Adler 743-121 Operating Instruction

Contents Page:

Home

Preface and General Safety Notes

Part 1: Operating Instructions for the 743-121

1. Product Description

1.1 Technical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Patents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Operating the Sewing Unit

2.1 Needles and Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Threading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Setting Thread Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Changing the Configuration Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Dart Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Dart Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Setting the Insertion Depth of the Folding Table . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Setting the Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.9 Positioning the Sewing Pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Maintenance

3.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1. Product Description

DÜRKOPP 743-121

The

single-point darts

Maximum seam l en gt h 1 50 mm .

The unit is e qu i pp ed wi t h a ma c hi n e h ea d i n do ub l e chain stitch

•

execution.

A configuration set ap pr o pr iate to the seam c on fi g ur a ti o n h ol d s

•

and guides the material.

The seam leng th c on trol occurs eit he r v i a l ight barrier or

•

programmin g, as d esi r e d.

Seam securing at the beginning and end of the seam through stitch

•

condensing i n t he ma te r i al a nd th rea d c h ai n

Thread trimming system: Controlled chain trimmer

•

Transport carriage drive via step motor.

•

The complete control of the sewing unit occurs through a

•

micro-computer. It assumes the control tasks, monitors the sewing

process and signals operating errors and malfunctions.

An electronic thread monitor prevents a renewed starting of the

•

sewing procedure by thread breakage or when the thread is used

up.

is a sewing un i t f or t he au to ma te d se wi n g o f

with straight or cu r ved s ea m co nf i gu r at ion s .

1.1 T echnical Specification

1.2 Patents

Machine head: Class 935 - 17 1 -100

Needle system: 934 SIN

Needle thickness: Nm 90

Threads: As needle and bobbin thread spun

monofilament sewing threads

Stitch type: 401 Double ch ain s ti t c h

Stitch number: 4.800 / min

Stitch length: 2,2 mm

Stitch cond en s i ng : 1,0 mm

Sewing len gt h: 150 mm

Folding tabl e : 0 - 10° adjustable

Operating pre s s ure: 6 ba r

Air consumption: approx. 5 NL per work cycle

Nominal voltage: 0743 000524 3 ~ 380 - 400 V + N, 50 Hz

0743 000574 3 ~ 220 - 230 V, 50 Hz

0743 000644 3 ~ 220 - 230 V, 60 Hz

The sewing unit is delivered with

appropriate to th e n om i na l v oltage.

one

of the listed v ol t ag e s e ts

Following patents and registered utility models apply:

Status September 1993

42 28 943

5

1.3 Optional Equipment

0794 013222

0794 000091

0794 000332

0794 013333

0794 013444

0797 003031

2. Operating the Sewing Unit

2.1 Needles and Threads

Needle system: 934 SIN

Needle thickness: Nm 90

Threads: As needle and bo bb i n t hr e ad s pu n

Bundle cla mp wi t h s w i ng ar m an d h ol d er p i pe hr.

Supporting ta bl e ( small).

(only in con j un c ti o n w i th th e b undle clamp)

Remover dev i c e f or s m oo th i ng th e b l own-out

sewing pieces.

(only in con j un c ti o n w i th th e b undle clamp)

Blower pipe from the top or the right.

Supporting ta bl e

(when using in-house bundle clamp wagons)

Compressed ai r c o nn ec t i on ho s e, c on ne c to r

plug,

connector s o ck et an d h os e c l am p.

sewing threads

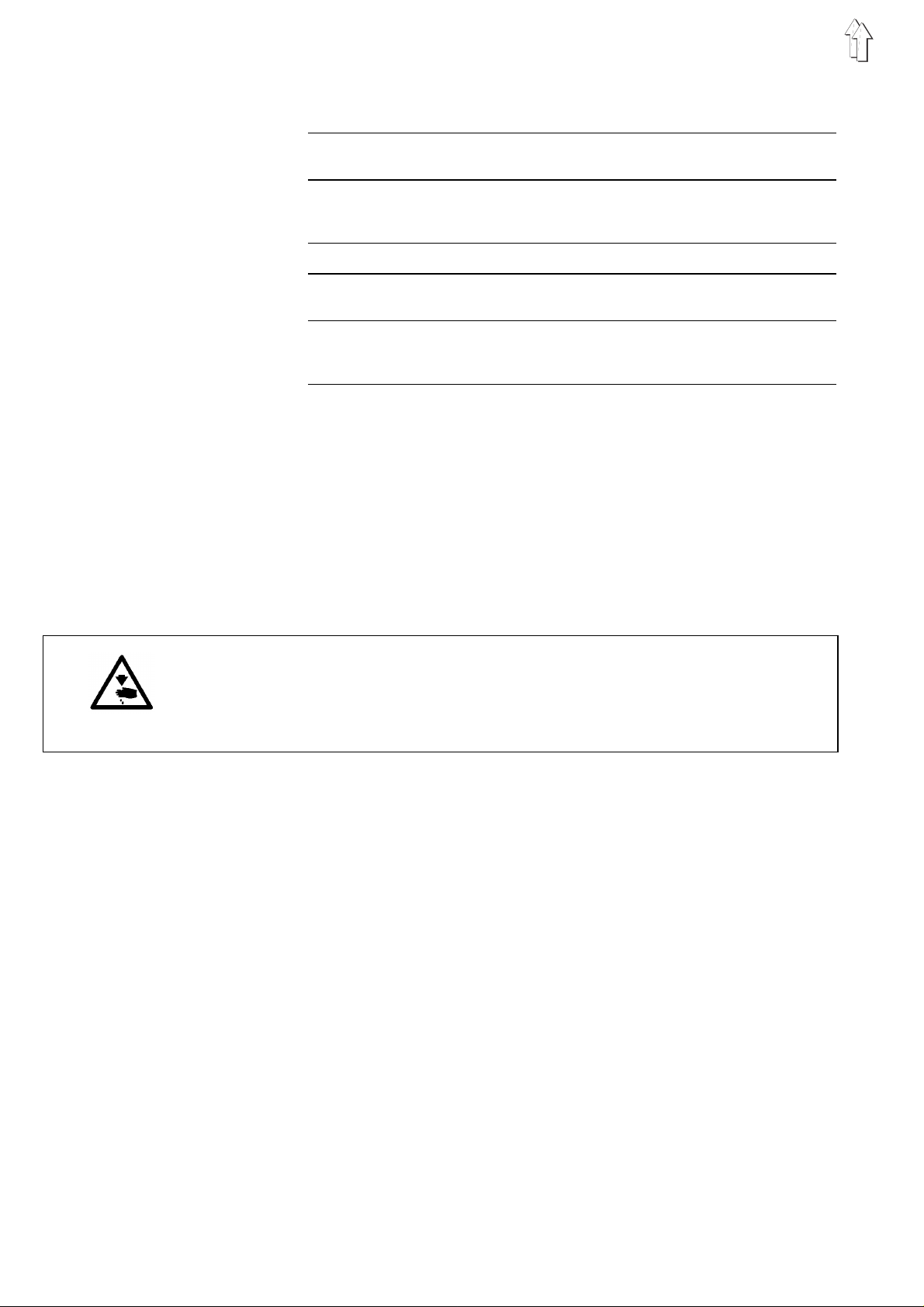

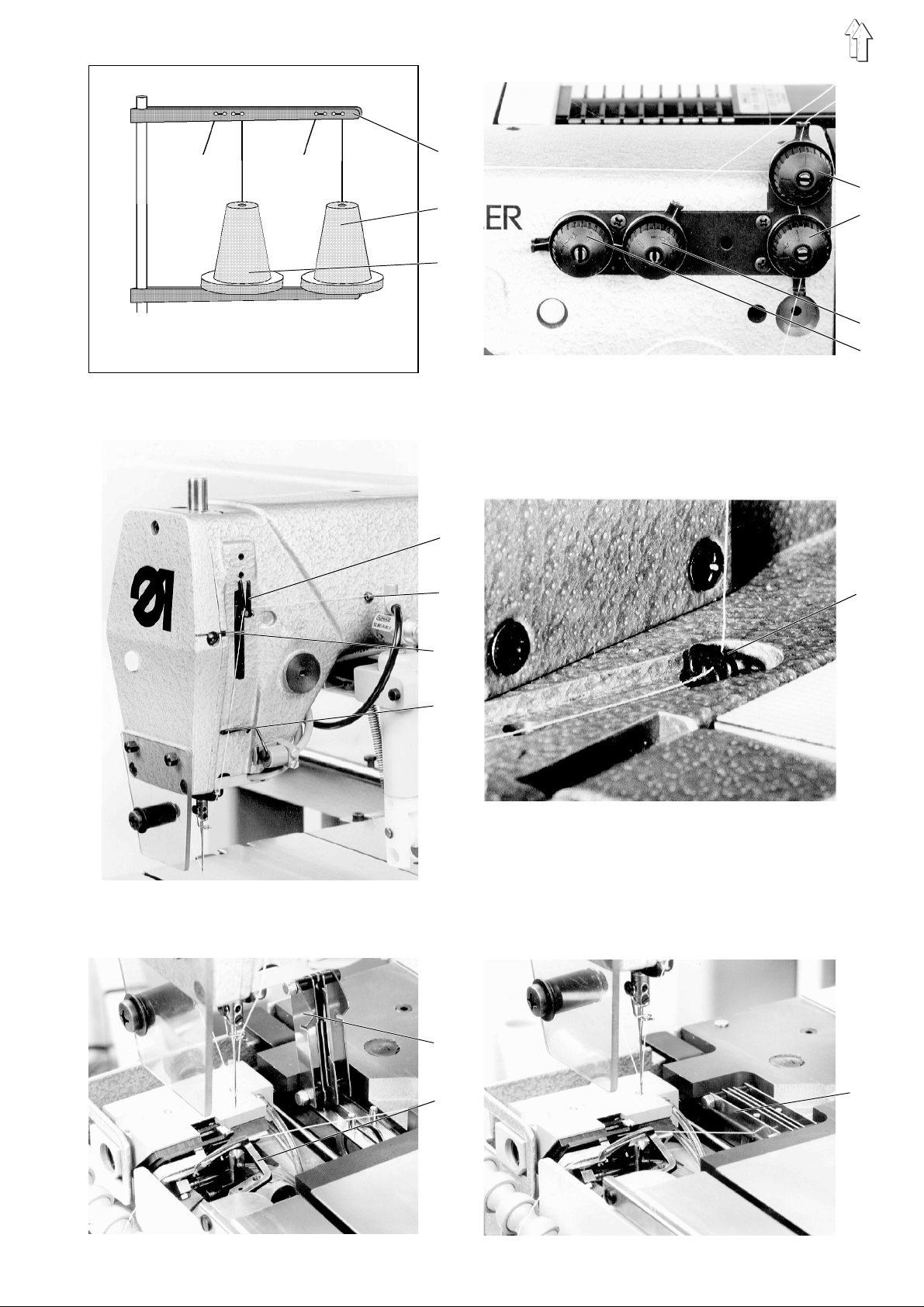

2.2 Threading

Caution Risk of Injury !

Turn main switch off.

Upper and lowe r th r eads m ay o nly b e t hre ad ed wi t h t he ma c hin e

switched off.

The configuration set must be in the left end position.

Threading lower thread (Bobbin thread)

–

Place thread spool 2 on the thread stand.

–

Alternatingly feed the thread through all 4 guide eyes of the take

off arm 1.

–

Unlock the slider bed and pull to the side.

–

Guide the thread through the thread tensioner 4 + 5 and the thread

guide 12.

–

Swing up the flap 13 over the thread take up disk. Guide the thread

to the right past the pins.

–

Lead the thre ad th rou gh the hook 14 and pul l t i gh t.

–

Close the flap 13 over the thread take up disk.

The thread mu s t b e i n th e f l ap s l ot .

–

Return the slider bed to its initial position.

Hereby the l ea f s p r i ng mu s t lock in place.

Threading the upper thread (Needle thread)

–

Place thread spool 3 on the thread stand.

–

Alternatingly guide the thread through all 4 guide eyes of the

takeoff arm 1.

–

Guide the thread through the thread tensioner 6 + 7, thread guide

9, check sp ri ng 10 an d thread monitor 11.

–

Lead the thread through the needle and the thread clamp.

Cut of the excess at the thread trimmer.

6

1

4

2

5

3

6

7

8

10

11

9

12

13

14

13

7

Loading...

Loading...