Contents Page:

Home

Preface and general safety instructions

Part 1: class 69 operating instructions

1. Product description

2. Designated use

3. Subclasses

3.1 Opt ional extras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Technical data

5. Operation

5.1 Folding down left-hand half of table plate (MG 56-2 frame only) . . . . 9

5.2 Threading the needle thread . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2. 1 Subclass 69-373 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2. 2 Subclass 69-FA-373 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 Adjusting t he n eedle-t hread tensi on . . . . . . . . . . . . . . . . . . . 13

5.4 Opening the nee dle-thread ten sioner . . . . . . . . . . . . . . . . . . . 13

5.5 Winding on the loop er thread . . . . . . . . . . . . . . . . . . . . . . . 15

5.6 Fitting the looper-th read bob bin . . . . . . . . . . . . . . . . . . . . . . 15

5.7 Adjusting the looper-thr ead t ension . . . . . . . . . . . . . . . . . . . . 17

5.8 Fitting and cha nging the needl e . . . . . . . . . . . . . . . . . . . . . . 17

5.9 Lifting the sew ing feet . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 0 Loc king the sewing feet in the raised position . . . . . . . . . . . . . . 19

5.11 Adjusting the sewing-foot str oke . . . . . . . . . . . . . . . . . . . . . 19

5.12 Adjusti ng th e sewing-foot pressure . . . . . . . . . . . . . . . . . . . . 20

5.1 3 Adjusting t he stitch le ngth . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 4 Welting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 5 Ribbon binder (class 69-373) . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. Control unit and operating panel

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 3

6.2 Efka VD5 54KV/6F82AV sewing drive . . . . . . . . . . . . . . . . . . . 24

6.2 .1 Control-b ox buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 .2 Altering parameter values . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Qui ck QD554/A51 K01 sewi ng drive . . . . . . . . . . . . . . . . . . . . 28

6.3 .1 Operat ing-panel b utt ons . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 .2 Altering parameter values . . . . . . . . . . . . . . . . . . . . . . . . . 30

Contents Page:

7. Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8. Maintenance

8.1 Cleaning and test ing . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9. Optional extra s

9.1 HP 11-1 pne umatic r apid str oke adjuster . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1. Product description

The

DÜRKOPP ADLER 69

Double-lockstitch free-arm machine with underfeed, needle feed and alternating

•

foot overfeed.

Depending on the subclass, a single-needle machine wi t h or without thread clippe r

•

beneath the needle plate.

Slim free arm wi th large pass age space and large sewing-foot stroke.

•

Maximum passage space beneath raised sewing feet: 12 mm (with

sewing-foot-raising knee lever).

Small horizont al shuttle.

•

The sewing machine can be supplied with a closed, cut-out or fold-down left-hand

•

table-plate half. The fold-down version permits the unobstructed manipulation of

large items round the free arm.

Smooth, draw-f ree edging and precision sewing of i nner and outer arcs by an

•

integral follow binder mechanism.

Knee-operat ed pneumatic rapid stroke-a djustment mechanism to swit ch the foot

•

overfeed to maximum sewing-foot stroke (optional extra).

is an all-purpose special sewing machine.

2. Designated use

The 69 is a special sewing machine d esigned to be u sed to sew light to medium-h eavy

materials. As a rule such material consists of textile or synthetic fibres, but it also

includes leather.

These materials are used in the clothing, footwear and leatherwear industries, as well

as in domestic and automobile upholstery.

This special sewing machine can also be used t o execute so-c al l ed technical seams.

However, the operator must carry out an assessment of the possi ble dangers (with

which

DÜRKOPP ADLER AG

comparatively unusual and they are potentially of enormous diversity. Depending on the

outcome of this assessment it may be necessary to take special safety precautions.

Generally speaking material processed with this special sewing machine must be dry,

its thickness when compressed by the lowered sewing fee t must not exceed 7 mm and

it must contain no hard objects, since otherwise the operator of the machine would have

to wear protective goggles (which cannot at present be supplied).

The seam is generally executed with textile-fibre sewing threads up to 30/3 NeB (cotton

yarns), 40/3 Nm (synthetic yarns) or 30/3 Nm (covering yarns) in size. The use of any

other threads must also be subject to an assessment of the risks involved and the

taking of any necessary safety precautions.

The premises in which this special sewing machine is set up and operated must be dry

and well-maintained. If it i s t o be used in premises which are no t dry and

well-maintained, special precautions may be necessary: these must be the subject of

an agreement (see EN 60204-3-1:1990).

As manufactu rers of industrial sewing machines we work on the assumpt i on that

personnel working on our machines will be at least semi-skilled, so that they can be

presumed to be familiar with all normal operations and with the dangers inherent in

them.

would be hap p y to assist), as such applicat i ons are

5

3. Subclasses

class 69-373

class 69-FA-373:

: single-needle double-lockstitch free-arm sewing machine with

underfeed, needle feed and alternating-f oot overfeed

as class 69-373, but with electromagneti c thread clipper beneath

the needle plate

3.1 Optional extras

order no. optional extra

FLP 14-2 ele ct ro-pneuma tic sewing-foot-raising mechanism

RAP 14-1 electro-pneumatic bar-tack and sewing-foot-raising mechanism

HP 11-1 Pneumatic rapid stroke-adjustment mechanism for the overfeed

WE-6 Maintenance unit

0797 003031 Pneumatic connection pack

9822 510001 Halogen lamp

0798 500088 Lamp transformer

0707 487519 Lamp-attachment set

pedal-operated.

pedal-operated.

knee-operated.

For pneumatic optional extras .

For the pneumat i c connection of frames with th e m aintenance uni t

and pneumatic optional extras.

Consisting of connecting hose (length 5 m, diameter 9 mm),

connectors, bands, coupler plug and socket.

WALDMANN, with 12V/20W bulb, attached to the upper part of the

machine.

For 230V, with mains connector, without switch,

for 9822 5101 25 and 9822 510001 lamps.

For 9822 510001 lamp.

4. T e chnical dat a

Lc noise-level

indicator:

6

workplace-related emission valuein accordance with

DIN 45635-48 -A-1-KL2

Lc = 81 dB (A)

class: 69-373, 69-FA-373

stitch length: 4 mm

sewing-foo t stroke: 3.2 mm

stitch rate: 1700 [min

material: double Skai 1.6 mm 900 g/m

-1

]

2

DIN 53352

Needle system: 134

Needle thickne ss (depending on E no.) [Nm] 110 - 130

Maximum sewing-thread thicknesses:

- cotton [NeB] 30/3

- synthetic endless [Nm] 40/3

- covering yarn [Nm] 30/3

stitch rate:

- maximum [min

- ex works [min

-1

]2000

-1

]1700

maximum stitch length:

- forwards [mm] 5

- backwards [mm] 5

maximum sewing-foot stroke: [mm] 7

maximum passage space beneath raised sewing feet:

- sewing foot raised by lifting lever [mm] 7

- sewing foot raised by knee lever [mm] 12

operating pre ssure: [bar] 6

rated voltage: 3 x 220-240 V, 50/60 Hz

3 x 380-415 V, 50/60 Hz

dimensions:

- MG 53-3 frame (H x W x D) [mm] 1540 x 1060 x 550

- MG 56-2 frame (H x W x D) [mm] 1560 x 1200 x 600

working height: ...

- MG 53-3 frame [mm] 760 - 850

- MG 56-2 frame [mm] 780

weight (upper part only): ca. [kg] 33

7

3

1 2 3 4

8

5. Operation

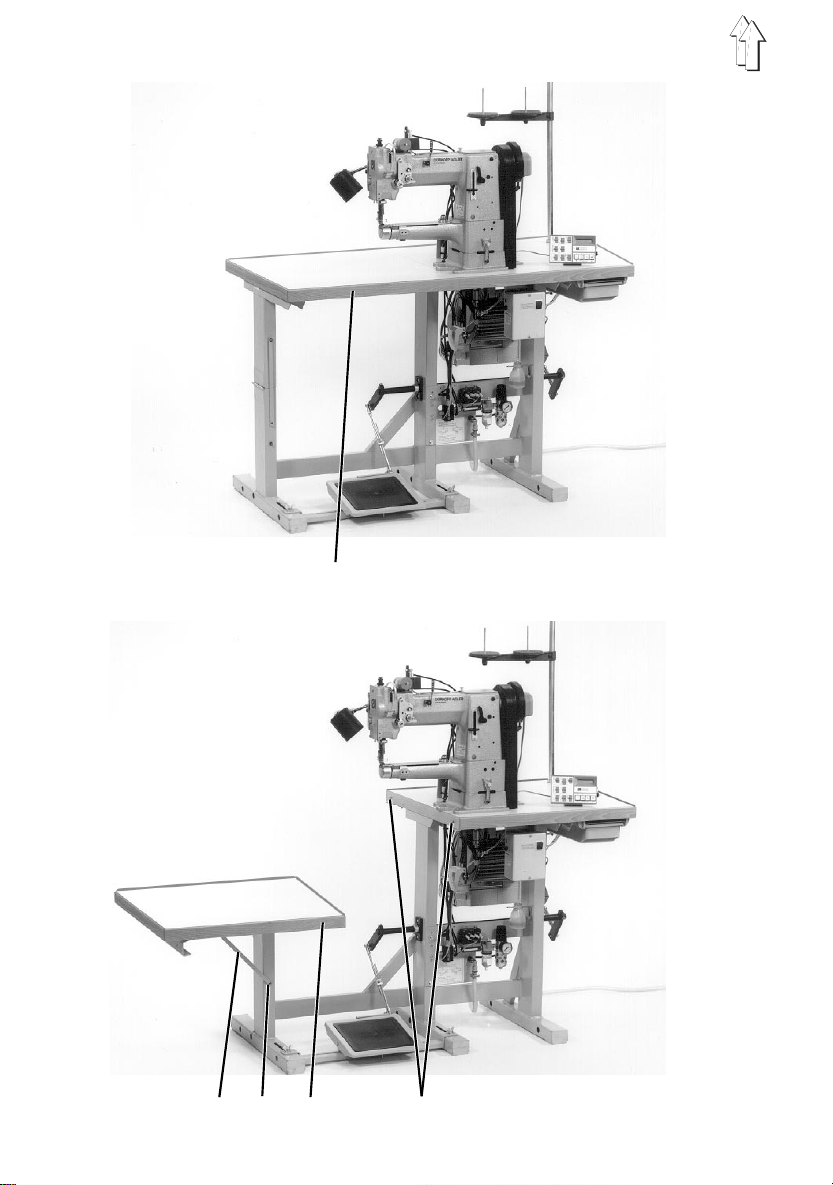

5.1 Folding down left-hand half of tab le plate (MG 56-2 f rame only)

When the special sewing machine is fitted with the

consists of two parts. The left-hand half 3 can be folded down to permit the

unobstructed manipulation o f large items ro und the free arm.

MG 56-2

frame the table plate

5

3

7

6

8

Folding down the left-hand half of the table plate

–

Turn fasteners 7 and 8 beneath the table plate anticlockwise to unlock the

left-hand half 3 of the table plate.

–

Fold the left- hand half 3 of the table plate down and to the l eft.

–

Hook shackle 1 onto the pin 2 of the left- hand frame upright.

Folding the left-hand half of the table plate back into place

–

Unhook shackle 1 from pin 2.

–

Lift the left-hand half 3 of the table plate, swivel it to the right and lower it onto

support plates 5 and 6.

The pins 4 in the right-hand half of the table plate must fi t i nto the holes i n the

left-hand half 3.

–

Turn fasteners 7 and 8 beneath the table plate clockwise to lock the left-hand

half 3 of the t able plate.

9

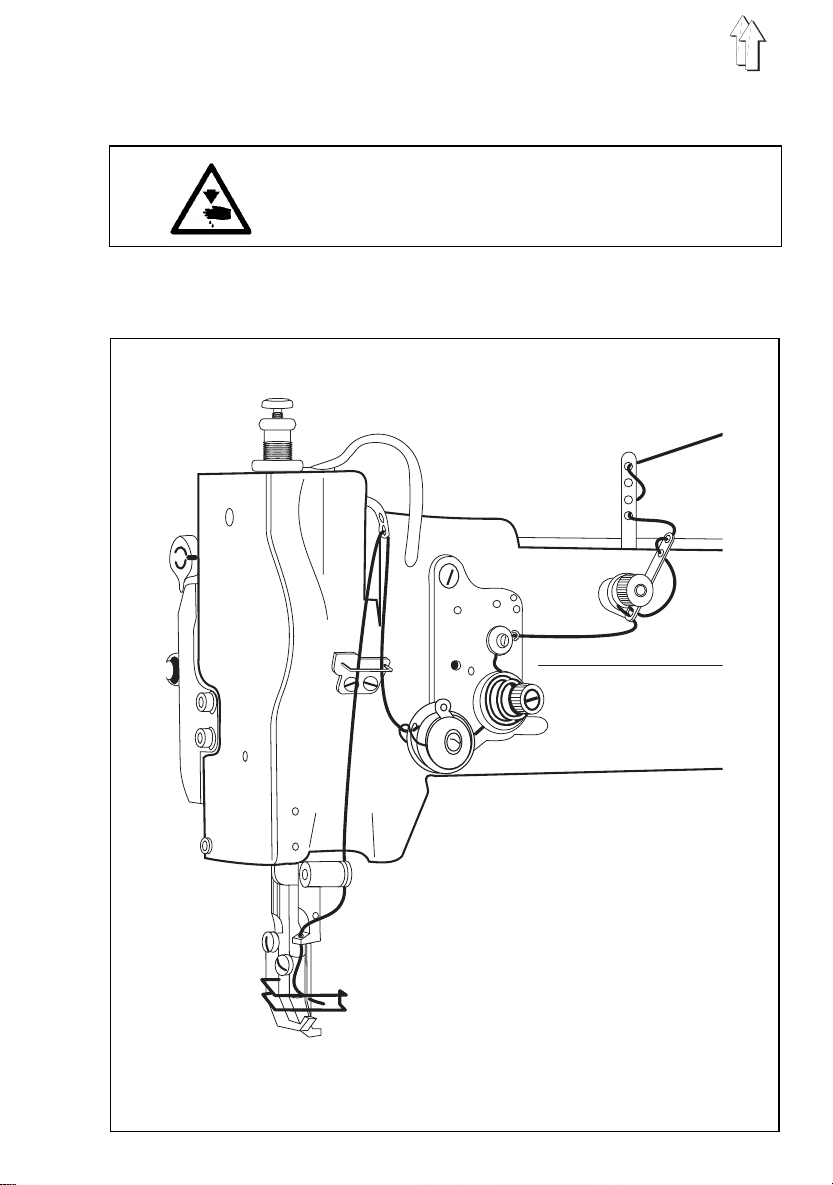

5.2 Threading the needle thread

5.2.1 Subclass 69-373

Caution: danger of injury

Turn off the main switch

The needle thread may only be threaded with the sewing

machine turned off.

10

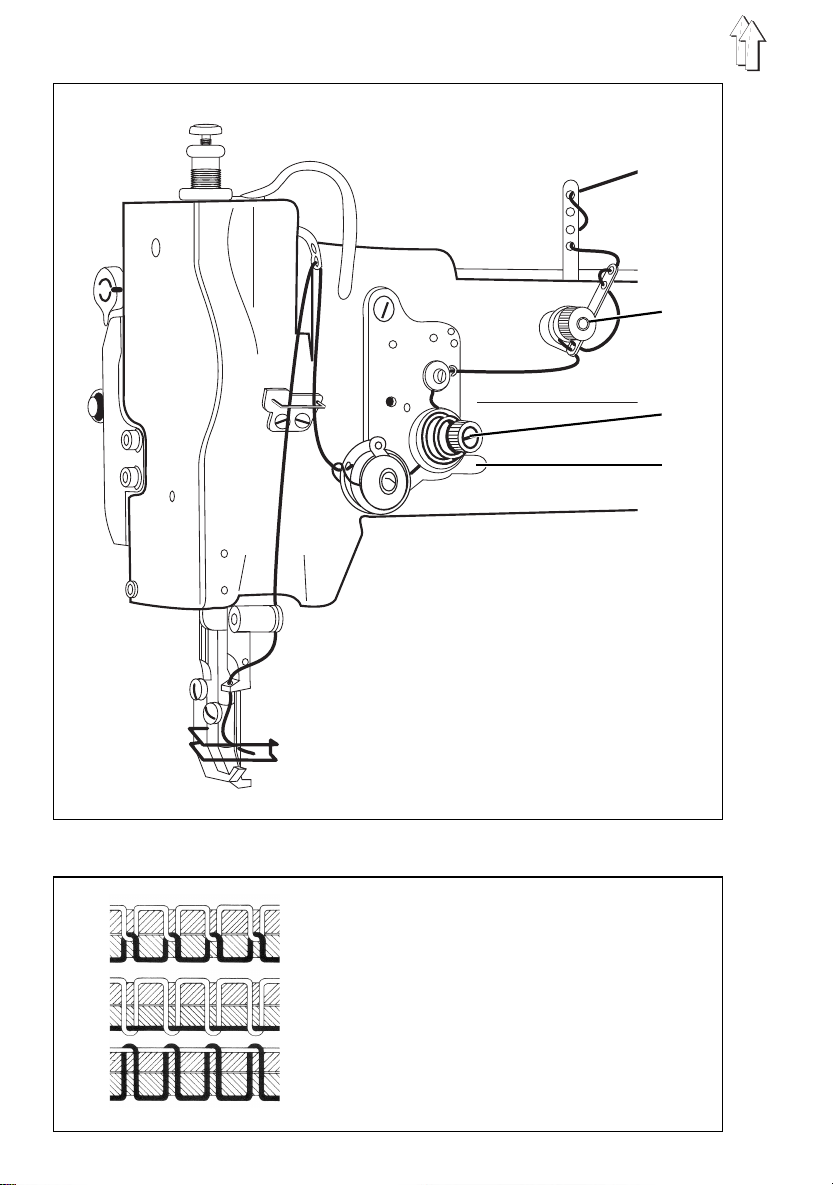

5.2.2 Subclass 69-F A-373

Caution: danger of injury

Turn off the main switch

The needle thread may only b e t hreaded with the sewing

machine turn ed off.

11

1

2

3

12

Fig. a: correct thread loop in the centre

Fig. b: needle-thread tension too weak or

Fig. c: needle-thread tension too strong

of the material

looper-thre ad tension too s t rong

looper-thread tension too weak

or

5.3 Adjusting the needle-thread tension

Pre-tensioning mechanism (subclass 69-FA-373)

On subclass

thread cutter to function reliably when the main tensioner 2 is open.

This residual tension is created by the pre-tensioning mechanism 1.

The pre-tensioning mechanism 1 also determines the length of the needle-thread end

after the thread has been clipped.

The pre-tension 1 should be set lower than the main tension 2.

–

Adjust pre-ten si oning mechani sm 1 by turning th e knurled nut.

–

After major changes to prel i minary tensi on 1 the main tension 2 should also be

adjusted accordingly.

Main tension

The main tension 2 should be set as low as possible.

The looping of the threads must be in the centre of the material (see fig. a).

With thin material excessive th read tension can cause unwanted gathering and thread

breakage.

–

Adjust the main tensioner 2 so that the stitches are uniform.

69-FA-373

the needle thread needs to be under residual tension for the

5.4 Opening the needle-thread tensioner

Automatic

The main tensioner 2 is opened automatically:

–

when the thread is severed (subclass

–

when the foo t is raised (pedal 1 position backwards)

69-FA-373

).

Manual

The main tensioner 2 is opened manually:

–

when the rele ase lever 3 is pr essed towards the arm.

The main tension er 2 remains open f or as long as pressur e is maintained on the

release lever 3.

–

when the sewing feet are raised mechanically with the knee lever (see chapter 5.9).

–

when the sewing feet are locked in the raised position (see chapter 5.10).

13

1

2 3

4

5

9

14

8 7 10 11

6 7 8

5.5 Winding on the looper t hread

Caution: danger of injury

Turn off the main switch.

The looper thread may be threaded for winding on only

when the sewing machine is switched off.

–

When winding on for sewing with no underlay material:

arrest the sewing feet in the up position (see chapter 5.10).

–

Thread looper thread as shown in the upper illustration.

–

Wind about 5 coi l s of looper thread clockwise onto the bobbi n core.

–

Place bobbin 3 on bobbin-winde r shaft 5.

–

Swivel bobbin-winder lever 4 against the bobbin.

The bobbin-wi nder wheel 2 is pr essed against t he V-belt.

–

Adjust tension 1.

The looper thr ead should be wo und on with mini m al t ension.

–

Sew.

The bobbin-wi nder lever 4 termi nates the process as soon as the bobbin is full.

5.6 Fitting the looper-thread bob bin

Caution - danger of injury

Turn off the main switch.

The looper-thread bobbin may only be changed with the

sewing machine switched off.

Removing empty looper-thread bobbin

–

Turn handwheel until the needle bar reaches its highest position.

–

Pull off cap 6 in t he direction of t he arrow.

–

Raise bobbin-housing flap 8.

–

Remove top 7 of bobbin housing with bobbin.

–

Remove empty bobbin from top 7 of bobbin housing.

Threading looper thread

–

Place full bobbin 11 in top 7 of bobbin housing:

when the thread is wound off the bobbin 11 must rotate in the direction of the arrow.

–

Draw looper thread down through slit 10 under tensioning spring 9. Pull about 8

cm of looper thread out of the top 7 of the bobbin housing.

–

Replace top 7 of bobbin housing.

–

Close bobbin-housing flap 8.

15

1

3

2 4 5

16

6

7

8

5.7 Adjusting looper-thread tension

Caution: danger of injury

Turn off the main switch.

The looper-thread tension may only be adjusted with the

sewing machine switched off.

Adjusting brake spring 1 (class 69-FA-373)

On subclass

the machine halts or if the looper thread is wound off spasmodically.

–

Unscrew regulating screw 4 until no tension remains in tension spring 3.

–

Adjust brake spring 1 with regulating screw 5.

The braking force is correctly adjusted if brake spring 1 is about 1 mm above

surface 2.

Adjusting tension spring 3

–

Adjust tensio n spring 3 with regulating screw 4.

to increase looper-thread tension: turn screw clockwise

to reduce looper-threa d t ension: turn screw anticlo ckwise

For stitch for mation see sketc h a on page 12.

69-FA-373

the brake spring 1 prevents the bobbin from "running on" when

5.8 Fitting and changing the needle

Caution: danger of injury

Turn off the main switch.

The needle may o nl y be changed wi t h the sewing machi ne

switched off .

–

Turn the handwheel until the needle bar 6 reaches its highest position.

–

Undo screw 7.

–

Pull needle dow nwards out of needle bar 6.

–

Insert new needle

Caution:

When seen from the operati ng side of the m achine the f urrow 8 of the needle must

point to the rights(see sketch).

–

Tighten screw 7.

Failure to comply with this instruction can cause the following faults:

when fitting a thinner needle: faulty stitches, damage to thread

when fitting a thicker needle: damage to the shuttle tip and needle

as far as it will go

CAUTION:

When a thicker needle is fitted the distance from the

shuttle to the needle must bed corrected (see servicing

instructions).

into the hole in needle bar 6.

17

1

2 3

4

5

18

2

6

5.9 Lifting the sewing feet

The sewing feet are raised mechanically or electro-pneumatically, depending on which

mechanism is fitted to the machine.

Mechanical sewing-foot-raising mechanism

–

Operate knee lever 1.

The sewing feet remain raised as long as pressure is maintained on knee lever 1 [].

Electro-pneumatic sewing-foot-raising mechanism

(when FLP 14-2 or RAP 14-1 are fitted)

–

Push pedal half-way back.

The sewing fee t are raised with t he machine at a h al t .

–

Push pedal all the way back.

The thread clipper is activated and the sewi ng feet raised.

(with the machine at a halt)

5.10 Locking the sewing feet in the raised position

The mechanically or pneumatically raised sewing feet 3 are locked in the raised

position with lever 2 (e.g. for the looper thread to be wound on or the sewing foot

changed). Lever 2 is locat ed on the back of the machine arm.

–

With the mach i ne at a halt, swivel lever 2 up.

The sewing feet 3 are locked in the raised position.

–

Swivel lever 2 down.

The sewing feet are no longer locke d.

5.11 Adjusting the sewing-foot stroke

The height of the sewing-foot stroke is determined by the position of tension bar 6.

Caution: danger of injury

Turn off the main switch.

The sewing-foot stroke may only be adjusted with the

sewing machine switched off.

Adjusting the sewing-foot stroke

–

Undo nut 4 on the back of the machine arm.

–

Push tension bar 6 into rocker lever 5.

tension bar fully up: maximum sewing-foot stroke (4.5 mm)

tension bar fully down: minimum sewing-foot stroke (2.5 mm)

–

Tighten nut 4.

19

5.12 Adjusting the sewing-foot pressure

1

Sewing-foot pressure is adjusted with screw 1.

–

to increase sewing-foot pressure: turn screw 1 clockwise

–

to reduce sewing-foot pressure: t urn screw 1 ant i clockwise.

2

3

4

5.13 Adjusting the stitch length

Caution: danger of injury

Turn off the main switch.

The stitch length may only be adjusted with the sewing

machine switched off.

–

Turn wing-nut 2 anticlockwise as far as it will go.

–

Adjust the desired stitch length with screw 3.

To increase sti tch length: turn screw 3 anticlockwise.

To reduce stitch length: turn screw 3 clockwise.

–

Tighten wing-nut 2 clockwise.

To sew bar tacks manually (backwards sewing):

–

Swivel the stitch-length handle 4 up as far as it will go (to position "R").

The machine sews backwards as long as the stitch-length handle 4 is held up.

20

The stitch-length handle 4 moves down.

The stitch-length handle 4 moves up.

5.14 Welting

1

2

The rapid-adjustment welt-guide mechanism with three positions is used to sew welts

between two layers of material. It can be swivelled in or out at the beginni ng and end of

the seam.

Four welt guides 2 are available (sewing attachments E20 - E23) with welt grooves from

3 to 6 mm.

Caution: danger of injury

Turn off the main switch.

The welt may only be inserted with the sewing machine

switched off .

Inserting the welt

–

Undo screw 1.

–

Feed welt in through welt guide 2.

–

Adjust welt guide 2 to the width of the welt.

The welt must be guided at t he sides, but at the same ti me it must be easy to pull it

through the welt guide 2.

–

Tighten screw 1.

Sewing in the welt

–

Lay the welt between the two layers of material.

–

Pull out ball handle 4 and turn lever 3 as far as it will go to the left (position P).

–

Start sewing until the needle has reached approximately the middle of the welt.

–

To continue sewing in the welt pull out ball handle 4 and turn lever 3 to the centre

position (pos i tion S), where it engages.

–

At the end of t he seam pull out ball handle 4 and turn lev er 3 to its basi c position

(position 0).

3

4

21

5.15 Ribbon binder (class 69-373)

1

4 5 6

Two ribbon-binder sets are available for subclass

sewing attachment E4: for narrow bindings

sewing attachment E5: for broad bindings

Caution: danger of injury

Turn off the main switch.

The ribbon band may only be inserted with the sewing

machine switched off.

2

3

69-373

7

8

:

Inserting the ribbon band

–

Place the ribb on band on the lower pulley of the reel holder 3 .

–

Place upper pu l l ey and pressure spring 2 on reel holder 3.

–

Screw knurled nut 1 onto reel holder 3.

The ribbon band should be kept under slight pressure.

–

Slightly raise t he arm cover 6 and swivel it forwards (towards t he operating side).

–

Pass the ribbon band between the guide pins 5, through the ribbon guide 4, into

the ribbon binder 8 and under the sewing fee t.

–

Swivel the arm c over 6 back into p l ace.

Adjusting the distance of the seam from the ribbon edge

–

Undo screws 7.

–

Adjust the d i stance of the seam from the ribbon edge as required by mo vi ng the

ribbon binder 8.

–

Tighten screws 7.

22

6. Control unit and operating panel

CAUTION:

These operatin g i nstructions describe

the buttons and the change of parameters by the operator.

For a detailed description of the control unit please see the

current oper ating instruc tions of the m otor manufacturer

(supplied).

6.1 General

The control unit is program m ed and the seam functions set with the cont rol-unit buttons

or the operat i ng panel (for programming see motor manufacturer’s manual).

Depending on the seam requi red, sewing c an be executed manually or by

seam-progra mming (only wit h the operating panel).

Three different seam cycles can be programmed for various sewing requirements, in

which the various functions (starting bar tack, ending bar tack, stitch count, thread

cutting etc.) and parameter values (stitch rate, seam length, rpm etc.) are individually

assigned.

Entry is carried out in program m i ng mode.

The paramete rs and the values assigned are di splayed.

The seam progr a m s are not lost even when the sewing machin e i s switched off (battery

buffer).

In order to a void the inadvertent alteration of pre-set functio n s, operation is divided into

various levels (operator, technician).

The operator (seamstress) can program directl y.

Access to the technician lev e l i s contingent on the entry of a code numb er (EFKA) or on

switching on the main switch by simultaneously holding down two buttons (QUICK).

the functions of

only

RESET

If the control unit is hopelessly misadjusted, this function allows the technician to reset

all adjusted values to their default (ex-works) settings.

This function is described in the Servicing instructions.

23

6.2 Efka VD554KV/6F82AV sewing drive

6.2.1 Control-box buttons

In programming mode

button function

P

E

+

-

>>

24

programming m ode (start / end)

confirm parameter-val u e change

switch to ne xt paramete r

increase displayed parameter value

switch to ne xt paramete r

increase code no.

reduce displayed parameter value

switch to l ast parameter

reduce code no.

select next character in display

Button functions in sewing mode

button function after the thread has been clipped LED display

select programming mode

starting bar tack

- single *

- double *

- OFF

ending bar tack

- single *

- double *

- OFF

Automatic sewing-foot-raising mechanism

- when stopping in mid-seam

- at the end of the seam

- when stopping in mid-seam and at the end of

the seam

- OFF

Basic needle position

- up

- down

* Starting an d ending bar tacks cannot be sewn with this m a chine.

CAUTION:

The + and - butt ons increase or reduce the maximum rpm

before the thread is clipped

.

25

6.2.2 Altering parameter values

Parameter values are altered at operator level with the five buttons "P", "E", "+", "-" and

">>" on the sewing-drive control box.

The parameter list on the nex t page gives all parameters which c an be altered at

operator level.

1. Selecting programming mode

-

Press the "P" button.

The first parameter number (

2. Displaying the first operator-level parameter

-

Press the "E" button.

The appropriate parameter value (

3. Changing the displayed parameter value

-

Increase or reduce the pa rameter value with the "+" and "-" buttons.

If the "+" or "-" button is held down, th e parameter va lue continue s t o change unt i l

it is released.

4. Selecting the next parameter value

-

Press the "E" button.

The next operator-level parameter appears in the display.

-

Press the "E" button.

The appropria te parameter value appears i n the display.

Repeatedly pressing the "E" button successively calls up all operator-level parameters and parameter values.

When the param eter is displayed the + or - buttons can also be used to switch to

the next or previous parameter.

) appears in the display.

0 0 0

) appears in the display.

0. 0. 0.

5. Leaving programming mode

-

Press the "P" button.

The control unit leaves progra mming mode.

CAUTION:

The changed pa rameter values are not saved until a seam

is started by pressing the pedal down.

If the sewing machine is sw i tched off imme di ately after

programming without sewing, the changed parameter

values are

26

not

saved.

"Operator-level" parameter list:

Paramet er fun ction setti ng

max. min. ex wo rks

000 *

001 *

002 *

003 *

004 *

005

006

007

008

009

013

014

015

this parameter is vacant on this machine class

*

starting ba r-tack stitches forwards 254 0 2

starting ba r-tack stitches backwards 254 0 4

ending bar- tack stitches backwards 254 0 2

ending bar-tack stitches forwards 254 0 2

light-barr i er compensation stitches 254 0 7

* light-barrier filter stitch rate 254 0 0

for knitted yard goods

* number of light-b arrier seams 15 1 1

seam stitch rate with stitch count 254 0 20

assigning ato the "3" button 3 1 1

technician -l evel parameters

(only when operating the control unit

with a Variocontrol operating panel)

1 = softstart ON / OFF

2 = ornamental- st itch bar tack ON/OFF

3 = sewing-on with light barrier light

blocked ON / OFF

* light barrier ON / OFF OFF

* thread clipper ON / OFF ON

* thread retractor ON / OFF ON

stitch co unt OFF

27

6.3 Quick QD554/A51K01 sewing drive

6.3.1 Operating-panel buttons

button function in programming mode

28

select programming mode leave progra m m ing mode

(in conjunction with "-" button) (in conjunction with "-" button)

suppress starting / ending bar tack switch to n ext parameter

single depression:sew 1 stitch increase displayed value

held down: sew at n

change program reduce displayed value

(MANUALLY - SEAM-A - SEAM-B)

min

number

button function

ornamental bar tack

normal bar tack

starting double bar tack

starting single bar tack

starting ba r tack on

starting ba r tack off

sewing-foot position up before thread clipping

sewing-foot position down before thread clipping

ending bar tack double

ending bar tack single

ending bar tack on

ending bar tack off

smooth seam start

normal seam start

vacant

29

6.3.2 Altering parameter values

A operator level par am eter values a re changed wit h t he four program buttons ("G", "F",

"+", "-") on the right-hand side of the operating panel.

The parameter list on the nex t page gives all parameters which c an be altered at

operator level.

1. Selecting programming mode

-

Turn on the main switch.

"

MANUAL

-

Press and hold down the "G" button.

-

Press the "-" button.

"

- - - - - - >F

-

Release both buttons.

The control unit is in programming mode.

NB:

The sewing drive is inoperative in programming mode.

2. Selecting parameter number

-

Press the "G" button.

The button must be pressed r epeatedly until the group number (e.g. 6xx) appears.

-

Press the "F" button repeatedly until the required parameter number appears in

the display (e.g. "

If the "F" button is held down the parameter number continue s to change un t i l it is

released.

" appears in t h e display.

" appears in t h e display.

102*0002

").

3. Changing the displayed parameter value

-

Use the "+" and "-" buttons to increase or reduce the parameter value.

If the "+" or "-" button is held down the parameter number continues to change until it is released.

-

If you leave the parameter-number routine the last-displayed parameter value is

automatically saved.

4. Leaving programming mode

-

Simultaneously press the "G" and "-" buttons.

The control unit leaves progra mming mode.

The last-displayed parameter value is saved.

-

"

MANUAL

-

The control uni t i s r eady for use.

The new settin g s can be checked by executing a test seam.

" appears in the display.

-

30

"Operator-level" parameter list:

paramet er function setting

101

102

103

108

109

111*

201

301

302

303

505

506

507

508

521

this parameter is vacant on this machine class

*

switch betwee n seam programs MAB

(the "P" button executes the switch)

MAB: MANUAL - SEAM-A - SEAM-B

M+A: MANUAL - SEAM-A

M+B: MANUAL - SEAM-B

A+B: SEAM-A - SEAM-B

starting ba r tack - stitch rate forwards 0 255 2

starting ba r tack - stitch rate backwards 0 255 1

ending bar tack - stitch rate backwards 0 255 2

ending bar tack - stitch rate forwards 0 255 1

light-barrier compensation stitches 0 30 1

stitch rate of seam section A 0 255 20

stitch rate of seam section B1 0 255 10

stitch rate of seam section B2 0 255 10

number of seam sections B1 and B2 0 255 2

starting or namental bar tack - stitch 0 30 3

rate forwards

starting or namental bar tack - stitch 0 30 3

rate backwards

ending ornamental bar tack - stitch 0 30 3

rate backwards

ending ornamental bar tack - stitch 0 30 3

rate forwards

needle position before thread clipping III II

(I = up, II = dow n)

min . max. ex work s

31

7. Sewing

This description is based on th e following assu mptions:

–

the machine in question is a special sewing machine with thread clipper

(subclass

-

RAP 14-1

-

HP 11-1

–

The following f unctions are set at t he operating pan el :

starting bar tack: ON

ending bar tac k: ON

sewing-foot position bef ore and after clipping: DOWN

–

The main switch is on.

–

The last sewing operation was concluded with an ending bar t ac k and thread

clipping.

Operating and function sequence f or sewing:

sewing operation operation / explanation

69-FA-373

electro-pneumatic bar-t ack and sewing- foot-raising mechanism,

pedal-operated

pneumatic rapid stroke-adjustment mechanism, operated by a knee lever

) and the fol l owing optional extras:

Before starting sewing

starting po si tion

position material at start of

seam

At start of seam

sew starting bar tack and

continue sewing

sew only star t ing bar tack

do

sew starting bar tack

not

- pedal i n neutral position

the machine is at a standstill

needle up - sewing feet down

- move pedal back and hold it there

the sewing feet rise

- place material under the needle

- release the pedal

the sewing feet lower onto the material

- move pedal forward and hold it there

starting ba r tack is sewn

the machine then continues sewing at the

motor speed set by the pedal

- move pedal briefly forwards

the machine stops after sewing the

starting ba r tack in the needle-down position

-press "F" button (suppress starting bar tack)

- move pedal forward and hold it there

the machine then sews at the

motor speed set by the pedal

- the next seam is begun with a starting bar tack

32

sewing operation operation / explanation

In mid-seam

interrupt sewing operation

resume sewing operation

sew transverse seam

(with rapid stroke-adjustment

mechanism)

At the end of the seam

remove material

do not raise sewing feet

do not sew ending bar tack

- release pedal (neu tral position )

the machine s t ops in the needle-down position

the sewing feet are lowered

-press the "F" button (ending bar-tack

suppression)

- move pedal briefly backwards

the machine assumes the needle-up position

- move pedal forwards

the machine sews at the motor speed

set by the pedal

starting bar tack is sewn

no

- operate knee switch

the maximum sewing-foot stroke is activated

the operatin g t i m e depends on what mode the

rapid stroke-adjustment mechanism is set to:

a) switch mode:

- activated until knee switch is operated again

b) key mode:

- activated for as long as knee switch is

operated

- move pedal back and hold it there

the ending bar tack is sewn

the thread is severed

the machine assumes the needle-up position

the sewing feet rise

- move pedal briefly backwards

the ending bar tack is sewn

the thread is severed

the machine assumes the needle-up position

the sewing feet remain lowered

-press the "F" button (ending bar-tack

suppression)

- move pedal back

the ending bar tack is not sewn

the thread is severed

the machine assumes the needle-up position

the position of the sewing feet depends on the

position of the pedal:

a) pedal pressed backwards and held:

- sewing feet raised

b) pedal released (i n neutral position):

- sewing feet lowered.

33

8. Maintenance

Caution: danger of injury

Turn off the main switch!

Maintenanc e work may only be carried out on the sewing

machine when it is switched off.

Maintenance work must be carried out no less frequently than at the intervals given in

the tables ( see "operating hours" column).

Maintenanc e i ntervals may need to be shorter when processing heavy -shedding

materials.

8.1 Cleaning and testing

A clean sewing machine i s a trouble-free sewing ma chine.

6

4

8

2

10

1

34

2

3

maintenance work explanation operating

to be carried out hours

Upper part of machine

- Remove lint, pi eces of

thread and other debris.

Sewing drive

- Check the co ndition and

tension

of the V-belt.

Compressed-air

maintenance

unit (optional extra)

- Check the water level in

the pressure regulator.

Places in specia l need of cleanin g:

- area under the needle plate

- feeder

- area around the shuttle

- bobbin housing

- needle-thread tensioner

- thread clipper (class 69-FA-373)

It must be p ossible to depress the V-belt

by about 10 mm by pressing on it with a

finger at its mid-point.

The water leve l must not reach

the filter insert 2.

- After screwing in the drain plug 3 blast

the water out of the water separator

under pressure.

8

160

40

- Clean the filter insert.

NB:

The water separator 2 is fitted with a

semi-automatic condensation drain.

Condensation is automatically drained

when the pressure falls below a pre-set

level.

Dirt and condensation ar e separated by

filter insert 1.

- Disconnect the machine from the

compressed-air supply.

- Screw in drain pl ug 3.

There must be no pressure in the

machine’s pneumatic system.

- Unscrew water separator 2.

- Unscrew filter i n sert 1

Wash the filter shell and insert

with cleaning fluid (

and blast clean.

- Re-assemble and connect the

maintenance unit.

not

solvent)

500

35

1 2 3 4 5 6 7 8

9 10 11

36

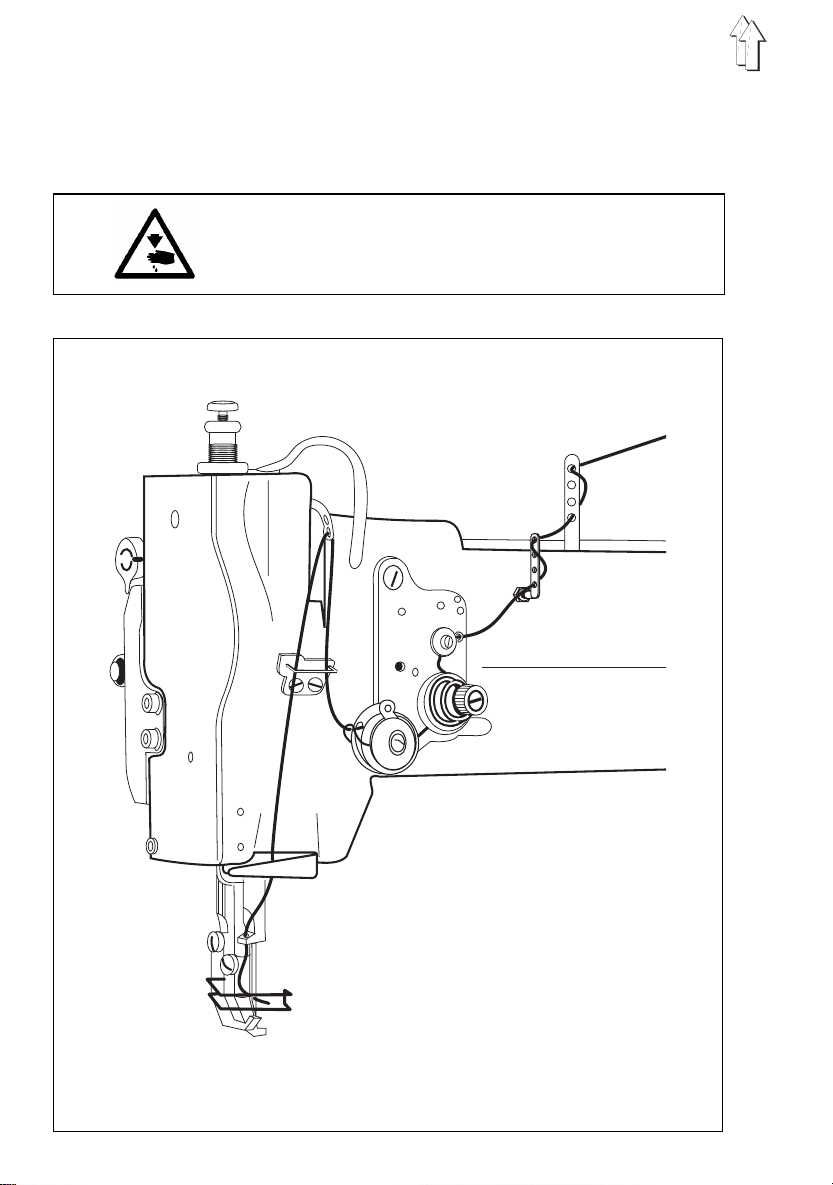

8.2 Lubrication

Caution: danger of injury

Oil can cause skin eruptions.

Avoid protracted contact wit h the skin.

In the event o f contact, thor oughly wash the a ffected area.

CAUTION:

The handling an d disposal of mi neral oils is subject to legal

regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

To lubricate the special sewing machine use only

ESSO SP-NK 1 0

or an equivalent oil of the fo l l owing specifica t i on:

–

viscosity at 40° C : 10 mm2/s

–

flashpoint: 150 °C

lubricating oil

ESSO SP-NK 1 0

following part numbers:

2-litre container: 9047 000013

5-litre container: 9047 000014

maintenance work explanation operating

to be carried out hours

oil lubrication points 1 to 17

is available from

DÜRKOPP AD LER AG

- Remove the top.

- Oil all the lubrication points shown

in the illustration with a few drops

of oil.

NB:

Subclass

lubrication point 8.

69-FA-373

retail outlets under the

has no

12 13 14 15 16 17

40

37

9. Optional extras

9.1 HP 1 1-1 pneu matic rapid st roke adjuster

The HP 11-1 pneumatic rapid stroke adjuster is only available for special sewing

machines with the

This optional extra allows a larger sewing-foot stroke to be set in mid-seam

(e.g. for t h i cker pieces of m aterial or to oversew transv erse seams).

Quick QD554/A51K01

sewing drive.

1

–

Operate knee switch 1.

This activates the maximum sewing-foot stroke, which has two operating modes.

Operating modes

The rapid stro ke-adjustment m echanism can be used in either

The desired operating mode is determined by the setting of parameter number

technician l evel - see servic i n g instructio ns or motor manufacturer’s manual (supplied).

mode operation / explanation

switch mode activated until the knee switch is operated again

401 = I - Operat e knee swit ch.

The maximu m sewing-foot stroke is activated.

- Operate knee switch again.

The seam is continued with the set sewing-foot stroke.

touch mode activated until the knee swit ch i s released

401 = II - Oper ate knee switch and hold it i n place.

The maximu m sewing-foot stroke is activated.

- Release knee switch.

The seam is continued with the set sewing-foot stroke.

switch

or

touch mode

401

at

38

.

Loading...

Loading...