Adler 506 Service Manual

Contents Page:

Home

Part 3: Service Instructions Cl. 506

1. General

2. Removing the Machine Head Cover and Tilting the Machine Head

2.1 Removing the Machine Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Tilting the Machine Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Barrel Shuttle, Needle Bar

3.1 Needle Bar Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Synchronizing the Hook and Needle Bar Movement . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Clearance Hook Point - Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Clearance Driver - Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Looping Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Worm Wheel Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. Clamps and Feed Plate

4.1 Position of the Feed Plate to the Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Position of the Clamps to the Feed Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5. Bobbin Ejector

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6. Curve Disk

6.1 Replacing the Drive Train and Worm Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Replacing the Curve Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Installing the Gear Reducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. Thread Pull

8. Thread Controller Spring

9. Needle Cooling

10. Shut Off Devices

10.1 Transport Levers for the Length and Crosswise Movement (Switches b09, b16) . . . . . . . 28

10.2 Base Position Stop (Switch b10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10.3 Synchronizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contents Page:

11. Thread Burning Device

11.1 Thread Deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11.2 Upper Burning Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.2.1 Position of the Fully Extended Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.2.2 Setting the Height Stop of the Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.2.3 Angle Position of the Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.3 Lower Burning Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.3.1 Prerequisite for the Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.3.2 Initial Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.3.3 Clearance between the Thread Puller and the Burner . . . . . . . . . . . . . . . . . . . . . . 40

11.3.4 Position of the Swung-forward Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11.3.5 Height of the Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11.3.6 Height of the Thread Puller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12. V-belt Tension

13. Setting the Bobbin Winder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2

1. General

These servi ce i n s tr u c tions describe t he s et ti n gs f or the sewing uni t i n

a practical o r de r.

Attention !

Various setting positions are interdependent.

It is therefore essential to make the settings while keeping to the order

described.

ATTENTION !

The tasks described in these service instructions may only be

conducted by skilled personnel or appropriately trained staff !

Danger of Breakage !

After disassembly work first conduct the required setting tasks as per

these service instructions before putting the sewing unit into service

again.

Never start the sewing unit with an incorrect direction of rotation of the

drive motor.

It is only possible to start a sewing sequence with closed head cover

and closed c over of the hook are a.

If the head cover or the cover of the hook area is open all functions of

the controls a re b l oc k e d.

Caution Risk of Injury !

During repair, conversi on an d m ain te na nc e wo r k tu r n t he ma in s w i tch

off and disconnect the sewing unit from the pneumatic supply.

Adjustment work and function testing with the unit running are to be

conducted only observing all safety measures and with the greatest

possible caution.

For setting work in the area of the clamps and the needle these must

be removed bef or e ha nd i n o r de r to av o i d i n j uri e s .

Setting Gauges

Along with th e u sual parts and to ols t he fo l l ow i ng s et ti n g g au ges are to

be found in th e a c ces s o ri es p ac k:

Setting Gauge Application

Gauge Setting the needle bar height,

synchronizing the hook and

needle bar movement

Timing pin Synchronizing the hook a nd

needle bar movement

On request you can also rece i ve the following s et ti n g g au ge s :

Setting Gauge Application Order no.

Gauge Se tt i ng th e l o op i ng s tr o k e 981 150012

Block Setting th e l o op i ng str o k e 981 150006

3

2. Removing the Machine Head Cover and Tilting the Machine Head

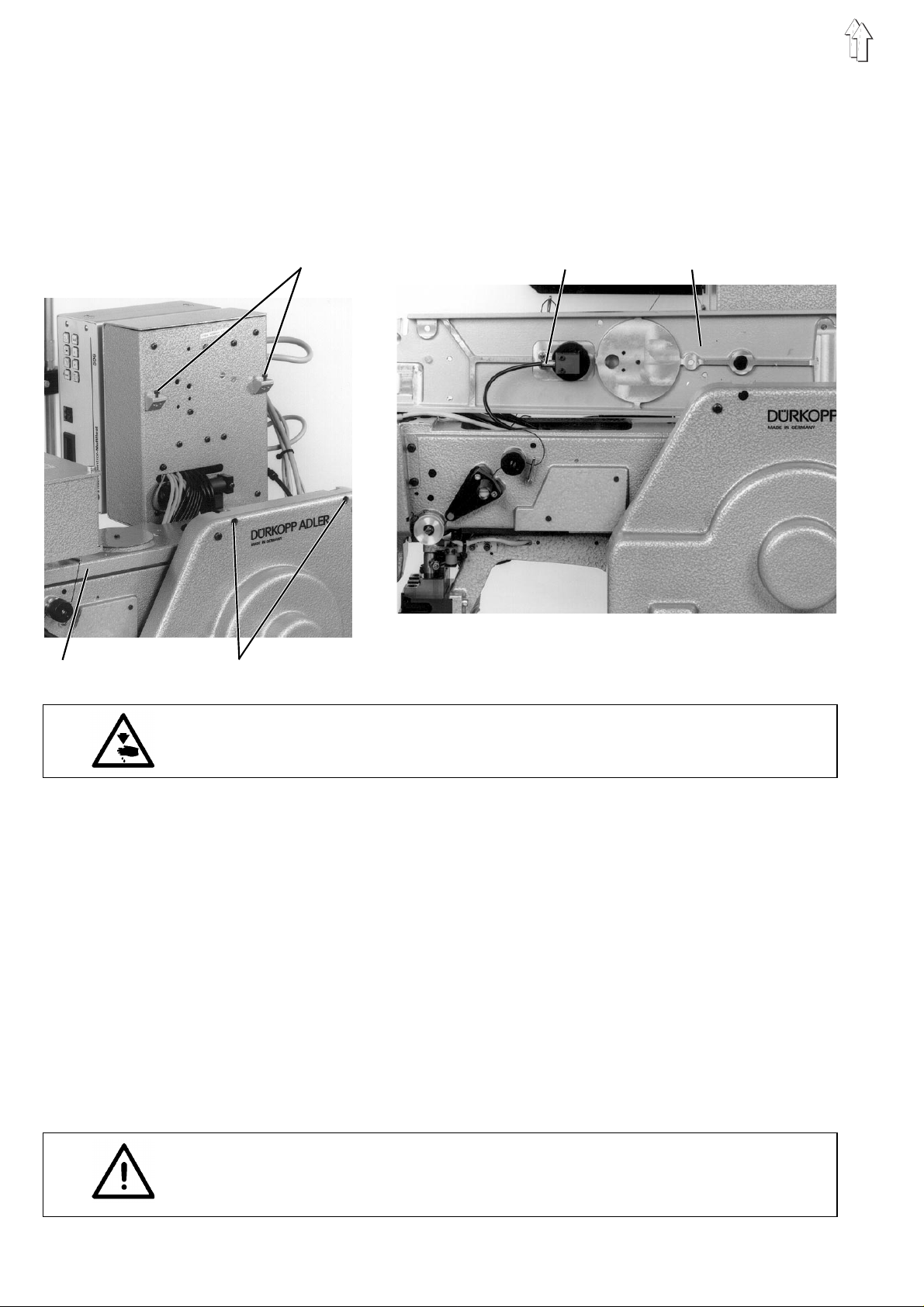

2.1 Removing the Machine Head Cover

For service work on the inside of the machine head the machine head

cover 2 is to be removed.

For this the Microcontrol control unit must first be swung to the side.

2 3

1

4 2

Caution Risk of Injury !

Turn the main switch off.

Remove the machine head cover only with the main switch turned off.

Swing the Microcontrol control unit to the side

–

Slightly loosen the Allen screws 1.

The Allen sc r e ws are ac c es sa bl e thr o ug h th e ho l es 3 i n th e c ove r.

–

Carefully sw i ng th e M i c roc o nt rol c o nt rol u ni t to th e si d e.

–

The machine head cover 2 is freely accessable and can be

removed.

Remove the bobbin winder

–

Loosen the mounting srews of the bobbin winder and remove the

bobbin winder.

Remove the machin e he ad c o ve r

–

Loosen the mounting screws of the machine head cover 2.

–

Carefully lift the machine head cover 2.

–

For the complete removal of the machine head cover loosen the

screws 4 of the compressed air hose.

ATTENTION !

Removing the machine head cover by force can lead to damage to the

compressed air feed.

4

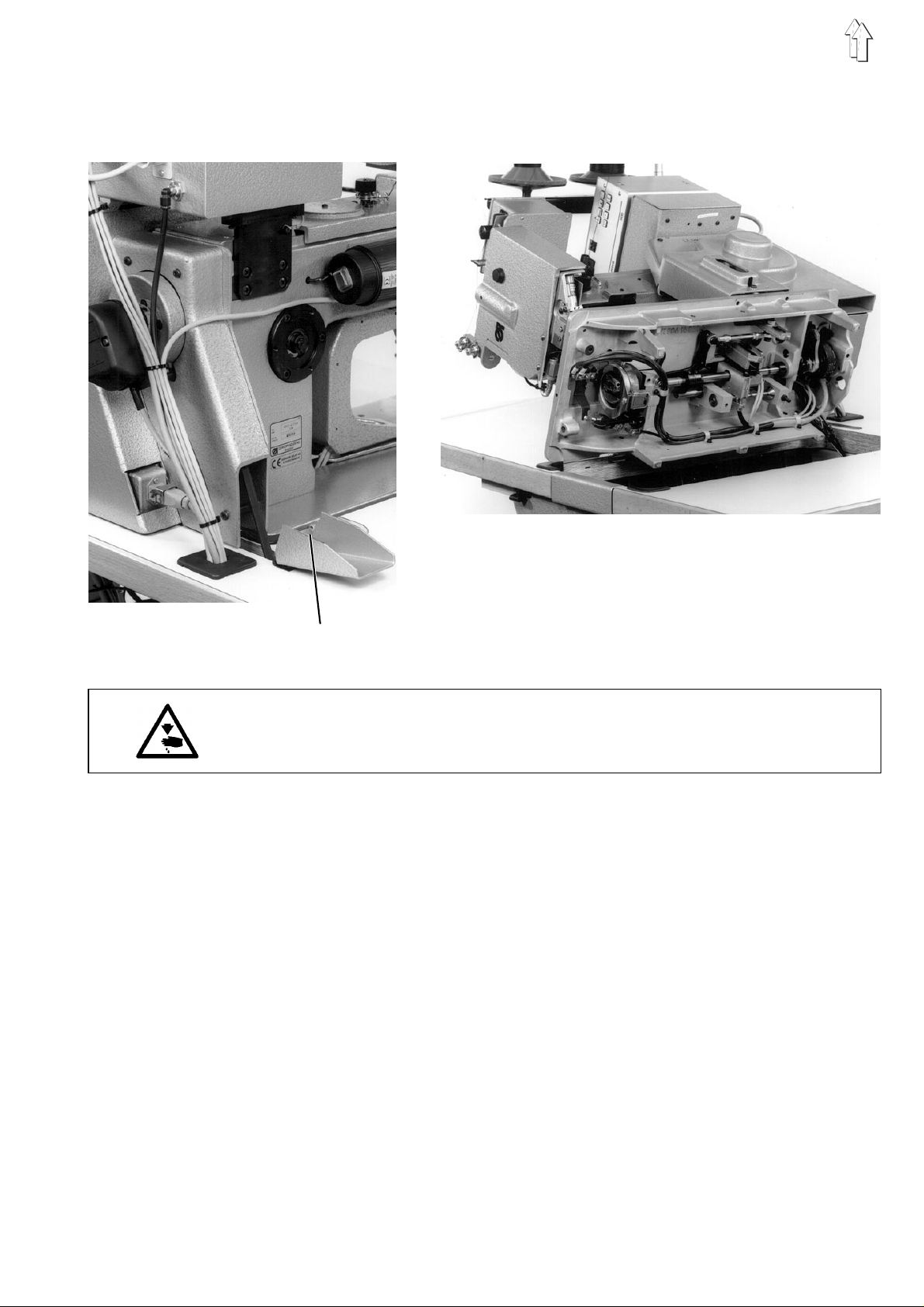

2.2 Tilting t he Machi ne Head

For service work on the unde rs i de of th e m ac h i ne he ad th i s mu s t b e

tilted to the b ac k.

1

Caution Risk of Injury !

Turn the main switch off.

Tilt the machine head only with the main switch turned off.

–

Swing the V-belt cover 1 to the back.

–

Carefully ti l t th e m ac h i ne he ad ov e r an d l a y on to th e s u pp or t on

the table.

The underside of the machine he ad i s acc e s s ab l e f or s e r vi c e w or k .

5

3. Barrel Shuttle, Needle Bar

ATTENTION !

The settings d es cr i b ed i n t he Ch ap te r s 3.1 to 3.4 are int er d ep en de nt .

It is therefore essential that the individual settings be made in the

order listed in the service instructions.

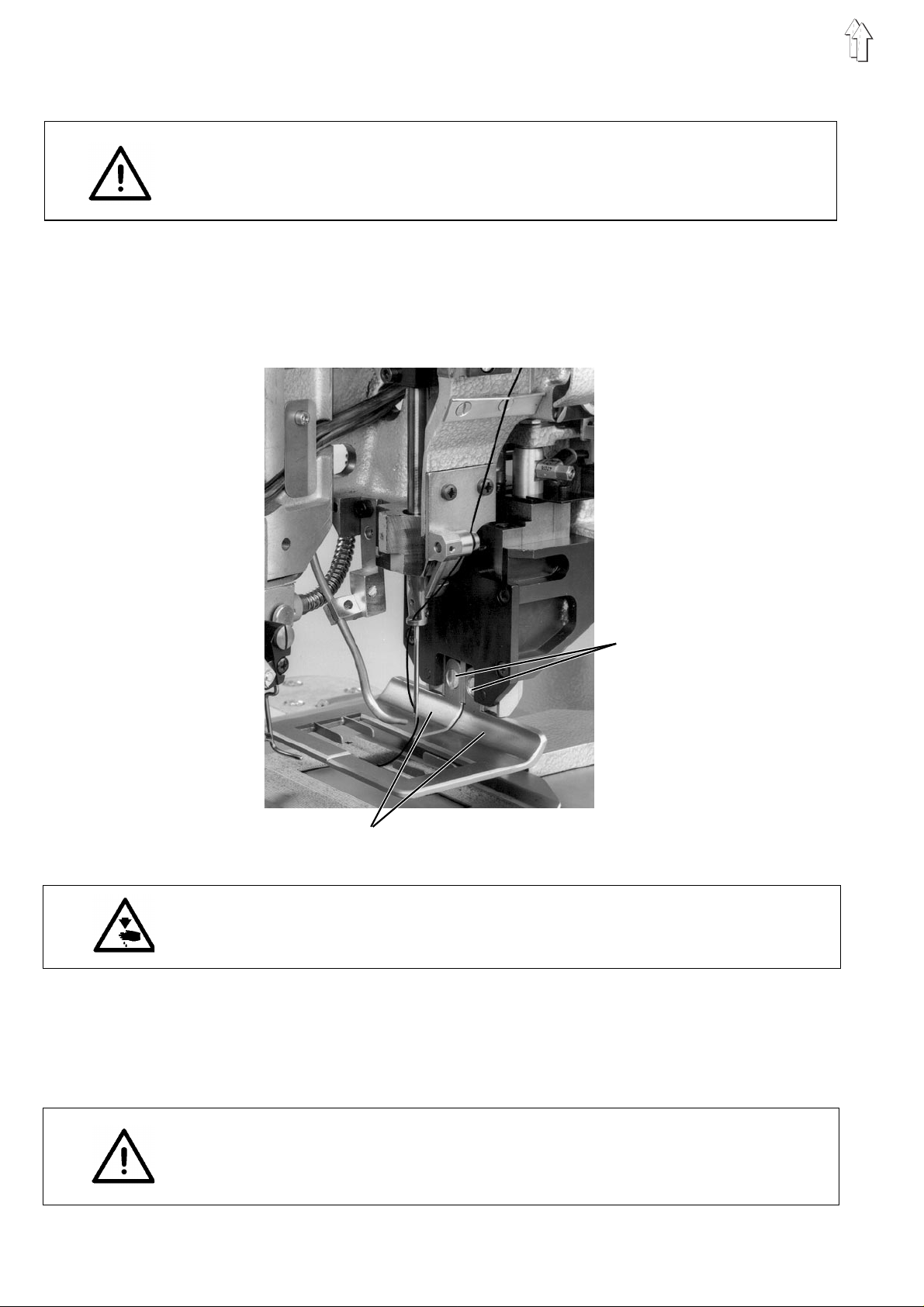

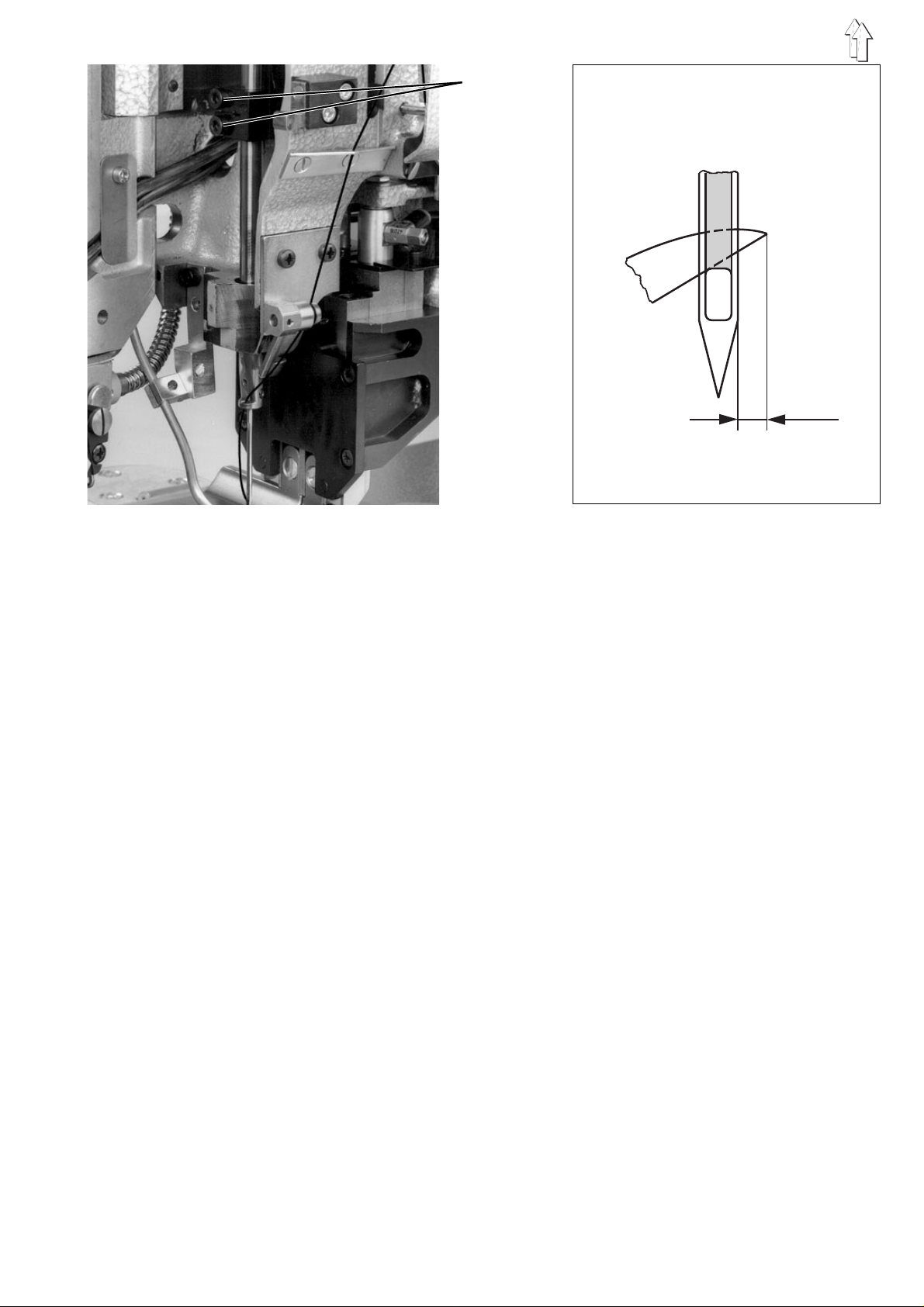

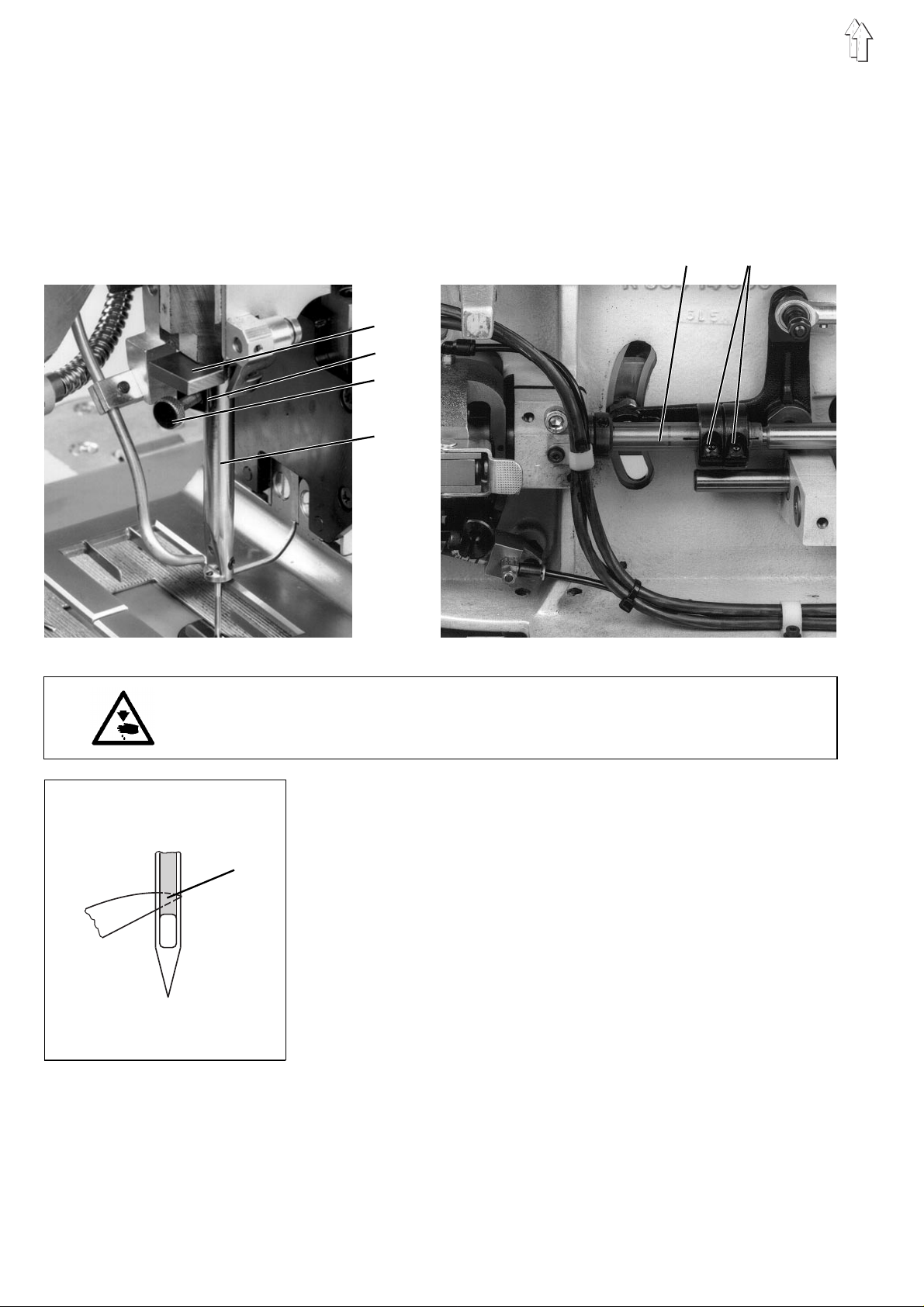

3.1 Needle Bar Height

When the hook point extends 2 mm beyond the right needle side

the eye of the needle must be under the hook point.

2

3

Caution Risk of Injury !

Turn the main switch off.

Adjust the needle bar height only with the main switch turned off.

–

Switch off the main switch.

–

Loosen screws 2.

–

Remove the clam ps 3 .

Caution Danger of Breakage !

Before conducting the following settings it is essential to remove the

clamps. This a v oi d s th e n ee dl e hi t ti n g a ga i nst the clamps duri ng the

settings following later.

6

4

2 mm

–

Turn the handwheel i n t he di re c ti o n o f r u n u nt i l th e h oo k po i nt

exceeds the ri g ht edge of the nee dle by 2 mm.

ATTENTION!

Care of the driver lying on the barrel shuttle in the direction of run.

–

Loosen the cl a mp i ng s c rews 4.

–

Set needle ba r he i gh t s o th at th e lo we r ed ge of th e h oo k j us t

becomes visi b l e i n th e e y e o f t he ne edle (see drawi ng ab ov e ) .

–

Tighten the clamping screws 4.

–

Attach again clamps 3 with screws 2.

7

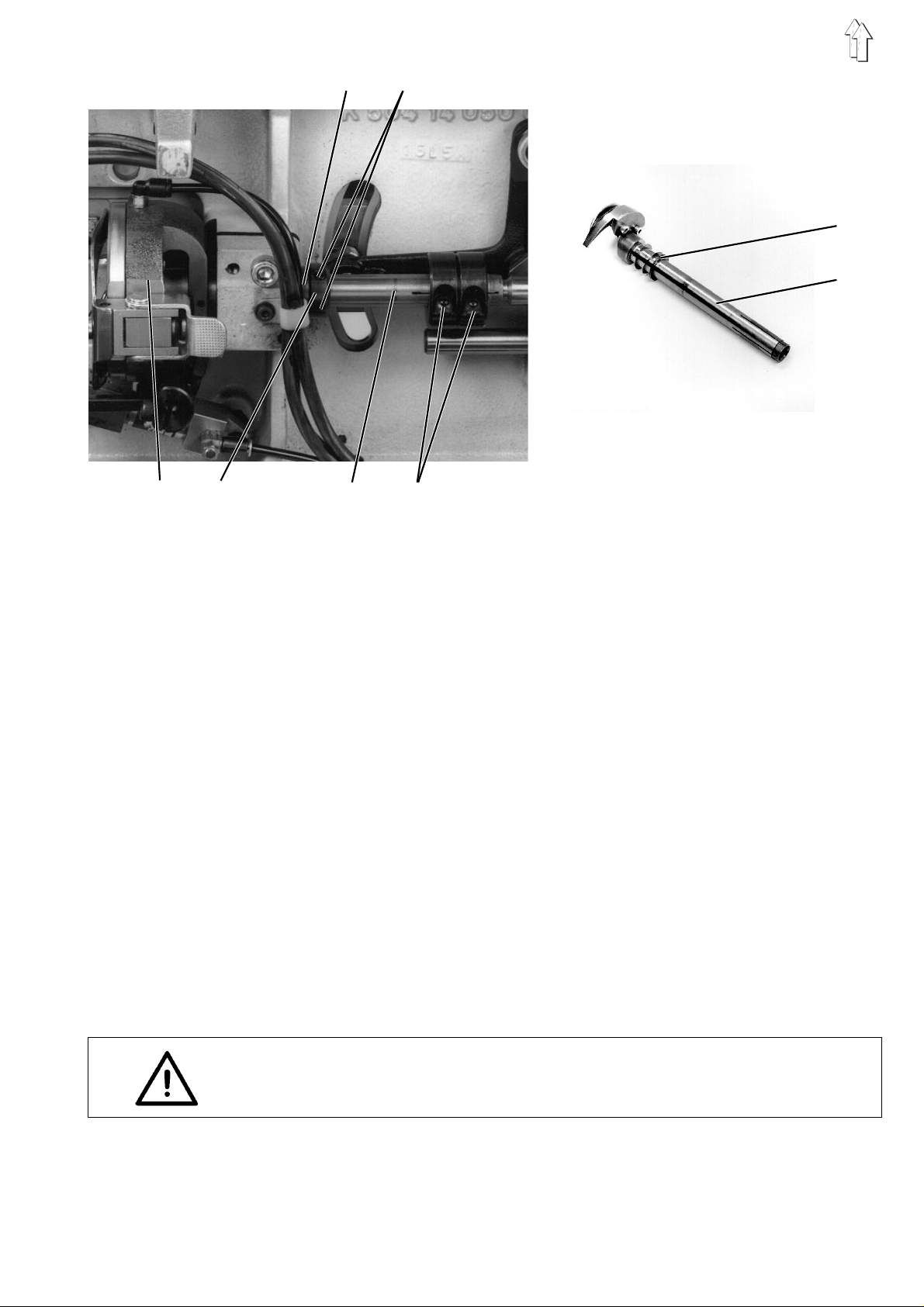

3.2 Synchronizing the Hook and Needle Bar Movement

The synchronization of the hook movement to the movement of the

needle bar is m ad e w i th ga ug e 1 an d timing pin 3.

1

2

3

Caution Risk of Injury !

Turn the main switch off.

Synchroniz e t he ho ok a nd ne edle bar movement only with the ma i n

switch turned off.

–

Insert the timing pin 3 into the hole in the housing on the machine head.

–

Turn the handwheel in the direction of run until the timing pin 3 can

be felt to ha v e ca ught in the groov e on th e a r m sh aft crank.

–

Tilt the machine head to the side.

–

Insert gauge 1 th r ou gh th e h ol e i n t he ho us i n g.

With a correct setting it must be possible to push gauge 1 into the

recess on the crank 2.

4

5

To correct:

–

Remove the machine head cover.

–

Loosen the cl am pi n g s c re w s 5 on the timing belt pu l l ey 4.

–

Turn the handwheel in the direction of run until the gauge 1 can be

pushed into the recess on the crank 2.

–

Tighten the clampin g s c rews 5.

–

Replace the machine head cover again.

8

3.3 Clearance Hook Point - Needle

The hook point 8 must lie as close as possible to the furrow of the

needle without touching it.

3

4

5

1

2

9

A

6

Caution Risk of Injury !

Turn the main switch off.

Set the clearance hook point - needle only with the main switch

turned off.

–

By turning the handwheel bring the hook point 8 to the the needle

and check the position of the hook point to the furrow of the needle.

7

A

To correct:

–

Tilt the machine he ad to the side.

8

A-A

–

Loosen the cl a mp i ng s c rews 7.

–

Loosen the clamping screws 2 on the set collar 6.

–

Remove driver with driver shaft 9 forward from shuttle run

bearing 3.

–

Loosen clam pi n g s cr e w 5 on the the base pl at e.

–

Screw in forcing screw 4 slightly.

The jaws on the base plate are spread.

–

Move the hook point 8 to the furrow of the needle by axial

relocation of th e s h ut tl e run bearing 3.

The upper surf ac e of th e s h ut tl e r un be ar in g 3 must thereby be

parallel to the needle plate.

–

Screw the forcing screw 4 back.

–

Tighten the clamping screw 5.

–

Re-insert dri v e r wi t h driver shaft 9 i nt o shuttle run beari n g 3 an d

push it back.

–

Push the set collar 6 up to the stop against bushing 1.

–

Tighten clamping screws 2.

–

Tighten clamping screws 7.

ATTENTION !

When insert i ng a t hi ck e r ne ed l e t he c l ea ran c e o f t he hook point to t he

needle also c h an ge s au to ma ti c a l ly.

The clearanc e h oo k po i nt - ne ed l e is t o b e c o r rec t ed .

9

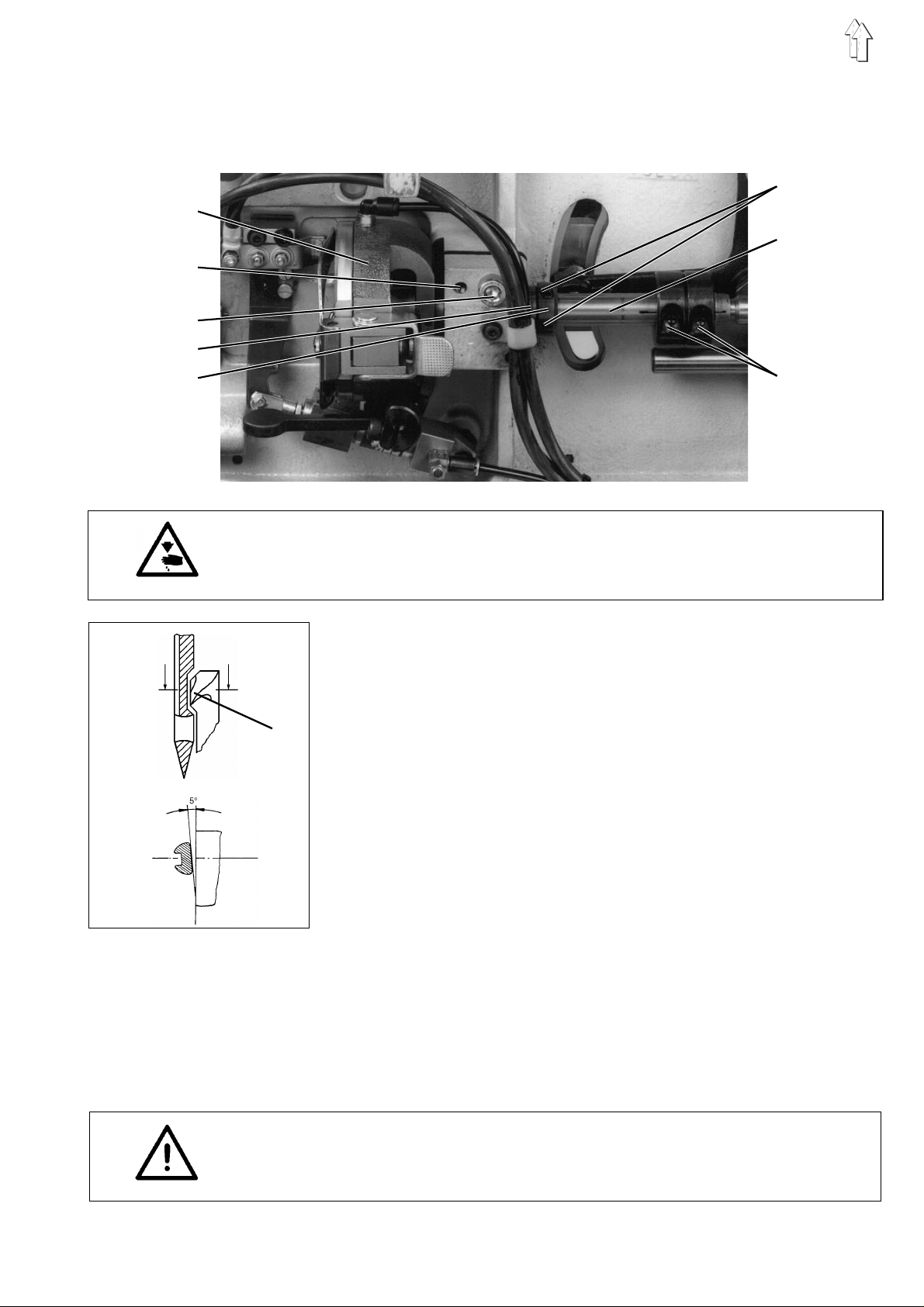

3.4 Clearance D river - Needl e

The encompassing driver 3 moves the barrel shuttle 1 in the shuttle

run.

With a correc t s et ti n g o f t he dr i v e r th i s al so s er ves as a guide fo r th e

needle in the v e r ti cal direction.

Missing stitches because of "shimmy" of the needle are avoided in this

manner.

The right side of the needle must touch the driver 3 without being

deflected.

For this the driver 3 must be set close to the the needle.

2

3 4 5

Caution Risk of Injury!

Turn the main switch off.

Set the clear a nc e dri v e r - ne ed l e o nl y w i th th e m ai n s wi t c h t urned off.

–

–

–

–

–

–

1

By turning t he ha nd wh ee l br ing the needle in to th e h i gh po s i ti o n

(Position 2).

Pull the spring lock 4 forward for unlocking of the shuttle run

spring 5.

Swing the s hu tt l e ru n s p r i ng 5 t o t he ba c k .

Remove the cover ring 2.

Take out the barrel shuttle 1.

To check the the sett i ng mo v e t he dr i ve r 3 t o t he ne edle by turning

the handwheel .

3

10

67

89 1011

12

10

To correct:

–

Tilt the machine he ad to the side.

–

Loosen the clamping screws 11.

–

Loosen the clamping screws 7 on the set collar 9.

–

Pull the dri v er 3 wi t h t he dri v e r s ha ft 10 fo rwa r d o ut of th e sh uttle

run bearing 8 .

–

Washers 12 to be ad de d t o o r rem ov e d f r om th e removed driver

shaft 10. You may find them in the accessories pack.

Remark

If using a thinner needle, sometimes it may be nessary to add a

washer and if using a thicker needle, to remove one.

–

Insert the dr i ver 3 with the dr iv er sh aft 10 into the sh ut tl e r un

bearing 8 agai n an d p us h to th e b ac k u p t o t he s to p.

–

Push the set collar 9 up to the stop against the bushing 6.

–

Tighten the clamping screws 7.

The driver 3 i s s e c ured against axial displaceme nt .

–

Reset the looping stroke (see section 3.5)

–

Check the setting by turning the belt pulley on the arm shaft. The

right side o f t he ne ed l e m us t to uc h th e d r iv er w i th ou t b ei n g

deflected.

If the setti ng is no t c o r rec t , r e pe at th e p r ocedure.

ATTENTION !

After the setting of the clearance driver - needle it is essential to reset

the looping stroke per Chapter 3.5.

11

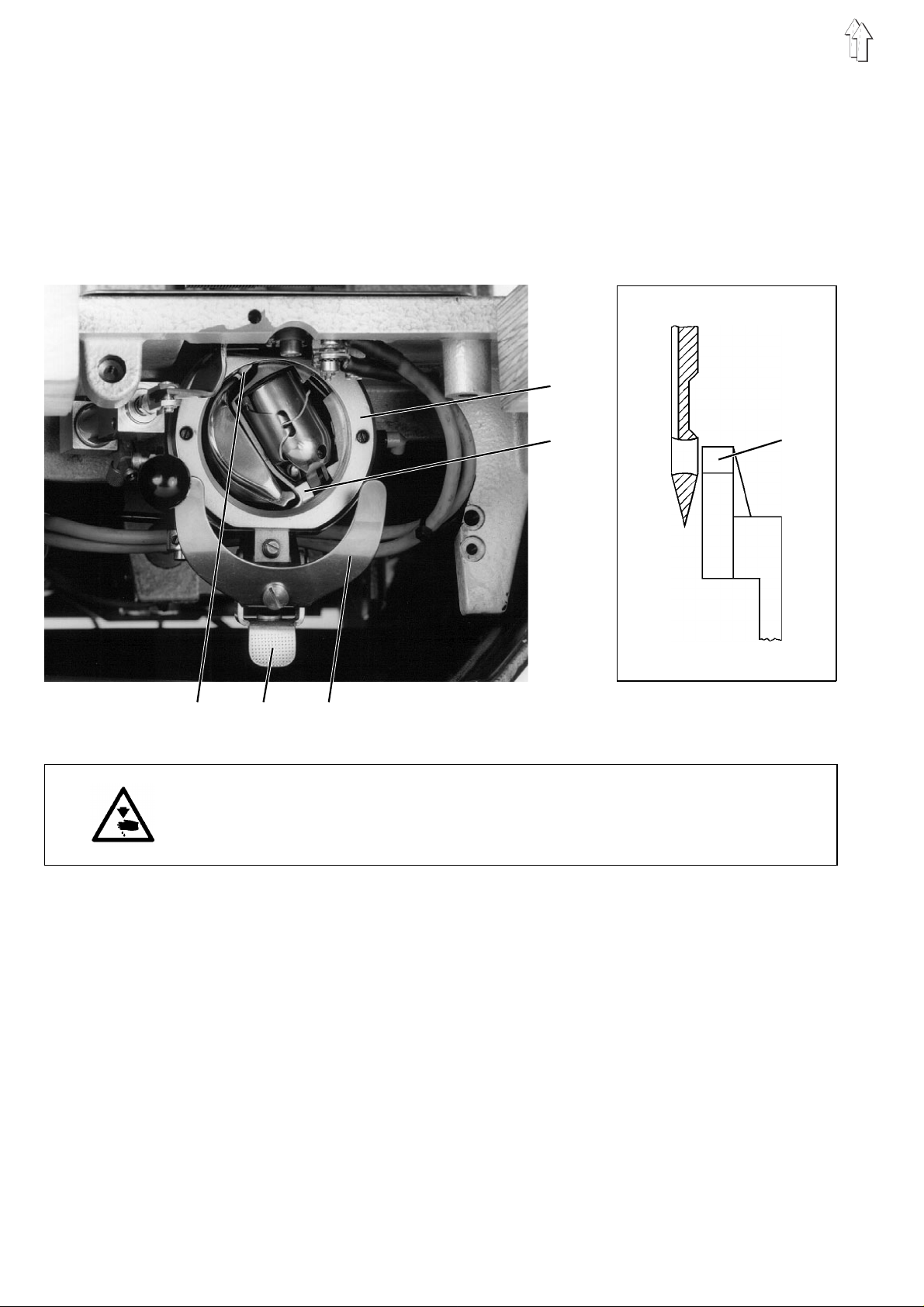

3.5 Looping Stroke

The looping s t rok e i s th e p at h o f t he needle bar from i ts l o we r de ad

center up to th e p oi n t where the hook p oi n t 7 en ds w i th th e r ight

needle side.

The looping stroke must be 5 mm.

It is set with gauge 1 (Order no. 981 150012) and block 2

(Order no. 981 15 00 06 ) .

56

1

2

3

4

Caution Risk of Injury !

Turn the main switch off.

Set the looping stroke only with the main switch turned off.

–

By turning t he ha nd wh ee l br ing the needle bar 4 i nt o i t s l ow es t

position.

–

Open the head cover.

–

Press gauge 1 w i th bl o c k 2 u pward against t he ho us ing.

–

7

Set the clamp i ng s c rew 3 tight to the block 2.

–

Pull out gaug e 1.

–

Turn the handwheel in the direction of run until the block 2 touchs

on the housing.

–

Check if the h oo k po i nt 7 e nd s at th e r i g ht ne ed l e s ide.

To correct:

–

Tilt the machine head to the side.

–

Loosen the clamping screws 6.

–

Turn the driver shaf t 5 ap pr o pri a tely.

–

Tighten the clampin g s c rews 6.

–

Check the cl ea rance driver - nee dl e ag ai n an d, i f n ec e s s ary,

correct (see Ch ap te r 3. 4) .

12

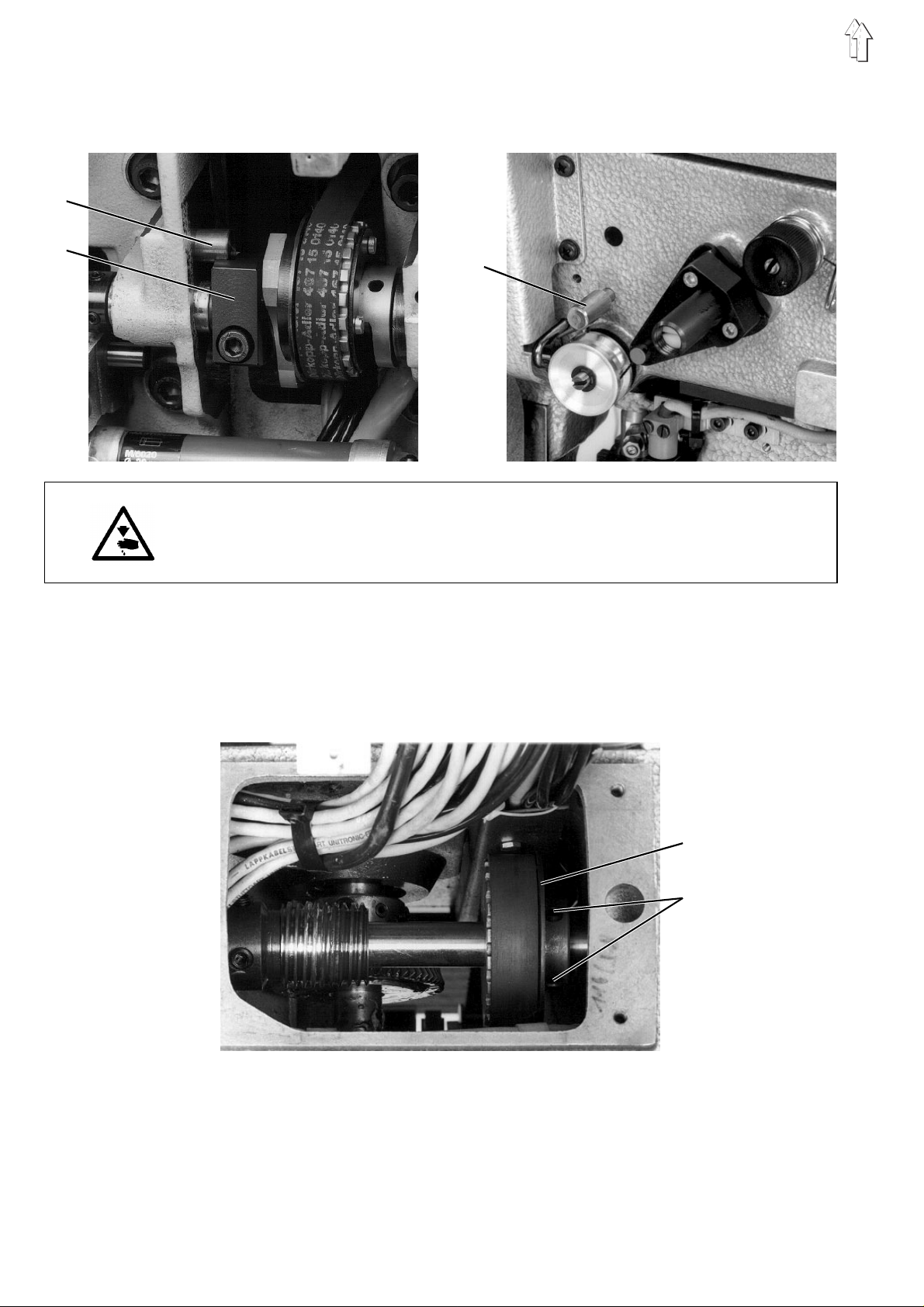

3.6 Worm Wheel Play

The tooth play between worm 2 and worm wheel 3 must as little as

possible.

12 3 4

Caution Risk of Injury !

Turn the main switch off.

Set the worm wh ee l pla y on l y wi t h t he ma i n switch turned off.

To check:

–

Turn the curve disk to the right and left.

A little play must be felt.

To correct:

–

Remove the machine head cover.

–

Loosen the cl a mp i ng s c rews 1.

–

Set the tooth p l ay b y ax i a l r el o cat i on of th e c o nic a l wo rm 2 on th e

arm shaft 4.

Attention !

The first screw - seen in the direction of rotation - must lie on the

surface of th e a r m sh aft.

–

Tighten the clamping screws 1.

–

Replace th e m achine head cove r ag ai n .

13

Loading...

Loading...