Page 1

Contents Page:

Home

Part 3: Service Instructions Cl. 745-22; -23; -24

1. General

2. Transport Carriage

2.1 Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Forward End Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Rear End Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Timing Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Changing the Timing Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Folder

3.1 Stroke Movement of the Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Aligning the Folder to the Center of the Pocket Opening . . . . . . . . . . . . . . . . . . . . . 13

3.3 Position of the Folder to the Needles and the Center Knife . . . . . . . . . . . . . . . . . . . . 14

3.4 Guide Plates on the Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Clearance of the Transport Clamps to the Folder sole

4.1 Manual Adjustment of the Transport Clamps (745-22) . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Pneumatic Quick Clamp Adjustment (745-23) . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Marker Lights

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6. Knife Brackets for Cutting the Corners

6.1 Adjusting the Position of the Corner Incisions . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Adjusting the Knife Brackets for Bias Corner Incisions (745-24) . . . . . . . . . . . . . . . . . 28

6.3 Changing the Corner Knives (745-22 and 745-23) . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4 Changing the Corner Knives (745-24) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7. Adjusting the Piping Reverser (745-23)

8. Cloth Slider Plate and Support Plate

9. Stroke Height of the Transport Clamps

9.1 Clearance of the flap clamps to the slider plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10. Synchronizer

11. Machine Head

11.1 Crank Pin on the Arm Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.2 Needle Bar Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.2.1 Slewing Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.2.2 Setting the Needle Bar Link to the Needle Bars . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.2.3 Turning the Needle Bars on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.2.4 Assembling and Removing the Needle Bar Link . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 2

Contents Page:

11.3 Hook Shaft Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.4 Tooth Play of the Hook Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.5 Looping Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.6 Height of the Needle Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.7 Clearance of the Hook Points to the Needles . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.8 Needle Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

11.9 Changing the Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11.10 Bobbin Case Holding Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.11 Aligning the Light Barriers of the Remaining Thread Monitor . . . . . . . . . . . . . . . . . . . 59

11.12 Center Knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.13 Thread Controller Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.14 Trimming and Clamping Device for the Needle Threads . . . . . . . . . . . . . . . . . . . . . 65

11.15 Trimming and Clamping Device for the Underthreads . . . . . . . . . . . . . . . . . . . . . . 66

11.16 Thread Puller for the Needle Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11.17 Winder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.18 Changing the Needle Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12. Setting the Optional Equipment

12.1 Draw-off Device and Bundle Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12.2 Length-controlled Feed and Trimming Device for Reinforcement Strips . . . . . . . . . . . . 73

12.3 Holder, Pocket Bag and Waistband Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

12.4 Reflecting Light Barrier for Flap Scanning (745-22 and 745-24) . . . . . . . . . . . . . . . . . 76

12.5 Throw-over Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.5.1 Setting the Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.5.2 Setting the Height of the Counterholder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.5.3 Setting the Position of the Placement Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.5.4 Setting the Speed of the Smoother Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 3

1. General

These Service Instructions describe the adjustments on the sewing

unit in a prac t i cal o r de r.

Attention!

The various setting positions are interdependent.

It is therefore essential that the individual settings be made in the

order described.

ATTENTION !

The tasks described in these Service Instructions may only be

conducted by skilled personnel or appropriately trained persons!

Danger of Breakage !

Before starting the sewing unit again after disassembly first conduct

the necessary setting work as per these Service Instructions.

Never start the sewing unit with an incorrect direction of turn of the

drive motor.

To avoid damage to the clamp linings:

Run the lowered transport clamps into the rear end position only with

cloth in pla c e.

Caution Risk of Injury !

Before repair, conversion and maintenance work:

–

Turn the main switch off.

Exception:

Setting work conducted with testing, setting or sewing programs

of the control u ni t .

Adjustment work and function testing with the sewing unit running

–

Conduct adjustment work and function testing with the sewing unit

running only under observance of all safety measures and with

greatest caution.

Setting work in the area of the corner knives, of the center knife

and the needles

–

Remove the app r op ri at e p art s be fo re c o nd uc t ing th e s e tt i ng wo rk

in order to avo i d i n j ur y.

Exception:

The parts are essential for the setting work.

Pedal

–

Attention!

In the sewing programs the sewing unit can be accidentally started

by stepping d own on the pedal.

3

Page 4

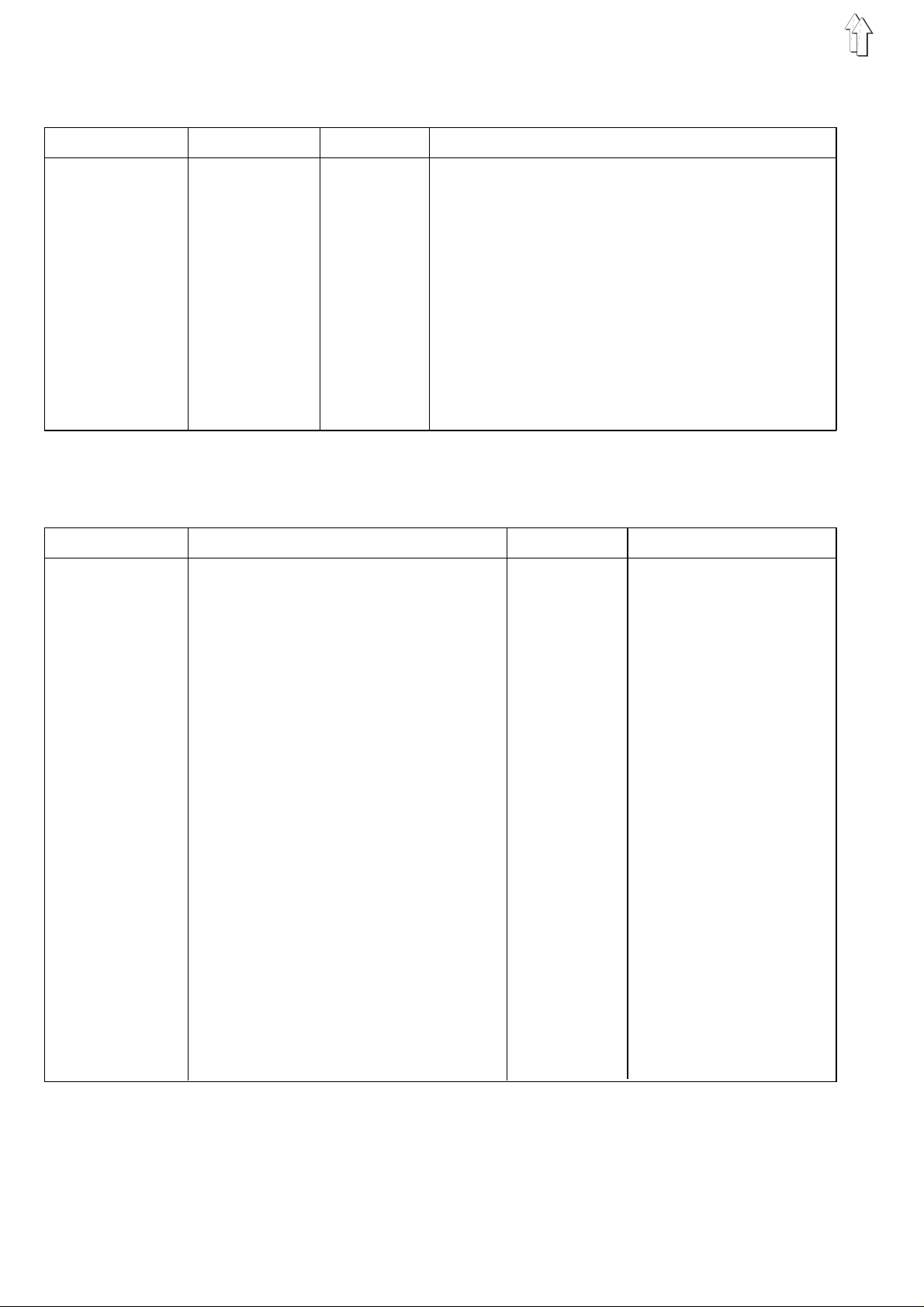

Setting gauges

The following setting gauges are available on request:

Subclass Setting gauges Order no. Application

745-22; -23; -24

745-24

Subclass Replacement part Pieces Order no.

745-22;-23;-24

Gauge 0246 002591 Crank pin to the arm shaft

Gauge 0244 001001 Hook shaft height

Arresting pi n 0211 000700 Looping stroke sett i ng

Measuring bridge 0212 0 04942 Ne edl e holde r heigh t

Measuring pi n 0216 001070 Needle h ol d er h ei g ht

Setting pin 0244 001014 Sidewa ys ho ok c l e ara nc e

Gauge 0246 000919 Clearance needle bar link to the needle bar

Gauge 0792 007677 Corner knife (NA = 16 mm)

Gauge 0792 007678 Corner knife (NA = 20 mm)

Replacement parts

The following replacement parts in the numbers listed are in the

accessories pack:

Center knife 1 0246 002553

Special bob bi n fo r th e 6 0246 003058

remaining thread monitor

745-22; -23

745-24

Corner knive s (N A = 8 mm) 2 0746 060693

2 0746 060694

or

Corner knive s (N A = 10 mm) 2 0746 060689

2 0746 060690

or

Corner knive s (N A = 12 mm) 2 0746 060691

2 0746 060692

or

Corner knive s (N A = 14 - 20 mm ) 2 0792 007217

2 0792 007217 a

Corner knive s (N A = 10 mm) 2 0746 000996

2 0746 000996 a

or

Corner knive s (N A = 12 mm) 2 0746 000997

2 0746 000997 a

or

Corner knive s (N A = 14 - 20 mm ) 2 0746 000998

2 0746 000998 a

4

Page 5

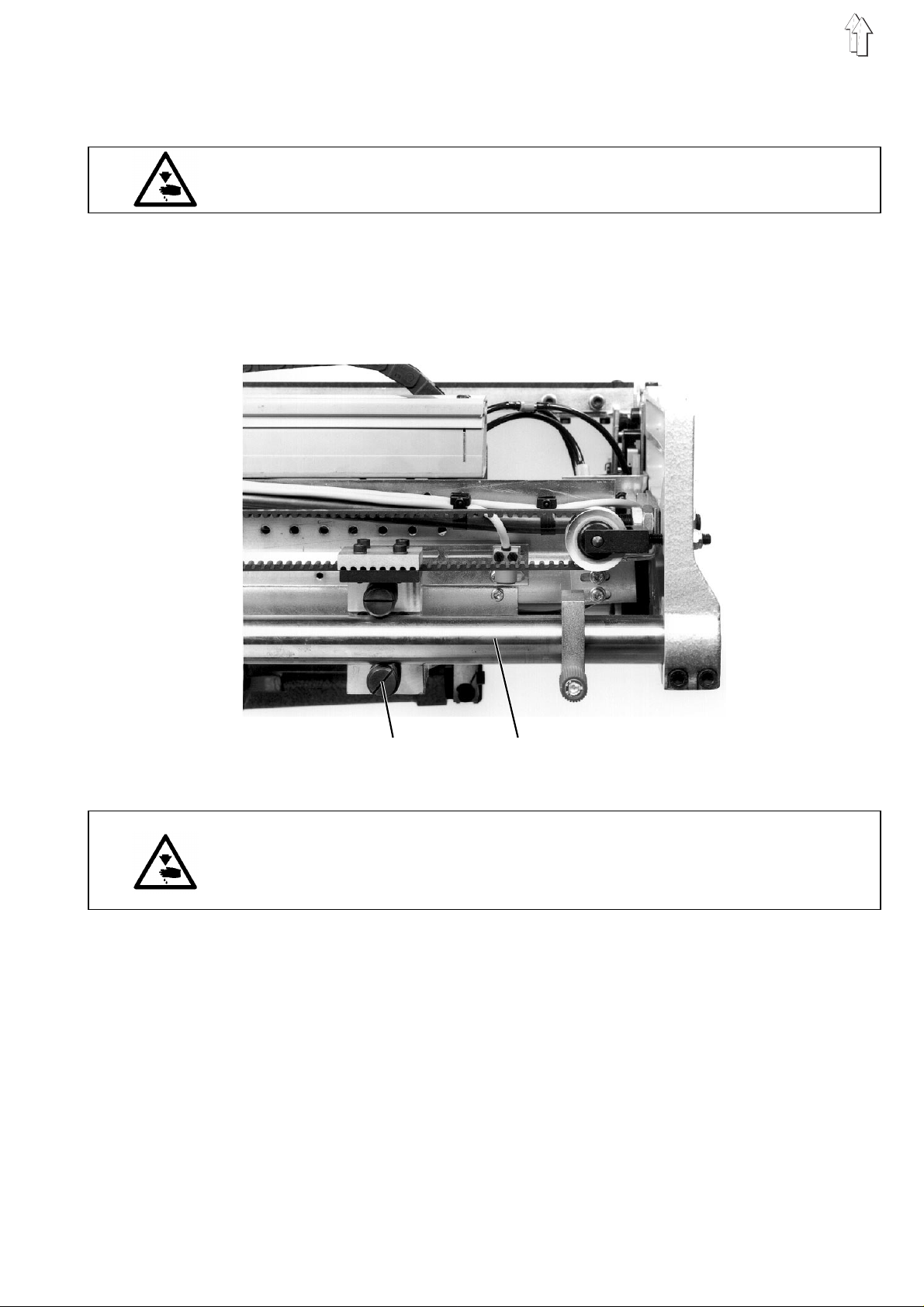

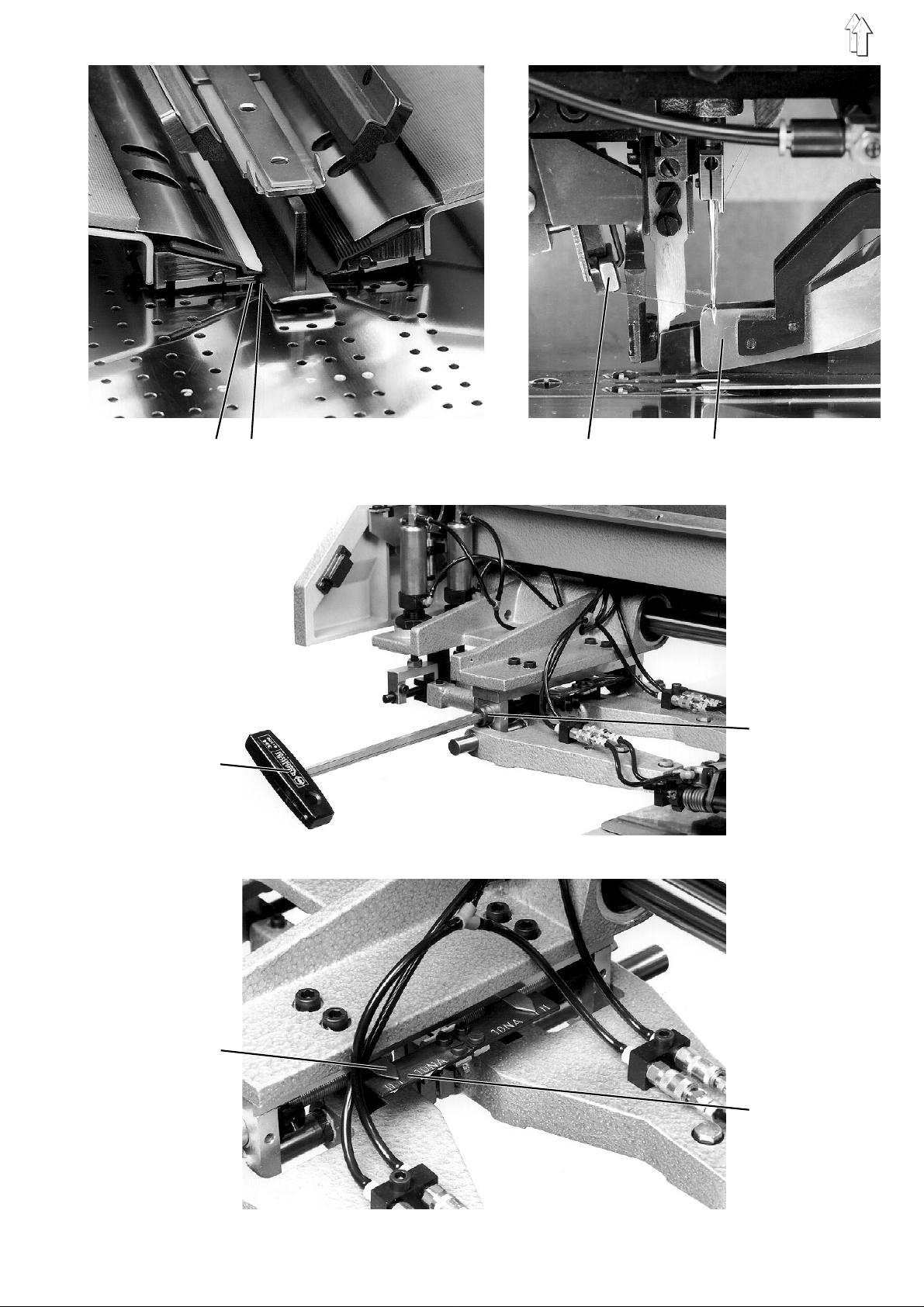

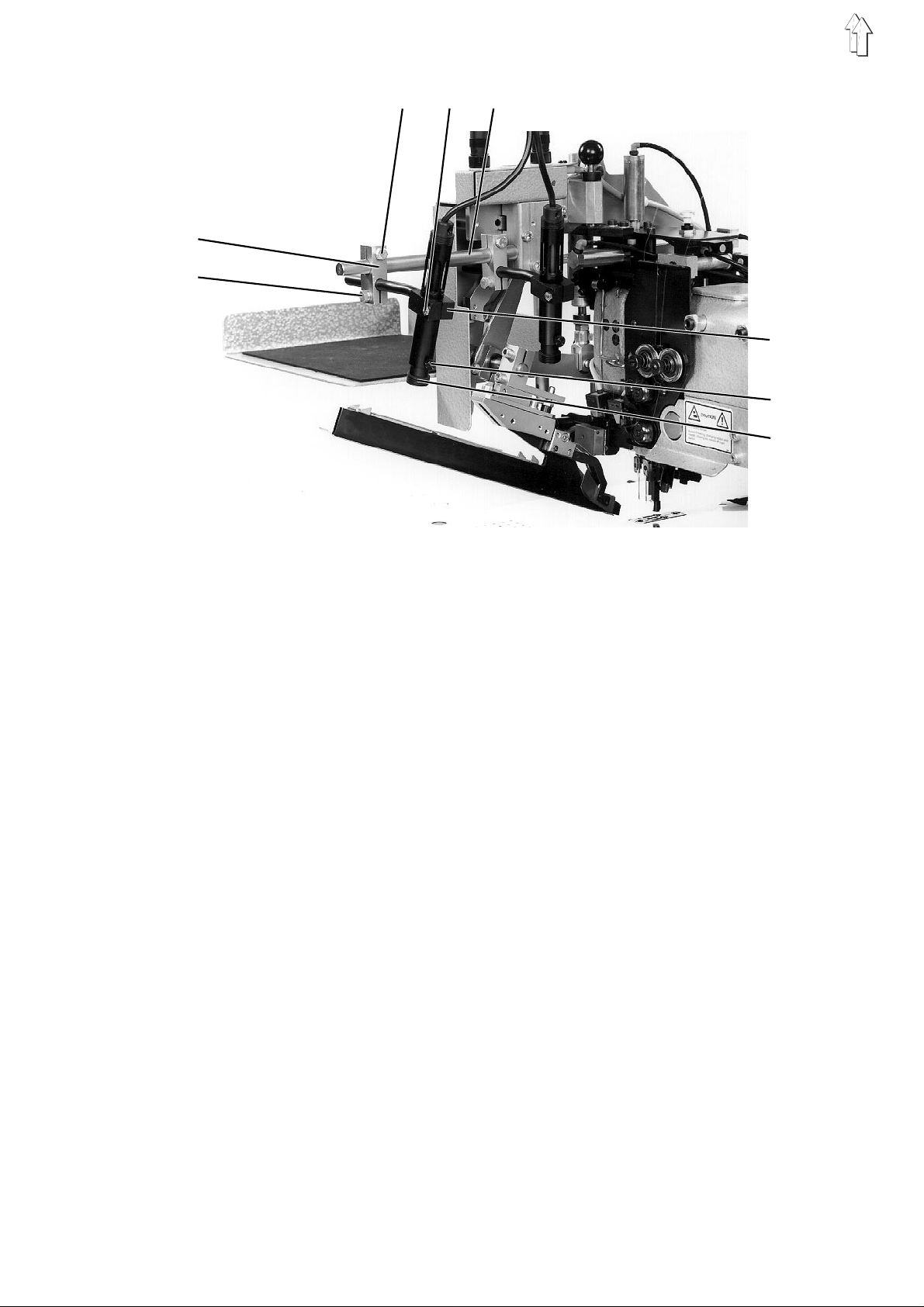

2. T ransport Carriage

2.1 Rollers

The advance of the transport carriage occurs via a step motor.

Caution Risk of Injury !

Do not reach into the area of moving machine parts.

The transport carriage is guided on the extension pipes 2 by ball

sleeves on the left and by rollers on the right.

The rollers 1 are set tight at the factory.

12

Caution Risk of Injury !

Turn the main switch off.

Set the play o f the rollers 1 o nl y with the main s wi t c h t ur n ed off.

To remove play:

–

Remove the c o ver p l at e a ft er l o os e ning the mounting s c re w s.

–

Loosen

one

of the eccentrically bearinged rollers 1 and set tight.

5

Page 6

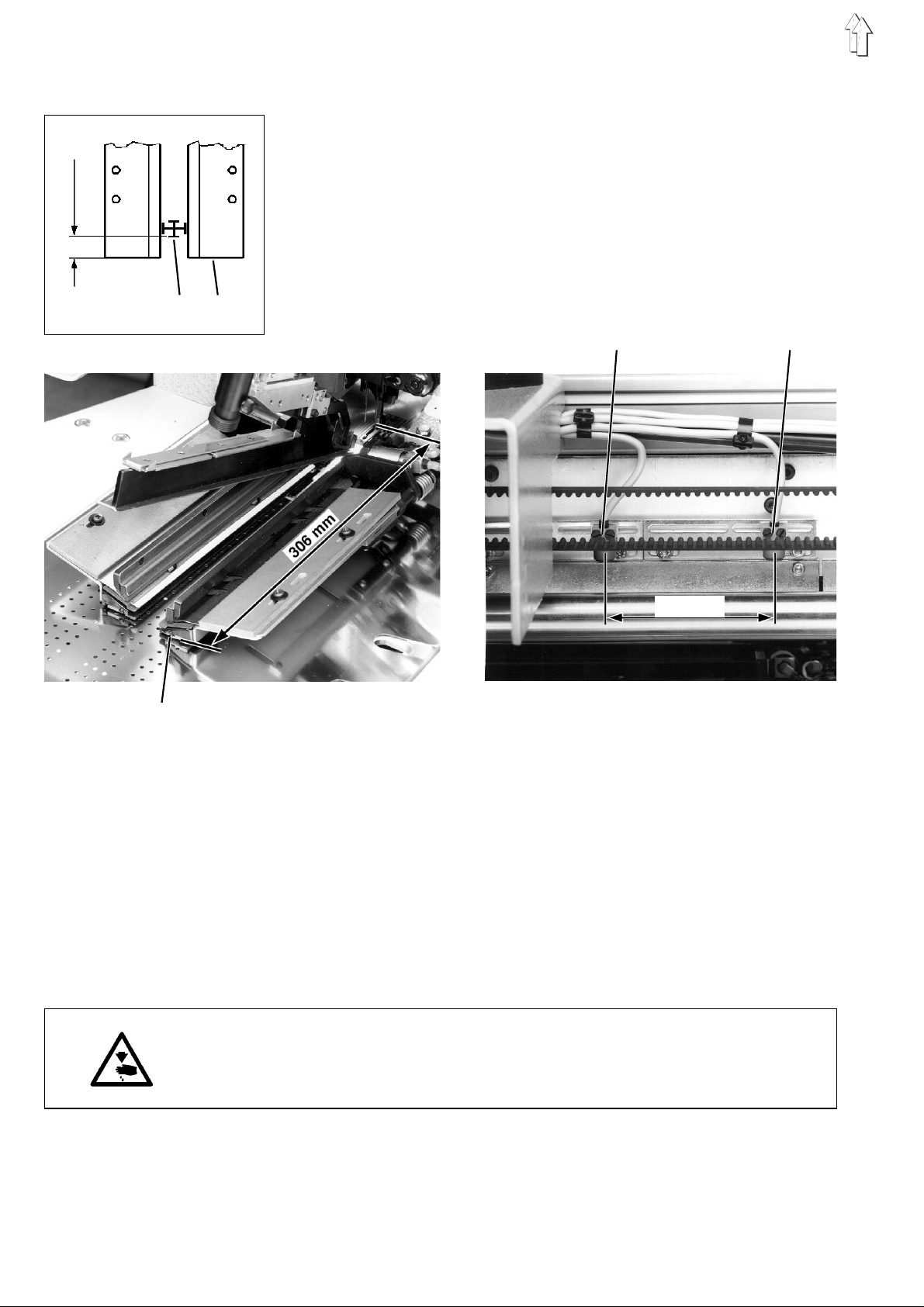

2.2 Forward End Position

15 mm

1 2

switch b2

The

carriage.

In this posi ti o n t he c l ea ran c e f r om th e f or w ar d ed ge s of th e

forward-lyi n g n ee dl e s to th e f or w ar d ed ge s 2 o f t he tr a nsport clamps

must be 306 mm.

This corresp on ds t o a c l ea r an ce o f 1 5 m m f rom the forward ed ge s 2 o f

the transport clamps to the H-light marker 1 (see sketch).

switch b3

The

It prevents a possible striking of the transport carriage on the machine

head.

The clearance between the switches b3 and b2 must be 90 mm.

determines the forward end position of the transport

serves as a safety switch.

b3 b2

90 mm

2

Checking the switch setting

–

Turn the main switch on.

–

Step back on the left pedal.

The transpo rt c a r ri ag e r u ns i n to i ts r e ar e nd position.

–

Step forward on th e l e ft pedal.

The transpo rt c a r ri ag e r u ns i n to i ts f or w ar d en d p os i t i on .

It runs over the switch b2 (reference po s i ti o n) a l on g i t s pa th .

After a furt he r run of approx. 80 mm it stops in the f orward end

position.

–

Check the clearance of 306 mm from the forward edge of the

forward-lying needles to the forward edges 2 of the transport

clamps.

Correcting the switch setting

Caution Risk of Injury !

Turn the main switch off.

Correct the pos it i on of th e s w i tch es b2 and

switch turned off.

b3

only with the main

–

Remove the cover plate after loosening the mounting screws.

–

Set the switches b2 and b3 after loosen i ng th e c l a mp i ng sc r ew s .

–

Tighten the clamping screws again.

6

Page 7

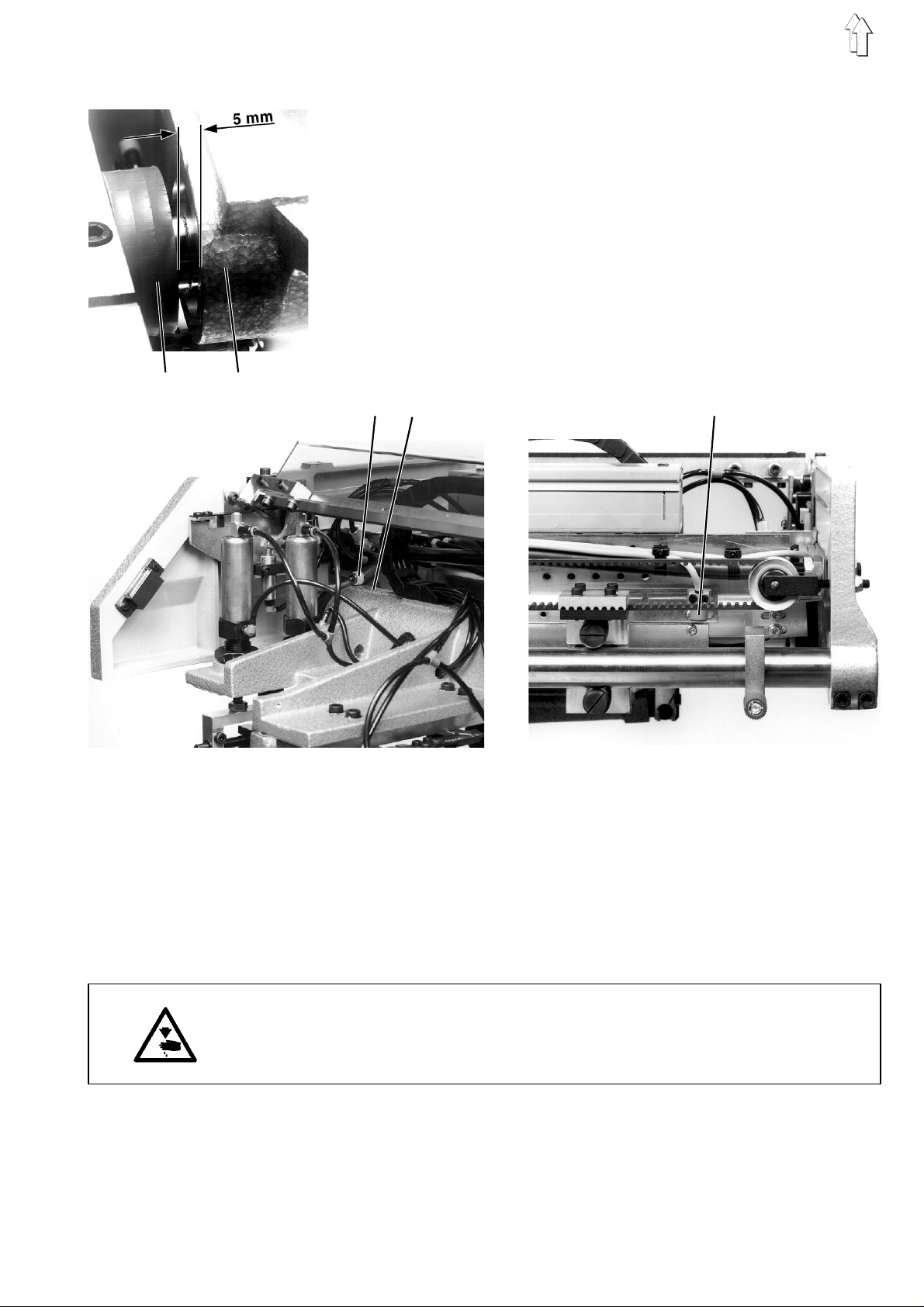

2.3 Rear End Position

switch b1

The

carriage.

Set switch b1 so that in the rear end position there is still a clearance

of 5 mm between the damper discs 1 and the transport carriage 2.

The surface 4 on the transport carriage must open the pneumatic

valve 3 when running into the rear end position.

With the main switch turned off and pneumatic valve 3 opened the

interlock of the cover hood and the cloth slider plate is released.

determines t he r ea r en d p os i t i on of the transport

1 2

34

Check the positions of the switch and the pneumatic valve

–

Turn the main switch on.

–

Step back on th e l e ft pedal.

The transport carriage runs into its rear end position.

–

Check the clearance dimension of 5 mm between the damper discs

1 and the tran spo r t c a rr i ag e 2 .

–

Check if the pneumatic va lv e 3 i s op en ed by t he s urface 2 on the

transport carriage.

b1

Correcting the positions of the switch and the pneumatic valve

Caution Risk of Injury !

Turn the main switch off.

Set the posit i on s of th e s w i tc h b1 and the pneumatic valve 3 only with

the main switch turned off.

–

Slide switch b1 after loosening the clamping screws.

–

Set pneumatic valve 3 so that it is opened by the surface 4 on the

transport carriage.

–

Tighten the clamp ing screws again .

–

Attach the cover plate.

7

Page 8

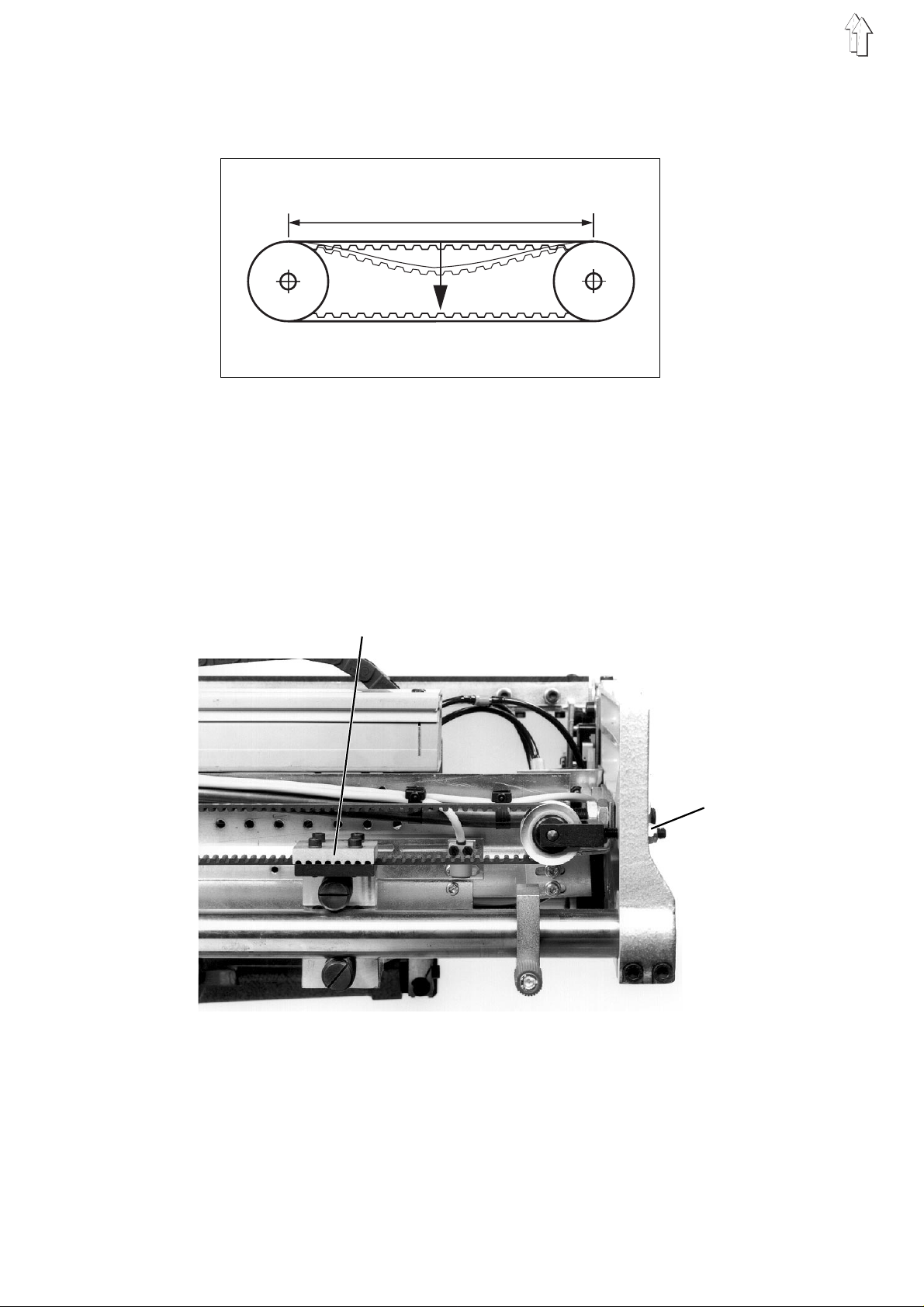

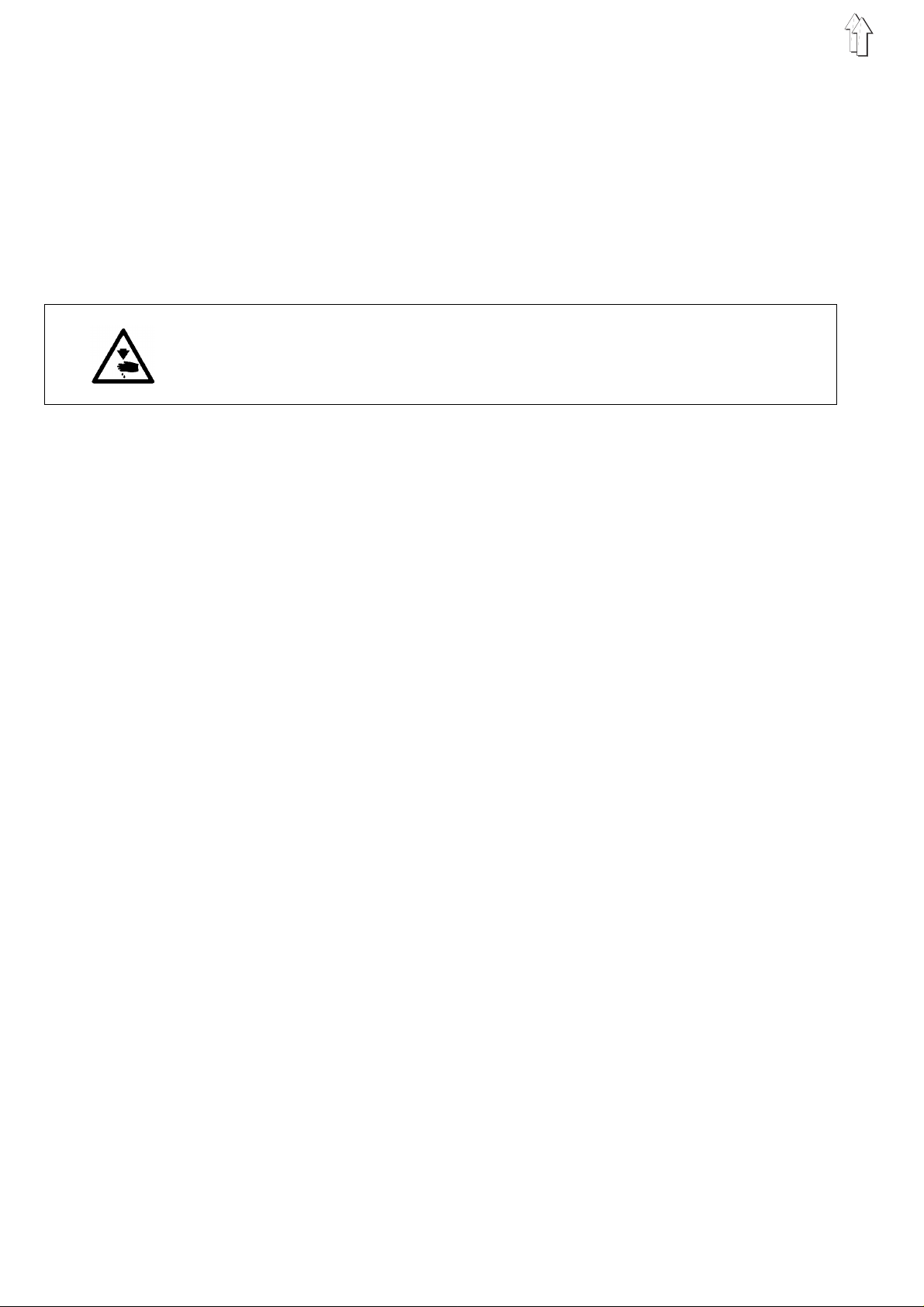

2.4 Timing Belt Te nsion

At the middle of the belt section S the timing belt must bend in 13 mm

under the test l oa d F V = 500g.

S

{

Consequences of too high timing belt tension:

–

Reduced life

–

Running noises

Consequences of too low timing belt tension:

–

No flawless tooth interlocking between the belt teeth and the pulley

teeth

–

Jumping of the teeth under load

1

2

–

Attach the tes t loa d i n th e m i dd le t he ti m i ng be lt (e .g . with the aid

of a spring scale).

The timing belt is correctly tensioned when the upper half of the

belt just touches the lower half of the belt.

To correct:

–

Correct the ti mi n g bel t te ns i o n a t n ut 2.

The nut 2 is e qu i pp ed wi t h a s el f -l oc k i n g t hre ad.

8

Page 9

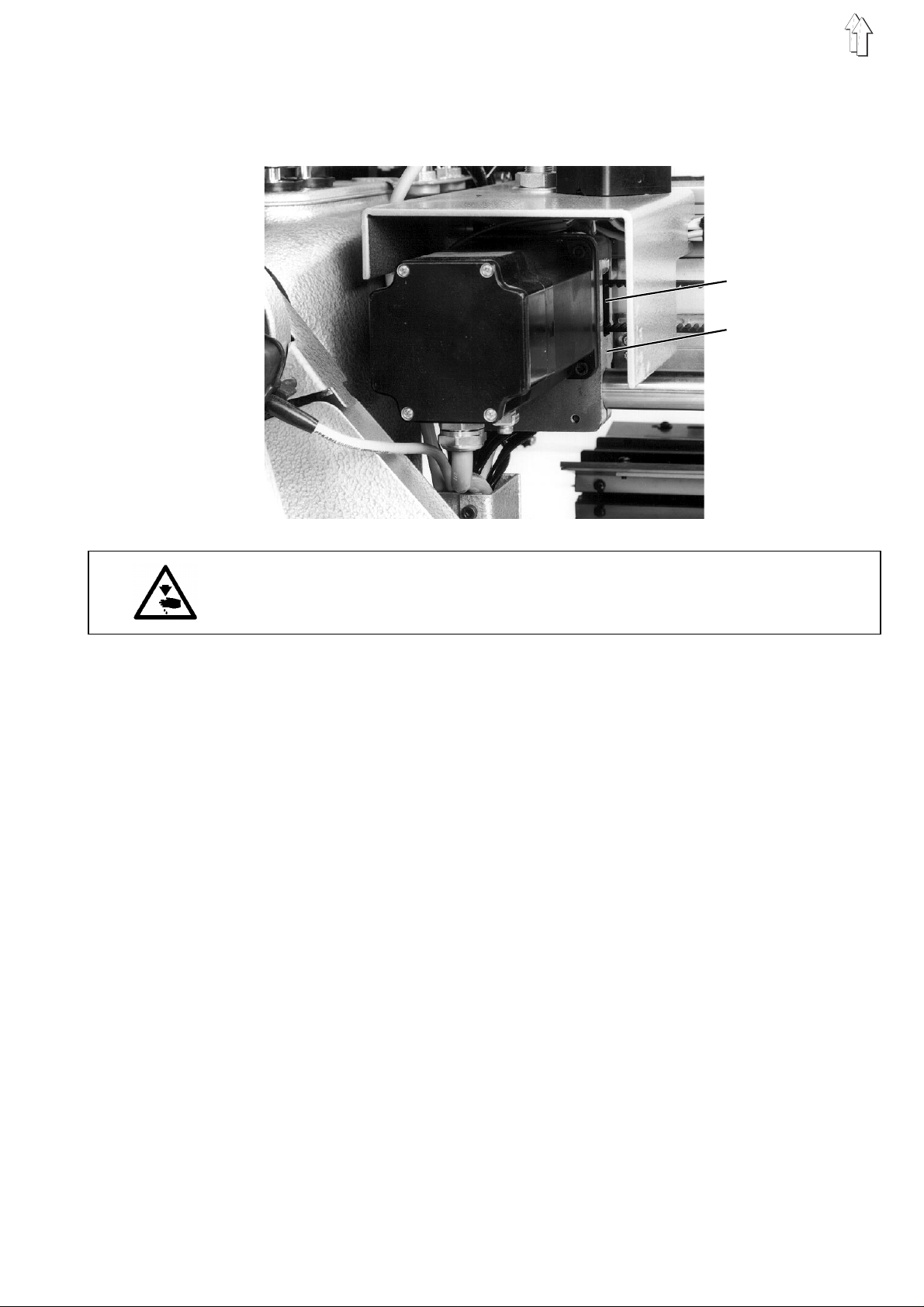

2.5 Changing the Timing Belt

To simplify changing, the timing belt is split.

It is held together by the timing belt clamp 1.

3

4

Caution Risk of Injury !

Turn the main switch off.

Change the timi n g b el t on ly wi t h t he ma in s w i tc h tu rne d o ff.

Remove the old timing belt

–

Loosen the four clamping screws on the timing belt clamp 1.

–

After loos en i ng th e t i mi n g b el t c lamp 1 pull the ti mi n g b el t ou t o f

the housing 4.

Inserting the new timing belt

–

Push one end of the timing be l t t hr o ug h t he op ening 3 on the

timing belt p ul l e y of th e s t ep mo to r.

–

Carefully turn the timing belt pulley for placement of the timing belt

with a suitable tool.

The timing be l t p ul l e y i s ac cessable throug h t he opening 3.

–

To connect the two timing belt ends slacken the timing belt tension

a little at nu t 2.

–

Join the tw o t i mi n g b el t en ds w i th th e t i mi n g b el t c lamp 1.

–

Set the timi ng be lt tension (see Chap te r 2. 4).

9

Page 10

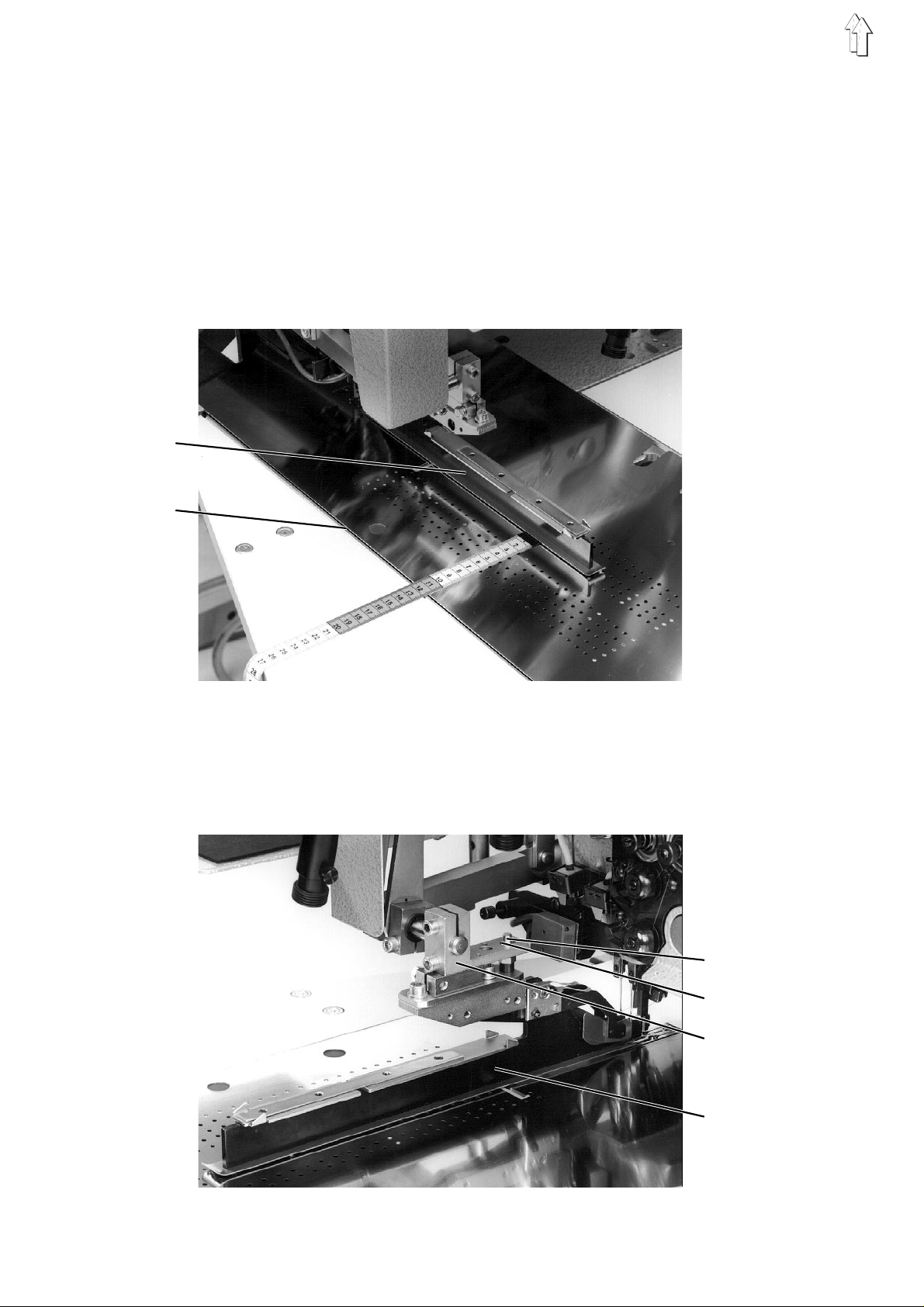

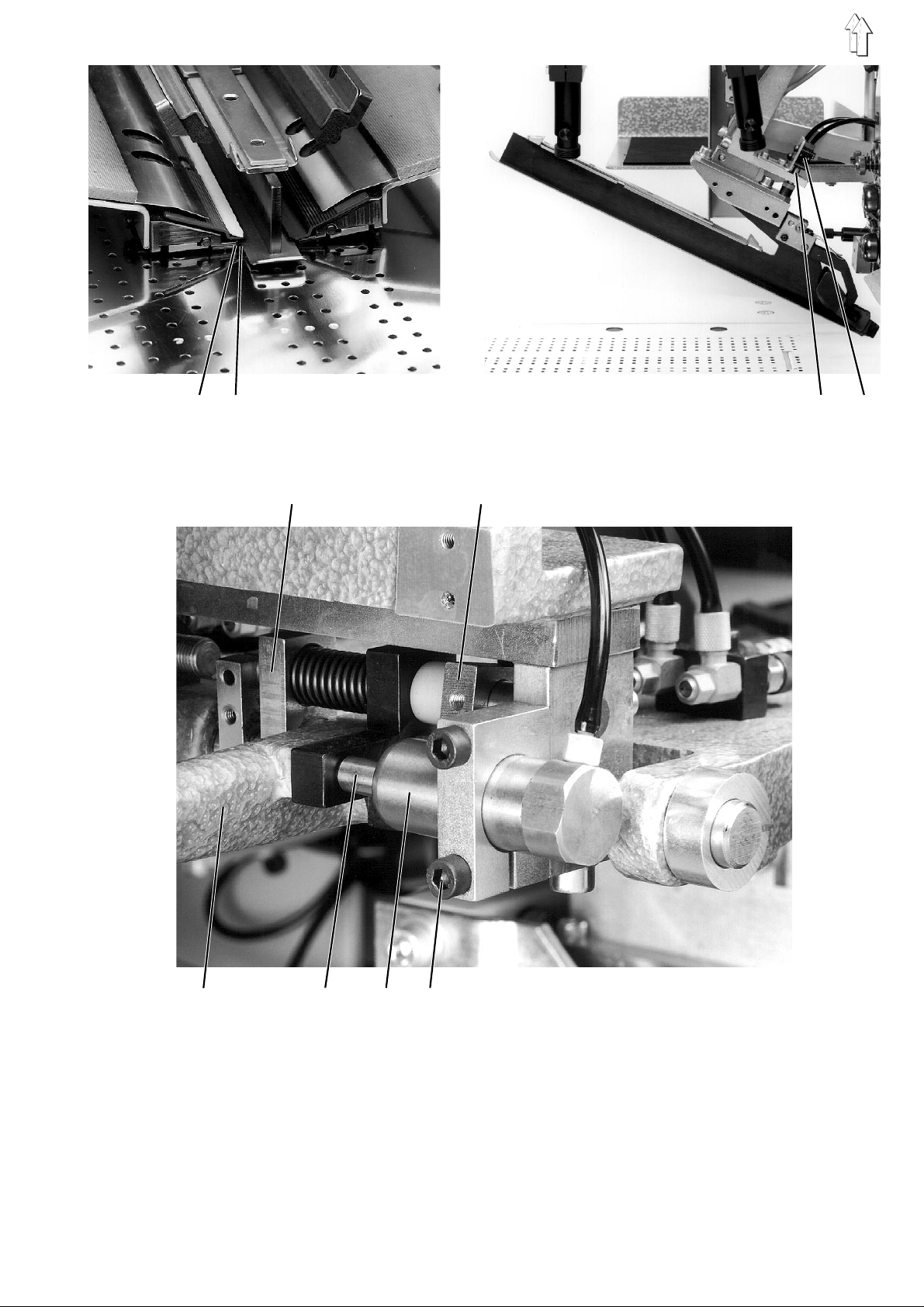

3. Folder

For the unimpaired transport of the material and a flawless fabrication

of the pocket o pening, the fold i ng an d c u tt i ng to ol s , as w el l a s th e

marker light s , m us t be al i g ne d t o t he c en te r of th e p oc k e t o pe ni n g.

The incision of the center knife is seen as the center of the pocket

opening.

The measurem en t l in e 2 was traced on th e machine plate at th e

factory.

It runs parall e l to th e c e nt er o f t he po c k et op en i ng , t hat is, to the

center knif e i n ci s i on at a c l e ara nc e of 12 5 m m.

By proper mounting of the fol de r 1 i t c an be al igned from the

measurement l i n e t o t he c en te r of th e p oc k e t o pe ni n g

(see Chapter 3. 2) .

1

2

Proper mounting of the folder:

–

The folder 1 is p us h ed up on to the clamping piece 5 until it to uch es .

–

The pin 3 catc h es i n s l ot 4.

3

4

5

1

10

Page 11

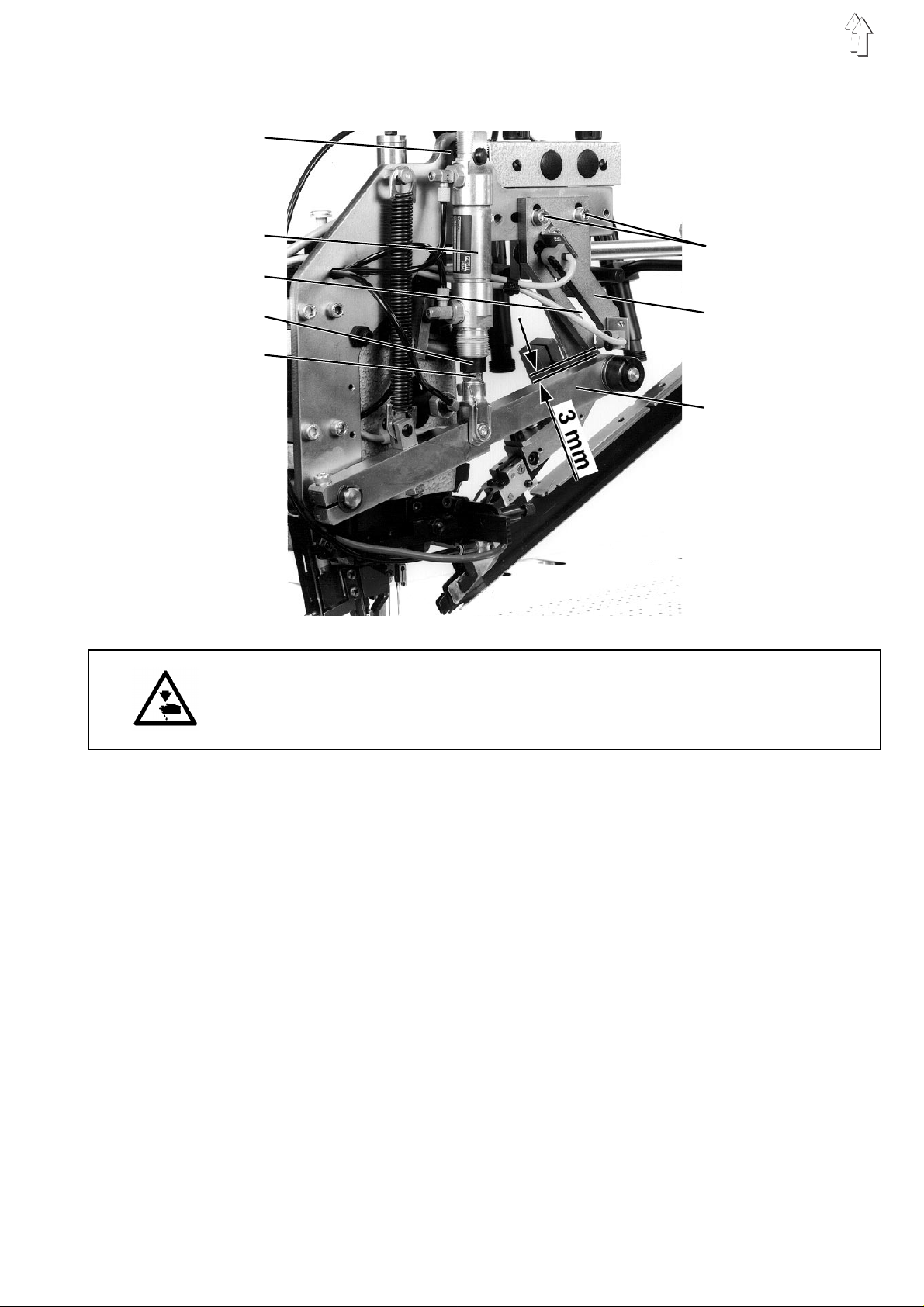

3.1 Stroke Movement of the Folder

6

10

7

11

8

9

12

13

Caution Risk of Injury !

Turn the main switch off.

Set the stroke movement of the folder only with the main switch turned

off.

With the folder raised:

There must be a safety clearance of 3 mm between the lever 13 and

the bottom of the curve piece 12.

–

Loosen nut 6.

–

Set the mounting of the cylinder 7 higher or lower accordingly.

–

Tighten nut 6.

With the folder lowered:

The clearance between the folder sole and the cloth slider plate must

be 2 mm along the wh ol e l engt h.

–

Loosen nut 10.

–

Set the clearance between the bottom of folder sole and the cloth

slider plate by turning the piston rod of the cylinder 7.

–

If the roller lays on in the lowest point of the curve path 8:

Loosen screws 11.

Set the curv e p i ece 12 lower.

11

Page 12

–

Loosen clamp i ng s cr ew 14 .

–

Turn the folder slig htly on the axle 15.

There must b e a un i fo rm c l e ar a nce between the fo l de r s ol e an d t he

cloth slider plate along the whole length.

–

Tighten clamping s c rew 14 and nut 10.

–

In the lowest p osi t i on of th e f ol d er s e t t he cur ve pi e c e 1 2 a s

follows:

There must b e a c l ea rance of 0.5 mm between the rolle r and the

lowest point of the curve path 8.

–

Tighten screws 11.

Proximity switches b4 and b5

The proximity switches b4 and b5 monitor the t w o en d p os itions of the

folder.

Switch b4: Monitoring of the upper folder position

switch b5: Monitoring of th e l o we r fol de r po s iti o n

The checking of the correct switch settings occurs in program

–

–

–

–

–

–

–

14 15

P63

Turn the main switch on.

Set the "

Press the "

The program i s ac t i vated.

Set the "

The display shows the switching status "-" or "+".

Loosen the mounting screws on the switch b4 or b5 slightly.

Align switch b4 and b5 to the roller i n th e c o r res p on di n g f ol d er

positions. The display must show the switching status "+".

Tighten the mounting screws of the switch again.

Program

STOP

Program

" switch to "63".

" key

" switch to "4" (switch b4) or "5" (switch b5).

11

:

b4

12

12

8

b5

10

16

Page 13

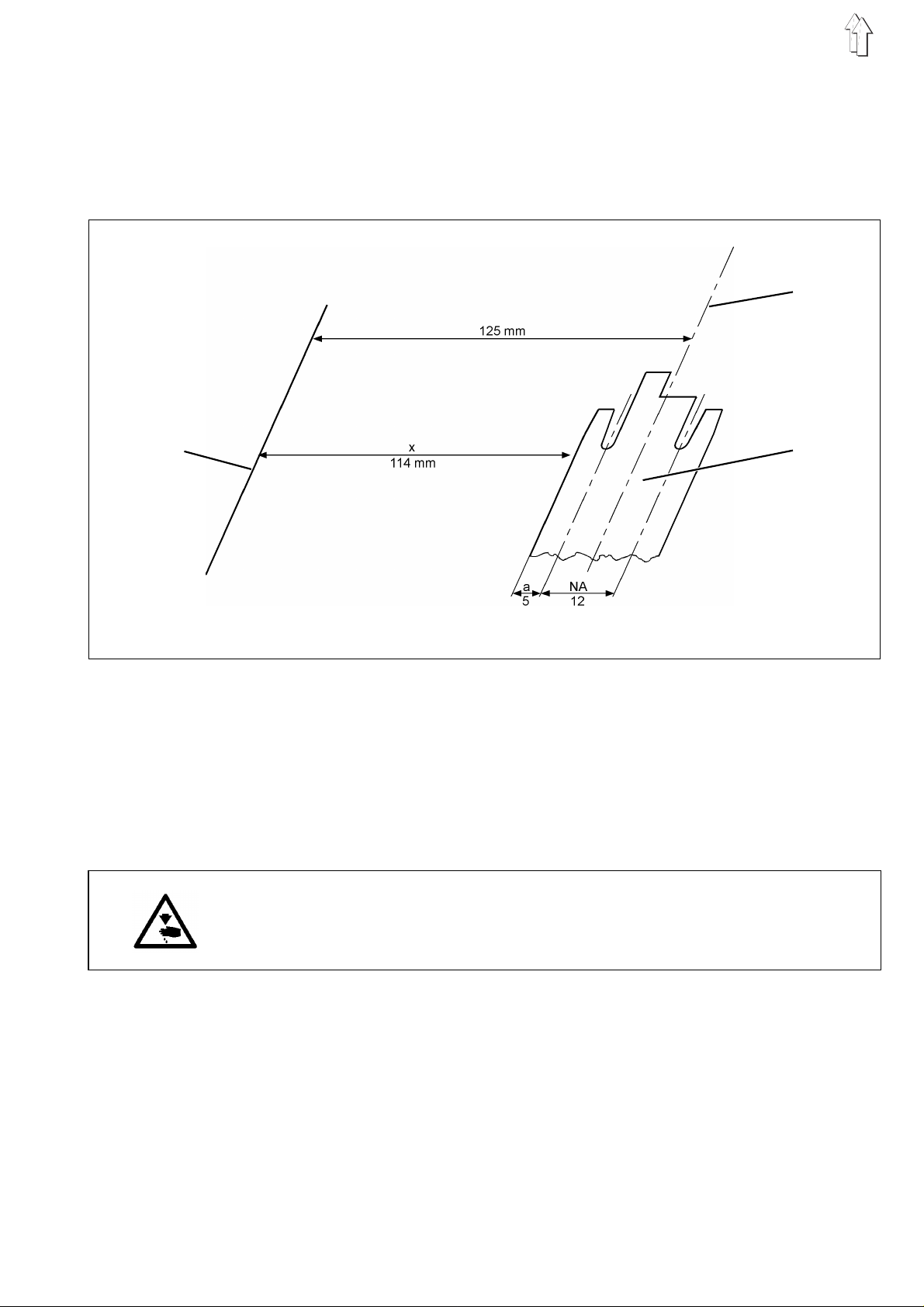

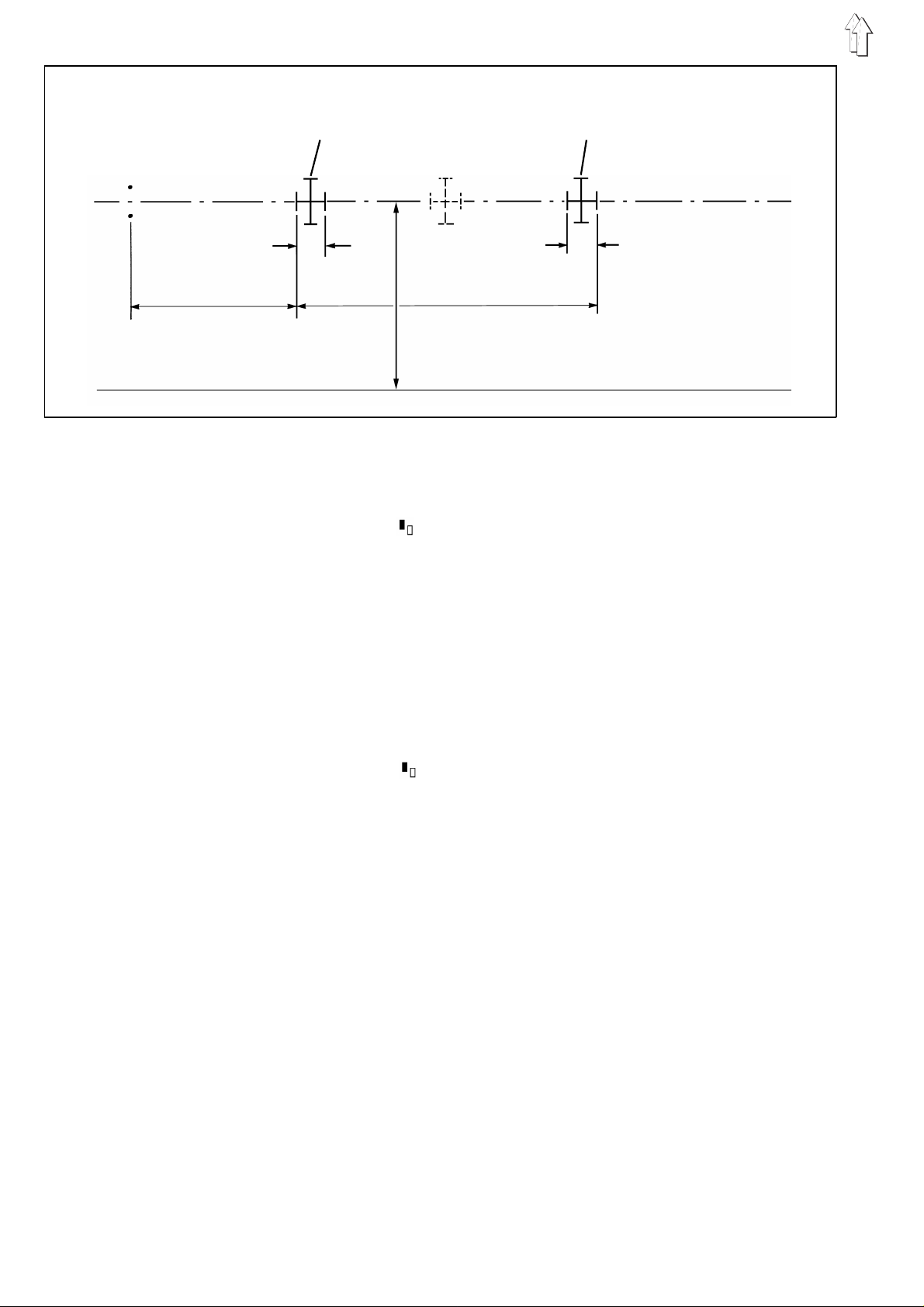

3.2 Aligning the Folder to the Center of the Pocket Openi ng

When properly mounted the folder can be aligned from the

measurement line 17 to the center of the pocket opening.

Dependent on the width of the folder sole 19 the dimension x can be

establishe d. W i th th e a i d o f t hi s d i me ns io n the folder can be ali g ne d to

the center of t he pocket openi ng 18 an d p ar a l lel t o the measuremen t

line 17.

18

17

19

–

Subtract th e p i pi n g w i dt h a and half of the

needle clearance NA from the dimension 125 mm.

Example f rom the sketch : 12 5 mm - a - 1/2 x NA x

125 mm - 5 mm - 1/ 2 x 1 2 m m = 114 mm

Piping widt hs a nd ne edle clearance s fo r ot her folders can be fo un d

in the Operating Instructions.

Caution Risk of Injury !

Turn the main switch off.

Align the folder to the center of the pocket opening only with the main

switch turned off.

–

Loosen screws 16 slightly.

–

Align the folder sole parallel to the measurement line 17 with the

aid of a measur i n g s t i ck .

–

Tighten screws 16.

–

Loosen clamping screw 14 slightly.

–

Set the clearance x (in the examp l e x = 114 mm) betwee n

measurement l i n e 1 7 a nd th e l e ft ed ge of the folder so le 19.

For this slide the folder sideways.

–

Tighten clamping screw 14.

13

Page 14

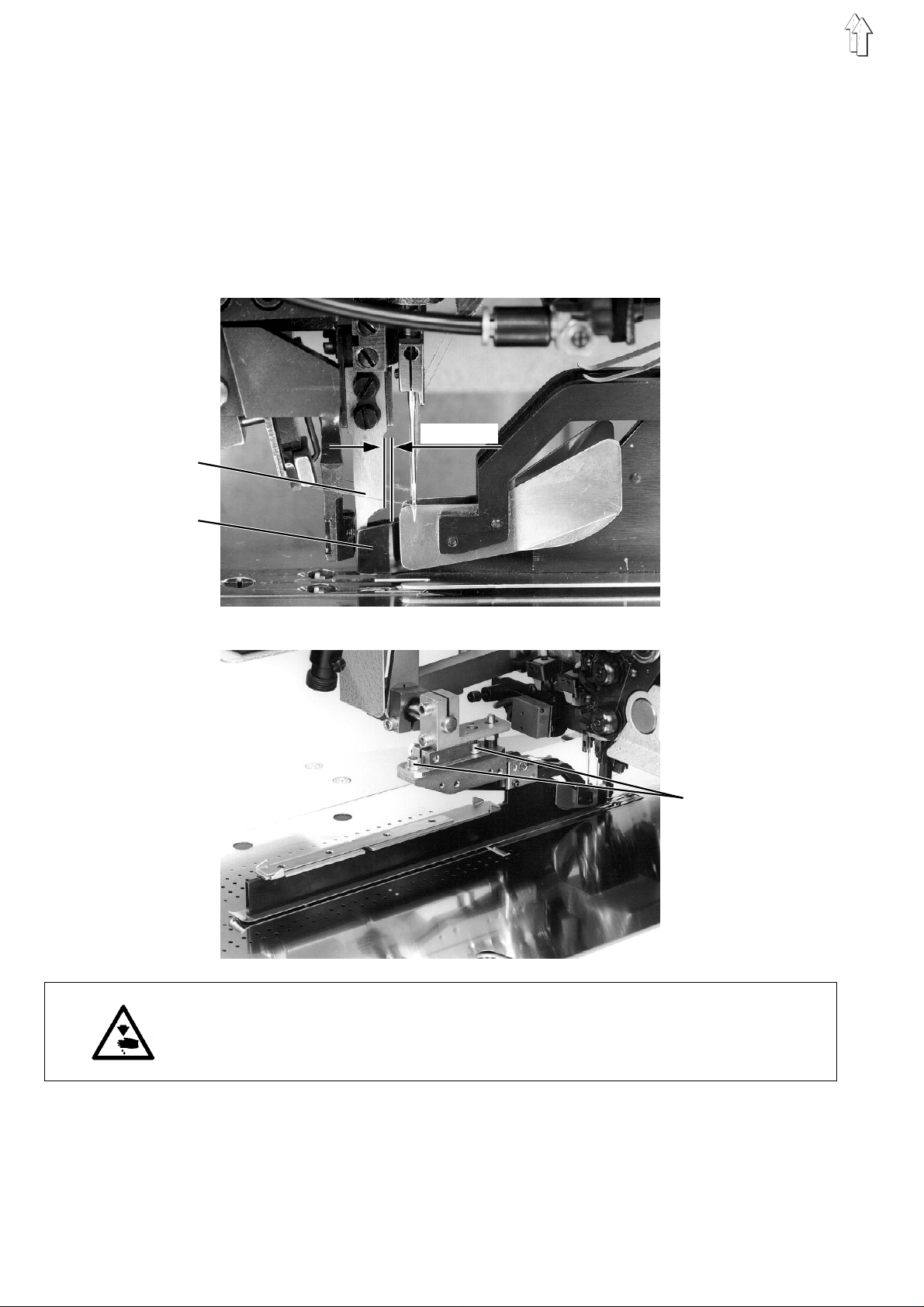

3.3 Position of the Folder to the Needles and the Center Knife

With a properly mounted folder the following positions must be

attained:

–

In the most forward position the needles must enter the needle

holes of the folder sole unhindered (without being deflected).

–

When the center knife 1 enters the knife guard 2 in the most

forward position there must still be a clearance of 0.5 to 1 mm

between the front edge of the knife and knife guard.

0,5 - 1 mm

1

2

3

Caution Risk of Injury !

Turn the main switch off.

Align the fol d er t o t he ne ed l es a nd th e c e nt er k n if e on l y wi t h t he main

switch turned off.

To correct:

–

Loosen screws 3 slightly.

–

Slide the fol d er i n th e d i rec t i on of tr a ns p ort .

–

Tighten screws 3 ag ai n .

14

Page 15

3.4 Guide Plates on the Folder

With the needle bar link in the most forward position the edges 2 of the

guide plate s mu s t e x te nd ap pr o x . 1 mm to th e r e ar b ey o nd th e n ee dl e s .

The leaf springs 1 hold the guide plates down on the folder sole with a

slight pressure.

The pressure must so dimensioned that the sprung guide plates can

be easily raised by the piping strip running in or by the flap.

1

2

1 mm

Caution Risk of Injury !

Turn the main switch off.

Correct the pressure of the leaf springs only with the main switch

turned off.

To correct:

–

Set the pres s ure by a dj u s ti n g t he l ea f s p r ing s 1.

15

Page 16

4. Clearance of the T ransport Clamps to the Folder Sole

There must be a certain cleara nc e be tw ee n t he outer edges 2 of t he

folder sole and the inner edges 1 of the transport clamps. By medium

weight cloth for ready-made clothes it must be e.g. 1 to 1.5 mm.

The clearance is necessary in order to assure uniform piping widths on

both sides an d a n u nh i nd er e d t r an sport of the mater i al.

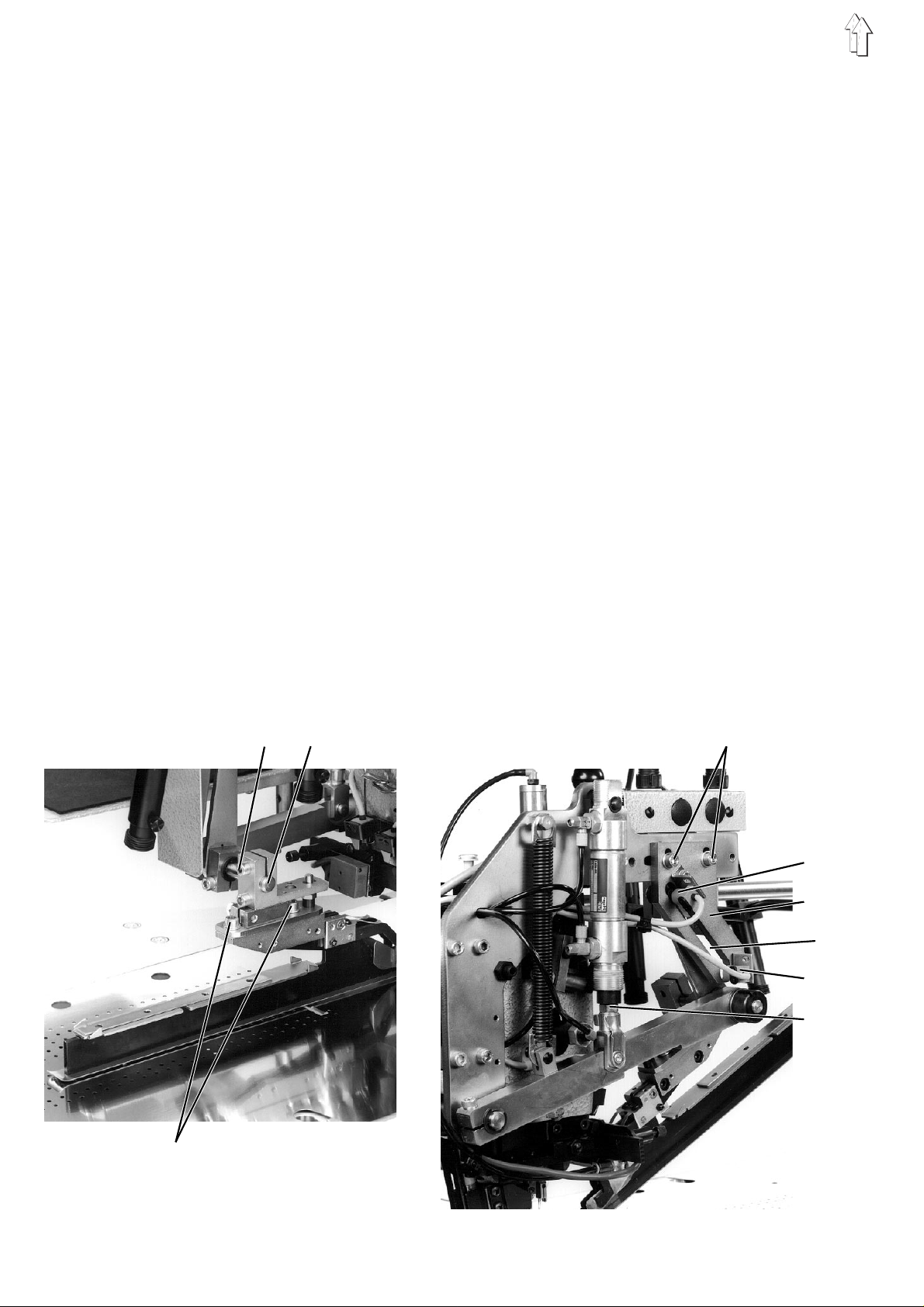

4.1 Manual Adjustment of the Transport Clamps (745-22)

With the

the Allen screws 6.

With the

The scale plates 8 serve as setting aids.

–

–

–

ATTENTION !

The markings on the scale plates 8 are matched to the needle

clearance of the machine head.

When attaching need le holders for other needle clearances the scale

plates 8 must al s o be r ep lac e d.

745-22

745-23

To set th e c lea r an c e tu rn the Allen screw 6. To turn use the socket

wrench 5 to be found in the acc ess o r i es p ac k .

The scale plates 8 were aligned at the factory as follows:

When the poi n te r 7 p oi n ts t o t he marking "I" the correct clearance

for sewing medium weight material of two-sided piped pocket

openings is set.

The second marking gives the clearance for sewing a greater

piping width or a one-sided piped pocket opening.

By stepping fo r wa r d o r ba c k on th e l e ft pe da l c on du c t t es t run s

with the tr an spo r t c a rr i ag e.

The transport clamps must pass the guide plates 4 and the thread

catcher 3 unhindered.

745-24

and

only the rig ht tr a ns p ort clamp is set m an ually.

both transpor t c l am ps a re s e t by turning

Pneumatic qu i ck cl amp adjustment

By frequent changes of the folder between single and dual piping the

pneumatic qui c k cl a mp ad j us t me nt s i mp l i fi e s the setting of th e

transport cl am ps .

With the

clamp adjustment as standard equipment (Description see

Chapter 4.2).

With the

(Order no. 792 00 5981).

745-23

745-22

the left trans p or t c lam p has the pneumati c q ui ck

745-24

and

it is available as option al e qu i pm en t

16

Page 17

12

5

34

6

7

8

17

Page 18

4.2 Pneumati c Quick C lamp Ad justm ent (7 45-23)

With the

clamp adjustment as standard equipment.

When changing the the folder between single and dual piping the left

transport clamp correctly sets itself automatically.

The clearance between the outer edges 2 of the folder sole and the

inner edges 1 of the lowered transport clamps is dertermined as

follows:

–

–

Caution Risk of Injury !

Turn the main switch off.

Set the quick c l a mp ad j us t me nt on l y wi t h t he ma i n switch turned off.

Folder for dual piping

Presetting :

The clearance between clamp arm 7 and clamping piece 5 must be

approx. 3 mm wi t h t he pi s t on r od 8 f ul l y e x te nd ed .

–

–

745-23

For dual piping by the position of the cylinder 9 with air.

For single piping by the position of the stop 6.

Insert the fol d er f or dual piping.

The extended pi n 3 o pe r at es t he v al ve 4 for the quick c l am p

adjustment.

The correct c learance of the tra ns p or t c l am ps to the folder s ole i s

automatically set.

Slide the tr an s po rt c a r ri ag e m an ua l l y un ti l t he tra ns p or t c l am ps l i e

at the level of the folder sole.

the left trans p or t c l am p h as t he pneumatic qui ck

–

Loosen clamp i ng s cr ew 10 .

–

Set the clearance between the folder sole and the inner edges of

the lowere d t ran s po r t cl a mp s by s li d i ng th e c y l inder 9.

–

Tighten clamping s c rew 10.

Folder for single piping

–

Insert the fol d er f or s i n gl e pi p i ng .

–

With the quick clamp adjustment vented and touching the stop 6

check the clearance dimension of 1 to 1.5 mm between the

transport clamps 1 and the folder sole 2.

To correct:

–

Loosen the clamping screws on the stop 6.

–

Slide the st op 6 i n th e a pp r op r iate direction.

–

Tighten the clamping screws again.

18

Page 19

12

3 4

5 6

7 8 9 10

19

Page 20

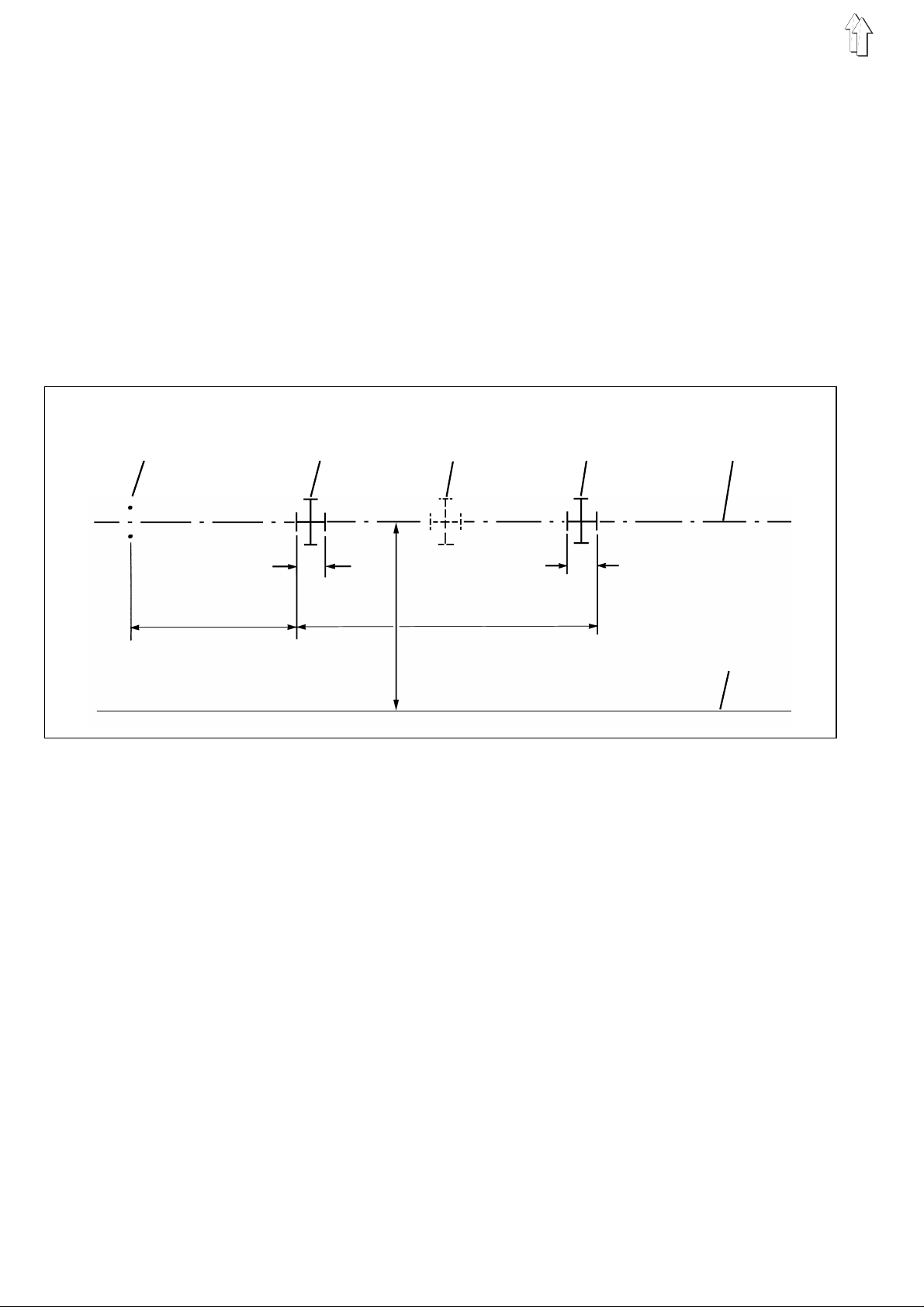

5. Marker Lights

1 2 3 45

The light markers 2 and 4 limit the sewing area.

Alternatively a 3rd marker light, available on request, can be attached

(Order no. 793 02 20 68 ) .

The multiple masks built into the lamp optics make possible the

following application:

–

Because of th e s m al l H - li gh t markers a clear a nc e of 10 mm

between che s t d art and flap edge c an be ac h i ev e d i n th e

positioni ng of j ac k e t f ron ts .

By setting the marker lights higher the clearance can be increased

to a maximum of 15 mm.

–

Turn the marker light 90°.

Clearances f r om 15 mm to a m ax i m um of 25 mm c an be s et by

setting the l a rge H-l i g ht ma rk er h i gh er o r l ow er.

10

111

1

: Needles

2

: Light mark er -f or w ar d po s i tio ni n g p oi n t

3

: 3rd marker l i g ht ( on req ue s t)

After setting the marker lights higher or turning them it is essential that

the following points be observed:

–

Reset the lamp ho l der.

–

Align the li g ht ma r ker s congruent to the c e nt er o f t he po c k et

opening.

–

Keep to the maximum sewing area.

10

180

125

6

4

: Light marker-rear positioning point

5

: Center of the po c ket op en i ng

6

: Measuremen t l i n e

20

Focusing the light markers sharp

–

Loosen clamp i ng s cr ew 13 s l i gh tl y.

–

Focus the lig ht marker sharp by s e tt i ng th e t ub e 1 4 higher or lower.

–

Tighten clamping s c rew 13.

Page 21

10

11

7 8 9

12

13

14

Aligning the light markers

All light markers must be aligned to the cutting line (center of the

pocket openi ng 5) .

The clearance between the lengthwise lines of the H-light markers and

the measurement line 6 must be 125 mm.

–

Loosen the clamping screws 8 of the lamp holder 12 slightly.

–

Set the lam ps h i gh er o r lower in the lamp ho l de rs 12 .

There must be a cl e ar a nc e of 10 mm be tween the crosswise lines

of the small H-light marke r ( s ee sk et c h) .

–

Turn the lamps in the lamp holders 12.

The crosswise line of the H-light marker must lie parallel to the

measurement l i n e 6 .

–

Tighten clamping screws 8.

–

Loosen the cl a mp i ng s c rews 11 on the hold er block 10 slig ht l y.

–

Set the clearance of the light markers to the measurement line 6

by pushing in or pulling out the lamp holder 12.

–

Tighten clamping screws 11.

–

Loosen clamping screws 7 slightly.

–

Slide the ho l de r bl o c k 10 on the support axle 9.

The clearances to be set between the light marker and the

forward-lyi n g n ee dl e s are to be found in the s k e tc h .

–

Tighten clamping screws 7.

21

Page 22

2 4

111

10

180

125

Check the exact position of the light markers

Light marker 2 (seam beginni ng ) :

–

Set the " " key on the front panel of the control unit to

"Positioning point-forward".

The LED above the key is lit.

–

Designate the desired seam beginning with a chalk mark on the

sewing piece.

–

Position the s e wi n g p iec e wi t h t he cha l k ma rk on th e f orw ar d

crosswise line of light marker 2.

–

Start the sew i ng pr o c ed ure .

The seam must begin on the chalk mark.

–

To corr ec t : R ea l i gn ma r ker l ight 2 after loos e ni n g i t s holder.

10

Light marker 4 (seam end):

–

Set the " " key on the front panel of the control unit to

"Positioning point-rear".

The LED above the key is off.

–

Make an analog ous check of the a l i gn me nt of the light mar ker 4 fo r

the seam end.

22

Page 23

6. Knife Brackets for the Cutting of the Corners

Caution Risk of Injury !

Do not reach into the area of the corner knives.

The rapidly rising corner knives can cause serious cuts.

Presetting:

The clearance between the cutting edges of the corner knives in the

knife bracke t " s e am en d" a nd th e f or w ar d - ly i ng ne ed l es m us t be

130 mm

(745-22;-23)

or 135 mm

(745-24)

(see sketch).

ca. 1-2 mm

130 mm (

135 mm (

The measuring and setting is to be made at the w i de s t p oi n t o f t he

corner knife with the knife bar raised.

–

Tilt the machine he ad to the back.

–

Set the clea r an c e d i me nsi o n o f 1 30 mm by t urn i ng th e s t op

screw 1 (

2 are in the ar ea un de r th e h oo k s.

–

The knife incisions must end at the seam beginning before the first

and at the seam end before the last stitch (see sketch).

This corresp on ds t o t he front edge of th e f l ap an d the rear edge of

the flap with the flap sewn on.

745-22 and 745-24

745-22;-23

745-24

) or 2 (

)

745-23

)

). The stop screws 1 and

745-22, 745-24: 745-23:

1

2

23

Page 24

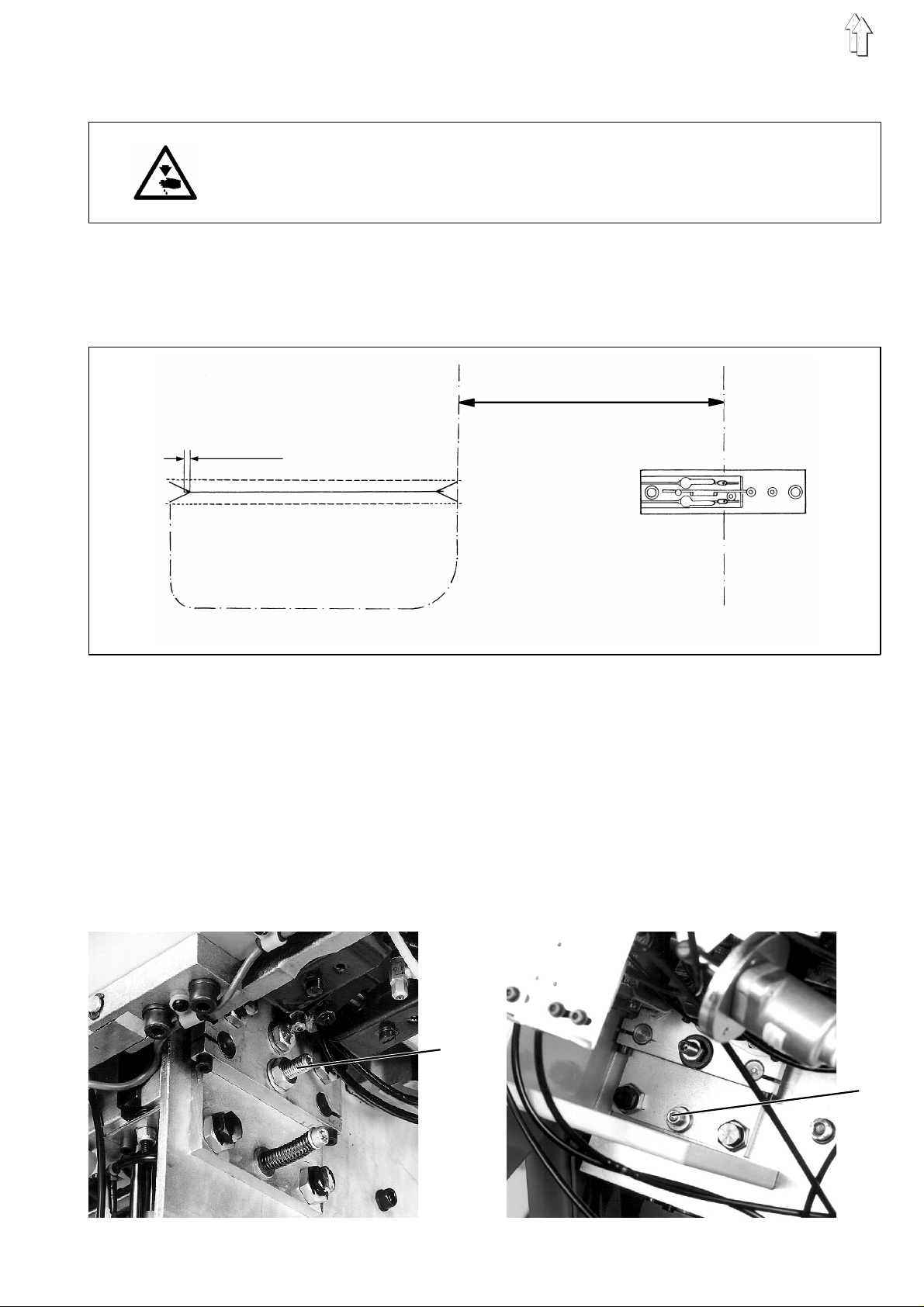

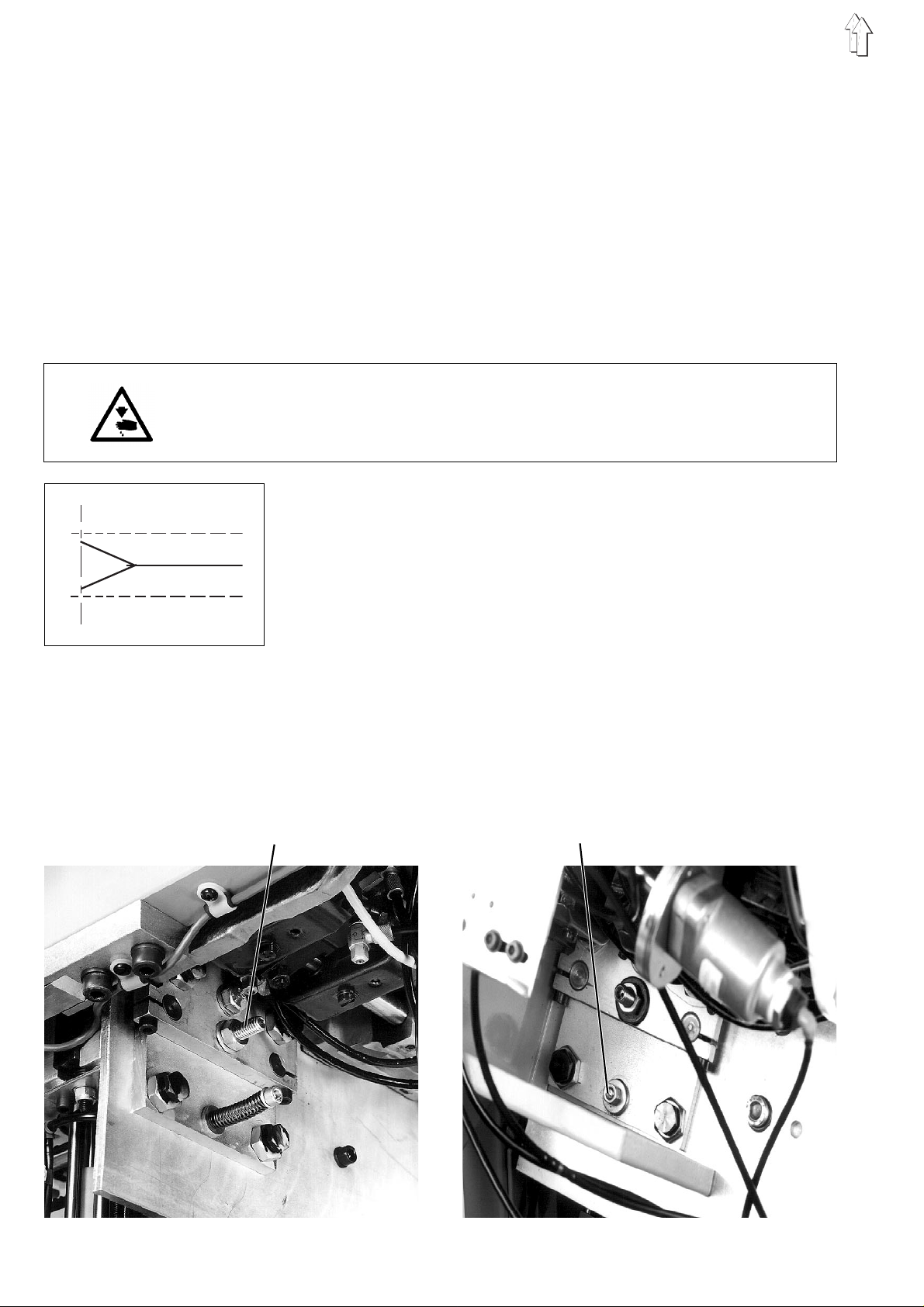

6.1 Adjusting the Position of the Corner Incisions

–

Call up the lo ng est s ew i ng di st an c e (e .g . 1 50 mm ) with the L1 key

on the front pa ne l of th e c o nt rol u ni t .

–

Conduct a trial s e am .

It is useful to first iron a piece of nonwoven fleece onto the sewing

piece. This shows the corner incisions well.

–

Check the seam and cut patterns.

–

To correct: Make the following settings.

Presetting:

–

Set the corr ect i on v al u es f or s e am be gi n ni n g ( N A ) an d seam end

(NE) to the m ed i an v al u e 5 0 (n o c o r rec t i on )

(see Short De sc r ipt i on Mu l tic o nt r ol) .

Caution Risk of Injury !

Turn the main switch off.

Adjust the position of the corner incisions only with the main switch

turned off.

Adjusting the corner incision of the knife bracket "seam

beginning"

The knife bracket "seam beginning" must cut up to

stitch (see sketch).

–

745-22;-24:

745-23:

–

Set the position of the corner incision at the seam beginning by

sliding the knife bracket 2.

–

Tighten clamping l ev e r 3 or screw 5 agai n.

Loosen the clamping lever 3.

Loosen screw 5 .

in front of

the first

745-22; -24:

Adjusting the corner incision of the knife bracket "seam end"

The knife bracket "seam end" must cut up to

–

If necessary, correct the corner incisions of the knife bracket

"seam end" a t s t op s c rew 1 (

745-22; -24

1

745-23:

2

in front of

) or 2 (

745-23

the last stitch.

).

24

Page 25

745-22: 745-23:

745-24:

3 4

5 4

3 4

25

Page 26

Adjusting the scale

With the

corresponding to the sewing distance (in the example 150 mm) must

lie congrue nt to th e e dg e 6 of the knife brack et 2

–

–

745-22

Loosen screw 9 slightly.

Set the scale 7 with the dimension 150 mm (see Example)

congruent to th e e dge 6 of the knife br a c ket 2.

and

745-23

the scale 7 with the dimension

("seam beginning")

.

With the

sewing dist an c e ( in the example 150 m m) m ust lie congruent to the

edge 15 of the k n i fe bra c k et 11

–

–

Thus the scale is also correctly set for the changeover to the sewing

distances L 2 a nd L3 ( see O pe r at i ng In s tru c ti o ns ).

Aligning the corner incisions to the seams

The corner incisions must lie symmetric to the seams (illustration a).

The clearance of the incision ends to the seams must be equal on both

sides (illustration b).

745-24

Loosen screw 10 slightly.

Set the scal e 1 4 w i th th e dimension 150 mm (s ee E x am pl e )

congruent to the edge 15 of the knife bracket 11.

a) b)

the scale 14 w i th th e d i me ns i o n c o rr es p on di n g t o t he

("seam end" )

.

–

Loosen screw 8.

–

Turn rod accordingly.

Set a clearance of approx. 5 mm between the block 1 and the knife

bracket 2 with the cylinder run in on both subclasses. The safety

clearance prevents a striking of the piston rod in the cylinder.

–

Tighten screw 8.

–

Set the same cl ea r an c e b et we en i nc i si o n e nd and seam on both

sides.

745-22

745-23

745-24

Setting the stroke speed of the corner knives

–

Regulate the stroke speed at the one-way restrictor valves 5

(745-22; -23)

The rising m ov e me nt s ho ul d be r ap i d, bu t n ot j erk y.

: Turn stop nut 4.

: Turn the eccentric 9.

: Turn stop nut 12.

(745-24)

or 13

.

26

Page 27

745-22: 745-23:

1 2 3

5 mm

7 9

745-24:

4 5 6 7 8 9

10 11

2 6 5 7 9

12 13 14 1 5

27

Page 28

6.2 Adjusting the Knife Brac kets for Bias Corne r Incisions (745 -24)

Caution Risk of Injury !

Turn the main switch off.

Adjust the knife brackets for bias corner incisions only with the main

switch turned off.

Do not reach into the area of the corner knives.

The rapidly rising corner knives can cause serious injuries through

cuts.

Aligning the scale plate 9

–

Turn star knobs 7.

The height of the stopper pla te s 5 must be set so t ha t t he s c rews 4

lie at the ce nt er o f t he s l ot s 3.

–

Loosen screws 8.

–

Set the heig ht of th e s c a le plate 9.

The wide mar k er l i n e 1 0 i n th e m i dd l e o f t he s c al e mu s t li e at one

level with th e l o we r ed ge s 6 o f t he s to pp er p l at es 5 .

–

Tighten screws 8.

Setting the awl rod and knife rods

The setting i s m ad e w i th ga ug e 11:

ATTENTION !

Only at the

–

Remove block 18 including stop screw 1.

Loosen screws 17 for this.

–

Loosen screws 27.

–

Remove clamping pieces 16 and corner knife 26.

–

Loosen screws 14.

–

Remove the awl rod 25 .

–

Loosen clamping screws 23, 32 and 33.

–

Insert gauge 11 into the groove of the awl r od 13 .

–

Tighten screws 14.

–

Turn the forks 22 on the knife rods 21.

The knife rods should be guided tight but still be easily movable.

Unhook the tension springs 24 and 34 to check.

–

Set the knife rods 21.

The upper edges of the knife holders 12 and the gauge 11 must be

at the same level.

–

Set the awl ro d 13.

When the clamping piece 31 is at its lower rest, the gauge 11 must

touch on position plate 15.

–

Tighten screw 32.

–

Align the knife holders 12.

The knife ho l de rs 12 mu s t l a y pa ral l e l on to th e o uter edges of the

gauge 11.

"seam beginning"

knife bracket.

28

Page 29

1 2

–

Turn the awl rod 13 and knife rods 21 ac c o rdi n gl y.

–

Tighten the clamping screws 23 and 33 again.

–

Check the ease of movement of the knife rods 21 and the awl

rod 13.

–

Attach the block 18 at the

It is then ess e nt i al t o s e t t he ba s e p os ition of the posi t i on pl a te 28 .

Setting the base position of the position plate 28 of the "seam

beginning" knife bracket

The base posi t i on of th e p os i t i on plate 28 is set at th e f ac t or y.

It must only b e r e s et af te r th e re mo v al o f t he bl o c k 18 (e.g. for settin g

the awl rods a nd k ni f e r o ds) .

–

Loosen lock nut 2.

–

Turn back the stop screw 1 slightly.

–

Turn the setting sc rew on star knob 20 un ti l its surface 19 l i es

centered in block 18.

–

Set the base position of the position plate 28 with the stop screw 1.

In the base position the marker lines on the knife bracket 29 and

on the positi on pl a te 28 must lie prec i s ely a bo v e o ne an ot her.

–

Tighten lock nut 2.

"seam beginning"

knife bracket again.

3

4

5

6

7

11

10

8

9

8

12

13

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

32

33

14

15

24

34

29

Page 30

6.3 Changing the Corner Knives (745-22 and 745-23)

Blunt corner knives are to be replaced with the knife set in the

accessories pack.

Please find th e o r de r numbers for the c or n er k n i fe s et s i n C ha pt er 1 of

these Service Instructions.

Caution Risk of Injury !

Turn the main switch off.

Change the cor ner k niv e s on l y wi t h t he ma in s w i tch tu r ne d o ff.

Danger of cuts!

Do not reach i nt o t he s ha r p b l ad es of the corner kn i v es.

1

2

3

45

–

Screw out screw 4.

–

Pull the knife holder 5, complete with the corner knives 2 and the

awl 1, off of the knife bar.

–

For safe working, clamp the knife holder 5 in a vise.

–

Loosen clamp i ng s cr ew 3.

The clamping collar in the knife holder 5 is released.

–

Remove awl 1 and both corner knives 2.

–

Insert new corner knives in the slits of the knife holder 5.

Attention!

The angle-g rou nd bl a de s mu s t s h ow to th e outside.

–

Insert the awl 1 into the appropriate drilled hole.

–

Push both cor n er k n i v es i n to th e k n i fe ho l de r 5 u p t o t he s to p.

Thereby bring the corner knives to the back until they touch the

awl 1.

–

Tighten clamping s c rew 3.

–

Push the knife holder 5 onto the knife bar up to the stop.

–

Tighten screw 4.

30

Page 31

6.4 Changing the Cor ner Kniv es (745-2 4)

Blunt corner knives are to be replaced with the knife set in the

accessories pack.

Please find th e o r de r numbers for the c or n er k n i fe s et s i n C ha pt er 1 of

these Service Instructions.

Caution Risk of Injury !

Turn the main switch off.

Change the cor ner k niv e s on l y wi t h t he ma in s w i tch tu r ne d o ff.

Danger of cuts!

Do not reach i nt o t he s ha r p b l ad es of the corner kn i v es.

1

2

3

4 5

–

Loosen screw 3.

–

Remove corner knife 2.

–

Carefully pu s h t he ne w c o rner knife 2 betw ee n c lamping piece 4

and knife hol de r 5.

Attention!

The angle-gro un d s u r fa c e 1 of th e c o rne r k ni f e 2 mu s t show to the

outside.

–

Tighten screw 3.

31

Page 32

7. Adjusting the Piping Reverser (745-23)

The corner cutting device of the

piping reve rs er.

The piping rev e r s er p ul l s t he s ew n-on piping stri p w i th c or n er i n c i si on s

(only dual p ipi n g) o nt o t he other side of th e m at eri a l .

1 2 3

745-23

a)

b)

is additionally equipped with a

ca. 25 mm

4 5 6 7

Caution Risk of Injury !

Turn the main switch off.

Set the piping reverser only with the main switch turned off.

Clearance between the cutting and reversing position

The knife brackets 5 and 6 are in the cutting position when cylinder 1

has air (see illustration a).

After the venting of cylinder 1 they move outward in the direction of the

arrow into the reversing position (see illustration b).

In the reversi n g p os i t i on th e r e ver s ing tools 2 and 3 m us t s ecurely

engage the pi pi n g strip when retra c ti n g.

The corner incision, however, should not be damaged by the retracting

reversing tools.

With a correc t s et ti n g t he c l ea rance between th e cu tting and the

reversing position is approx. 25 mm.

The stop screws 4 and 7 determine the position of the reversing tools

in the reversing position.

3

32

–

Correct the re v er si n g p os i t i on of th e k n i fe br a ck et s 5 a nd 6 b y

turning the s t op s c rews 4 and 7 in or o ut .

Page 33

Height of the extended piping reverser

With fully extended piping reversers the clearance between

their upper edge and the cloth slider plate must be approx. 115 mm.

1

2

3

115 mm

4

–

Loosen lock nut 4.

–

Set the height of the extended piping reverser by turning the rod 3.

Thereby align the reversing tools of the piping reverser parallel to

the pocket opening.

–

Secure rod 3 against turning and tighten lock nut 4.

Converting the reversing tools by altered needle clearance

When changing to another needle clearance NA:

–

Replace the rings 1.

–

Adjust the number of plates 2 to the new needle clearance.

Note:

The individual operating steps of the piping reverser can be tested in

the aid programs P43 to P45

(see Short Description Microcontrol).

33

Page 34

8. Setting the Cloth Slider Plate and Support Plate

The cloth sli d er p l at e 1 i s to be so aligned that i ts cutout has the sa me

clearance to both sides of the needle plate elevation.

The support plate 6 must be at one level with the base plate of the

machine head.

ATTENTION !

Turn the main switch off.

For safety re as o ns the cloth slid er p l at e 1 i s on ly un l oc k e d in the

transport car ri a ge end position an d w i th th e m ai n s wi t c h t ur n ed off.

1

3

2

7

4

5

6

7

–

Remove the cl ot h s l i d er p l at e 1 (see Operati ng In s tru c ti o ns ).

–

Loosen screws 3 slightly.

–

Set the cloth slider plate 1 forward by sliding the holder plate 2.

–

Tighten screws 3 ag ai n .

–

Loosen the sc r ew s to be fo un d u nd er p l at e 4 .

–

Set the cloth slider plate 1 at the rear by sliding the plate 4.

–

Tighten the screws un de r pl a te 4 a ga i n.

–

Set the support plate 6 at one level with the table top by turning the

setting screws 5 and 7.

34

Page 35

9. Stroke Height of the T ransport Clamps

With the flap c l am ps (o ptional equipm en t) cl o s ed th e r a i sed tr a ns p ort

clamps must pa s s th e machine arm wit ho ut hitting.

With the

1 of the raise d t r an s po rt c l a mp s an d t he c l ot h s li d er p l at e 2 mu s t b e

approx. 30 mm.

With the

transport cl am p.

The clearanc e t o t he cloth slider p l at e m us t be ap pr o x. 4 0 mm.

If the sewing u nit

0791 011161 (c l am p l e ft ) and/or 0792 01116 2 (c l a mp r i gh t), th e

clearance of the flap clamps to the slider plate is 40 mm.

745-22

745-23

and

a greater stroke height is required for the

745-22

745-24

and

the clearanc e be tw ee n t he forward edges

left

745-24

is equipment with flap clamps

3

ca. 30 mm (745-22 u. 745-24) ca. 40 mm (745-23) ca. 19 mm (745-22 u. 745-24)

1 2

–

Step back on th e l e ft pedal.

The transport carriage runs into its rear end position.

Caution Risk of Injury !

Turn the main switch off.

Set the strok e he i gh t o f t he tr a ns p ort clamps only w i th th e main switch

turned off.

–

Turn the main switch off.

–

Raise the cover hood.

–

Remove the compressed air hoses at the cylinders 3.

–

Loosen lock nut 4.

–

Set the stro k e h ei g ht of th e transport cla mp s at the cylinder s 3.

Increased stroke: Screw cylinders 3 in

Decreased stroke: Screw cylinders 3 out

–

Attach the compressed air hoses to the cylinders 3 again.

–

Tighten lock nut 4.

4

35

Page 36

9.1 Clearance of t he flap c lamps to t he slider plate

If the sewing unit is equipment with flap clamps 0791 011161 (clamp

left) and/or 0792 011162 (clamp right), the clearance of the flap clamps

to the cloth slider plate should be 40 mm.

1

1: Flap clam p

2: Slider pl a te

3: Transport clamp

2 3 4

4: Center of the po c k et

opening

Caution Risk of Injury !

Turn the main switch off.

Set the flap cl am ps o nl y w i th th e m ai n s wi t c h t ur n ed off.

5

6

10. Synchronizer

–

Losen screw 5.

–

Set stop 6.

The clearanc e of th e flap clamps t o t he c loth slider plat e s h ou l d b e

40 mm.

–

Tighten srew 5 again .

It is practica l to firs t s et th e 2 nd ne ed le p os i t ion .

2nd needle position: Needle high position

With the needle bars turned off in the highest position the thread lever

must position 2 mm behind its upper dead center.

–

Turn the main switch off.

–

Bring the thread lever into a central position by turning the

handwheel.

–

Turn the main switch on.

The sewing unit positions in the needle high position (Position 2).

–

Check the position of the thread lever.

If necessary, correct the positioning.

Caution Risk of Injury !

Turn the main switch off.

Correct the positioning only with the main switch turned off.

36

–

Loosen clamping screws 2 on the synchronizer collar 1.

–

Hold the synchronizer collar 1.

–

Move the threa d l e v er 2 mm behind its up pe r de ad center by

turning the handwheel.

–

Tighten the clampin g s c rews 2.

–

Check the positioning again.

Page 37

1st needle position: Needle low position

The 1st needl e p os i t i on tri g ge r s th e swing timing of th e n ee dl e

bar link for the seam bartacking at the seam beginning and the seam

end.

The light screen 3 determines the precise swing timing through its

position. The slewing movement of the link must occur outside the

material.

3

2

4

1

2

Caution Risk of Injury !

Turn the main switch off.

Set the light screens only with the main s wi t c h t ur n ed off.

–

Remove the cover of the synchronizer after loosening the

mounting screws.

–

Loosen clamping screw 5.

–

Turn light screen 4 .

The light apertures of the light screens 3 and 4 must lie exactly

opposite eac h o th er (displaced 180°).

Attention!

When turning light screen 4 light screen 3 should not also turn.

–

Tighten clamping screw 5.

5

ATTENTION !

The light screens should not turn when the clamping screw 5 is turned.

–

Turn the main switch on.

–

Set the "

–

Press the "

The program is activated.

The left half of the display shows "SW".

–

Preselect the rpm of the sewing drive with the "

Set the "

–

Press the "Σ" key and release again.

The machine h ea d p os i t i on s i n t he 1st needle pos i t i on .

–

Check the p osi t i on i ng ag ai n .

Program

STOP

Program

" switch to "67".

" key

Program

" switch to "13" (maximum rpm ).

" switch.

37

Page 38

1 1. Machine Head

11.1 Crank Pin on the Arm Shaft

The clearance of the eccentric crank pin 1 to the arm shaft 4

determines the size of the needle bar stroke and thus the upper dead

center of the needle bars.

The crank pin 1 i s p rec i s e ly s et at th e factory!

After a replcement of the thread lever the crank pin 1 must be reset.

12

3

4

The setting of the crank pin 1 is made with the gauge 13

(Order no. 246 00 25 91 ) . T h e cr a nk a nd th e a r m sh aft need not be

removed for the setting.

Caution Risk of Injury !

Turn the main switch off.

Set the crank p i n o nl y with the main s wi t c h t ur n ed off.

–

Turn the main switch off.

–

Loosen screw s 7 and 9.

–

Remove the cylinder 11 with swing lever 12.

–

Remove the he ad c ove r 10 af te r l oo sening the mounti ng s c rews.

–

Take out t he ne ed l e b ar l i n k ( s ee Ch ap te r 11.2.4).

5

6

38

–

After screw in g out its mounti ng s c rew ( A tt en ti o n: l ef t- h an de d

thread!) lo os e n t he ne ed l e t i e rod from the crank p i n 1 an d p ul l o ff

with the needle cage.

–

Turn the handwheel until the Allen screws 2 point downward.

The Allen screws 2 are accessable in this position.

–

Loosen the Allen screws 2.

–

Swing the thread tension plate 8 away to the side after loosening

its mounting screws. The drilled hole underneath in the machine

arm is freel y ac cessable.

–

Loosen the support screw 3 accessable through the drilled hole.

Page 39

–

Insert gauge 13 wi t h i t s pe gs i n to th e a c cep ti n g h ole s 6.

–

Turn the crank pin 1 so that it catches in the recess in the gauge.

–

Press the crank pin 1.

The thread lever 5 must be set tight except for a lubrication gap.

–

Tighten the Allen screws 2 and support screw 3.

–

Remove gaug e 1 3.

–

Check the ease of movement of the machine by turning the

handwheel.

–

Place the needle tie rod with the needle cage on crank pin 1 and

tighten its m ou nting screw (A tt en ti o n: l ef t- h an de d t hr e ad !) .

–

Replace the needle bar link and set (see Chapter 11.2.4).

–

Reattach the head cover 10 and cylinder 11 with swing lever 12.

7

10 11 1 2

8

9

13

39

Page 40

11.2 Needle Bar Link

11.2.1 Slewing Movement

For securing the seams the seam beginning and the seam end are

made with stitch condensation and seam bartacking (slewing the

needle bar link) or only stitch condensation.

–

Turn seam bartacking on and off by pressing the " " key on the

front panel of the control unit. With seam bartacking turned on the

LED above the key is lit.

–

By 1.4 mm sti tc h l en gt h i n s ti t c h co nd ensation the se am ba rt a ck i ng

is generally turned off.

The slewing of the needle bar link at the seam beginning and seam

end occurs t hro ug h t he cylinder 2.

After the setting of the eccentric axle 4 the seam bartacking plus the

needle trans po r t g i ve a s wi n g r a ng e o f a pp r ox . 3. 5 m m.

The slit 7 must lie in the lower semicircle of the eccentric axle 4.

In the idle pos i t i on of th e c y l inder 2 (spring r et ur n po s iti o n) t he

clearance o f t he ne ed l es (n ee dl e th i c k ne ss Nm 10 0) t o t he fo r wa r d

edges of the n ee dl e ho l e m ust be 0.2 to 0.3 mm .

The needle tr an s po rt i s f or ci b l y acuated after entr y i n to the material.

The swing timing for the seam bartacking must be moved outside of

the material by s e tt ing th e s y n chr o niz e r ( see Ch ap te r 10 ).

1

2

13,5 mm

3

5

4

6

7

40

Page 41

–

Step back on th e l e ft pedal.

The transport carriage runs into its rear end position.

Caution Risk of Injury !

Turn the main switch off.

Set the slew in g movement of the n eedle bar link o nl y w i th th e m ai n

switch turned off.

–

Remove the c yl i n de r an d swing lever for th e t hr e ad pu l l er a nd

head cover wit h f ol d er.

–

Clamp a suitable spacer 3 (13.5 mm thick) between cylinder 2 and

nut 5 of the pi s to n ro d.

–

Press the latch 1 down.

Bring the needle bars into the low position by turning the

handwheel.

–

Loosen clamping screw 6.

–

Turn the eccentri c ax l e 4 u nt i l th e n ee dl e s en te r in the middle of

the needle hole.

The slit 7 must thereby lie in the lower half of the semicircle of the

eccentric ax l e 4.

–

Tighten clamping screw 6.

–

Remove spacer 3.

The needles a re i n th e forward positi o n.

–

The clearanc e of th e forward edges of th e n ee dl e (needle

thickness Nm 100) to the forward edges of the needle hole must

be 0.2 to 0.3 mm .

–

Loosen screws 9 slightly.

–

Set clearance by setting the holder plate 8 higher or lower.

–

Tighten screws 9.

8

9

41

Page 42

11.2.2 Setting the Needle Bar Link to the Needle Bars

For a sure turning on and off of th e needle bars the needle bar link

must be precisely set to the needle bars.

The setting i s m ad e w i th ga ug e 3 ( Or de r no . 2 46 00 09 19 ) .

Caution Risk of Injury !

Turn the main switch off.

Check and correct the setting of the needle bar link to the needle bars

only with the main switch turned off.

Checking the setting

–

Press latch 1 down.

Switch in t he ne ed le b ar s b y tu rni n g t he ha nd wh ee l .

–

Push the 2.6 mm high setting side of the gauge 3 into the drilled

hole 2 on the machine arm.

The gauge must seat itself without play between the needle bar

link 9 and th e c l a mp i ng c oll a r s 10 of th e n ee dl e ba r.

–

Bring the needle bars into the high position by turning the

handwheel.

A little resistance must be felt.

–

Push in the 2.8 mm high setting side (marked by the drilled hole).

With a correct setting this side of the gauge should

be pushed in between the needle bar link and clamping collars.

–

Turn the handwheel.

The handwheel should

dead center.

not

be able to

not

be able to be turned beyond the upper

Correcting the setting

–

Loosen screws 6.

–

Loosen lock nu ts 7 .

–

Set the clear a nc e be tw ee n t he needle bar lin k 9 a nd th e c l a mp i ng

collars 10 by turning the setting screws 4 and 8.

Decreasing the clearance: Turn the lower setting screw 8 clockwise

Increasing the clearance: Turn the upper setting screw 4 counter

clockwise

Each setting screw lying opposite must first be turned back.

After the setting is made, turn th e s e tt i ng sc r ew l yi ng op po si te

against the pin 5.

–

Tighten screws 6.

–

Tighten lock nuts 7 .

–

Check the set ti n g with gauge 3 agai n .

–

Check the setting of the center knife and adjust, if necessary

(see Chapter 11.12).

42

Page 43

12

9

0,2 mm

10

3

45 6

7

8

43

Page 44

11.2.3 Turning on the Needle Bars

With cylinder 6 not operated the needle bars are turned off and

arrested in the high position.

The extending piston rod of the cylinder 6 operates the latch 3.

The couplin g-i n of th e n eedle bars occu rs at th at moment in whic h th e

crosshead re ac h es its upper dead cen t e r.

Caution Risk of Injury !

Turn the main switch off.

Make the sett in g only with the m ai n s wi t c h t urn ed off.

ATTENTION !

The subclass

The 2nd latch is to be set in the same manner.

To turn on the needle bars manually:

–

Press the latch 3 down and hol d op er a te d.

–

Couple in the needle bars by turning the handwheel.

–

If latch 3 is no t h el d op er a te d t he ne ed l e b ar s u ncouple in the hi gh

position at th e next revoluti on .

745-24

is equipped w ith two latches.

In the highest (unoperated) position of the latch 3:

The clearance between the bottom 2 of the stopper 1 and the

edge 4 of the l at c h m us t be

–

Set the clear a nc e by s l i d i ng th e c yl i n de r 6.

In the lowest (operated) position of the latch 3:

The swing lev er 9 wi t h i t s bo tt om 8 m us t mo v e p ast ap pr o x.

above the edg e 4 of th e l a tc h .

–

Loosen the lock nut on setting screw 7.

–

Pull the lat c h 3 to th e b ac k a ga i ns t th e s t op pe r 1.

Press latch 3 down into its lowest position manually and

–

Turn the handwheel until the swing lever 9 moves into the recess

of the latch 3.

The bottom edge 8 of the swing lever lies opposite edge 4 of the

latch.

–

Set the clearance between both edges by turning the setting

screw 7.

Measure the clearance with a feeler gauge.

–

Tighten the lock nut on setting scre w 7 .

Position of the swing lever 9:

When the cylinder 6 is vented the latch 3 with its shoulder 4 catches

under the stop pe r 1.

At its furthest swing to the ba ck (in the direction of the arrow) the

swing lever 9 must still just push the latch 3 off of the stopper 1.

–

Swing the swing lever 9 out of the area of the latch 3 by turning the

handwheel.

–

Release latch 3.

The latch catches with its shoulder 10 under the stopper 1.

–

Loosen clamp i ng s cr ew 13 s l i gh tl y.

0.5 mm

.

1 mm

hold fast

.

44

Page 45

12

–

Turn the handwheel un ti l the swing lev er 9 ha s r ea c he d its furthest

swing to the ba c k ( i n t he di re c ti o n o f the arrow).

–

Turn the swing lev er 9 on th e s h af t 11 so that the sh oulder 10 of

the latch is still just pushed off of the stopper 1.

–

Tighten clamping screw 13.

–

Attach all removed parts (head cover, cylinder with swing lever for

the thread pu ll er ) a ga i n.

Position of the needle bars to the center knife:

–

The needle bars must move counter to the center knife. With the

needles lying low the drive lever 12 must be in its upper dead

center.

–

It is essential to make a precise setting as per Chapter 11.12.

6

7

34 5

34 8 9

1

10

9

11

12

13

45

Page 46

11.2.4 Removing and Attaching the Needle Bar Link

Caution Risk of Injury !

Turn the main switch off.

Remove or atta ch t he ne ed l e b ar l i n k on l y wit h t he ma i n s w i tch tu r ne d

off.

1 2 3 4 5 6 7

12 13 1 4

15

16

17

18

8 9 10 11

Removing the needle bar link

–

–

–

–

–

–

–

–

–

–

ATTENTION !

Do not

The link frame is set at the fa ctory with the setting screws 2 so

that the cros s he ad do es n ot hi t .

19

Loosen screw s 8 and 11.

Remove cylin de r 9 w i th th e s w i ng lev e r 10 .

Remove the he ad c ove r af te r l oo sen i ng th e mounting screws.

Loosen clamp i ng s cr ew 13 s l i gh tl y.

Pull the knife drive lever 14 off of shaft 12 (Attention wedge!).

Loosen screws 19.

Remove guide p lat e 1 8.

Loosen screws 5.

Carefully p ul l the holder pla te 7 w i th ne ed l e b ar li n k 15 off of the

stop pin 1.

The pulling-off is made easier with a little turning back and forth.

If necessar y l oo s en on e s e tt i ng s cr ew 2.

loosen both setting screws 2.

46

Page 47

–

Loosen clamping screw 4 slightly.

–

Pull out the bearing bolt 3.

–

Remove the holder plate 6 from the needle bar link 15.

Attaching the needle bar link

–

Mount the needle ba r link 15 with bearing bolt 3 on holder plate 6.

–

Tighten clamping screw 4.

There must be a l u bri c a ti o n c le ar a nc e be tw ee n holder plate 6 an d

needle bar li n k 15 .

–

Insert the needle bar link.

The peg of the crosshead 21 must catch in the needle tie rod.

The peg 20 must c at c h i n th e p l at e 7 .

The sliding pad 23 must catch with its drilled hole over the peg of

the tie rod for t he l i nk swing movement.

–

Screw screws 5 in and tighten only slightly (because of a sett ing to

be made later) .

–

Remove the cover found on the head of the machine arm after

loosening the mounting screws.

–

Insert the oil w i c k 22 un de r th e o il fe l t i n th e m ach i ne arm wi t h a

screwdrive r.

The oil wick 22 serves for lubricating the needle bars.

–

Fasten guide plate 18 with the screws 19.

–

Loosen clamping screw 16 slightly.

–

Press bolt 17 in until the ne ed l e b ar li n k 15 i s set close except fo r a

lubrication clearance.

–

Tighten clamping screw 16.

–

Check the ease of movement of the machine by turning the

handwheel.

–

Attach all removed parts (head cover, cylinder 9 with swing

lever 10) agai n .

20

21

22

23

47

Page 48

11.3 Hook Shaft Height

The clearance between the needle plate support 4 and the shoulder 1

of the hook shaft must be 17.7 mm.

The precise h ei g ht of th e hook shaft is s et wi t h the gauge 3

(Order no. 244 00 10 01 ) .

5 6

1 2 3 4

Caution Risk of Injury !

Turn the main switch off.

Set the hook shaft height only with the main switch turned off.

–

Remove the need l e p lat e.

–

Remove both hoo ks ( see Ch ap te r 11.9).

–

Place gauge 3 on the needle plate support 4.

The measurin g s l e ev e 2 o f t he ga uge must catch o ver t he pe g o f

the hook shaft.

–

Tilt the machine head to the back.

–

Remove oil ba ffle s 7 a ft er l o osening the mounti n g s c re w s.

–

Remove the pla sti c p lug s 6.

Loosen the sc r e ws f ou nd un de r th e p l astic plugs.

–

Loosen screws 5.

–

Remove the pres s ure pi n s 8.

–

Push the hook shaft with its shoulder 1 until under the measuring

sleeve 2 of t he ga uge.

–

In this posi ti o n t i gh te n t he s c rews found under t he pl a s tic p l ug s 6.

–

Slide the pr es su r e p i ns 8 up to th e s t op ag ai n s t t he ho ok shaft.

–

Tighten screws 5 on th e s u rfaces the press ure pi n s 8.

–

Attach the o il ba ffle s 7, ho ok a nd ne ed l e p l at e a gain.

7 8

48

Page 49

11 .4 Tooth Play of the Hook Drive

The tooth play between worm and worm wheel should be as little as

possible. E a s e o f m ov e me nt mu s t, ho we v er, remain a s sur e d.

After every adjustment of the hook drive in axial direction the to oth

play must be r e set.

1

2 3 4 5

Caution Risk of Injury !

Turn the main switch off.

Set the tooth play only with the main switch turned off.

–

Remove oil baffle 3 after loosening the mounting screws.

–

Loosen screw 4.

–

Loosen screw 1 slightly.

–

Loosen the cl a mp i ng s c rews of the worm wh ee l 3 s l ig htly.

–

Slide the worm wheel 3 axially.

The clearanc e b et w e en th e w or m wh ee l 3 a nd th e i n ne r si de of the

hook housing must be

The clearanc e m us t , a t t he right hook hous i n g, be at the right and,

at the left hook housing, at the left of the worm wheel.

–

Measure the clearance with a feeler gauge.

–

Set the toot h p l ay b y turning the ecce nt r i c bu shi n g 5 .

The tooth play between worm wheel and worm should be small but

still perceptible.

Increase tooth play: Turn bushing 5 upward

Decrease tooth play: Turn bushing 5 downward

–

Check the looping stroke (see Chapter 11.5) and the clearance

hook point - nee dl e (s ee Ch ap te r 11.7) and correct , i f ne c ess a ry.

–

Tighten screws 1 and 4.

–

Attach oil ba ffle 3 a ga i n.

0.3 mm

.

49

Page 50

1 1.5 Looping Stroke

The looping stroke is th e path of the needle bars from lower dead

center up to the point at which the hook points lie at the center of the

needle.

The looping stroke is 2 mm.

It is set with the arresting pin 4 (Order no. 0211 000700).

1

5

4

13,5 mm

2

3

Caution Risk of Injury !

Turn the main switch off.

Set the looping stroke only with the main switch turned off.

–

Remove the folder an d needle plate.

–

Remove the tops o f t he bo bb in c a s e 3 wi t h t he bo bb i ns.

–

Swing the needles to the center of the needle hole.

Here clamp a s ui t ab l e s p ace r 2 ( 1 3. 5 m m t hi c k) b et ween the

cylinder 1 and its piston rod.

–

Tilt the machine head to the back.

–

Remove the pla sti c p lug s 5.

–

Remove the scr ew s fo un d u nd er t he pl a sti c p lug s 5.

–

Tilt the machine head forward.

–

Push the arresting pin 4 through the drilled hole in the machine

arm.

The arresting pin 4 must catch in the groove of the arm shaft crank.

–

Turn the hook manually until the hook points lie at the center of the

needle.

–

Tilt the machine head to the back.

–

Tighten the first of th e s c rews found unde r th e p l as t i c plu gs 5 .

–

Remove the arre s tin g p i n 4 .

–

Tighten the second of th e s cr e ws f ou nd un de r th e p l as t i c pl u gs 5 .

–

Press the plastic plugs 5 into the drilled holes again.

–

Remove the spacer 2.

50

Page 51

11 .6 Height of the Needle Holders

For setting the needle holde r s 5 the needle 7 mus t l i e ab ov e th e c e nt er

of the the need l e h ol e an d i n th e l o op i ng s tro k e p os i t i on .

The clearance from the upper edge of the eye of the needle to the

hook point 8 mu s t b e 1 . 5 mm i n t hi s p os i t i on ( see s k et c h).

The setting is made with the measuring bridge 4 (Order no.

212 004942) and the setting pin 6 (Order no. 216 001070).

1 2

13,5 mm

3

7

0,1 mm

8

1,5 mm

5

6

4

Caution Risk of Injury !

Turn the main switch off.

Set the height the needle holders only with the main switch turned off.

–

The looping stroke must be set as per Chapter 11.5.

–

Remove the f ol d er and needle plat e.

–

Swing the n ee dl e s to th e center of the need l e h ol e .

Here clamp a su ita bl e s pa cer 3 (13 .5 mm th i c k) be tw ee n t he

cylinder 1 an d i t s pi s t on rod.

–

Remove the needles from the needle holders 5.

–

For turning t he needle holders t ur n on e o f t he needle bars off.

For this press latch 2 down and hold.

By turning the ha nd wh ee l at th e sa me ti m e, tu r n b ot h nee dl e ba rs

on.

–

Turn the handwheel fa rth er.

Before reac hin g the upper dead c en te r ma nu al ly p r es s u nd er t he

needle holder s 5 of th e n ee dl e ba r to be tu r ne d o ff.

A little resistance can be felt.

51

Page 52

11 12

10

3

9

5

6

4

13

Caution Risk of Injury !

Danger of cuts!

When working on the needle holders 5 do not reach into the area of

the center kn i fe 9.

–

Press under the need le holder 5 of the needle bar to be turned off.

At the same time turn the handwheel backwards.

The needle bar is turned off.

–

Bring the needle bar into the looping stroke position

(see Chapter 11.5).

–

Insert the arresting pin 10 through the drilled hole in the machine

arm.

The arresti ng pi n 10 mu s t c a tc h in the groove of th e a r m sh aft

crank.

–

Push the setting pin 6 into the needle holder 5 up to the stop.

–

Tighten screw 13.

–

Screw screw 11 out.

–

Turn needle holder 5 do wn wa rd.

It should be possible to push the measuring bridge 4 under the

setting pin 6 with the least po s si bl e pl a y.

–

If necessary, turn the needle holder 5 back (higher) accordingly.

The front su rfa c es 1 2 o f t he needle holder 5 mu st hereby face

forward and l i e at on e l e v el .

–

Screw in screw 11 in the needle holder 5 and tighten.

–

Remove arrest i ng pi n 10 an d s e tt i ng pi n 6.

–

Remove spacer 3.

52

Page 53

11 .7 Clearance of the Hook Points to the Needles

The clearanc e o f t he hook points t o t he ne ed l es m us t be 0. 1 m m.

It is precisely set at the factory with setting pin 5 (Order no.

244 001014).

The set clea ran c e m ak e s po ss i bl e th e w or k ing with needles w i th th e

needle thickness Nm 90 to Nm 110.

A correction of the clearance of the h oo k po i nt s to the needles i s not

required when changing between these needle thicknesses.

After a needl e c h an ge on l y th e n ee dl e gu ar d mu s t b e a dj u s te d

(see Chapter 11.8).

The setting o f t he l ef t h oo k point is to be ma de wi t h t he ne ed l e b ar l ink

swung forward.

The right hook point is set with the needle bar link swung to the back.

5

1 2 3 4

Caution Risk of Injury !

Turn the main switch off.

Set the cleara nc e of th e h oo k po i nt s to th e n ee dle on l y wit h t he ma i n

switch turned off.

–

The looping stroke and the needle holders must be set as per

Chapter 11.5 and 11.6.

–

Remove the f ol d er and needle plat e.

–

Remove the t op of th e b obbin case 4 wi th bo bb i n.

–

Screw the mounting screws 3 of the hook cover 2 out.

–

Remove hook cover 2.

–

Remove the bottom of the bobbin case 1 from the hook.

For this turn th e h an dwheel slight l y ba c k an d f or t h.

Attention!

Do not use force to remove the bottom of the bobbin case 1.

53

Page 54

–

Loosen screw 8.

–

Set the needl e gu ard 7 back by turnin g t he ec c e nt ri c bo l ts 6 .

–

Remove the need l e f rom th e n ee dl e ho lde r.

–

Push the sett i ng pi n 5 i n to th e n ee dl e ho l de r up to th e s t op .

–

Tilt the machine head to the back.

–

Remove the oil baffles 11 after loosening their mounting screws.

–

Loosen screws 10 and 13.

–

Slide the hoo k br a ck et 12 s ide wa y s .

The hook point should lightly touch the measuring surface 9 of the

setting pin 5, but not displace it.

–

Tighten screws 10.

–

Tighten screws 13.

–

Mount the oil baffles 11 again.

10

6

5

7

9

8

7

54

12

13

11

Page 55

1 1.8 Needle Guard

The needle guard 2 prevents a deflecting of the needle 4 into the path

the hook point 5.

Before the hoo k po i nt 5 r e ac h es the needle the ti p of the needle mus t

touch on the n ee dl e gu ard 2. The needle should not be allow ed to be

pressed int o t he pa th of th e h ook point 5.

With the hoo k po i nt l y i ng at th e c e nt er o f t he ne ed l e t he r e m us t be a

clearance o f 0 .1 mm be tw een the furrow of th e n ee dl e an d t he hook

point 5.

4

1

2

3

0,1 mm

Caution Risk of Injury !

Turn the main switch off.

Set the needle guard only with the main switch turned off.

–

The looping stroke and the needle holder must be set as per

Chapter 11.5 and 11.6.

–

Remove the hook cover and bottoms of the bobbin case

(see Chapter 11.9).

–

Loosen screw 3.

–

Set the needle guard 2 by turning the eccentric bolts 1.

–

Tighten screw 3.

5

1,5 mm

55

Page 56

11.9 Changing the Hook

2 71 2 3 4 5 6 7 8

Caution Risk of Injury !

Turn the main switch off.

Change the hook on l y wi t h t he ma i n switch turned off.

–

Remove the ne ed l e p l at e 7 af te r loosening the mou nt i ng s c rew s .

–

Remove the top of the bobbin case 6 with bobbin.

–

Loosen the sc r ew s 5 o n t he ho ok c o ver 4 .

–

Take off ho ok cover 4.

–

Take the bottom of the bobbin case 3 out of the hook.

For this tur n t he ha nd wh eel back and fort h s l i g ht l y.

Attention!

Use no force to remove the bottom of the bobbin case.

–

Loosen the mounting screws 1 of the hook.

–

Lift the hook f rom the hook shaft an d r e mo v e.

–

Place a new hook on the hook s h af t.

The positi on of th e h oo k on th e h oo k s ha ft i s de te rmi n ed by t he

arrangement of the drilled holes in the bottom of the hook.

This assur es that the hook poi n t l i e s at th e c e nt er o f t he ne ed l e

again after the looping stroke is completed.

–

Insert the bottom of the bobbin case 3 in the new hook.

Attention!