Page 1

Contents Page:

Home

Part 4: Instructions for programming DA-Microcontrol Cl. 745-22; -23; -24

Program-Version: 745-22; -23 = 745 P08; 745-24 = 745 Q01

1. General

2. Description of the Controls

2.1 Keys on the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Internal Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 Display of the 745-22;-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.2 Display of the 745-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Description of the Function Keys

3.1 Setting and Adjusting the Sewing Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Sewing a Seam Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Setting the Piece Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Selecting the Positioning Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Switching the Tape Feed On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Switching Tacking On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7 Selecting the Closing Order of the Flap Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8 Switching the Corner and Center Knives On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.9 Switching the Light Barrier On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.10 Correcting the Seam Beginning and Seam End . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.11 Correcting the Corner Knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.12 Tape Length when Sewing with the Light Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Sewing of Bias Pocket Corners (745-24)

5. Selecting the Sewing and Testing Programs

6. Sewing Progr ams 745-22

6.1 Sewing of Simple, Dual and Asymmetrical Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Sewing with Automatic Carriage Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Sewing with Material Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Sewing with Zipper Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.5 Sewing with Zipper Cutter and Automatic Carriage Return . . . . . . . . . . . . . . . . . . . . 18

6.6 Sewing with Zipper Cutter and Material Return . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7. Sewing Progr ams 745-23

7.1 Sewing of Dual Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2 Sewing of Dual Piping with Automatic Carriage Return . . . . . . . . . . . . . . . . . . . . . . 19

7.3 Sewing of Dual Piping with Material Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.4 Sewing of Dual Piping with Piping Reverser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.5 Sewing of Dual Piping with Piping Reverser and Automatic Carriage Return . . . . . . . . . . 20

7.6 Sewing of Single Piping with Piping Reverser . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.7 Sewing of Single Piping with Piping Reverser and Automatic Carriage Return . . . . . . . . . 21

7.8 Sewing of Asymmetrical Piping with Piping Reverser . . . . . . . . . . . . . . . . . . . . . . . 21

7.9 Sewing of Asymmetrical Piping with Piping Reverser and Automatic Carriage Return . . . . . 21

7.10 Sewing of Simple and Asymmetrical Piping without Piping Reverser . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page 2

7.11 Sewing of Simple and Asymmetrical Piping without Piping Reverser

with Automatic Carriage Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.12 Sewing of Simple and Asymmetrical Piping without Piping Reverser

with Material Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8. Sewing Programs 745-24

8.1 Sewing of Dual Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 Sewing of Dual Piping with Automatic Carriage Return . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Sewing of Dual Piping with Material Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9. Aid Programs

9.1 Center Knife Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 Setting the Bobbin Thread Counter (745-22;-23) . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.3 Changing the Positioning Point Manual / Automatic . . . . . . . . . . . . . . . . . . . . . . . . 24

9.4 Testing the Piping Reverser for Dual Piping (745-23) . . . . . . . . . . . . . . . . . . . . . . . 25

9.5 Testing the Piping Reverser for Simple Piping (745-23) . . . . . . . . . . . . . . . . . . . . . . 25

9.6 Testing the Piping Reverser for Asymmetrical Piping (745-23) . . . . . . . . . . . . . . . . . . 25

10. Setting Programs

10.1 Testing the Positioning Procedure for Dual Piping (745-23) . . . . . . . . . . . . . . . . . . . 26

10.2 Loading of standard values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.3 Setting the Remaining Thread Monitor(Light Reflection Barriers) . . . . . . . . . . . . . . . . 26

10.4 Testing the Zipper Cutter (745-22) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.5 Checking Needle und Center Knife Actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.6 Testing the Positioning Procedure (745-23) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.7 Setting the Light Barrier for Seam Beginning/Seam End . . . . . . . . . . . . . . . . . . . . . 28

10.8 Setting the Material Strip Reverser (745-23) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11. Testing Programs

11.1 Program Version and Check-Sum Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11.2 Checking the Step Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11.3 Checking the Seriel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11.4 Testing the Memory and Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11.5 Checking Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11.6 Checking the Front Panel Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

11.7 Checking the Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

11.8 Selecting Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11.9 Selecting Output Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11.10 Sewing Drive: Pedal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.11 Positioning the Machine Head in the 2nd Needle Position/Revolution Test . . . . . . . . . . . 36

11.12 Positioning the Machine Head in the 1st Needle Position . . . . . . . . . . . . . . . . . . . . . 37

11.13 Positioning the Machine Head with Cutting Revolutions . . . . . . . . . . . . . . . . . . . . . 37

11.14 Positioning the Machine Head and Thread Trimming . . . . . . . . . . . . . . . . . . . . . . . 37

12. Function Displays and Error Messages

12.1 Displays for Operating Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12.2 Displays by Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12.3 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

13. Step Motor Output

13.1 Programing Switches on the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

13.2 Displays on the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Page 3

1. General

MICROCONTROL

The

-24

include the integrated comprehensive

monitoring system.

A microcomputer assumes the control tasks, monitors the sewing

process and s i gn al s o pe rating faults an d m al f un c ti o ns.

Special programs facilitate mechanical adjustments and make

possible a ra pi d te s ti n g o f t he input and output elements wi th ou t

additional m ea s ur i n g a pp ara tus.

Errors and test results are shown in a 2 x 16 digit display.

Under normal working conditions the display shows information to

operation and the sewing process.

When an operating error or malfunction occurs the functions are

interrupted . The cause is sho wn i n t he di s p l ay b y t he app rop r i at e err o r

symbol.

In most cases the error symbol will disappear when the cause of the

fault has been remedied.

In some cases the main switch must be turned off during error

correction for safety reasons.

A portion of the error messages are meant only for the service

personnel.

All functions can be called up and changed by pressing the

appropriate key. The unit must be in its initial position for this.

When the uni t i s s w i tc h ed on th e c o nt r ol s c o nd uc t s ev e ral

comprehensive self-tests. Among other things the program and data

memories and the display are checked for flawless operation at this

time.

After the ma chi n e i s s w i tc h ed off th e s e t va l ue s of th e i n div i d ua l

functions ar e sto r ed i n t he pro gr a m a nd da ta me mo ri es (b at te r y

buffered) and aut om at i c all y a c tiv a te d w he n s w i tc h ed on

again.

controls of the

DÜRKOPP ADLER 745-22;-23;

MULTITEST

testing and

ATTENTION !

The controls for the Class

for the Class

Controls

Controls

745-22;-23

745-22;-23:

745-24:

Parts no. 985 0 745030

.

Parts no. 9850 745040

745-24

are

not

compatible with the controls

3

Page 4

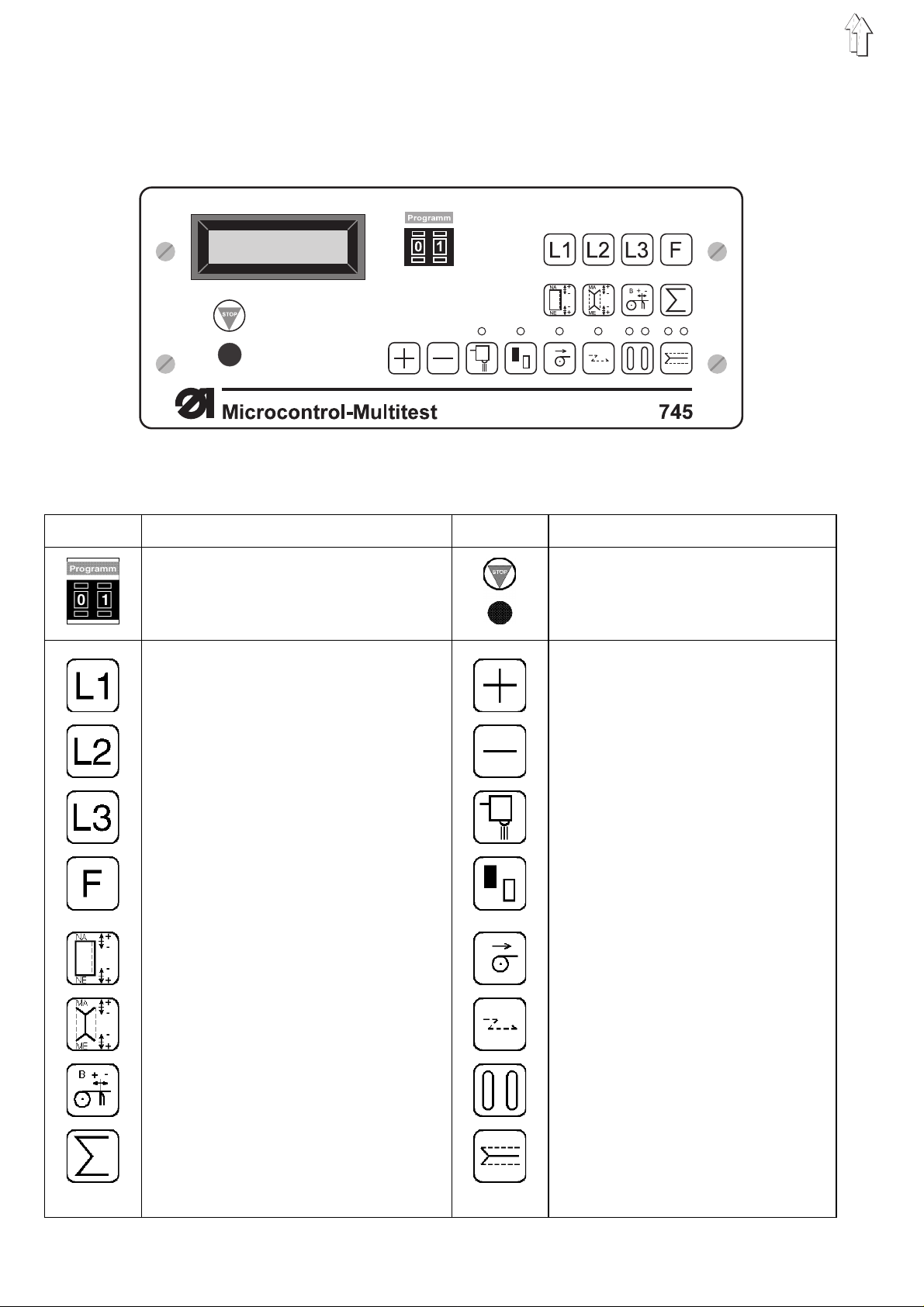

2. Description of the Controls

2.1 Keys on the Front Panel

Key Function Key Function

Selecting Se wi n g an d Testing Programs

Sewing Leng th L1

Sewing Leng th L2

Sewing Leng th L3

Sewing a Se am S eri e s

Correcting of Seam Beginning/End when

Sewing Flaps wi t h L igh t b ar ri e r

Correcting th e C orn er K n iv es a t

Seam Beginning and Seam End

Stopping th e C ur re nt P r og ram,

Activating a Selected Program

Increase Parameter Value

Decrease Parameter Value

Light Barrier On

Selecting the Positioning Point

Tape Feed On/Off

Tacking On/Off

Setting Tape Length when Sewing wi th

Light Barrier

Setting the Counter

4

Selecting the Closing Order of the

Flap Clamps

Center Knife an d C orn er Kn i fe

On/Off

Page 5

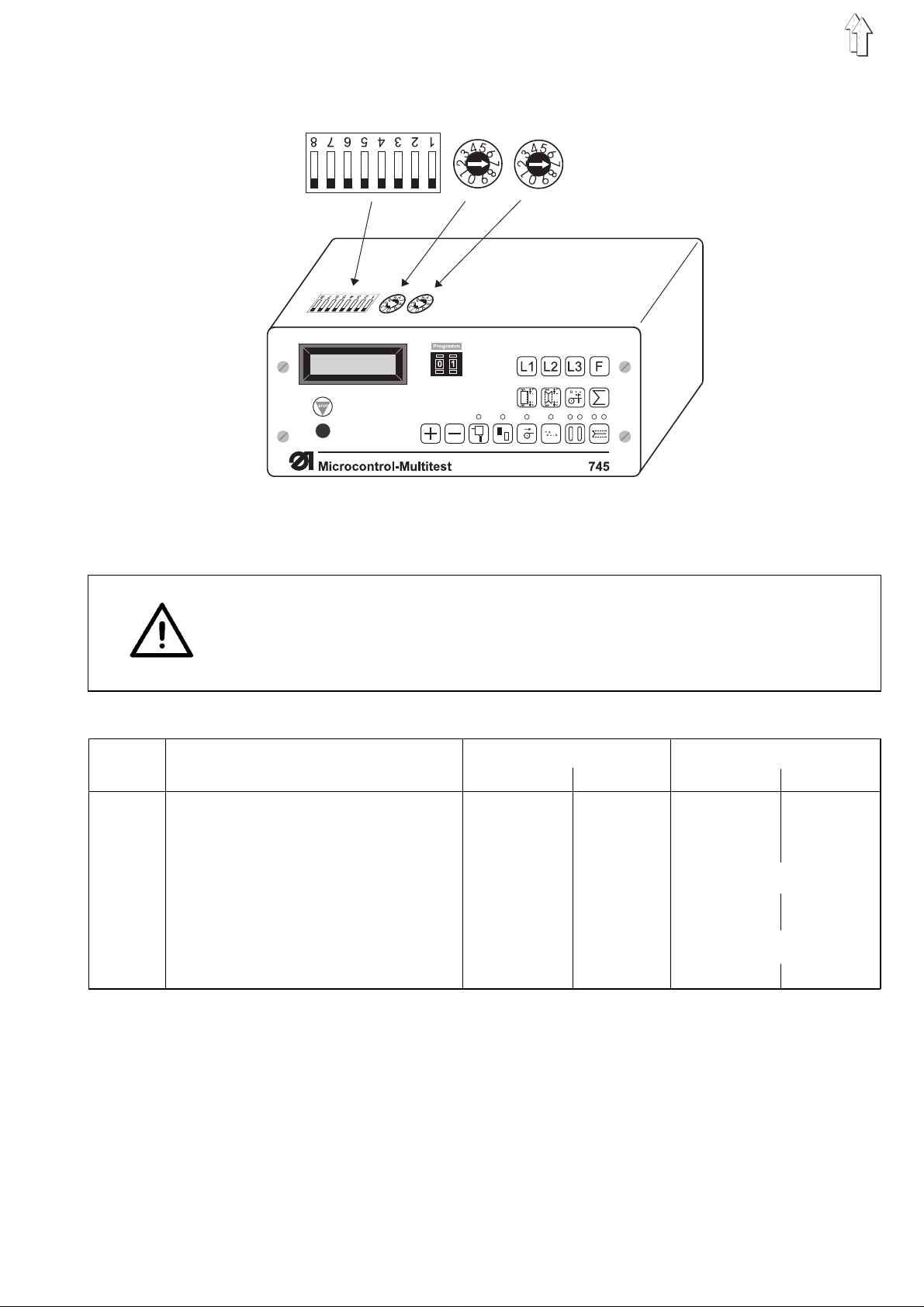

2.2 Internal Switches

DIP-Schalter

on

off

b417 b401 b40 2

In the control behind the display there are three pre-selector switches

for setting certain machine parameters.

CAUTION !

The switches are only evaluated once when the sewing unit is turned

on.

After changing a switch setting switch the main switch off and then on

again or oper at e t he

DIP-Switch b417:

b417 Function OFF ON OFF ON

.1 Stitch Leng th 2,5 mm 3,2 mm 2,5 mm 3,2 mm

.2 Stitch Cond ensation Stit c h L en gt h 0,8 mm 1,4 mm 0,8 mm 1,4 mm

.3 Maximum Sewing Length 180 mm 200 mm 180 mm 200 mm

.4 Thread Monitor ON OFF No function

.5 Locking Vacuum (b8 / s14) OFF ON OFF ON

.6 Late Opening of the Flap Clam ps OFF ON OFF ON

.7 with Re verser Dev ice OFF ON N o funct ion

.8 Continuous Op er a ti o n OFF ON OFF ON*

(only in combination with .4 "OFF")

* Thread monitor is turned off

745-22;-24

745-23

Dial b401: Dial b402:

Sewing Revolutions Operation Mode of the Left Transport Clamp

b401 = 1 250 0 1 /m i n b402 = 0 No fun c ti o n

b401 = 2 275 0 1 /m i n b402 = 1 Lower le ft transport cl am p

b401 = 3 300 0 1 /m i n separately

: b417.7 = OF F

: b417.7 = ON (with Reverser Device)

STOP

key.

745-22;- 23 745-24

b402 = 2 Lower left transport clamp with the

right

5

Page 6

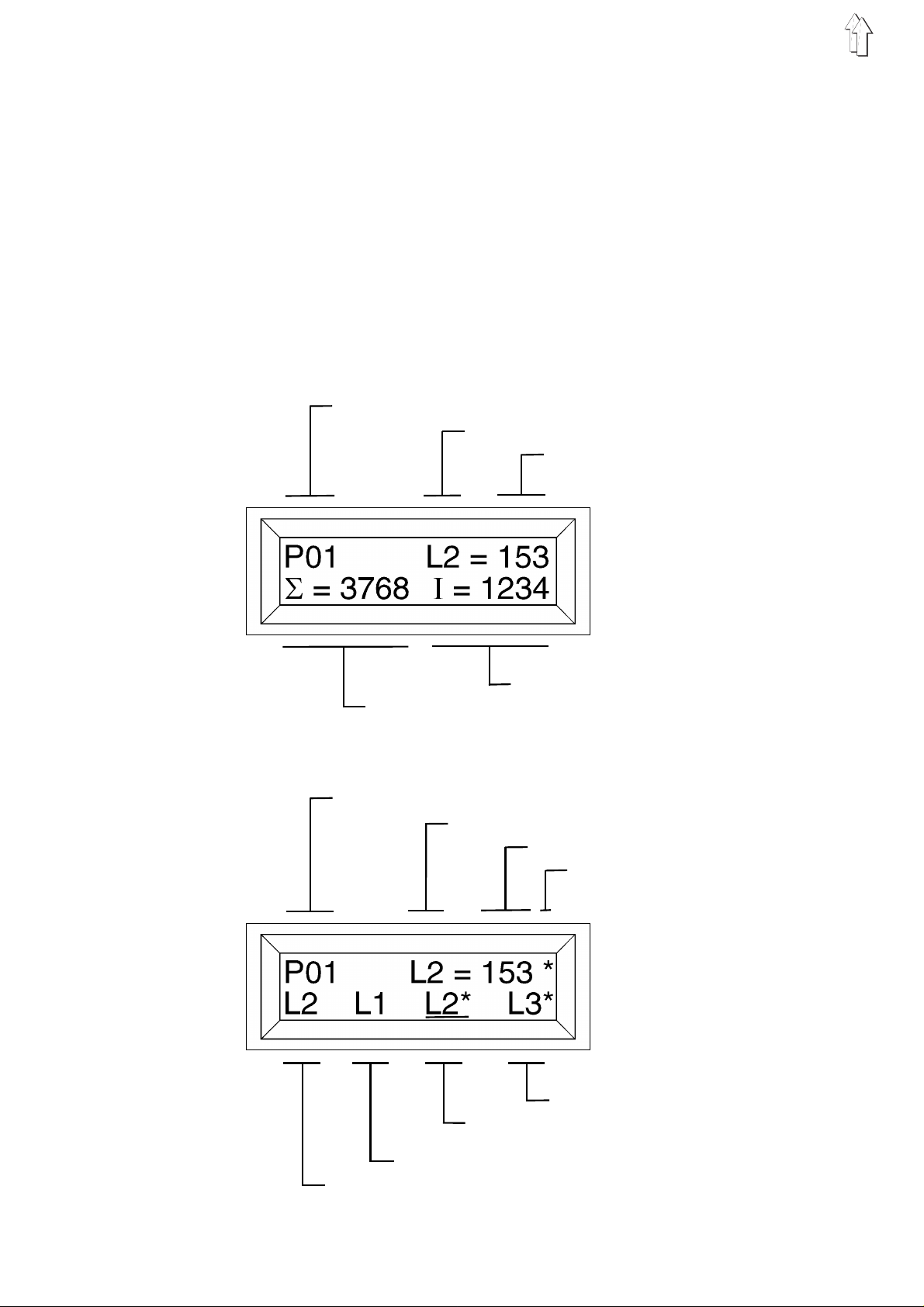

2.3 Display

2.3.1 Display of the 745 -22;- 23

The Microcontrol is equipped with a 2 x 16-digit display.

It shows the program number, sewing lengths, bobbin thread reserve

and piece cou nt . B y o pe r at i ng err o r s or m al f un c ti o ns the functions are

interrupted an d t he c au s e s h ow n b y th e a pp r op ri at e e r ror s ymbol.

The operatio na l rea di n es s o f t he s ew i ng un i t i s shown by having th e

current param et er s i n th e d i spl a y. The setting s are the same as those

last selected before the machine was switched off.

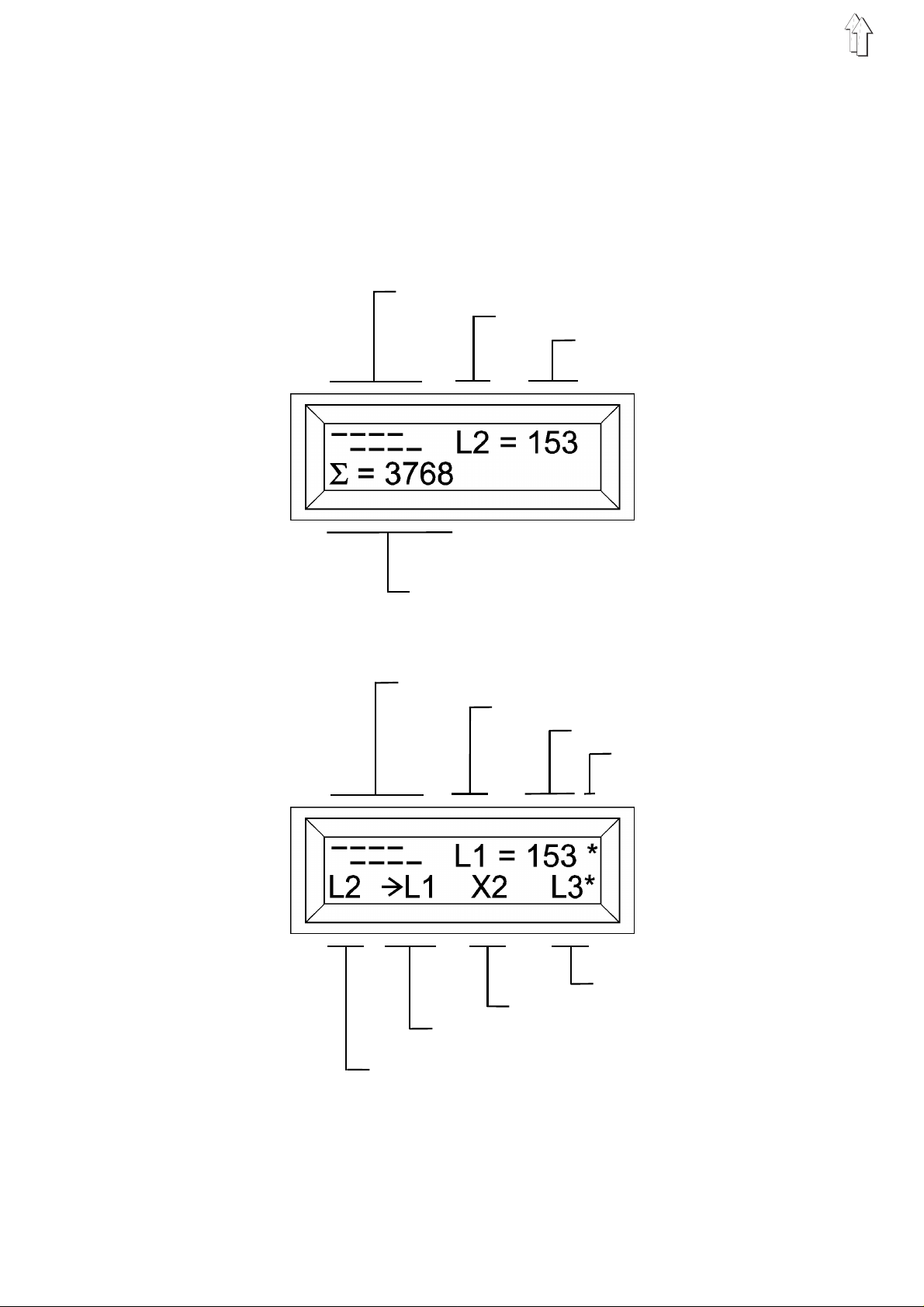

Display example 1: With selected sewing length

Program numb er

Selec ted sew ing len gth

Stored se wing le ngt h in mm

Bobbin th rea d reserve

Piece counter

Display example 2: With programmed length series

Program numb er

Current sewi ng l eng th

Stored le ngt h in mm

The n stack ing

4. Length to be sewn

3. Length to be sewn

(Current sew ing dis tance i s un derlin ed)

2. Length to be sewn

1. Length to be sewn

6

Page 7

2.3.2 Display of the 745-24

With the

in the right h al f of the first lin e o f the display.

Through this s y m bo l the seamstress c an es t ab l i s h w hi c h bi a s ha s

been set for th e c u r r en tl y selected progra m.

The "=====" symbol, for example, denotes straight pocket corners at

the seam beginning and seam end.

Display example 1: With selected sewing length

Bias p ocket o pening s

Selec ted sew ing len gth

Stored se wing le ngt h in mm

745-24

a symbol for th e b i as o f t he c or n er i n c is i on s ap pears

Piece counter

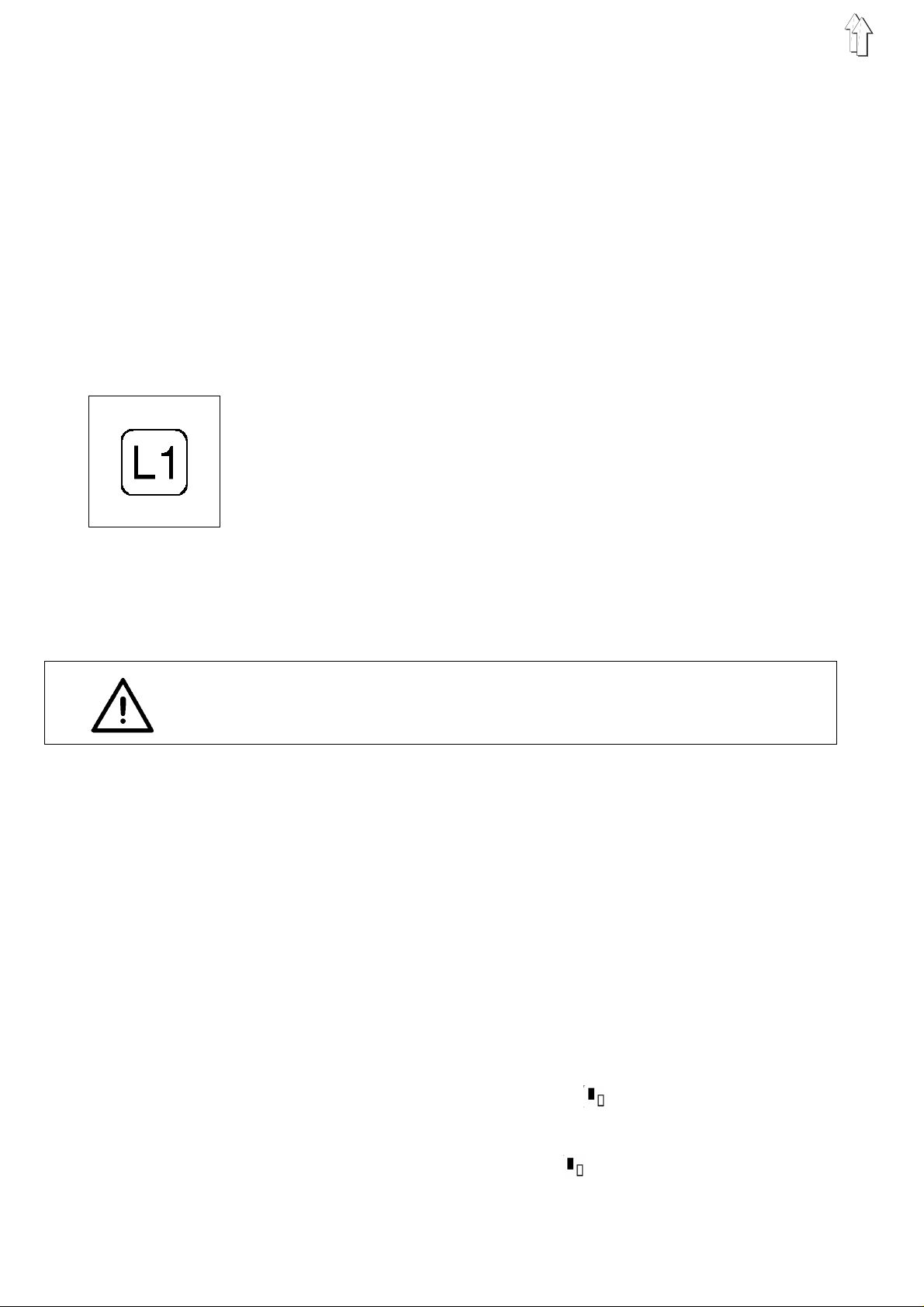

Display example 2: With programmed length series

Bias p ocket o pening s

Current sewi ng l eng th

Stored le ngt h in mm

The n stack ing

4. Length to be sewn

3. Length to be sewn ( here: L igh t barrier s eam)

2. Length to be sewn

(The arrow marks the current sewing length)

1. Length to be sewn

If the display remains blank after the main switch has been turne d

on, then the 1,6 A fuse(on the underside of the mains unit) is to be

replaced.

7

Page 8

3. Description of the Function Keys

The values for the various functions can be set as follows:

–

Call up the desi r e d f un cti o n b y pre s si ng th e a pp rop r i at e f un cti o n

key.

The function will be shown in the display with a blinking cursor.

–

Change the set v a lue wi t h t he "+ / -" keys.

–

Press the same function key again.

The change i s com pl e te d.

The unit is rea dy t o s t ar t ag ai n .

3.1 Selecting and Changing Sewing Length

With the L1, L2 and L3 keys three sewing lengths stored in memory

can be selected. A change of the sewing length can only occur before

the feed procedure has begun.

–

Select the stored sewing length by pressing the key L1, L2 or L3.

The select ed sewing length is s h ow n i n th e r ig ht half of the fir s t

display line.

–

If "L?" appears in th e d i s pl a y, then a sewing length without an

allowable value in memory was selected.

Enter an allo wa bl e v alu e w i th th e "+/-" keys or select a different

sewing length.

–

Change the set s e win g l e ng th wi t h t he "+/-" keys.

–

Press the function key (L1, L2 or L3).

The set sewing length will be stored in memory.

It will remain in memory until it is changed again.

–

For further details see chapter 5 and 6 ("Sewing Programs").

CAUTION !

When changing the sewing length L1 it is essential that the corner

knife inter val a l s o b e a l te r ed at th e s a me ti m e.

Setting the Corner Knife Interval

That sewing le ng th wh i ch i s m ost of te n s e wn s houl d be s to red un de r

L1.

The interval be tween the corner k n i v es m ust be set so that i t i s th e

same as the sewi n g l e ng th sto r ed un de r L1 .

With all other sewing lengths the corner incision occurs seperately in

two strokes . A f te r th e i nci s i o n of the fi r st c or n er k ni f e th e ma te r i al i s

transported to the second corner knife.

Exception:

With Class

together.

Positioning the Material

–

With short se ams under 75 mm place the materi al a t t he fo rw a rd

positioning point.

–

If, by sewing lengths under 75 mm, the rear positioning point is

chosen, then the error message "

display. You must the n ch an ge to the forward po s iti o ni n g po i nt .

–

With placing at th e r e ar p os it i on i ng po int th e following cond iti o n

must be satisfied:

Otherwise the error message "

display. You must the n ch an ge to the forward po s iti o ni n g po i nt .

745-23

the corner knives must always be switched on or off

ERROR

L1 - L2(L3) < 50

ERROR

" will appear in the

" will appear in the

8

Page 9

3.2 Sewing of a Seam Series

With the aid of the "F" key a stored series of up to four seams can be

called up.

745-22;-23

745-24

Calling up the Series

–

Call up the series by pressing the key "F".

The series is shown in the lower display line.

The current sewing length has a special marking:

745-22;-23:

745-24:

The current sewing length with the appropriate value in millimeters

is shown in the right half of the upper display line (see display

example 2).

–

A star "*" behind a se wi n g l e ng th me an s th at s ta c k i ng occ u r s after

this length is sewn.

Without stac k i n g t he ma te r ial i s t r an spo r te d b ac k t o t he fe ed ar e a

after sewing .

Then the next se wi n g le ng th i s au to ma tic a l l y ac t i vat ed .

–

Using the "+/-" keys any desired sewing length in the series can be

activated.

Key "+": Cursor to the right

Key " -": Cursor to the left

–

To exit from the series press the keys L1, L2 or L3.

The approriate sewing length (L1, L2 or L3) is activated.

–

To exit form the series with the

The light barrier seam is activated.

:The series can be made up of any desired order of the

three sewing l e ng th s L1, L2 and L3.

: The series can be made up of any desired order of the

sewing lengths L1, L2, L3 and the light barrier seam s

LX2

LX3

and

The current sewing length is underlined (e.g.

The current sewing length is preceded by an arrow

(e.g.

.

"->L1"

).

745-24

press the key " ".

"

L2"

LX1

,

).

Programming a New Series

The values f or t he pr o gr a mm ed s ew i ng l en gt hs m us t established

before enteri ng the se ri es mo de (se e " S el e c ting and Adjustin g th e

Sewing Leng th " ).

–

Press and hold the key "F".

–

At the same time press the key "-".

The previous series is erased.

–

By pressing the keys L1, L2 and L3 up to four sewin g l e ng th s c an

be entered in t he de s i red or d er.

–

745-24 only:

After selecting a sewing length the following functions

can be set for this length using the appropriate keys:

Light Barri er O n / Off

Positioning Point

Tape Feed On / Off

Tacking On / Off

Closing Order of the Flap Clamps

Corner and Center Knives On / Off

9

Page 10

CAUTION !

The functions set with the keys only valid for the sewing program

the series mode

The settings h ave no effec t on th e s e win g p r og ram m b ey o nd th e

series mode .

–

745-24

"Σ" key.

–

745-24

Press the " " key until the desired light barrier seam

X3

appears in th e d i s pla y.

Set the des ir ed fu nc t i on s fo r th e s e l ec t ed s ew i ng l en gh t u s i ng th e

keys listed on page 9.

Confirm with the "Σ" key.

–

After selecting a sewing length (L1, L2 or L3) stacking after this

sewing leng th c an be pr o gra mmed by pressin g t he "+" key.

CAUTION !

With the

must first b e confirmed with th e "Σ" key.

Then stacking after this sewing length can be programmed by pressing

the "+" key.

–

–

745-24

By pressing th e "-" key the last entry is erased.

To start the series press the key "F" again.

The first sewi n g l e ng th i s au to ma ti c a ll y set .

.

: E a c h e nt r y of a sewing length mu s t b e c o nf i rme d with the

: Programming the light barrier seam

the selection of th e s e wi n g le ng th an d t he fu nc t i on s

LX1, LX2 or LX3

X1, X2

in

:

or

3.3 Setting the Piece Counter

By pressing this key the piece counter is reset to

The current pi e c e c o un t i s s h ow n i n th e l e ft half of the lower display

line. The pi ec e cou nter shows the n um be r of pieces made sin c e th e

last resetting of the counter.

3.4 Selecting the Positioning Point

Depending on th e t y pe of s ew i ng pi e c es the feed occurs at th e forward

or rear posit i on i ng po i nt .

By pressing th i s key t he positioning poi n t i s c h an ge d.

If the LED abov e t he k ey i s l i t th en th e f orward positionin g p oi n t w as

selected.

The changeover between manual and automatic alteration of the

positionin g p oi n ts o cc ur s i n pr o gr a m P 4 2.

3.5 Switching the Tape Fe ed On/Of f

0000

.

10

By pressing this key the tape feed is switched on and off.

If the LED above this key is lit then the tape feed is switched on.

Page 11

3.6 Switching Tacking On/Off

By pressing this key tacking is switched on and off.

If the LED above the key is lit then tacking is switched on.

CAUTION !

With 1.4 mm stitch length in stitch condensation

tacking is generally switched off.

3.7 Selecting the Closing Order of the Flap Cl amps

With this key the order of the closing of the flap clamps can be set.

In sewing pro gr a ms P07 to P12 the ord er o f t he c l osi n g o f the flap

clamps cann ot be s et .

Operating the key switches between four possibilities.

The order is s h ow n b y th e t wo LE Ds above the ke y:

–

Both LEDs lit:

The flap clamps close at the same time.

–

Only the left LED is lit:

First the lef t flap clamp clo s es , th en th e r i g ht .

–

Only the right LED is lit:

First the ri gh t f l ap c lamp closes, then the left.

–

Both LEDs are off:

Operation without flap clamps (optimally timed procedure).

The timing for the opening of the flap clamps in the feed area is

establishe d b y th e s e tt i ng of th e p r ese l ec t or switch b417.6 i ns i d e t he

controls (see "Internal Switches"):

–

–

OFF

In the

lowers.

In the ON setting the flap clamps open after the folder lowers.

setting the flap clamps open af te r the transport cl a s p

3.8 Switching the Corner and Center Knives On/Off

With this key the corner knives or the center and corner knives can be

switched on and off.

In sewing pro gr a ms P07 to P12 the cor n er a nd the center kni v es

cannot be switched off.

Operating the key switches between three possibilities.

The different s et ti n gs a re s h ow n b y th e t w o LE D s ab ov e th e k e y:

–

Both LEDs are l i t:

Corner and ce nt er k n i v es are switched on.

–

Only the right LED is lit:

The corner kn i ves a r e switched off.

–

Both LEDs are off:

All knives are switched off.

11

Page 12

3.9 Switching On the Light Barrier

By pressing this key the light barrier is switched on.

The light barrier recognizes the seam beginning and seam end on

flaps.

The light barrier cannot be activated in the operating modes for piping

reversing and zippers.

–

–

CAUTION !

When sewing w ith th e l i g ht ba rr i er, the flap mus t be pl a ced

the two positi o nin g p oi n ts .

If the flap i s po s i ti o ne d i n front of the forw ard or e x te nd s beyond the

rear positioning point, the error message

Press the key.

The lit LED ab ov e th e k e y si gn al s , th at th e l i g ht ba r r ier i s s witched

on.

745-22;-23:

745-24:

To switch off the l i g ht ba r ri er press one of the k e y s L1, L2 or L3.

Instead of t he s ew i ng l en gt hs

shows "LX".

Through repeated pressing of the key, the display

shows the li g ht ba r r ier s e am s

sequence.

"LS"

L1, L2, L3,

LX1, LX2

appears in the display.

the display

LX3

and

between

in

3.10 Correcting the Seam Beginning and Seam End

This key calls up the correction function for seam beginning and seam

end.

The correcti o n o f s e am be gi n ni n g (NA) and seam en d (NE) occurs for

the sewing leng th s

(745-22;-23) and

By changing th e v a lue s fo r NA and NE th e c o rne r k ni f e a cti o n i s

appropriately adjusted for sewing with the light barrier.

–

Press the fu nction key.

The set values for NA and NE are shown in the display.

–

Increase or decrease the value for NA in steps by pressing the

"+/-" keys.

Minimum: 0

Maximum: 99

Median valu e: 50 (no correc ti o n)

Step distance: 1 cycle = 0.085 mm

–

Press the function key again.

This s wit che s from N A t o NE .

–

Increase or decrease the value for NE in steps by pressing the

"+/-" keys.

–

Complete the correction procedure by calling up the selected

sewing length.

L1, L2, L3

LX1, LX2, LX3

and for the li g ht ba r ri er s e am s

(745-24).

LX

12

Page 13

3.11 Correcting the Corner Knives

This key calls up the correction function for the corner knives at the

seam beginning (MA) and the seam end (ME).

The correction can be made for the sewing lengths

as for the light barrier seams

(745-24).

–

–

–

–

–

L1, L2, L3

LX

(745-22;-23) and

Press the function key.

The set values for MA and ME will be shown in the display.

Increase or decrease the value for MA in steps by pressing the

"+/-" keys.

Minimum: 0

Maximum: 99

Median value: 50 (no correction)

Step distance: 1 cycle = 0.085 mm

Press the function key again.

This switch es f r om MA to ME.

Increase or decrease the value for ME in steps by pressing the

"+/-" keys.

Complete the correction procedure by calling up the selected

sewing length.

LX1, LX2

as well

and

LX3

CAUTION !

With the

together.

Set the parame te r s MA and ME at th e m ed i an v alu e 50.

Special note for 745-23:

When sewing with piping reverser only sewing length L1 can be set.

745-23

the corner knives must always be switched on or off

3.12 T ape Length when Sewing wi th Light Barrier

This key sets th e t ap e le ng th at th e s e am en d w he n s e wi n g w ith l i gh t

barrier.

The set valu e co r r esp on ds t o the distance f rom the initial po si ti o n o f

the transport c la s ps t o cu tt i ng .

–

Switch on th e t ap e f ee d.

–

Press the function key.

The set valu e f or the tape length i s s h ow n i n th e d i s pl a y.

–

Increase or decrease the tape length in steps by pressing the

"+/-" keys.

Minimum: 20 mm

Maximum: 1 00 mm

Step distance: 1 cycle = 1 mm

–

Complete the setting procedure by calling up the selected sewing

length.

13

Page 14

4. Sewing of Bias Pocket Corners (745-24)

The bias poc ket c or n ers r e sul t fr o m t he off set between the lef t a nd th e

right seam row.

The desired seam offset is programmed separately at the control unit

for the seam be gi n ni n g (

If all parame te r s ar e s et to th e m ed i an v al u e

pocket results.

Parameters for the programming of the bias pocket corners:

Seam begi nni ng Seam e nd

BR ER

1 ... 10 ... 20 1 ... 10 ... 20

Right seam

Left seam

1 ... 10 ... 20 1 ... 10 ... 20

L EL

B

BR,BL

) and the seam en d (

"10"

, then a strai g ht

ER,EL

).

Programmin g e xam pl e :

and seam end (Seam offset = 2 stitches)

Seam beginning Seam end

BR = 9 ER = 9

1 ... 10 ... 20 1 .. 10..20

Right seam

Left seam

1 ... 10 ... 20 1 . 10..20

BL = 11 EL = 11

Seam offset Parameter to be set (Seam beginning)

[Stitches] Right seam Left seam

2BR

4BR

6BR

• •

• •

• •

16 BR

18 BR

Bias pocket corners at the seam beginning

Seam offset = 2 stitches

= 10 - 1 =

= 10 - 2 =

= 10 - 3 =

= 10 - 8 =

= 10 - 9 =

9BL

8BL

7BL

2BL

1BL

= 10 + 1 =

= 10 + 2 =

= 10 + 3 =

•

•

•

= 10 + 8 =

= 10 + 9 =

11

12

13

18

19

14

Page 15

Display exam ple : S t r aig ht pocket corners

BL = Beginnin g- le ft needle

BR = Beginnin g- ri g ht ne ed l e

ER = End-right ne edle

EL = End-left needle

Selec ted sew ing distance

Programming the bias of the pocket corners:

–

Simultaneo us l y p res s t he k ey f or t he desired sewi ng di s t an c e (L1,

L2

or L3) and the " " ke y.

–

For selecting a light barrier seam:

Press the " " k ey u nt i l th e d es ir e d l i g ht ba r ri er s e am

LX3

or

Simul taneou sly press the " " an d th e " " key s.

–

The parameters for the programmed bias of the selected sewing

distance appear in the display (see display example).

–

Increase or decrease the parameter values in steps by pressing

the "+/-" keys.

appears in th e d i s pla y.

LX1, LX2

Minimum: 1

Maximum:20

Median value : 1 0 ( s t rai g ht pocket corner)

Steps: 1 step = 1 stitch of the current stitch condensation

Attention!

The left and r i gh t s e am rows must always be offs et an equal

number of sti tc h es w i th r ef ere nc e to th e m edian value "10".

The parameters BR and BL to be set for the desired seam offset

can be found in the table on page 14.

The parameters ER and EL are arrived at in the same manner.

–

Press the "Σ" key.

The cursor moves to the next parameter.

–

Complete the setting procedure by pressing the key for the

selected sewing distance L1, L2, L3 or the " " k ey ( for light

barrier seam s ).

ATTENTION !

bias

With

conducted:

–

pockets the fo l l ow i ng ad dit i on al s e tt ing wo r k mu s t b e

Manually adjust the angle and height of the corner knives

according to the programmed seam offset (see Operating

Instructions)

or:

Switch the corner knives off via the " " key on the controlunit.

15

Page 16

5. Selecting the Sewing and T esting Programs

The sewing an d t es t i ng pr o gra ms l i s t ed be l ow c an be s el e cted with the

Program

"

–

–

–

–

Switch Program Function Subclass

00

P00

Display of th e P r o gra m Version

" preselecto r s wi t c h.

Set the "

Switch on the main switch or press the key "

The desired p r og r am i s ac t i v at ed .

If the symbol "P?" appears in th e ri ght half of the fir s t di s p l ay l i n e,

then an illegal program number was selected.

A sewing procedure running at the time the "

operated will be cancelled.

Correct the se tt ing an d p r ess t he "

Program

" switch to the desired program.

STOP

STOP

STOP

" switch.

745-22 745-23 745-24

XXX

".

" key was

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

40

41

42

43

44

45

46

47

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

P13

P14

P15

P40

P41

P42

P43

P44

P45

P46

P47

P51

P52

P53

P54

P55

P56

P57

P58

P59

P60

P61

P62

P63

P64

P65

P66

P67

P68

P69

Sewing program

as P01, with au to ma ti c c a rr iag e r e tu rn

as P01, with mate rial re tu rn

as P01, wi th zi pp er c u tt er

as P04, with au to ma ti c c a rr iag e r e tu rn

as P04, with mate rial re tu rn

as P01, with piping reverser for dual piping

as P07, with mate rial re tu rn

as P01, with piping reverser for simple piping

as P09, with au to ma ti c c a rr iag e r e tu rn

as P01, with piping reverser for asymmetr. piping

as P11, with material return

as P01 without piping reverser for

as P02 asymmetrical piping and

as P03 simple piping

Center knife adjustment

Setting the bobbin thread counter

Changing th e p os i t i on i ng po i nt ma nu al / au to ma ti c

Testing the pi p i ng rev e r ser f or d ua l pi p ing

Testing the pi p i ng rev e r ser f or si m pl e pi p i ng

Testing the pi p i ng rev e r ser f or a s ymm etrical pipin g

Testing the po s i tioning procedur e ( d ua l pip i ng )

Loading of standard values

Setting th e re ma i ni n g t hr e ad mo ni t or

Testing the z i pp er c u tt er

Checking th e n eedle and center kn i fe ac t ua ti o n

Testing the po s i tioning procedur e ( si m pl e pi p i ng )

Setting th e li g ht barrier for se am be gi n ni n g/ en d

Setting the material strip reverser

Checking th e s t ep mo tor control

Checking th e s e r i al i n te r fa c e

Testing the timer and memory

Checking continuity

Checking th e front panel el em en ts

Checking th e i n pu t e l em en ts

Selecting input elements

Selecting ou tp ut el e me nts

Sewing driv e: pe da l op era ti o n

Sewing driv e: set v al u e X , po si ti o n 2

Sewing driv e: set v al u e X , po si ti o n 1

Sewing drive: set value X, position 1, position 2

Sewing drive: set value X, position 2,

with thread trimming proc ed ure

XXX

XXX

XXX

X

X

X

X

X

X

X

X

X

X

X

X

XXX

XX

XXX

X

X

X

X

XXX

XXX

X

XXX

X

XXX

X

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

XXX

16

Page 17

6. Sewing Programs 745-22

6.1 Sewing of Simple, Dual and Asymmetri cal Piping

–

Turn the DIP-Switch

–

Turn on main switch.

<---REF

"

–

Step back on th e l e ft pedal.

The transport clasps are raised.

The transport carriage runs to its rear position.

–

The display signals start readiness by showing the current

parameters (see display example 1).

The settings correspond to the last settings selected before the

machine was t ur n ed off.

–

Set the "

–

Press the "

The program is activated.

–

By tapping the left pedal bring the carriage return out of the hold

position, s wi t c h o n t he fe ed pr o c ed ure and start.

–

By stepping back on the left pedal during the feed procedure the

previous steps can be activated again.

–

By stepping back on the left pedal the sewing process can be

interrupted af te r st a rti n g.

–

When the sewi n g u nit i s eq uip pe d w i th a r ig ht pe da l th i s ac t i v at es

the holder and the vacuum.

When the sewing unit is equipped with a knee switch this operates

the vacuum.

" appears in the lower display line.

Program

STOP

b417.7

" switch to "01".

" key.

in switch setting "

OFF

".

6.2 Sewing with Automatic Carriage Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

After stacking the transport clasps are automatically run back to

the feed area.

Program

6.3 Sewing with Material Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

There is no s ta c k i ng af te r s ewing.

–

The material is transported back to the feed area by the transport

clasps.

Program

STOP

STOP

b417.7

" switch to "02".

" key.

b417.7

" switch to "03".

" key.

in switch setting "

in switch setting "

OFF

OFF

".

".

17

Page 18

6.4 Sewing with Zipper Cutter

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

In contrast to P01:

–

After sewing the sewn zipper is cut off.

–

The material i s g en er a l ly pl a c ed at th e r e ar p os i t i on i ng po i nt .

–

The shortest sewing length is 75 mm.

–

The light barrier cannot be activated.

Program

STOP

b417.7

" switch to "04".

" key.

in switch setting "

6.5 Sewing with Zipper Cutter and Automatic Carriage Retur n

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

In contrast to P04:

–

After stacking the transport clasps are automatically run back to

the feed are a.

–

The light barrier cannot be activated.

Program

STOP

b417.7

" switch to "05".

" key.

in switch setting "

OFF

OFF

".

".

6.6 Sewing with Zipper Cutter and Mater ial Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

In contrast to P04:

–

After sewing there is no stacking.

–

The material i s t r an s po rte d b ac k t o t he fe ed ar e a b y th e t r an s po rt

clasps.

–

The light barrier and the flap clamp cannot be activated.

Program

STOP

" switch to "06".

" key.

b417.7

in switch setting "

OFF

".

18

Page 19

7. Sewing Programs 745-23

7.1 Sewing of Dual Piping

–

Turn the DIP-Switch

–

Turn on main switch.

<---REF

"

–

Step back on th e l e ft pedal.

The transport clasps are raised.

The transport carriage runs to its rear position.

–

The display signals start readiness by showing the current

parameters (see display example 1).

The settings correspond to the last settings selected before the

machine was t ur n ed off.

–

Set the "

–

Press the "

The program is activated.

–

By tapping the left pedal bring the carriage return out of the hold

position, s wi t c h o n t he fe ed pr o c ed ure and start.

–

By stepping back on the left pedal during the feed procedure the

previous steps can be activated again.

–

By stepping back on the left pedal the sewing process can be

interrupted af te r st a rti n g.

–

When the sewi n g u nit i s eq uip pe d w i th a r ig ht pe da l th i s ac t i v at es

the holder and the vacuum.

When the sewing unit is equipped with a knee switch this operates

the vacuum.

" appears in the lower display line.

Program

STOP

b417.7

" switch to "01".

" key.

in switch setting "ON".

7.2 Sewing of Dual Piping with Automatic Carr iage Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

After stacking the transport clasps are automatically run back to

the feed area.

Program

STOP

b417.7

" switch to "02".

" key.

7.3 Sewing of Dual Piping with Material Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

There is no s ta c k i ng af te r s ewing.

–

The material is transported back to the feed area by the transport

clasps.

Program

STOP

b417.7

" switch to "03".

" key.

in switch setting "ON".

in switch setting "ON".

19

Page 20

7.4 Sewing of Dual Piping with Piping Reverser

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

In contrast to P01:

–

After the corner incision the pipings are reversed and the material

overlaps a re d r aw n t hr o ug h t he i nc i si o n.

–

The light barrier and the flap clamp cannot be activated.

–

Only one sewing length L1 can be activated.

Program

STOP

b417.7

" switch to "07".

" key.

in switch setting "ON".

7.5 Sewing of Dual Piping with Piping Rever ser and Automatic Carr iage Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

In contrast to P07:

–

After stacking the transport clasps are automatically run back to

the feed are a.

Program

STOP

b417.7

" switch to "08".

" key.

in switch setting "ON".

7.6 Sewing of Simple Piping with Pipi ng Reverser

Presupposition:

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

In contrast to P01:

–

After the corner incision the piping is reversed and the material

overlap of the piping and the right material strip is drawn through

the incision.

–

Before this op eration the left transport cla sp i s removed aside.

–

The light barrier and the flap clamp cannot be activated.

–

Only one sewing length L1 can be activated.

Optional equ i pm en t

for simple p ipi n g) required.

Program

STOP

" switch to "09".

" key.

b417.7

0792 030901

in switch setting "ON".

(Reverser device

20

Page 21

7.7 Sewing of Simple Piping with Piping Reverser and Automatic Carr iage Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P09:

–

After stacking the transport clasps are automatically run back to

the feed area.

Program

STOP

b417.7

" switch to "10".

" key.

7.8 Sewing of Asymmetrical Piping wi th Piping Reverser

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

After the co r ne r i nc i si o n t he pipings are r eversed and the ma te ri al

overlaps are drawn through the incision.

–

Before this operation the left transport clasp is removed aside.

–

The light ba r ri er a nd th e f l ap c lamp cannot be act i v at ed .

–

Only one sewi n g le ng th L1 c an be ac t iv at ed .

Program

STOP

b417.7

" switch to "11".

" key.

in switch setting "ON".

in switch setting "ON".

7.9 Sewing of Asymmetrical Piping with Piping Reverser and Automatic Carriage Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program is activated.

In contrast to P11:

–

After stacking the transport clasps are automatically run back to

the feed area.

Program

STOP

b417.7

" switch to "12".

" key.

in switch setting "ON".

21

Page 22

7.10 Sewing of Simple and Asymmetrical Piping without Piping Reverser

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

–

The running of the program is suitable to sewing program

Program

STOP

b417.7

" switch to "13".

" key.

in switch setting "ON".

7.1 1 Sewing of Simple and Asymmetrical Piping without Pi ping Reverser

with Automatic Carriage Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

–

The running of the program is suitable to sewing program

Program

STOP

b417.7

" switch to "14".

" key.

in switch setting "ON".

P01

P02

.

.

7.12 Sewing of Simple and Asymmetrical Piping without Piping Reverser

with Material Return

–

Turn the DIP-Switch

–

Set the "

–

Press the "

The program i s ac t i vated.

–

The running of the program is suitable to sewing program

Program

STOP

b417.7

" switch to "15".

" key.

in switch setting "ON".

P03

.

22

Page 23

8. Sewing Programs 745-24

8.1 Sewing of Dual Piping

–

–

–

–

–

–

–

–

–

Turn on main switch.

<---REF

"

Step back on th e l e ft pedal.

The transport clasps are raised.

The transport carriage runs to its rear position.

The display signals start readiness by showing the current

parameters (see display example 1).

The settings correspond to the last settings selected before the

machine was t ur n ed off.

Set the "

Press the "

The program is activated.

By tapping the left pedal bring the carriage return out of the hold

position, s wi t c h o n t he fe ed pr o c ed ure and start.

By stepping back on the left pedal during the feed procedure the

previous steps can be activated again.

By stepping back on the left pedal the sewing process can be

interrupted af te r st a rti n g.

When the sewi n g u nit i s eq uip pe d w i th a r ig ht pe da l th i s ac t i v at es

the holder and the vacuum.

When the sewing unit is equipped with a knee switch this operates

the vacuum.

" appears in the lower display line.

Program

STOP

" switch to "01".

" key.

8.2 Sewing of Dual Piping with Automatic Carr iage Return

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

After stacking the transport clasps are automatically run back to

the feed area.

Program

STOP

" switch to "02".

" key.

8.3 Sewing of Dual Piping with Material Return

–

Set the "

–

Press the "

The program is activated.

In contrast to P01:

–

There is no s ta c k i ng af te r s ewing.

–

The material is transported back to the feed area by the transport

clasps.

Program

STOP

" switch to "03".

" key.

23

Page 24

9. Aid Programs

9.1 Center Knife Adj ustment

Program P40 alters the incision of the center knife.

If a higher value is selected the incision moves to the outside at the

seam beginning and at the seam end.

With a smaller value the incision moves in the seam.

–

Set the "

–

Press the "

The program i s ac t i vated.

The lower left display line shows the current value for the center

knife incision.

–

Correct the set value with the "+/ -" keys.

Program

STOP

" switch to "40".

" key.

9.2 Setting the Bobbin Thread Counter (745-22;-23)

With the sub-classes

monitored by a c o un td ow n c o un te r.

The setting of t hi s co un te r is ma de wi t h p rog r am P41 .

–

Set the "

–

Press the "

The program i s ac t i vated.

The lower disp l ay li n e s h ow s th e p res e t va l ue .

The positi on to be s et bl i n ks .

–

Set the desired value for each of the positions with the "+/ -" keys.

–

The next higher position is selected with the key "Σ".

–

By operatin g b ot h k e y s " + " an d " -" a t t he s am e t i me th e c o un te r i s

reset to "

Setting the value "0000" causes the bobbin thread monitor to

be shut off by the counter.

Program

STOP

0000

745-22

" switch to "41".

" key.

".

and

745-23

the bobbin thread is

Note:

The set value multiplied by factor four is approx. the number of

possible stitches.

9.3 Changing the Positioning Point Manual/Automatic

Program P42 switches over between manual and automatic changing

of positioni n g p oi n t.

An automatic change is only possible when sewing a sewing length.

–

Set the "

–

Press the "

The program i s ac t i vated.

The set stat us i s s h ow n i n th e display.

–

The switch o v er b et w e en ma nu al a nd au to ma ti c c h an ge i s made

with key "Σ".

Program

STOP

" switch to "42".

" key.

24

Page 25

9.4 T esting the Piping Reverser for Dual P iping (745-23)

Program P43 corresponds to sewing program P07.

During the reversing procedure there is a stop after each step.

–

Set the "

–

Press the "

The program is activated.

–

After the fi r s t st ep of the draw-th r ou gh pro c ed ur e th e p r oce s s i s

stopped.

–

By pressing the "+" key the process is continued to the next stop

point.

Program

STOP

" switch to "43".

" key.

9.5 T esting the Piping Reverser for S imple Piping (745-23)

Program P44 corresponds to sewing program P07.

During the reversing procedure there is a stop after each step.

–

Set the "

–

Press the "

The program is activated.

–

After the fi r s t st ep of the draw-th r ou gh pro c ed ur e th e p r oce s s i s

stopped.

–

By pressing the "+" key the process is continued to the next stop

point.

Program

STOP

" switch to "44".

" key.

9.6 Testing the Piping Reverser for Asymmetrical Piping (745-23)

Program P45 corresponds to sewing program P11.

During the reversing procedure there is a stop after each step.

–

Set the "

–

Press the "

The program is activated.

–

After the fi r s t st ep of the draw-th r ou gh pro c ed ur e th e p r oce s s i s

stopped.

–

By pressing the "+" key the process is continued to the next stop

point.

Program

STOP

" switch to "45".

" key.

25

Page 26

10. Setting Programs

10.1 T esting the Positioning Procedur e for Dual Piping (745-23)

Program

–

–

–

–

–

–

10.2 Loading of standard values

Program

Correction seam beginning (NA) / seam end (NE): 50

Correction of corner knife seam beginning (MA) / seam end (ME): 50

745-24: Seam beginning (BL) / seam end (EL) left needle: 10

745-24: Seam beginning (BR) / seam end (ER) right needle: 10

P46

serves to test the positioning procedure for dual piping.

Set the "

Press the "

The program i s ac t i vated.

A reference run is conducted.

Press the pe da l .

The transpo rt c a r ri ag e r u ns to the feed stat io n.

The positio ning procedure is ru n t hr o ug h a s i n a s ew i ng program.

Then the display shows the symbol "

Run the transport carriage into the rear position by tapping the "Σ"

key.

When the rear edge of the transport clasps is under the needles

the zipper c u tt er i s o pe r at ed .

Program

STOP

P47

serves for loading of the following standard values:

" switch to "46".

" key.

<---

".

7

–

Set the "

–

Press the "

The program i s ac t i vated.

–

Press the "Σ" key for starting the program.

The display shows the loaded standard values.

Program

STOP

" switch to "47".

" key.

10.3 Setting the Remaining Thread Monitor (Light Reflection Barriers)

Program P51 serves for aligning the light reflection barriers of the

remaining thread monitor.

–

Set the "

–

Press the "

The program i s ac t i vated.

The middle of the lower display line shows two bobbins.

–

With correctly aligned light barriers a reflection occurs when an

empty bobbin is turned.

A reflection of the left light barrier is shown in the left half of the

lower display line by the symbol "

A reflection of the right light barrier is shown in the right half of the

lower display line by the symbol "

Program

STOP

" switch to "51".

" key.

]->>

<<-[

".

".

26

Page 27

10.4 Testing the Zipper Cutter (745-22)

Program P52 can start a zipper cutter cutting sequence.

–

Set the "

–

Press the "

The program is activated.

–

Press the "Σ" key.

The zipper cutter cutting sequence is started.

–

If the transp or t c arr i a ge i s no t in its rear position, this is s h ow n by

the symbol "

–

Step back on th e l e ft pedal.

The transport carriage runs to the rear.

Program

STOP

<---

".

" switch to "52".

" key.

10.5 Checking Needle and Center Knife Actuation

Program P53 checks the actuation of the needles and center knife with

the sewing dri v e ru nn i ng .

–

Set the "

–

Press the "

The program is activated.

–

Set the desired revolutions (1 - 13) with the "

The lower display line shows the set value belonging to the

selected revolutions.

–

Press the "Σ" key.

The sewing drive starts and runs until the "Σ" key is pressed again.

When the sewing drive is stopped there is a positioning sequence

in the 2nd nee dl e po s iti o n ( n ee dl e up ) .

–

The needles an d t he c en te r k nife can be actuat ed at an y ti m e b y

pressing the key "L1" (needles ) an d "L2" (center knife).

Program

STOP

" switch to "53".

" key.

Program

" switch.

CAUTION !

When exiting program

allowed to run f or a sho r t t i me wit h n ee dl e s an d ce nt er kn i fe s hu t o ff.

Otherwise the next seam will not be sewn correctly.

P53

it is essential that the machine head be

27

Page 28

10.6 T esting the Positioning Procedur e for Simple Piping (745-23)

Program

–

–

–

–

–

–

P54

serves to test the positioning procedure.

Set the "

Press the "

The program i s ac t i vated.

A reference run is conducted.

Press the pe da l .

The transpo rt c a r ri ag e r u ns to the feed stat io n.

The positio ning procedure is ru n t hr o ug h a s i n a s ew i ng program.

Then the display shows the symbol "

Run the transport carriage into the rear position by tapping the

"Σ" key.

When the rear edge of the transport clasps is under the needles

the zipper c u tt er i s o pe r at ed .

Program

STOP

" switch to "54".

" key.

10.7 Setting the Light Barrier for Seam Beginning / Seam End

With progra m

seam beginning and seam end is aligned.

–

Set the "

–

Press the "

The program i s ac t i vated.

–

Move the transport clasp by hand.

By reflection the first display line will show "

By interruption "

P55

the reflecting light barrier for recognition of the

Program

STOP

" switch to "55".

" key.

-B44

" appears.

<---

".

+B44

".

28

Page 29

10.8 Setting the Material Strip Reverser (745-23)

–

Set the "

–

Press the "

The program is activated.

–

Press the "Σ" key.

The material and piping reve r s er i s switched on and o ff.

–

If the transp or t c arr i a ge i s no t in its rear position, this is s h ow n by

the symbol "

–

Step back on th e l e ft pedal.

The transport carriage runs to the rear.

Program

STOP

<---

".

" switch to "56".

" key.

29

Page 30

1 1. Testing Programs

11. 1 Program Version and Check-Sum Display

–

Set the "

–

Press the "

Das Program ist activated.

In the lower display line the program version and a check-sum

appear.

e.g.:

By program ve r si on s wi t h t he s am e c l a s s de s i gn at i on an d

same ID letter the higher version replaces all lower versions

(Example: 745P03 replaces 745P01 and 745P02).

The check-Sum is only meant for the factory service department.

In it special i sts c a n se e i f th e p rog r am me mo ry (E P RO M ) of th e s e wi n g

unit controls faultlessly contains the complete program.

11.2 Checking the Step Motor Control

Program P57 tests the step motor controller and the step motor output.

Program

STOP

745P06 CE9D

745 = Class designation of the sewin g u ni t

P = ID l etter

06 = Series number

CE9D= Check-sum

" switch to "00".

" key.

(for 745-22;-23)

–

Set the "

–

Press the "

The program i s ac t i vated.

The results of th e test are shown i n t he di splay.

Display Explanation

AMP ERR

LINK OK

LINK ERR

EPROM OK

EPROM ERR

XCOU OK

XCOU ERR

SCOU OK

SCOU ERR

Program

STOP

" switch to "57".

".

Fault in the s t ep mo to r ou tp ut or li n k i ng c ab l e

unplugged

Transmission to the step motor controller

Fault in the transmission to the step motor controller

EPROM on the s t ep motor card OK

EPROM on the s t ep motor card defec ti v e

Cycling counter module on t he s te p m ot or card OK

Cycling counter module on t he s te p m ot or card

defective

Counter module for cycle generation on the step

motor card OK

Counter module for cycle generation on the step

motor card defective

30

Page 31

1 1.3 Ch ecking t he Seria l Int erface

Program P58 checks the SIO module of the controls.

–

–

–

Display Explanation

Plug the SI O t es t pl u g i n to th e s o c k et b1 09 on th e m ai n c i rc ui t

board.

The test plug links the transmitter with the receiver.

This makes a loop test possible.

Set the "

Press the "

The program is activated.

Program

STOP

" switch to "58".

" key.

11.4 Memory and Timer Test

OK

Err

kein SIO

Program P59 checks the working memory (RAM) and all timer

switches of the controls.

–

Set the "

–

Press the "

The program is activated.

Display Explanation

OK

ERROR 0

ERROR 6

ERROR 7

ERROR 8

ERROR 9

SIO module i s OK

SIO module is defective

SIO test pl ug i s no t p l ug ge d i n

Controls ar e op erated without SIO module

(optional equipment)

Program

STOP

" switch to "59".

".

Working memory and all timer switches are OK

RAM error

Timer 1 defective

Timer 2 defective

Timer 3 defective

Timer 4 defective

31

Page 32

11.5 Continuity Check

Program P60 checks to see if the 24V current supply supplies current

when the output d r i ver s a r e sh ut off.

Then the program checks all existing output elements (including

output drive r s an d i n s ta l l at i on ) for continuity.

–

Set the "

–

Press the "

The program i s ac t i vated.

Display Explanation

V?

OK

S17

(Example) installation or driver

11.6 Checking the Front Panel Elements

Program P61 checks the front panel elements.

Program

STOP

" switch to "60".

" key.

Short in the installation or

one of the outp ut dr i vers defective

All circuit have continuity

Interruptio n i n th e o ut pu t e l em en t s 1 7, i n i t s

Output element s17 does not exist because it is

optional equipment

Continue the test with the next element

by pressing the "Σ" key.

–

Set the "

–

Press the "

The program i s ac t i vated.

–

Operate the preselector switch on the front panel.

The display will show the current set value of the preselector

switch operated.

When a key on th e f r on t p an el i s o pe rated (Exceptio n: S TOP key)

the numbers r e l at i ng to th i s s wi t c h ( 1 , 2 , 4 or 8 ) ar e di splayed.

–

The LEDs on th e f r on t p an el a r e selected using c od e nu mb er s . The

short desi gn at i on fro m the circuit di a gram (1 - 8) acts as th ei r co de

number.

The LEDs are switched on with t he " Σ" key.

Switch Function Designation

b417

b401

b402

b413/412

b416

Program

STOP

" switch to "61".

" key.

Function switch

Revolutions

Operation mo de of th e

left transport clamp

Program switch PROGRAM

Stop (Key 13) STOP

32

Page 33

Key Function Symbol Indicator

b814 Posit i on i ng po i nt fo r wa rd LED

b815 Set cou nt er Display

b816 Minus

b817 Plus

b818 Center a nd c or n er k n i v es o n / off LED / LED

b819 Order of c l os ing of the flap cl a mp s LED / LED

b820 Tacking o n / off LED

b821 Tape feedon / off LED

b822 Light barrier on LED / Display

b823 Tape length wh en s ew i ng wit h l i g ht ba rr i er Di sp l ay

b824 Correct ion th e c o rne r kni f e Display

b825 Correct i on of seam beginni ng an d s e am en d Display

b826 Sewing of s ea m se r ies Display

b827 Sewing length 3 Display

b828 Sewing length 2 Display

b829 Sewing length 1 Display

LED Function Indication

H1b Positioni ng po i nt fo rwa r d

H2 Light barrier NA / NE

H3c F l ap cl am p l e ft

H4c Co rne r kni fe

H5b Center knife

H6b Flap clamp ri g ht

H7a Tacking

H8a Tape guide

1 1.7 Checking the Input El ements

–

Set the "

–

Press the "

–

Press the in put element to be c h ec k e d.

The display will show the circuit diagram designation and switching

status of th e in put elements (e.g. "+B25").

The display will change when the switching status of any other

input elements is changed.

The switch status "+" means:

–

for switch es w i th c on ta c t = contact open

–

for proximity switches = metal in front of the switch

–

for reflecting light barriers = no reflection

–

Continuous beam light barrier = beam uninterrupted

Program

STOP

" switch to "62".

" key. The program is activated.

33

Page 34

1 1.8 Selecting Input Elem ents

CAUTION !

All input elements have been carefully set at the factory.

Adjustment and correction may only be undertaken by trained service

personnel.

Program P63 serves for setting the input elements.

–

Set the "

–

Press the "

The program i s ac t i vated.

–

Set the "

element.

The short de si gn ation in the ci rc ui t di a gra m a c ts a s th e c o de

number (see ta bl e ). T h i s do es n ot apply for the key s on the fr on t

panel (see "Checking the Front Panel Elements").

–

The display s h ow s th e c i rc u i t d i ag r am de si gn ation and the swi t c h

status of the input element (e.g. "+B14").

–

Adjust the input element (e.g. proximity switch) until the desired

switching status is shown in the display.

The meaning of the switch status corresponds to the switching

status in pr o gra m P 6 2.

Input Function

Element

b1 Carriag e a t r e ar

b2 Reference position

b3 Carriag e f orward

b4 Folder up

b5 Folder down

b8 Material holder lowered / Vacuum on

b9 Pedal 3 (External transmitter for sewing drive)

b10 Pedal 4 (External transmitter for sewing drive)

b11 Pedal 1 (External transmitter for sewing drive)

b12 Pedal 2 (External transmitter for sewing drive)

b13 Transmitter control

b14 Thread monitor left

b15 Thread monitor right

b35 Posit ion 1 ( N ee dl e do wn )

b37 Posit i on 2 ( N ee dl e up )

b39 (Posi t i on 3)

b44 Light ba rr i er N A / NE (opti on al e qu i pm en t)

b45 Stacker control

b46 Remaining thread monitor left

b47 Remaining thread monitor right

Program

STOP

Program

" switch to "63".

" key.

" switch to th e c o de nu mb er o f t he de s i r ed input

(second peda l / K n ee sw i t ch, optional equi p me nt )

34

Page 35

1 1.9 Selecti ng Output Elements

Caution Risk of Injury !

During the function testing of the output elements do not reach into the

running machine.

Program P64 checks the function of the output elements.

–

Move the transport carriage at a distance of 50 mm to its rear end

position by ha nd .

–

Set the "

–

Press the "

The program is activated.

–

Set the "

element.

The short designation in the circuit diagram serves as the code

number (see t ab l e).

–

Turn the selected output element on and off by tapping the "Σ" key.

Output Function 745-22 745-23 745-24

Element

Program

STOP

Program

" switch to "64".

" key.

" switch to the code number of the desired output

s1 Raise flap clamp left

s2 Swing link

s3 Corner knife seam beginning

s4 Corner knife seam end

s5 Close fo l d p l at es

s6 Smoother f or w ar d

s7 Raise flap clamp right

s8 Smoother b ac k

s9 Stacking / Blowing out

s10 Raise transport clasp

s11 Lower transport cla s p

s12 Raise tensioning s t r ip

s13 Center knife

s14 Material holder / Vacuum

s15 Loosen thread tension

s16 Open thread clamp

s17 Close zipper cutter

* Lower piping r eve r ser

s18 Pull thread forward

s19 Blow out lint

s20 Lower folder

s21 Raise folder

s22 Zipper cutter back

* Knife bloc k f orward

s23 Transport clasp closed

s24 Thread trimmer / Thread catch

s25 Needle right and lef t (7 45 - 22 ;- 2 3)

Needle right (745-24)

s26 Needle left

s27 Close tape trimmer

s28 Advance tape

s29 Raise piping reve rs er

* Zipper cutt er f or w ar d

s30 Lock hood

s31 Lift left transport clamp

s32 Lower left transpor t cl am p

* = Alternative designation with different optional equipment

x

= Standard e qu i pm en t

0

= Optional equipment

XXX

XXX

XXX

XXX

XXX

000

XXX

000

XXX

XXX

XXX

-XXXX

000

XXX

XXX

0- -

-XXXX

XXX

XXX

XXX

0- -

-X-

-XXXX

XX

X

--X

000

000

-X0- XXX

000

000

35

Page 36

11.10 Sewing Drive: Pedal Operation

After the pro gr a m P 6 5 i s a c ti v a te d t he un i t c a n b e o pe r at ed wi t h

revolutions selected via the pedal.

–

Set the "

–

Press the "

The program i s ac t i vated.

–

Step forward on the pedal.

The drive ru ns a t t ho s e re v ol u ti o ns corresponding t o t he pe dal

position.

After a few sec o nd s th e r i g ht ha l f o f t he fi r st display lin e s h ow s

current revolutions (actual revolutions of the machine head).

–

Bring the pedal to the neutral position.

The machine head is stopped without a positioning sequence.

Program

STOP

" switch to "65".

" key.

1 1.11 Positioning the Ma chine Head i n the 2nd Need le Position/R evolution Test

Program P66 serves for setting the 2nd needle position (needle up).

After the main switch is turned on the right display half shows the

symbol "

Different revolut i on s of th e m ot or c a n b e p res e l ect ed wi t h t he pro gr a m

switch.

–

–

–

–

–

–

SW?

".

Set the "

Press the "

The program i s ac t i vated.

Preselect the revolutions of the drive with the "

A total of 13 revolut ion stages are ava i l ab l e (s e e t ab l e) .

With an allowa bl e v alu e the right half of th e f i rs t d i spl a y l i ne sho w s

0000

"

Press and hold key "Σ".

The drive ru ns w i th th e s e l ected revolution s .

After a few sec o nd s th e r i g ht ha l f o f t he fi r st display lin e s h ow s

current revolutions (actual revolutions of the machine head).

Release the key "Σ".

The machine head will be positioned in the 2nd needle position

(needle up) .

Program

STOP

", with an illegal value "

" switch to "66".

" key.

SW?

Program

".

" switch.

36

Revolutions 1/min

13 3000

12 2750

11 2500

10 1700

91000

8720

7540

6410

5310

4230

3170

2130

1100

Page 37

1 1.12 Po sitioning t he Machi ne Head in the 1st Ne edle Posi tion

Operation of th e p r og ram P 67 i s as d es cr i b ed un de r pro gr a m P 6 6.

–

Set the "

–

Press the "

The program is activated.

In contrast to P66:

–

The machine head is positioned in the 1st needle position (needle

down).

The slots in the synchronizer for the two needle positions must be

opposite eac h o th er.

Program

STOP

" switch to "67".

" key.

11 .13 Positioning the Machine Head with Cutting Revolutions

Operation of th e p r og ram P 68 i s as d es cr i b ed un de r pro gr a m P 6 6.

–

Set the "

–

Press the "

The program is activated.

In contrast to P66:

–

The machine head is positioned in the 1st needle position (needle

down).

–

After a shor t pa us e th e n ee dl e i s po s i ti o ne d i n th e 2 nd ne ed l e

position (n ee dl e up ).

Program

STOP

" switch to "68".

" key.

1 1.14 Positioni ng the Machine Head and Thread Trimming

Operation of th e p r og ram P 69 i s as d es cr i b ed un de r pro gr a m P 6 6.

–

Set the "

–

Press the "

The program is activated.

In contrast to P66:

–

The positi on i ng of th e m ac h i ne he ad i n t he 2n d n ee dl e po s i ti o n

(needle up) o cc ur s with a thread tr imming sequenc e.

Program

STOP

" switch to "69".

" key.

37

Page 38

12. Function Displays and Error Messages

12.1 Displays for Operat ing Aids

Display Explanation Remedy

P?

745N06

<----REF

<----REF

PEDAL STOP

<---F?

- - - L?

LS

ER ROR

I I

I I

I I

-- X - =xxxx

Σ

=xxxx

I

]->>

<<-[

SW?

SMC-TEST

LINK OK

XCOU OK

SCOU OK

EPROM OK

Illegal pro gra m s e l ec t ed

Display of the program version

Carriage not i n re ar p osi t i on wh en

switched on (reference run)

Sewing sequence interrupt ed , r u n

carriage to rear

Run carriage t o re ar

Entry of a new s er i e s i s ex p ected

Illegal sewing length selected

(e.g. Length in P 0 4 - P 0 6 s m al ler than

75 mm)

Fabric to be s c an ne d b y th e l i g ht ba rr i er

is positioned outside the sewing area

Positioning error, rear positioning point

chosen by se wing lengths unde r 75 mm

Left bobbin e mp ty

(left blinks)

Right bobbin empty

(right blinks)

Bobbins empty (blinks)

Thread tear (blinks)

Piece counter

Bobbin thread reserve

Left bobbin t hread monitor

has reflect i on

Right bobbin t hre ad mo ni t or

has reflect i on

Invalid revolution level set

Step motor controller being tested

Transmission to step motor

controller OK

Counter module for cycle counting on

the step moto r c ar d OK

Counter module for cycle generation on

the step moto r c ar d OK

EPROM on the s t ep motor card OK

Reset "Program" switch

Step back on pedal

Step back on pedal

Step back on pedal

Program a new seam series

Reset sewing length

Reposition fabric inside the sewing

area

Select the front positioning point

Change left bob bi n

Change right b ob bin

Change bobbins

Reinsert thread

Reset "Program" switch

38

Page 39

12.2 Displays by Malfunctions

Display Explanation Remedy

E2

V?

STOP

POS2

POS-Err

--<>-START ERROR

ERROR --> [b3

ERROR b1 ] <-? <----> ?

REF ERROR

PROG ERROR1

PROG ERROR2

? b417 ?

? b401 ?

ERROR1 LS ] <-ERROR2 LS ] <-ERROR3 LS ] <--

ERROR4 LS ] <-ERROR5 LS ] <--

ERRORLS --> [END

Fuse e2 in transformer defec ti v e

Error message in P60

Hood open

Hood control or Stop key defective

Machine head will not position

Synchroniz er n ot i nstalled,

Motor protection switch off

Synchronizer not plugged in

Short in the lead for switch on pedal,

pedal was alr e ad y op era te d when the

main switch was turned on

Transport carriage r u n u p a ga i ns t

forward stop

Transport carriage r u n u p a ga i ns t r ea r

stop

Transport carriage r u n i n th e w r on g