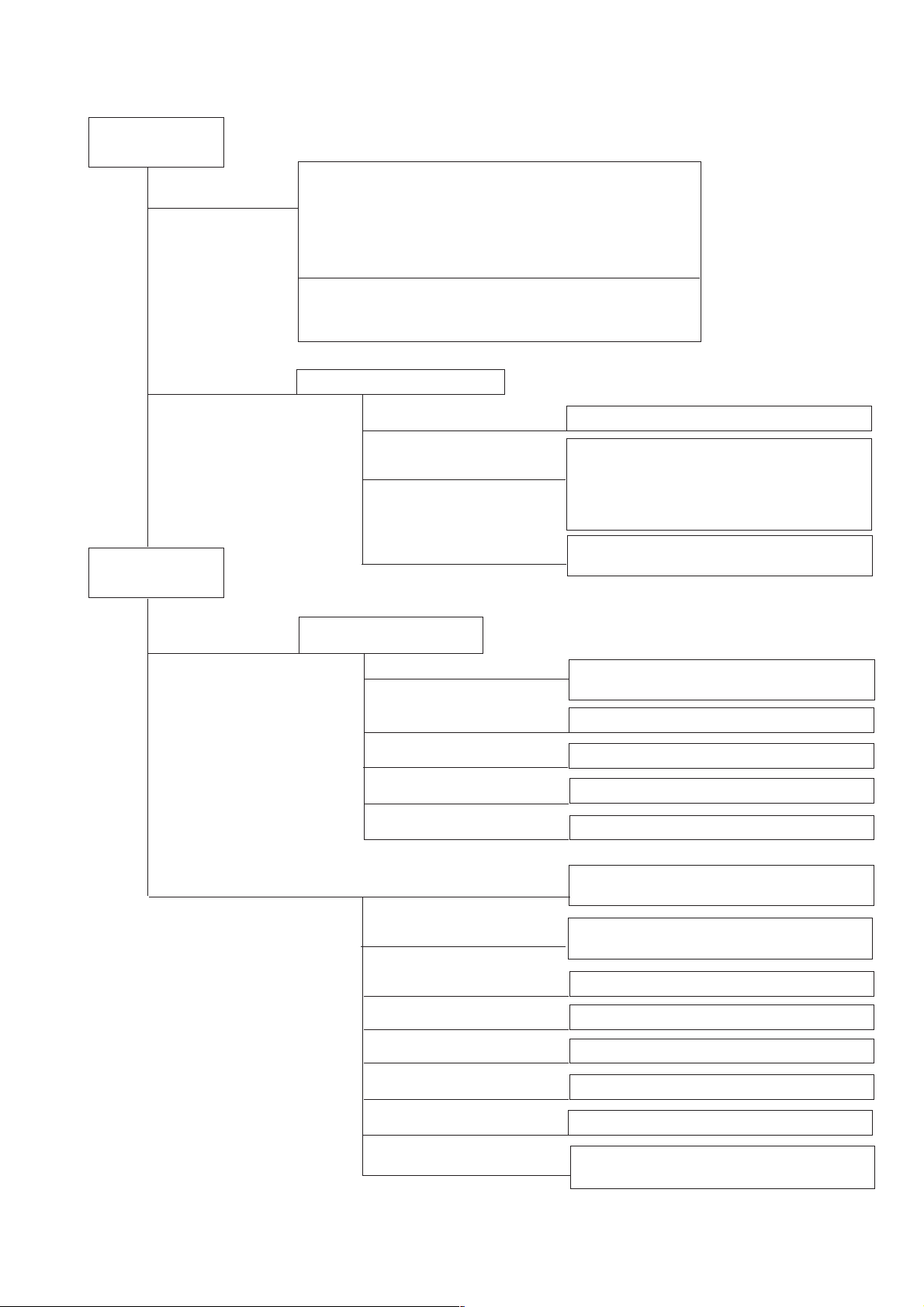

1. Structure of menu

Switch-on

“P” and “ç” 902 Input elements, manual

“P” and “è” Initializing the parameters Code : 2548

Multitest 901 Output elements

903 Input elements, automatic

904 Testing the ROM

905 Testing the RAM

906 Testing the sewing motor

950 Testing the corner knives

951 Testing the center knife

952 Setting the light-barrier for the flap

400 Machine parameters

Initializing the parameters

500 501 Machine parameters

502 Pockets

503 Sequence

504 All parameters

Produced

Sewing mode

“P” and “F” Setting programs

600 Displaying the counter of pieces

301 Indicating / Deleting

the counter for the bobbin thread quantity

302 Setting the bobbin thread counter

303 Testing the feeding process

304 Step-by-step mode

305 Dongle

“P” Editing the current seam parameters,

100 -136

“F” short/long Sequence, short = on/off,

long = editing

“ESC” and “ç” Indicating / Deleting the piece counter

“ESC” and “ê” Center knife on/ off

“ESC” and “é” Corner knife on/ off

“ESC” and “è” Stacker on/ off

“é”or“ê” Changing the current seam length

“ç”or“è” Changing over to the next seam

program

3

Page 6

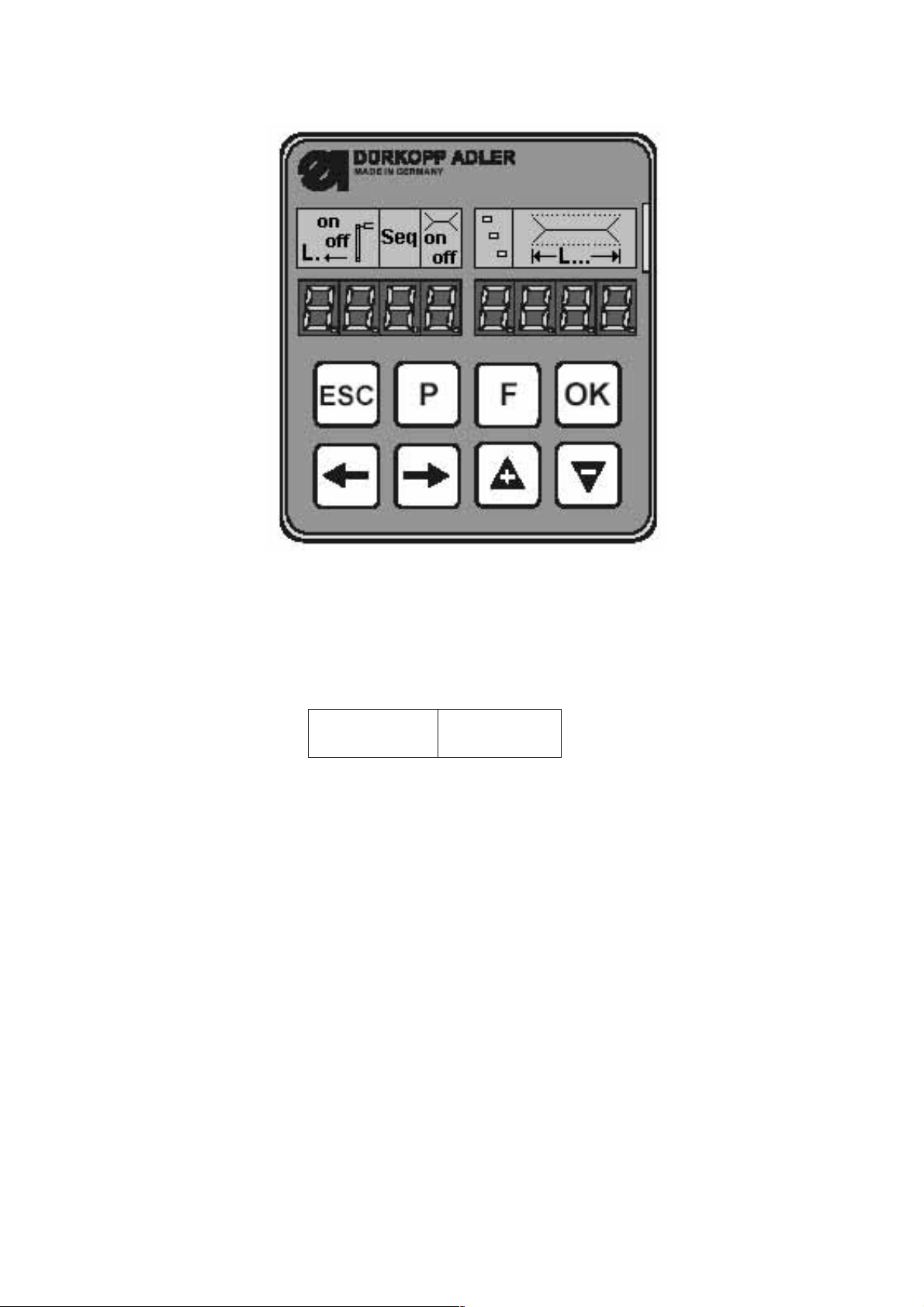

2. Operation

If neither the key ( “P” and “è” ) nor the key ( “P” and “ç” )

is pressed within 2 seconds after switching on, the program

starts the sewing mode.

First the machine has to carry out the reference run initiated

by the pedal.

Until then the display will flash.

rEF

4

Page 7

2.1 Editing the pocket program

When the machine is in basic position and in the sewing mode and the

key “P” is actuated, you get into the level for editing the current pocket

program.

In case the feeding process has started already, this is not possible.

For this purpose the feeding operation w ould have to be cancelled so

that the machine is in its basic position again.

Selecting the seam parameter

100 23

current parameter value

The parameter number flashes, select with the keys”é“ and ”ê“.

After “OK” the display changes, e.g. ->

Editing the seam parameter

108 054

Initializing the pocket program

1P P I n I

One digit of the value 054 flashes and can be changed with the keys

”é“ and ”ê“andsavedwith“OK”.

“ESC” -> no alteration and back.

With the keys “¬ “or“®” you can change to the next editable digit.

Parameter No. 108

After a short actuation of “F” the display changes to this submenu.

The initialization is carried out with “OK” and aborted with “ESC”. With

the initialization a pocket program with standard values is loaded.

9P P I n I

With a long actuation of “F” all 9 seam pograms are initialized.

Afterwards the display changes to the mode for selecting a seam

parameter in the current seam program again.

5

Page 8

2.2 Editing the sequence

1

When in the sewing mode key “ F ” is pressed longer than 2 seconds,

you get into the level for editing the sequence.

With a short actuation of “F” the sequence is switched on or off.

At the beginning of editing the sequence the current sequence is

cancelled and the first digit after the “S” flashes.

123 4 5 67

2.3 Piece counter

S 1054

With the keys ““and”¯“ the program number can be altered. With the

keys”¬“or“®” you change to the next position.

After actuating the key ”¬” the position right of the flashing digit is

cancelled. Thus, the number of seam programs per sequence is

determined. Max. 7 seam programs can be entered per sequence.

With “OK” the editing of the sequence is finished and the display goes

back to the sewing mode with sequence.

When actuating “ESC” and “¬” in the sewing mode, the daily piece

counter is displayed.

With a short touch of key “ESC” you change to the sewing mode again.

With a long actuation of “OK” the counter is set to “0” and the display

“0” appears until the “ESC”-key is actuated.

6

Page 9

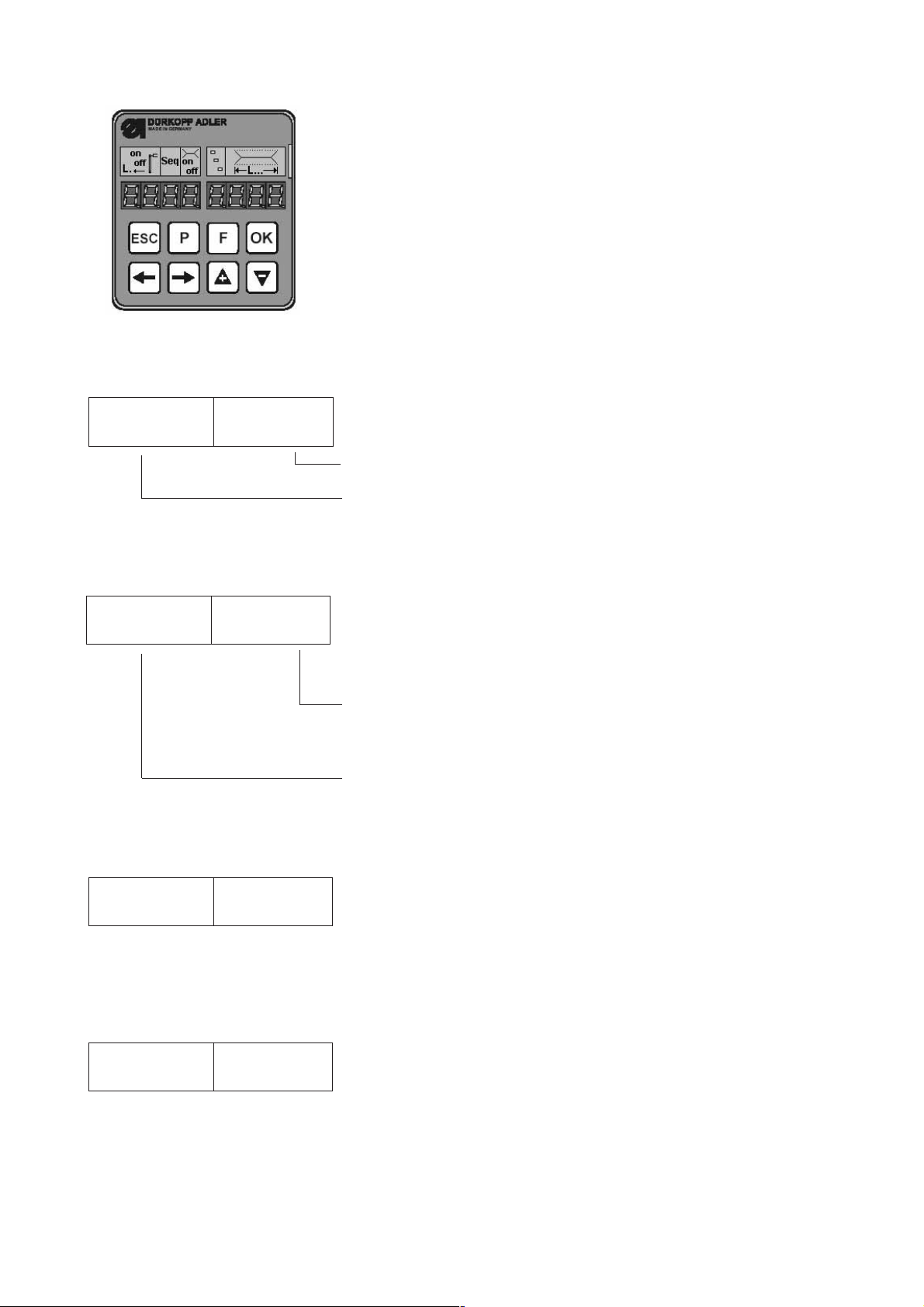

3. Setting programs of the machine

The setting programs can be reached from the sewing mode by

actuating “P” and “F” simultaneously

List of setting programs:

301 Indicating the counter for the bobbin thread quantity / Deleting

302 Setting the counter for the bobbin thread quantity

303 Testing the feeding process

304 Step-by-step mode

The various setting programs can be selected with the keys ““ and

” ¯“, activated with “OK” and quitted with “ESC”.

30x ____

After actuating “ OK” the selected program is activated.

3.1 Indicating the counter for the bobbin thread quantity / Deleting

301 12 34

The current value can be reset to the programmed maximum value by

a long actuation of “ OK”.

The indicated value has to be multiplied by 10.

3.2

Setting the counter for the bobbin thread quantity

302 1 2 34

The value flashes and can be altered with the keys ““ and ” ¯“. When

actuating “OK” the value is saved and a setting program can be

selected again.

The indicated value has to be multiplied by 10.

At the value 0 the bobbin thread counter is switched off.

3.3 Testing the feeding process

303 on

After a long actuation of “OK” the program changes to the sewing

process.

After the reference run the feeding process is carried out as in the

sewing program. When actuating the pedal in inching operation the

transport carriage runs in its rear position. The feeding clamps are

lifted and the flap clamps open. The process can be started anew or

quittedwith“ESC”.

Switch the machine off in order to quit the program.

7

Page 10

3.4 Step-by-step mode

304 StEP

SP PEd

Withalongactuation of “OK” the program changes to the sewing

process.

At the stops at the seam beginning and seam end the following display

appears:

After stepping on the pedal the sewing process continues up to the

next stop.

While the sewing program is running, the display changes to the

normal sewing process again.

Switch the machine off in order to quit the program.

8

Page 11

3.5 Dongle Menu

305

do dir

Data dongle, e.g. for Cl. 745-34S

d745 -34S

Important:

To save the parameters you will need an empty dongle. It can be

bought at the sales point of Dürkopp Adler AG under the following part

number 9835 901005.

After actuating the “OK” k ey, the display display changes to a lower

level. Using the key “¬” will bring it back, one level higher. For other

choices within the menu use the ““ and ”¯“keys.

At the same time, the right half of the display flashes.

If no dongle is connected at the plug connection “X110“, the message

“Info 4301“ will be displayed. The left and right half of each menu item

will flash during the data transmission.

Menu item display dongle content

The following displays may appear after actuating the “OK”key

(to save the parameters)

Boot dongle, e.g. for C l. 745-34S

b745 -34S

Empty Dongle (not formatted)

Info 4302

do L PPP

InFo 4323

(The dongle has to be formatted first, check menu item format dongle).

Exit and go back to the Menu item display dongle content by

actuating the “OK“key.

Menu item load the machine parameter

Confirmation

After actuating the “OK” k ey, the machine parameter will be loaded

from the dongle to the control.

Exit and go back to the Menu item load the machine parameter by

actuating the “ESC“key.

If the dongle contains no machine parameter, the message “Info 4325“

displays, it has to be confirmed by actuating the “OK“key.

9

Page 12

do L 9PS

InFo 4324

do S PPP

InFo 4321

Menu item load pocket program and sequence

Confirmation

After actuating the “OK” k ey, the pocket parameter and the sequence

will be loaded from the dongle to the control.

Exit and go back to the Menu item load pocket program and

sequence by actuating the “ESC “key.

If the dongle contains no pocket program, the message “Info 4326“

displays, it has to be confirmed by actuating the “OK“key.

Menu item save machine parameter

Confirmation

do S 9PS

InFo 4322

do For

After actuating the “OK” k ey, the machine parameter of the sewing unit

will be saved onto the dongle.

Exit and go back to the Menu item save machine parameter by

actuating the “ESC“key.

Menu item save pocket program and sequence

Confirmation

After actuating the “OK” k ey, the pocket parameters and the sequence

will be saved onto the dongle.

Exit and go back to the Menu item save pocket program and

sequence by actuating the “ESC “key.

Menu item format dongle

InFo 4320

10

Confirmation

After actuating the “OK” k ey, the dongle will be formatted.

Format cancel and go back to the Menu item format dongle by

actuating the “ESC“key.

Page 13

d745 For

d745 -34S

Boot-Dongle, e.g. for cl. 745-34S

b745 -34S

Empty Dongle

During the format process the display flashes

When the format process ends, the Menu item format dongle is

displayed again.

I

mportant:

The data on the dongle will be erased through the formatting.

A formatting of the dongle is necessary, if in the Menu item display

dongle content does not display

but for example

, the following.

Info 4302

11

Page 14

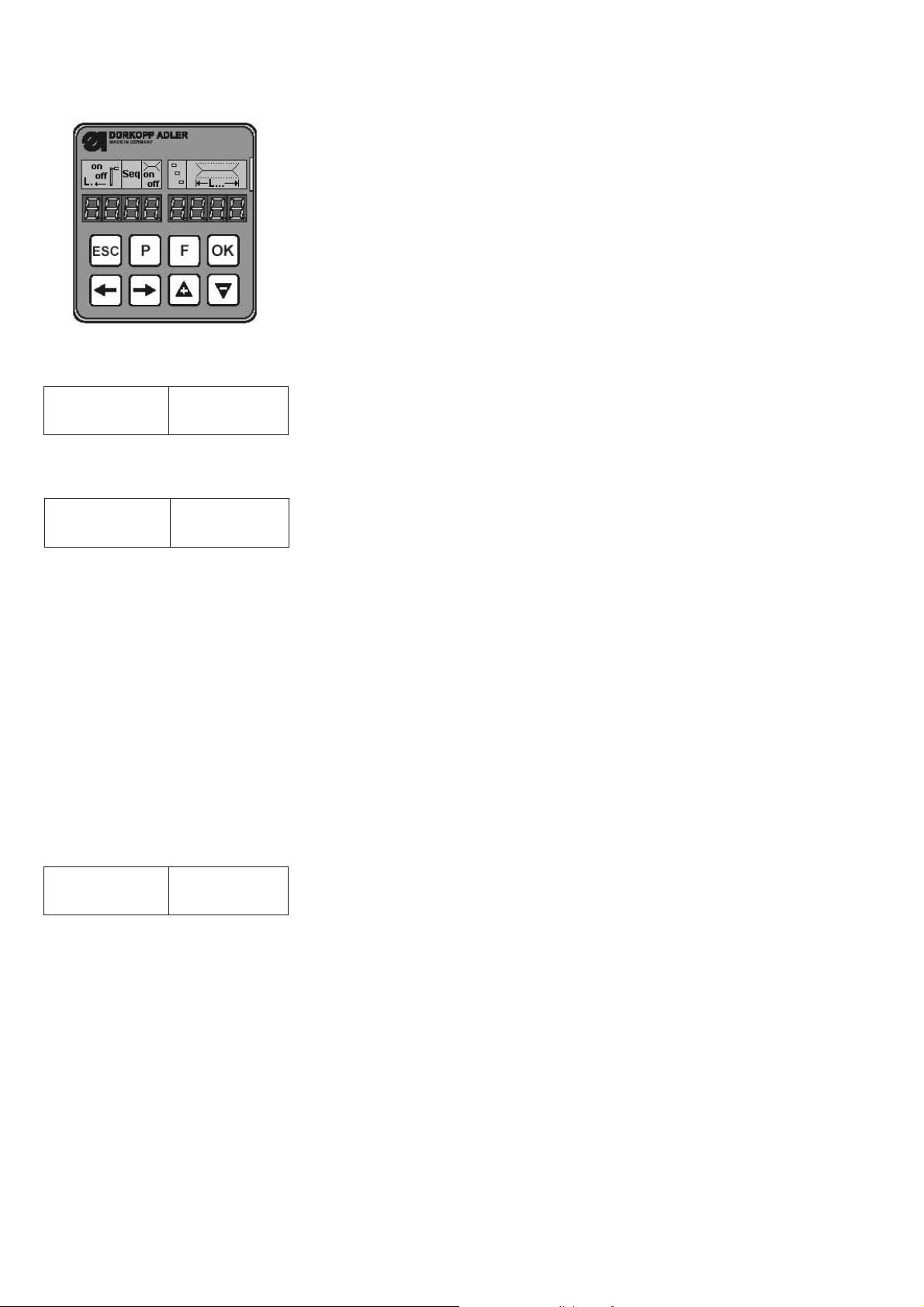

4. Multitest

4.1 Testing the output elements

901 ____

The Multitest programs can be reached by switching on and actuating

“P”and “ç” simultaneously.

List of programs:

901 Testing the output elements

902 Testing the input elements manually

903 Testing the input elements automatically

904 Testing the ROM

905 Testing the RAM

906 Testing the sewing motor

950 Testing the corner knives

951 Testing the center knife

952 Setting the light-barrier for the flap

After “OK” the display changes to

Y01 0

In the left half of the display the number of the output element flashes,

the right half shows its state:

0=off,

1 = on.

With the keys “é” and “ê” the number of the output element can be

selected.

With “OK” this output element is switched on or off.

When changing over to the next output element the state of the

preceding one remains unchanged.

4.2 Testing the input elements manually

902 ____

After “OK” the display changes to

S01 0

12

In the left half of the display the number of the input element flashes.

In the right half the state is indicated;

0 or 1 respectively.

With the keys “é” and “ê” the number of the input element can be

selected.

Page 15

4.3 Testing the input elements automatically

903 ____

After “OK” the display changes to

E01 0

In the right half the state of the input element is indicated which

changed last.

4.4 Testing the ROM

904 ____

buSY

1C3F H 1

4.5 Testing the RAM

905 ____

buSY

R1.1r2.1

Display during the test

Display after the test

check sum, e.g.

1=OK

0 = Error

Display during the test

Display after the test

1=OK 1=OK

0 = Error 0 = Error

4.6 Testing the sewing motor

906 ____

After “OK” the display changes to

n0

With the keys “+” and “-” the speed can be changed in steps of 100

r/min.

13

Page 16

4.7 Testing the corner knives

950 123

In the right LED field the c urrent seam length of L1 flashes.

With key “P” the corner knives are moved up and down.

4.8 Checking the center knife activation

951 on

The center knife is switched on and off with key “F”.

4.9 Setting the light-barrier for the flap

–

Swing out the folding station.

–

Place the fabric under the feeding clamp.

952 ____

952 LS 1

After actuating the “OK“ k ey, the switching status of the light-barrier to

the flap-scanning will be shown in the right half of the display flashing.

Reflecting ® LS 1

No reflection ® LS 0

Activate the following output elements:

Lower the feeding clamps left and right

Close the folding sheets

Close the flap clamps

–

Pull the feeding clamp to the feeding area.

–

Align the light-barrier with the center of the reflecting foil.

Please check the area from the seam beginning to the seam end

on the clamp.

–

Determine the distance between the switch actuation point of the

light-barrier to the needle. For this purpose lay a pattern made of

paper having the same size as the flap under the flap clamps.

Then push the feeding clamps from the feeding area to the

machine head until the light-barrier has no longer reflexion. Then

measure the distance between the front edge of the pattern to the

needle.

–

Enter the distance between the switch actuation point of the

light-barrier and the needle in the machine parameters. Switch the

machine off, when swithching it on strike the “P“ and “ ® “keys

simultaneously in order to switch over to the programming level

(400) for machine parameters (Code 2548). In the menu item 406

enter the distance in 1/10 mm.

14

Page 17

Orange LED on = reflection available

Orange LED off = no reflection

Green LED on = stable switching signal

If the green LED does not shine, the light-barrier should be cleaned,

readjusted, replaced or a new reflecting foil should be fitted.

15

Page 18

5. Table Seam Parameters

Press key “P” in the main level.

In the programming level initialize key “F” -> current program and

“F-Long” all seam programs.

Number Description Minimum Maximum Standard

Menu item value value value

100 Seam length mm 20 180 180

101 Stacker on / off on

102 Center knife on / off on

103 Center knife correction seam beginning 1/10 mm -9,9 9,9 0

104 Center knife correction seam end 1/10 mm -9,9 9,9 0

105 Corner knife on / off on

106 Corner knife correction seam beginning 1/10 mm -20 20 0

107 Corner knife correction seam end 1/10 mm -20 20 0

108 Stitch length 1/10 mm 2,0 3,0 2,5

109 Sewing motor speed 2000 3000 2750

110 Sewing motor soft start on / off on

111 Sewing motor number of soft start stitches 1 20 2

112 Sewing motor soft start speed 500 900 900

113 Clamping mode 0

0 = Lower left and right feeding clamp

simultaneously

1 = Lower left feeding clamp first

2 = Lower right feeding clamp first

114 Positioning point 0

0 = front

1 = center

2 = rear

115 Positioning point offset mm 1 170 90

116 Type s eam tightening seam beginning 1

0=Bartack

1 = Condensed stitches

117 Number of condensed stitches seam beginning 1 10 4

118 Stitch length condensed stitches / Bartack

Seam beginning 1/10 mm 0,5 3,0 1,0

119 Number of bartacks seam beginning 1 5 3

120 Type seam tightening seam end 1

0=Bartack

1 = Condensed stitches

121 Number of condensed stitches seam end 1 10 4

122 Stitch length condensed stitches / Bartack

Seam end 1/10 mm 0,5 3,0 1,0

123 Number of bartacks seam end 1 5 3

124 Material feed type 2

0 = Material runs to the loading position

1 = Material runs to the stacking position

2 = no run, in stacking position

16

Page 19

Number Description Minimum Maximum Standard

Menu item value value value

125 Type of waiting position 1

0 = Feeding clamp runs to the waiting position

1 = Feeding clamp remains in stacking position

126 Material feed to the stacking position 1 100 40

127 Loading speed % 10 100 80

128 Return speed % 10 100 80

129 Downholder on / off on

130 Sewing mode 0

0 = Constant sewing length

1 = Light-barrier for flap scanning

131 Light-barrier correction seam beginning 1/10 mm -20 20 0

132 Light-barrier correction seam end 1/10 mm -20 20 0

133 Material feed to the waiting position 1 515 100

134 Max. flap length 30 180 180

135 Flap clamp on / off on

136 Pedal mode 0

0 = normal

1 = Pedal has to be in basic position before the

next step

2 = Pedal actuation for moving in sewing position

(flap clamp)

17

Page 20

6. Machine parameters

When starting the machine hold the keys “P” and “è” pressed.

Enter code : 2548

Number Description Minimum Maximum Standard

Menu item value value value

400 Submenu machine configuration

401 Stacker available

402 Downholder available 1=available

403 Thread monitor on / off 1=on

404 Needle distance (10, 12) 10

405 Max. sewing length 180 / 200 180 200 180

406 Dist. light-barrier - needles 1/10 mm 1 375 60

407 Dist. between corner knife seam end and needles 1 375 13 0

500 Initialize parameter

501 Machine parameter

502 Pocket parameter

503 Sequence

504 All parameters

600 Indicate counter of pieces produced

1=available

501 InI

502 InI

503 InI

504 InI

When selecting an initializing program (501 to 504) “InI” flashes in the

right half of the display.

For initializing in the programs 501 to 504 hold the key “OK” pressed.

After initializing the machine parameters to the defautl values (factory

setting), the parameters 401-407 must be adapted to the machine

equipment.

After initialization of the pocket parameters, the default values will be

loaded.

After initialization the sequence will be loaded with the default value.

Initialize all parameters i.e. load the standard values for the machine,

pocket parameters and sequence.

18

Page 21

7. Error messages / Functional indications

Error/ Info Meaning Remedy

Control

1051

1052

1053

1055

1056

1058

1062

Sewing motor Timeout

· Faulty cable to the sewing motor

reference switch

· Faulty reference switch

Sewing motor excess current

· Faulty sewing motor cable

· Faulty sewing motor

· Faulty control

Too high mains voltage

Sewing motor overcharge

· Sewing motor blocked/ moves too

heavy

· Faulty sewing motor

· Faulty control

Sewing motor excess temperature

· Sewing motor moves too heavy

· Faulty sewing motor

· Faulty control

Sewing motor speed

Faulty sewing motor

Sewing motor defect of IDMA

Autoincrement

· Exchange the cable

· Exchange the reference switch

· Exchange the sewing motor cable

· Exchange the sewing motor

· Exchange the control

Check the mains voltage

· Eliminate the blocking/ rough running

· Exchange the sewing motor

· Exchange the control

· Eliminate the rough running

· Exchange the sewing motor

· Exchange the control

· Exchange the sewing motor

Switch machine off and on again

1302

1342

1344

2101

2103

2152

2153

2156

2162

Sewing motor error

Control receives no impulse from

the impulse transmitter in the motor

Sewing motor failure

Internal fault

Step motor X-axis Timeout

Reference

· Cable to the reference switch

defective

· Defective reference switch

Step motor feed clamp (X-axis)

has step loss

Step motor X-axis excess current

Step motor X-axis excess voltage

Too high mains voltage

Step motor X-axis

excess temperature

· Step motor X-axis moves too

heavy

· Step motor X-axis defective

· Faulty control

Step motor X-axis

Defect of IDMA Autoincrement

Check the cable from the impulse

transmitter in the motor to the control

· Switch machine off and on again

· Software update

· Information to the DA-Service

· Exchange the cable

· Exchange the reference switch

Check that the feed clamp moves freely

· Exchange the step motor X-axis

· Exchange the control

Check the mains voltage

· Eliminate the rough running

· Exchange the step motor X-axis

· Exchange the control

Switch machine off and on again

19

Page 22

Error/ Info Meaning Remedy

3100

3101

3102

3103

3107

3210

3215

3220

3500

3507

3520

3530

3540

3545

3721

3722

Machine Control voltage

Temporary mains voltage dip

Machine Power voltage

Temporary mains voltage dip

Machine Voltage Sewing motor

Temporary mains voltage dip

Machine Voltage Step motors

Temporary mains voltage dip

Machine Temperature

· Vent holes closed

· Ventilation grid soiled

Thread breakage

Bobbin thread counter is zero

Empty bobbin

Error Control command interpreter /

Motor synchronization

Internal fault

Check the mains voltage

Check the mains voltage

Check the mains voltage

Check the mains voltage

· Check the vent holes

· Clean the ventilation grid

Thread in the thread again

Insert a full bobbin

Insert a full bobbin

· Switch machine off and on again

· Software update

· Information to the DA-Service

Dongle

4301 No dongle plugged in

4304 Wrong dongle type, to be able to

save, a data dongle must to

available

4320 Confirmation before formatting the

dongle

4321 Confirmation before saving the

machine parameter onto the dongle

4322 Confirmation before saving the

pocket parameter onto the dongle

Confirmation before loading the

machine parameter from the dongle

to the control.

4324 Confirmation before loading the

pocket parameters from the dongle

to the control.

4325 The loading of the machine

parameter f rom the donlge to the

control is not possible because

there is no machine parameter

stored.

The dongle must be formatted

“OK” key ® format

“ESC” key ® cancel

“OK”key ® save

“ESC” key ® cancel

“OK” key ® speichern

“ESC” key ® cancel

Info 4323

“OK” key ® save

“ESC” key ® cancel

“OK” key ® save

“ESC” key ® cancel

20

Page 23

Error/ Info Meaning Remedy

Dongle

4326 The loading of the pocket parameter

6551

6554

6651

-6653

6751

6761

6952

7451

7453

7454

7452

7455

from the donlge to the control is not

possible because there is no pocket

parameter stored.

Error Machine head position/ AD

Converter/

Processor error

Internal fault

Error Step motor driver

Internal fault

Communication Test interface

Internal fault

Communication Test interface

· Line fault

· Cable Test interface defective

· Internal fault

· Switch machine off and on again

· Software update

· Information to the DA-Service

· Switch machine off and on again

· Software update

· Information to the DA-Service

· Switch the machine off and on again

· Eliminate the malfunction

· Exchange the cable

· Switch the machine off and on again

7551

7555

7558

7559

7556

7557

8151

8156

8159

8152

8154

8251

8255

8252

8257

8258

/

8253

8256

8254

Communication Control panel

interface

Internal fault

Communication Control panel

interface

· Line fault

· Cable Control panel interface

defective

IDMA error

· Malfunction

· Faulty control

IDMA error

Internal fault

Error ADSP Booting/ Booting

Internal fault

ADSP Booting/ XILINX Booting/

Booting

Malfunction

· Switch the machine off and on again

· Software update

· Information to the DA-Service

· Eliminate the malfunction

· Exchange the cable

· Switch the machine off and on again

· Exchange the control

· Switch the machine off and on again

· Software update

· Information to the DA-Service

· Switch the machine off and on again

· Software update

· Information to the DA-Service

Switch the machine off and on again

21

Page 24

Error/ Info Meaning Remedy

8351

8801

8805

8806

8890

8891

System

Info 9001

Err 9001

Info 9002

Err 9002

Error Testpins/ Signals / Event

processing/ Memory Wrapper/ List

of functions

Internal fault

Corner knife station is swung out

Corner knife station is swung out

during the sewing process.

Step back on the pedal; afterwards

the transport carriage runs to the

back; start the process.

Folding station is swung out

Folding station is swung out during

the sewing process.

Step back on the pedal; afterwards

the transport carriage runs to the

back; start the process.

· Switch the machine off and on again

· Software update

· Information to the DA-Service

Swing corner knife station in

Check/ adjust fastening of the corner knife

station

Swing folding station in

Check/ adjust fastening of the folding

station

9003

9601

9604

9700

9701

9710

9720

9721

9722

Wrong needle position before

sewing start

Pedal has been stepped back

during the sewing process

Light-barrier (s4) for fabric removal

inactive

Folder not in top position

Folder not in low position

Limit switch feeding clamp active

Error when scanning the flap by

light-barrier

Flap has been positioned in front of

the front positioning point

Flap protrudes from the maximum

sewing area (behind the rear

positioning point)

Turn manually the hand wheel in lever

up position

For cancelling the pedal has to be

actuated once again.

Afterwards the feeding clamp runs in its

rear position

Adjust light-barrier (s4) for fabric removal

Correct folder adjustment (mechanical

collision; check switch S8)

Correct folder adjustment (mechanical

collision; check switch S8)

Check material feed and limit switch

Check the reflecting foil; check alignment

of the light-barriers

Position the flap correctly

Check the flap size; Position the flap

correctly

9723

9726

22

Fluff at the flap beginning

Flap too large or reflecting foil

soiled or defective

Feed flaps with smooth edges; Check the

reflecting foil

Check flap size and reflecting foil

Page 25

Error/ Info Meaning Remedy

9730

9800

9900

9901

9902

reF

Current seam length flashes

Corner knife at the seam beginning

cannot be driven to

Hardware error DC motor control

Defective machine parameters

(check sum error)

Defective pocket sequences (check

sum error)

Defective pocket programs (check

sum error)

Request to carry out the reference

run after switching the machine on

Corner knife for seam beginning

cannot be reached

Alter L1 (adjust corner knife distance) or

change positioning point of the current

seam

Check DC motor, DC controller and cable;

check voltage supply

Initialize machine parameters anew (test

program); Set machine parameters

Initialize pocket sequences anew (test

program);

Set pocket sequences

Initialize defective pocket programs (test

program);

Set pocket programs

Step back on t he pedal

Change the present seam length, or

change the loading position, or change L1

(adjust distance counter knife).

23

Page 26

8. Input elements

9. Output elements

S1 Folding device swung in

S2 Folder in low position

S3 Knife support swung in

S4 Light-barrier workpiece removed / Hood monitoring

S5 Pedal forward

S6 Pedal back

S9 Needle thread monitor right needle

S10 Needle thread monitor left needle

S17 Light-barrier for flap scanning

S100 Reference switch sewing motor

S101 Reference switch feeding clamp

Y1 Close folding sheets

Y2 Open flap clamp

Y3 Lower left feeding clamp

Y4 Lower right feeding clamp

Y5 Lower folder

Y6 Folder lifting off

Y7 Downholder on

Y8 Reserve

Y9 Knife support seam beginning

Y10 Knife support seam end

Y11 Stacking tongs forward

Y12 Swing stacking bow out

Y13 Reserve

Y14 Reserve

Y15 Reserve

Y16 Reserve

24

Y17 Open needle thread scissors

Y18 Lower center knife

Y19 Blow fluff out

Y20 Open bobbin thread clamp

Y21 Close bobbin thread scissors

Y22 Close thread tension

Loading...

Loading...