Adler 743-221 Operating Instruction

Contents Page:

Home

Preface and General Safety Information

Part 1: Operating Instructions Cl. 743-221

1. Product Description

1.1 Proper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Short Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Operating the Sewing Unit

2.1 Tilting the Machine Head Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Turning On - Quick Stop - Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Threading the Needle Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Setting the Needle Thread Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Thread Monitor for the Needle Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Setting the Thread Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Winding the Underthread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8 Changing the Bobbin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8.1 Counter for the Control of the Underthread Reserve . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9 Remaining Thread Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.10 Setting the Underthread Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.11 Changing the Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.12 Changing the Form Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.13 Work Area, Angle and Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.14 Setting the Insertion Depth of the Folding Table . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Setting the Controls

4. Sewing

5. Maintenance

5.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Oil Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1. Product Description

1.1 Proper Use

743-221

The

sewing of light to medium weight material.

Such materi al is , as a r ule, material ma de up of te x ti l e fibers or of

leather. These materials are used in the garment, furniture and

automobile upholstry indu s tri e s . Further, it may also be po ss i bl e to

execute so- cal l e d t ec h ni c a l s ea ms w i th th i s s ew i ng un i t. He r e,

however, the operator must in any case (Dürkopp Adler will be glad to

help) make an ev a l ua tion of the possi bl e da ng ers s i n c e su c h

applicatio ns a re, on the one hand , re l at i v el y s e l do m a nd , o n the other,

the variety i s i mm en s e. De pe nd en t o n t he res u lts o f t hi s e v al u at ion , i t

may be necessary to take suitable safety precautions.

Generally, only dry material may be worked with this sewing unit. The

material may not be thicker than 3 mm. The material may contain no

hard objects.

The seam is generally made with textile fibers of dimensions up to

40/NeB (cotton yarns), 65/2 (synthetic yarns) or 65/2 Nm (covering

twists). Those wanting to use other threads must first evaluate the

dangers aris i ng th er e fro m and, if necessary, take appropriate safet y

measures.

This sewing u ni t ma y on l y be i nstalled and oper a te d i n dry a nd c l ea n

premises. I f t he s ew i ng un i t i s u sed on other premise s wh i ch are not

dry and clean, further measures, which are to be agreed upon, may be

necessary (see EN 60204-3-1:1990).

We, as a manufacturer of industrial sewing machines, assume that at

least semi-skilled operating personnel will be working on our products

so that all normal operations and, where applicable, their dangers are

presumed to be k no wn .

is a sewing uni t wh i c h ca n p r op er ly b e u s ed fo r th e

Noise Level Value Lc

Workstation-specific emmission value to DIN 45635-48-B-1

Number of stitc h es : 4.800 min

Stitch length: 2,2 mm

Seam length : 70 mm

Sewing cycle: 2,5 s ON and 1,0 s OFF

Material: G1 DIN 23328 2-play

Measuring point to DIN 4895 Part 1

X = 0 mm Y = -400 mm Z = 300 mm

-1

Lc = 82 dB (A)

3

1.2 Short Descript ion

DÜRKOPP 743-221

The

single-point darts

sewing of

The unit is equipped with a machine head in lockstitch execution.

•

A form set appropriate to the seam form holds and guides the

•

material.

The seam len gt h c o nt r ol occurs, as desi r e d, v i a a l igh t b arr i e r or

•

through programming.

Seam secur ing at the seam begi n ni n g a nd s ea m e nd th r ou gh ba r

•

tacking or stitch condensation in the material

Thread trimmming system: Controlled chain shears

•

Transport carria ge dri v e v ia s t ep mo tor.

•

The complete control of the sewing unit occurs via a

•

microcompu te r. It assume s the control fun cti o ns , mo ni t or s t he

sewing proc es s a nd s i gn al s o pe rating errors and malfunctions .

Electronic thread monitor prevents a restarting of the sewing

•

sequence by t hr e ad bre ak a ge or u s ed -up threads.

pleats

.

is a sewing un i t f or t he au to ma te d se wi n g

with straight or cu r ved s ea m f orm an d f or t he

1.3 T e chnical D ata

Machine head: Class 935 - 2 71 - 710

Needle system: 134 Serv 7

Needle thickn es s: 80 - 100

Yarns: 40 NeB , 65/2 N m

Stitch type: Single-needle lockstitch

Number of sti tc h es : Sewing: 3.800; 3.900; 4.00 0 - 4 .8 00 / min

Bar tacking: 1 000 - 3 000 / min

Advance: 3 000 - 4 000 / min

Thread chain: 1 000 / min

Stitch leng th : Adva nc e : 1,9; 2,2; 2,5; 2,8 mm

Normal seam: 1,9 - 2,8 mm

Seam tacking: 2,2 mm

Stitch cond en s at i on : 0,5; 0,8; 1,1; a. 1, 4 m m

Sewing len gt h: 45 - 150 mm

Folding tabl e : 0 - 10°, adjustable

Operating pressure: 6 bar

Air consumption approx. 2 NL no blow cycle

per work cycle: approx. 12 NL with short blow cycle

Nominal voltage:

9880 743002

9880 743003

9880 743004

The sewing unit is delivered with

the listed

nominal voltage.

voltage sets

3 ~ 380 - 400 V + N , 5 0 Hz

3 ~ 220 - 240 V, 50 Hz

3 ~ 220 - 240 V, 60 Hz

appropriat e t o t he

one

of

4

1.4 Optional Equipment

0794 013222

0794 000091

0794 000332

0794 013333

0794 013444

0797 003031

2. Operating the Sewing Unit

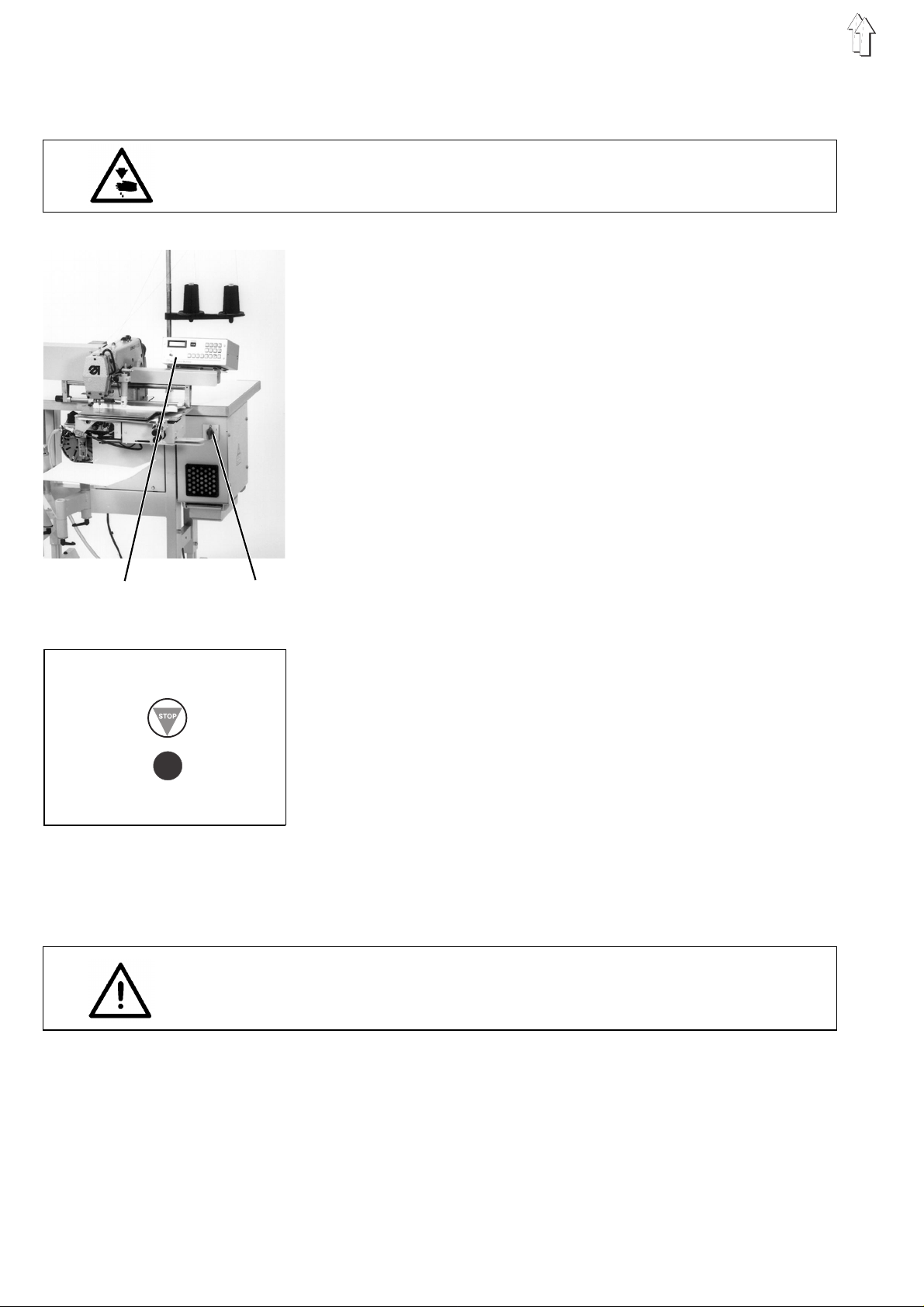

2.1 Tilting t he Machi ne Head Up

Bundle clam p w i th s l ew i ng ar m an d h ol d i ng pi p e.

Placement table (small).

(only in conjunction with the bundle clamp)

Smoother dev i c e f or s m oo th i ng th e b l own-out

sewing piec es .

(only in conjunction with the bundle clamp)

Blower pipe from above or from the right.

Placement table

(when using in-house bundle clamp carriages)

Compressed air connection hose, coupling plug,

coupling socket and hose nozzle.

2

1

The machine head can be tilted up for maintenance work.

Caution Risk of Injury !

Turn the main switch off.

Tilt the machine head up only with the sewing unit turned off.

–

Swing the p l ace ment table 1, bundle clamp and sm oother to the

side.

–

Bring the form set 3 into the left end position.

–

Carefully ti l t th e m ac h i ne he ad up at th e l e v er 2 .

The machine head is held in this position through the location of

the center of g r av ity.

3

5

2.2 T ur ning On - Quick Stop - Restarting

Caution Risk of Injury !

Do not reach into the area of moving machine parts.

Turning on

–

Turn the main switch 2 on.

The controls are initialized.

The sewing unit requests a reference run.

–

Press the " Σ " key.

The referenc e r u n i s c o nd uc t ed .

The sewing uni t i s op er a tio na l .

Turning off

–

Turn the main switch 2 off.

The sewing uni t i s s ep ara te d f r om th e p ow er s u pp l y.

not

It is

operational.

12

Quick stop

To immediately sto p t he s ew i ng un i t b y op er a ti n g e rr ors , ne ed l e

breakage, thr e ad breakage, etc. th e "

must be pressed.

–

Press the "

All runni ng pro c ed ur e s of the sewing uni t ar e immediately st op pe d!

The sewing unit is returned to the same status which it is in after

being turned on .

Restarting

ATTENTION !

The restarti ng of th e s e wi n g u ni t af ter a quick stop ma y on l y oc c u r

after the cor res p on di n g m al f un c ti o n h as b ee n c o rr ec t ed .

STOP

" key.

STOP

" key on the controls 1

–

Turn main switch 2 off.

–

Correct the mal f un cti o n.

–

Turn main switch 2 on.

The sewing uni t i s r ea dy t o s t art ag ai n .

6

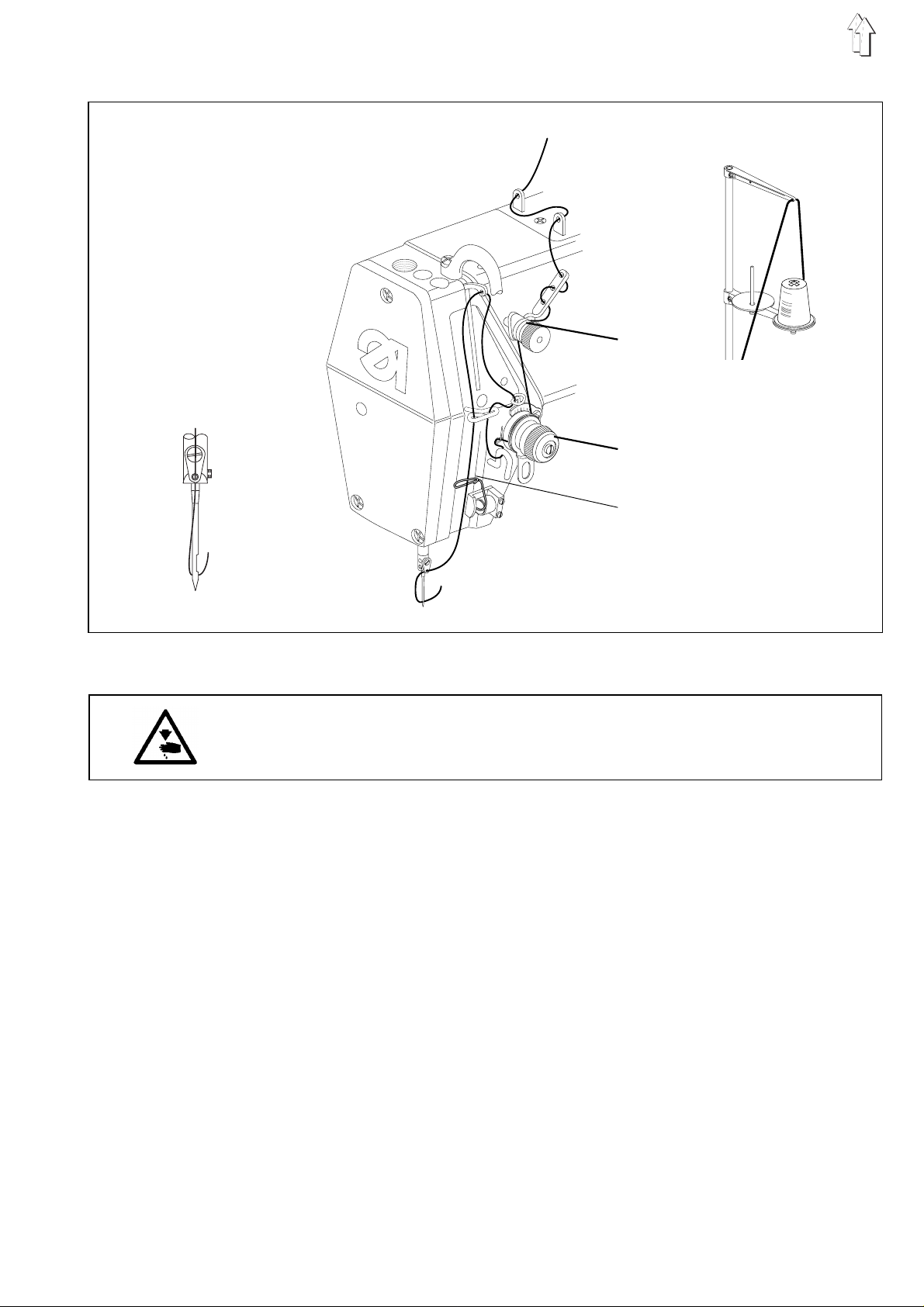

2.3 Threading the Needle Thread

1

2

3

Caution Risk of Injury !

Turn the main switch off.

Thread the needle thread only with the sewing unit turned off.

–

Thread the needle thread as shown in the illustration.

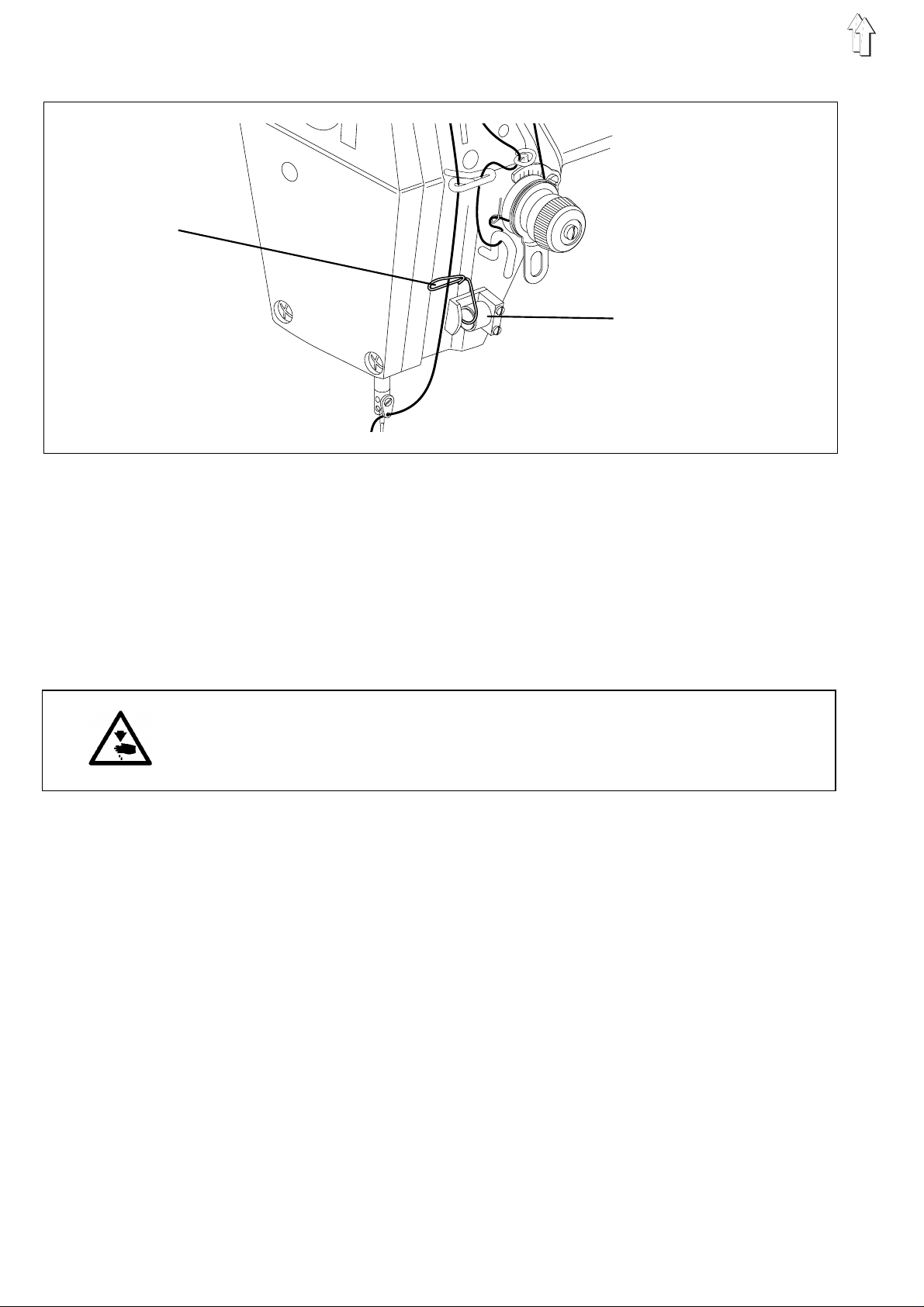

2.4 Setting the Needle Thread Tension

Pre-tensioning 1

If the sewing unit is on, than the maintension is open. For the save

function of th e n ee dl e th rea d monitor a resi du al t en s ion of the needle

thread is necessary.

–

Set pre-tensioning 1.

If the needle thread is fixed by the thread trimmer than the thread

clamp 3 shoul d be ho l d i n i ts highest positi o n b y th e p r e-tensioning.

Maintension 2

The recommen de d n ee dl e th read tension ( ap p. 60 - 80 g) i s t he res u l t

of pre-tensioning 1 and main te ns i o n 2 .

–

Turn knurled nut 1 a pp r op ri at el y.

Increase tension = Turn knurled nut 1 clockwise

Decrease tension = Turn knurled nut 1 counterclockwise

7

2.5 Thread Monitor for the Needle Thread

1

b14

The switch

Function

–

After a break ing of the needle thread the thre ad gu i de 1 d rops

down.

The switch

–

The machine h ea d p os i t i on s i n p os i t i on 2 ( n ee dl e up ).

The display of the control unit shows the symbol "

thread break ).

Caution Risk of Injury !

Before threa di n g t he ne ed l e t hr e ad tu r n t he ma i n s w i tc h off.

Renewed start ing i s on l y po s si bl e af te r tu r ni n g t he ma in s w i tch off an d

on again.

–

Thread the needle thread again and lead it through the thread

clamp.

–

Turn the main switch on.

–

Start a new sewing sequence.

b14

monitors the needle thread.

b14

remains unop erated.

-x-

" (needle

8

Loading...

Loading...