Adler 743-221 Installation Instruction

Contents Page:

Home

Part 2: Installation Instructions Cl. 743-221

1. Scope of Delivery

2. General Information and Transport Safeguards

3. Installing the Sewing Unit

3.1 Transport of the Sewing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Setting the Working Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Mounting for the Form Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Attaching the Yarn Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Checking the V-belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Electrical Connection

4.1 Connecting the Microcontrol Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Checking the Nominal Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Setting the Motor Protection Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 Checking the Direction of Rotation of the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Checking the Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5. Pneumatic Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6. Lubrication

7. Sewing Trial

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2

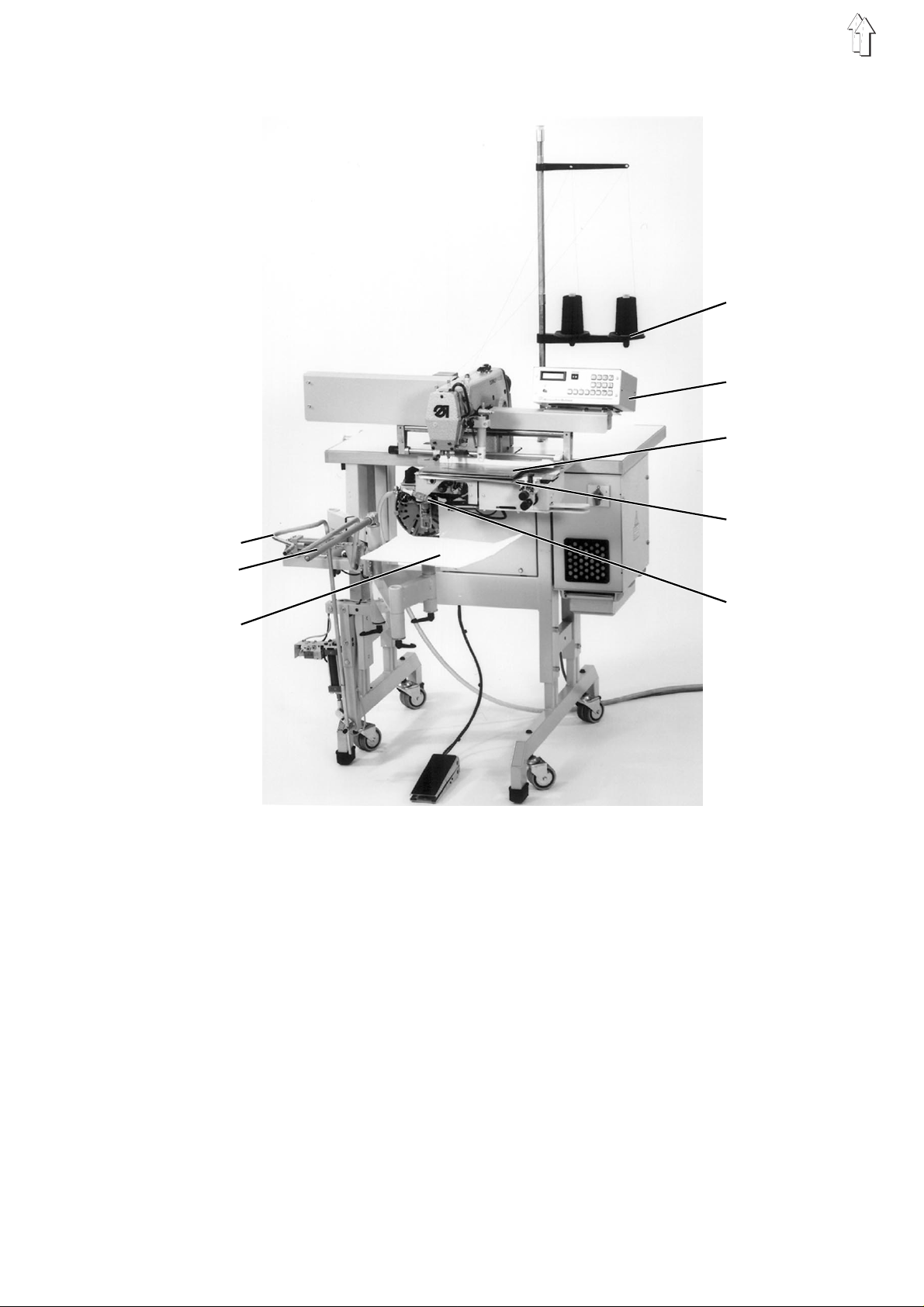

1. Scope of Delivery of the Sewing Unit

1

4

5

6

7

2

8

3

The scope of delivery is dependent on your order.

Before inst al l a tion please check i f al l re qu i r ed pa rt s a r e p r ese nt.

Standard equipment and optional equipment:

–

1

Smoother dev i c e

–

2

Bundle clamp with slewing arm and holder pipe

–

3

Placement t ab l e

–

4

Ya rn sta nd

–

5

Microcont rol c o nt r ol u ni t

–

6

Form set

–

7

Folding table

–

8

Blower pip e f r om ab ov e an d/ or f rom the right

–

Small parts in the accessories pack

3

2. General Information and T ransport Safeguards

ATTENTION !

The sewing unit may only be installed by trained, skilled personnel.

All work on the electrical e qu i pm en t o f t he s ew i ng un i t m ay o nl y b e

conducted by electricians or appropriately instructed persons.

The mains plug must be pulled.

The operatin g i n st ru c ti o ns f or the sewing driv e an d the step motor

drive are to be observed.

Before installation of the sewing unit the following

safeguards

–

The securing band from the sewing drive.

–

The angles which on the wooden pallet lock over the feet of the

frame.

–

Securing bands of the smoother and bundle clamp.

–

Securing bands of the placement table.

3. Installation of the Sewing Unit

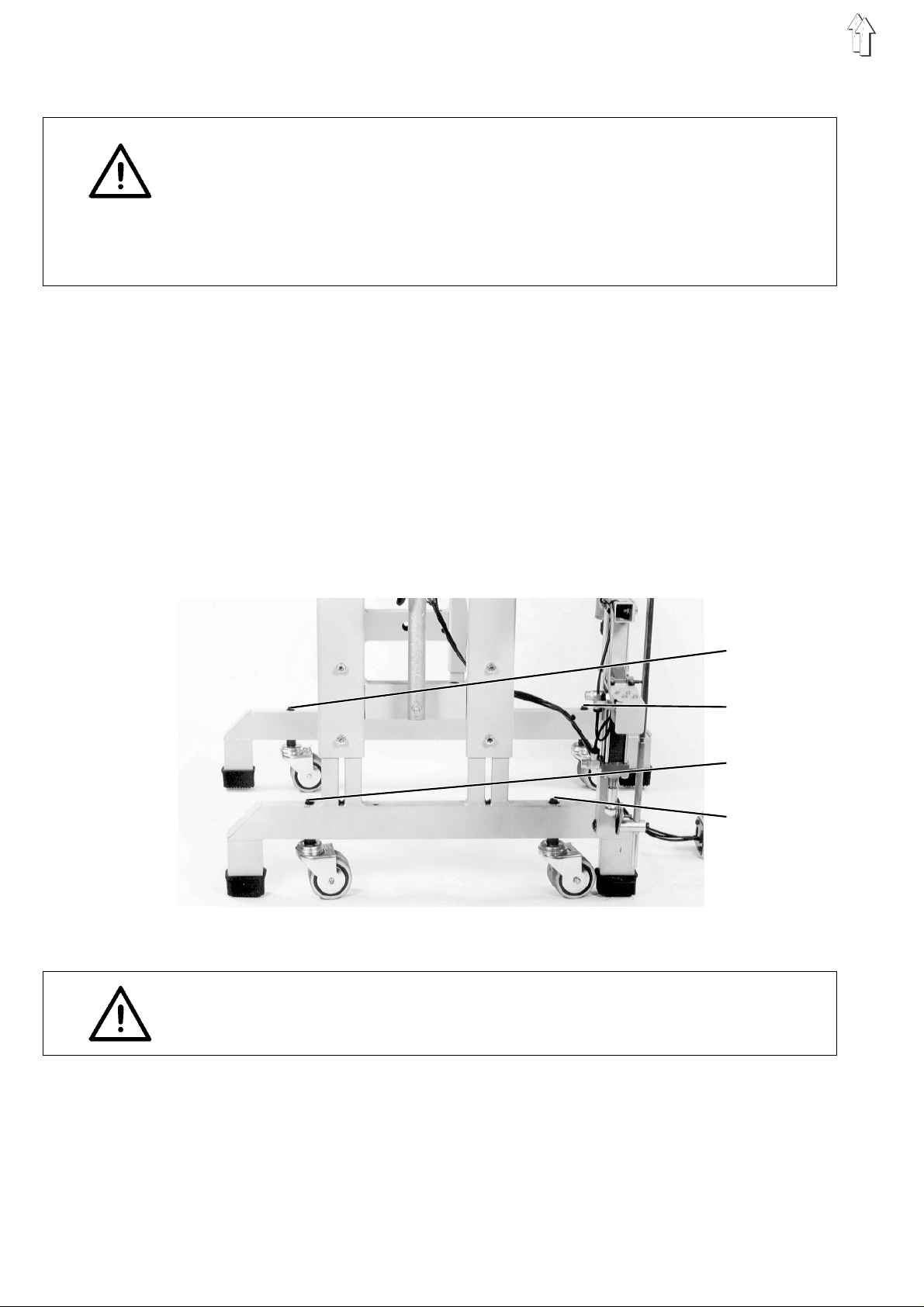

3.1 T ransport of the S ewing Unit

transport

are to be remov e d:

1

2

3

4

The sewing unit has 4 castors for in-house transport.

ATTENTION !

During opera ti o n o f t he s ew i ng un i t t he c as t or s m us t be turned in so

far that the unit rest s firm l y on i ts f ee t.

–

For transport turn the setting screws 1 to 4

The feet must h av e en ou gh fl o or c learance for tra nsport.

–

Transport the sewing unit.

–

To lower the sewi ng un i t t urn the setting scr ew s 1 t o 4

The feet must rest firmly on the floor.

4

to the left

.

to the right

.

Loading...

Loading...