Contents Page:

Home

Part 2: Installation Instructions Cl. 745-22; -23; -24

1. Scope of Delivery

2. Installing the Sewing Unit

2.1 Removing the Transport Fastening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Setting the Work Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Checking the V-belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Filling Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Attaching the Machine Parts Removed for Shipment

3.1 Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Yarn Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Table Extensions (Optional Equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Throw-over Stacker (Optional Equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Electrical Connection

4.1 Connecting the Microcontrol Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Checking the Nominal Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Setting the Motor Protection Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Checking the Direction of Turn of the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Checking the Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Pneumatic Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1. Scope of Delivery

–

–

–

–

–

–

–

–

–

–

2. Installing the Sewing Unit

ATTENTION !

The machine may only be installed by trained, skilled personnel.

Stand with s ew i ng dri v e

Step motor for the m at eria l tra nsp ort

Two needle-double saddle stitch machine Class 935-246-00

745-22;-23:

745-24:

Microcont rol c o nt r ol u ni t

Right and left transport clamps with folding plate

Folder for du al p i pi n g

Two marking lights as positioning aids

Compressed air maintenance unit with compressed air gun

Ya rn sta nd

Tools and small parts in the accessories pack

with parts s e t 9 35 74 53 01 for the common

switching of the needle bars

with parts s e t 9 35 74 53 10 for the independ en t

switching of the needle bars

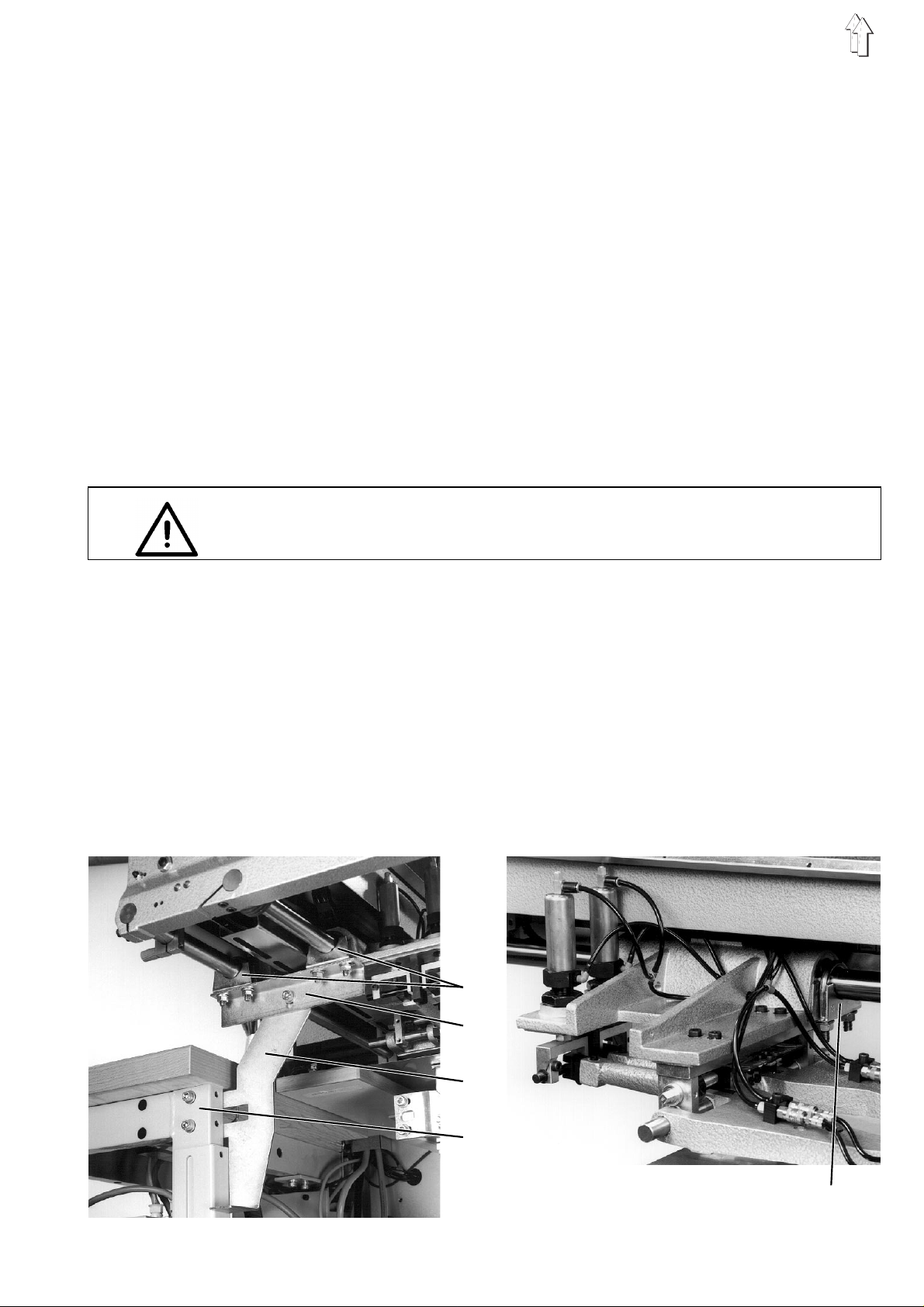

2.1 Removing the T ransport Fasteni ng

The machine head, machine plate and transport carriage are

assembled as a unit for delivery.

The transport fastening 2 prevents

–

the machine head swinging up

–

the transpor t c arr i a ge run ni n g b ac k t hr o ug h centrifugal fo rc es .

Before installing the sewing unit remove the transport fastening 2:

–

Loosen brace 3 on spar 4.

–

Loosen brackets 1 and 5.

–

Remove the t r an spo r t f as t en i ng 2.

1

2

3

4

5

3

2.2 T ran sport

The stand of the sewing unit is equipped with four castors for in-house

transport.

3

1

2

2.3 Setting the W ork Height

ATTENTION !

Before commi s si o ni n g t he s ew i ng un i t p l ac e th e s o un d a bs o r be rs 2

(in the acce ss or ies pack) on the f ou r fe et of th e s t an d.

Turn in the castors until the stand is stable.

–

Run the castors out for transport by turning the setting screws 1 to

the left.

The feet of the stand must have sufficient ground clearance for

transport.

–

After transport lower the sewing unit by turning the setting screws

1 to the right.

The feet of the stand must be firmly on the ground.

The work heigh t is a dj u s ta bl e be tw ee n 87 cm and 110 cm (measured

to the upper edge of the table).

The sewing uni t i s s e t a t t he fa c to ry at th e l o we st work height of 87 cm.

–

Loosen the fa st e ning screws 3 on al l f ou r spars of the stan d.

–

Set the base plate horizontally to the desired work height.

In order to pr e ven t twisting pul l ou t o r push in the base plate

uniformly on bo th s i de s.

–

Tighten the fastening screws 3.

4

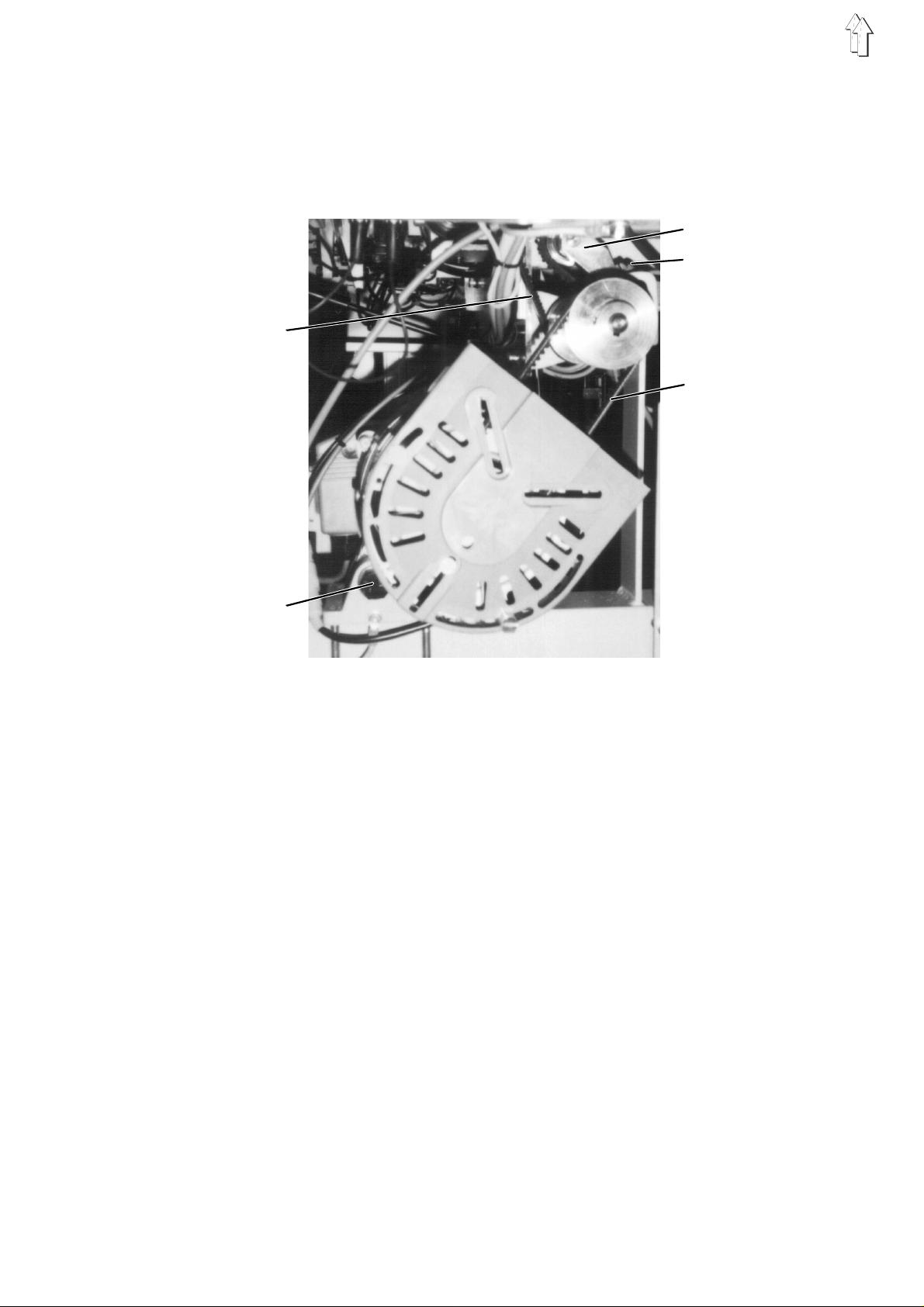

2.4 Checking the V -belt Tensi on

After transport check the V-belt tension set at the factory.

With correc t t en s i on th e V-belts 5 (f ro m t he s ewing drive to th e

intermediate gear) and 1 (from the intermediate gear to the machine

head) can still be pressed in approx. 10 mm at the center with finger

pressure.

1

3

4

5

2.5 Filling Oil

2

Tensioning V-belt 5:

–

Remove the b el t gu ar d af te r l oo s en i ng th e m ou nting screws.

–

Loosen screw 2.

–

Swing the sewing drive until the desired V-belt tension is achieved.

–

Tighten screw 2.

Tensioning V-belt 1:

–

Loosen clamping screw 4.

–

Press the b elt tensioner 3 o nt o V-belt 1 un ti l t he c orr e c t V-belt

tension is a c hie v ed .

–

In this position tighten clamping screw 4.

–

Replace th e b el t gu ard again.

Use only

SP-NK 10 is available from the

–

ESSO SP-NK 10

Fill the oil reservoir for the hook lubrication and the reservoir for

the lubrication of the machine head up to the "Max" mark with oil

(see Chapter 3. 2 o f t he O pe rat i ng In str u cti o ns ).

lubricating oil for filling the oil reservoir.

DÜRKOPP ADLER AG

sales offices.

5

Loading...

Loading...