Contents page:

Home

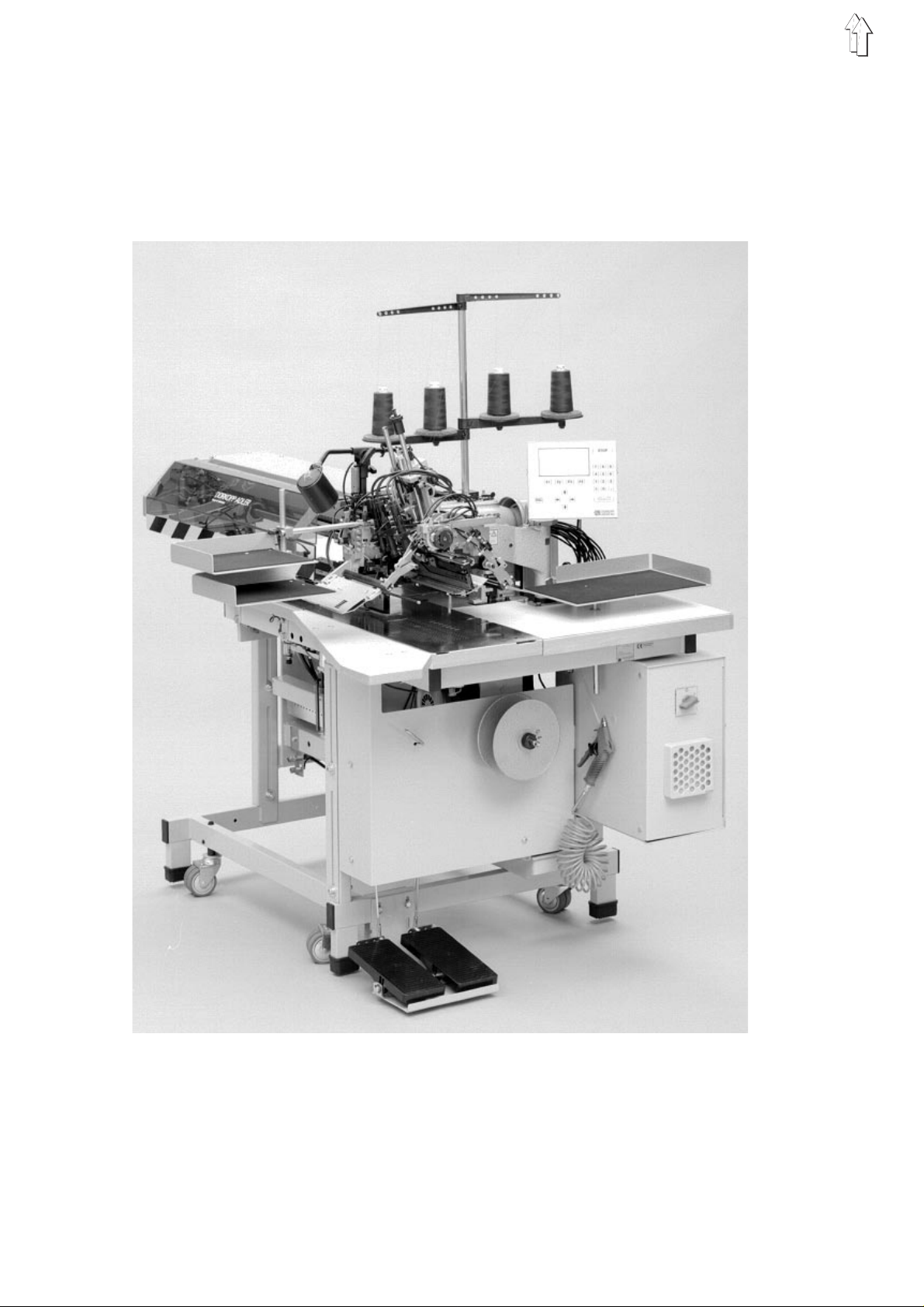

Part 2: Installing instructions Kl. 745-26/ -28

1. Items supplied

2. Setting up the sewing machine

2.1 Removing the carriage safety device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Adjusting working height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Checking V-belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Attaching fitments removed for despatch

3.1 Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Thread pillar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Folder (working method A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Folder and

3.6 Table wideners (accessories) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 Stacker (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8 Suction device (accessory) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. Electrical connection

4.1 Connecting the DAC operating panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Checking rated voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Checking positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

gripper-folder (working methods B, C) . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. Pneumatic connection

6. Lubrication

7. Starting up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1. Items supplied

–

frame with DC mo to r fo r th e u pp er m ac h i ne ass e mb l y

–

stepping motors for handling material and for the longitudinal

adjustment of th e t r imm i ng de v i c e

–

class 935-246-00 twin-needle double-lockstitch machine

745-26: with component s e t 0 93 5 745304 for joi nt ne ed l e-b ar

switching

745-28:with component set 0935 745307 for separate needle-bar

switching

–

DAC control device

–

reflex light barrier for flap sensing

–

two guide lamps for fabric placement

–

sewing lamp

–

compressed- a i r maintenance uni t wi t h c o mp res s e d- a ir pi s t ol

–

thread pillar

–

trays for it em s to be s ew n on operator’s right and left

–

tools and hard wa r e se t

2. Setting up the sewing machine

Attention!

The sewing machine may only be set up by specialist trained

personnel.

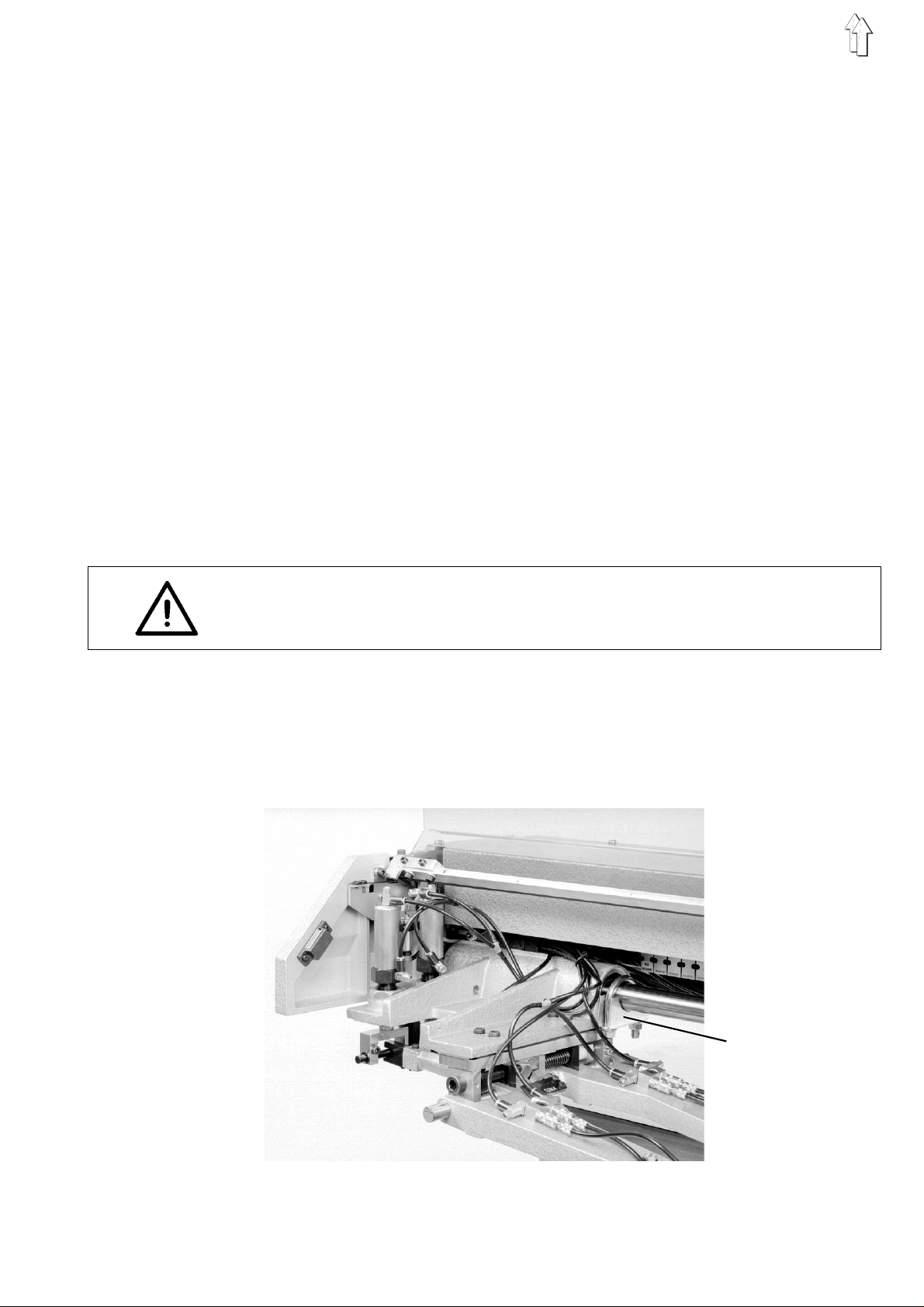

2.1 Removing the carriage safety device

The carriage safety device 1 locks the carriage in its rearmost position.

It must be remo v ed be fo r e t he s ew i ng ma c hi n e i s s e t u p.

1

–

Remove the carriage safety device 1 after undoing the nuts.

3

2.2 Movement

The sewing-machine chassis is fitted with four castors for movement

around the plant.

1

2

2.3 Adjusting working height

3

Attention!

Prior to commissioning the sewing machine the sound absorbers 3 (in

the tools and hardware set) must be fitted to the four chassis supports.

Reverse the castors so that the machine is motionless and stable.

–

To move the machine extend the four castors by turning the

adjusting screws 2 to the left.

The chassis s u pp orts must have en ou gh fre e floor space to a l l ow

for movement .

–

After movin g t he s ew i ng ma c hi n e, l ow er i t by t urn i ng th e

adjustment screws 2 to the right.

All four chassis supports must be firmly on the floor.

Working height can be adjusted between 87 and 110 cm (measured to

the top of the t ab l e p l at e) .

It is set to the minimum of 87 cm prior to despatch.

–

Undo locking screws 1 on all four spars of the chassis.

–

Adjust the base plate to the required working height.

To prevent the base p l at e f r om ti l t i ng , p ul l it out (or push it i n) b y

the same amount on both sides.

–

Tighten locking s cr ew s 1.

4

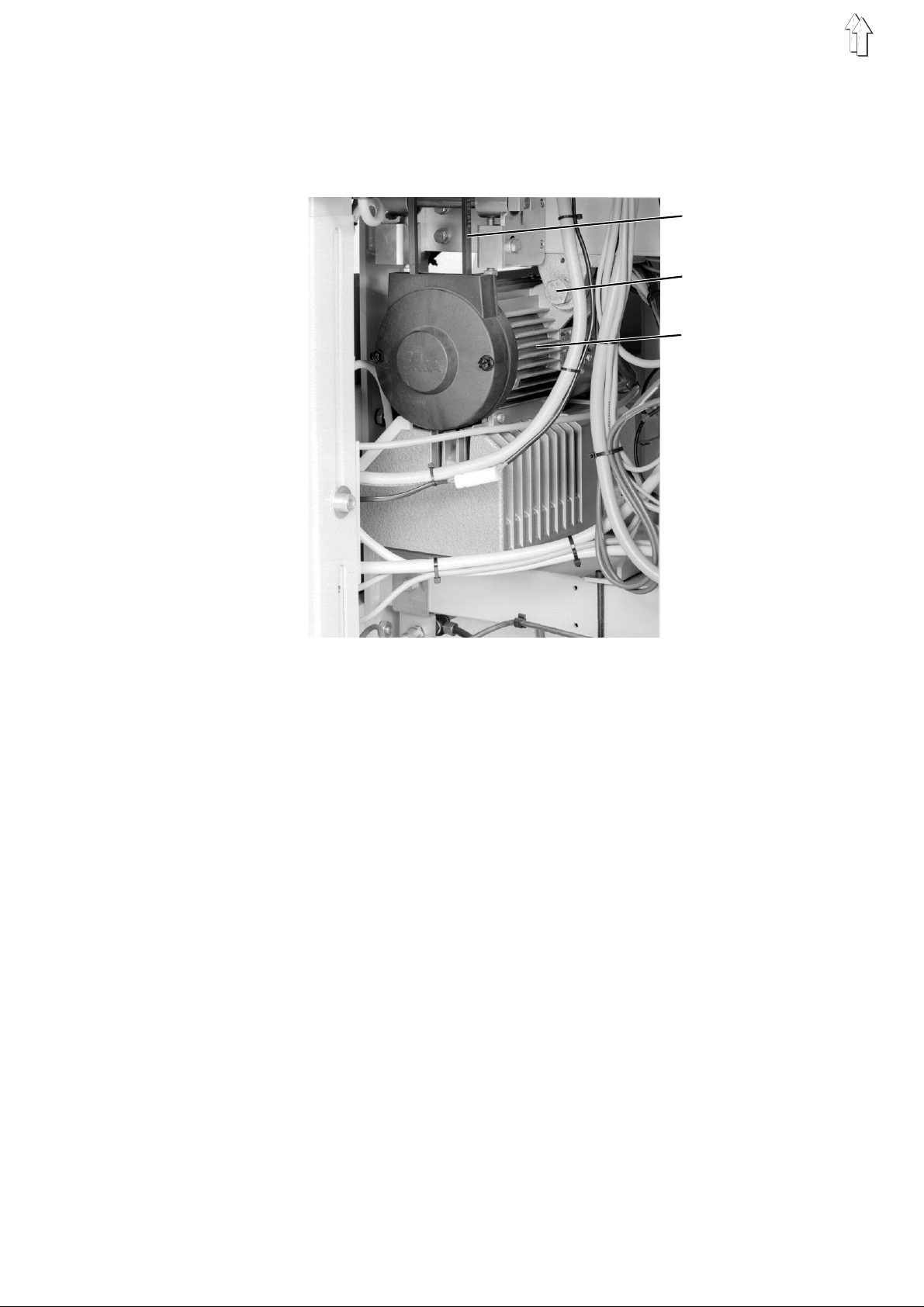

2.4 Checking V -belt tension

When the machine has been moved the V-belt tension (which is

pre-set prior to despatch) must be checked.

When the tension is correct it should be possible to depress the middle

of the V-belt 1 by about 10 mm by pressing on it with a finger.

1

2

3

Correcting V-belt tension:

–

undo screw 2

–

swivel sewing drive 3 until the required V-belt tension is produced

–

tighten scr e w 2

5

3. Attaching fitments removed for despatch

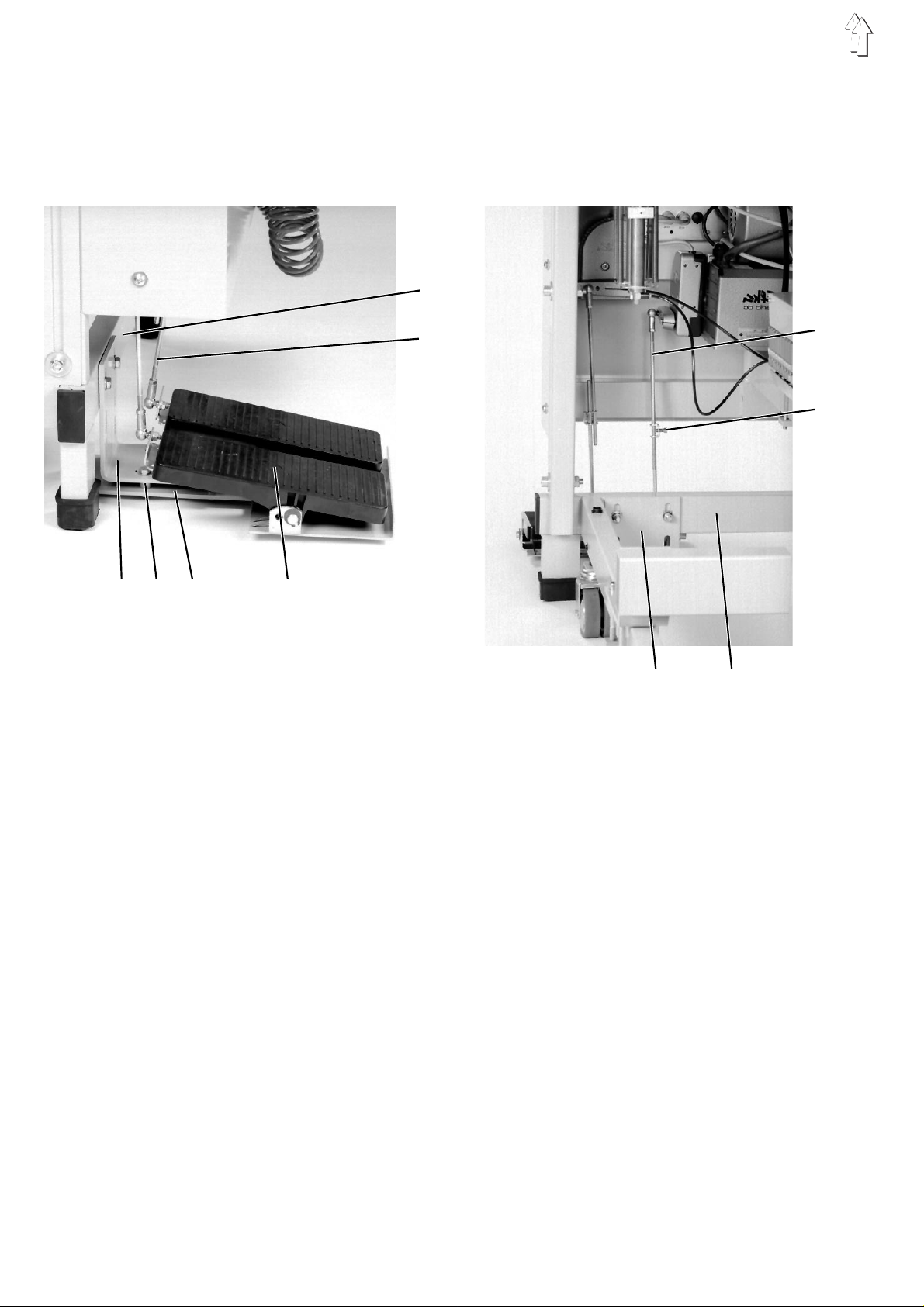

3.1 Pedal

Depending on th e v e rs i on, the sewing machi n e is e qu i pp ed either with

a single peda l or w i th tw o ( ri g ht an d l e ft).

5

1 2 3 4

6

3 5

The pedal 4 is a tt ac h ed to th e lo we r cr oss - m embe r 5:

–

Fix the pedal 4 to the lower cross-member 5 with the bracket 3.

The oblong s l ot s in the bracket 3 e na ble the height to be s l i gh tl y

adjusted.

Adjust the h ei g ht of bracket 3 so th at the pedal 4 can be ea s i ly

operated.

–

The second bracket 1 (supplied) acts as a support.

Attach bracket 1 as shown in the illustrations,

placing the fo ur s e pa rator rings 2 betw ee n b r ac kets 1 and 3.

6

7

–

Fit pedal linkage 6.

–

Slightly loosen locking screw 7.

–

Adjust the he i gh t of the pedal li nk a ge 6 s o th at th e p ed al 4 i s

horizontal when fully depressed.

–

Tighten locking s cr ew 7.

6

3.2 Thread pillar

1

2

3.3 Trays

–

Insert thread pillar 1 into the hole in the table plate and secure it

with nuts 2 and washers.

–

Fit and align thread discs and unwinder arms as shown in the

illustration.

3

4

5

–

Insert trays

–

Tighten locking lever 3.

with rod 5 into locking piece 4 and align.

7

3.4 Folder (working method A)

3

1

4

2

5

6

–

Place Folder

piece 1 as far as it will go.

The pin 3 mus t e nt er o bl o ng s lot 4.

–

Tighten locking s cr ew 2.

The resulting setting will be as pre-set prior to despatch.

6 with span bearing 5 on the m ou nt i ng bo l t o f l o c k ing

3.5 Folder and gripper-folder (working method B, C)

Fixing the Folder

–

swivel folding unit away to the side

–

place Folde r

–

tighten locking screw 1.

Mounting 2 i n cor p or a te s a ce ntering hole.

Tightening the lo ck i ng s c rew 1 automaticall y b r i ng s ab ou t t he

correct setting.

3 on mounting 2

1

2

3

8

1

6

2

7

3

8

4

5

Fixing the gripper-folder

–

swivel folding unit inwards

–

push gripper-folder with mounting 5 onto rod 7 as far as it will go

The pin 4 must enter oblong slot 3.

–

tighten lo ck i ng s cr ew 8

The resulting setting will be as pre-set prior to despatch.

–

Insert compressed-air connection 6 for needle spreading.

–

With working method C insert compressed-air connections 1 and 2

for braiding c u tt er s .

9

3.6 Ta ble wideners (accessories)

1 2

3

Table widener for trouser seats

–

Attach table widener 1 with screws 2 and the strap located behind

the frame member 3.

–

Slightly loosen the screws on the upper side of the table.

Push table widener 1 to create a gap between it and the table plate.

This gap is n ee ded so that the poc k e t c a n p ass f r ee l y th rou gh

once it has been placed in position.

(order no. 07 94 00 21 51 )

4

5

10

Table widener for jacket fronts

–

Attach table widener 4 to support table with screws 5.

(order no. 0794 002101)

3.7 Stacker (accessory)

1 2 3 4 5

6 7 8

9

10

15

13

14

11

12

13

The throw-over stacker (Order no. Z112 427514) is attached to the

frame of the sewing unit with holder pipe 1.

At deliver y of the sewing unit th e h ol d er pipe 1 is alrea dy p rem ounted

on the frame b rac e 3.

If the throw-o v er s t ac k e r i s de l i ver e d s e pa r at el y p ac k e d, th e h ol d er

pipe 1 must f ir s t b e a tt ac h ed to th e f r am e b r ace 3 of the sewing un i t.

–

Mount guard pla t e 12 on th e h ou s i ng 11 of the throw-o v er s t ac k e r

with screws, washers and spring washers.

–

Fasten holder pipe 1 on the frame brace 3 of the sewing unit with

screws, washers and brackets 6.

–

Fasten spar 4 on the brace 5 of t he s ta c ker s t an d w i th s c rews,

washers and bracket 7.

–

Insert the r i bb ed pl u g 8 i n spar 4.

–

Push the th row - ov e r s ta c k er t oward the frame o f t he s ew i ng un i t s o

that spar 4 ca tc h es i n th e holder pipe 1.

The height of spar 4 is adapted to the holder pipe 1 via the slots in

brace 5 of the s t ac k e r s ta nd .

–

Insert the c ou pl i n g p l ug of th e c o mp r ess e d a i r fe ed i nt o h os e

coupling 10.

–

Insert the c ou pl i n g p l ug of th e c o nt r ol le ad into hose cou pl in g 9.

–

Attach one en d o f t he po te nt i al c a bl e 13 to th e s t op pe r pl a te 14 of

the throw-over s t ac ke r wi t h t he en cl os e d w i ng nu t.

Attach the other end to the frame of the sewing unit with the

existing win g n ut .

The potential cable 13 serves to conduct static charges to ground.

–

After starti n g t he sew i ng un i t w i th th e t hro w- o ver stacker open, set

the clearance to the sewing unit.

The sewing pi e c es must securely e nt er the opening between the

smoother and the stacked-goods support.

–

Tighten clamping lever 2.

11

3.8 Suction devic e (acc essory)

The suction device (order no. 0722 004282) facilitates the exact

positionin g o f m at er i a l s on the working tab l e.

1

2

2 3 4 5

6 7 8

Attention!

Do not reverse hos es 2 an d 5 .

Hose 2 must always be connected to pipe socket 6.

The pneumatically-operated air valve is fitted to pipe socket 6.

–

Lay hose 2 from the settling container 7 to the vacuum-connection

socket 1 of the sewing-machine table.

–

Connect compre s sed - air h ose 3 from cylinder 4 of the air valve to

the Y41 solenoid valve.

–

5

Connect hose 5 to pip e s o c ket 8 o f s e tt l ing c on ta i ne r 7.

Connect other end of hose to on-site vacuum equipment or to the

centrifuga l bl o we r.

Note:

If there is no on-site vacuum equipment a centrifugal blower must

also be ordered.

9

Attention!

It is essential for filter bag 9 to be fitted beneath hose 5.

Filter bag 9 pro te c ts t he v ac u um ge ne rator from being penetrated by

dust and parti c l e s of dirt.

Hoses 2 and 5 mu s t t he r ef or e on no ac count be swapped.

12

4. Electrical connection

Attention!

All work on the electrical e qu i pm en t o f t he s ew i ng ma c hi n e m us t be

carried out by specialist electricians or other appropriately-trained

persons.

The mains pl ug mu s t b e re mo v ed .

4.1 Connecting the DAC operating panel

The DAC operating panel 1 is mounted on the right-hand side of the

machine, see n f r om th e o pe r at or’s viewpo i nt .

1

–

Fit operating panel 1 with clamps 4 and 6 to attachment bracket 5

and adjust angle.

–

Firmly tighten clamping screws on clamps 4 and 6.

Attach pote nt i al c a bl e 3 t o c l a mp 4.

The function of the potential cable is to discharge static charges to

earth.

–

Slightly un do l oc k n ut 7 on attachment bracket 5.

–

Rotate operating panel 1 until the operator has the best possible

view of the d i spl a y.

–

Firmly tighten lock nut 7.

2 3 4 5 6

7

–

Carefully insert plug 2 into the back of the operating panel.

–

Tighten screws of plug 2.

13

4.2 Checking rated voltage

3 - 2 : 190V

3 - 1 : 200V

4 - 2 : 210V

4 - 1 : 220V

5 - 2 : 230V

5 - 1 : 240V

5 4 3 2 1

The rated voltage specifi ed on th e i d en ti f i cation plate mus t c o i nci d e

with the mains voltage.

The sewing ma c hi n e c a n b e a da pt ed to th e l o c al m ai n s vol t ag e b y

means of terminals 1 to 5 on the transformer (see sketch).

230V

The wiring for connection to 3-phase mains supplies is shown in the

terminal co nn ection diagram.

If several D C d r i ves a r e connected these s ho ul d be un i fo rml y

distribute d o v er a l l ph as e s.

14

4.3 Checking positioning

Before the machine is started the positioning set prior to delivery

should be checked.

1 2 3

4 5

Once the main s wi t ch i s t urn ed on th e s e wi n g mac h i ne ad op ts t he

thread-lever-up position.

Caution - danger of injury

Turn off the main swit ch.

Positioning should only be checked or adjusted with the main switch

turned off.

Checking positioning

–

Turn off the main switch.

–

Turn thread lever with handwheel to top dead centre position.

The thread lever must be just commencing its downward

movement.

–

In this position notch 2 on the positioning ring 1 must be in line

with notch 3 on the position indicator 5.

–

Adjust positioning if necessary.

Adjusting positioning

–

Undo clamping screws 4 on positioning ring 1.

–

Rotate positioning ring until notch 2 on it is in line with notch 3 on

position in di cator 5.

–

Firmly tighten clamping screws 4.

15

5. Pneumatic connection

The sewing machine must have a supply of water-free compressed air

to operate its pneumatic components.

Attention!

For the pneuma ti c co ntrol processes t o f unction properl y the

compressed- ai r s u pp l y mu s t b e c o nf i gu red as f ol l o ws :

Even when air consumption is at its peak the op er a ti n g p res s u re m us t

not fall below

If pressure fall-off is excessive:

–

increase compressor power

–

increase diameter of compressed-air lines.

5 bar

.

2

3

1

Connecting compressed-air maintenance unit

–

Connect connection hose 1 (order no. 797 3031) to the

compressed-air supply with a R 1/4" hose connection.

Adjusting operating pressure

–

Operating pressure is

It can be read off pre s s ure ga ug e 3.

–

To adjust operating pressure lift and turn knob 2.

To increase pressure: turn clockwise

To decrease pressure: turn anti-clockwise

Attention!

No compressed air containi ng oi l m us t be ad mi t te d f r om th e a i r sup pl y.

Clean compressed air is taken from behind the filter to clean machine

components and material by air-blasting.

Any oil droplets in the compressed air cause malfunctions and leave

marks on the m at er ia l .

6 bar

.

16

6. Lubrication

NB

Before star ting the machine i t s up pe r as s e mb l y mu st b e su pplied with

oil.

The oil-supply container must be filled only with

lubricating oil.

SP-NK 10 can be obtained from

sales outlets.

Oil-supply container 1 for upper-assembly lubrication

–

Fill oil-supply container 1 with oil through the holes in the sight

glass.

The oil level must be between the "Min." and "Max." marks.

Oil-supply container 3 for gripper lubrication

–

Move upper as s e mb l y of machine to one s i de .

–

Fill oil-supply container 3 with oil through nipple 2 up to the "Max."

mark.

DÜRKOPP ADL ER AG

1

ESSO SP-NK 10

2 3

2

3

17

7. Starting up

<==== REF

–

Turn on main switch .

Control is initialised.

The DÜRKOPP-ADLER logo briefly appears in the operating-panel

display.

–

The control unit checks whether the carriage is in its rearmost

position.

If not, "

–

Depress left-h an d p ed al .

Reference tr a v el co mmences.

The carriage moves to its rearmost position.

Reference travel is necessary to ensure that the carriage is always

in its defi ne d s t ar t i ng po s iti o n.

–

The display ch an ge s to th e se wi n g-m ac h i ne ma i n sc re en .

–

By operatin g t he ap pr o pri a te pedals the vari ou s pl a cem ent stages

are activate d i n seq ue nc e an d se wi n g i s c o mm en c ed.

The individ ual stages depe nd on th e w or k ing method and on th e

configurat i on of th e m ac h i ne .

Attention!

At the commencement of sewing the material must be beneath the

feeding clam ps .

Moving the ca r ri ag e w i th ou t material dama ge s the covering of t he

feeding clam ps .

<====REF

" (reference travel) appears in the display.

–

For the choice of sewing program and further control-unit

adjustment see part 4 ("DAC 745-26/-28: brief description").

–

Placement an d o peration are des c ri be d i n pa r t 1 ( "74 5- 2 6/ - 28 :

operating instructions").

18

Loading...

Loading...