Page 1

Contents Page

Home

Part 4: Instructions f or pr ogramming D A-Micr ocontr ol cl. 743-121

Progra m version : 7 43LC-A0 3

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Description of the Controls

2.1 Operating Elements on the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Operating Elements in the Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Setting the Sewing and Testing Programs

3.1 Display of the Program Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Sewing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Setting Blower Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Step Motor Controller Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Timer and Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Current Passage Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.7 Test of the Front Panel Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.8 Test of the Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.9 Selecting the Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.10 Selecting the Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.11 Positioning the Machine Head in the 2nd Needle Position . . . . . . . . . . . . . . . . . . . . . 10

3.12 Positioning the Machine Head in the 1st Needle Position . . . . . . . . . . . . . . . . . . . . . 11

3.13 Positioning the Machine Head without Thread Trimming . . . . . . . . . . . . . . . . . . . . . . 11

3.14 Positioning the Machine Head with Thread Trimming . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Operation Displays and Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5. Step Motor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Status display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Page 2

2

Page 3

1. General

The DÜRKOPP ADLER 743-121 controls, with the int egrat ed MU LTITEST testing and monitoring system, assumes control and supervision

of the sewing process. Operating errors and malfunctions are displayed.

Special programs simplify mechanical adjustments and allow a quick

checking of the i np ut an d o ut pu t e le me nt s.

The data is sh own i n a 2 • 16-digit display.

All functions c an be al te r ed by pres sin g th e ap pr o priate button. The

machine must be in its in it ial setting. The set values (seam leng th , fu nction on/off, etc.) are put into the memory (battery- powered buffer)

and activated when th e m ac h in e i s next switche d o n.

3

Page 4

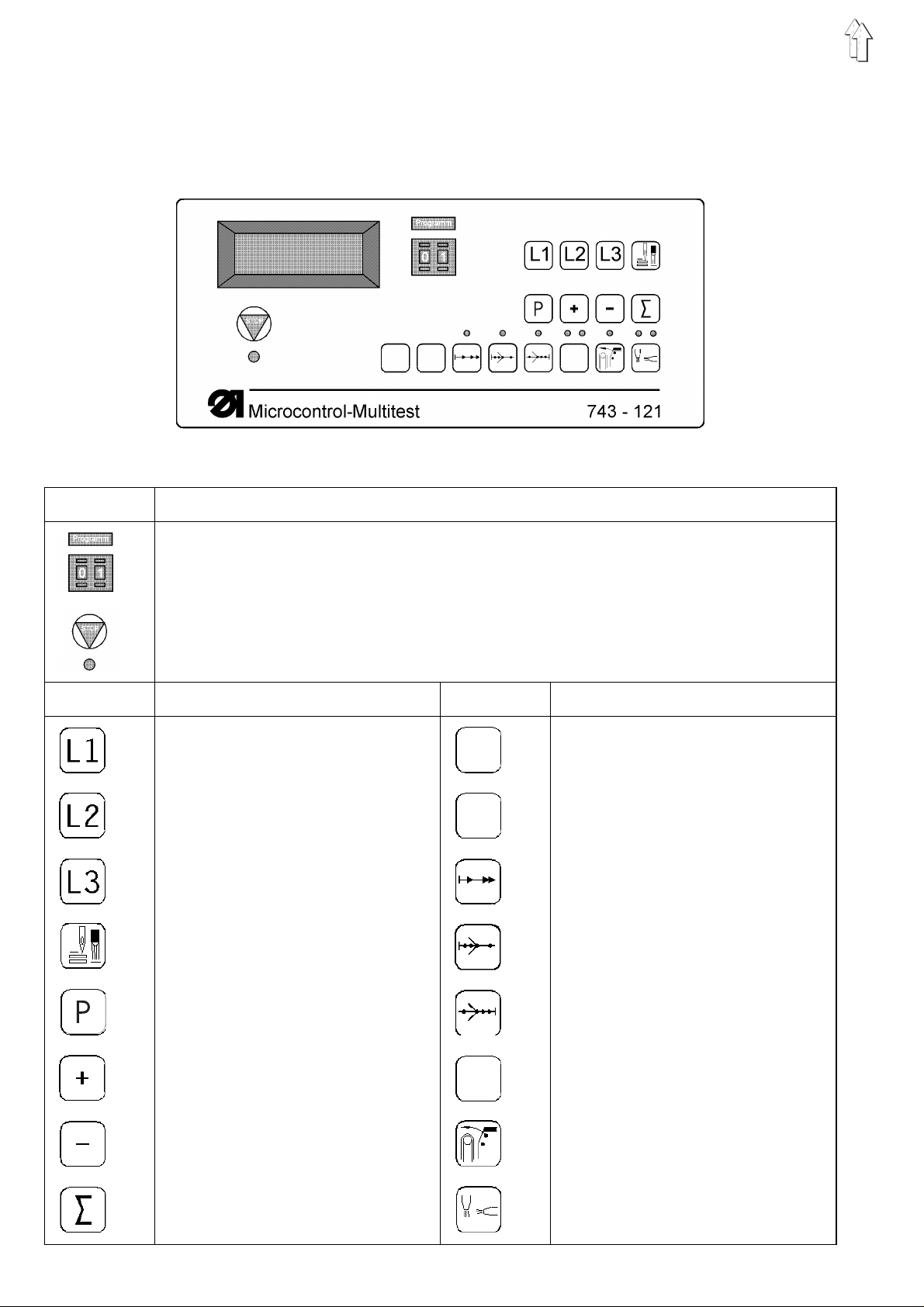

2. Description of the Controls

2.1 Operating El ements on t he Fr ont P ane l

Button Description

Selecting the sewing and testing programs

Stopping th e cu r r en t p rogr am

Activating the se lected program

Button Description Button Description

Seam length 1

Seam length 2

Seam length 3

Seam length v ia li gh t b a rrier

Normal stitch /

Stitch condensing stitch

- Reserve -

- Reserve -

Soft start

Stitch condensing at the seam

beginning

Stitch condensing at the seam end

Increase value

- Reserve -

Decrease value

Set counter

Start test program

4

Smoother

Blower from above/be low

Page 5

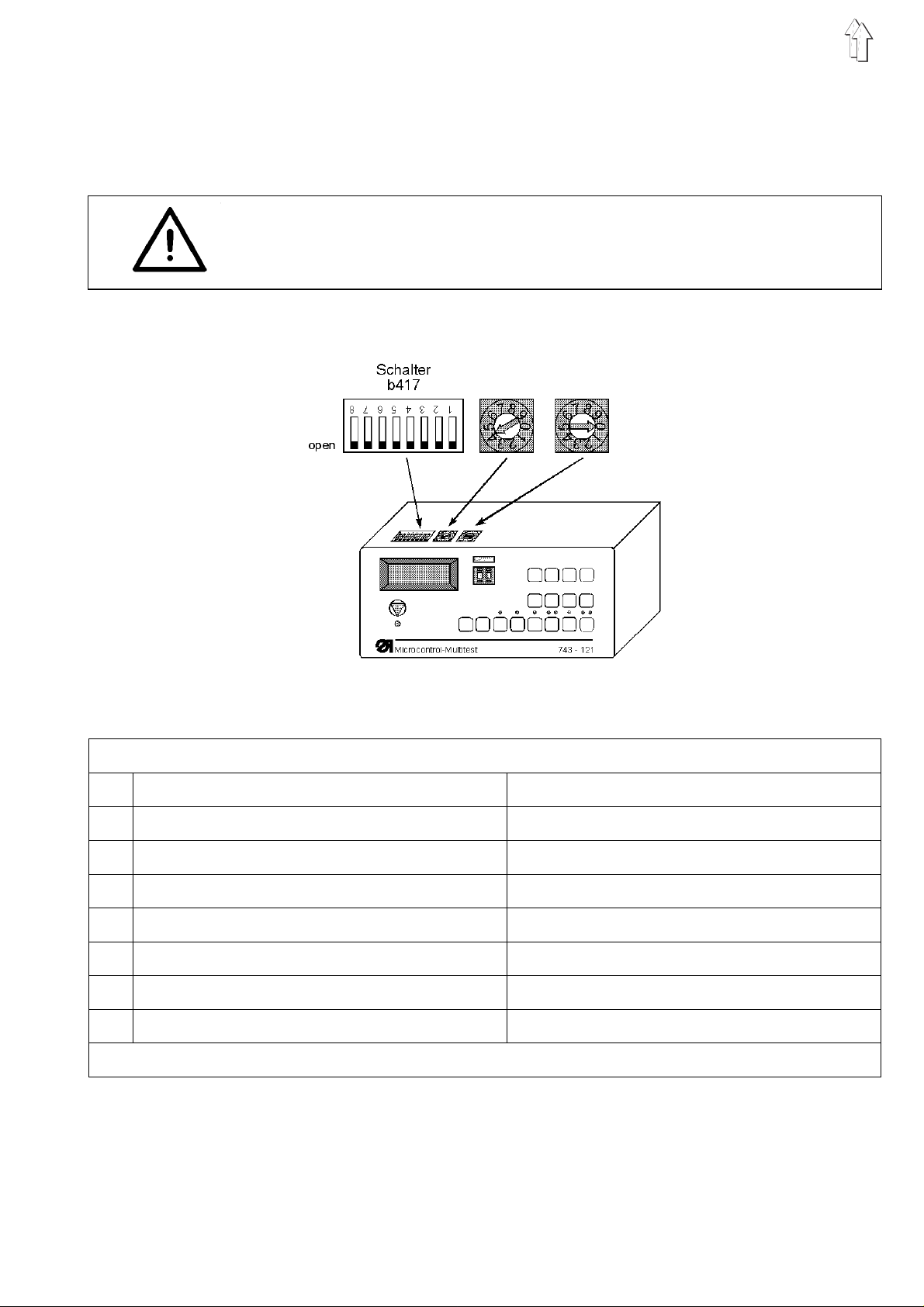

2.2 Operating Elements in the Controls

The switch b417 in the control must be set suitably for the individual

work methods.

The dials b401 un d b 40 2 a r e w it ho ut fu nc t io n f r om version " A 03 " .

Caution Current !

The switches may only be changed when the main switch is turned off.

Switch b417 open clo sed

1 Smoother - Reserve 2 Thread monitor activ Thread monitor not activ

3 - Reserve - - Reserve 4 Nmax. = 4.800 RPM Nmax. = 4.300 RPM

5 Chain stitch - Reserve 6 - Reserve - - Reserve 7 - Reserve - - Reserve 8 - Reserve - - Reserve Initial position = all switches in open status

5

Page 6

3. Setting the Sewing and T esting Pr ograms

The sewing and testing programs are selected via the

" Programm " preselector switch.

Switch Function

Program

00

01

02

40

57

59

60

61

62

63

64

66

67

68

69

–

Set " Programm " switch t o t he desired program.

–

" Turn on main switch " or press the " STOP " button.

The selected program is activated.

If the " P? " message appears, then an illegal program has been set.

Correct the setting and press the " STOP " button.

3.1 Display of the Pr ogram Version

Display of the program version

Sewing program e.g. dar t

Sewing program e.g. waist pleat

Setting the blower tim es

Step motor c on tr o ll er t es t

Timer and mem ory test

Current pa s s ag e c h eck

Test of the fron t p an el el em en ts

Test of the input el em en ts

Selecting th e i np ut el em en ts

Selecting the output elements

Sewing drive: Set value X, Pos. 2

Sewing drive: Set value X, Pos. 1

Sewing drive: Set value X, Pos. 1 Pos. 2

Sewing drive: Set value X, thread trimming,Pos.2

3.2 Sewing Pr ogram

The program version an d a c he ck su m a r e s h own i n t he di s play.

e.g.: 743A01 743 = class designation

A01 = code let te r an d s e r ia l nu mb er

All program version s wi th th e s a me c las s de s ignation and the same

code letter but a hi gh er serial number replac e al l l ower num be r ed versi ons ( e.g.: 743A03 replaces 743A01 and 743A02 ).

The check sum is o nl y me an t for use by th e facto ry servi c e d ep artment. This value shows whether the complete machine program is installed prop erly in the program me mo ry.

–

Set " Programm " switch to " 00 ".

–

Press " STOP " button.

The program is a c ti vated .

The 01 sewing pr ogram or t he 02 s ewing pro gra m c a n b e c a lled up.

The operating procedure is described in the operating instructions.

–

Set " Programm " switch to " 01 " or " 02 ".

–

Press " STOP " button.

The sewing program is activated.

6

Page 7

3.3 Set blower times

3.4 Step Motor Controller T est

The blower period for blowing out the piece to be sewn are adjustable.

–

Set " Programm " sw itch t o " 40 ".

–

Press " STOP " button.

The program is activated. The blower time is displayed.

–

The desired value is set with the " + " and " — " button s.

Adjustment ra ng e: 01...20 = 0, 1. ..2,0 seconds

This program ch ecks th e s t ep mo to r c on tro ll er a nd th e s t ep mo to r ou tput levels.

–

Set " Programm " sw itch t o " 57 ".

–

Press " STOP " button.

The test program is activated. The results are displayed.

Display Explanation

3.5 Timer and Memory T est

AMP ERR

LINK OK

LINK ERR

EPROM OK

EPROM ERR

XCOU OK

XCOU ERR

SCOU OK

SCOU ERR

CAUTION !

This program completely erases t he me mory.

Sewing lengths, blower ti me s an d a ll other values must be set anew.

The RAM and the timer switchings are checked automatically by the

program.

–

Set " Programm " sw itch t o " 59 ".

–

Press " STOP " button.

The program is ac t ivated.

Fault in the power output

Transmission cable not plugged in

Transmission to the controller OK

Fault in the transmission

EPROM OK

EPROM defective

Counter component for pulse counting OK

Counter compo ne nt for pul s e co un ti ng de fective

Counter component for pulse generation OK

Counter component for pulse generation defective

Display Explanation

OK

ERROR 0

ERROR 6

ERROR 7

RAM and timer OK

RAM-error

Timer 1 defective

Timer 2 defective

7

Page 8

3.6 Current P as sage Che c k

1. This program checks to see if the 24 V power unit supplies current

when the output drivers are switched off.

2. The program checks all output elements, the output drivers and the

installation for current passage.

–

Set " Programm " switch to " 60 ".

–

Press " STOP " button.

The program is a c ti vated .

Display Explanation

V?

S17

(Example)

3.7 T est of the Front P anel Elements

The program checks the front panel elements.

–

Set " Programm " switch to " 61 ".

–

Press " STOP " button.

The program is a c ti vated .

1. Check buttons

–

Press the button to be tested.

The display shows the allocated value.

e.g. P61 8 (allowable values: 1, 2, 4, 8 )

2. Check LED s

–

Set " Programm " switch to " 61 .. .6 8 " .

–

Press " Σ " butt on.

The selected diode will light up.

Shor t c i r cui t i n t he in s ta ll at io n o r an output driver is de fective.

Interru pt io n i n the output elemen t S 1 7, in its installation od er d river.

Continue the i ns p ection at the next element by

pressing th e " Σ " butt on.

No. LED

61

62

63

64

65

66

67

68

8

Stitch co nd en s in g a t t he be gi nn ing of the seam

- Reserve Soft start

Blower from above

Blower from underneath

Smoother

- Reserve Stitch condensing at the seam end

Page 9

3.8 T est of the Input Elements

The program check s th e status of the input e le me nt s.

–

Set " Programm " sw itch t o " 62 ".

–

Press " STOP " button.

The program is ac t ivated.

–

Operate input el em en t.

If any input element is operated, then the display will show the circuit

diagram designa ti on an d i ts s t at us.

The display changes when any other input element is operated.

e.g.: b03+ The switch for "Table forward" is switched on.

+ means:

contact switch = open contact

proximity switch = metal in front of the switch

reflecting light barrier = no reflection

transmitted light barrier = beam not broken

Input Designation

Element

3.9 Selecting the Input Elements

CAUTION !

All input elements are carefully set at the factor y.

Adjustment an d c o r rec t io n c a n o nl y be un de rtaken by trained se rvice

personnel.

The program is used to set the input elements.

–

–

–

–

b03

b04

b05

b07

b15

b16

b45

Set " Programm " sw itch t o " 63 ".

Press " STOP " button.

The program is ac t ivated.

Set " Programm " switch to the desired input element (see section

3.8).

Adjust the input element (switch flag, control cam, etc.) until the de-

sired status i s di spl ayed.

Tabl e forward

Sewing released

Transport carriage left

Transport carriage right

Form assembly slew

Form assembly control

Light barri er s e am en d

9

Page 10

3.10 Selecting th e Output El ements

Caution Danger of Injury !

Do not put your hands into the machine while it is operating.

Choose your position so that no injury is possible

(e.g. Function check s17: Table back).

The program checks the function of an output element.

–

Set " Programm " switch to " 64 " .

–

Press " STOP " button.

The program is a c ti vated .

–

Set " Programm " switch to the output element.

–

Press " Σ " butt on.

The selected output element is switched on.

–

Press " Σ " butt on.

The selected output element is switched off.

Output Designation

Element

s17

s18

s19

s 9

s10

s25

s28

s29

s30

s31

s32

Table back

Table free

Thread tension

Blower from right

Blower from above

Smoother

Trimmer

Sle w form as semb l y

Trimmer trans po rt and

Pressure increase for thread clamp

Release thread chain

Low er form assembly

3.11 P osit ioning the Ma chin e Head in t he 2nd Needle P o sition

The machine head is positioned in the 2nd position (needle up) with

this program.

–

Set " Programm " switch to " 66 ".

–

Press " STOP " button.

The program is a c ti vated . Display " SW? "

–

With the " Programm " switch s e t t he drive revolutions to " 01 "...

" 13 " .

01 = Minimum revolutions

13 = Maximum revolutions

–

Press " Σ " button and hold down.

The drive runs at th e s elec t ed revolutions. The actual revolutions

will be displayed after a few seconds.

After the " Σ " button is released the needle is positioned in the

2nd (needle up) position.

10

Page 11

3.12 Positioning the Machine Head in the 1st Needle Position

The machine he ad is p oi s it io ne d i n the 1st position ( n ee dl e down) with

this program.

–

Program procedure and description as 3.11.

Positioning is in the 1st position.

3.13 Positioning the Mac hine Head without Thread T rimm ing

The operation is as described under program P66, but the positioning

of the machin e h ea d o c cur s i n t he 1s t ne ed le po s it io n (n ee dl e d own) .

–

Set the "program" switch to "68".

–

Press the "STOP" key.

8

The program is ac t ivated.

After a short break the needle positions in the 2nd needle position

(needle up).

3.14 Positioning the Machine Head with Thread T rimming

The operation is as described under program P66, but the positioning

of the machine head occurs in the 2nd needle position (needle up).

–

Set the "program" switch to "69".

–

Press the "STOP" key.

9

The program is ac t ivated.

During the last half machine head revolution thread trimming occurs.

11

Page 12

4. Operation Displays and Err or Messa ges

Display Explanation Comments

P?

743A01

---REF--->

REF--->

---x--POS-ERR

--( )-SW?

E2

STOP

b417

b16

b4

SMC-TEST

AMP ERR

LINK OK

LINK ERR

EPROM OK

EPROM ERR

XCOU OK

XCOU ERR

SCOU OK

SCOU ERR

Illegal progra m

Display of the program version

Run to reference point

Run to reference point

Thread breakage

Motor not turning

No signal from the position transmitter

invalid r evol u tion level s e t

Fuse E2 on the control trans former defective

Stop button defective

Glide plate not locked in

invalid switch position from b417

Form assembly not present

Sewing released

Step motor controller is being tested

Fault in the power ou tput

Transmission cable no t pl ug ge d in

Transmission to controller OK

Error in data transfer

EPROM OK

EPROM defective

Counter componen t for pulse co un ti ng OK

Counter comp. for pulse counting defective

Counter compon en t for pulse ge ne ra ti on OK

Counter comp. for pulse generation defective

Set

" Programm "

-

-

Reinsert thread

Check motor protection switch

Check position tran sm it te r

Set

" Programm "

Replace fuse

Replace stop button

Lock-in glide plate

Set b417 switch anew

Insert form assembly

-

Call factory service dept.

Plug in transmission cable

Call factory service dept.

Install new EPROM

Call factory service dept.

Call factory service dept.

switch anew

switch anew

ERROR 0

ERROR 1

ERROR 2

ERROR 3

ERROR 4

ERROR 5

ERROR 6

ERROR 7

ERROR B5

ERROR B45

Error Bxx

PROG

ERROR 1

PROG

ERROR 2

RAM-error

Fault in the input elements

Fault in the front panel elements

Program switch defective

Error in data transfer to sewing drive

controller

Short voltage drops in the mains

Timer 1 defective

Timer 2 defective

Transport carriage lef t (en d po si ti on)

Light barrier (no sewing material present)

Fault in input element Bxx

Error in the values in the memory

Error in putting the check sum into memory

Call factory service dept.

Check input elements

Check front panel el em en ts

Replace progra m switch

Call factory service dept.

Stabilize voltage supp ly

Call factory service dept.

Call factory service dept.

Manually push into the initial position

Insert sewing material

Bxx defective or mis-adjusted

Reset seam lengths, blower tim es, etc.

Program not pro pe r ly s tor ed in me mo ry

12

Page 13

1

2

5

3

6

4

13

Page 14

5. Step Motor Output

Caution Electric Current !

Turn the main switch off !

The switches may not be adjusted carrying currrent.

5.1 Status Dis pla y

The switches must be in the positions shown !

1 = Step motor output

2 = Status indicators see Chapter 5 .1

3 = Parameter switches see Illustration

4 = Current selector F

5 = Voltage convertor 230 V

6 = Operation light on / off

LED 1 Undervoltage

Shor t fall in t he operating voltage of m ore than 30 %

LED 2 Phase monitoring

Interrupti on in on e o r mo re m otor wires

14

LED 3 Short circuit

Short circuit between two or more motor phases

or motor phase and ground

LED 4 Overheating

Exceeding the allowable temperature of the unit

LED 1 and 2 Reset

ENABLE in pu t is no t a c ti vated by the c o nt rol s

Loading...

Loading...