Page 1

Contents Page:

Home

Part 4: Service manual, cla ss 743-221

1. General

2. Adjusting the upper part of the machine

2.1 Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Description and adjustment of integral adjusting disc . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Arm-shaft crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Upper-thread tensioner release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Thread take-up spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Needle-bar height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Shuttle settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7.1 Loop lift and distance between shuttle beak and needle . . . . . . . . . . . . . . . . . . . . . . 11

2.7.2 Shuttle-drive housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Bobbin-housing holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.9 Light barrier of residual-thread monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 Bobbin winder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.11 Position sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.12 Replacing the right-hand arm-shaft bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.13 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.13.1 Shuttle lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Adjusting the sewing machine

3.1 Thread clipper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.1 Fitting and removing the blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1.2 Replacing the piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Folding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Retraction of folding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.2 Angle adjustment, switch point b03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Transport carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.1 Overrun protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4 Shaping module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.1 Shaping-module guide roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.2 Shaping-module pressure cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.3 Shaping-module closing movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.4 Adjusting the shaping module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4. Maintenance unit

5. Maintenance

6. Summary o f ad j ust m en t s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 2

Page 3

1. General

This service manual describes the adjustment of the

sewing machi n e i n an ex p ed i en t s e qu en c e.

IMPORTANT !

Various adjustments are mutually interdependent.

The adjustme nt pr o c ess m us t th er e fo re be carried out i n th e o r de r

given.

IMPORTANT !

The activities described in this Service manual may only be carried out

by specialists or by persons with appropriate training.

Danger of breakage

Before the sewi n g m ach i ne i s r e-s t art ed fo l l ow i ng di sm an tl i n g t he

necessary adjustments must be carried out as specified in this service

manual.

Avoidance of damage to the material clamps:

The sewing machine must never be operated without material. This

also applie s to ad j ustment work and f un c ti o n-t es t i ng .

Adjustment work on stitch-forming components

For all adjus t me nt s of s ti t c h-forming components a flawles s n ew

needle must be fitted.

743-221

model

Caution: danger of injury

Before all repair, conversion and maintenance work:

–

turn off the main switch

–

isolate the s ew i ng ma c hi n e f r om th e p ne um at i c s up pl y.

Exception:

Adjustment work which is carried out with testing, adjustment or

sewing programs of the control device.

Adjustment work and function-testing with the sewing machine

running

–

When carryin g o ut ad j ust me nt work and functio n- t es t ing wi t h t he

machine runn i ng , c o mp l y wi t h a l l s af et y me as u res a nd ta k e t he

utmost care.

Pedal

–

In the sewi ng programs the sew i ng ma chi n e c a n b e s t ar t ed by

inadvertently depressing the pedal.

IMPORTANT !

All colour- m ark e d c o mp on en ts a r e f ac t ory - se t. These settings sh ou l d

only be alter e d b y spe c i al i sts.

3

Page 4

2. Adjusting the upper part of the machine

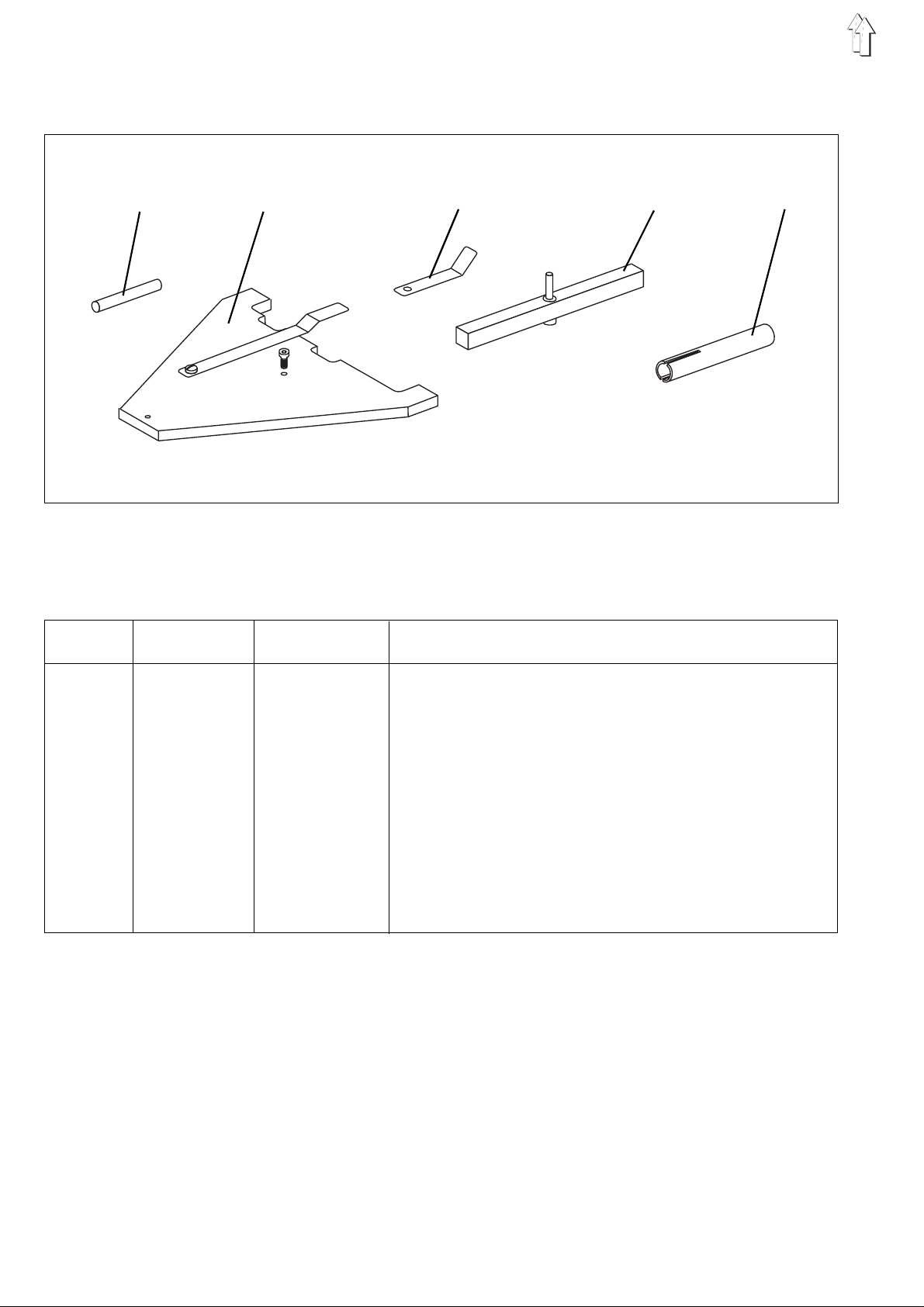

2.1 G auges

12

With the adjustment gauges listed below the sewing machine can be

precisely adjusted and tested.

item adjustment order no. use

gauge

345

1

2

3

4

5

adjusting pin 9301 022608 lock sewing machine in positions A -

gauge 0935 107077 al i g n t ran s po r t c a rr i ag e, c he ck r ef ere nc e po i nt , guide

roller and needle centre

feeler gauge 0933 080200 c he ck an d a dj u s t g ui d e r o l ler

gauge 0935 107071 align needle-bar height and shuttle-drive housing

sleeve 0935 107090 al i g n re s i du al -t hr e ad mo ni t or

F

4

Page 5

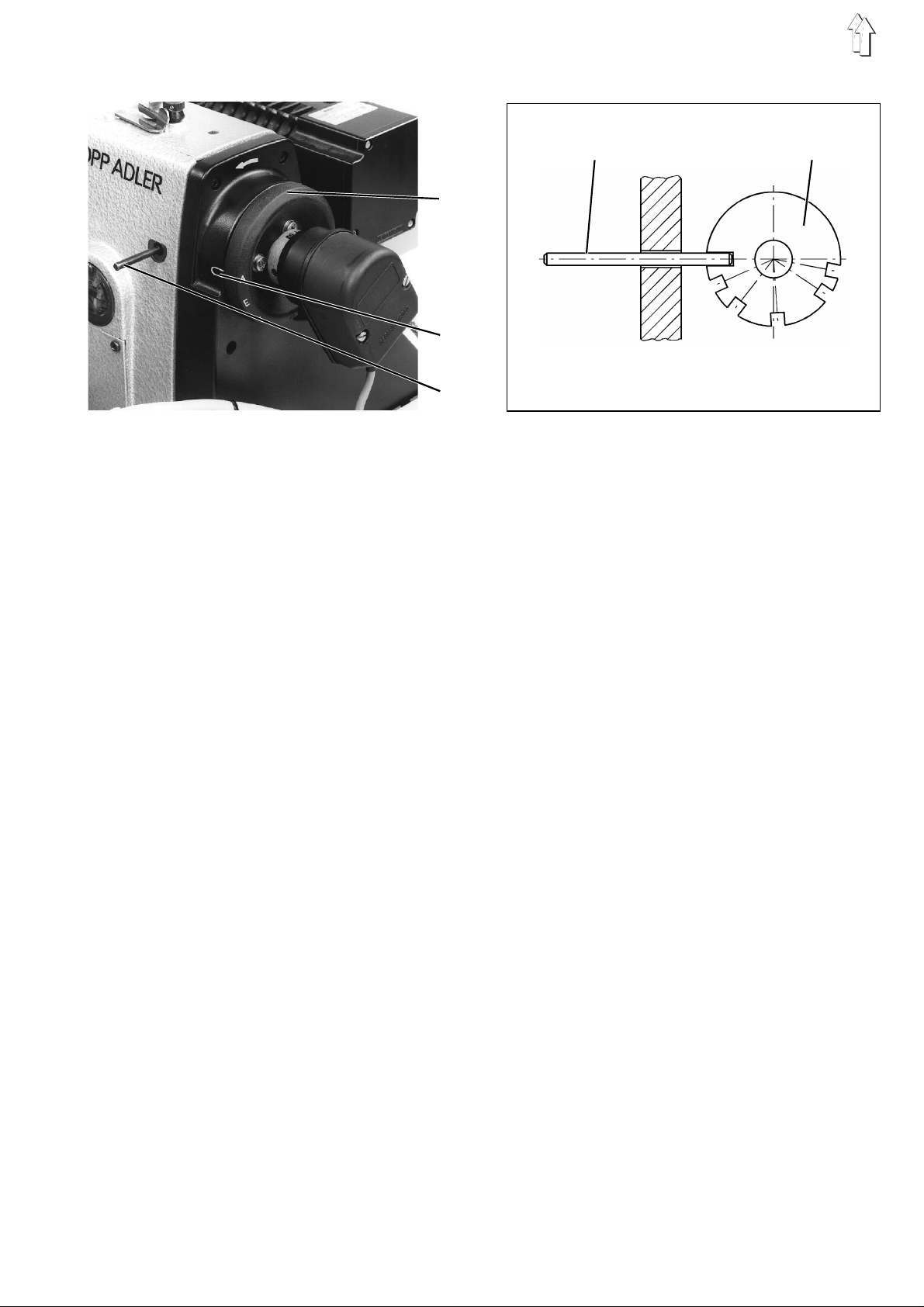

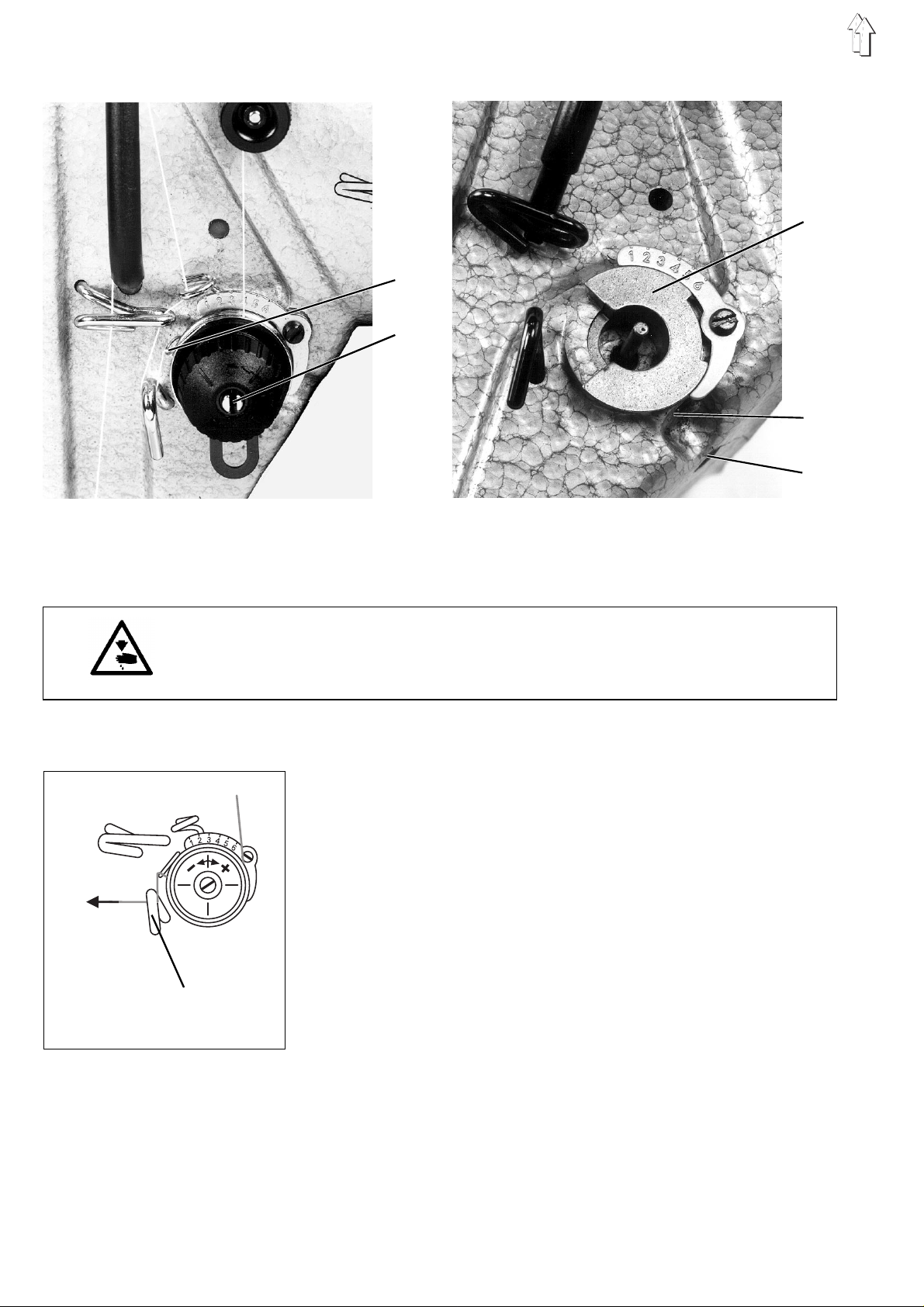

2.2 Descripti on and adjustment of integral adjusting disc

3 4

1

2

3

The sewing ma c hi n e c a n b e l o ck ed i n a l l ad j ustment positio ns w i th

locking pin 3 and the integral adjusting disc 4 on the cogged-belt

pulley of the arm shaft.

The adjusting disc has 6 notches which are marked on the

handwheel 1 by th e l e tt ers A, B, C, D, E and F. In conjunction with

marking 2 the letters indicate the position of the notches in which the

machine can be l o c ked wi t h p i n 3 .

Notch A (loop-lift position) is deeper than the other notches.

A

B

E

F

D

C

The following adjustments can be carried out in the various positions:

A

adjusting di s c with respect to the groove in the arm-shaft crank,

belt wheel, l oo p l ift, distance o f s h ut tl e be ak f rom needle

B

- no function -

C

2nd needle position (raised thread-lever position)

D

- no function -

E

needle-bar h ei g ht

F

- no function -

5

Page 6

2.3 Arm-shaft crank

1

2

3

4

X

Regulation and inspection

The groove 4 and notch A of the adjusting disc on the cogged-belt

pulley must coincide on the

–

Lock the arm shaft with a loc k i ng pi n or a 5 m m Ø p i n i n th e

arm-shaft g roo v e 4 ( th rough hole 3).

–

It must be possible to pass the locking pin through the hole 2 in

position A into the integral adjusting disc.

X - Y

line.

Y

IMPORTANT !

Adjustments carried out with the adjusting disc will only be correct if

the disc itself has been adjusted as described below.

If the arm shaft is moved, all subsequent settings must be checked

and adjusted if necessary.

Caution: danger of injury

Turn off the main swit ch.

The positio n o f t he ar m shaft may only be ad j usted with the sewing

machine swi tc h ed off.

Adjustment

–

Remove bobbin-winder cover 1.

–

Undo the first screw of the cogged-belt pulley 6 from above with

the Allen key 5 through the hole.

–

Lock cogged-belt pulley in position A with the locking pin.

–

Undo second s c rew of cogged-bel t pu l l ey 6 .

–

Insert a 5 mm- th i ck pi n i nt o t he r i g h ol e 3 a nd al l o w it to engage in

the arm-sha ft gr o ove 4 by turning the ha nd wh ee l .

–

Retighten the screws on the cogged-belt pulley 6.

The cogged- be l t p ull e y mu s t n ot be ax i a l l y s hi f te d.

6

5 6

Page 7

2.4 Upper-thread tensi oner release

1

2

3

Regulation and inspection

The cylinder 2 must open the tension discs 1 by about 1 mm.

When closed, the tension discs 1 must keep the upper thread securely

under tensio n.

–

Turn t he

–

Press "STOP" button.

The program is activated.

–

Turn

Switch on solenoid valve s24 by pressing the "Σ" button.

The upper-thread tensioner opens.

–

Check distance between tension discs 1.

Caution: danger of injury

Turn off the main swit ch.

The upper-thread tensioner release may only be adjusted with the

motor-protection s w itc h tu rne d off.

Adjustment

–

Slightly un do s cr ew 3.

–

Move cylinder 2.

With the upp er- t hre ad tensioner open there should be a distance

of 1 mm between the tension discs 1.

The distanc e ca n be checked wi th a g au ge (s ee s ec t i on 2. 1 n o. 3) .

–

Retighten s cr e w 3 .

"program"

"program"

switch to 64.

switch to 24.

7

Page 8

2.5 Thread take-up spri ng

3

1

2

4

5

20...30 cN

Regulation and inspection

The thread take-up spring 1 must keep the upper thread under tension

at least until the tip of the needle has penetrated the material.

Caution: danger of injury

Turn off the main swit ch.

The thread take-up spring may only be adjusted with the sewing

machine swi tc h ed off.

Adjusting the spring travel

–

Undo screw 4.

–

Rotate bush 3.

The spring 1 m us t pr e - te nsi o n t he upper thread a t least until the ti p

of the needl e p en et r at es t he ma te r i al.

–

Retighten screw 4.

Adjusting the spring tension

–

Undo screw 5.

–

Adjust the te ns i o n b y rotating tensio n b ol t 2.

Depending on the material and thread the tension of the thread

take-up spring must be between 20 and 30 cN (1 cN = 1 g).

6

The tension i s me asu r ed at th r ea d g ui d e 6 .

The thread i s dra wn parallel to th e a r m s h af t.

–

Retighten screw 5.

8

Page 9

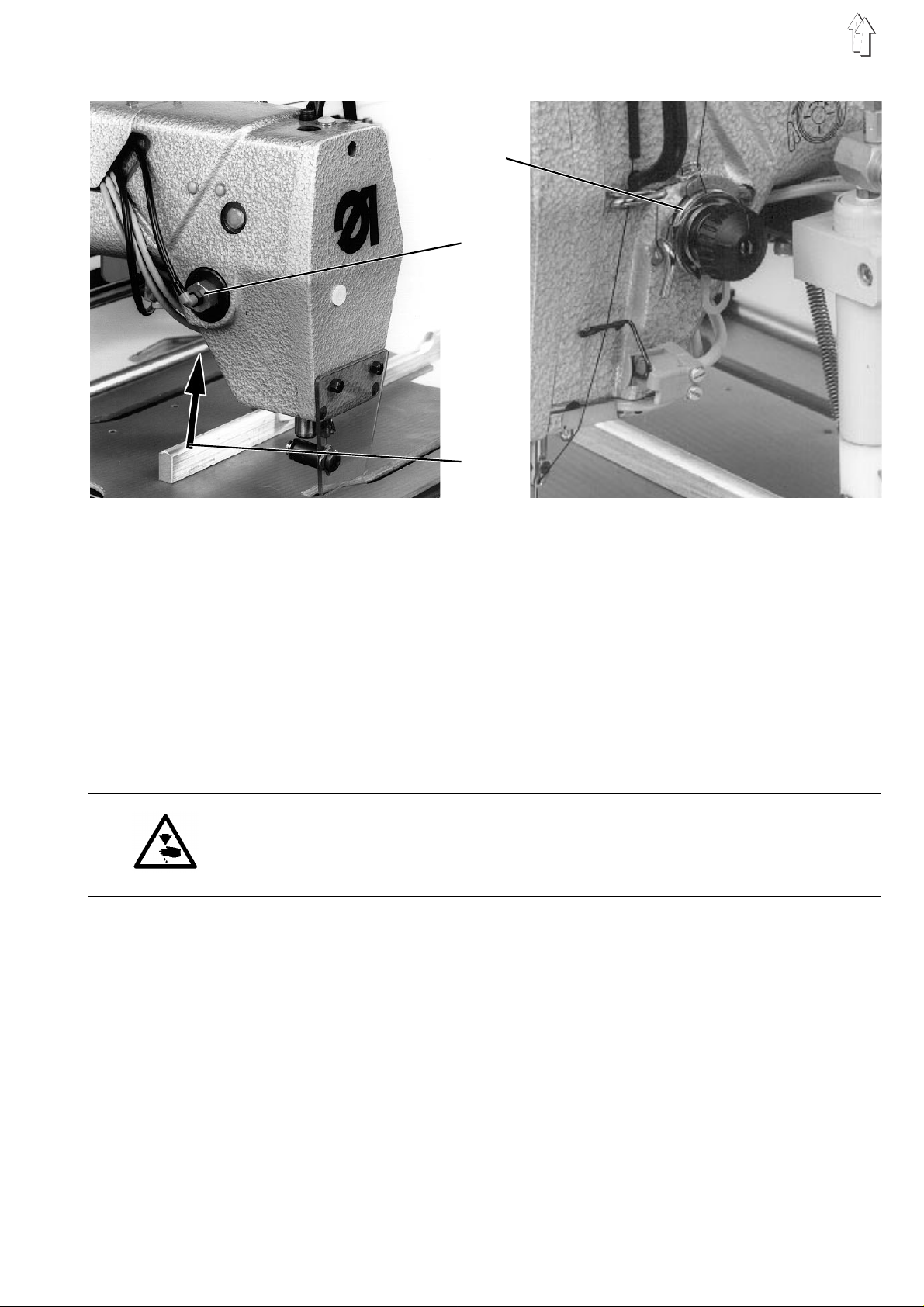

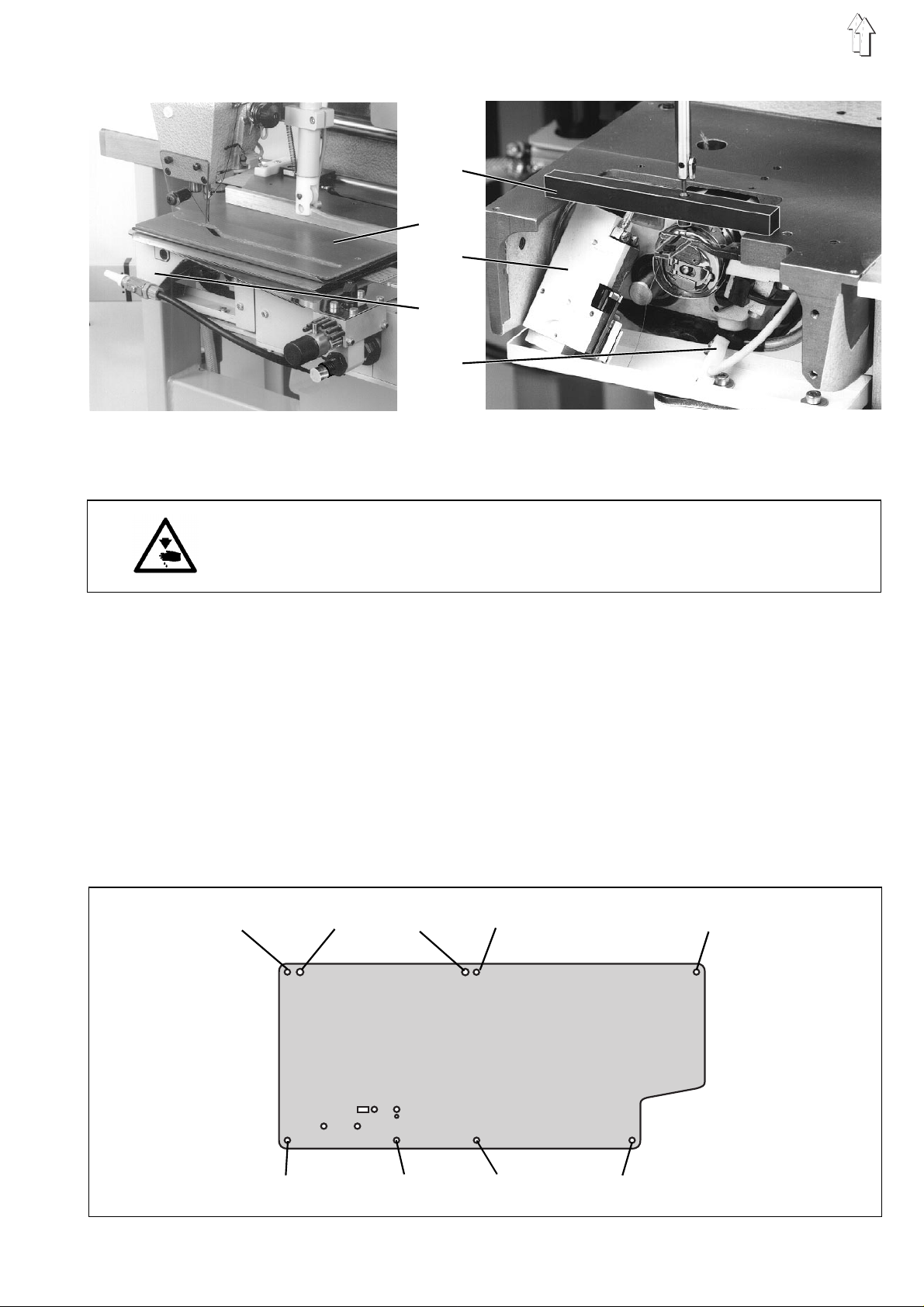

2.6 Needle-bar hei ght

1

2

3

4

5

Regulation and inspection

Adjustment and inspection are carried out with gauge 1.

Caution: danger of injury

Turn off the main swit ch.

The needle-b ar h ei g ht may only be adjus t ed wi t h the sewing mac hi n e

switched off.

Adjustment

–

Remove shaping module 2.

–

Remove casing 4.

–

Undo light ba rr i er 5 and thread clipp er 3 an d l a y th em on th e o i l

reservoir.

–

Undo screws 6 on th e s l i d e p l at e a nd r em ove the slide plat e.

IMPORTANT !

The centring screws 7 must not be rotated.

These are used to align the slide plate to the needle.

There are 2 shi m s be tw ee n t he slide plate an d t hre ad clipper.

6 7 7 6 6

6 6 6 6

9

Page 10

10

8

1

9

–

Place gauge 1 on th e base plate.

–

Unscrew safety shutter and he ad cover.

–

Undo clampin g sc re w 9 .

–

Lock the sewing machine in position E.

–

Lower the needl e ba r 8 o nt o t he gauge 1.

The pin of gauge 1 must fully penetrate th e needle bar.

–

Tighten needle-bar attachment screw 10.

The needle- at ta c hm en t s cr e w 1 0 must be aligne d i n pa ral l e l to th e

arm shaft and po i nt to the rear (toward s th e h an dw he el ) .

–

Replace all th e p ar t s wh i c h h ave be en r em ove d.

IMPORTANT !

When fitting the thread clipper place both shims between the

thread clipper and slide plate.

10

Page 11

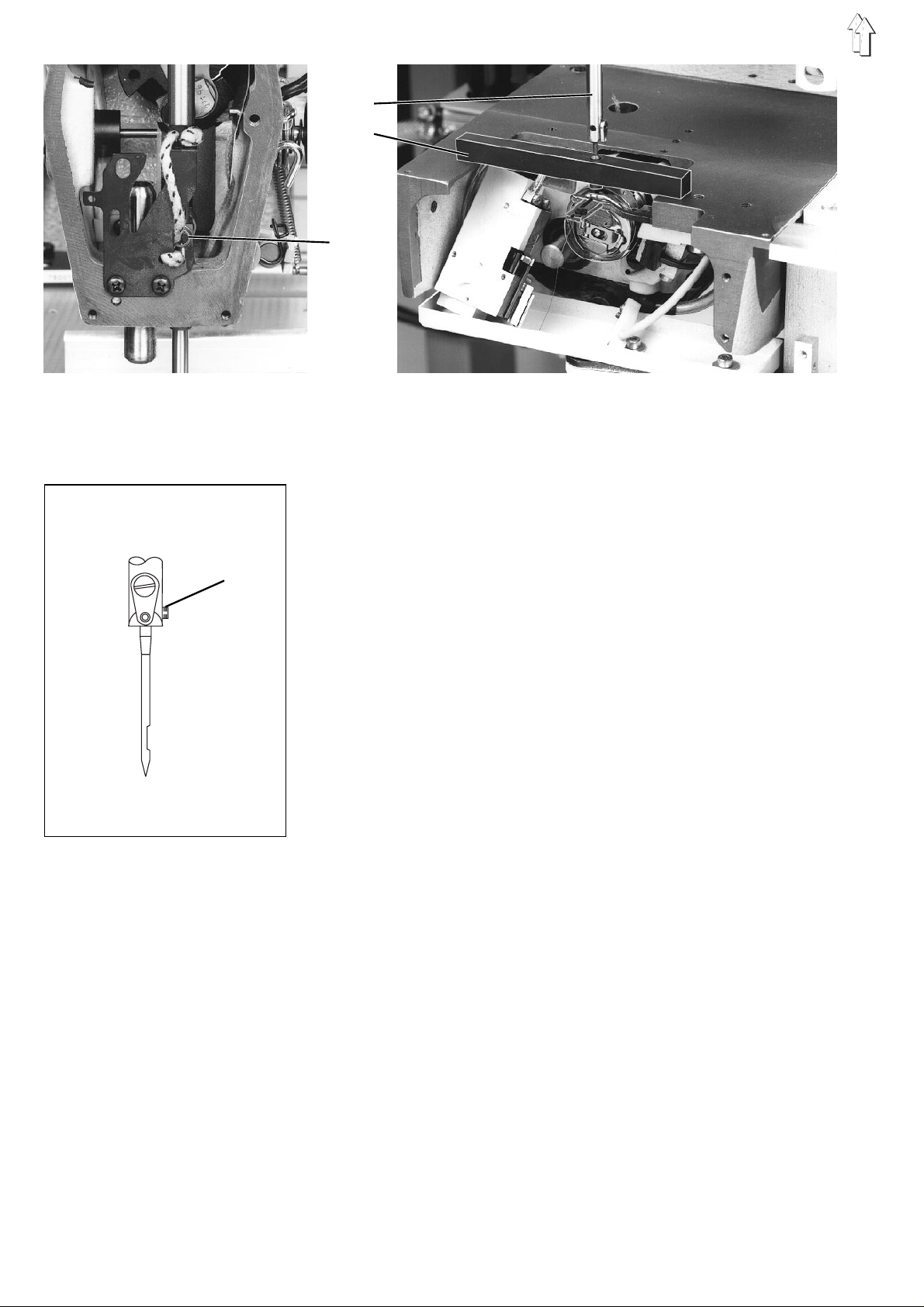

2.7 Shuttle settings

2.7.1 Loop lift and distance between shuttle beak and needle

0,1 mm

2

3

1

4

Regulation and inspection

The loop lif t i s the travel of t he ne ed l e b ar from bottom dead c en tr e to

the point at which the shuttle beak is at the centre of the needle.

The loop lift is 1.8 mm.

–

Lock the machine in position A.

The shuttle b ea k 1 m us t be at th e c e nt r e o f t he ne ed l e.

The distanc e b et we en th e s h ut tl e be ak 1 an d the needle must be

0.1 mm.

Caution: danger of injury

Turn off the main swit ch.

The loop lift and the distance between the shuttle beak and needle

may only be ad j us t ed wi t h t he s ew i ng ma c hi n e s w i tc h ed off.

Adjustment

–

Remove shaping module and slide plate (see section 2.6).

Fit new needl e.

–

Undo first a ttachment screw 3 of shuttle 4.

–

Lock sewing machine in position A.

–

Undo secon d a tt ac h me nt s cr ew 3 o f sh uttle 4.

–

Place shut tl e be ak 1 at c en tre of needle.

The distanc e b et we en th e s h ut tl e be ak 1 an d the furrow of th e

needle must be 0.1 mm.

In this position there is a distance of about 0.4 mm between the

shuttle 4 an d t he bu s h 2 .

If the dista nce of 0.4 mm is not ac h i eved, the shuttle - dri v e ho us i n g

should be adjusted accordingly (see section 7.2).

–

Retighten 2 at ta c hm en t s c re w s 3 of the shuttle 4.

–

Replace all the parts which have been removed.

11

Page 12

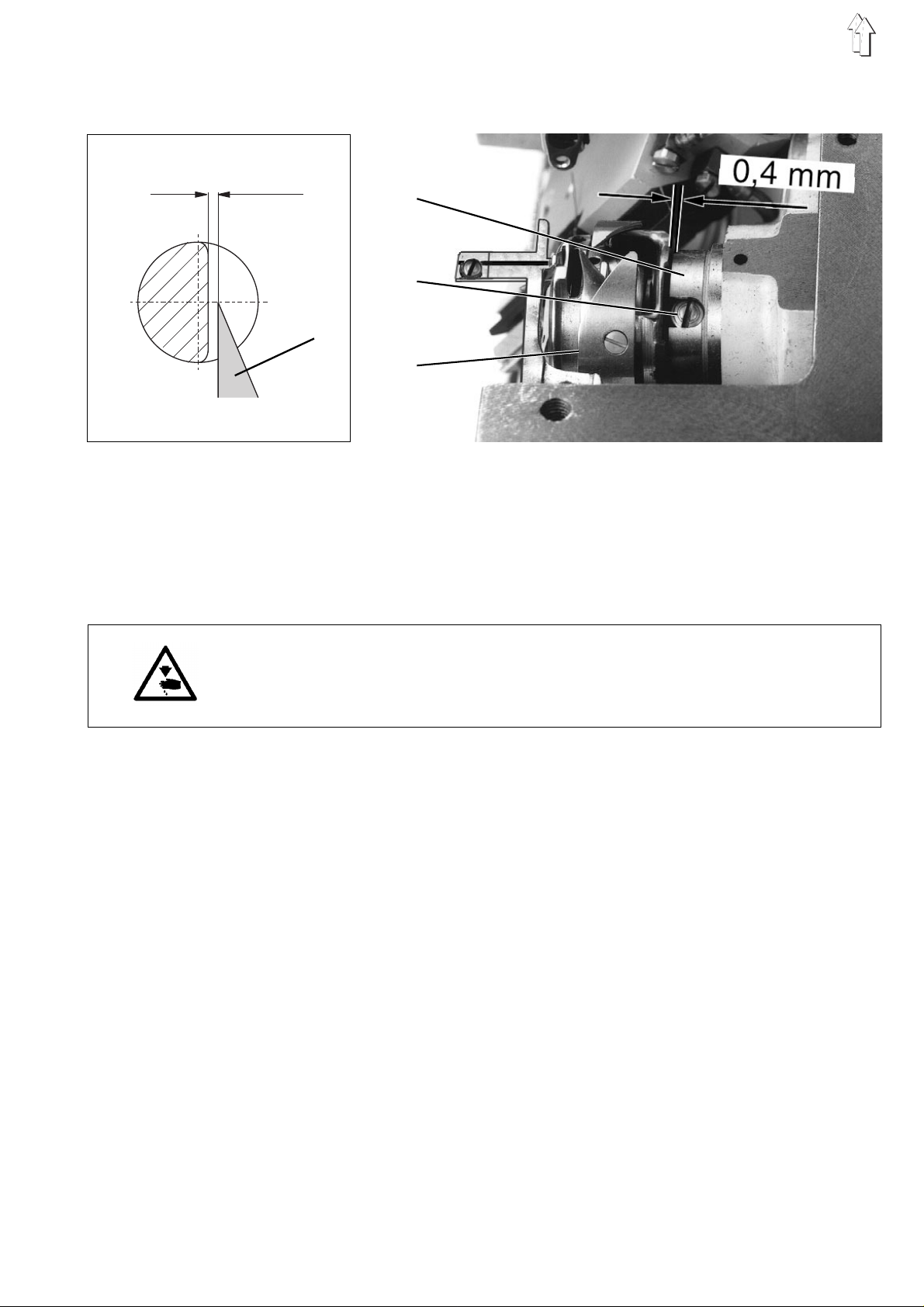

2.7.2 Shuttle-drive housing

1

3,8 mm

2

3

Regulation and inspection

The shuttle-drive housing 4 is factory-aligned.

It may only be altered in exceptional circumstances.

With the shut tl e - dri v e ho us i n g correctly alig ne d there must be a

distance of 0 .4 mm between the s hu tt l e a nd th e a dj u s ti n g ri n g

(see section 2.7.1).

The distanc e b et we en th e s l i d e-plate surface a nd the thread-drawi n g

plate 3 is 3.8 mm.

4 5

Caution: danger of injury

Turn off the main swit ch.

The shuttle-drive housing 4 may only be adjusted with the sewing

machine swi tc h ed off.

Adjustment

–

Remove the sha pi n g m odule and slide plate (see sec ti o n 2 .6 ) .

–

Unscrew locking screw 5.

Beneath the locking screw there is a stop screw.

–

Adjust stop screw.

The distanc e be tw ee n t he slide-plate s urface and the

thread-drawin g p l at e 3 i s 3. 8 m m

The distance is checked with gauge 1.

–

Retighten locking screw 5.

–

Undo screws 2 of the shuttle-drive housing.

–

Move shuttle - dri v e ho us i n g 4 .

There must be a distance of 0.4 mm between the shuttle and the

adjusting ring (see section 2.7.1).

–

Retighten screws 2 of the shuttle-drive housing.

–

Check the distance of the shuttle beak to the needle and adjust if

necessary (see section 2.7.1).

12

Page 13

2.8 Bobbin-housing holder

1

1 3

2

3

4

5

6

Regulation and inspection

The bobbin-h ou s ing holder is facto r y- al igned.

After the ho lde r ha s be en r ep lac e d i t ma y be ne c es sary to re-align th e

new one.

The spring wire 1 must be in close contact with the bobbin-housing

holder with no gaps.

Half the width of th e s p ri ng wi re 1 m us t be ove r th e re ta i ni n g t ab 3.

Caution: danger of injury

Turn off the main swit ch.

The bobbin-h ou s ing holder may only be ad j us t ed wi t h t he s ew i ng

machine swi tc h ed off.

IMPORTANT !

Alignment ma y on l y be c arr i e d o ut i n t he c ros s -h atched area 5

(see sketch) .

The extreme h ard ne s s i n t he r eg ion of the retaini n g t ab 3 m ea ns t ha t

there is a dan ge r of bre ak a ge th er e .

Adjustment

–

Align the bo bbin-housing ho l de r 6.

The distanc e b et we en th e r e ta i ni n g t ab 3 o f the bobbin-hou s ing

holder 5 and the lower part of the bobbin housing 4 must be

+0.1

0.6

–

Undo screw 2.

–

Move the wire s o th at it i s i n cl os e con ta c t w i th th e re ta ini n g t ab or

is 0.1 mm away from it.

–

Tighten screw 2.

mm.

Note

If the holding wire 1 is worn it can be reversed and the other end used.

13

Page 14

2.9 Light bar rier of residual -thread monitor

12

3

Regulation and inspection

If the light barrier is properly aligned a reflection occurs when an

empty bobbin i s r o ta te d.

The alignment of the light barrier is carried out in program 42.

Caution: danger of injury

Turn off the motor safety switch .

The reflex light barrier may only be aligned with the motor safety

switch turned off.

IMPORTANT !

The residual-thread monitor is only operational if the value for the

shuttle-thread counter in program 41 has been set to

Checking the alignment

–

Place an empt y bo bb i n o n t he s l ee v e (g auge 5, section 2. 1) a nd

insert it in the bobbin housing.

–

Move the shuttle by turning t he handwheel unti l t he i nf r a-r e d

radiation of the light barrier 1 can fall on the bobbin hub th rough

the light aperture in the bobbin housing (shuttle beak down).

–

–

–

program

Set "

Press "

The program i s ac t i vated.

Rotate empty bo bb i n w i th th e sl e ev e (ga ug e 5 ).

If the infrared radiation from light barrier 1 falls on the reflective

surface 3 of the bobbin hub, this must appear in the display:

STOP

" switch to 42.

" button.

0000

.

14

display with reflection:

display with no reflection:

Page 15

2.10 Bobbin winder

Adjusting the alignment

–

Clean the lenses of the light barrier 1 and the reflection surface 3

of the bobbin hu b w i th a s o ft c l ot h.

–

Undo clamping screw 2.

–

Press the light barrier 1 into the light-barrier holders as far as it will

go.

–

Gently tighten clamping screw 2.

–

Align lig ht ba r ri er.

Rotate light barrier 1 until

appears in th e d i s pla y.

–

Re-tighten clamping screw 2.

–

Check alig nm en t a fter clamping an d r e - ad jus t i f n ec e s s ary.

3

1

2

A

Regulation and inspection

The bobbin wi nd er s h ou l d a ut om at i c al ly t ur n off wh en th e b obbin is

fully wound t o a po i nt about 0.5 mm unde r th e r i m .

Caution: danger of injury

Turn off the main swit ch.

The bobbin winder may only be adjusted with the sewing machine

switched off.

Adjustment

1. Minor adjustments to the wind-on quantity

–

B

Bend bobbi n-w i nd er f l ap 3.

2. Major adjustments to the wind-on quantity

–

Remove bobbin-winder cover.

–

Undo screw 2.

–

Rotate trip cam 1:

in the direction of arrow A: to reduc e th e wind-on quanti t y

in the direction of arrow B: to incr e as e th e w i nd - on qu an ti t y.

–

Retighten s cr e w 2 .

–

Replace bo bb i n-w i nd er c o ver.

15

Page 16

2.1 1 Position sensor

1

2

3

7

4

5

6

8

Regulation and inspection

After sewin g t he up pe r pa r t o f t he ma c hi n e m us t mo v e t o p os ition C of

the adjusting disc.

Caution: danger of injury

Turn off the main swit ch.

The light apertures may only be adjusted with the main switch turned

off.

–

Partly undo c lam pi n g s c re w 6 .

–

Rotate light apertures 1 and 4 so that their light slits 2 and 5 are

opposite each other (offset by 180°).

The positi on of l i gh t a pe r tu re 4 al s o de te r mines the moment at

which the thread clipper switches on.

–

Tighten clamping s c rew 6.

IMPORTANT !

The light apertures 1 and 4 must not be rotated when tightening the

clamping screw 6.

16

–

Turn on the main swit c h.

–

Set the "

a sewing pro gr a m (

–

Press the "

Set the motor-speed parameter to maximum.

–

Place the mat er i a l in position and start the sewin g p roc e s s .

IMPORTANT !

Never star t u p w i th no ma te r i al i n pl a c e: th i s ma y da ma ge th e

material clamps.

–

After the thread is cut the upper part of the machine moves to the

second needle position (position C).

program

P

" switch on th e f r on t p l at e o f the control de vi c e t o

" 10...29 ")

" button for 3 seconds.

.

Page 17

–

Check the e xac t s ec o nd ne ed l e p os ition C with the lo ck i ng pi n .

–

If the locking pin will not go into notch C of the adjusting disc,

correct the second needle position.

Adjustment

–

Undo both clamping screws 7 on the position-sensor ring 8.

–

Hold position-sensor ring 8 steady and rotate handwheel.

–

Fully tighten clamping screws 7.

–

Carry out s ew i ng process.

–

Check the second needle position with the locking pin.

–

If necessary, correct the position of the position-sensor ring 8

again.

17

Page 18

2.12 Replacing the right-hand arm-shaft bearing

1

2 3

4 5 6

Regulation and inspection

The right-hand arm-shaft bearing must be replaced if the arm shaft

does not run smoothly.

Caution: danger of injury

Turn off the main swit ch.

The arm-shaft bearing may only be replaced with the sewing machine

switched off.

IMPORTANT !

Do not use an extractor tool.

When the right-hand arm-shaft bearing is removed and replaced no

axial press ur e mu st b e exe r te d on the ar m s ha ft . A x i al pr e s sur e in the

direction of the head cover will damage the thread lever.

Replacing the arm-shaft bearing

–

Remove position sensor, handwheel, arm and head covers.

–

Unfasten the belt protector and remove it together with the belt.

–

Remove the 2 reta i ni n g sp r i ng s 1.

–

Undo screws 2 a nd 6.

–

Carefully prise off the V-belt pulley with 2 screwdrivers or similar.

–

Remove the ball-race 4 with the extractor tool and remove circlip 5.

–

Fit the circl i p t o t he ne w b al l -r a ce ( o rde r no .: 02 11 000361) and

carefully press the complete unit onto the V-belt pulley.

–

Gently tap the V-belt pulley into place with a synthetic hammer.

–

Replace in rev e rs e o rde r th e p art s wh ic h h av e be en rem ove d.

18

Page 19

2.13 Lubrication

1

2

3

4

5

6

The oil passes from the oil reservoir 5 to the sump 1, from where the

lubrications points in t he arm an d s e wi n g- h ea d re gi o ns a r e supplied

with oil.

The oil thrown off by t he c ran k me c ha nis m pa s ses a lon g the wick 2 to

the central distributor pipe 4 for the lubrication points located under

the base plate. Excess oil drips into the oil-collection tray 6 and is

returned to th e s u mp 1 b y th e p um p 3 .

This provides effective lubrication with minimum oil consumption.

Caution: danger of injury

Turn off the main swit ch.

Work on the oil-circulation system may only be carried out with the

sewing machi n e s w i tc h ed off.

IMPORTANT !

After work is completed it is essential to ensure that the hoses are

correctly reconnected to the pump.

S = suction

D = pressure

Regulation and inspection

The oil level must be checked every week.

–

Check the oil level at the oil reservoir 5.

The oil level m us t be be tw ee n t he MI N a nd MA X m ark s.

If necessary top up the oil to the MAX mark.

19

Page 20

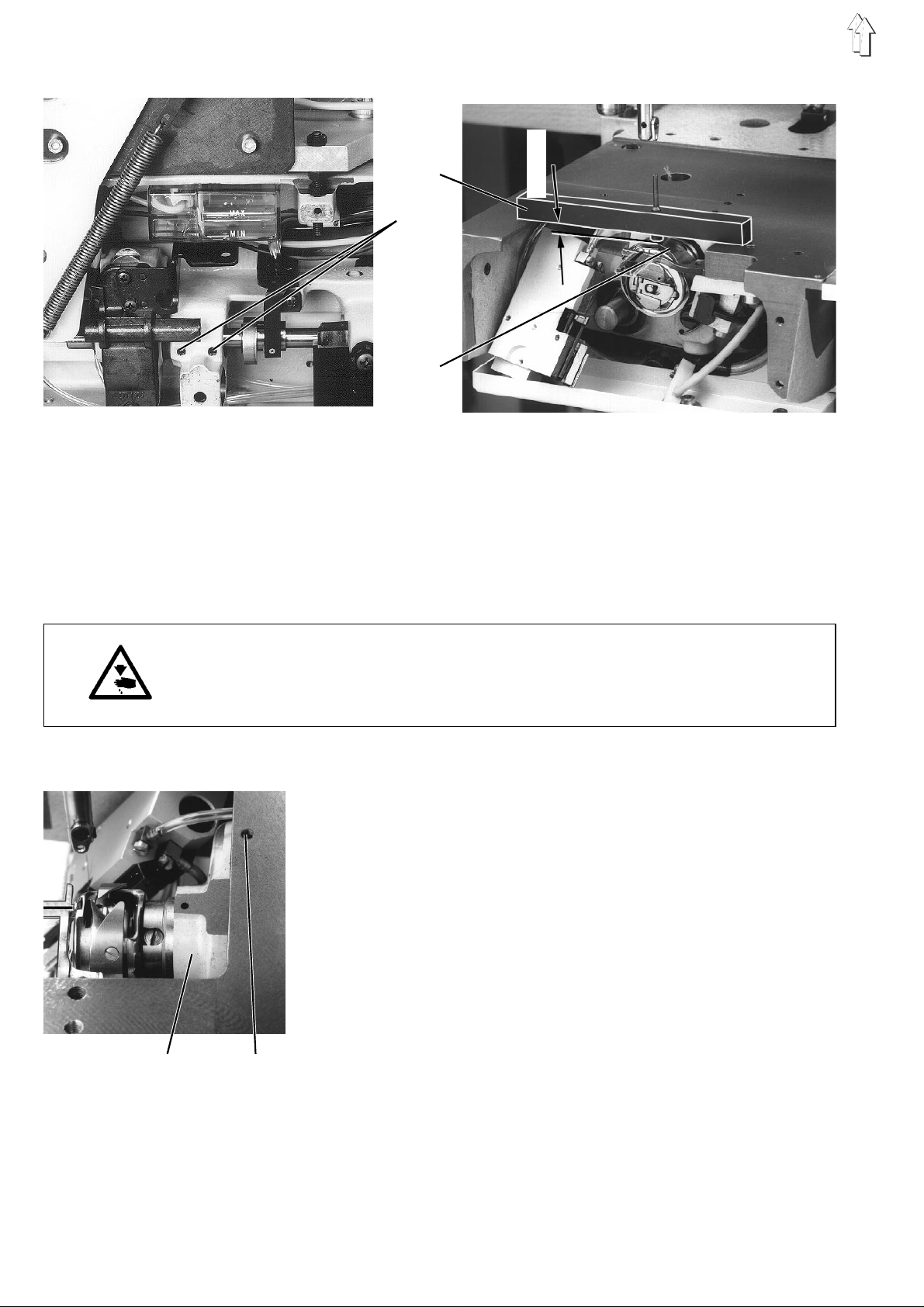

2.13.1 Shuttle lubrication

1

2

Caution: danger of injury

If shuttle lubrication is checked with the sewing machine switched on,

the utmost care must be taken.

Oil can cause skin rashes.

Avoid protracted contact with the skin.

In the event o f contact, thorou gh l y wa s h t he affec t ed ar e a.

Turn off the main swit ch.

Shuttle lubrication may only be adjusted with the sewing machine

switched off.

IMPORTANT !

The handling and disposal of mineral oils is subject to legal

regulations.

Used oil must be delivered to an authorised acceptance point.

Protect the e nv i ro nm ent.

Take care that no oil is spilled.

Regulation and inspection

The oil quanti ty re qu i red fo r shu tt l e l u bri c a tio n v a ri es w i th th e se wi n g

yarns and mat eri a l to be pr o c ess e d.

A piece of paper - ideally blotting paper - held beneath the shuttle

should be lightly sprayed with oil when 8-10 stitches are sew n.

Adjustment

–

Adjust screw 2:

anti-clockwise = more oil

clockwise = less oil

20

1 = shuttle-lubrication oil reservoir

Page 21

3. Adjusting the sewing machine

3.1 Thread clipper

1

Regulation and inspection

When the thread is being cut the moving blade must be able to move

freely in th e sl i t of th e s h ap i ng mo du l e.

2 3 4 5 6

Caution: danger of injury

Turn off the main swit ch.

The thread clip pe r ma y on l y be rem ov e d w i th th e se wi n g m ach i ne

switched off.

Removing the thread clipper

–

Remove sha pin g module and cas ing 1.

–

Remove screws 2 and 4.

IMPORTANT !

Between the slide plate and thread clipper there are 2 shims.

–

Mark 3 hoses on the thread clipper 7 and then unscrew them.

–

Remove the thread clipper 7.

Fitting the thread clipper

–

Connect the hoses to the correct connections.

–

Attach the thread clipper 7 under the slide plate 3.

Make sure the ho s es c a nn ot be fouled by mo v i ng pa rts .

–

Attach screws 2 and 4.

7

When the thread is being cut the moving blade must be able to

move freely in the slit of the shaping module.

IMPORTANT !

When fitting the thread clipper place the shims between the slide

plate and thre ad clipper.

–

Replace cas i n g 1 an d s h ap i ng mo du l e.

Function-testing the thread clipper

–

The function of the thread clipper 7 can be checked with

program 64 (se e b r i ef de s cr i pt i on of Mi c ro c on tr o l) .

21

Page 22

3.1.1 Fitting and removing the blades

S30 6

1

2

3

4

5

S31

S28

17

The blades mu s t b e re pl a c ed an d a dj u s te d with the thread c li pp er

removed. The th rea d m us t be rel i a bly s e ver e d wit h th e mi n i mu m

possible pre s s ure .

Regulation and inspection

The distance from the edge of the fixed blade 12 to the surface of the

body of the clipper is 1.5 mm.

The edge of the moving blade is just beneath that of the fixed blade.

This is the case if the distance from the edge of the blade to the

surface of th e b od y of th e c l i p pe r i s 2 m m.

Caution: danger of injury

Turn off the main swit ch.

The thread clip pe r ma y on l y be rem ov e d w i th th e se wi n g m ach i ne

switched off.

Blades may o nl y be fitted and re mo v ed wh en th e t hr e ad c l ipper has

been removed.

Removing the blades

–

Remove thread clipper (see section 3.1).

–

Remove screws 3 and 5.

Remove cover plate 1 and blade-guide plate 6.

IMPORTANT !

Do not lose the pressure spring 4.

–

Remove moving blade 2

This is nec es sary to ensure th at th e b l ad e i s n ot da ma ge d.

–

Undo screws 15 an d 1 7.

Remove the pressure plate 16.

–

Remove blade 1 2 (f i x ed bla de ) .

downwards

from the blad e- g ui d e p l at e 6 .

22

Position ma r ki ng s

denote the res pe c ti v e sol e no i d v a l v es.

S28, S30

and

(compressed - air c o nn ec t i on s)

S31

Page 23

12

13

14

7

89 1011

Fitting the blade

–

Screw the bla de 12 on to th e p res s u re p l at e 1 6.

The distance from the edge of the blade to the surface of the body

of the clippe r i s 1.5 mm.

–

Tighten screws 15 an d 1 7.

–

Undo pressure screw 13.

–

Fit the moving blade 2

Check that the blade moves freely.

2 12

–

Tighten the pressure screw 13 and adjust for Cutting pressure.

The sewing threads must be reliably severed with the minimum

possible pre s s ure .

Carry out a cut tin g t es t ( see al s o sec t i on on fu nc t i on te s tin g) .

The lower end of screw 13 is split. It may be slightly expanded for

a secure fit.

–

Fit blade-guide plate 6.

The collar 18 mu s t e ng ag e with the cylin de r 8.

Pin 10 must en ga ge wit h t he ho l e 1 4.

Pin 9 must engage with the slot of the moving blade 2.

–

Fit the cov er p l at e 1 wi t h p r es sure spring 4 ont o t he bl a de - gu i de

plate 6.

–

Fully tighten screws 3 and 5.

15 16 17 2 18

from below

into the blade-guide plate 6.

Adjusting the height of the moving blade 2

–

The height of the moving blad e 2 i s ad j us t ed wi t h s c re w 11.

If this screw 11 ha s be en un s c rewed it must be r ep l aced in the

hole together with Teflon tape and screwed in to its previous

position.

The setting of the moving blade 2 must be such that its edge is just

beneath the ed ge of the fixed blade 12 . This is the case if the

distance from the edge of the blade to the surface of the body of

the clipper is 2 m m.

23

Page 24

3.1.2 Replacing the piston

6

7

1 2 3 4 5 6 7

The moving blade is raised pneumatically.

The piston 4, wh i c h o pe rates the blade, i s l o cated in the body o f t he

clipper.

Regulation and inspection

When the piston is replaced it must be adjusted so that the edge of the

moving blade i s j ust beneath the edge of th e f i x ed bl a de 12 .

Caution: danger of injury

Turn off the main swit ch.

The thread clip pe r ma y on l y be rem ov e d w i th th e se wi n g m ach i ne

switched off.

The piston ma y on l y be r ep l ac e d w he n t he thread clipper ha s be en

removed.

IMPORTANT !

The surface of the hole is an od i sed .

When replacing the piston take care not to damage the anodised layer.

Adjustment

–

Remove thread clipper (see section 3.1).

–

Remove retaining ring 1.

IMPORTANT !

Washer 2 is under spring pressure.

–

Remove wash er 2 , p r es su r e s p ri ng 3 a nd pi s t on 4 with O-ring 5.

–

Grease the surf ac e of th e h ole wi t h

(Order no.: 0791 000304)

–

Re-assemble t he pis t on i n t he rev e rs e o rde r.

ESSO S420

grease.

24

If this screw 11 has been unscrewed it must be replaced in the hole

together wit h Teflon tape (see section 3. 1. 1).

–

Fit the thread clip pe r.

–

Carry out a cutting test with sewing threads (test program).

Page 25

3.2 Folding tabl e

5

1

6

2

7

3

8

4

Regulation and inspection

Depending on th e t hi c kn es s o f t he ma te r i al t he fo l di n g p l at e 1 s ho ul d

be in parallel with the slide plate at a height of between 1 and 1.5 mm

above it. The height is determined by the thickness of the material.

In the 0 position the leading edge of the folding plate 1 runs parallel to

that of the sl id e plate.

The insertio n d ep t h is de te r mi n ed by t he ma te r ial . The fi rs t

penetration o f the needle into th e m aterial should be as c lo s e a s

possible to th e f ol d - ove r ed ge .

9

Caution: danger of injury

Turn off the main swit ch.

The folding table may only be adjusted with the sewing machine

switched off.

Adjustment

1. Adjusting the height

–

Unscrew screws 2 and 6.

–

Adjust the height of the folding plate 1 by inserting or removing

separators (contained in the accessory kit) between the block 8

and the foldi n g p l at e 1 .

–

Tighten screws 2 and 6.

2. Adjusting the position

–

Move the sw iv el a r m t o t he 0° position.

–

Undo screws 2 and 6 and the clamping lever 5.

–

Align the folding plate 1 in parallel with the slide plate.

The leading edge of the folding plate should be above the centre of

the needle ho l e a nd th e 0 ° edge of the sca l e.

The depth setting must be adjusted if necessary.

–

Retighten s cr e ws 2 an d 6 an d c l a mp i ng l ev e r 5.

3. Adjusting the insertion depth

–

Undo locknut 9.

–

Adjust the depth setting 4.

With medium- h ea v y material the fir s t pe ne tr a ti o n o f t he ne ed l e i n to

the material s ho ul d be as cl o s e a s po s si bl e to th e f ol d - ov e r ed ge .

–

Retighten l o c knu t 9 .

25

Page 26

3.2.1 Retraction of folding table

1

2

3

4

5

The folding t ab l e i s e xte nded by a pneumati c cy l i n de r an d re tr a c te d b y

a tension spring.

Regulation and inspection

The tension i n th e s p ri ng mu s t b e s u c h t ha t w i th th e folding table

retracted th e l e ver l i e s parallel to the e dg e of the base plat e.

The extension movement of the folding table must be rapid, but not

instantaneous.

67

Caution: danger of injury

Turn off the main swit ch.

The retracti on of th e folding table ma y on l y be adjusted with t he

sewing machi n e s w i tc h ed off.

Adjustment work and function testing with the sewing machine running

must be carri ed ou t with the utmost c ar e .

Adjustment

1. Adjusting the retraction of folding table

–

Push the folding table in.

–

Remove the right-hand casing and detach the tension spring 4.

–

Undo screw 2.

–

Press the pre s s ure r ol l e r 6 o nt o the control cam 7, at the same

time aligni n g t he l ev e r 3 in parallel wit h t he edge 1 of the base

plate and tighten screw 2.

The axial play in the shaft must not exceed 0.5 mm.

–

Re-attach the te nsi o n s p ri ng 4.

2. Adjusting the extension speed

–

Adjust the extension speed of the folding table at the throttle valve.

The movement s ho ul d be r ap i d, bu t n ot i ns t an ta ne ou s .

The throttle valve can be reached through hole 5.

26

Page 27

3.2.2 Angle adjustment, switch point b03

1

b03

4

5

6

2

7

3

The angle is ad j ust ed manually. The manual grip i s co mp res s e d an d

the angle adjusted in accordance with the scale.

Regulation and inspection

The angle set mu s t b e k e pt c on s ta nt wi t h t he br a ke.

5 mm

When the table is in the forward position the proximity switch

operate.

Caution: danger of injury

Turn off the main swit ch.

The angle adj us t me nt ma y on l y be ad j usted with the sew i ng ma c hi n e

switched off.

Adjustment work and function testing with the sewing machine running

must be carri ed ou t with the utmost c ar e .

Adjustment

1. Angle adjustm ent

–

Tighten 2 screws 1.

The manual gr i p 6 mu st p res s u ni f orm l y on th e p r ess u r e p l at e 2 .

The distance of the manual grip 6 to the base plate 7 is about

5 mm on the oute r ed ge .

–

Tighten locknuts 3.

b03

must

2. Adjusting the switch point for b03

–

Adjust switch with program 63.

–

Undo locknut 5.

–

Rotate the index ring 4 until the proximity switch

securely (see display).

–

Tighten locknut 5.

operates

b03

27

Page 28

3.3 Transport carriage

1

2

3

4

5

11 4

8

6

The transport carriage holds the shaping module and moves it in

accordance with the seam pattern.

Regulation and inspection

The transport carriage must be at an angle of 90° to the arm shaft.

The reference point must be adjusted with the gauge.

Caution: danger of injury

Turn off the main swit ch.

The transport c ar ri a ge ma y on l y be ad j ust ed with the sewi ng ma c hi n e

switched off.

Adjustment work and function testing with the sewing machine running

must be carri ed ou t with the utmost c ar e .

Adjustment

–

Remove the sha pi n g m odule and slide plate (see sec ti o n 2 .5 ) .

–

Place the gauge 5 (order no. 0935 107077) on the base plate of

the sewing machine and attach it with screw 3.

–

Undo 2 screws 1.

–

Align the tr an s po rt c a r ri ag e with the gauge.

The shaft 2 must be in contact with the gauge.

–

Tighten 2 screws 1.

–

Align the st op pl a te 4 a t about 5° (anti-clockwis e) to the surface 11

of the gauge 5 .

–

Move the transport carriage about 100 mm to the left.

–

Select program 01 (sewing program) and turn on the main switch.

When the di spl a y

the " Σ " button.

The transpo rt c a r ri ag e m ov e s to th e reference posit i on .

The positi on of th e s t op pl a te 4 i s a l te red by t he pi n 6. In this

position th e s t op pl a te 4 m us t be i n c l o s e co ntact with the ed ge 11

of the gauge.

–

If it is not, undo screws 7 and adjust the switch plate 10.

–

Check positi on i ng ag ai n .

–

Adjust stop screw 8 and secure with locknut 9.

The distance between the support and the screw head is

about 1 mm.

" <--- REF ---> "

78 910

or

" REF ---> "

appears press

28

1 mm

Page 29

3.3.1 Overrun protection

1

2

b05

3

Regulation and inspection

Overrun prot ec t i on on th e l e ft of th e t r an s po rt c a r ri ag e i s p rov i d ed by

proximity switch

b05

.

Caution: danger of injury

Turn off the main swit ch.

Overrun prot ec t i on ma y only be adjusted with the sewi ng ma c hi n e

switched off.

Adjustment work and function testing with the sewing machine running

must be carri ed ou t with the utmost c ar e .

Adjustment

–

Adjust the height of proximity switch

can pass through without a gap.

If this is not t he c ase , b en d t he ta b 2 .

–

Push the transport carriage manually to its left-hand end position.

–

Select pro gra m 62 and turn on the main switch.

Press

Set the

–

Push the switch plate 3 towards the proximity switch until this

operates sec u rel y.

Bend the lug s of the plate into th e n ea r es t to ot h g ap s .

–

Undo 2 screws 1.

–

Move tab 2.

This carries o ut th e fine adjustme nt of th e s w i tc h po i nt .

–

Retighten 2 s c rew s 1.

–

Check the switch function.

"STOP"

"program"

button.

switch to 05.

so that the switch plate 3

b05

29

Page 30

3.4 Shapi ng module

3.4.1 Shaping-module guide roller

1

2

3

4

5

6

789

Regulation and inspection

The position of the guide roller 4 is adjusted with gauges 5 and 6.

The pneumatic cylinder 8 is only needed for seams with a small radius

of curvature.

Caution: danger of injury

Turn off the main swit ch.

The guide roll e r ma y on l y be adjusted with t he s ew i ng ma c hi n e

switched off.

Adjustment

–

Remove the sha pi n g m odule and slide plate (see sec ti o n 2 .6 ) .

–

Place gauge 5 ( ord er n o. 09 35 107077) on the bas e pl a te of th e

sewing machine and attach it with screw 3.

–

Pivot the upper part of the machine to the left.

–

Undo adjusti ng r i ng s 1 a nd 3.

Move the shaft 2 until the guide roller 4 is at a distance of 1 mm

from the fir s t su r fa c e o f t he ga uge 5.

Check the distance with gauge 6 (order no. 0933 080200).

–

Re-attach adjusting rings 1 and 3.

–

Undo the locknu t a nd un s c rew s c rew 7 a fe w t ur n s.

–

Screw 9 press e s on th e p i s to n rod.

Turn screw 9 until the guide roller 4 is at a distance of 1 mm from

the second surface of the gauge 5.

Check the distance with gauge 6.

–

Tighten locknut onto screw 9.

–

Screw in screw 7 as far as it will go and lock it.

–

Use gauge 6 to che c k th at th e g ui d e r o l l er i s a t a di stance of 1 mm

from both sur f ac e s of the gauge 5.

If it is not, repeat the process.

30

46

Page 31

3.4.2 Shaping-module pressure cylinder

1

2

3

4

5

78

6

Regulation and inspection

The pressure c yl i nd er 3 cl os e s th e s h ap i ng mo du l e.

The clamping frame 1 is supported on a shaft. The pressure cylinder 3

is free to swing. The return movement is carried out by the spring

plate 7. When the shaping module is fitted the roller bracket is

opposite the c o nt r ol cam 6.

Caution: danger of injury

Turn off the main swit ch.

The pressure cylinder may only be adjusted with the sewing machine

switched off.

Adjustment

1. Adjusting the height.

–

Turn the handwheel un ti l the needle is a t t op de ad c en tr e .

–

Move the shap i ng mo du l e. T he gu i de r oll e r 5 of the pr es su r e

cylinder 3 must press on the curve of control cam 6.

–

Undo screw 2 an d move the pressu r e cy l i n de r 3 i n th e c l a mp i ng

frame 1.

The distance between the tip of the needle and the upper side of

the shaping mo dule is 2.5 mm. Th e i n ne r s urf ac e s 4 of the ro l ler

bracket must be parallel to the control cam 6.

–

Retighten s cr e w 2 .

2. Adjusting the spring plate 5.

–

Undo clamping screw 8.

–

Move the spr i ng pl a te 7 a l on g t he s ha ft .

5 mm of the spri n g p l at e m us t be i n c o nt ac t wi t h t he c l am pi n g

frame.

The guide roll e r 5 i s above the centr e of th e c o nt rol c a m.

–

Retighten c l a mp i ng sc r ew 8.

IMPORTANT !

The slide sur f ac e of th e s p ri ng pl a te 7 must always b e ke pt greased.

31

Page 32

3.4.3 Shaping-module closing movement

Regulation and inspection

The closing m ov e me nt for the shaping module is determ i ne d b y th e

throttle and the closing for c e by t he pre s s ure regulator.

The closing m ov e me nt of the pressure c yl i n de r mu s t b e ra pi d , b ut not

instantaneous.

The material must be properl y tra ns f er red with the mini m um po s s i ble

pressure.

1

2

Caution: danger of injury

Adjustment work and function testing with the sewing machine running

must be carri ed ou t with the utmost c ar e .

Adjustment

1. Adjusting the closing movement

–

Adjust the throttle 1.

2. Adjusting the closing force

–

Activate pro gr a m 6 4 ( select output el e me nt s ) .

Press

–

Check that the ma te ri al is p rop er l y t r an sfe r red .

Place the thinnest mate rial in position and push in the folding

table. Press the "Σ" button. The cylinder is operated.

Check that the material is securely held.

–

Adjust the pressure regulator:

to increase pressure: screw in tap screw 2

to decrease pressure: unscrew tap screw 2

The material must be properly transferred with the minimum

possible pressure.

"STOP"

button and set

"program"

switch to 32.

32

IMPORTANT !

If the pressure is insufficient the pressure cylinder is not vented.

Page 33

3.4.4 Adjusting the shaping module

5

The sewing mac hi n e ca n b e f i tt ed wi t h va r i ou s s ha pin g m od ul e s fo r

different seam patterns.

See section 2. 12 of the Operating manual.

Regulation and inspection

The shaping module must be mounted on the support shaft with no

play.

The material clamps must be fitted so that the adjusting pins

(gauge 1, section 2.1) can be inserted through holes 4.

The pressure of th e f ol d i ng r ims ( p re- t en s i on of th e m at er i a l cl am ps ) is

determined by the curvature of the shaping module.

1

2,5 mm

2

3

4

Caution: danger of injury

Turn off the main swit ch.

Remove the shaping module from the sewing machine and adjust it.

Adjustment

1. Adjusting the holding claws

–

Undo the attachment screws 2 of the holding claws 1.

–

The shaping mo du l e m us t be mo un te d o n the support shaft with no

play.

Otherwise adjust the position of holding claws 1 and 6.

–

Retighten a tt ac h me nt s c rews 2.

2. Adjusting the position of the material clamps

–

Compress th e s h ap i ng mo du l e (to the same dime ns i o ns a s i n t he

6

7

sewing machi n e) .

It must be possible to pass the adjusting pins through the holes 4.

If it is not, undo the screws 3 and adjust the plates accordingly.

3. Adjusting the pressure of the folding rims

–

Bend the mat eri a l c l am ps t o t he c orr e c t curvature.

Standard set ti n g: 2.5 mm.

The distanc e m ust be the same alo ng th e e ntire length of th e

material clamp. The distance must also be the same for both

plates.

4. Using the shaping module on the 743-121 sewing machine

–

The shaping mo du l es o f t he

If the shaping module is to b e u s ed on th e

slot 5 with nut 6.

The stop must be ad j us t ed . S e e t he

743-221

do not have stop 7.

743-121

743-121

, fit stop 7 into

service manu al .

33

Page 34

4. Maintenance unit

1

The maintenan c e u ni t pr o te c ts the sewing mac hi n e f r om wa te r and

particles of dirt in order to avoid blockages an d r u s t f orm ation in the

pneumatic system.

Regulation and inspection

The water level in the pressure regulator must not reach the filter.

The filter in s er t 1 m us t be c leaned every 160 ho ur s .

Caution: danger of injury

Turn off the main swit ch.

Isolate the sewing machine f rom the compresse d- a i r s up pl y.

The filter may only be cleaned when the system has been

depressurised.

–

Blow the water out of the water separator under pressure.

–

Wash the filter holder and filter insert 1 with petroleum ether.

Blow the filter insert 1 clean with the compressed-air gun.

Important !

Do not use solv en ts t o w as h th e f il te r ho lde r an d f il te r ins e rt.

They destroy th e f i l te r ho l de r.

34

Page 35

5. Maintenance

Caution: danger of injury

Turn off the main swit ch.

Maintenance of the sewing machine may only be carried out when it is

switched off.

The maintenance work to be carried ou t daily or weekly by the sewing

machine’s oper a ti n g p ers o nn el ( cl e an i ng an d l u br i ca ti o n) i s described

in part 1: Ope r at i ng ma nu al . It i s giv e n i n th e f ol l o wi n g t ab l e f or t he

sake of completeness.

Work to be carried out operating hours

upper part of machine

clean up dust , l i n t a nd th r ea d f r ag me nt s in the region of th e s h ut tl e an d

needle plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

clean light barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

check oil level in reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

check oil level in shuttle-lubrication reservoir . . . . . . . . . . . . . . . . . X

check shuttle lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

clean lenses of residual-thread monitor . . . . . . . . . . . . . . . . . . . . X

check cogged belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

8 40 160 500

sewing machine

clean motor-fan screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

check condition and tension of V-belt . . . . . . . . . . . . . . . . . . . . . . X

clean filter for stepping-motor drive . . . . . . . . . . . . . . . . . . . . . . . X

inspect condition and tension of transfer-carriage V-belt . . . . . . . . . . . X

lubricate laminated spring on pressure cylinder . . . . . . . . . . . . . . . . X

pneumatic system

check water level in pressure regulator . . . . . . . . . . . . . . . . . . . . X

clean filter insert in maintenance unit . . . . . . . . . . . . . . . . . . . . . . X

check system impermeability . . . . . . . . . . . . . . . . . . . . . . . . . . X

35

Page 36

6. Summary of adjustments

IMPORTANT !

Adjustments to the sewing machine must be carried out in the order

given.

no.: subject section correct adjustment correction

arm-shaft cra nk

1 position of adjusting disc 2 .3 groove and notch A in line rotate cogged-b el t pu ll ey

upper-thr ea d te ns io ne r

2 upper-threa d tensioner

release

3 thread take-up sp ri ng 2.5 spring travel:

needle-bar height

4 needle-bar height 2.7 set with gauge move needle bar

2.4 distance of tension discs: 1mm when closed move cylinder

keep upper thread under tension until tip of

needle

has penetrated material

spring tension: about 20 to 30 cN

rotate bush

adjust tensio n bo lt

shuttle settings

5 shuttle-drive housing 2.7.2 distance between shuttle and bush 0.4 mm.

6 loop lift 2.7.1 in position A shuttle beak at ce ntre of ne ed le

7 bobbin-hous in g hold er 2.8 distance from retain in g ta b to hou si ng : 0.6

residual-thread monitor

8 light barrier 2.9 reflection on turning empty bobbin align light barrier

bobbin winder

9 filling level of bo bb in 2 .10 to 0.5 mm ben ea th bob bi n ri m rotate switch ca m

position sensor

10 positioning 2.11 move to position C after sewing proc es s rotate position -s en so r

thread clipper

11 position of the thread

clipper

12 fixed blade 3.1.1 must protrude 1.5 mm from body of clipper move blade

13 moving blade 3.1.1 must protrude 2 mm from body of clipper move blade

14 cutting pressure 3.1.1 cut safely with minimum pressure adjust pressure screw

3.1 moving blade must be able to move freely in

distance between slide surface and

thread-drawing plate 3.8 mm.

and distanc e fr om shut tl e be ak to fu rr ow: 0.1

mm

+0.1

mm

shaping-module slit while thread is being cut

adjust housin g la te ra ll y

adjust stop screw in

base plate

adjust shuttle

bend retainin g ta b

ring

align thread clipper

36

Page 37

no.: sub ject section correc t a d j ustment correc t i on

folding table

15 heig ht 3.2 1 to 1.5 mm parallel to and above slide pl at e

16 posi ti on 3.2 parallel to slide plate - leadin g ed ge abov e

17 inse rt ion de pt h 3.2 first penetration as close as po ss ib le to fo ld in g

18 retr ac ti on of fo ld in g ta bl e 3. 2. 1 tens io n of ten si on spr in g su ch tha t leve r is

19 extend folding table 3.2.1 movement rapid but not instantaneous adjust throttle

20 angl e ad ju stmen t 3.2.2 distanc e of man ua l gr ip s on out er edg e abou t

21 swi tch po in t b3 3. 2 with table in forward po si ti on pro xi mit y swi tc h

transport carriage

22 angle 3.3 90° to a rm shaft. adjust with gauge

23 posi ti on 3.3 check reference point w it h ga ug e adjust switch pla te

24 over ru n prot ec ti on 3.3.1 transpor t ca rria ge in le ft -h and en d po si ti on adjust switch pla te

shaping module

25 guide roller 3.4.1 align position with gauges:

26 position of pressure

cylinder

27 spring plate on pressure

cylinder

28 clos in g mov eme nt 3.4.3 rapid but not in st an ta neou s adjust throttle

29 closing force 3.4.3 hold material securely with minimum pressure adjust pressure

30 hold in g cl aws 3.4.4 shaping mod ul e mus t be moun te d on sup port

31 material clamps 3.4.4 adjusting pins must go into inspection holes adjust plates

32 pressure of foldin g rims 3.4.4 curvature of material clamps 2.5 mm. bend material clamps

3.4.2 needle at top dead c entr e an d gu ide ro ll er on

3.4.2 5 mm must be in contact with clamping frame move spring plate

height is determi ne d by thi ck ne ss of mater ia l

centre of needle hole and 0° mark on scale

edge

parallel to base plate

5 mm

must operate safely

distance to needle

position in direction of t ravel of transport

carriage

curve of control cam:

distance betwee n ti p of nee dle an d up pe r si de

of shaping module 2.5 mm

inner surfaces of roller bracket parallel to

control cam

shaft with no play

add intermediat e la ye rs

align folding pl at e

adjust depth setting

align lever

adjust distance

rotate index ring

adjust position of

pistons in pneumatic

cylinder

move shaft

move cylinder

rotate cylinder

regulator

move holding claws

37

Loading...

Loading...