Contents Page:

Home

Part 2: Installation Instructions Cl. 506

1. Scope of Delivery

2. Installation of the Unit

2.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Setting the Work Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Attaching the Yarn Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Checking the V-belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Electrical Connection

3.1 Connecting the Microcontrol Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Checking the Nominal Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Setting the Motor Protection Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Checking the Direction of Rotation of the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Checking the Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4. Pneumatic Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Scope of Delivery

2. Installation of the Unit

–

Frame with se win g d r i ve a nd ta bl e 1100 x 736 mm

–

Sewing machine with integrated bobbin winder

–

Microcont rol c o nt r ol u ni t

–

Compressed air maintenance unit

–

Ya rn sta nd

–

Foot switches

–

Sewing light

–

Tools and small parts in the accessories pack

ATTENTION !

The unit may only be set up by trained personnel.

Before installing the unit it is essential that all transport fastenings be

removed!

2.1 Transport

2.2 Setting the Work Height

For in-house transport lift the unit and transport on a suitable wagon

(e.g. lift truck).

The work height can be set between 76 cm and 106 cm (measured to

the upper edge of the table).

The unit is set at a work height of 82 at the factory.

1

–

Loosen the locking screws 1 on both sides of the frame.

–

Set the base plate horizontally at the desired work height.

In order to avoid a tilt pull out or push in the base plate uniformly

on both sides .

–

Tighten the locking screws 1.

3

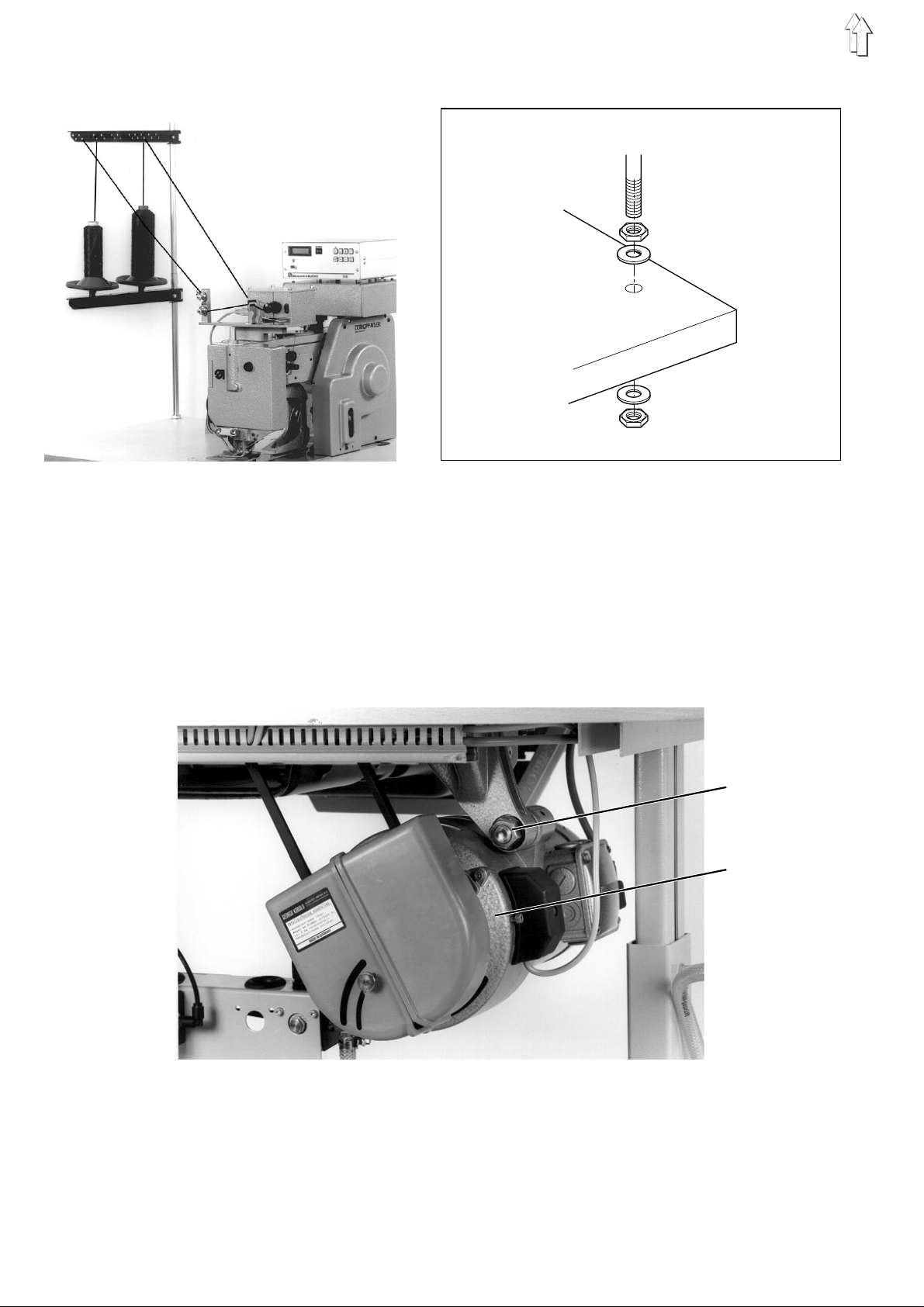

2.3 Attaching the Ya rn Stand

–

Insert the ya rn s t an d i n to the appropriate h ol e i n t he table and

attach with the nuts and washers.

2.4 Checking the V -belt Tension

After transport the V-belt tension set at the factory is to be checked.

The notched V-belt must be under sufficient tension for the unit to run

softly into th e e nd po s iti o n.

Tension the V-belt so that it can be pushed in at the center approx.

10 mm by finger p r ess u r e.

1

2

Correcting the V-belt tension:

–

Loosen nut 1.

–

Swing the s ew i ng dri v e 2 u nt i l th e d es i re d V-belt t en si on i s

achieved.

–

Tighten nut 1.

4

3. Electrical Connection

ATTENTION !

All work on the electrical components of the s ewing unit may b e

carried out only by electr ic i an s or a ppropriately t rai n ed personnel.

The mains plug must be pulled.

3.1 Connecting the Microcontrol Control Unit

The Microcontrol control unit is equipped with the catch plate 1 for

quick attachment and removal.

1

–

Place the Microcontrol control unit on the catch plate 1 and push

back until it catches.

–

Make the cable connections.

Attention !

Insert the pl ug s c are fu l l y into the back of th e c o nt r ol u nit.

In as far as these are present, match the designations on the

cables and the unit back.

Also observ e t he di ffer e nt ou tf i tting of the plug s wi t h c o nt ac t pi n s

or contact sockets, as well as their number and arrangement.

–

Tighten the screws on the plugs.

5

3.2 Checking the Nominal Voltage

The nominal voltage listed on the rating plate of the sewing drive and

the mains vol t ag e m us t ag r ee !

For conversi on to a different mains v ol t ag e t he appropriate vol t ag e k i t

must be mounted.

The voltage kit consists of:

V-belt pulley, V-belt, protection switch insert

Nominal voltage: Order no.:

3 ~ 380 - 415 V + N, 50 Hz 9880 506001

3 ~ 220 - 240 V, 50 Hz 9880 506002

3 ~ 220 - 240 V, 60 Hz 9880 506003

Delta"

"

When converting to a different mains voltage the wiring must be

changed. The wiring is shown in the components connection schematic.

The bridges i n t he motor terminal b ox a re to be switched i n "

Delta

"

" according to the mains voltage .

3.3 Setting the Motor Protection Switch

The motor prot e cti o n s w i tc h 1 m us t be s et ac c o rdi n g t o t he mains

voltage.

220 - 240 V: 2.5 - 4 A

380 - 415 V: 4 - 6.3 A

"Star"

Star

" or

1

6

3.4 Checking the Direction of Rotation of the Motor

ATTENTION !

Before commisssioning of the unit it is essential that the direction of

rotation of the motor be check e d.

Turning the unit on with an incorrect direction of rotation can cause

damage to the u ni t .

The direction of rotation of the ventilator fan on the sewing drive must

agree with the dir e cti o n o f r o ta tio n s h ow n i n th e p i ctu r e (c lo c k wi se ) .

–

Insert the mains plug.

–

By turning on the main switch for a brief period check the direction

of rotation of the ventilat or f an .

–

With an incorrect direction of rotation check if the current supply

creates a rig ht - ha nd r ot ary f i el d .

In this case 2 p ha s es o n the mains plug mu s t b e i n te rc ha ng ed .

7

3.5 Checking the Positioning

1

Before commissioning check the positioning set at the factory.

2

After being t ur n ed on th e u ni t mu s t p os i t i on i n t he 2n d n ee dl e po s i ti o n

(thread lever h i gh po s i tion).

Checking the positioning

–

Turn the main switch off.

–

By turning the ha nd wh ee l bri n g t he th rea d l e v er i n to a m idd l e

position.

–

Turn the main switch on.

The unit pos i ti o ns i n th e 2nd needle posi t i on

(thread lever high position).

–

Check the position of the thread lever.

Correct the positioning if necessary.

Correcting the positioning

–

Loosen the cl am pi n g s c re w s 2 on the synchronizer ring 1.

–

Hold the synchronizer ring 1 tight.

–

By turning the handwheel bring the thread lever into its upper dead

center.

–

Tighten the clampin g s c rews 2.

–

Check the positioning again.

For setting the 1st and 3rd needle positions see the Service

Instructions.

8

4. Pneumatic Connection

1

2

3

For the operation of the clamp lifting, thread tension opening, needle

cooling, etc. the unit must be supplied with water-free, lightly oiled

compressed air.

ATTENTION !

For a flawless functioning of the pneumatic control processes the

compressed air supply must be laid out as follows:

Even at the in s ta nt of greatest air c o ns u mp ti o n t he mi n i mu m o pe r at i ng

pressure may no t f al l b elo w

5 bar

.

4

Connecting the compressed air maintenance unit

–

Connect the connection hose 3 for the maintenance unit to the

compressed air supply with the enclosed coupling.

Filling the oil reservoir of the oil mister

For filling the oil reservoir use only

SP-NK 10 can be obtained from

–

Shut the co mp res s e d a i r off c om pl e te l y by turning the kn ob 1

counterclockwise.

–

Screw out the oil filler screw 4.

–

Fill the oil reservoir 5 up to the groove marking with

ESSO SP-NK 10

–

After filling the oil release the compressed air again by pulling up

on and turning th e k n ob 1 c l o c kw i se .

Setting the operating pressure

–

The operating pressure is

It can be seen on the pressure gauge 2.

–

For setting the operating pressure pull knob 1 up and turn.

Turning clockwise = Increase pressure

Turning counterclockwise = Decrease pressure

lubricating oil.

ESSO SP-NK 10

DÜRKOPP ADL ER AG

6 bar

.

lubricating oil.

sales offices.

5

9

Loading...

Loading...