Additel ADT 761 Operating Manual

ADT761 Series Automated Pressure Calibrator

ADT761 Series Automated Pressure Calibrator

User Manual

Please download the latest version from www.additel.com

[Version: 1903V06]

Additel Corporation

STATEMENT

This technical manual provides operating and safety instructions for the ADT761

Series Automated Pressure Calibrator. To ensure correct operation and safety, please

follow the instructions in this manual. Additel reserves the right to change the contents

and other information contained in this manual without notice.

Warnings .. .. .. .. ............................................................................................................................. 1

General safety .................. .. .. .. .. .. .. ............................................................................................... 2

1. Introduction ......................................................................................................................... .. .. 3

1.1 Overview ................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... . 3

1 .2 Featu res .. ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .......... 3

1.3 Specifica tions .... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ................... 4

2. Installation ................................................................................................................... .. .. .. .. .. ..5

2 .1 Featu res .. ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .......... 5

2.1.1 Basic struc ture . ......... ......... ......... ........... ......... ......... ......... ........... ......... ......... ......... ......... ........... ........5

2.1.2 Elec trical termin als and signal interf ace ......... ......... ......... ......... ........... ......... ......... ......... .................... .. 6

2.1.3 RS-23 2 interface ... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ... 6

2 .1.4 K eypad ......... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ..7

2 .1.5 Pneumati c port ... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ......8

2.2 Inital prepa ration ........ ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ........... 8

2.2.1 Batter y in stallation .... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ........ 8

2.2.2 Chang ing th e belt strap ..... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ......... ...9

2 .2.3 P neumatic connec tion ........ ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ....... 9

2.2.4 View the displa y .. ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ..... 9

2.3 Getting started .. ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ........1 0

2.3.1 Power o n ............. ............. .. ........... .. ............. ............. .. ........... .. ........... .. ............. ............. .. ........... .. ...10

2 .3.2 S etting t he syste m date and time ... ......... ......... ......... ......... ........... ......... ......... ......... ........... ......... ....... 10

2. 3.3 Generating a pressure ....... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... .......10

3. Func ti on and operation ...................................................................................... .. .. .. .. .. .......... 11

3.1 Disp lay and basic operation ... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ....... 11

3.1. 1 Home screen .......... ......... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... . 11

I

3.1 .2 Pre ssure output ...... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ........ 12

3.1.3 Press ure measure ... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .......... 13

3.1.4 Press ure unit ...... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ...............14

3 .1.5 Current output ... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... .....14

3.1.6 Curre nt / voltage measu re ... ......... .................... ......... ......... ......... ........... ......... ......... ......... ......... ........15

3.1.7 Switc h test ..... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ......... ........... ........1 5

3.1.8 Exter nal pressure mo dule ...... ......... .................... ......... ......... ......... ........... ......... ......... ......... ...............16

3.1.9 Scaling ....... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ..17

3 .1.10 Ze ro ....... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ....17

3.1.11 Step ....... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ....17

3.1. 12 Snaps hot .... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... 19

3.1.1 3 Vent ....... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ....19

3.2 HAR T.......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......20

3 .2.1 Pol l ........ ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......20

3 .2.2 Process variab les ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ...21

3 .2.3 Set up ....... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ....22

3.2.4 Servi ce .. ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......23

3.3 Typ ical applica tions in the m ain screen ........... ......... ......... ......... .................... ......... ......... ......... ..........2 4

3 .3.1 Calib rating pre ssure gaug es ..... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... 24

3 .3.2 Calib rating p ressure tr ansmitters. ......... ......... ......... ......... ........... ......... ......... ......... ........... ......... ......... 24

3.3. 3 C alibratin g H ART tr ansmitters ... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... .25

3 .3.4 Calib rating pre ssure swit ches .............. ......... ......... ......... ........... ......... ......... ......... .................... ......... 26

3.3 .5 Calibra ting I/P converters ...... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ...27

3.3. 6 Calibr ating is olator / conve rt / si gnal-acqu iring de vices .. ......... ......... ........... ......... ......... ......... ..............27

3.4 Setup ....... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... .......28

3.4.1 Control setup . ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ......... ........... ........2 8

3 .4.2 24V power .... ......... ......... ......... ........... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... 29

II

3.4.3 Display setup . ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ........2 9

3.4.4 Date and t ime .. ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... .......30

3.4.5 Langu age ......... ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................31

3.4.6 Fa ctory default ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... .......31

3.4 .7 Too ls ....... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... .....31

3 .4.7.1 Leak test ... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ........3 1

3.4.7.2 Vent ... ......... ......... ......... ........... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... .....33

3.4.7.3 Unit conv ersion ... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ......... .......33

3.4 .7.4 Help ... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ......... .....34

3 .4.8 Inf ormation . ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ......... ..34

3.4.9 System Calibrati on ..... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... .....34

3.4.9.1 Current / voltag e measur e ...... .................... ......... ......... ......... ........... ......... ......... ......... ..................35

3.4.9.2 Current s ource .... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ......... .......35

3.4 .9.3 High / lo w range ... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......35

3.4 .9.4 Externa l pressure module ... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... .36

3. 4.9.5 Se lf tune . ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... .36

3 .4.10 RS23 2 setup . ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... .......36

3.5 Task .. ......... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......36

3 .5.1 Calib rating dia l pressure gauges . ........... ......... ......... ......... .................... ......... ......... ......... ........... .......37

3.5.2 Calibr ating digita l pressure ga uges ....... ......... ......... ......... .................... ......... ......... ......... ........... ........4 0

3.5.3 Calibr ating pressu re transmitt ers ........ ......... ......... .................... ......... ......... ......... ........... ......... ......... .40

3.5.4 Calib rating HART t ransmitte rs .. ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ......... ..43

3.5.5 Calibrating pressure s witches .... ......... ......... ......... ......... ........... ......... ......... ......... .................... ......... .44

3.5.6 Ca librating I/ P conver ters ..... ........... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ....45

4.Troubleshooting....... .. ..................... ..................... .. ..................... .. ..................... ..................... 47

4.1 Device informat ion ... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... 47

4.2 P rompt.... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... 47

II I

4.3.1 Check ing for leaks ... ......... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ......... 48

4.4 I nstability ...... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......... ..49

5. Special Application for Barometric Pressure .......................................... .. .. .. .. .. ......................50

5.1 ADT761 B asic diffe rences... ......... .................... ......... ......... ......... ........... ......... ......... ......... ...................5 0

5.2 Gas head cor rection ......... ......... ......... ........... ......... ......... ......... ........... ......... ......... ......... ......... ........... .50

5.3.1 Digital b arometer ... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ......... ........5 0

5 .3.2 Mercu rial bar ometer ... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ....52

5.3.3 Aner oid barometer ... ......... ......... ........... ......... ......... ......... ........... ......... ......... ......... ......... ........... ......53

5.3.4 Bar ometer altimet er ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... .......54

5 .3.5 Pressure trans mitter ....... ........... ......... ......... ......... .................... ......... ......... ......... ........... ......... ........5 5

5. 3.6 Pressure switch ..... ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... .................... ........5 5

Appendix A Data Sheet ...... ......... ......... ........... ......... ......... ......... .................... ......... ......... ......... ........... ........5 6

A.1 En vironment . ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... .. 56

A.2 Power ..... ......... ......... .................... ......... ......... ......... ........... ......... ......... ......... .................... ......... ........5 6

A.3 Tech nical spe cification ......... ........... ......... ......... ......... ......... ........... ......... ......... ......... ........... ......... .......56

IV

Warnings

Additel's wa rranty will not c over this app lication.

◆ Do not apply pr essures great er than the max imum working pr essure. Ad ditel's war ranty will not co ver this

applicati on.

◆ Not for use in fl ammable, high h umidity, or dusty envir onments.

◆ Only charge w ith supplied ba ttery (mode l 9722) and make su re the batter y has not short c ircuited.

1

General safety

◆ If condensa tion has occurr ed, thoroug hly dry out the 761 b efore start up.

◆ Connectin g the REF/FLT port to the r eference port o f unit under te st (UUT) with a s mall diff erential pres sure range

might resul t in control prob lems over tim e as the environmental tempe rature chan ges. Disconne ct the ports an d

reconnect t o resolve contr ol issues.

◆ The vent port s hould not face th e operator du ring venting.

◆ Do not apply ex cessive volta ge or current t o the electrica l terminals .

◆ Do not use any ad apter other tha n Additel mode l 9818. Charge as s oon as the batt ery symbol in dicates.

◆ If the calibr ator is not worki ng properly, turn it off, remove the b attery and co ntact Addite l.

◆ Do not remove t he battery whil e it is chargin g or when the calib rator is in use .

◆ Before turn ing off the c alibrator, mak e sure the syst em pressure i s reduced to the at mosphere pr essure.

2

1. Introduction

1.1 Overvie w

The ADT7 61 Series Au tomated Pre ssure Calibra tor generat es pneumatic pr essure rapi dly with high p recision and

stability. Precisio n measurement a nd digital co ntrol techn ology develop ed by Additel ar e used in the ADT7 61.

With dual pre ssure sensors , precision e lectrical mea surement an d source, the AD T761calibra tor provide s many

differe nt ways to cali brate and test a va riety of devi ces such as, di al pressure gau ges, digita l pressure gaug es,

pressure tr ansmitters, p ressure swi tches and I/P converte rs.

1.2 Feature s

◆ Automatic ally generate s pressure wi th high precisi on.

◆ Excellent r esponse time.

◆ HART co mmunicati on.

◆ Loop power su pply at 24V.

◆ Task manageme nt firmware whi ch stores and a rchives test pr ocedures an d results.

◆ 800x480 TFT LCD with f riendly HMI .

◆ Multi-lin gual display.

◆ Rechargea ble Li battery.

◆ Light weigh t and portable.

◆ Built-in le ak test.

◆ Updateabl e firmware.

3

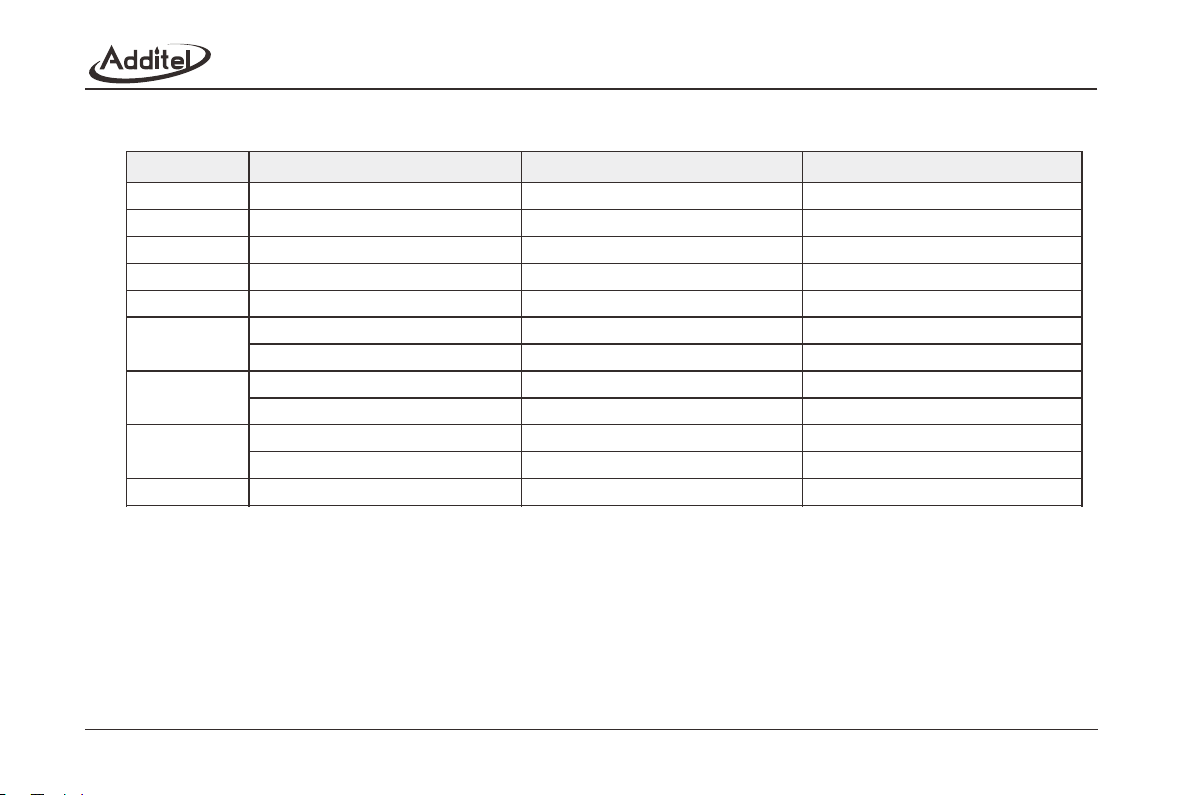

1.3 Specifications

Model Pressure Ra nge Range 1 Range 2

ADT76 1-LLP

ADT76 1-D

ADT76 1-L

ADT76 1-M

ADT76 1-H

ADT76 1-LA

ADT76 1-MA

ADT76 1-HA

ADT76 1-BP

-25 to 25 m bar (-1 0 to 10 inH O)

-0.95 t o 1 bar (-1 3.5 to 15 p si)

-0.95 t o 7 bar (-1 3.5 to 10 0 psi)

-0.90 t o 25 bar (- 13 to 375 p si)

-0.90 t o 40 bar (- 13 to 600 p si)

-0.95 t o 7 bar (-1 3.5 to 10 0 psi)

0.05 to 8 b ar.a (1. 2 to 115 psi .a)

-0.90 t o 25 bar (- 13 to 375 p si)

0.1 to 26 b ar.a (1. 7 to 390 ps i.a)

-0.90 t o 40 bar (- 13 to 600 p si)

0.1 to 41 b ar.a (1. 7 to 615 ps i.a)

100 to 12 00 hPa

-2.5 to 2 .5 mbar ( -1 to 1 inH O)

2

-25 to 25 m bar (-1 0 to 10 inH O)

-0.95 t o 2.5 bar ( -13.5 t o 35 psi)

-0.90 t o 2.5 bar ( -13 to 35 p si)

-0.90 t o 2.5 bar ( -13 to 35 p si)

-0.95 t o 2.5 bar ( -13.5 t o 35 psi)

0.05 to 3 .5 bar.a ( 1.2 to 50 p si.a)

-0.90 t o 2.5 bar ( -13 to 35 p si)

0.1 to 3. 5 bar.a (1 .7 to 50 ps i.a)

-0.90 t o 2.5 bar ( -13 to 35 p si)

0.1 to 3. 5 bar.a (1 .7 to 50 ps i.a)

100 to 12 00 hPa

2

2

-25 to 25 m bar (-1 0 to 10 inH O)

-0.95 t o 1 bar (-1 3.5 to 15 p si)

0 to 7 bar (0 t o 100 psi )

0 to 25 bar ( 0 to 375 ps i)

0 to 40 bar ( 0 to 600 ps i)

-0.95 t o 7 bar (-1 3.5 to 10 0 psi)

0.05 to 8 b ar.a (1. 2 to 115 psi .a)

-0.9 to 2 5 bar (-1 3 to 375 ps i)

0.1 to 26 b ar.a (1. 7 to 390 ps i.a)

-0.9 to 4 0 bar (-1 3 to 600 ps i)

0.1 to 41 b ar.a (1. 7 to 615 ps i.a)

N/A

Additel reserves the right to change specifications and other information contained in this manual without notice.

2

4

2. Installation

2.1 Feature

2.1.1 Basic s tructure

Status Bar

Measure terminals

Source terminals

Measure

Source

Function Keys

Shortcut Keys

On Off

HART, Task and Setup keys

Control Keys

Strap Connections

Vent Port

Outlet Port

REF/FLT Port

Lock

/FLT

/FLT

Portable Automated Pressure Calibrator

Numeric Keypad

Battery

Label

Rs232 Interface

Pressure module

Power supply input

Figure 2-1 Basic structure

5

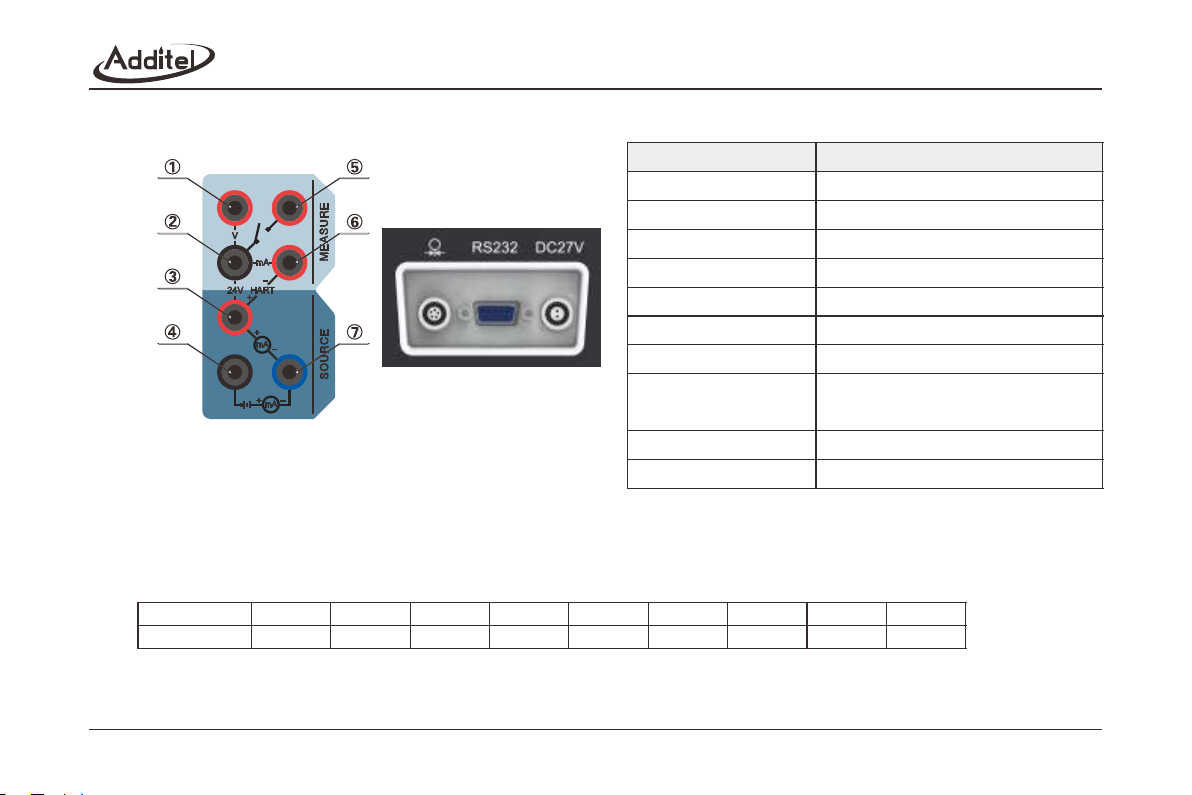

2.1.2 Electrical terminals and signal interface

Figure 2-2 Electrical terminals and signal interface

Terminal and Interface

6 and 2

1 and 2

5 and 2

3 and 6

7 and 4

3 and 7

3 and 2

Pressure module

connection

RS-232 interface

DC27V input

Introduction

Current measure.

Voltage measure.

Switch test.

HART communication.

Current output (external power).

Current output (internal power).

Loop power supply at 24V.

Works with ADT160 pressure modules.

Computer interface.

Power supply and battery recharge.

Table 2-1 Electrical terminals and signal interface

2.1.3 RS-232 interface

◆ The RS-232 interface is designed as a 9 pole SUB-D-socket, Pin-configuration see Figure table 2-2.

Pin

Configuration1N.C.

TX

2

3

RX

4

N.C.

5

GND

6

N.C.

7

N.C.

8

N.C.

N.C.

Table 2-2 Pin configurations

9

6

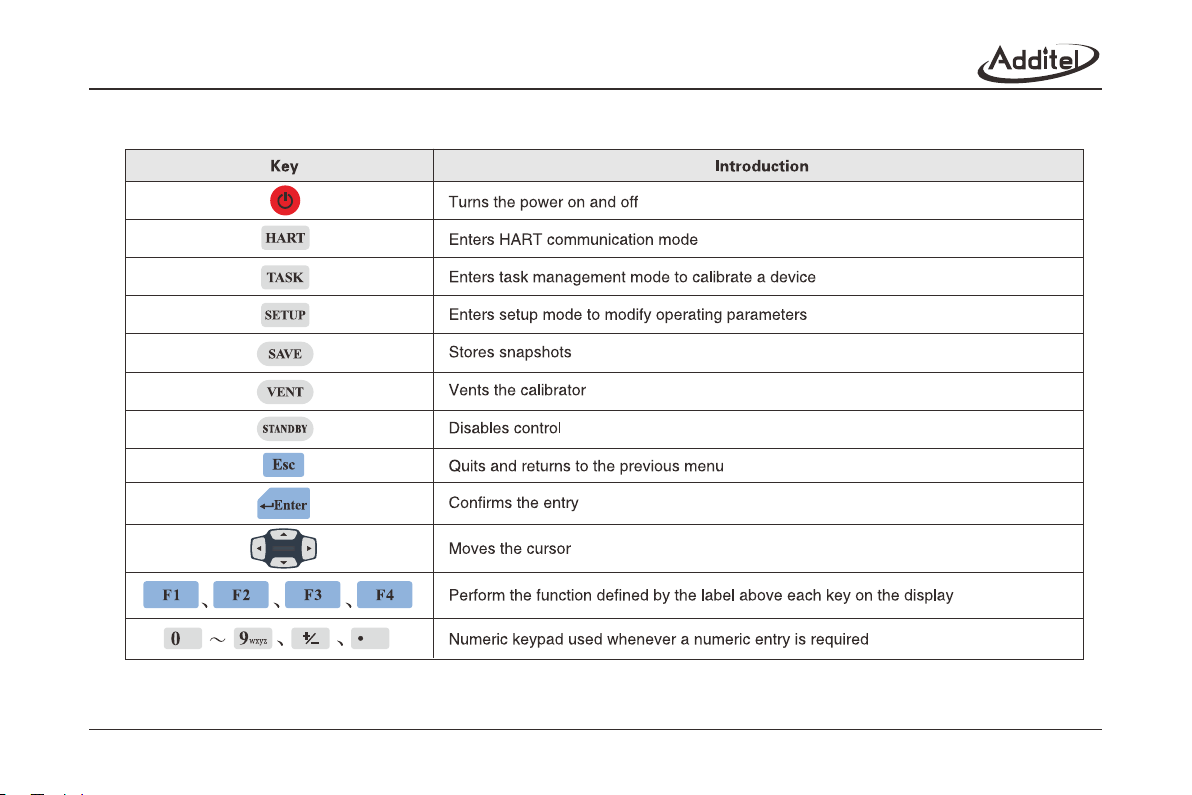

2.1.4 Keypa d

Table 2-3 Key functions

7

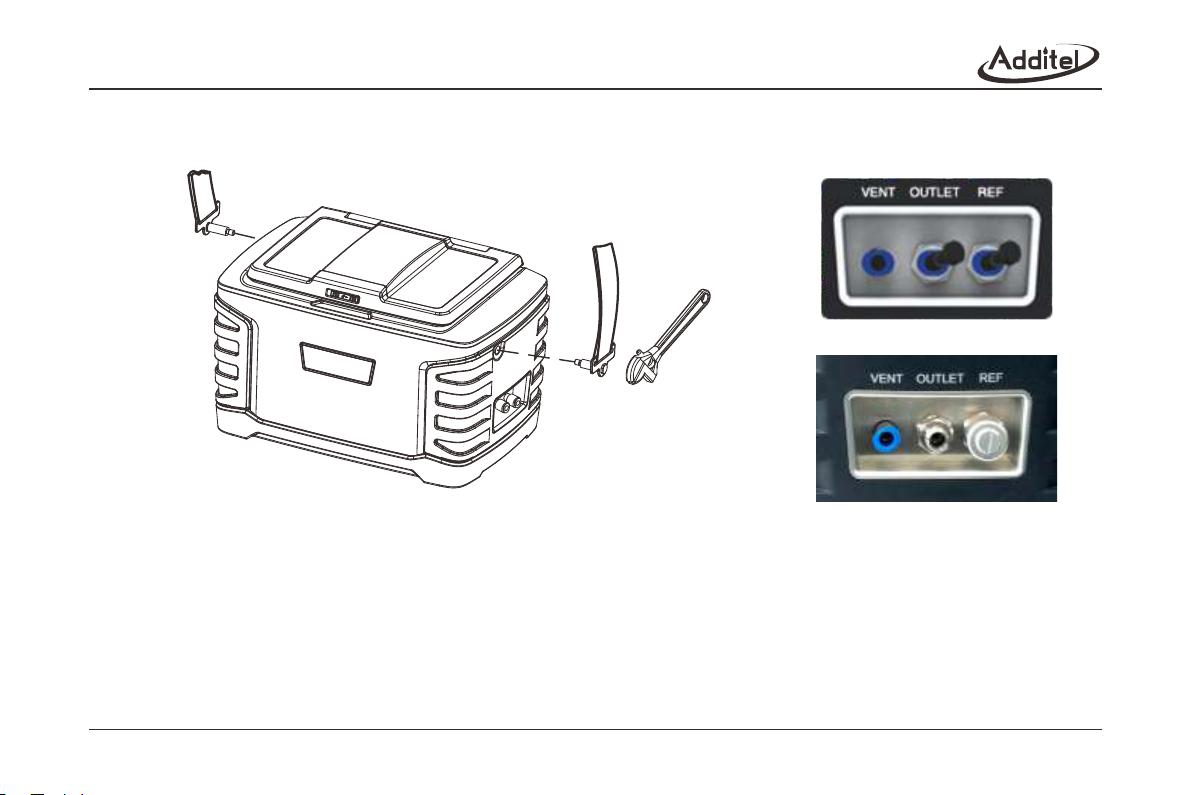

2.1.5 Pneumatic port

control is (0~100) cc and should not be exceeded.

◆ REF/FLT port: ADT761-BP (port is blocked). ADT761-LLP/D (port is the reference or low port. Leave open to measure in

gauge mode). All other ADT761 models (port contains a filter for internal pump. The filter should be changed when dirty,

as shown in figure 2-3).

◆ VENT port: The port which pressure is released from the system.

2.2 Initial preparation

2.2.1 Battery installation

As shown in Figure 2-4, install the model 9722 battery in the bottom of calibrator with a 3mm wrench.

PN:1220211190 FILTER

PN:1220211189 FILTER CAP

Figure 2-4 Battery installation

Figure 2-3 How to change filter

8

2.2.2 Chang ing the belt stra p

As shown in Figu re 2-5, change th e belt strap wi th an 8 inch wrench .

/FLT

Figure 2-6 Pneumatic connection

Figure 2-5 Changing the belt strap

Figure 2-7 Pneumatic connection

/FLT

2.2.3 Pneum atic connecti on

As shown in Figu re 2-6 shows pneu matic conne ction of ADT761- LLP and ADT761-D.Fi gure 2-7 show s pneumatic

connectio n of ADT761-L, AD T761-LA, ADT 761-M, ADT76 1-MA, ADT761 -H and ADT761- HA., connec t the

OUTLET an d REF/FLT ports to the UU T or use plug s when necess ary.

2.2.4 Vie w the display

Push the fron t lock to the right a nd raise the sc reen to the pro per position.

9

2.3 Getting started

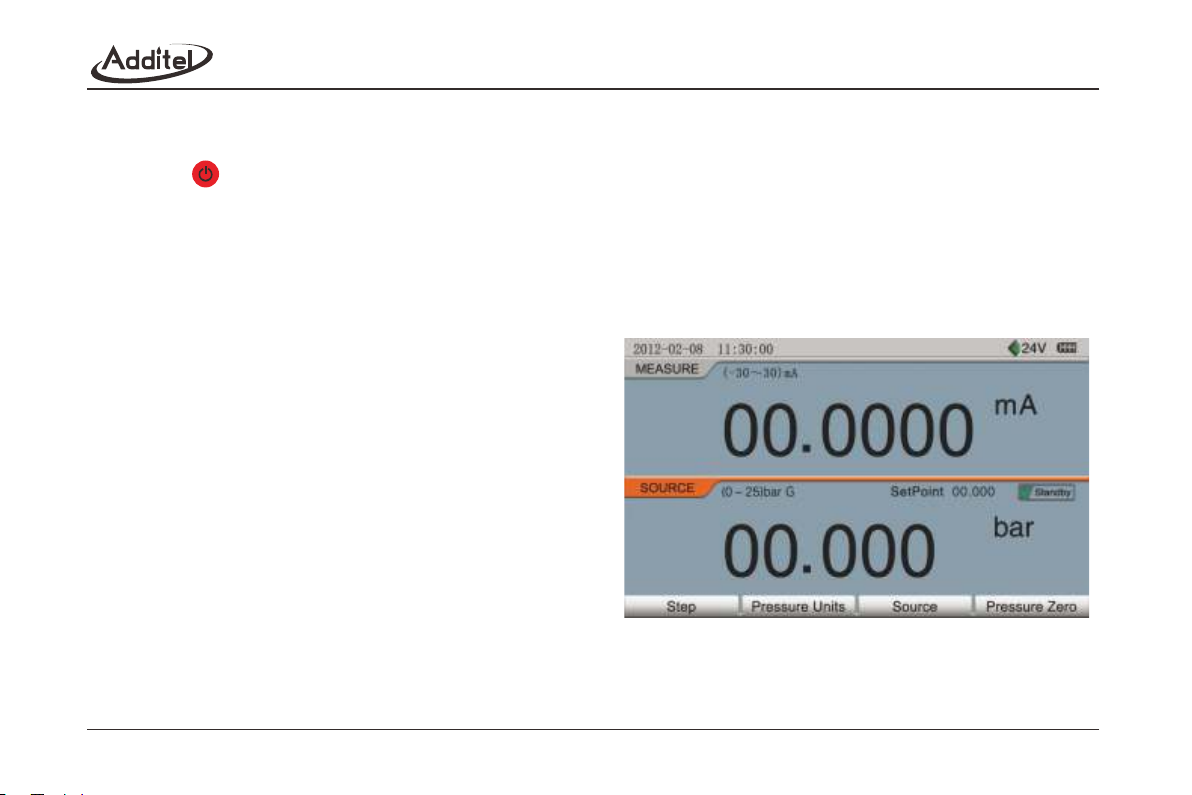

2.3.1 Power on

◆ Press to turn the power on.

◆ The startup screen shows the manufacturer's logo.

◆ After a short time the system enables the home screen and enters STANDBY mode as shown in Figure 2-8.

◆ Connect the power supply for charging if power is low.

2.3.2 Setting the system date and time

Refer to section 3.4.4 to set date and time.

2.3.3 Generating a pressure

Ensure the source screen is highlighted, enter an

appropriate pressure value using the numeric

keypad, press enter and calibrator will generate

and control to the desired pressure (see section 3.1.2).

Figure 2-8 Main screen

10

3. Function and Operation

3.1 Display a nd basic operat ion

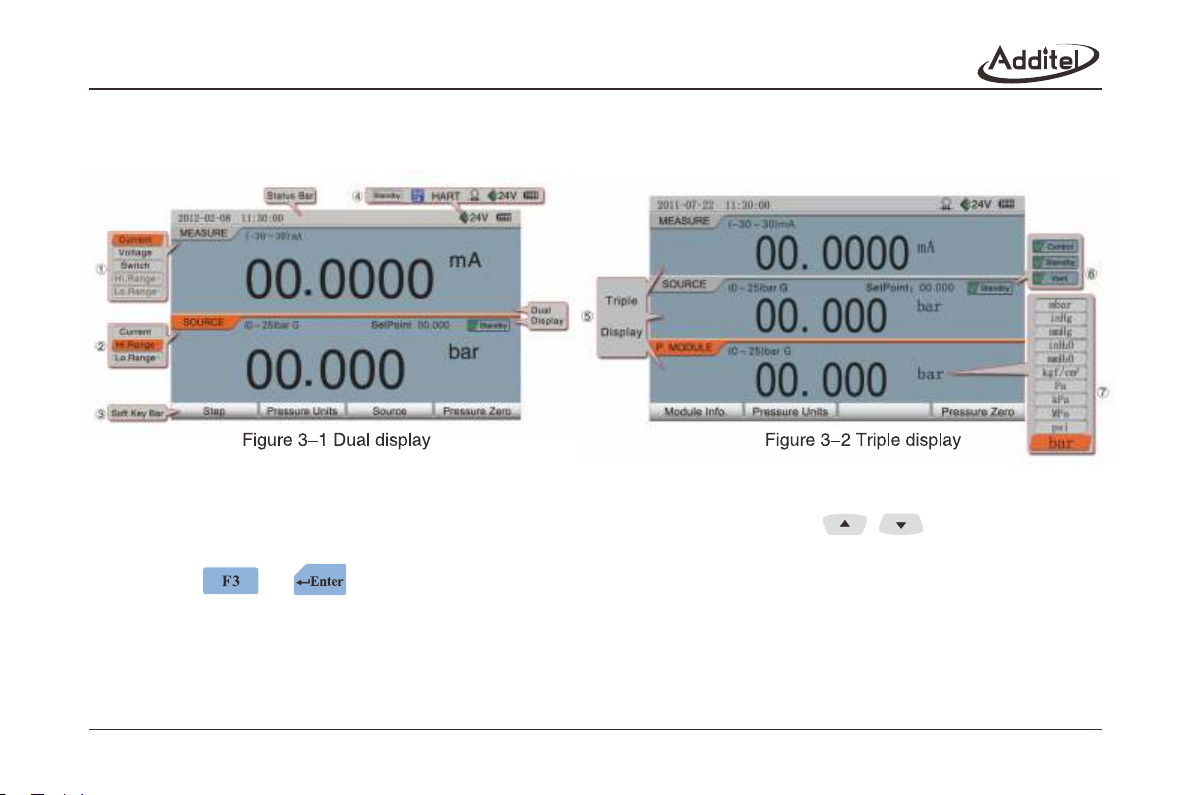

3.1.1 Home Sc reen

The home sc reen normal ly contains a MEA SURE window a nd a SOURCE windo w (see figure 3 -1). If you sel ect

the Triple Dis play in the SETUP mode and con nect the exte rnal pressu re module, thre e windows wil l be shown

(see figure 3 -2). To selec t between the MEA SURE and SOUR CE window, pre ss / till the desir ed

window is hig hlighted in ora nge. The so ftkeys disp layed at the bottom of the scree n relate to the s elected mode.

Press or to sel ect what is bei ng measured in th e MEASURE win dow or the pres sure sensor

used when in th e SOURCE window.

① Items of MEAS URE: Current me asure, volt age measure , switch, high pr essure rang e, low pressure r ange, or

pressure mo dule.

② Items of Sour ce: Current sou rce, high pre ssure range , low pressure ra nge, or press ure module.

11

④ Status bar: Run mode (not visible in the home screen), snapshot, HART online, pressure module online, 24V

、 、 、

power status, battery level.

⑤ Triple display: If the triple display is enabled, then three windows will be shown when the pressure module is connected.

⑥ The pressure output mode: Press / to change to standby mode, exit the control mode, or to vent the

calibrator.

⑦ Pressure units menu: Up to 11 selectable pressure units.

3.1.2 Pressure output

1. Select High/Low Pressure Range in source mode.

◆ The calibrator must be vented or in standby mode.

◆ The calibrator will automatically vent when switching ranges.

2. Connection: Complete the pneumatic connection as shown in

Figure 3-3 or Figure 3-4.

3. Entering a value

◆ Use the numeric keypad to enter the value, and press

/ to confirm.

◆ If there is no operation within 10 seconds, the calibrator will

automatically cancel the entry.

◆ The value must meet the control range of the calibrator.

◆ The maximum negative pressure is -13.5 psi (-0.95 bar).

But this is dependent on the local atmospheric pressure.

◆ The value cannot exceed the control range of the CONTROL SETUP,

or the calibrator will prompt the user to reset the limits.

12

Figure 3-3 Gauge pressure source

REF/FLT

Figure 3-4 Differential pressure source

◆ If you've selected the low pressure sensor and enter a pressure value that exceeds the low sensor range, then the

calibrator will ask if you would like it to automatically switch to the high pressure sensor.

4. Control

◆ Confirm the set value, and the calibrator will automatically start controlling to the set point.

◆ The control may be paused at any time by pressing .

◆ The following functions are disabled in the CONTROL mode: Pressure Zero (Section 3.1.10), Step (Section 3.1.11),

Leak Test (Section 3.6.1), VENT (Section 3.6.2), and Calibration (Section 3.7).

5. Stabilize

◆ When the calibrator reaches a stable condition as defined in the CONTROL SETUP (Section 3.4.1), the color of the

displayed value will change from black to green.

3.1.3 Pressure measure

1. Select the High/Low Pressure Range in measure mode.

/FLT

◆ The calibrator will vent as it switches ranges.

2. Connection: Complete the pneumatic connection to the

external pressure source as shown in Figure 3-5.

3. External pressure source:

◆ Avoid applying pressure greater than the maximum working

pressure to the calibrator.

◆ If the value falls outside the current pressure range, the color

of the displayed value will change from black to red and the

Figure 3-5 Pressure measure

calibrator will alarm.

◆ If the external pressure is potentially damaging to the calibrator, it will automatically vent and an over pressurization

prompt will appear.

13

3.1.4 Pressure unit

◆ Press to select a pressure unit in the SOURCE window,or when measuring an external pressure module in the

MEASURE window.

◆ The selected units relate to the range and resolution of the internal sensors (Section3.4.3).

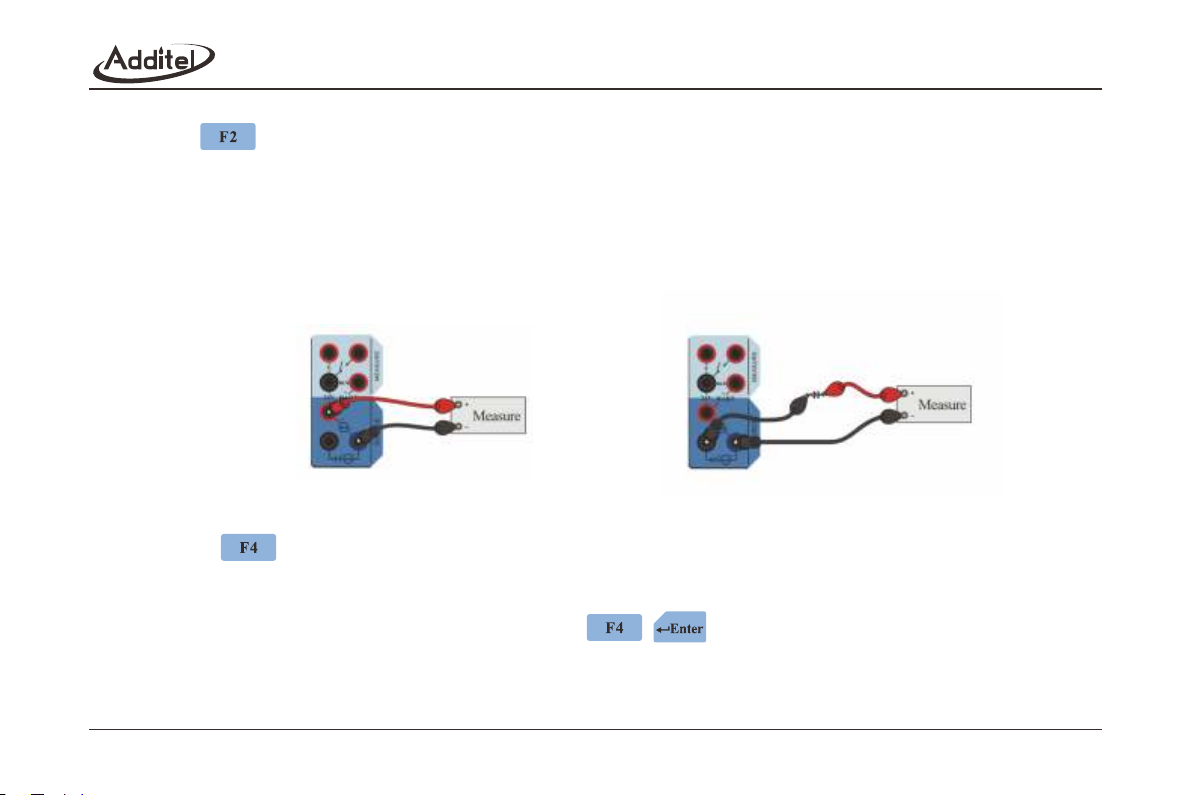

3.1.5 Current output

1. Select Current in SOURCE mode

◆ The calibrator must be vented or in standby mode to change from sourcing pressure to current.

2. Connection: Complete the electrical connection as shown in Figure 3-6 or Figure 3-7.

Figure 3-6 Internal 24V power supply

3. Power supply

◆ Press to select internal loop power or external loop power.

◆ The default setting for the DC24V power is to remain on unless external loop power is selected

4. Entering a value

◆ Use the numeric keypad to enter a value, and press / to confirm.

◆ If there is no operation within 10 seconds, the calibrator will automatically cancel the entry.

◆ The value must be within the range of (0~22) mA.

Figure 3-7 External power supply

14

Loading...

Loading...