Contents Page:

Home

Part 4: Instructions for programming DA-Microcontrol Cl. 506

Program v ersion: 50 6 B03

1. General

2. Description of the Controls

2.1 Keys on the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Internal Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Description of the Function Keys

3.1 Softstart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Foot Switch Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Burner Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Machine Head Rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Bobbin Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Resetting the Counter for the Bobbin Winder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Resetting the Piece Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Calling up the Sewing, Service and Testing Programs

5. Base Position a n d O per ati o nal Re ad i nes s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6. Sewing Programs

6.1 Sewing Program P01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 Sewing Program P02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3 Sewing Program P03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Sewing Program P11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7. Service Programs

7.1 Setting the Underthread Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.2 Programming Variable rpm Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 Burner T est: Glowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.4 Burner T est: Lowering and Glowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.5 Burner T est: Lowering in Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.6 Burner T est: Slow Sewing, Lowering in Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8. Testing Programs

8.1 Displaying the Program Version and Check Sum . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2 Checking the Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 Memory Test and Timer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Continuity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.5 Checking the Front Panel Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.6 Checking the Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.7 Calling Up Input Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contents Page:

8.8 Calling Up Output Eleme nts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.9 Sewing Drive: Rpm Test, Position 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.10 Sewing Drive: Rpm Test, Position 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.11 Sewing Drive: Rpm Test, Position 1, Position 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9. Function Displays and Error Messages

9.1 Displays of Operating Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 Displays of Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.3 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1. General

MICROCONTROL controls

The

as an integra l pa rt the comprehensi v e

monitoring system.

A microcomputer assumes the control tasks, monitors the sewing

process and displays operator errors and malfunctions.

Special programs simplif y m ec h an i c al se ttings and make po ss i bl e th e

quick inspec t i on of i np ut and output elem en ts without additi o na l

measuring de v ic es .

Errors and test results are shown in a 2 x 16 digit display.

During fault- fre e f un c ti o nin g t he di s p lay s h ow s i nf or m at ion to th e

operation and the sewing process.

With an opera to r err o r or a ma l fu nc t i on th e f un c ti o n s e qu en c e i s

interrupted . The cause is sho wn i n t he di s p l ay by the appropriat e er ro r

symbol.

In most cases the error symbol disappears after the cause of the error

has been remed i ed .

In some cases the main switch must be turned off for safety reasons

while the error is being corrected.

A part of the error messa ge s i s me an t o nl y f or t he maintenance s t aff.

All functions can be called up and changed by pressing the

appropriate key. For this the unit must be in the base position.

When the uni t i s t ur n ed on th e c o nt r ol s c o nd uc t a n um ber of

comprehensive self-tests. Thereby the program and data memories

and the displ ay, among other t hi n gs, are checked as t o f l aw l es s

functioning .

After the ma chi n e i s t urned off the set val ue s of the individua l

functions ar e st o red i n t he pr o gr a m a nd da ta me mo r i es ( b at te r y

buffered) and automatically activated when next turned on.

of the

DÜRKOPP ADL ER 50 6

MULTITEST

testing and

have

3

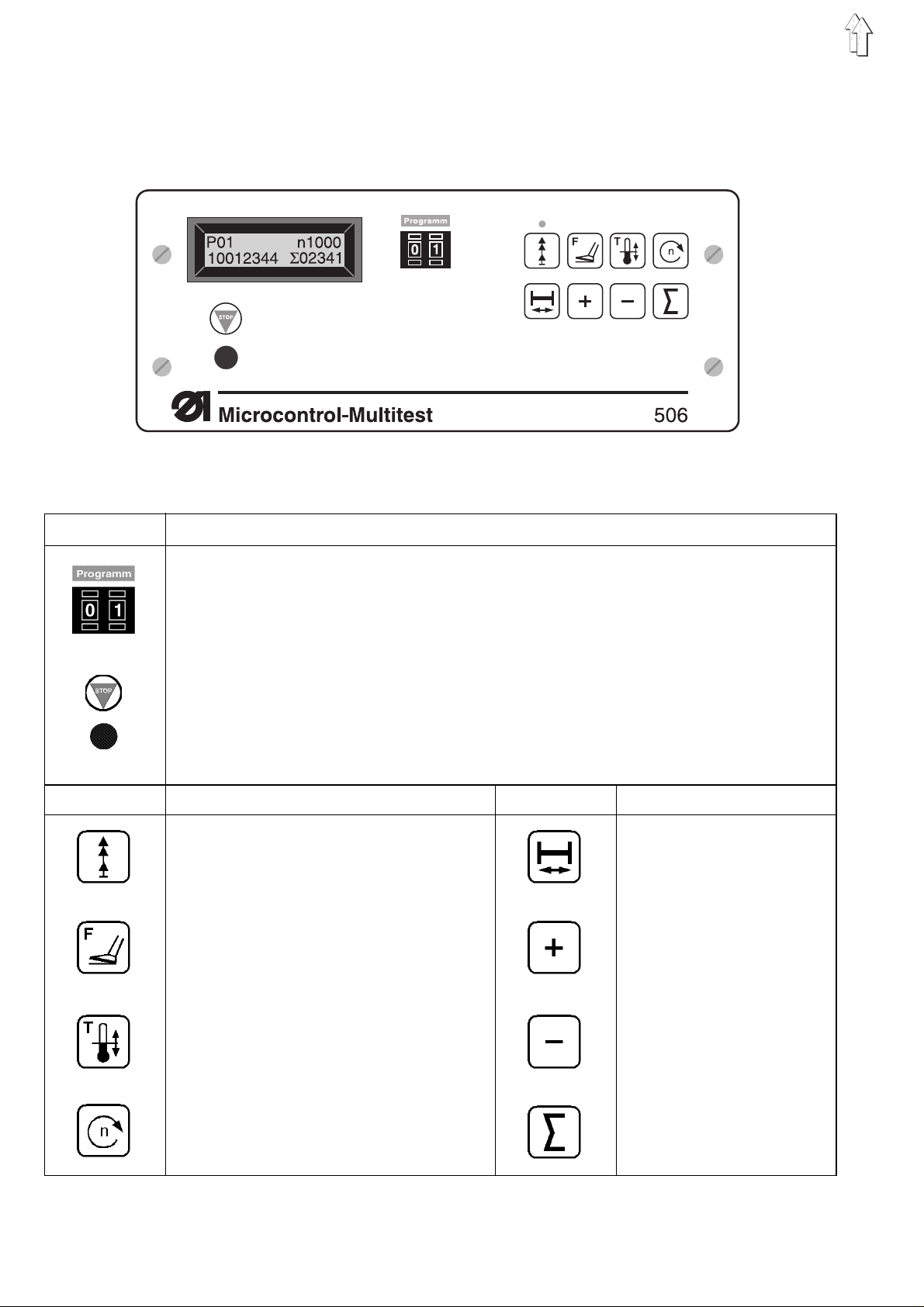

2. Description of the Controls

2.1 Keys on the Front Panel

Key Function

Calling up sewing and testing programs

Stopping the current program

Activating the selected program

Key Function Key Function

Switching t he softstart on / o ff Bobbin chang e

Setting the fo ot s wi t c h m od e Increasing th e p ara me ter

value

Setting the bu rne r Decreasing th e p ara me te r

value

Setting the rpm Setting the counter

4

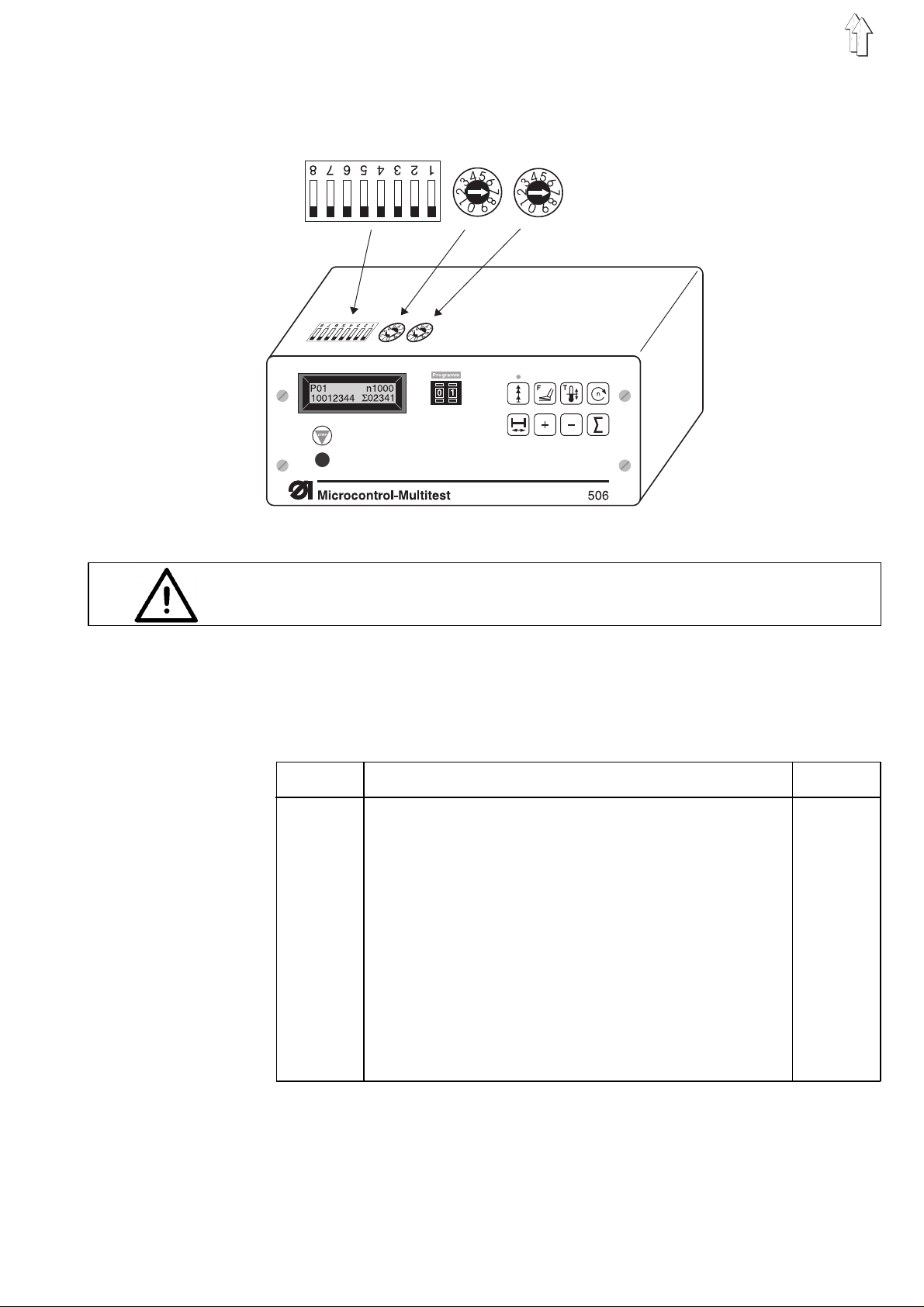

2.2 Internal Switches

on

off

DIP switch b500

Caution Electrical Current !

Set the switch only with the main switch turned off.

DIP switch b500:

With the aid of the internal DIP switch b500 the number of stitches per

curve disk revolution is set.

The allowable settings are to be found in the following table.

Switch12345678No. of Stit.

off off off off off X Y Z 42

on off off off off X Y Z 58

off on off off off X Y Z 72

on on off off off X Y Z 84

off off on off off X Y Z 116

on off on off off X Y Z 144

off on on off off X Y Z 21

on on on off off X Y Z 29

off off off on off X Y Z 36

on off off on off X Y Z 14

off on off on off X Y Z 24

off on off on off X Y Z 168

6: X = on: needle cool i ng no r ma l

6: X = off: needle cooling continuous operation

7: Y = on: without burner

7: Y = off: with burner

8: Z = on: w i th transport lever

8: Z = off: withou t t r an spo r t l e v er

5

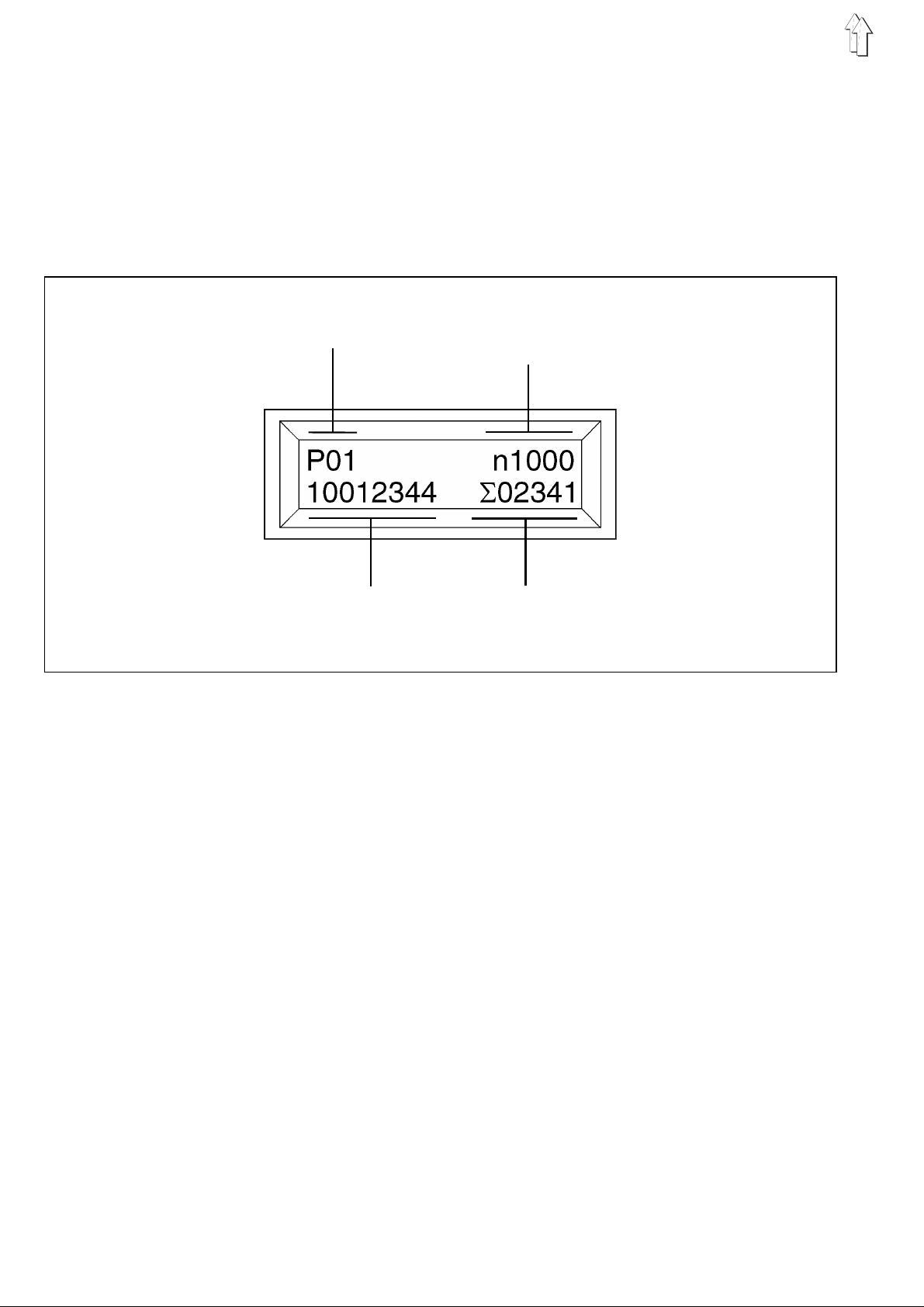

2.3 Display

The Microcontrol controls are equipped with a 2 x 16 digit display.

It shows the program number, machine head rpm and piece count.

With operato r err o rs or m al f un c ti o ns the function s eq ue nce is

interrupted an d t he c au s e s h ow n b y th e a pp r op ri at e e r ror s ymbol.

The display o f the piece coun t in the right half o f t he s eco nd half of the

display signals the operational readiness of the unit.

Program Numb er Machine Head Rp m ,

Error Messages

Production Counter Piece Counter

Program number

The left half of the first line o f t he di s p l ay s h ows the number of th e j u st

selected program.

Machine head rp m / er ror me ss ag e s

The right half of the first li n e o f the display sh ow s th e c u rr en tl y set rpm

of the machine head.

By the occura nc e of an operator error or malfunctions the appropriate

error symbol is shown.

Production counter

The production counter shows the sum of the pieces sewn up to that

moment. It ca nn ot be r es e t.

Piece counter

The piece counter shows the number of pieces sewn since the last

resetting of th e c o un te r. It can be res e t t o z e ro by pressing th e "Σ" key.

When the main switch is tu rned off the current count of the piece

counter is stored.

If the display remains blank after the main switch is turned on

then the 1.6 A fuse (on the underside of the mains unit) is to be

replaced.

6

3. Description of the Function Keys

The values for the various functions can be set as follows:

–

Call up the desired function by pressing the appropriate function

key.

The selected function is shown in the display with a blinking cursor.

–

Change the set value with the "

–

Press the sa me function key aga i n.

The change is completed.

The unit is re ad y fo r op era t io n again.

3.1 Softstart

With the softstart switched on the first stitches on the seam beginning

are sewn at reduced rpm.

The softstart is turned on and off by operating the key.

The softstar t i s ac t i v e w he n t he LE D above the key is l i t.

+ / -

" - keys.

3.2 Foot Switch Mode

Two different foot switc h mo de s are av a i l ab l e.

–

Set the desired foot switch mode with the "+/-" keys.

Mode 1

–

–

–

Mode 2

–

–

–

–

(Display:

After the first operation of the right fo ot switch both clamps are

lowered together.

With the clam ps l o we red th e s e win g s e qu en c e is s t art ed by

operating the l ef t f oo t s w i tc h .

With the sec o nd op er a ti o n o f t he r i gh t f oo t s w i tc h bo th c l am ps a re

raised again.

(Display:

Through operation of the left foot switch the left clamp is lowered.

Through opera tio n o f t he r i gh t f oo t sw i tc h th e l o we ri ng of th e ri g ht

clamp occurs.

As long as only one clamp is lowered this can be raised again by a

second opera ti o n o f t he ap pr o pr ia t e fo ot s wi t c h.

If both clamps are already lowered the sewing sequence is started

by operating th e l e ft fo ot s wi t c h.

F=01

F=02

)

)

7

3.3 Burner Sett ings

Two different types of bu rne r op era t io n are available :

–

with preheatin g

–

without preheating

If the sewing t i me ne ces sa r y fo r th e s e am fo rma ti o n is s h ort er t ha n t he

heating tim e re qu i r ed by the burner the co nt r ol s automatically s w i tc h

over to "wit h p r eh ea ti n g" .

With aid of th e preheating the bu rne r i s pre he at ed to a specific ba s e

temperature. T hi s r e du c es the time requir ed fo r he at i ng to the

operating tem perature.

The sewing ti m e r e qu i red i s de pe nd en t o n t he number of stitch es p er

curve disk revolution and the selected rpm.

With preheating

–

In the first line of the display the symbol "*" appears in fro nt of the

machine head rpm.

–

Press the key.

"G" blinks in the display.

–

Set the period for the preheating with the "

period, 10 = longest period).

Without preheating

–

Press the key.

"B" blinks in the display.

–

Set the time for tu rni n g o n t he th rea d b urn er w ith th e "

(1 = earliest switch-on time, 10 = latest switch-on time).

Note:

The earliest switch-on time means a longer glowing period.

–

Press the key again.

"E" blinks in the display.

–

Set the switch-off time of the thread burner with the "

(1 = shortest period switched on, 10 = longest period switched on).

+ / -

" keys ( 1 = shortest

+ / -

+ / -

" - keys

" - keys

3.4 Machine Head R pm

With the aid of this key the machine head rpm can be set.

The rpms which can be set can be found in the table below.

–

Set the desir e d rpm with the "

Rpm [1/min]

Attention!

At plans with a middle to large zig-zag-stitch the machine head rpm

must be lowered to a adequate level.

+ / -

" - keys.

1400

2500

3600

4700

5800

6900

71000

81100

8

3.5 Bobbin Change

Caution Risk of Injury !

Turn the main switch off.

Change the bobbi n on l y wi t h t he ma i n switch turned off.

–

Press the " " key.

The machine head positions in position 3.

The bobbin ca n b e c h an ge d.

Note:

For better accessibility by the seamstress there is a second alternative

key on the left side of the head cover of the unit.

3.6 Resetting the Counter for the Bobbin Winder

If the windi ng procedure is int err u pt ed pr e ma tu r el y m an ually the

counter must be reset as follows:

–

Turn the main switch off.

–

Turn the main switc h on an d at the same time pr e ss th e " " k e y.

The counter is reset to the beginning value set in program P41.

–

As long as t he k ey is o pe r at ed "

SP-RESET

" appears in the display.

3.7 Resetting the Piece Counter

The piece counter is reset to zero with this key.

The piece counter shows the number of pieces sewn since the last

resetting of th e c o un te r.

The production counter cannot be reset !

9

4. Calling Up the Sewing, Service and T esting Programs

The sewing, service and testing programs listed below are selected

with the "

Switch Setting Program Function

00 P00 Displays t he program version

01 P01 Sewing progr a m

02 P02 Sewing program with intermediate stop after 50% of the stitches

03 P03 Sewing program with intermediate stop after 50% of the stitches

11 P11 Sewing progr a m w i th th e r p m ranges programme d i n P 41

40 P40 Setting the number of bartacks per bobbin

41 P41 Program used to set the progra mm ab l e r p m ranges used

42 P42 Burner test : g l ow i ng

43 P43 Burner test: lo we r ing an d g l ow i ng

44 P44 Burner test: lo we r ing i n s t ag es

45 P45 Burner test: slow sewing, lowering in stages

Program

and opening o f t he r ight half of the cl a mp

and opening of the left half of the clamp

in P11

" selector switch.

58 P58 Checking the serial interface

59 P59 Timer test and memory test

60 P60 Continuity t est

61 P61 Checking the front panel elements

62 P62 Checking the input elements

63 P63 Selecting i n pu t e l em en ts

64 P64 Selecting output elements

66 P66 Sewing driv e : rpm test, posit i on 2

67 P67 Sewing driv e : rpm test, posit i on 1

68 P68 Sewing driv e : rpm test, posit i on 1, po s iti o n 2

–

Set the "

–

Turn the main switch on or press the "

The select ed pro gr a m i s a cti v a te d.

–

If the symbol "P?" appears in th e ri ght half of the fi r s t l i ne of th e

display an i nv a l i d p rogram number was s e t.

A sewing sequence running at the time the "

pressed will be interrupted.

–

Correct the se tt ing an d p r ess t he "

Program

" switch to the desired program.

STOP

" key.

STOP

STOP

" key.

" key was

10

5. Base Position and Operational Readiness

Base position

–

Turn the main switch on.

–

The microcomputer checks the base position of the unit.

–

When findin g a n error this is shown by the appr op ri at e s y m bo l i n

the display.

The unit can n ot be s ta r te d.

–

Correct the error.

If the display shows "

position manually with the handwheel.

–

Turn the main switc h off and on again or pre s s th e "

The base posi t i on of th e u ni t i s che c k ed ag ai n .

–

After the unit is turned on the note "

right half of th e f i r s t li n e o f the display:

–

Press the "Σ" key.

The machine head runs into the unit’s base position.

Operational re adi n es s

The sewing sequence can only be started when the unit is in

operational r ea di n ess .

Operational readiness is signaled by the display of the piece count in

the right half of the first line of the display.

Before the st ar t of a s e wi n g s e qu en c e t he mi cr o c om pu te r pe rma ne ntly

checks the momentary positions of the devices.

Errors found are shown in the display.

POS2

" the unit mu st b e turned into the 2n d

REFERENZ->

Σ" ap pe ars i n th e

STOP

" key.

11

6. Sewing Programs

6.1 Sewing Program P01

6.2 Sewing Program P02

The exact wor k s e qu en c e o f t he s ewing program P0 1 i s d esc r ibed in

the Operatin g I ns t r uct i on s .

–

Set the "

–

Press the "

The program i s ac t i vated.

–

With the preheating of the burner switched on the symbol "*"

appears in the right half of the first line of the display in front of the

value for the machine head rpm.

With low machine head rpms the preheating is automatically

turned off. The "*" symbol di sa pp ears.

Program

STOP

" switch to "01".

" key.

6.3 Sewing Program P03

–

Set the "

–

Press the "

The program i s ac t i vated.

Difference to P01:

–

After complet i ng 50 % o f t he nu mb er o f s t i tch es t he s ew i ng dri ve

stops in position 2.

The right ha l f o f t he c l am p i s r a i s ed .

In this posi t i on , f or e x am pl e , l a bles to be sewn in to th e m at er i a l

can be aligned.

–

Operate the r i gh t f oo t s w i tc h .

The right hal f o f t he cl am p i s lo we r ed .

Through renewed operation of the right foot switch the right half of

the clamp ca n b e r a i sed again.

–

With the right ha l f o f t he c lam p l o we red op er a te th e l e ft fo ot sw it c h.

The sewing s e qu en c e is s t ar t ed ag ai n .

–

Set the "

–

Press the "

The program i s ac t i vated.

Program

STOP

Program

STOP

" switch to "02".

" key.

" switch to "03".

" key.

12

Difference to P02:

–

At the intermediate stop in position 2 the left half of the clamp is

raised.

6.4 Sewing Program P1 1

–

Set the "

–

Press the "

The program is activated.

Difference to P01:

–

The constant machine head rpm selected for the entire seam

before starting work is replaced by rpm ranges which are

programmed i n t he

This makes it possible to adjust the speed profile individually to the

seam pattern. The current machine head rpm is shown in the

display, and is also tag ge d w i th a p r ec e ding symbol for th e

variable machine head rpm.

–

Pressing th e "n" key to set th e m ac h i ne he ad rpm has no effect in

this program.

–

Altering t he nu mb er o f s t i tc h es p er c a m-d i s c rev o l ut i on

automatical l y era s es t he pr o gra mm ed rpm ranges for th e o l d

number of sti tc h es .

The number of stitches of the cam-disc is displayed with a

preceding "?".

–

Press the "Σ" key to leave this display.

–

The "=> P41 !" prompt appears.

This is to re mi n d t he us e r that the

program new rpm ranges.

–

Turn t he "

–

Press the "

Program 41 i s ac t i v at ed ( see s ec t i on 7. 2)

Program

STOP

Program

STOP

" switch to "11".

" key.

P41

setting prog r am .

" switch to "41"

" key.

P41

program must be used to

13

7. Service Programs

7.1 Setting the Underthread Counter

Program P40 sets the number of pieces which can be sewn per bobbin.

–

Set the "

–

Press the "

The program i s ac t i vated.

In the display, next to the bobbin symbol, the set value appears.

–

Set the desired value with the "

(input = e.g. 0020)

–

The cursor can be moved to different positions with the "Σ" key.

7.2 Programming vari able rpm r anges

Up to 6 different r p m r a ng es c a n b e p r og r am me d i n P rog r am P4 1. The

programmed rpm ranges are only execut ed in sewing program P11.

–

Set the "

–

Press the "

The program i s ac t i vated.

Programmin g rp m r a ng es ca n be carried out i n tw o d i ffer en t w ay s :

–

Programmin g in s i ng l e-s t i tc h mo de .

The display is as follows: S+1 +> Sx-Sy

This proces s s h ou l d b e u s ed i f n o r p m ra nges have yet been

assigned to th e s e am pa tt er n .

–

Programming in range-specifying mode.

The display is as follows: S+1 <+ Sx-Sy

This proces s s h ou l d b e u s ed i f r p m ra ng es h av e al ready been

assigned to th e s e am pa tt er n .

Program

STOP

Program

STOP

" switch to "40".

" key.

" switch to "41".

" key.

+ / -

" - keys.

Press the "+" key to toggle between the two modes.

–

Press the "Σ" key to invoke the selected programming mode.

Programming in single-stitch mode

Setting the first rpm range

–

The machine head rpm "n" flashes in the display.

Set the required initial value for the machine head rpm with the

+/-

"

" keys.

Caution Risk of Injury !

Do not reach into the ma chine while it is in operation.

–

Press the "Σ" key and hold it down until the number of completed

stitches a ft er w hi c h a n ew ma c hi n e h ea d r p m i s t o take effect

appears in the display. As long as the "Σ" key is held down the

stitches are executed and the number of completed stitches is

increased.

As soon as t he " Σ" key is released the machine head rpm set is

saved for th e ra nge in question .

14

Setting the second rpm range, at maximum up to the sixth one

–

The machine he ad r pm " n" flashes in the d i s pl a y.

Set the required initial value for the machine head rpm with the

+/-

"

" keys.

–

Press the "Σ" key a nd ho l d i t do wn un ti l t he nu mb er o f c o mp l et ed

stitches after which a new machine head rpm is to take effect

appears in the display. As long as the "Σ" key is held down the

stitches are ex e c ut ed an d the number of co mp l et ed s titches is

increased.

As soon as the "Σ" key is released the machine head rpm set is

saved for the range in question.

–

When the in dic a te d s t i tc h nu mb er (S ) is r e ac h ed , t he

previously-programmed rpm ranges are saved.

There is then an automatic return to the start of program

Attention:

If the value of the currently co nducted indivi du al s t i tc h es i s l e s s

than "4" or greater than/equal to the result of "number of stitches-2",

then no new machine head speed "n" can be set with the aid of the

+/-

"

" keys. Thes e v al u es are indicated i n th at th ey ar e shown blinking

in the display and the machine head speed does

Programming in range-specifying mode

not

blink.

P41

.

ATTENTION!

In order to ensure trouble-free operation in sewing program P11,

programming must always encompass the entire stitch-number range.

Setting the first rpm range:

–

The cursor f l ashes in the termi na l v al u e o f t he s ti t c h-n um ber range.

The cursor can be moved with the "Σ" key.

The value at t he c urs o r po s iti o n c a n b e c h an ge d with the "

–

Once the required terminal value of the stitch-number range has

been set, sw i tch to rpm setting by pr e s si ng th e "n" key.

The machine head rpm "n" flashes in the display.

Set the machine head rpm with the "

–

Confirm th e rp m r a ng e s e t b y pre s s ing the "Σ" key.

–

The terminal value of the rpm range is increased by one to form

the starting v al u e o f t he ne x t r p m ra ng e.

Setting the second to sixth rpm ranges:

–

These are pro gr a mm ed i n t he s am e w ay a s th e f i rs t r p m ra nge.

–

Care must be taken that the terminal value of each stitch-number

range is between the starting value and the highest stitch number.

–

Input is termi n at ed wh en th e h i gh est s ti t c h num be r is en te r ed as a

terminal value.

There is then an automatic return to the start of program

+/-

" keys.

+/-

P41

" keys.

.

Attention:

If the final value of the stitch number range is less than "4" or greater

than/equal t o t he r esu l t o f "n umber of stitche s - 2", then no new

machine head s p ee d " n " c an be s et wi t h t he ai d of th e "

In the first c a se no change over to th e s p ee d s e tt i ng oc o ur s a fter the

"n" key is oper at ed . I ns t ea d, the value "

as the final v a l ue of th e s t i tc h nu mb er ra ng e. In the second cas e t he r e

is also no change over to the speed setting after the "n" key is

operated. Instead, the "number of stitches" is shown in the display as

the final value of the stitch number range.

0004

" is shown in the display

+/-

" keys.

15

7.3 Burner Test: Glowing

Caution Risk of Injury !

Danger of Burns !

During the burner test keep hands clear of the area of the glowing

burner.

–

Set the "

–

Press the "

The program i s ac t i vated.

–

B-TEST->

"

display.

The set number of stitches per curve disk revolution (e.g. S = 72)

appears in the right half of the first line of the display .

–

Press the "Σ" key.

The burner is t ur n ed on fo r a sh or t pe r i od .

7.4 Burner Test: Lowering and Glowing

Caution Risk of Injury !

Danger of Burns !

During the burner test keep hands clear of the area of the glowing

burner.

–

Set the "

–

Press the "

The program i s ac t i vated.

–

B-TEST->

"

display.

In the right h al f of the first lin e o f t he di s p l ay t he s et nu mb er o f

stitches per curve disk revolution (e.g. S = 72) appears.

–

Press the "Σ" key.

The burner is t ur n ed on .

A sequence as at the seam end is run through.

Program

STOP

Σ" appears in the right half of the second line of the

Program

STOP

Σ" appears in the right half of the second line of the

" switch to "42".

" key.

" switch to "43".

" key.

7.5 Burner Test: Lowering in Stage s

–

Set the "

–

Press the "

The program i s ac t i vated.

–

B-TEST->

"

display.

In the right h al f of the first lin e o f t he di s p l ay t he s et nu mb er o f

stitches per curve disk revolution (e.g. S = 72) appears.

–

Press the "Σ" key repeatedly.

With each operation of the key the sequence as at the seam end is

run through i n s ta ge s .

The burner re ma i ns sh ut off hereby.

16

Program

STOP

Σ" appears in the right half of the second line of the

" switch to "44".

" key.

7.6 Burner T est: Slow Sewing, Lowering i n Stages

–

Set the "

–

Press the "

The program is activated.

–

B-TEST->

"

display.

In the right half of the first line of the display the set number of

stitches per curve disk revolution (e.g. S = 72)appears.

–

Press the "Σ" key.

The unit sews slowly to the seam end.

–

Press the "Σ" repeatedly.

With each ope r at i on of th e k e y th e s e qu en c e a s at the seam end is

run through in stag es (see program P44).

The burner remains shut off hereby.

Program

STOP

Σ" ap pe ars i n th e ri g ht half of the sec o nd l i ne of th e

" switch to "45".

" key.

17

8. T esting Programs

8.1 Displaying the Program V e rsion and Check Sum

The display shows in succession the program version and a check

sum.

e.g.:

By program versions with the same class designation and the same

identification letter the higher version replaces all lower versions

(Example: 506V03 replaces 506V01 and 506V02).

The check sum is meant only for the factory service staff.

It allows ex pe r ts to see if the prog r am me mo r y (E P RO M ) of the unit

controls flawlessly contains the complete program.

Dürkopp Adler AG

506A01 5C A9

506 = Class desi gn at ion of th e u ni t

A01 = Identif ic at i on l et te r an d s e ri al n um be r

5CA9= Check sum

–

–

8.2 Checking the Serial Interface

Program P58 checks the SIO component of the controls.

–

–

–

Display Explanation

OK

Err

no SIO

Set the "

Press the "

The program i s ac t i vated.

Plug the SIO testing plug into the socket b109 on the main board.

The testing pl u g c o nn ect s th e t ran s mi t te r wi t h t he rec e i ver.

In this man ne r a t es t of the loop is poss i bl e .

Set the "

Press the "

The program i s ac t i vated.

Program

STOP

Program

STOP

" switch to "00".

" key.

" switch to "58".

" key.

SIO componen t i s o k ay

SIO componen t i s d ef ec t i ve,

SIO testing plug is not in place

Controls are b ein g r u n w i th ou t S I O

18

8.3 Memory Test and Timer Test

ATTENTION !

Program P59 erases all values in the memory!

All values must be reset.

Program P59 checks the working memory (RAM) and all timer

switchings of the controls.

8.4 Continuity T est

–

Set the "

–

Press the "

The program is activated.

Display Explanation

OK

ERROR 0

ERROR 6

ERROR 7

Program P60 checks if the 24V power supply delivers current with the

output drive r s s wi t c he d o ff.

Program P60 checks all output elements (including output drivers and

installation) for continuity.

–

Set the "

–

Press the "

The program is activated.

Program

STOP

Program

STOP

" switch to "59".

" key.

Working memory and all timer switchings

are okay

RAM error

Timer 1 defective

Timer 2 defective

" switch to "60".

" key.

Display Explanation

V?

OK

s17

(Example) installation or driver

Short circuit in the installation or

one of the output drivers is defective

All circuits have continuity

Interruption in the output element s17, in its

Output eleme nt s17 does not ex is t be c au s e i t i s part

of the special optional equipment

Continue th e t es t i ng at th e n ex t el e me nt

by pressing th e "Σ" key.

19

8.5 Checking the Front Panel Elements

Program P61 checks the front panel elements.

–

–

–

Key Function

b513/512 Program switch

b829 Softstart on/off

b828 Foot switch mode, lowe r cl am ps

b825 Bobbin change

b826 Machine head rpm

b827 Burning period correction

b500 Number of stitches per curve disk revolution

8.6 Checking the Input Elements

Program P62 checks the switching status of the input elemen ts.

Set the "

Press the "

The program i s ac t i vated.

Press the key to be checked.

The display shows the value assigned to this switch.

Program

STOP

" switch to "61".

" key.

(together or individually)

–

Set the "

–

Press the "

The program i s ac t i vated.

–

Press the input element to be checked.

The display shows the wiring diagram designation and the

switching status of the input elements (e.g. "+b25").

–

The display c h an ge s wh en th e s w i tc h i ng s ta tu s of an y ot he r input

element is c h an ge d.

The switching status "+" means:

–

By contact switch = Contact open

–

By proximity switches = Metal in front of the switch

The following switches cannot be checked with program P62:

–

b101 Head cove r mo ni t or ( S t op )

Program

STOP

" switch to "62".

" key.

20

8.7 Selecting Input Elements

ATTENTION !

All input elements were carefully set at the factory.

Adjustments and corrections may only be made by trained service staff.

Program P63 ser v e s for the setting of the input elem en ts .

–

Set the "

–

Press the "

The program is activated.

The display shows "B?".

–

Set the "

element.

The short designations of the circuit diagram serve as code

numbers (see table). This does not apply for the keys on the front

panel (see Chap te r 7. 5).

The display s h ow s th e wiring diagra m d es ig nation and the

switching status of the input element (e.g. "

–

Adjust the i n pu t e l em en t ( e .g . p r oxi m i ty s w i tc h ) un ti l t he de s i r ed

switching s t at us i s s h own in the displa y ( see program P 62).

Input Function

Element

b09 R ear transport lever in the base position

b10 Base position Stop

b12 R ight clamp up

b16 Forward transport lever in the base position

b17 Left clamp up

b18 Foot switch right

b20 Foot switch left

b23 Bobbin change

b35 Synchronizer position 1 (needle down)

b37 Synchronizer position 2 (needle up)

b38 Synchronizer position 3

Program

STOP

Program

" switch to "63".

" key.

" switch to the code number of the desired input

(needle mov i ng fro m down to up)

+B25

").

The following switches cannot be checked with program P63:

–

b101 Head cover monitor (Stop)

21

8.8 Selecting Out put Element s

Caution Risk of Injury !

During the function testing of the output elements do not reach into the

running machine, especially not under the clamps.

Program P64 checks the function of the output elements.

–

Set the "

–

Press the "

The program i s ac t i vated.

The display shows "S?".

–

Set the "

element.

The short de si gn ations of the cir c u it diagram serve as c o de

numbers (see table).

–

Turn the selected ou tp ut el e me nt on and off by press i ng th e

"Σ" key in tapping operation.

Output Function

Element

s01 Lower left clamp

s02 Lower right clamp

s03 Open thread tension

s04 Pull thread

s18 Needle cooling

s19 Transport lever forward

s20 Thread wiper forward

s22 Lower burner

s26 Burner forward

s28 Hook lubrication

Program

STOP

Program

" switch to "64".

" key.

" switch to th e c o de nu mb er o f t he de s i r ed input

22

8.9 Sewing Drive: Rpm Test, Position 2

Program P66 serves for testing the different rpms of the sewing drive.

Different rpms can be selected with th e "

Program

" switch.

–

Set the "

–

Press the "

The program is activated.

The display shows "

–

Press the "Σ" key.

–

Select the rp m o f t he s ew i ng dri ve wi t h t he "

A total of 13 rpm levels are available.

Switch setting "13": Maximum rpm

Switch setting "01": Minimum rpm

–

With an allowable value "

line of the di spl a y, with an unallo wa bl e v alu e "

–

Press the "Σ" key and hold.

The sewing dr iv e r un s at th e s e l ect ed rpm.

After a few seconds the current rpm (actual rpm of the machine

head) is sho wn i n t he r igh t half of the fir st l i n e o f t he display.

–

Release th e " Σ" key.

The sewing un i t p os i t i on s in p os i t i on 2 ( t hre ad lever high pos i t i on ).

8.10 Sewing Drive: Rpm Test, Position 1

–

Set the "

–

Press the "

The program is activated.

The display shows "

Program

STOP

Program

STOP

" switch to "66".

" key.

N-TEST->

" switch to "67".

" key.

N-TEST->

Σ".

0000

" appears in th e ri g ht ha l f o f t he fi rs t

Σ".

Program

SW?

" appears.

" switch.

Difference to program P66:

–

After releasing the "Σ" key the sewing unit positions in position 1

(thread lever l o w p osi t i on ).

8.11 Sewing Drive: Rpm Test, Position 1, Position 2

–

Set the "

–

Press the "

The program is activated.

The display shows "

Difference to program P66:

–

After rele ase of the "Σ" key the sewing unit stops fo r a b r i ef pe ri od

in position 1 ( t hre ad l ev e r low position).

–

Then the sewing unit positions in position 2 (thread lever high

position).

Program

STOP

" switch to "68".

" key.

N-TEST->

Σ".

23

9. Function Displays and Error Messages

9.1 Displays of Operating Aids

Display Explanation Remedy

P?

506B01

REFERENZ->Σ

STZ-ERR

H->

B-TEST->Σ

N-TEST->Σ

UNTFVZ-RESET

S+1 <+> Sx-Sy

Invalid program selected

Display of the program version

Machine head must co nduct a re ferenc e run

The "number of stitches" (b500) switch

in an invalid switch setting

Underthread bob bi n em pt y

Activate th e t es t pr o gra m f or t he bu r ne r

Activate the test i ng pro gram f or rp m

Underthread co un te r r ese t

Selection between single-stitch

operation (S +1 ) or ra ng e s e tt i ng ( S x- S y )

for the requi red r pm s ection

9.2 Displays of Malfunctions

Display Explanation Remedy

E2

V?

STOP

--<>-POS2

POS2->Σ

STRT-ERR

KL-ERR

TIME

GRUNDST

TR-ERR

STICHZAHL-ERR.

TAB.-OV

=> P 41 !

Fuse e2 in the transformer (24V)

defective

Error message in program P60

STOP key defective,

Termination of the sewing sequence

Synchronizer not plugged in

Needle not in t he up pe r po s i tio n

Needle not in t he up pe r po s i tio n

Short in the switch lead at the

foot switch,

Foot switch was already operated when

the main switch was turned on

Incorrect clamp lowering

Sewing driv e do es n ot s to p q ui ck l y

enough

Machine not i n t he base position

Incorrect transport lever operation

Stitch-num be r ran ge s et i s to o s m all

Table for a maximum of 6 rpm ranges

exceeded.

No rpm ranges programmed

Reset the "

Press the "Σ" key

Reset the "number of stitches" (b500)

switch

Change the bobbin

Press the "Σ" key

Press the "Σ" key

Replace fuse e2

See Chapter 5. 6 (" Co nt i nu i ty Test")

Replace STOP key

Plug in the synchronizer

Turn the needle into the upper position

with the handwheel

Press the "Σ" key

Check the le ad

Release the foot switch, press the STOP

key

Check switches b12, b17 and movement

of the clamps

In program P66 check if motor and

controls function correctly

Reset switch b10

Carry out programming in P41

Program

" switch

24

9.3 Error Messages

Display Explanation Remedy

PROM-ERR

RAM-ERR

DISP-ERR

Faulty EPROM check sum when turning

on

Faulty RAM tes t wh en tu r ni n g o n

Display error when turning on

Program not correctly stored in memory

Call factory service

ERROR 0

ERROR 1

ERROR 2

ERROR 3

ERROR 4

ERROR 5

ERROR 6

ERROR 7

ERR Bxx

no SIO

ERR

RAM error

Error in the i n pu t e l em en ts

Error in the f r on t p an el e l em en ts

Program switch defective

Regulator card for the sewing drive defective

Short voltage drops in the mains

Timer 1 defective

Timer 2 defective

Error in rea din g i n pu t element bxx

Controls have no S IO c o mp on en t

Interruption in th e S I O s en d /

receive loop

Call factory service

Check the input elements

Check the front panel elements

Replace the pro gr a m switch

Replace the regulator card

Stabilize the voltage supply

Call factory service

Call factory service

Replace defective switch bxx,

reset switch bxx

Press the STOP key

Press the STOP key

25

Loading...

Loading...