Contents Page:

Home

Part 3: Service Instructions for the 743-121

1. General

2. Setting the Machine Head

2.1 Arm Shaft Crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Needle Evasion Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Symmetry of Looper Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Hook at Needle Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Needle Bar Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Needle Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Thread Take-up Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8 Rocker Bolt and Left Lower Shaft Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.9 Hook Drive Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Setting the Sewing Unit

3.1 Thread Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Check Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Folding Table

4.1 Folding Table Retraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Angle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. Transport Carriage

5.1 Run-off Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Guide Roller for the Configuration Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. Contact Cylinder for the Configuration Set

6.1 Locking Movement for the Configuration Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. Setting the Configuration Set

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1

2

1. General

ATTENTION !

The tasks described in the service instructions must only be conducted

by speciali z ed pe r sonnel or persons w i th ap pr o pri a te tr a i ni n g !

Caution Risk of Injury !

Bei Reparatur-, UmFor repair, conversion and maintenance work the

main switch mu s t b e t ur n ed off an d the sewing uni t d i s connected from

the pneumatic air supply.

Adjustment work and function testing on a machine under power must

only be condu c te d w i th s tr ic t ad he r en c e t o t he s af et y me as u r es a nd

extreme caut i on .

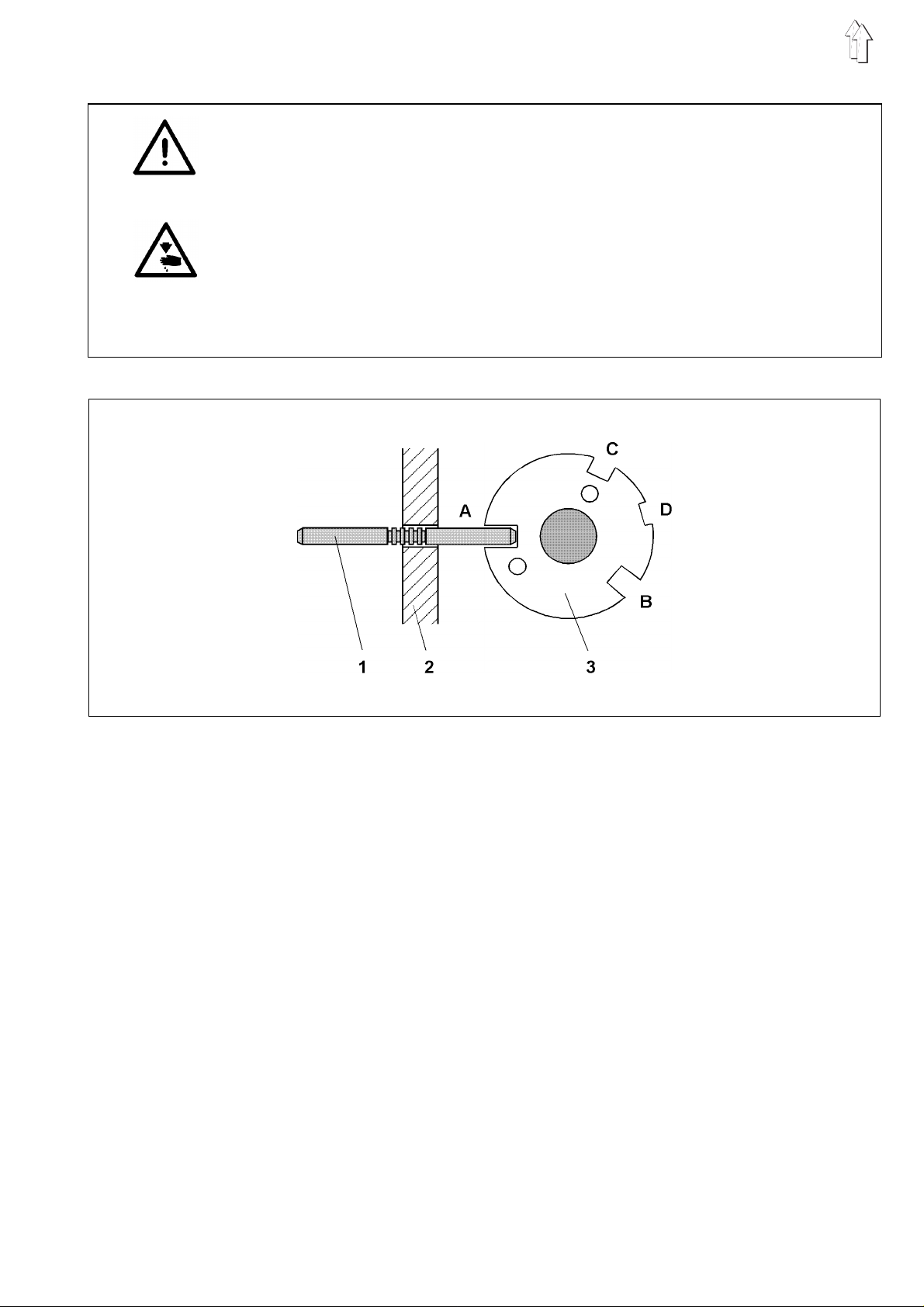

The machine head is equipped with adjustment aids which make it

possible to ad j ust the machine qu i c kl y an d e as i ly.

With the adjustment pin 1(in the accessories package) and an

adjustment ri ng 3 a tt ac h ed to th e pulley on the a rm s h af t t he sewing

unit can be ar r est ed in 4 adjustme nt po s i tions.

Dependent on the selected position, 2 to 5 grooves are visible on the

adjustment pin 1 ( 2 = ho us ing wall).

The positions A, B, C and D stamped into the handwheel for ease of

location. T he ma rk i ng on th e c o v eri n g h oo d s e r v es as an in di cator.

A = 2 grooves visible

B = 3 grooves visible

C = 4 grooves visible

D = 5 grooves visible

3

2. Setting the Machine Head

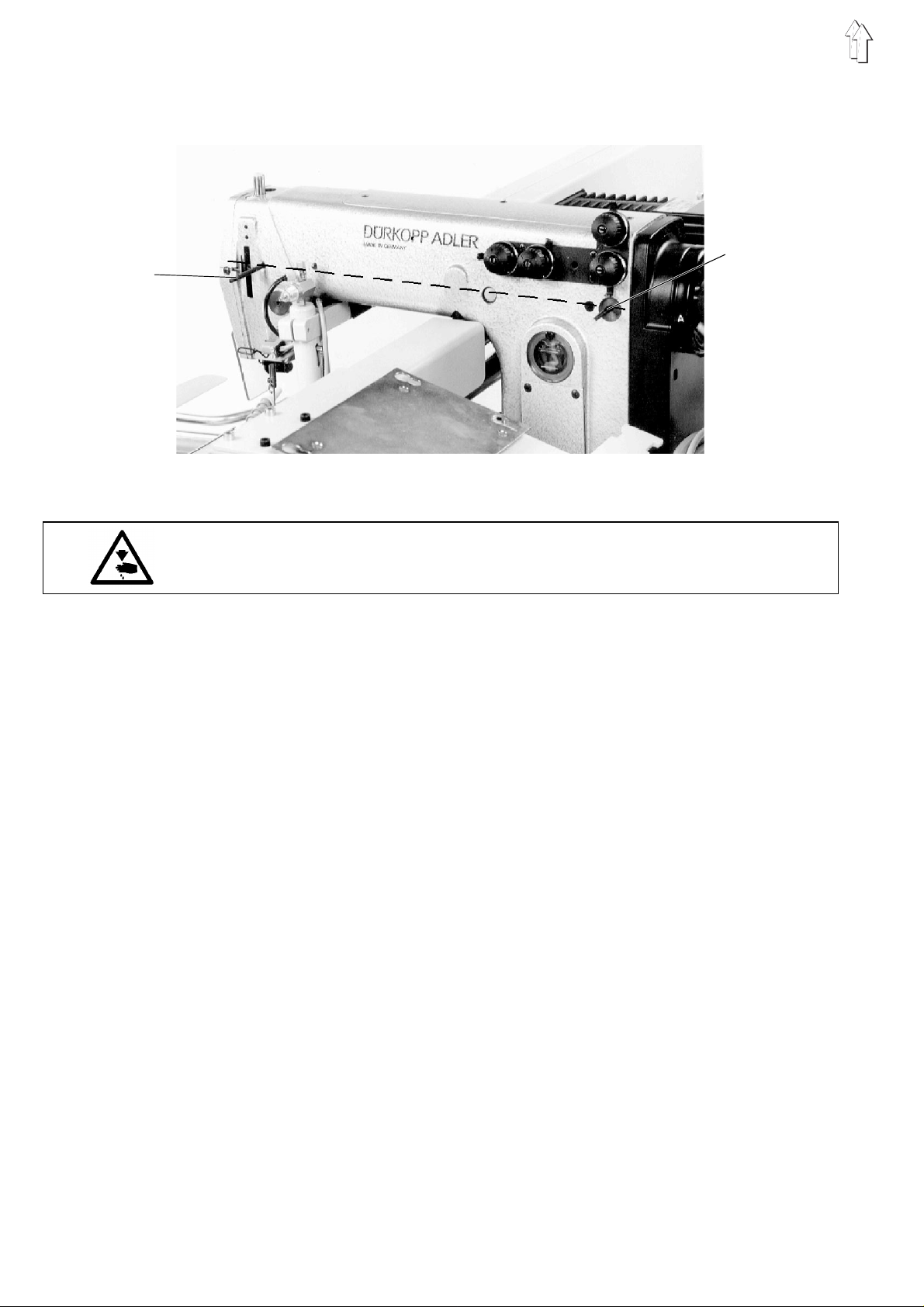

2.1 Arm shaft cr ank

1

The tracing groove of the arm shaft crank and the slot A of the

adjustment ri ng mu s t b e i n -l i ne .

2

Caution Risk of Injury !

Turn main switch off before adjusting.

–

Push the second adjustment pin 1 into the tracing hole and allow

the arm shaft crank tracing groove to lock on.

A pen or a 5 mm drill bit can also be used instead of the second

adjustment pin.

–

Check to see if in this position the adjustment pin 2 can be inserted

into positio n A (2 grooves visible).

If not, the arm shaft crank must be adjusted on the arm shaft.

Setting the arm shaft

–

Remove the front cover.

–

Loosen the arm shaft crank locking screws and adjust the crank

appropriately.

–

Tighten the locking screws.

4

2.2 Needle Evasion Movement

1

2

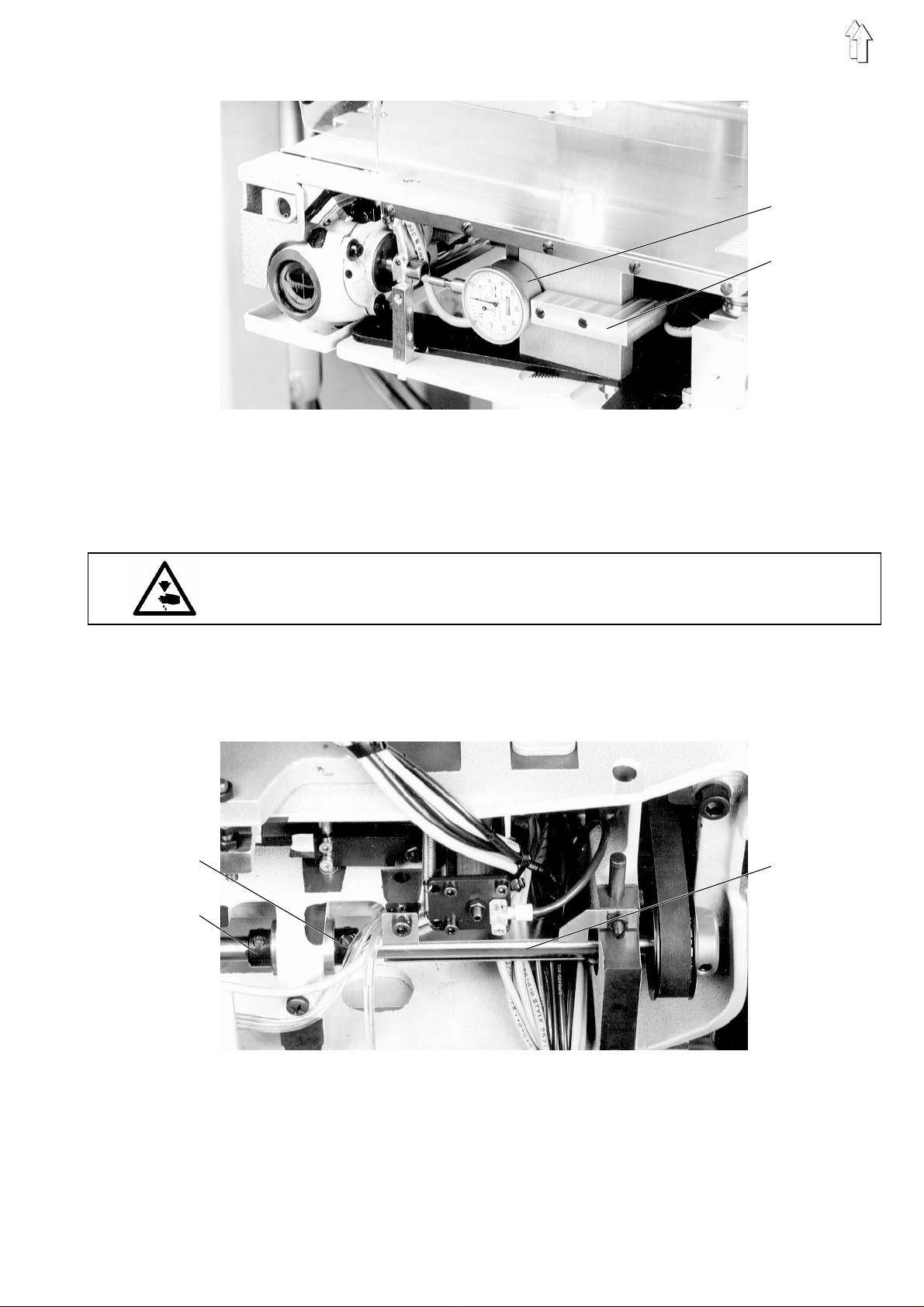

With needle evasion movement (ellipse width) is meant the movement

which the hook m ak e s in o r de r to pa s s

moving from right to left and

left to right.

With this sewing unit the ellipse width should be 1.9 mm.

( Needle thickness Nm 90 )

infront

behind

of the needle wh en mo v ing fr o m

the needle when

Caution Risk of Injury !

Turn the main switch off before measuring and adjusting.

Measuring the ellipse width

–

Attach the me asuring dail 1 w ith the parts kit 2

(Order no. 935 00 80 21 ) .

–

Set the lowest and highest points by turning the handwheel. The

difference sho ul d be 1. 9 m m.

4

3

5

Setting the ellipse width

–

Displace the lower shaft 3 along its axis

To the right: Ellipse width decreases

To the left: Ellipse width increases

–

Then set the s e t c o l lar s 4 an d 5 at th e c e nt er b ea r ing ti g ht again.

Check the lower shaft for ease of movement !

5

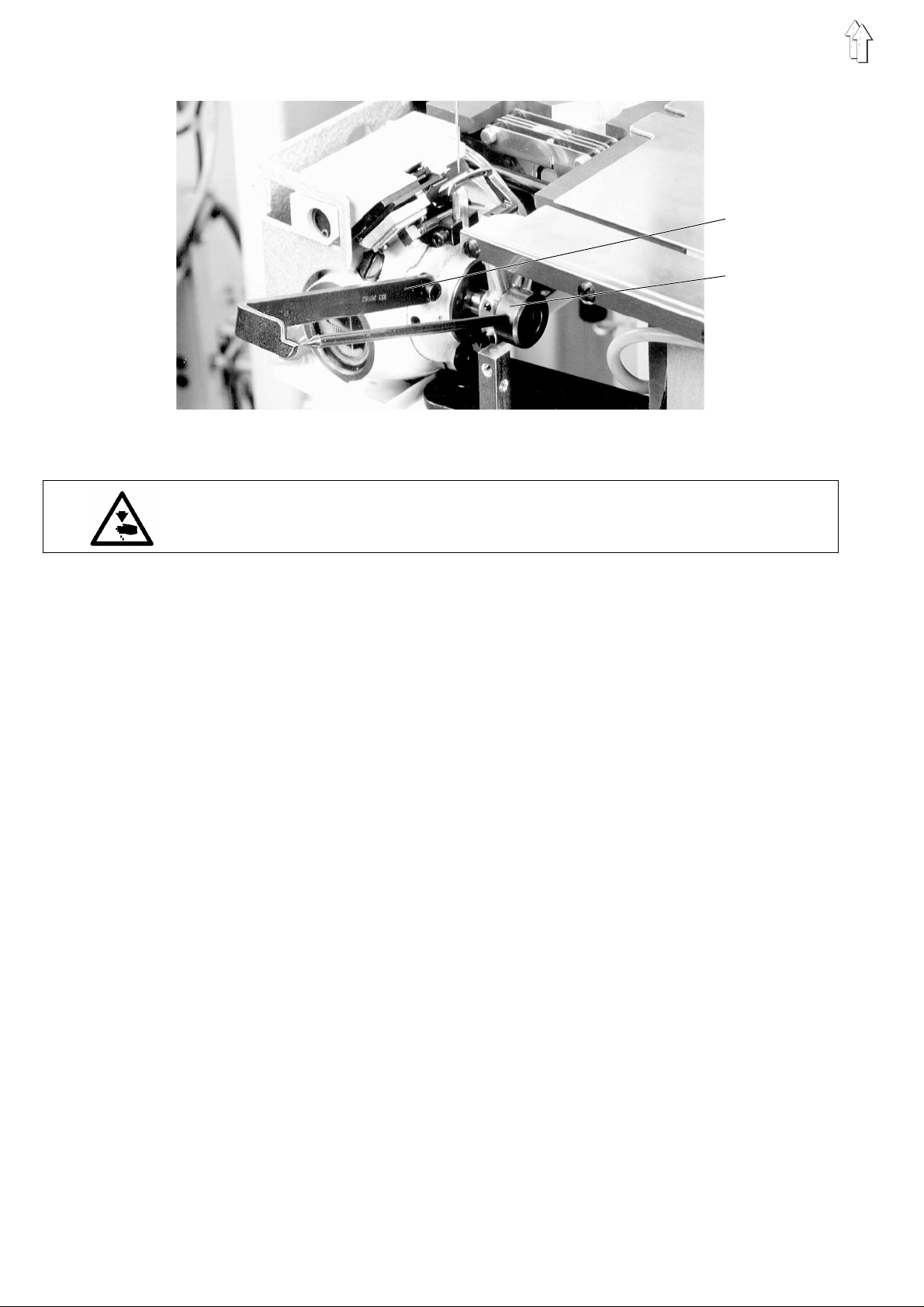

2.3 Symmetry of Looper Motion

Looper motion s y mm et r y i s s et wi t h t he ga ug es 1 an d 2

(Order no. 0933 080192).

Caution Risk of Injury !

Turn the main switch off before adjusting.

1

2

–

Arrest the sewing unit in position A (2 grooves visible).

–

Attach angle 1 and pointer 2 (see illustration).

–

Loosen the set sc rews on the lower pu l ley.

–

Check to see if the pointer moves up by turning the lower shaft in

the direction of rotation.

If not, the lower shaft must be turned accordingly.

–

Tighten the set screw s on th e lo we r pu ll ey.

–

Align the pointer to the measuring edge of the angle 2.

–

Pull out the adjustment pin and move the sewing unit to position

(5 grooves visible) by turning the handwheel and arrest there.

The pointer 2 should have made a pendulum movement up and

back to the slit again.

If not, loose n t he set s c rew s on th e l o we r pu l l ey.

Reduce the d i st a nce between the poi nt er a nd the slit by

through turning the handwheel.

Adjust the a ng l e 1 ( me as u ri ng ed ge to pointer).

Repeat the adjustment as often as necessary until the pointer 2

lies exactly on the measuring edge in positions A and D.

–

Withdraw the adjustment pin an d m ov e th e m ac h i ne to po s i tio n

by turning the ha nd wh ee l an d a rr est th er e .

The pointer 2 should have made a pendulum movement down and

back again to the measuring edge.

This pendul u m m ov e me nt res u l ts a ut om at i c al l y from the pendul um

movement fir s t s et .

half

D

A

6

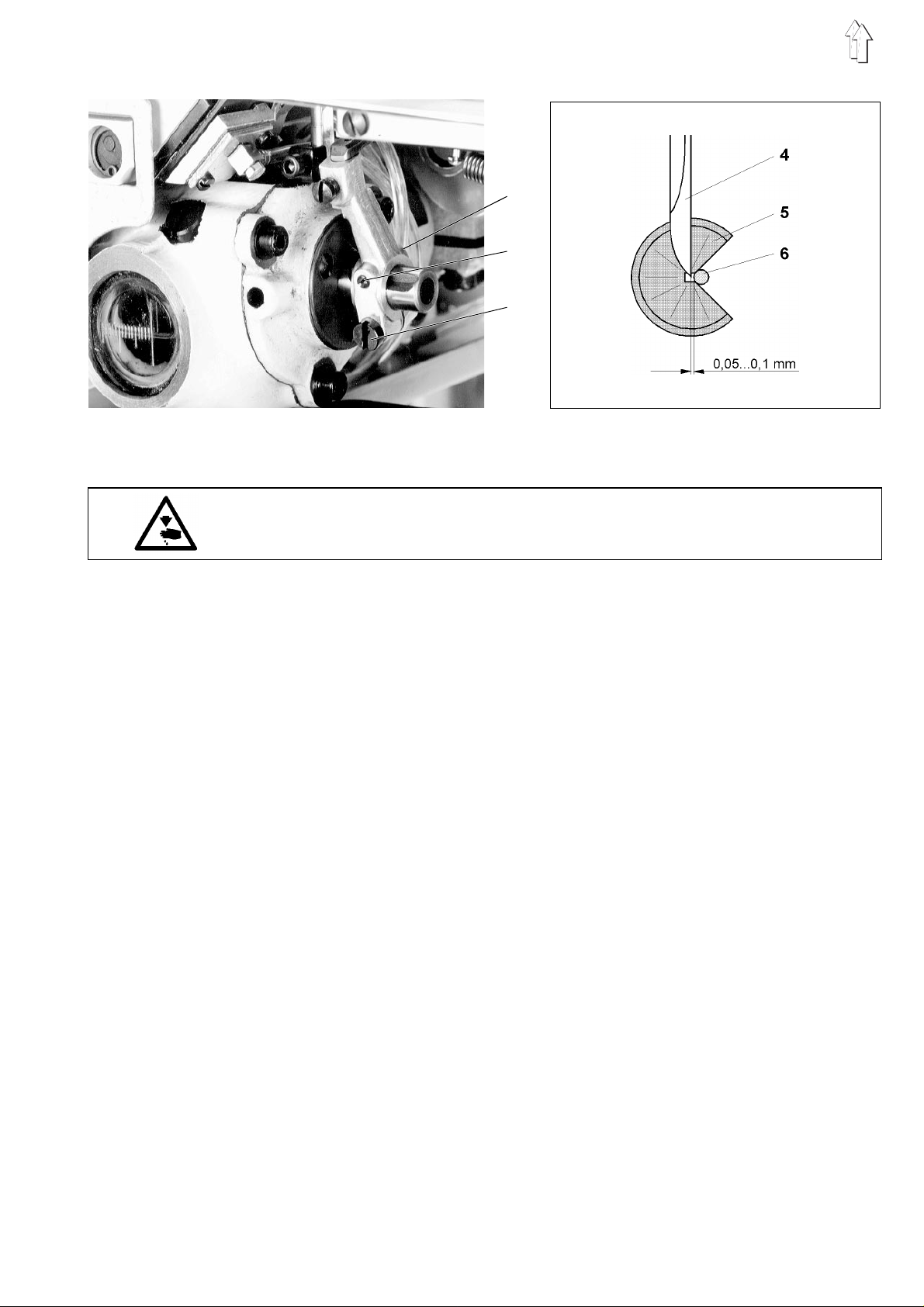

2.4 Hook at the Needle Center

1

2

3

In position C the hook point should lie at t he ne ed l e c e nt er.

The distance between the hook point and the needle is 0.05...0.1 mm.

Caution Risk of Injury !

Turn off the main switch before adjusting.

–

Arrest the sewing unit in po s i tion C (4 grooves visible).

–

Set the pos iti o n o f the hook with th e s t op s c rews 1 and 2.

–

Set the dist ance to the needl e b y s l idi n g t he hook in the ax ial

direction.

Screw 3 fast en s th e h oo k .

7

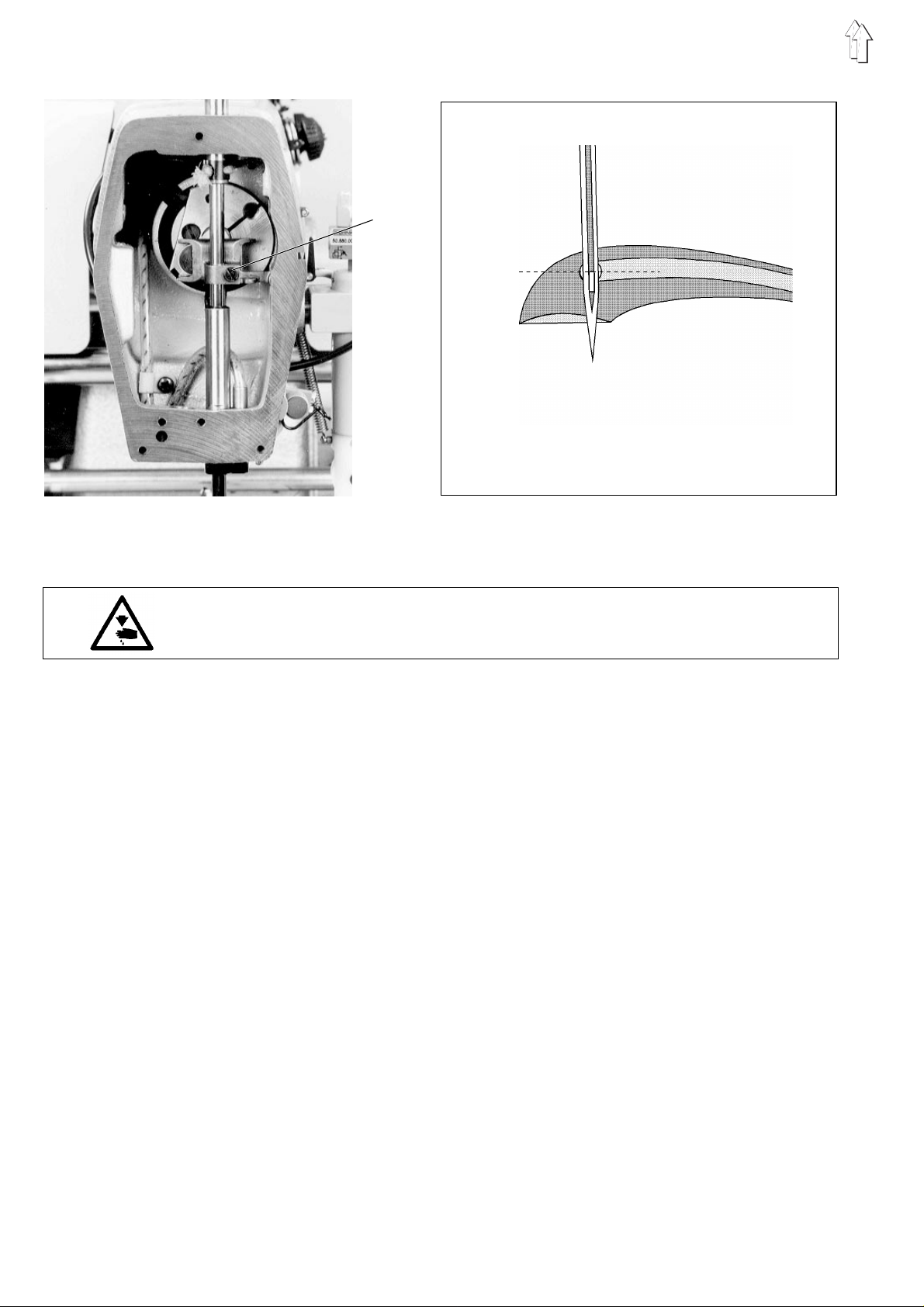

2.5 Needle Bar Height

1

The height of the needle bar is correctly set when the hook eye lies at

the center of t he needle

the center of t he hook eye.

Caution Risk of Injury !

Turn off main switch before adjusting.

–

Unscrew front cover.

–

Set needle b ar h ei g ht .

–

Tighten the needle b ar se t s c re w 1 .

and

the upper edge of the needle eye lies at

8

Loading...

Loading...