Contents Page:

Home

Part 4: Instructions for programming DAC Cl. 745-26; -28

Program-Version 745A05

1. General

2. Operator Terminal

3. Memory Card

3.1 Saving and Loading Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Replacing the Memory Card Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Operator Interface

4.1 Menu Structure of the Sewing and Testing Programs . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Changing of Parameter Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Sewing Programs

5.1 Calling Up the Sewing Program Parameter Screens . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Starting the Machine Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3.1 Automatic recognition of the flap angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3.2 Sewing distance measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Global Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5 Pocket Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Pocket Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.7 Seam Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Setting and Testing Programs

6.1 Calling Up Setting and Testing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Machine Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Machine-specific Setting and Testing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.1 Setting the Underthread Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.2 Initializing the Program Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.3 Checking the Smoother Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.4 Aligning the Light Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.5 Setting the Corner Knife Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.6 Checking the Switching-in of the Needle and Center Knives . . . . . . . . . . . . . . . . . . . 32

6.3.7 Checking the Tape Feed Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.8 Checking the Catch-folder without the Transport Clamp . . . . . . . . . . . . . . . . . . . . . . 33

6.3.9 Checking the Placement Procedure with the Transport Clamp . . . . . . . . . . . . . . . . . . 33

6.4 Multitest System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.1 Displaying the Program Version and Check Sum . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.2 Testing the Working Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.3 Displaying the Setting of the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.4 Selecting Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.5 Checking Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.6 Selecting Output Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.7 Checking the Step Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.8 Checking the Sewing Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4.9 Displaying the Error Messages Generated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Terminal Selftest

7. Output Card of the Step Motor

7.1 Switches on the the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2 Status Displays on the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8. Error Messag e s

8.1 Error Messages of the Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.2 Error Messages of the Machine Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

A. Appendix

A.1 Standard Seam Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1. General

This short des c ri pt i on con ta i ns i m po r ta nt inf or m at i on to th e s a fe , p r oper and econom i c al u se o f t he ne w c o nt rol s g en er a ti o n "

kopp Adler Control).

Screen displays in this short description

The display of the symbols in the various screens is dependent on the

settings, th e s u bc l a s s an d the equipment of th e sewing unit.

The screen di s pl a ys s ho wn i n t hi s s h ort description mus t t he r ef ore not

always exactly match the screen shown in the display of the control

unit.

Operator terminal with graphic guidance of the operator

The operator te rmi n al is e qu i pp ed wit h a LCD display and a key p ad .

The guidance of th e o pe r at or o cc ur s exclusively v i a i n te rna t io nally understood symb ols . T he v ari o us sy m bo l s ar e com bi n ed in to grou ps within the menu structure of the sewing and testing programs.

The simple operation makes possible short training times.

Ease of programing

The user can combine 99 freely programmable pocket programs with

up to 25 seam patterns.

For the sewing of sequences, 10 pocket sequences are available.

Each pocket sequence can be put together in any desired order out of

a maximum of 6 pocket programs.

With the "angled pocket version" Class 745-28 all practically suitable

angles can be pr o gra mm ed by the operator with the push of a bu tt on .

The time consuming adjustment of the corner knives and the inconvenient programmi n g o f s e am offs et s are av o i de d.

DAC

" (Dür-

Setting and testing programs

DAC

The

monitoring system.

A microcomputer assumes the control tasks, monitors the sewing

process and displays operator errors and malfunctions.

Error and testing results are shown in the LCD display.

During fault- fre e f un c ti o nin g t he di s p lay s h ow s i nf or m at ion to th e o pe ration and the s ewing procedure.

With an opera to r err o r or a ma l fu nc t i on th e f un c ti o n s e qu en c e i s i n te r rupted. The display shows the cause through the appropriate error

symbol.

In most cases the error symbol disappears after the cause of the error

is remedied.

In some cases the main switch must be turned off for safety reasons

during the co rr ec t i on of th e e r ror.

A part of the error messa ge s i s me an t o nl y f or t he maintenance st aff.

Special programs aid in making the mechanical settings and make possible a quick checking of the input and output elements without additional measuri ng de v ic es .

RAM memory card

The RAM memor y car d s erv e s fo r th e l o ng - te r m storage of all prog r am med data.

It can be used to transfer the data to other sewing units.

The controls transmit the data to the memory card.

Stored data can be l oa de d f rom th e m em or y c a rd i n to a D A C c o nt rol

again.

This procedu r e ca n be repeated as oft en as d es i re d within the life of

the memory card (approx. 4 years).

has integrated the comprehensive

MULTITEST

testing and

3

2. Operator T erminal

The entering an d d i spl a y i ng of da ta oc c u rs v i a a n o pe r at or t er m i na l

with a LCD dis pla y an d a c om pre he ns iv e k eyp ad .

STOP

Display

Function keys

keys

Escape Enter

key key

ESC

DURKOPP

ADLER AG

Cursor keys

Stop key

Number

Key/ Key Group Function

Function keys

Cursor keys

Numeric keys

Escape key

Enter key

Stop key

Calling up the parameter screens of the sewing programs (from the main screen).

Calling up testing programs (during the display of the logo).

Turning functions on/off.

Exiting te s ti n g p rograms and paramete r s cr ee ns (F 1 ) .

Changing parameter values.

,

: Selecting the symbol for the desired parameter

,

: Turning the function of the parameter on/off,

selecting the previous/next step of the parameter value,

activating th e t es t i ng pr o gra m

Entering parameter values.

: Reversing t he s ign of th e p ar a me te r v alu e

Displayi ng th e o l d p ar a me te r v al u e a ga i n.

Calling up screen to set the selected parameter.

The set para me te r v al u e i s st or e d.

Exiting the machine program.

Stopping t he c urr e nt program.

4

3. Memory card

3.1 Saving and Loading of Programs

The memory card (RAM card) serves for the longterm storage of sewing programs.

With its aid, sewing programs, seam patterns and machine parameters

can be transfered to other sewing units.

Write protection

Label

ESC

Start

STOP

DURKOPP

ADLER AG

–

With the main screen as shown insert the memory card in the direction of th e a r row into the side of th e c o nt r ol u ni t .

The label must face the operator.

–

The controls s w i tc h i nt o t he me mo r y mo de .

The arrow in the center of the display shows the direction of transfer:

Loading

data from the memory card

to the controls

Saving

data from the controls

on the memory card

(Observe the write protection!)

–

Set the desired direction of transmission.

Load

data: Press the " " cursor key.

Save

data: Press the "" cursor key.

–

Press function key F4 (Start).

The data trans f er s t ar t s .

The symbols for the data to be transfered appear above the arrow

in the center of the display.

Upon completion of the transfer all symbols are erased again.

–

Remove the memory card.

The display returns to the main screen.

–

After the

loading

of data press th e

STOP

key.

The controls are initialized again.

This is nece s sar y b ec a use , a long with the loadi ng of programs,

new machine parameters are also loaded.

3.2 Changing the Battery of the Memory Card

Life of the memory card without a battery change: approx. 4 years

ATTENTION !

Programs sav e d o n t he me mo r y car d ar e l ost when the battery i s cha n ged.

Load the programs into the control unit before the battery change!

5

4. Operator Interface

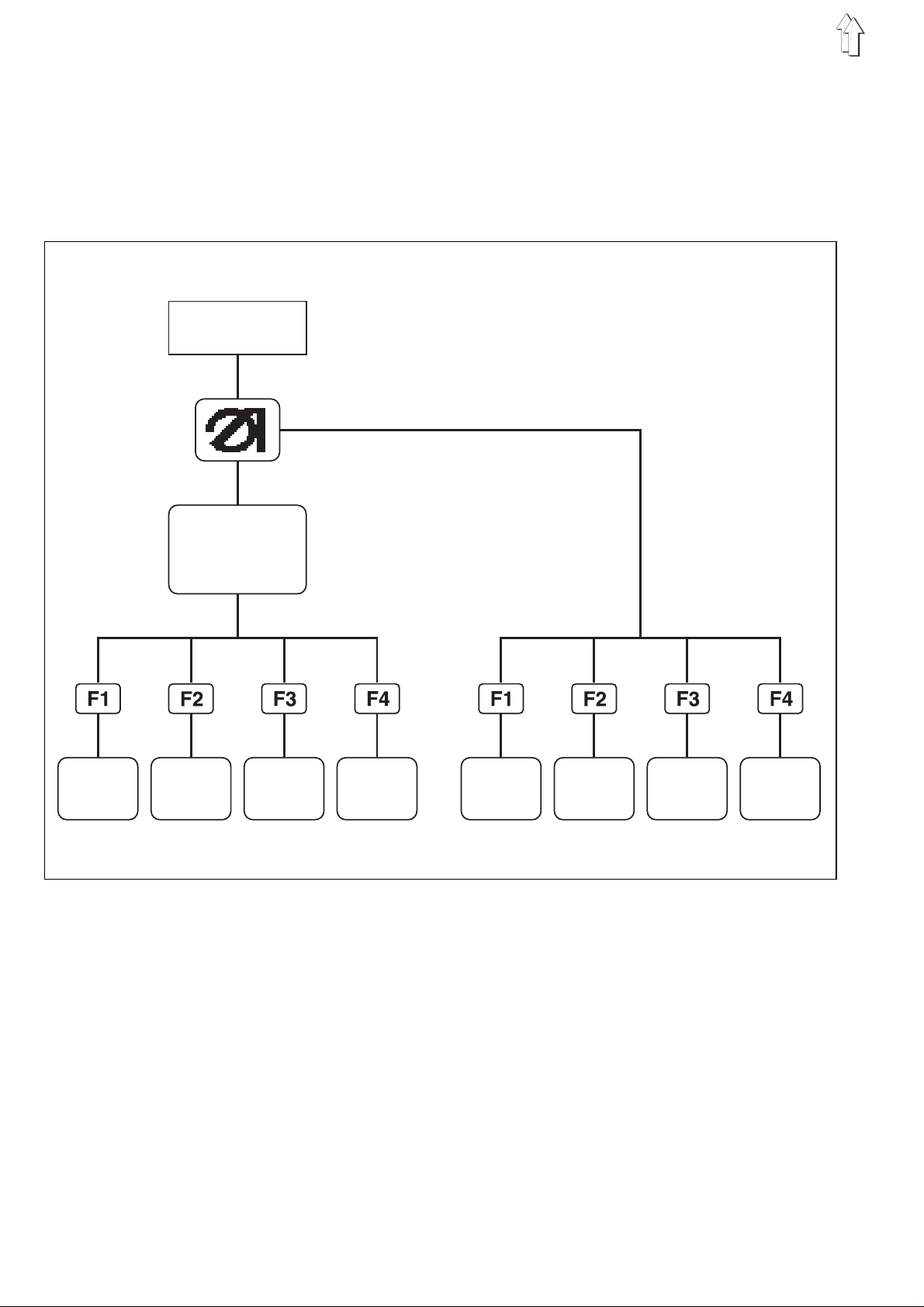

4.1 Menu Structure of the Sewing and Testi ng Programs

In the design of the operator interface only internationally understood

symbols are used.

The individu al p ar a me te r s and setting and tes t i ng pr o gra ms a r e combined in different groups.

Turn on the

main switch

Main screen

Parameter me nu s of th e s e wi n g p rog r am s Setting and te s ting programs

Calling up sewing programs

–

Turn the main switch on.

The controls are initialized.

The DÜRKOPP-ADLER logo appears in the display for a short period.

–

The display c h an ge s to th e m ai n s c ree n.

By pressing one of the function keys F1 to F4 the correspon di n g

parameter menu of th e s e wi n g p rog r ams i s c al le d u p.

Calling up setting and testing programs

–

Turn the main switch on.

The controls are initialized.

The DÜRKOPP-ADLER logo appears in the display for a short period.

–

During the display of the logo

to F4.

The display changes to the corresponding group of the setting or

testing programs.

6

press one of the function keys

F1

4.2 Changing Parameter V alues

The parameter values can be changed in the different parameter screens.

–

–

–

–

Select the desired parameter with the cursor keys "" or "" .

The symbol of the selected parameter appears inversely.

Press the enter key.

The parameter sc r e en ap pe ars with the prompt an d w i th th e c u r rent setting of th e p ar a me te r v alu e.

Enter parameter value as described in 1. to

Press the enter key.

The new setting of th e p ar a me te r v alu e i s st or e d.

4.

(on) (off)

20

Enter: 08, 12, 14, 16, 20

-35

Enter: -99 ... +99

When changin g t he parameter value s i t m us t be di ffer e nt i at ed be tw ee n

four groups o f p ara meters.

1. Functions , which a re turned on/off

–

Turn the function of the parameter on or off with the cursor keys

"" or "".

2. Parameters with different functions

–

Set the desi red fu nc t ion of the parameter wit h t he cur so r key s ""

or "".

3. Parameters, whose values are changed in steps

–

Select the p r ev ious or next step of the parameter val u e with the

cursor keys "" or "".

4. Parameters, whose values are entered via the nume ric keys

–

Enter the desired parameter value with the numeric keys.

Attention!

The value must lie within the fixed limits.

Should a too lar g e o r to o s m all a v al u e h av e be en en te r ed , t he n

the upper or lower limit is display after the enter key is pressed.

–

If a sign ap pe ars i n fro nt of the parameter v alue, this can be c ha nged with the " " ke y.

7

5. Sewing Programs

With the

745-26/28

99 different sewing programs can be combined

with up to 25 se am pa tt ern s .

The individu al s e wi n g p r og ram s ( po ck et pr o gr a ms) c a n b e f r ee ly pr o grammed hereby.

For the sewi ng of po c k et sequences 4 indepe nd en t s e qu en c es are

available. E ac h i nd iv i du al s e qu en c e ca n be put together in an y de s i red

order out of a maximum of 6 pocket programs.

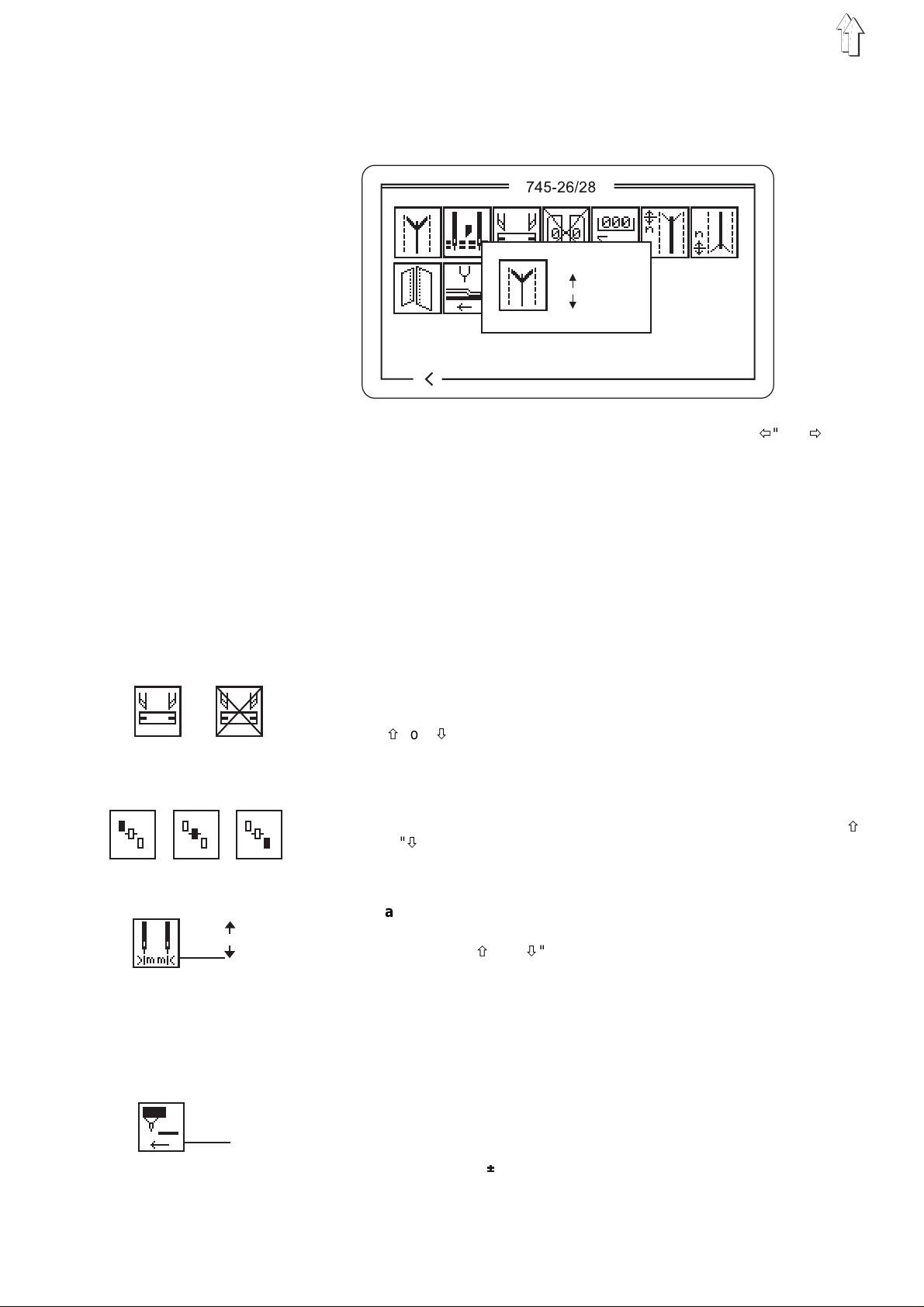

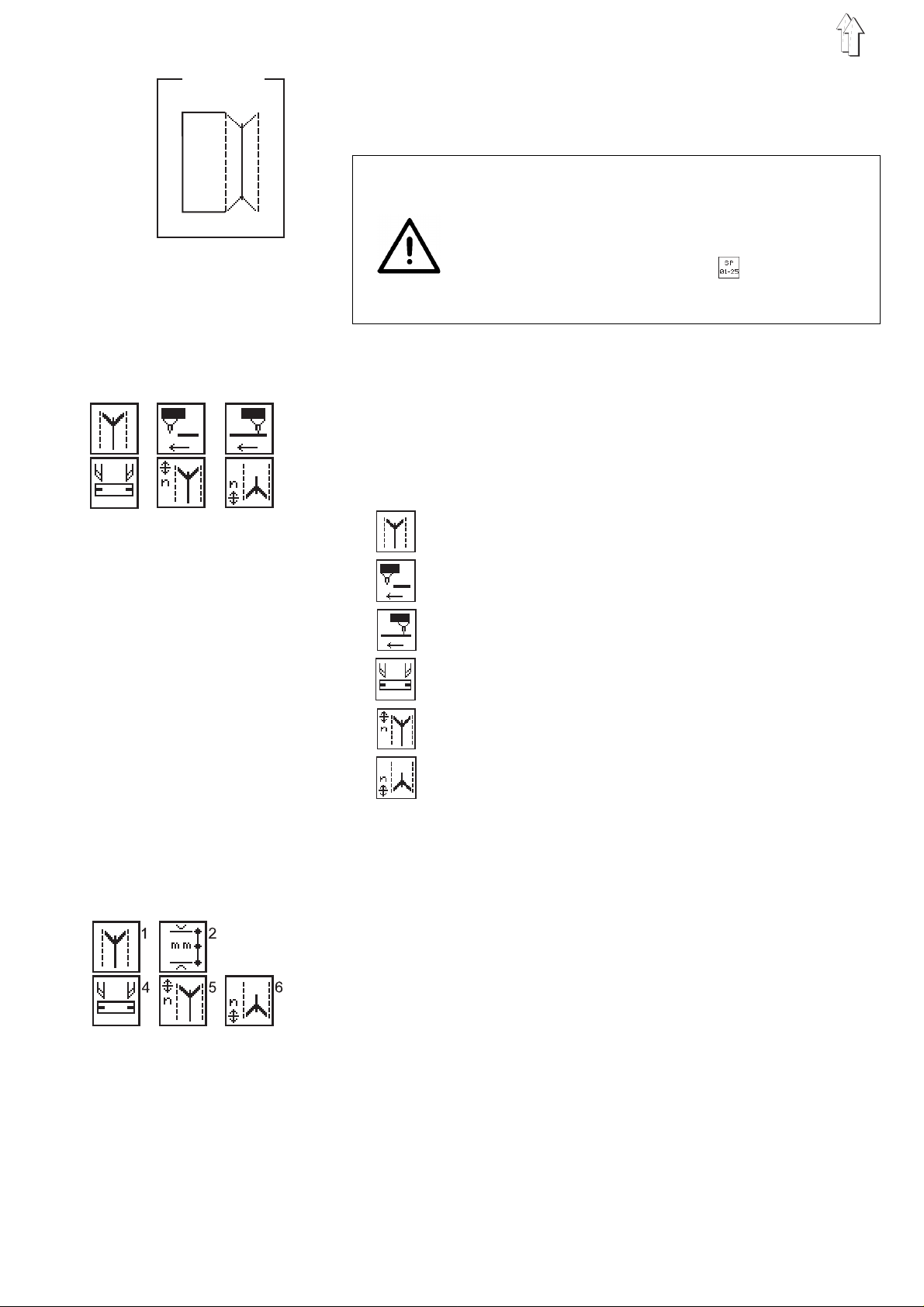

5.1 Calling Up Sewing Program Parameter Screens

From the main sc r ee n i t i s po s s i bl e to change to the different parameter screens o f t he s ew i ng pr o gr a ms with the functio n k e y s F1 to F4.

745-26/28

Σ

01

: 0100

03

02

1

4

2

5

3

6

SAKKO

GP

PP

PS

1.

2.

3.

4.

01

02

03

04

020304

745-26/28

05

06

SP

745-26/28

01

000

Global para me te rs Pocket prog ram Pocket sequ en c e Seam patterns

GP PP PS SP

Parameter screens of the sewing programs

Global parameters (GP): Parameters, which are valid for all

pocket progra ms

Pocket program (PP): Parameters for programming the seam

run and the ass o c i at ed s up pli m en tary

functions

Pocket sequence (PS): Programming of pocket sequences

Seam patterns (SP): Parameters for programming the seam

patterns

8

5.2 Starting the M achine P rogram

–

–

<==== REF

–

–

–

Turn the main switch on.

The controls are initialized.

The DÜRKO P P- A DL E R l o go ap pe ar s in the display fo r a s h ort period.

If, during the display of the logo, one of the function keys

F1

to F4 is pressed, the display switches over to the corresponding

group of the se tt i ng or t es t i ng programs.

The controls c h ec k i f the transport car ri ag e i s in its rear end pos i ti -

on.

If this is not the case the display shows "

<==== REF

" (reference

run).

Start the reference run by stepping back on the left pedal.

The display changes over to the main screen of the sewing unit.

From the main screen it is possible to change to the various parameter screens o f t he s ewing programs by pre s s i ng th e f un c ti o n

keys F1 to F4.

The machine program is exited by pressing the "

STOP

" key.

The controls are initialized.

9

5.3 Main Screen

On the main screen are displayed all important parameters, the seam

pattern and t he sel e c te d p oc k e t s e qu en c e.

01

01

01

01

01

01

03

03

03

03

03

03

02

02

02

02

02

02

745-26/28

SAKKO

01

Σ

: 0100

GP

03

02

L : 140

1

4

2

5

PP

3

6

PS

SP

Selecting a pocket sequence

In the upper left corner of the display the selected pocket sequence is

shown.

If the automatic change of pocket programs is active, arrows are

shown betwee n t he i nd i v i du al p ock e t p r og r am s of the sequence.

–

Change the pock e t se qu en c e w i th th e cu r s or k e ys "" or "".

"" key: Select the previous pocket sequence

"" key: Select the next pocket sequence

01

01

01

01

01

01

03

03

03

03

03

03

: 0100

Σ

L : 140

02

02

02

02

02

02

Selecting a pocket program in the current pocket sequence

In the pocket s e qu en c e a ba r ma rk s th e s e l ect ed pocket program.

A double bar indicates that in that pocket program the stacker is switched on.

–

Select a pocket program with the cursor keys "" or ""

"" key: Select the previous pocket program of the pocket sequence

"" key: Select the next pocket program of the pocket sequence

Piece counter

To the left under the pocket sequence the current piece count is shown

(e.g. "Σ : 0100").

The piece counter shows the number of pieces finished since the last

resetting of th e c o un te r.

The setting o f t he pi e c e c o un te r occ u r s under the "Global P ar a me te rs "

(function key F1).

Seam length

When sewing with distance measurement (without light barrier) the set

seam length appears at the right under the pocket sequence (e.g. "L :

140").

10

SAKKO

1

4

2

5

3

6

Seam pattern

In the right half of the display the seam pattern of the selected pocket

program is sh ow n.

Above the seam pattern the corresponding program name appears.

ATTENTION !

In order to as sociate the pock et pro gr a m w i th a s p ec i f i c

seam pattern , c h an ge to the parameter scr ee n o f t he

pocket programs (PP) with the function key F2.

There the des ir e d s e am

pattern can be accessed with the " " symbol.

The association of a seam pattern

not

is

possible via the main screen!

Altering parameters

The six parameters in the lower left half of the display make possible a

quick access to the six most important parameters of the current

pocket progra m.

They can be altered directly with the numeric keys.

The number of the key to be pressed is shown at the right next to the

parameter symbol.

1: Switching the corner knife on/off

2: Correcting the seam beginning with the light barrier

( seam length )

3: Correcting the seam end with the light barrier

( seam length )

4: Switching the piping knife on/off

5: Correcting the corner knife incision at the seam beginning

6: Correcting the corner knife incision at the seam end

The function s an d s e tt i ng s of the individua l pa ram et er s a re d es c ri b ed

in more detail i n t he Ch ap te rs 5. 4 (" Gl o ba l P ara me te rs " ) an d 5 .5

("Pocket Program").

The function c orr e c ti n g t he s ea m b eg i nn i ng or c o r rec t i ng th e s e am en d

with the light barrier ( seam length ) can be changed to

measurement

Description see chapter 5.3.2.

Selecting t he fu nc t i on oc c u rs un de r th e " P o ck et P r og ram " .

( Number 2 ).

distance

11

Correction the seam beginning with the light barrier

With the chan ge of the value the co rne r k ni f e i s d r aw n o nward accordingly at the seam beginning.

Enter: -99...+99 0 = No correction

+ = Seam beginning earlier

- = Seam beginning later

Step size: 0.1 mm

Correction the seam end with the light barrier

With the chan ge of the value the co rne r k ni f e i s d r aw n o nward accordingly at the seam end.

Enter: -99...+99 0 = No correction

- = Seam end earlier

+ = Seam end later

Step size: 0.1 mm

Correction of the corner knife on the seam beginning

With the chan ge of the value a fine ad j us t me nt of th e c o r ne r k ni f e i n c i sion at the se am be gi n ni n g o c c urs .

Enter: -99...+99 0 = No correction

+

-

+ = Corner incision earlier

- = Corner incision later

Step size: 0.1 mm

Correction of the corner knife on the seam end

With the chan ge of the value a fine ad j us t me nt of th e c o r ne r k ni f e i n c i sion at the se am en d o c c urs .

Enter: -99...+99 0 = No correction

- = Corner incision earlier

+

Selecting parameter screens

By pressing th e a pp r op r iate function key F1 to F4 the display changes

to one of the fo ur p ara meter screens.

F1

: GP (Global parameter)

F2

: PP (Pocket program)

F3

: PS (Pocket sequence)

F4

: SP (Seam patterns)

By pressing the function key

ens to the main s c reen.

F1

one returns from the parameter scre-

+ = Corner incision later

Step size: 0.1 mm

5.3.1 Automatic recognition of the flap angle

When the unit is supplied with the kit 0794 002472 , Automatic Detection of Inclination, (auxiliary equipment), the 2nd LED must be activated.

The flap to be sewn, shown on the main screen, will appear dashed.

12

5.3.2 Sewing distance measurement

For measuring the seam length, two possibilities are available.Use the

pocket programme for selecting. The two possibilities are reciprocally

locked, i.e. that only one of the two possibilities can be selected. The

other one is d ea c ti va ted.

Automatic recognition of the flap beginning and end

With this setting the reflecting light barrier for the recognition of the

seam beginni ng an d s e am en d when sewing with fl a p i s s w i tc h ed on .

Distance measure me nt

The shortest seam lengths which can still be sewn with the distance

measurement are dependent on the following parameters:

- Maximum seam length (180 or 220 mm)

- Subclass (-26 or -28)

- Selected po s iti o ni n g p oi n t

Forward positioning point:

Rear positioning poi nt:

Central positioning point:

Needle Clea rance Shortest Seam Length

max. Seam Length Shortest Seam Length

[mm] [mm]

815

10 20

12 25

14 30

16 35

20 40

[ mm] [mm]

745-26 745 -28

180 20 60

220 60 100

Sewing Length Shortest Seam Length

[mm] [mm]

745-26 745 -28

180 20 20

220 60 90-APM

*

APM = Position of the central positioning point

*

The shortest seam length, however, may not fall short of that

given for the fo r wa r d p osi t i on i ng po i nt .

The change of the seam length parameter value is done on the main

screen.

–

Operate the k e y " 2 " .

The setting window, prompting to enter, will appear.

–

Change the parameter as described under chapter 4.2.

13

5.4 Global Parameters ( )

Global parame te rs are pa r am et ers , wh i ch a pp l y fo r

grams.

Example: If the co r ne r k ni f e i s switched off

made without corner knife incisions.

–

With the main s c ree n as shown press fu nc t i on k ey F1.

The display changes to the screen for the global parameters.

–

Select the desired parameter with the cursor keys "" or "".

The symbol of th e s e lec t ed parameter appears i nv e rs el y.

–

Change the sel ect ed pa r am et er a s de sc r ibe d i n Ch ap te r 4. 2.

–

By pressing the function key F1 the display returns to the main

screen.

all

all

pocket pro-

pockets will be

Switching the corner knife on/off

Enter: on/off

Switching the center knife on/off

Enter: on/off

ATTENTION !

When the center knife is switched off the

corner knives are also automatically switched off.

When the cen te r k ni f e i s switched on again ,

the corner knives remain switched off.

They must be switched on separately.

Switching the piping knife on/off

Enter: on/off

14

Setting the closing order of the flap clamps

6 different settings can be chosen:

Without flap clamps

Close first th e le ft , t he n t he ri gh t f l ap cl am p

Close first the right, then the left flap clamp

Close both flap clamps simultaniously

Only the right flap clamp exists

Only the left fl a p cl a mp ex is t s

Piece counter

The piece counter shows the number of pieces completed since the

last resetting of the counter.

Enter: 0...9999

Correcting the center knife incision at the seam beginning

With a change of the value a fine ad j us t me nt of th e c e nt er k n if e inc i s i on at the seam be gi n ni n g o cc ur s.

Enter: -15...+15 0 = No correction

+ = Turn the center knife on earlier

- = Turn the center knife on later

Step size: 1 cycle = 0.4 mm

ATTENTION !

An Offset can be en te red fo r th e p ock e t p ara me te r s.

Correcting the center knife incision at the seam end

With a change of the value a fine ad j us t me nt of th e c e nt er k n if e inc i s i on at the seam en d o c cur s .

Enter: -15...+15 0 = No correction

+ = Turn the center knife off earlier

- = Turn the center knife off later

Step size: 1 cycle = 0.4 mm

ATTENTION !

An Offset can be en te red fo r th e p ock e t p ara me te r s.

Activate working method for breast welt pocket (745-28 A)

The breast welt pocket working method will be connected / disconnected.

Enter: on/off

15

5.5 Pocket Program ( )

Under this menu i te m a re l o c at ed th e p ara me te rs fo r pro gra mm i ng th e

various pocket programs.

With the aid of the parameters the seam run and the supplimentary functions assoc i a te d with it are freel y pr o gra mm ed .

16

–

With the main s c ree n as shown press fu nc t i on k ey F2.

The display changes to the pocket program screen.

By pressing the function key F4 the display changes to the second

screen of the pocket program.

–

In the upper left line of the display is shown the currently selected

").

PP : 01

").

SP : 01

").

pocket program (e.g. "

If it exist s , t he as s o ci at ed program name app rea r s be l ow i t

<JACKET>

(e.g. "

–

In the upper right corner of the display the seam pattern number of

the selected pocket program appears (e.g. "

–

Select the desired parameter with the cursor keys "" or "".

The symbol of th e s e lec t ed parameter appears i nv e rs el y.

–

Change the sel ect ed pa r am et er a s de sc r ibe d i n Ch ap te r 4. 2.

–

By pressing the function key F1 the display returns to the first

screen of the pocket program or to the main screen.

Pocket program number

With this pa r am et er the pocket progra m t o b e c h an ge d i s s e l ected.

After compl et i on of th e e ntry the new pocket program and the corre-

sponding program name appear in the upper left corner of the display.

Enter: 1...99

Sewing distance measurement

Two different possibilities can be selected. Use the pocket programme

for selecting. The two possibilities are reciprocally locked, i.e. that only

one of the two possibilities can be selected. The other one is deactivated.

Distance measure me nt

When useing distance measurement, the seam length is entered with

the main scr ee n b ei n g o n.

Automatic recognition of the flap beginning and end

With this setting the reflecting light barrier for the recognition of the

seam beginni ng an d s e am en d when sewing with fl a p i s s w i tc h ed on .

Automatic recognition of the flap angle

When the unit is supplied with the kit 0794 002472 , Automatic Detection of Inclination, (auxiliary equipment), the 2nd LED must be activated.

The flap to be sewn, shown on the main screen, will appear dashed.

Selecting the positioning point

Depending on th e t y pe of go od s to be s ew n, po s i ti o ni n g o c cur s a t t he

rear, central or forward positioning point.

Rear positi o ni n g p oi n t (toward the operat or )

Central positioning point

Forward positioning point (to the machine head)

All positioning lights on/off

Enter: on/off

on = all positioning lights are switched on

off = positioning lights are switched as set in the

pocket programm

17

Stitch condensation or bartacking at the seam beginning and

seam end

By changing this parameter a coice is made whether the seam beginning

and seam end are executed with stitch condensation or with bartacking.

with stitch condensation

with bartacking

ATTENTION !

By 1.4 mm stitch length in stitch condensation the

bartacking is sewn with a stitch length of 0.8 mm.

Flap feed on/off

Enter: on /o ff (only bei fe ed me th od s B , C , F )

Sewing patterned or plain goods

Patterned goods (only with feed methods D, F)

Plain goods

Transport carriage return after sewing

Wait position

After the sewing the transpo rt c l a mp s au to ma ti c a ll y r un

back into the wait position without sewing goods.

Feed position

After the sewing the transpo rt c l a mp s au to ma ti c a ll y r un

back into the feed position without sewing goods.

Returm with sewing goods

(only with feed method A)

After the sewing the transport clamps transport the

sewing good s ba c k i nt o t he fe ed ar e a.

Stacker on/off

Enter: on/off

18

Smoother on/off

Enter: Active period: t = 5...20

Step size: 1 cycle = 0.1 s

Speed level: v = 5...15

Note:

With the smoo th er t he r e i s a du al u s e o f t he solenoid valv es :

–

Stacker switched on: The smoother is triggered as a stacker

supplement (Y63).

–

Stacker sw itched off: The smoother is t ri gg er e d a s an ejector (Y42) .

ATTENTION !

If both a stacker and a smoother are available and

no stackin g p roc e du r e t ak e s place, then both

parameters mu st b e switched off!

Tape feed on/off

Enter: Tape length at the seam beginning:20...100 [mm]

Tape length at the seam end: 20...100 [mm]

Hold-down on/off

Enter: on/off

Vacuum on/off

Enter: on/off

Setting the feed speed

The feed speed, between the loading station and the needle, can be reduced in step s of ea c h 1 0%.

Enter: 50...100 (100%)

Associating a seam pattern to the pocket program

After this parameter is selected the display changes to the seam pattern screen.

There the selected seam pattern can be changed or a different seam

pattern selected (see Chapter 5.1).

After the ret ur n to th e m ai n s cr ee n ( f un c ti o n ke y F1) the last seam pattern created is associated to the current pocket program.

ATTENTION !

The association of a specific seam pattern with a

pocket program must be made with the " " symbol.

This association is

screen (SP/F4)!

not

possible vi a t he main

19

Copying a pocket program

With this parameter the selected pocket program can be copied into

another pock et .

The number to b e e nt er e d s h ow s th e p oc k e t p rog r am i nt o w hi c h th e s e lected pock et pr o gra m i s t o b e c o pi e d.

After compl et i on of th e e ntry the number and n ame of the pocket pr o gram into whic h t he c opy wa s ma de ap pe ars i n th e u pper l e ft cor n er o f

the display.

Enter: 1. .. 99

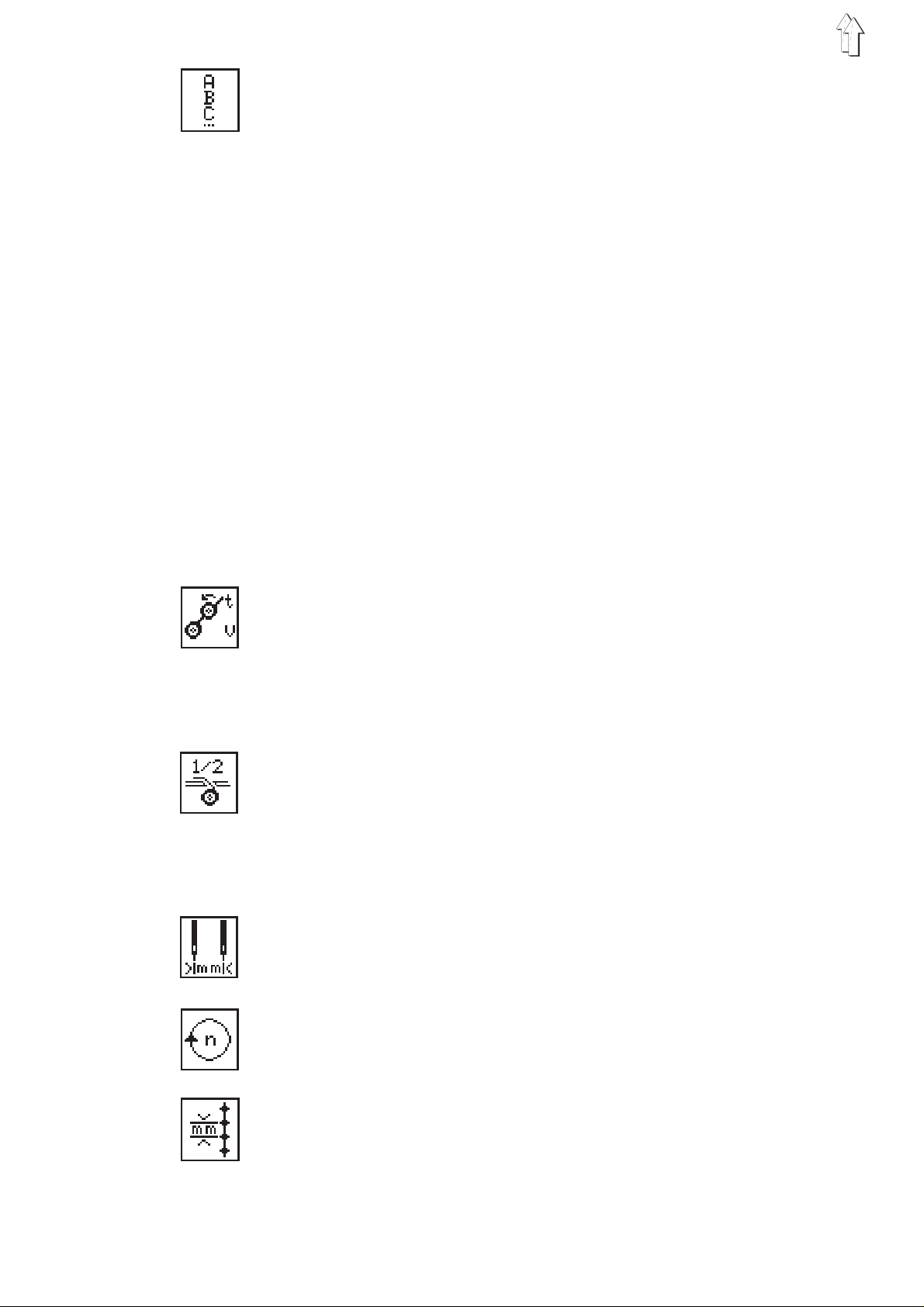

Entering program names

This paramete r en ab l es t he l ab el i n g o f e ac h po c ket pr o gr a m w i th an i ndividual program name (e.g. "JACKET").

The program name may have a maximum of 8 letters.

–

Press the "" or "" cursor key.

A window is opened in the lower right corner of the display.

The program name of the current p ock e t p r og ram appears in this

window.

If the curre nt po c k et pro gr a m w as n ot y et gi v e n a pr o gra m n ame

the window remains empty.

–

One moves through the alphabet with the function keys F2 and F3.

F2

: move forward

F3

: move back

–

By pressing the cursor keys "" or "" the cursor moves one position to the l e ft or r i g ht r esp ec t i v el y.

–

Press the enter key.

The entry is completed.

The entered p r og ram na me is stored.

By pressing the "

ESC

" key the ol d p rogram name is used a ga i n.

Selecting pedal mode

When using the loading mode with vacuum and/or holding-down

clamp, it is p os si b l e t o s e l ec t be tw ee n t w o v ari a nt s .

For selecting th i s mo de wi t h t he po c ket pr o gra mm e, th e

Vacuum and/or the Down-holde r c l am p m ust be ac t i ve.

When loading , the pedal must fi r st be treaded into i ts b asi c

position. T he n i t mu s t b e o pe r at ed on c e ag ai n , be fo re the

feeding clam p t r av e l s to th e s e am be gi n ni n g.

When using th i s mo de , o nl y o ne pe da l op eration is requir ed

for starting the loading process.

20

5.6 Pocket Sequence ( )

Under this menu item the individual pocket programs are combined

into sequences which can be called up.

A total of 10 independ en t p ock e t s e qu en c es a re a v ai l a bl e .

Each pocket sequence can be combined out of up to six pocket programs in any de si r ed ord er.

745-26/28

02

03

04

05

06

01

1.

02

2.

03

3.

04

4.

Programming a pocket sequence

–

With the ma i n sc r e en as s h own press the function key F3.

The display changes to the pocket sequence screen.

The display shows the four current pocket sequences.

–

Move the cursor with the cursor keys "" or "" to the desired

pocket sequence.

The number of the selected pocket sequence appears inversely.

–

Program the pocket sequence.

Enter the numbers (01...99) of th e d es i red pocket program s c on secutively with the numeric keys.

With singl e d i git pocket program n um be r s a " 0 " must be entered in

front of the desired number.

After the si x th po c ket program is enter e d t he pr o gra mmed pocket

sequence is automatically saved.

–

Press the enter key.

The pocket sequence is saved.

By pressing th e "

quence is re sto r ed .

–

By pressing the function key F1 the display is ret urned to th e m ain

screen.

ESC

" key during programming the old pocket se-

Automatic change of the pocket programs on/off

If this function is switched on the controls automatically move to the

next pocket p r og ram of the pocket sequ en c e a ft er a pocket program

has been worked th r ou gh.

–

Turn the automatic c h an ge of the pocket prog ram s on or o ff by

pressing the function key F4.

The automatic change is shown in the display by arrows between

the individual pocket programs of the pocket sequences.

21

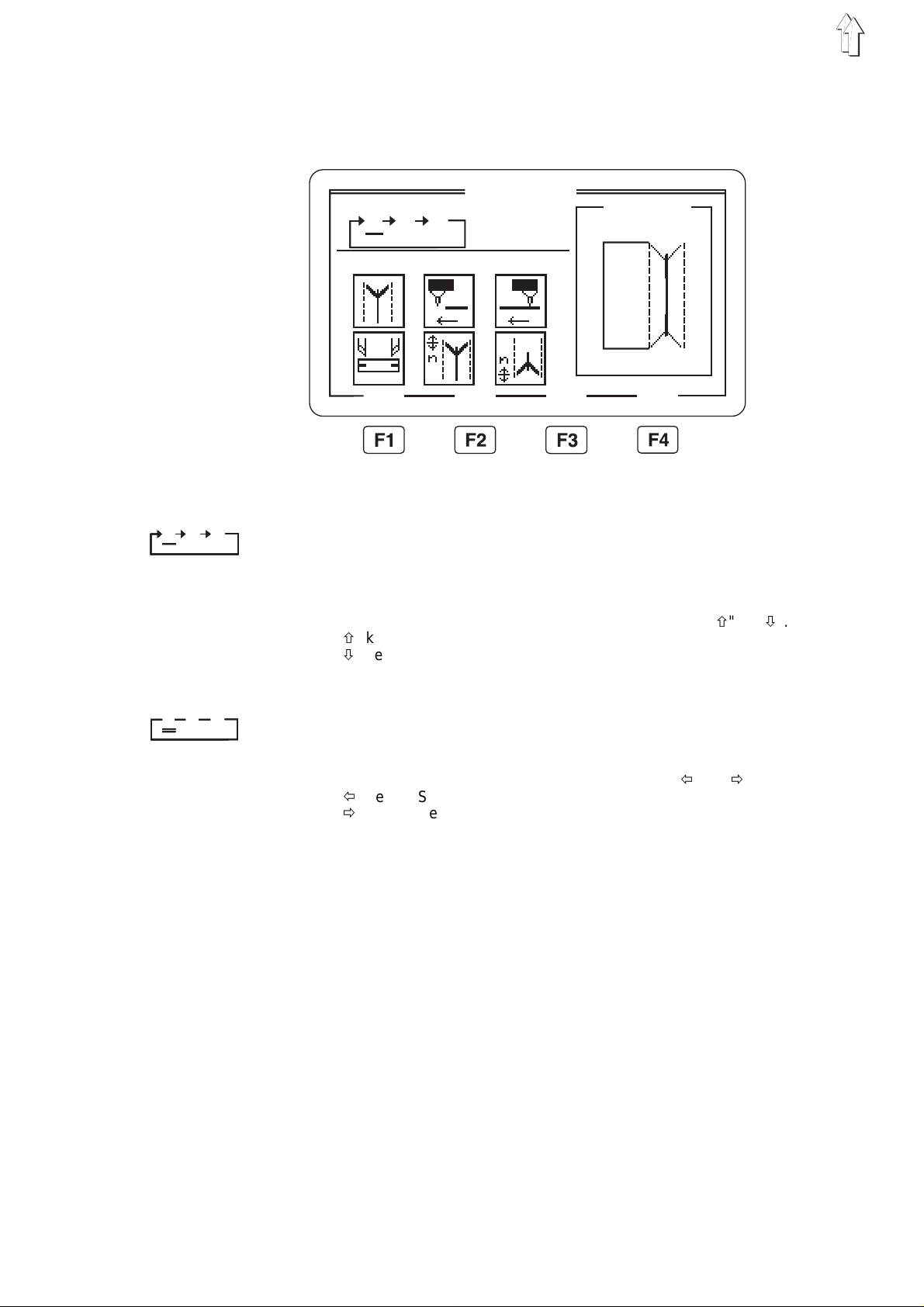

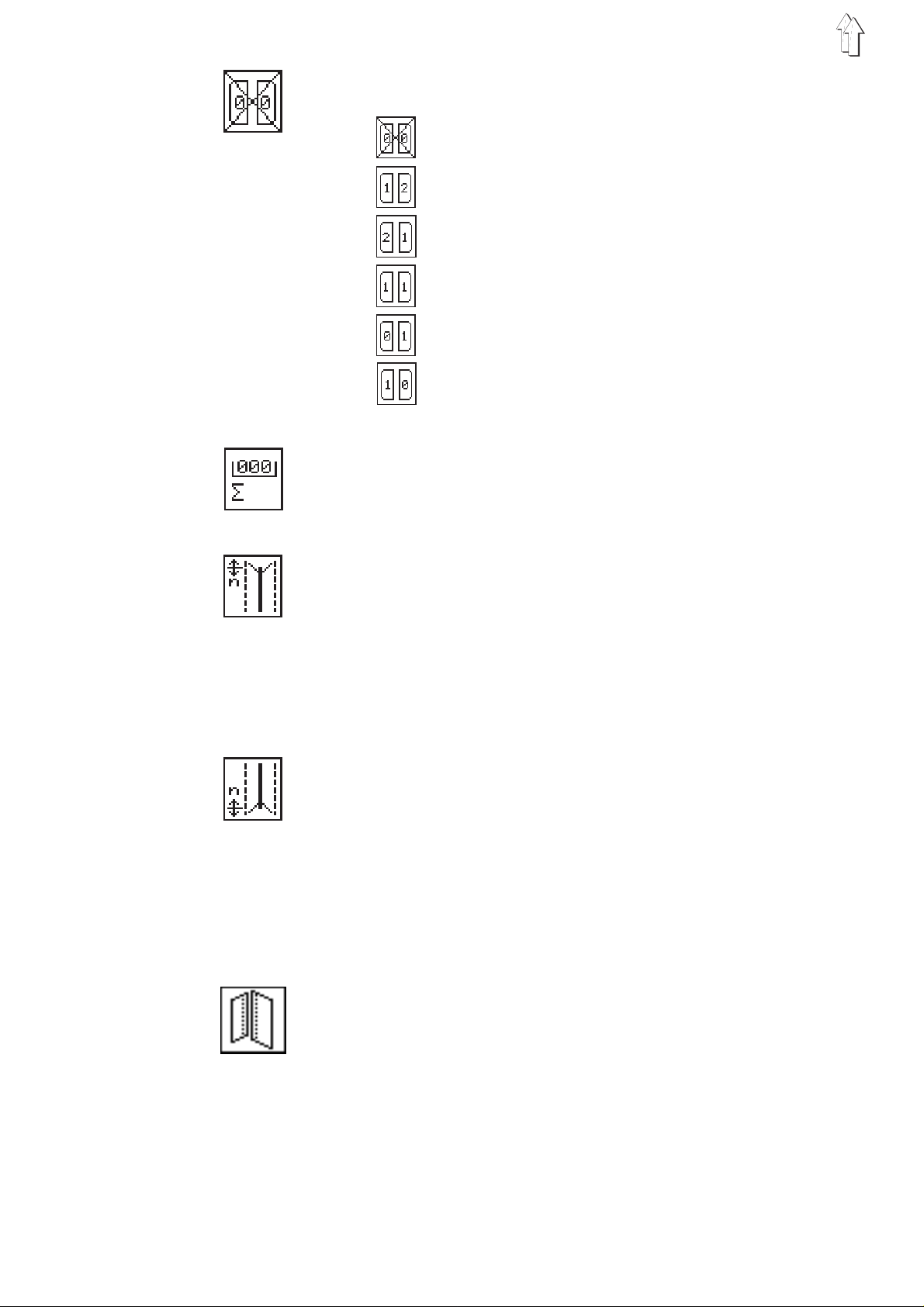

5.7 Seam Patterns ( )

Under this menu i te m u p t o 2 5 d iffer en t se am pa tterns can be progra mmed.

745-26/28

01

000

–

With the main screen as shown press the function key F4.

The display changes to the seam pattern screen.

–

Three parameters for the programming of the seam pattern number, the flap side and an ad di t i on al seam offset appear in th e l e ft

third of the d i s pl a y.

In the windows in the center of the display are shown the flap form

(left window ) a nd th e s e am pa tt ern ( ri gh t w i nd ow ).

In the window in the right third of the display is shown the

complete seam pa tt er n wi t h f lap .

–

Select the desired parameter with the cursor keys "" or "".

The symbol of th e s e lec t ed parameter appears i nv e rs el y.

–

Change the sel ect ed pa r am et er a s de sc r ibe d i n Ch ap te r 4. 2.

–

By pressing the function key F1 the display returns to the main

screen.

Selecting a seam pattern

After the initialization of the program memory 25 standard seam patterns are filed in the cont rols (see Appendix A1).

They can be called up directly by entering the seam pattern number.

Enter: 1...25

Selecting a flap side

The sewing unit is equipped with a reflected light barrier for the recognition of the seam beginning and seam end when sewing with flap.

The parameter shows the side on which the flap is positioned.

With the a change of the parameter the flap side of the seam pattern in

the right third of the display automatically changes.

flap at the left

flap at the right

22

Additional seam offset

Enter: 0...20 [mm]

Selecting the flap form at the seam beginning

With the cursor keys "" or "" a choice can be made between the following seve n f l ap fo r ms :

The numbers above the flap forms denote the different angles.

Selecting the flap form at the seam end

With the cursor keys "" or "" a coice can be made between t he fo l l owing seven flap forms:

The numbers under the flap forms denote the different angles.

Selecting the seam pattern at the seam beginning

With the cursor keys "" or "" a choice can be made between the following seve n s e am pa tt er n s :

The numbers over the seam patterns denote the different angles.

Selecting the seam pattern at the seam end

With the cursor keys "" or "" a choice can be made between the following seve n s e am pa tt er n s :

The numbers under the seam patterns denote the different angles.

23

6. Setting and T esting Programs

The machine s o ft wa re encompasses differ e nt ma c hi n e-s p ec i f i c s et ti n g

and testing programs and the well-known Multitest system.

A terminal selftest checks the individual components of the operator

terminal.

6.1 Calling Up Setting and Testing Pr ograms

After the sewing unit is turn ed on one can change ov e r to the different

groups of setting and testing programs with the function keys F1 to F4.

Turn the

main switch on

Dürkopp Adler AG

745-26/28

05.05.95

Selftest

F

RAM

EPROM

RAM-Card

Keyboard

F

F

Interface

Display

List

Exit

Machine Parameters Machine-specific Multitest System Terminal Selftest

Setting and Testing (only for service staff)

Programs

24

–

Turn the main switch on.

The controls are initialized.

The DÜRKO P P- A DL E R l o go ap pe ar s in the display fo r a s h ort period.

–

While the lo go i s vi s i bl e pre s s on e o f t he fu nc t i on k ey s F1 to F4.

The display changes to the corresponding group of setting and testing programs.

6.2 Machine Parameters ( + )

STOP

The machine p arameters describe the technical exe c ut i on of the sewing unit, as well as the machine settings and their correction values.

ATTENTION !

As a rule changes in the machine settings result in mechanical conversions.

For this reas o n t hi s part of the program c an on l y be ac cessed after entering the co de nu mb er "

25483

".

Code

–

While the DÜRKOPP-ADLER logo is visible press the function key

.

F1

The prompt for the code number appears in the display.

–

Enter the co de nu mb er "

–

After the entering of the corr e c t code number the dis p l ay c h an ge s

to the machine parameter screen.

With an incorrectly entered code number the display changes to

the main scr ee n.

–

Select the desired parameter with the cursor keys "" or "".

The symbol for the selected parameter appears inversely.

–

Change the selected parameter as described in Chapter 4.2.

–

To exit the machine parameters press the "

Selecting the subclass

Enter: 26, 28

Maximum sewing di st a nce

Enter: 180, 220 [mm]

" with the numeric keypad.

25483

STOP

" key.

25

Feed device

Enter: A, B, C, D, F, H

745-26 745-28

X

XXB: Pip ed pockets,

XXC: Pip ed pockets,

: Pip ed pockets,

A

manual positioning of the piping strip,

flap and oth er s u pp l i me nt ar y p art s

automatic fe ed of th e p i pi n g s t ri p,

without cutting of the piping ends

automatic fe ed of th e p i pi n g s t ri p,

with cutti n g o f t he pi p i ng en ds

X

X

XXH: Sewi n g i n of th e s e win g u ni t

Activating the smoother

This paramete r s i gn als t he c on tr o l s if the sewing unit i s e qu i pp ed wi t h

a smoother.

The smoother is turned on and off in the main screen under the menu

item "Pocket Program" (F2).

Enter: on/off

Switching the tape feed on/off

This paramete r s i gn als t he c on tr o l s if the sewing unit i s e qu i pp ed wi t h

a tape feed.

The tape feed is turned on and off in the main screen under the menu

item "Pocket Program" (F2).

Enter: on/off

: Bre as t po c k et s,

D

automatic fe ed an d a l i gn ing of

the breast selvage

: Piped pockets,

F

automatic fe ed of th e p i pi n g s t ri p,

automatic fe ed an d a l i gn ing of the flap,

with cutti n g o f t he pi p i ng en ds

(only for service staff)

26

Needle clearance

Enter: 8, 10 , 1 2, 14 , 1 6, 20 [mm]

Sewing rpm

Enter: 25 00 , 2 75 0, 30 00 [r p m]

Stitch length

Enter: 2.55, 3.10 [mm]

Stitch length in the stitch condensation

Enter: 0.50, 0.80, 1.40 [mm]

Number of stitches in the stitch condensation

Enter: 5...10 [stitches]

Switching the thread monitors on/off

With this pa r am et er the needle thread

switched on and off.

Enter: on/off

Displays: Needle thread breakage:

Underthread bobbin empty:

Clearance of the rear positioning point to the central positioning

point

Enter: 40...120 [mm]

underthread monitors are

and

The empty bobbin blinks.

Switching the remover on/off

This paramete r s i gn als t he c on tr o l s if the sewing unit i s e qu i pp ed wi t h

a remover.

The remover is turned on and off in the main screen under the menu

item "Pocket Program" (F2).

Enter: on/off

Switching the stacker on/off

This paramete r s i gn als t he c on tr o l s if the sewing unit i s e qu i pp ed wi t h

a stacker.

The stacker i s t urn ed on and off in the main s c ree n u nder the menu

item "Pocket Program" (F2).

Enter: on/off

27

6.3 Machine-specific Setting and Testing Programs ( + )

The machine-s p ec i f i c testing programs s erv e fo r th e setting and testing of the individual machine components.

–

While the DÜRKOPP-ADLER logo is visible in the display press

the function key F2.

The display changes to the machine-specific testing programs screen.

–

Select the desired testing program with the cursor keys "" or "".

The symbol fo r th e s e l ec t ed te s ti n g p rog r am ap pe ar s in v er sely.

–

Start the selected testing program with the enter key.

Attention!

play did not c ha ng e, on l y th e s m oo th er w or ks .

After starting the pro gram "Testing smoother" the dis-

STOP

6.3.1 Setting the Underthread Monitor

This program s erv e s fo r th e alignment of the r e fl e c te d l ig ht barriers of

the underthread monitor.

–

Start the testing program with the enter key.

The displa y s ho ws t w o un de rt h rea d b ob bi n s an d t he r ef l ec t i ng

heads of the light barriers.

–

With a correct alignment of the light barriers a reflection occurs

when an empty bobbin is turned.

A reflection is sho wn by a n a r row between the reflec t i ng he ad an d

the underth rea d b ob bi n .

At the same time a signal tone can be heard.

–

To exit the testing program press the function key F1.

745-26/28

28

6.3.2 Initializing the Program Memory

The program se r ves t o l o ad a s t an da r di z e d f ac t ory s e tt i ng fo r th e p arameters of the se wi n g p rog r am s.

ATTENTION !

After start i ng on e o f t he fo ur p r og ram s a s t an da r diz e d f ac t or y se tting

will overwrite the set parameters!

For this reas o n t he pr o gra m c a n o nl y b e s t art ed after entering th e co de

number "

25483

745-26/28

".

Code

–

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

The display s h ow s th e p r om pt fo r th e c o de nu mb er.

–

Enter the co de nu mb er "

–

After the entering of the corr e c t code number the dis p l ay c h an ge s

to the five parame te rs de s cr ibe d b elo w.

After the entering of an incorrect code number the display returns

to the machine-specific parameter screen.

Initialization of defective machine parameters

Initialization of defective pocket programs

Initialization of defective pocket sequences

Initialization of defective seam patterns

Initialization of

–

Select the desired program with the cursor keys "" or "".

The symbol for the selected program appears inversely.

–

Start the se l ec t ed pr o gra m with the enter ke y.

–

To ex i t th e t es t i ng pro gr a m p r ess t he function key F1.

" with the numeric keypad.

25483

programs and parameters

all

29

6.3.3 Checking the Smoother Function

With this program the smoother function is tested.

–

Start the testing program with the enter key.

The symbol ap pe ars i n th e lo we r ri gh t c o rne r of th e d is pl a y wi t h a

prompt.

–

Enter the desired values for "t" and "v".

Enter: Active period: t = 5...20

745-26/28

20

15

Step size:1 cycle = 0.1 s

Speed level: v = 5...15

–

–

6.3.4 Aligning the Light Barriers

The program serves for the alignment of the reflected light barrier for

the recognition of the seam beginning and seam end.

After confirmation of the value for "v" the smoother runs for the selected acti v e pe ri od at the selected spe ed .

To exit the testing program press the function key F1.

745-26/28

30

–

Start the testing program with the enter key.

Two light barrier symbols appear in the center of the display.

–

Manually pus h th e t r an s po rt c l a mp un de r th e re fl e c te d l i g ht ba r ri er.

With a refl ec t i on an ac o ustic signal is h ea rd.

The displa y of the light barri er sy m bo l s c ha ng es from inverse to

normal.

–

To exit the testing program press the function key F1.

6.3.5 Setting the Corner Knife Adjustment

With this program the corner knife clearance and the angle of the corner knife ca n b e set.

The minimum a nd ma x i mu m c o rne r k nife clearances are dependent on

the subclas s and the equipment of th e s e wi n g u ni t .

–

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

–

Set the max imu m or minimum corne r k ni f e c l e ara nc e wi t h t he cursor keys "" or "".

–

Set the angl e of th e c o rne r k ni f e w i th th e f un c ti o n k e y s F3 (corner

knife seam be gi n ni n g) a nd F4 (corner kni f e seam end).

The seam beginning and seam end each have a choice of seven

angle settin gs a v ai l a ble.

745-26/28

Corner knife se am be gi n ni n g (F3):

Corner knife se am en d (F4):

Caution Risk of Injury !

Danger of cuts!

Do not reach int o t he ar e a o f t he ri si ng c orn er kn i v es.

–

Press the "" cursor key.

The corner knives rise.

–

Press the "" cursor key.

The corner kni ves l o we r ag ai n .

–

To ex i t th e t es t i ng pro gr a m p r ess t he function key F1.

31

6.3.6 Checking the Switching-in of the Needle and Center Knife

This program checks the switching-in of the needles and the center knife with the sewing drive running.

745-26/28

–

Start the testing program with the enter key.

–

Press function key F2.

1st operation: Start of the sewing drive at 1000 rpm

2nd operation: Running the sewing drive at 3000 U/min

3rd operation: Stop in position 2 (thread lever high position)

–

Turn the center kni fe on an d o ff wi th th e function key F3.

–

Turn the needles on and o ff wi th th e f un c tio n k e y F4.

–

To exit the testing program press the "

STOP

" key.

ATTENTION !

Before exiting the program it is essential to let the machine head run

briefly wi th th e n ee dl e s an d center knife turne d o ff.

Otherwise the next seam will not be executed correctly.

6.3.7 Checking the Tape Feed Function

This program te s ts t he tra ns p or t an d c u tt i ng fu nc t i on of th e t ap e feed.

745-26/28

ON OFF

32

–

Start the testing program with the enter key.

–

Press function key F2. The tape feed starts.

–

Press function key F3.

The motor of the tape feeds stops.

The tape is automatically cut.

–

To exit the testing program press the function key F1.

6.3.8 Checking the Catch-folder without T r ansport Clamp

This program te s ts t he fu nc t i on of th e ca tc h - fo lde r.

The transport c l am ps re ma i n i n th ei r re ar e nd po s i tio n hereby.

745-26/28

–

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

–

Press function key F3.

The catch-fol d er s w i ng s into the vertical p os i t i on an d l o we r s on to

the material slide plate.

–

Press function key F2.

The catch-fol d er ri s e s an d s w i ng s ove r th e f ee d b oard.

–

To ex i t th e t es t i ng pro gr a m p r ess t he "

STOP

" key.

6.3.9 Checking the Feed Procedure with T ranspor t Clamp

This program s erv e s fo r te s ti n g t he feed procedure.

745-26/28

–

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

A reference run is cond uc t ed .

–

Step on the p ed al .

The transport carriage runs to the feed station.

–

The feed proc e du re i s r u n t hro ugh as in a sewing pro gr a m.

After operat i on of th e l a s t s t ag e a n a r row appears in the d i spl a y.

–

Run the tran s po rt c a r ri ag e i n to th e r e ar p os i t i on by stepping on the

pedal in tap pin g operation.

In this position the transport carriage waits until the pedal is at rest.

–

The transport clamps rise and the flap clamps open.

–

The program i s r est ar t ed by s t ep pi n g o n t he pe da l .

–

To ex i t th e t es t i ng pro gr a m p r ess t he "

STOP

" key.

33

6.4 Multitest System ( + )

STOP

The testing programs of the Multitest system make possible the quick

checking of i np ut an d o ut pu t elements.

Additional measuring devices are not necessary.

–

While the DÜRKOPP-ADLER logo is visible in the display press

function key F3.

The display changes to the Multitest system screen.

–

Select the desired testing program with the cursor keys "" or "".

The symbol fo r th e s e l ec t ed te s ti n g p rog r am ap pe ar s in v er sely.

–

Start the selected testing program with the enter key.

6.4.1 Displaying the Program Version and Check Sum

The program checks the permanent store memory (ROM) of the

microcompu ter.

MULTITEST

EPROM-Test

ROM-Size

Class

Version

Date

Checksumme

Program vers io n

By program versions with the same class designation and the same

identification letter the higher version replaces all lower versions (Example: 745A03 replaces 745A01 and 745A02).

If a replacem en t i s p oss i b l e a l th ou gh th e i d en ti f i c at i on l et te r is di fferent this will be noted in a special communication to the customer.

: 192k EPROM

: 745-26/28

: 745A01

: 19.06.95

: 0x64AE

34

Check sum

The check sum is meant only for the factory service personnel.

It shows speci a l is ts if th e p r og ram me mo r y ( E PR OM ) of th e se wi n g

unit control s f l aw l ess l y contains the comp l et e p r og ram .

–

To exit the testing program press the function key F1.

6.4.2 Testing the Working Memory

The program checks the working memory (RAM) of the microcomputer.

–

MULTITEST

RAM-Test

RAM OK

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

The display shows the test results.

Display Explanation

RAM OK

RAM-Error

–

To ex i t th e t es t i ng pro gr a m p r ess t he function key F1.

6.4.3 Displaying the Setting of the DIP Switches

The program sh ows the setting of th e DIP switches on th e CPU board

of the control u ni t.

MULTITEST

1

ON

OFF

Working memory functioning flawlessly

Error in the working memory

DIP-Switch

2345678

ATTENTION !

Currently the DI P swi tc h es a r e n ot em plo y ed on an y ma chi n e c la s s .

The setting of the various DIP switches has no influence on the operation of the sewin g u nit.

–

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

–

To ex i t th e t es t i ng pro gr a m p r ess t he function key F1.

35

6.4.4 Selecting Input Elem ents

The program serves for the setting of the input elements.

MULTITEST

Input-Select

S ?

Input-Nr. :

ATTENTION !

All input elements were carefully set at the factory.

The setting and correction may only be conducted by trained service

personnel.

–

Start the testing program with the enter key.

–

Enter the code number of the desired input element with the numeric keypad.

The short de si gn ations of the circ u i t d i ag ram s er ve as c o de nu mbers (see following table).

–

The display s h ow s th e wiring diagram d es i g na ti o n a nd th e s w i tching status of the selected input element (e.g. "

+S17

").

The display changes when the switching status of the input element changes.

The switching status "+" means:

Contact swi tc h = Contact open

Proximity switch = Metal in front of the switch

Reflected light barrier = No reflection

Continuous beam barrier = Beam not interrupted

–

Set the input element until the display shows the desired switching

status.

–

To exit the testing program press the function key F1.

36

Input elements

745-26 745-28 Input Function

element A B C D F

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

S01

S02

S03

S04

S05

S06

S07

S08

S09

S10

S11

S15

S17

S18

S23

S25

S26

S27

S28

S29

S30

S31

S32

Left pedal 1 X X X X X

Left pedal 2 X X X X X

Left pedal 3 X X X X X

Left pedal 4 X X X X X

Right pedal 1 XXXXX

Right pedal 2 XXXXX

Right pedal 3 XXXXX

Right pedal 4 XXXXX

Limit switch Knife bracket forward X X X X X

Limit switch Knife bracket back X X X X X

Knife bracket Reference point X X X X X

Limit switch Transport carriage forward X X X X X

Limit switch Transport carriage back X X X X X

Needle thread monitor left X X X X X

Needle thread monitor right X X X X X

Transport carriage Reference position X X X X X

Folder up X

Catch-folder up X X X

Positioning device up X

Folder down X

Catch-folder down X X X

Positioning device down X

Catch-fold er s w un g X X X

Positioning device swung X

Catch-folder vertical X X X

Positioning device vertical X

Flap seat up O

Pocket bag p l ac e me nt ti l t ed O

Pocket bag f ee d down O

Feed method

Light barrier inputs

745-26 745-28 Input Function Feed method

element A B C D F

XX

X

XX

XX

XX

X = S t an ar d eq ui p me nt

O = Optional equipment

S100

S101

S104

S106

S107

Flap scanning 1 XXXXX

Flap scanning 2 OOOOO

Stacking control X X X X X

Remaining thread monitor left X X X X X

Remaining thread monitor right X X X X X

37

6.4.5 Checking Input Elements

The program serves for the testing of the input elements.

MULTITEST

Input-Test

S26 :

–

Start the testing program with the enter key.

–

Operate the input element to be tested.

–

The display s h ow s th e wiring diagram d es i g na ti o n a nd th e s w i tching status of the selected input element (e.g. "

+S17

").

The display changes if the switching status is changed or some

other input element is changed. A change of the switching status is

shown by an aco us t i c s ign al .

–

To exit the testing program press the function key F1.

38

6.4.6 Selecting Output Elements

With the program the function of the output elements is checked.

It is possible to test one (single-mode) or several (multi-mode) output

elements at a t i me .

Caution Risk of Injury !

During the function testing of the output elements do not reach into the

running machine.

–

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

–

Make the sel ec t i on be tw ee n s i n gl e - mo de an d m ul t i -mo de by t he

ten-key keyboard.

1 = SINGLE-Mode Only one output element is tested.

2 = MULTI-Mode A group of output elements are tested.

–

Enter the co de nu mb er o f t he de s i red output element by the key F2

(forwards) or F3 (backwards).

The code designations used in the circuit diagram are used as

code numbers (see the following tables).

–

The display shows the switching status (ON/

output eleme nt .

–

Turn the selected output element on and off by pressing the function key F4 in tapping operation.

–

To ex i t th e t es t i ng pro gr a m p r ess t he function key F1.

) of the selected

OFF

39

Inside output elements

745-26 745-28 Output Function Feed method

element ABCDF

XX

Y01

Folder lifting X

Catch-folder lifting X X X

Positioning device lifting X

XX

Y02

Folder lowering X

Catch-folder lowering X X X

Positioning device lowering X

XX

Y03

Catch-folder swi n g X X X

Positioning device swing X

XX

Y04

Catch-folder vert i cal X X X

Positioning device vertical X

XX

Y05

Piping knife forward X

Positioning device right X

XX /

Y06

Piping knife back X

Positioning device left X

XX

Y07

Needles spreading X X X

Positioning device closing X

X

Y08

Needle left XXXXX

X Needle left and right XXXXX

X

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

Y09

Y10

Y11

Y12

Y13

Y14

Y15

Y16

Y17

Y18

Y19

Needle right XXXXX

Link swing XXXXX

Center knife XXXXX

Transport clamp lifting XXXXX

Transport clamp lowering X XXXX

Flap clamp right lifting XXXXX

Flap clamp left lifting XXXXX

Folding plates closing X XXXX

Thread drawing XXXXX

Thread tension release XXXXX

Flap feed swi n g i n O O X

Pocket bag feed fo rwa r d O

XX /

Y20

Flap feed swi n g o ut O O X

Pocket bag feed back O

XX

Y21

Flap feed L closing O O X

Pocket bag placement lifting O

XX

Y22

Flap feed L opening O O X

Pocket bag gripping O

XX

XX

XX /

Y23

Y24

Y99

Flap feed R clo s ing O O X

Flap feed R ope nin g O O X

Cover monitoring XXXXX

/ = Open when idle

X = Standard equipment

O = Opt i on al e qu i pm en t

Valve arrangement 745-26:

Y99 Y24 Y23 Y22 Y21 Y20 Y19 Y16 Y15 Y14 Y13 Y12 Y7 Y6 Y5 Y4 Y3 Y2 Y1 Y17 Y18 Y11 Y10 Y8

Valve arrangement 745-28:

Y99 Y24 Y23 Y22 Y21 Y20 Y19 Y16 Y15 Y14 Y13 Y12 Y7 Y6 Y5 Y4 Y3 Y2 Y1 Y17 Y18 Y11 Y10 Y9 Y8

40

Outside output elements

745-26 745-28 Output Function

Feed method

element A B C D F

XX

XX

XX

XX *

XX *

XX

XX

XX

XX

XX

Y33

Y34

Y35

Y36

Y37

Y38

Y39

Y40

Y41

Y42

Stopper Fl ap fe ed L X

Corner knife Seam beginning X X X X X

Corner knife Seam end X X X X X

Blower Reflecting foils X X X X X

Blower Flap feed O O O

Sewing threads cutting XXXXX

Thread clamp opening X X X X X

Holder OOOOO

Vacuum OOOOO

Stacking XXXXX

Ejector lowering XXXXX

X X Blower XXXXX

XX

Y43

Remover forward O O O O

Pocket bag f ee d press forward O

XX

X

X

X

X

X

X

X

X

XX /

XX

XX

XX /

XX

XX

XX /

XX

X

X

XX

Y44

Y45

Y46

Y47

Y48

Y49

Y50

Y51

Y52

Y53

Y54

Y55

Y56

Y57

Y58

Y59

Y60

Y61

Y62

Y63

Remover back O O O O

Knife bracket Seam beginning 1 X X X X X

Knife bracket Seam beginning 2 X X X X X

Knife bracket Seam beginning 3 X X X X X

Knife bracket Seam beginning swing X X X X X

Knife bracket Seam end 1 X X X X X

Knife bracket Seam end 2 X X X X X

Knife bracket Seam end 3 X X X X X

Knife bracket seam end swing X X X X X

Flap seat l i ft i ng X

Flap seat lowering X

Flap seat s wi n g f or w ard X

Flap seat swing back X

Flap seat op en i ng X

Flap seat closing X

Tape brake OOOOO

Tape scissors (directly at the scissors) O O O O O

Corner knife lock left O O O O O

Corner knife lock right O O O O O

Stacker ad di t i on lowering O O O O O

* = Oil-free ai r

/ = Open when idl e

X = S t an da r d e qu i pm en t

O = Optional equipment

Valve arrangement 745-26:

Y34Y35Y38Y39Y40Y41Y42Y43Y44Y53Y54Y55Y56Y57Y58Y59Y60Y36Y37

Valve arrangement 745-28:

Y34 Y35 Y38 Y39 Y42 Y45 Y46 Y47 Y48 Y49 Y50 Y51 Y52 Y40 Y41 Y43 Y44 Y53 Y54 Y55 Y56 Y57 Y58 Y33 Y59 Y60 Y61 Y62 Y36 Y37

41

Supplimentary outputs

745-26 745-28 Output Function

element ABCDF

XX

XX

XX

XX

XX

XX

XX

XX

Y100

Y101

Y102

Y103

Y104

Y105

Y106

Y107

Y104

Y105

Y106

Y107

Smoother 0 O O O O

Smoother 1 O O O O

Smoother 2 O O O O

Smoother 3 O O O O

Lamp back A1 X

Lamp back A2 X

Lamp forward A1 X

Lamp forward A2 X

Lamp forward 1 X X X

Lamp forward 2 X X X

Lamp back 1 X X X

Lamp back 2 X X X

X = Standard equipment

O = Opt i on al e qu i pm en t

6.4.7 Checking the Step Drives

Feed method

The program show s th e s oft wa r e ve r si on of th e st ep dr iv e s.

Steppermotor-Test

Software-Version

SMC

Version-Nr

SMC

1

SMC

2

SMC

3

4

5

6

–

Start the program with the enter key.

A0 1 M

A0 1 S

A0 1 S

Checksum

0x C BB3

0x 9 0B6

0x 9 0B6

Status

0x00

0x40

0x40

The display shows the software versions of the step drives.

–

To exit the testing program press the function key F1.

42

6.4.8 Checking the Sewing Drive

The program serves for the testing of the needle positions and the different rpm levels of the sewing drive.

–

–

–

Sewingdrive-Test

AB85A.B0

STAR T STOP

Start the t est i ng pr o gr a m w i th th e e nt er k e y.

Select the symbol of the desired parameter with the cursor keys

"" or "".

The selected symbol appears inversely.

Set the parameter with the cursor keys "" or "".

Display th e p r og ram v er si o n o f t he s ew i ng dri v e

Sewing drive runs at the selected rpm,

machine head positions in the set position

Machine head positions in pos i ti o n 2

Machine head positions in pos i ti o n 1

Machine head stops unpositioned

Selecting motor rpm

Enter: 70...maximum rpm [rpm]

–

Press function key F2.

The sewing dr iv e r un s at th e s e t rp m.

The current rpm (e.g. "

0199 rpm

") appears in th e u pp er r ig ht cor-

ner of the dis pl a y.

–

Press function key F3.

The sewing drive stops.

The machine head positions in the set position.

–

To ex i t th e p rogram press the "

STOP

" key.

43

6.4.9 Displaying th e Error Messages Generate d

The program shows the last 10 error messages in the display.

The error messages and their meaning are listed in Chapter 8.

MULTITEST

error messages

01. 902/-8

Error

->

Error

->

02.

Error

->

03.

Error

->

04.

Error

->

05.

Error

->

06.

Error

->

07.

Error

->

08.

Error

->

09.

EXTERN STOP

->

10.

–

Start the testing program with the enter key.

The last 10 e r ror m ess a ge s ap pe ar i n th e d i spl a y.

–

To exit the program press function key F1.

902/-8

902/-8

902/-8

902/-8

902/-8

903/-22358

903/-22358

959/201

44

6.5 Terminal Selftest ( + )

STOP

With the terminal selftest service personnel check the individual components of th e o pe r at or t er m i na l .

Selftest

RAM

EPROM

F

RAM-Card

F

Keyboard

F

Interface

Display

List

–

While the DÜRKOPP-ADLER logo is shown in the display press

the function ke y F4.

The terminal selftest runs through the following test programs consecutively.

The testing p r oce du r es a re s h own in the displa y by r u n b ars .

–

RAM test

The RAM test checks the working memory ("Video RAM") of the

operator ter min al .

After compl et i on of th e RAM test the term i na l s elftest automatic al l y

changes to the EPROM test.

–

EPROM test

The EPROM test checks the program memory ("Program Memory")

of the control u ni t .

By pressing the function key F2 the terminal selftest continues with

the RAM card t es t .

–

RAM card test

The RAM card test checks the memory card.

After compl et i on of th e RAM card test th e t erm i na l s el f te s t a ut om atically changes the keyboard test.

–

Keyboard test

The keyboard test checks the keypad of the operator terminal.

After pressing any key a checkmark appears in the display behind

this key by fa ult fre e functioning.

By pressing th e "

The display c h an ge s to th e i n te r fa c e t es t .

–

Interface te st

The interface test checks the interface of the operator terminal

(special ca bl e required!).

After compl et i on of th e i n te r fa c e t es t th e t er m i na l s el f te s t a ut om atically changes to the display test.

–

Display test

The display test shows the available character set ("Character

Set") and the graphics characters ("Graphic") of the display.

By pressing the function key F2 the display changes to the main

screen of the terminal selftest (see illustration).

–

M

ain screen

From the main screen a complete

with the function key F2.

To exit the terminal selftest press the "

" key the keyboard test is ended.

ESC

Test Protocol

STOP

can be called up

" key.

45

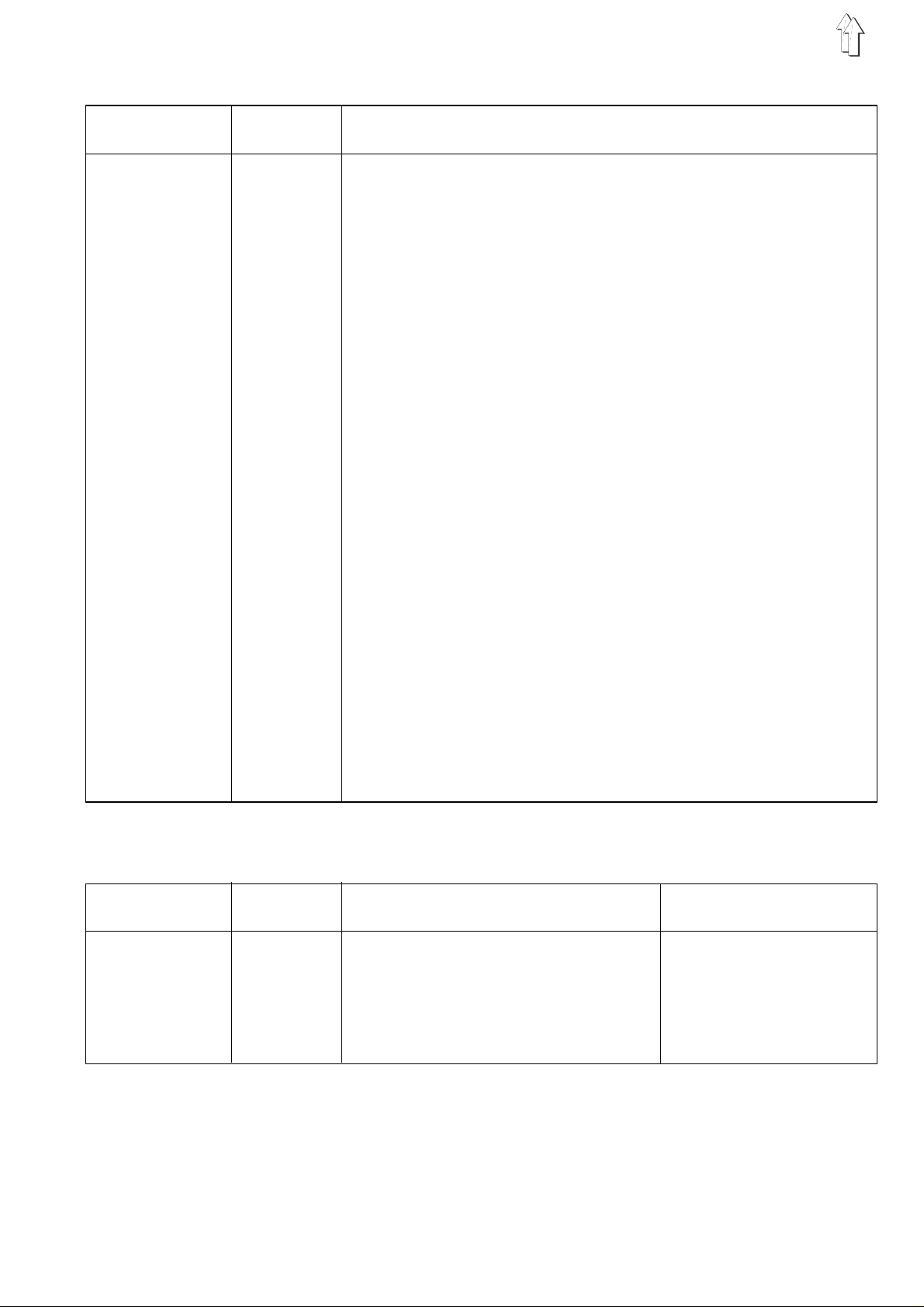

7. Output Card of the Step Motor

ATTENTION !

Before starting operation it is essential to check the settings of the

step motor output card.

The step motor output is to be found at the right under the table.

After remov ing the metal cover the setting elem en ts s h ow n b el o w a r e

accessable.

7.1 Switches on the Front

Caution Electric Current !

Turn the main switch off.

The switches may not be adjusted carrying current.

Step motor

output

LED 1 LED 2

LED 3 LED 4 Voltage

Parameter

switches

Current

selector

The switches must be in the positions shown!

LED 1 - LED 4

Parameter switches

Current selector

Voltage convertor

see Chapter 7 .2

see illustrat i on

F

230 V

convertor

46

7.2 Status Displays on the Front

The four red li g ht diodes (LEDs) on th e o utput card show th e o pe r at i ng

status and malfunctions of the step motor.

With flawless operation none of the LEDs may be lit.

LED 1

LED 2

LED 3

LED 4

LED 1 and LED 2

A fault in the output card is shown as follows:

–

After the recognition of the error the step motor is turned off for safety reasons (Reset).

For this reaso n L ED 1 an d L E D 2 ar e always lit after an erro r me s sage of the controls.

–

The displa y s ho ws t he appropriate erro r nu mb er.

–

The statuse s of th e o ut pu t c a r d c a n o nl y b e c a l l ed up wi t h t he appropriate testing program of the Multitest system (

Undervoltage

Shortfall i n t he op er a ti n g v o lt a ge of

more than 30%

Phase monitoring

Interruption in one or more motor wires

Short circuit

Short circ ui t be tw een two or more

motor phases o r mo to r ph as e an d g r ou nd

Overheating

Exceeding the allowable operating

temperature

Reset

ENABLE input is not activated by the controls

+ F3).

STOP

Check the st ep dr i v e s

–

After corre c ti o n o f t he fa ul t th e malfunction mes sage is cleared by

turning the ma i n s w i tc h off an d o n a gain.

47

8. Error Messages

With an error in the control system or in the machine program the display shows t he c orr e s po nd i ng err o r nu mb er.

With the aid o f the following ta bl e s th e e r ror c a use c an be fo und and

remedied.

8.1 Error Messages of t he Control s

Error number Explanation Remedy

100

101 - 199

EXTERN STOP

300 - 399

400 - 411

412

413

414

418 - 420

Undervoltage

Processor fault

External stop input operate d

Error in the data transmission

to the sewing drive

General st ep mo to r fa ul t

Output fault AMP1 error (Sewing goods)

Output fault AMP2 error (Knife)

Output fault AMP3 error (Tape)

Error in the step motor card during the

acknowledg em ent ( Time Out )

Stabilize the voltage supply

--Close the cover hood

Check the cable

--see Chapter 7.2

---

---

---

8.2 Error Messages of the Machine Program

Error number Explanation Remedy

700

701

702

703

704

Catch-folder not up

Catch-folder not vertical

Catch-folder not swung

Positioning device not up

Folder not down

Correct the setting

Correct the setting

Correct the setting

Correct the setting

Correct the setting

48

720

721

722

723

724

730

731

740 - 742

Light barrier error at the seam beginning

Refecting fo i l at th e s e am be gi n ni n g n ot re cognized

Safety stop

Jumper J308 at th e s t ep mo to r

controlle r no t p l ug ge d

Jumper J309 at th e s t ep mo to r

controlle r no t p l ug ge d

with flap se at and transport ca r ri ag e

in the feed position

carriage re tu r n w i th s ew i ng go od s set to

work procedure B - H

Error in the mo v i ng of th e k n i fe tr a nsp or t

Replace th e re fe c ti n g f oi l

Replace th e re fe c ti n g f oi l

Flap outside of seam area or

the missin g c o nn ec t i on of th e 2 nd l i gh t

barrier for the detection of inclination or

for activating the pocket program.

Plug in jumper J308

(see sketch pg. 49)

Plug in jumper J309

(see sketch pg. 49)

Carriage return in the wait position

Reset the carriage return or feed

device

Check the knife drive

Error number Explanation Remedy

745

746

748

749

900

901

902

903

910 - 991

Step motor main axle has not

reached the rear limit switch (S17)

Step motor main axle has not left the

forward lim i t switch (S15) afte r 10 0 m s

Step motor main axle has run past the

forward limit switch (S15)

Step motor main axle has run past the

rear limit switch (S17)

Check sum error in the machine

parameters

Check sum error in the pocket sequences

Check sum error in the pocket

programs

Check sum error in the seam patterns

Error in reading or writing on the

memory card

Check the sew ing go od s tra ns p ort an d

limit switch

Check the sew ing go od s tra ns p ort an d

limit switch

Check the sew ing go od s tra ns p ort an d