Page 1

ECOWASH-M2

USER AND MAINTENANCE MANUAL

EWH-25 M2 / EWH-30 M2 / EWH-40 M2 / EWH-60 M2

EWS-25 M2 / EWS-30 M2 / EWS-40 M2 / EWS-60 M2 / EWS-80 M2

EWR-25 M2 / EWR-30 M2 / EWR-40 M2 / EWR-60 M2

Part No. 113687-3

Page 2

1 INTRODUCTION

Dear customer,

Thank you for the confidence you have placed in our product. We hope it meets your needs.

ADC products embody advanced concepts in engineering, design, and safety . If this product is properly maint ained,

it will provide many years of safe, efficient, and trouble free operation.

The warranty, as explained in the warranty sheet shipped with the washer covers it against defects in materials and

workmanship. It does not cover damage to glass components; to consumables (seals, bulbs, etc.); damage due to

the incorrect installation of the appliance; to inappropriate use, to inadequate maintenance or poor repair processes.

This appliance is subject to changes and modifications for its technical progress.

RETAIN THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation manual included

with the washer.

The following “FOR YOUR SAFETY” caution must be posted near the washer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d'essence ni d'autres vapeurs ou liquides inflammables à proximité de cet appareil ou de

tout autre appareil.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right to

make changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to

change or discontinue models. The illustrations included in this manual may not depict your particular washer exactly .

IMPORT ANT

For your convenience, log the following information:

DA TE OF PURCHASE _____________________________________________ MODEL NO.

RESELLER’S NAME

Serial Number(s)

__________________________________________________________________________________________

___________________________________________________________________________________

_____________________________________________________________________________

________________

__________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory . When ordering replacement p arts from the

factory , you can F AX your order to ADC at (508) 678-9447 or telephone your order directly to the ADC Parts Department

at (508) 678-9000. Please specify the washer model number and serial number in addition to the description and

part number, so that your order is processed accurately and promptly.

2 113687-3

Page 3

1.1 CONTENTS

1 INTRODUCTION ..................................................................................................................................................2

1.1 CONTENTS .............................................................................................................................................. 3

1.2 IMPORTANT INSTRUCTIONS REGARDING SAFETY AND USE .......................................................... 4

2 USE .................................................................................................................................................................... 11

2.1 Controls .................................................................................................................................................. 11

2.2 Programs ................................................................................................................................................ 11

2.3 Cycle Stop .............................................................................................................................................. 11

3 OPL ....................................................................................................................................................................12

3.1 Operation ................................................................................................................................................ 13

3.1.1 Running a program.................................................................................................................................13

3.1.2 Program end...........................................................................................................................................13

4 COIN...................................................................................................................................................................14

5 COIN/CP MODE ................................................................................................................................................. 15

5.1 Operation ................................................................................................................................................ 15

5.2 Pay center/card ......................................................................................................................................15

5.3 COIN ......................................................................................................................................................15

5.4 Operating modes ....................................................................................................................................16

5.4.1 OPL Mode ........................................................................................................................................16

5.4.2 Coin Mode ........................................................................................................................................16

5.4.3 CP Mode .......................................................................................................................................... 17

5.4.4 Credit Mode ..................................................................................................................................... 17

5.5 Configuration Menu ................................................................................................................................17

5.5.1 PRIC (Price) .....................................................................................................................................17

5.5.2 LEuL (Configuration of levels) ..........................................................................................................17

5.5.3 StCL (Configuration of standard cycles)...........................................................................................17

5.5.4 ECL (Configuration of extended cycles) ........................................................................................... 18

5.5.5 P7 (Configuration of the OPL program) ...........................................................................................18

5.5.6 Cur (Currency) .................................................................................................................................18

5.5.7 TiMr (Wash time remaining).............................................................................................................19

5.5.8 PAY (Operating mode) .....................................................................................................................19

5.5.9 AVAn (Advance cycle) ......................................................................................................................19

5.5.10 StOP (Thermal stop switch) .............................................................................................................19

5.5.11 Grd (Change between °F & °C) .......................................................................................................19

5.5.12 Beep (Acoustic signal) .....................................................................................................................19

5.5.13 deLA (Cycle Stop Grace Period) ...................................................................................................... 19

5.6 Maintenance Menu .................................................................................................................................20

5.6.1 In/Out (Inputs/Outputs) .................................................................................................................... 20

5.6.2 Std (Statistics) .................................................................................................................................. 20

5.6.3 Def ................................................................................................................................................... 20

5.6.4 Last ..................................................................................................................................................20

5.7 Menu Mod...............................................................................................................................................20

5.8 Machine operating ..................................................................................................................................20

6 MAINTENANCE .................................................................................................................................................21

6.1 Electrical and mechanical troubleshooting .............................................................................................21

6.2 Error messages ......................................................................................................................................21

113687-3 3

Page 4

1.2 IMPORTANT INSTRUCTIONS REGARDING SAFETY AND USE

WARNING: To reduce the risk of electrical shocks or

injury when using the appliance, the basic precautions

should be observed, including the following:

1- READ all the instructions prior to using the appliance

and KEEP THEM in an easily accessible place for

reference in the event of doubt.

2- Do NOT wash clothes which have been previously

treated, washed, soaked or stained with gasoline,

dry cleaning solvents, or other inflammable or

explosive substances, as these give off vapors,

which may catch fire or explode.

3- Do NOT add gasoline, dry cleaning solvents or other

inflammable substances to the washing water.

These substances give off vapours which could

catch fire or explode.

4- In some conditions, hydrogen gas may be produced

in a hot water system which has not been used for

more than two weeks. Hydrogen gas is explosive.

If the hot water system has not been used for a

while, before using the washing machine turn on all

the hot water taps and let the water run for a few

minutes. This will release any accumulated

hydrogen gas. As the gas is inflammable, do not

smoke or use open flames during this operation.

5- Do NOT allow children to play in or on the appliance.

Children should be strictly supervised when in the

vicinity of a machine which is operating.

6- Remove the door from the appliance before disposal

or before leaving it out of service.

7- DO NOT TRY TO OPEN THE DOOR if the drum

is moving.

8- Washer MUST be installed in a location/

environment, which the ambient temperature

remains between 40° F (4.44° C) and 130° F

(54.44° C).

12- Do NOT remove any safety device or modify any

components in the washing machine. DO NOT

INSTALL component s not belonging to the machine

in the appliance.

13- Failure to comply with any of the instructions given

in the Instruction Manual may result in personal

injury to the user. It is not possible to provide for all

possible situations and contingencies with warnings

about risk and hazards. Therefore, any person

involved in the transportation, installation, use or

maintenance of the machine should always employ

common sense, caution and care.

14- Do NOT use the machine unless all the covers and

guards are correctly fitted and secured.

15- The distributor (vendor) MUST correctly instruct the

user during commissioning.

16- Pour the correct doses of detergent, fabric sof tener

and lay into the dispenser drawer, as indicated by

the manufacturer. Heed tips concerning the

treatment of different materials given by the

manufacturers.

17- Daily remove any traces of detergent or liquids from

the dispenser drawer. Never use powdered or

abrasive detergents for cleaning; use only water and

soap.

18- Clean the water inlet filters and the external

dispenser conducts once a month.

19- Never clean the exterior by water injection;

functional parts of the machine could damage.

20- If the washing machine is to be idle for long periods,

apply a coat of Vaseline oil to all its stainless steel

surfaces.

21- An annual general revision is recommended.

9- Do NOT try to force the controls.

10- Washer must not be installed or stored in an area

where it will be exposed to water or weather.

11- Do not repair or replace part s of the appliance or

carry out any servicing unless recommended to do

so in the User Instruction Manual. Make sure that

you fully understand the instructions and have the

necessary skills to carry out the operations

described.

4 113687-3

Page 5

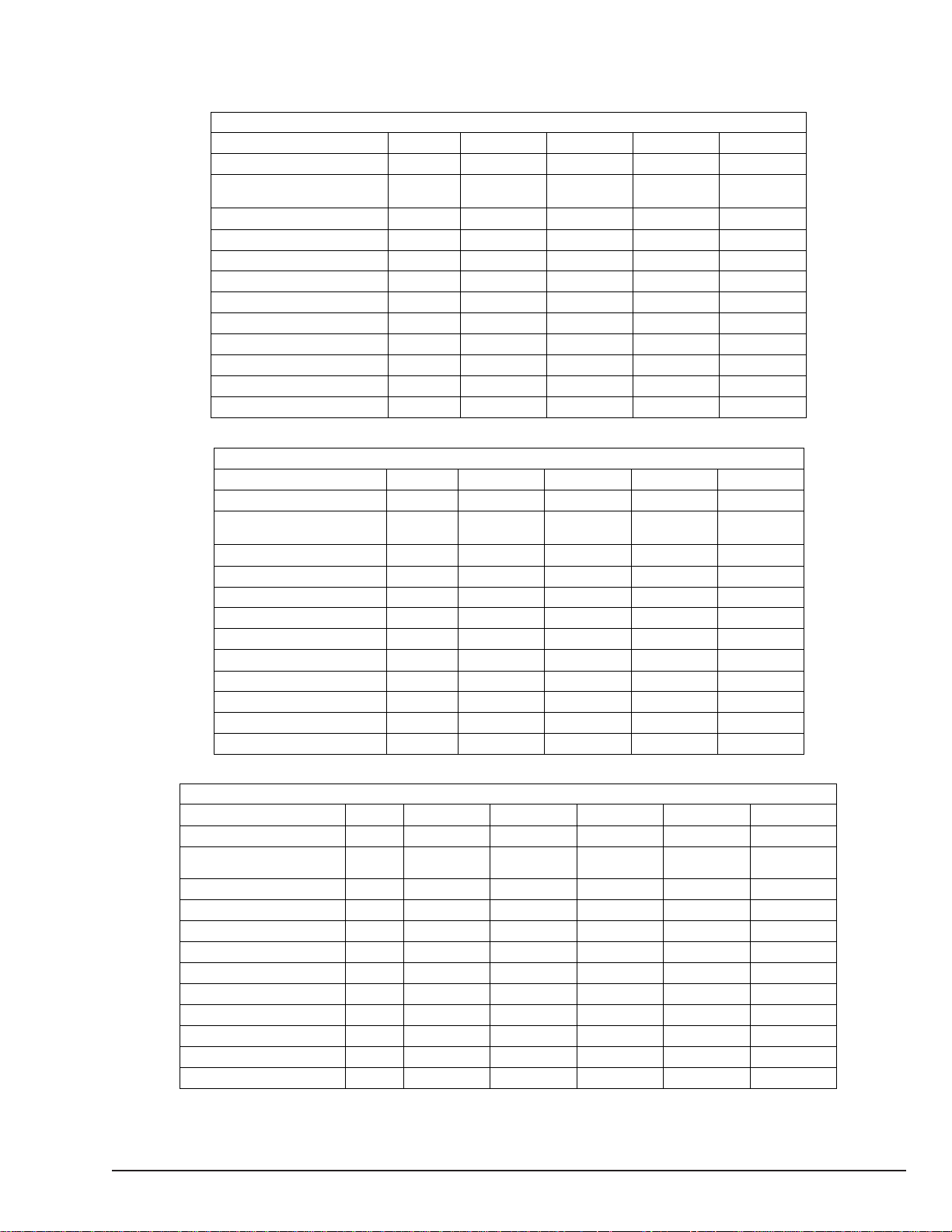

GROUP S - Standard Spin Rigid Washing Machines

EWS-25 EWS-30 EWS-40 EWS-60 EWS-80

DC (Drum capacity)

liters 100 130 180 250 350

CM (Maximum load)

Lb

Kg

25

10

30

13

40

18

60

25

80

35

SP1 (Wash speed)

rpm 53 53 50 48 45

SP2 (low spin)

rpm 538 538 507 483 458

SP3 (High spin) rpm

538 538 507 483 458

SP4 (Delicates spin)

rpm 538 538 507 483 458

LV1 (Minimum level)

mm 75 75 85 95 125

LV2 (Low level)

mm 105 105 115 125 155

LV3 (Medium level)

mm 135 135 145 155 175

LV4 (Highl level)

mm 165 165 175 185 205

LV5 (Maximum level)

mm 225 225 240 260 290

Minimum safety level

mm 40 40 40 20 20

GROUP R - Fast Spin Rigid Washing Machines

EWR-25 EWR-30 EWR-40 EWR-60

DC (Drum capacity)

liters 100 130 180 250

CM (Maximum load)

Lb

Kg

25

10

30

13

40

18

60

25

SP1 (Wash speed)

rpm 53 53 50 48

SP2 (low spin)

rpm 538 538 507 483

SP3 (High spin) rpm 760 760 720 690

SP4 (Delicates spin) rpm 538 538 507 483

LV1 (Minimum level) mm 75 75 85 95

LV2 (Low level)

mm 105 105 115 125

LV3 (Medium level)

mm 135 135 145 155

LV4 (Highl level)

mm 165 165 175 185

LV5 (Maximum level)

mm 225 225 240 260

Minimum safety level

mm 40 40 40 20

GROUP H - High Spin Floating Washing Machines

EWH-25 EWH-30 EWH-40 EWH-60

DC (Drum capacity)

liters 94

130 180 250

CM (Maximum load)

Lb

Kg

25

10

30

13

40

18

60

25

SP1 (Wash speed)

rpm 50 50 47 45

SP2 (low spin)

rpm 500 500 475 450

SP3 (High spin)

rpm 1245 1150 1080 900

SP4 (Delicates spin)

rpm 800 800 750 700

LV1 (Minimum level)

mm 40 75 85 95

LV2 (Low level) mm

50 105 115 125

LV3 (Medium level) mm

70 135 145 155

LV4 (Highl level) mm

80 165 175 185

LV5 (Maximum level) mm 90 225 240 260

Minimum safety level mm 40 40 40 20

113687-3 5

Page 6

TRAY

CONTROLS

SOFTENER BLEACH PREWASH WASH

6 113687-3

Page 7

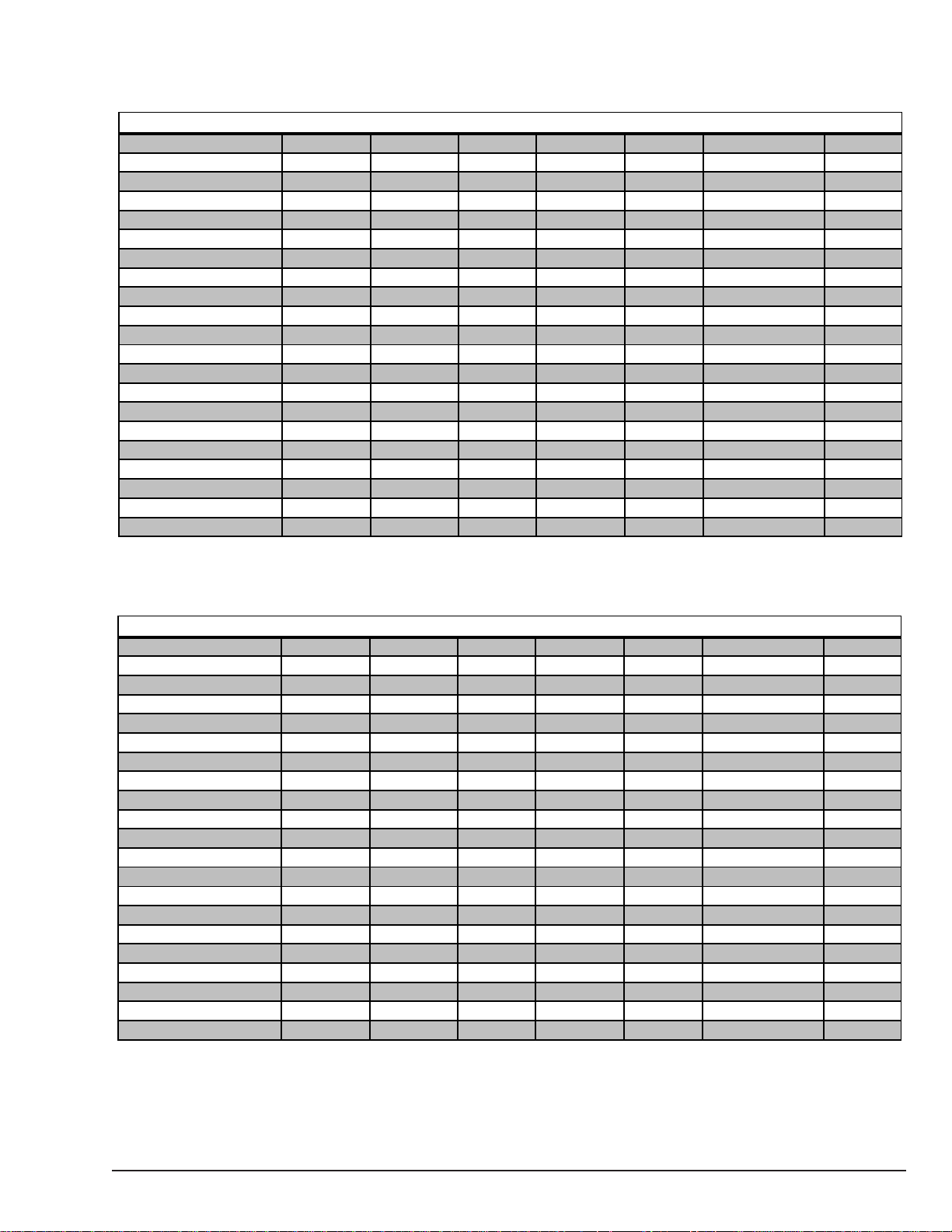

P2 - WARM

PHASE Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP3 rpm

RHYTHM

12/3 12/3 12/3 12/3 --- 12/3 ---

HOT WATER INPUT

NO REGULATED NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO --- NO ---

WATER LEVEL MINIMUM MINIMUM MEDIUM MEDIUM --- MEDIUM ---

MOVEMENT DURING FILLING

YES YES YES YES --- YES ---

WATER TEMPERATURE COLD 104ºF

COLD

COLD --- COLD ---

THERMAL STOP

NO YES --- --- --- --- ---

TIME(min)

0

10

0

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

YES YES YES YES --- YES ---

DISPENSER 1

T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

---

0

---

P1 - COLD

PHASE Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP3 rpm

RHYTHM

12/3 12/3 12/3 12/3 --- 12/3 ---

HOT WATER INPUT

NO NO NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO --- NO ---

WATER LEVEL MINIMUM MINIMUM MEDIUM MEDIUM --- MEDIUM ---

MOVEMENT DURING FILLING

YES YES YES YES --- YES ---

WATER TEMPERATURE COLD COLD

COLD

COLD --- COLD ---

THERMAL STOP

NO NO --- --- --- --- ---

TIME(min)

0

10

0

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

YES YES YES YES --- YES ---

DISPENSER 1

T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

---

0

---

113687-3 7

Page 8

P4 - DELICATES

PHASE Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP4 rpm

RHYTHM

8/4 8/4 8/4 8/4 --- 8/4 ---

HOT WATER INPUT

NO NO NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO --- NO ---

WATER LEVEL MEDIUM MEDIUM HIGH HIGH --- HIGH ---

MOVEMENT DURING FILLING

NO NO NO NO --- NO ---

WATER TEMPERATURE COLD COLD

COLD

COLD

--- COLD ---

THERMAL STOP

NO NO --- --- --- --- ---

TIME(min)

0

10

0

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

NO NO NO NO --- NO ---

DISPENSER 1

T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

---

0

---

P3 - HOT

PHASE Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP3 rpm

RHYTHM

12/3 12/3 12/3 12/3 --- 12/3 ---

HOT WATER INPUT

NO REGULATED NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO --- NO ---

WATER LEVEL MINIMUM MINIMUM MEDIUM MEDIUM --- MEDIUM ---

MOVEMENT DURING FILLING

YES YES YES YES --- YES ---

WATER TEMPERATURE COLD 140ºF

COLD

COLD --- COLD ---

THERMAL STOP

NO YES --- --- --- --- ---

TIME(min)

0

10

0

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

YES YES YES YES --- YES ---

DISPENSER 1

T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

---

0

---

8 113687-3

Page 9

P6 – EXTENDED HOT

PHASE Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP3 rpm

RHYTHM

12/3 12/3 12/3 12/3 --- 12/3 ---

HOT WATER INPUT

NO REGULATED NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO --- NO ---

WATER LEVEL MINIMUM MINIMUM MEDIUM MEDIUM --- MEDIUM ---

MOVEMENT DURING FILLING

YES YES YES YES --- YES ---

WATER TEMPERATURE COLD 140ºF

COLD

COLD --- COLD ---

THERMAL STOP

--- --- --- --- --- --- ---

TIME(min)

5

10

2

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

YES YES YES YES --- YES ---

DISPENSER 1

T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

---

0

---

P5- EXTENDED COLD

PHASE Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP3 rpm

RHYTHM

12/3 12/3 12/3 12/3 --- 12/3 ---

HOT WATER INPUT

NO NO NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO --- NO ---

WATER LEVEL MINIMUM MINIMUM MEDIUM MEDIUM --- MEDIUM ---

MOVEMENT DURING FILLING

YES YES YES YES --- YES ---

WATER TEMPERATURE COLD COLD

COLD

COLD --- COLD ---

THERMAL STOP

NO NO --- --- --- --- ---

TIME(min)

5

10

2

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

YES YES YES YES --- YES ---

DISPENSER 1

T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

---

0

---

113687-3 9

Page 10

P7 / P8 / P9 / P10 - OPL

PHASE Soak Pre-wash Wash Rinse1 Rinse2 Short spin Final rinse Long spin

STOP PROGRAM

NO NO NO NO NO NO NO NO

SPEED SP1 rpm SP1 rpm SP1 rpm SP1 rpm SP2 rpm SP1 rpm SP3 rpm SP1 rpm

RHYTHM

12/3 12/3 12/3 12/3 12/3 --- 12/3 ---

HOT WATER INPUT

NO NO REGULATED NO NO --- NO ---

COLD WATER INPUT

YES YES YES YES YES --- YES ---

DECALCIFIED WATER INPUT

NO NO NO NO NO --- NO ---

WATER LEVEL MINIMUM MINIMUM MINIMUM MEDIUM MEDIUM --- MEDIUM ---

MOVEMENT DURING FILLING

YES YES YES YES YES --- YES ---

WATER TEMPERATURE COLD COLD 104ºF(CONF) COLD COLD --- COLD ---

THERMAL STOP

NO NO NO --- --- --- --- ---

TIME(min)

0

5

10

2

2

2

2

6

OPTIMUM DISTRIBUTION

--- --- --- --- --- YES --- YES

MOVEMENT DURING DRAINING

YES YES YES YES YES --- YES ---

DISPENSER 1

T60/R0 T60/R0 T60/R0

0

0

---

0

---

DISPENSER 2

0

0

T60/R0

0

0

---

0

---

DISPENSER 3

0

0

T60/R0

0

0

---

0

---

DISPENSER 4

0

0

0

0

0

--- T60/R0 ---

DISPENSER 5

0

0

0

0

0

--- T60/R0 ---

DISPENSER 6

0

0

0

0

0

---

0

---

DISPENSER 7

0

0

0

0

0

---

0

---

10 113687-3

Page 11

2.1 Controls

Program Remarks

P1

Cold Wash in cold water and two rinses

P2

Warm (104ºF) Wash at 104ºF and two rinses

P3

Hot (140ºF) Wash at 140ºF and two rinses

P4

Delicates Wash in cold water and delicates spin

P5

Extended cold Wash in cold water and three rinses

P6 Extended hot (140ºF) Wash at 140ºF and three rinses

P7

OPL (programmable) Default setting: Prewash, wash at 104ºF, three rinses and fast spin

Screen (2) The screen has 4 displays with 7 segments each and gives information regarding

the current operation.

START key Press Start to start a program, pause or continue the program after the pause. In

the menu navigation use the ENTER function to enter or go the next level in a

menu.

ADVANCE (>>) key

OPL

Press advance to accelerate a program. When this key is pressed the programmer

goes directly to run the next cycle of the program; where the cycle currently running

is the last, the program ends. Please note that if you press this key during a spin

cycle, the machine will not move to the next cycle until completion of the required

safety time to permit the drum to come to a complete standstill.

This option is not available in self-service mode.

INC (

∧

) and DEC (∨ ) keys The INC (∧) and DEC (∨) keys have different functions depending on the screen

and the programmer operating mode. Use these keys to select a wash program or

to scroll through different menus.

STOP key

Use this button to stop the washer for any reason. When the stop is pressed the

washer stops immediately regardless of mode or cycle. The water will drain and

after two minutes the door will unlock.

See the stop key section for a complete description of it’s function.

Cycle indicators (LEDS)

The user interface has 6 amber LEDs that indicate the status of the washer

extractor and the progress of the washing program in its different cycles. The

seventh LED is green and shows the door status: if it is lit then the door can be

opened, as the drum is no longer moving.

2.2 Programs

2 USE

NOTE: When the thermal stop is deactivated, the programmed wash time starts to run immediately without waiting

for the programmed water temperature to be reached.

2.3 Cycle Stop

The cycle stop is an important safety feature on all washers. It allows the washer to be stopped at any time, for any

reason.

When the cycle stop is pressed all motion stops immediately. The water will drain, and after 2 minutes the door will

unlock and the user will be prompted to open the door.

If the washer is in any of the self service modes (Central Pay , Card Reader, or Coin) there is a grace period at the st art

of the wash cycle where the program can be restarted by the user after the cycle stop has been pressed.

a) The user can open the door to add or remove garments at this time.

b) The user can restart the same cycle, or choose a new cycle at this time. If the new cycle is more expensive than

c) If there is no activity with 5 minutes of the open door prompt, the program will automatically end.

If the cycle stop is pressed after the grace period, the cycle will end, and the washer cannot be restarted without

the original program the user will be prompted to insert additional vend.

initiating a new cycle and inserting another payment.

The grace period is variable between 0 and 9 minutes (default value is 1 minute), and is set in the configuration

menu. See that section of the manual for information on setting this parameter.

The cycle stop function cannot be turned off.

113687-3 11

Page 12

3 OPL

Start/Pause wash

INC

Scroll through menus/

Up

DEC

Scroll through menus/

Down

Advance cycle

Cycle S top

Prewash cycle

Wash cycle

Rinse cycle

Spin cycle

Program ended/

Door unlocked

12 113687-3

Page 13

3.1 Operation

This machine has been designed to wash or treat most

materials. Its use for other purposes than those given

is considered as undue and dangerous.

The machine should be loaded with the nominal load,

smaller or bigger loads should be avoided.

1- Put garments to be cleaned in washer

extractor drum.

2- Close washer extractor door.

3- Add detergent.

4- Select desired program.

5- Press START key.

Clothes should not be washed in sacks or cloth bags.

If this is absolutely necessary, make sure the machine

is loaded to the nominal load to avoid possible

unbalanced loads.

Canvas, waterproof items, mops, carpets or rugs should

not be spun.

The machine is controlled using a microprocessor able

to adapt to the needs of each user.

There are 7 programs, which can be modified to varying

degrees. In the standard cycles (P1, P2, P3 & P4), it is

possible to change the time of each cycle, making the

same changes to all four programs. The cycle times for

the extended programs (P5 and P6) can also be

changed, without affecting the other programs. Lastly,

in OPL mode, it is possible to configure P7, which offers

more options, allowing the cycle time, the wash

temperature and the spin speed to be changed.

For further details, please see the sections Configuration

and St andardized Programs.

The machine has an intelligent control to control the

water temperature; if hot water is available, it should

be connected. The machine adjusts the different water

inputs to maintain the programmed temperature.

It has intelligent control for spin cycle management. The

washer extractor controls any unbalanced loads and

manages the spin to ensure a good spin, reducing noise

and extending the useful life of wearable components,

thus significantly reducing fatigue in the mechanical

components.

After starting a program, the L.E.D.s indicate its condition

and evolution.

With the START key the program stops, and pauses. If

you want the program to continue, press the Start key

again. If the program is in spin mode, it is not possible

to pause the machine, and therefore pressing the

START key will have no effect.

With the STOP key the cycle can be stopped at any

time, in any mode, in any program. When the STOP

button is pressed, all motion will stop. The water will

drain. WAIT will be shown on the display while the water

is allowed to drain. Once the water has drained the

door will unlock and OPEn dOOR will be displayed.

3.1.2 Program end

The program can finish in several ways:

• Normal end: the program finishes when all cycles

have been carried out.

• By pressing the STOP key at any time.

• By pressing the ADVANCE key from any point in

the program, repeatedly, the end of the program

can be reached. If a spin is being carried out, the

ADVANCE key will not respond until the braking

safety time has finished (approx 1 min.).

When a program ends, before allowing the door to be

opened, the clothes are untangled during 30 seconds.

An acoustic signal indicates when the door can be

opened.

3.1.1 Running a program

In order to carry out a wash program, the following steps

should be followed:

113687-3 13

Page 14

4 COIN

Start/Pause wash

INC

Scroll through menus/

Up

DEC

Scroll through menus/

Down

Cycle Stop

Prewash cycle

Wash cycle

Rinse cycle

Spin cycle

Program ended/

Door unlocked

14 113687-3

Page 15

5 COIN/CP MODE

Self-service programs

P1

Cold

P2

Warm (104ºF)

P3

Hot (140ºF)

P4

Delicates

P5

Extended cold wash

P6

Extended hot wash

(140ºF)

P7

OPL (programmable)

5.1 Operation

The configuration of the machine is different for selfservice models.

As long as the left-hand control door lock is closed,

the machine will be configured as a self-service

machine. Therefore the user will only be able to

select the required program and start the machine.

By default, only 6 programs are activated:

The price rate is the same for all the programs. To

change the price, please see the pay center manual or

the card reader if using card payments.

5.3 COIN

Use this option if the machine has a coin slot.

In order to carry out a wash program, the following steps

should be followed:

1- Place dirty washing in the machine.

2- Close the door.

3- Add detergent.

4- Select program.

5- Confirm price.

6- Insert the coins.

7- Press START.

The program number and price are shown on the screen

intermittently; use the INC and DEC (∧,∨) keys to change

the program and the price will be updated. If, after five

minutes there has not been any activity in the keys or in

the coin slot, the P1 price is displayed continuously until

any button is touched or a coin is inserted.

In order to use P7, it is necessary to change to

CREDIT MODE or go to CONF/P AY and activate the

OPL option.

To change the washer extractor configuration, go to

CONF/PAY (see section 5.5.8) and select the required

option.

The different functions in each case are shown below:

5.2 Pay center/card

Use this option if the washer extractor is a pay center or

card model.

Program execution

In order to carry out a wash program, the following steps

should be followed:

1- Place dirty washing in the machine.

2- Close the door.

3- Add detergent.

4- Insert card or coins in the pay center.

5- Select program.

6- Press START.

This type of coin slot allows you to allocate a price to

each program; the configuration menu has two

submenus, CUR and PRIC, allowing you to define the

currency and the price respectively (see sections 5.5.6

& 5.5.1).

113687-3 15

Page 16

5.4 Operating modes

The machine can be used in three different modes,

offering different options: OPL MODE, COIN MODE &

CP MODE.

5.4.1 OPL Mode

The operating mode, OPL MODE, permits access to

all the machine options, and use of the machine without

paying.

If the washer extractor does not have a prepaid device,

the factory settings of the machine are set to this mode.

After turning the key , go to the CONF menu and then to

the PAY submenu (see section 5.5.8). In this menu,

select the OPL option using the INC and DEC keys (∧,∨)

and press START.

The user will have access to all the configuration options

and all the programs.

5.4.2 Coin Mode

This operating mode is used for a coin-operated selfservice washer extractor. In this mode, the user is only

able to select the required program and start the

machine. All other options are disabled.

If machine is in Coin Mode and OPL is desired, insert a

key , in the left-hand lock of the control door and turn.

To ensure the machine in Coin Mode, insert a key in the

left-hand lock of the top cover and turn.

16 113687-3

Page 17

After turning the key, go to the CONF menu and then to

the PAY submenu (see section 5.5.8). In this menu,

select the COIN option using the INC and DEC keys

(∧,∨) and press START.

5.4.3 CP Mode

The CP Mode is also used in self-service machines,

but in this case, the machine is operated using a pay

station or card. As with the Coin Mode, the user is only

able to select and start the program.

To ensure the machine in CP Mode, insert a key in the

left-hand lock of the top cover and turn.

After turning the key, go to the CONF menu and then to

the PAY submenu (see section 5.5.8). In this menu,

select the CP option using the INC and DEC keys (∧,∨)

and press START.

5.4.4 Credit Mode

When the machine is configured to Coin Mode or CP

Mode, the owner can choose to access certain additional

options that will allow them to modify certain parameters.

To do so, enter Credit Mode.

On entering the CONF menu, different submenus are

available which permit the modification of some of the

parameters of the wash programs. These submenus

are not always available. Access to the menus will

depend on the current operating mode (OPL MODE,

COIN MODE or CP MODE) of the washer extractor.

5.5.1 PRIC (Price)

This allows the price of each program to be established

independently. It is only available in COIN MODE (see

section 5.4.2).

Use the INC & DEC (∧,∨) keys to select the program for

which the price is to be changed. Press START to enter

the program, and select the price using the INC & DEC

(∧,∨) keys; press START to confirm the price. The price

is conditioned by the currency selected; if the currency

is changed, the prices will be reset, therefore it is

IMPORTANT to select the currency first (see section

5.5.6).

5.5.2 LEuL (Configuration of levels)

To enter CREDIT Mode, insert a key in the left-hand

lock of the top cover and turn. Then press and hold the

upper left key for 3 seconds. A short buzz is heard.

To exit CREDIT MODE, turn the key in the other direction

to close the lock and remove the key.

5.5 Configuration Menu

To access the menu, with the washer extractor turned

on and stopped, press the INC and DEC (∧,∨) keys at

the same time for 3 seconds. With self-service washer

extractors, it is first necessary to open the lock in the

top cover, as this enables access to the menus. The

screen displays the CONF (Configuration) menu.

Use the INC and DEC (∧,∨) keys to scroll through the

different available options in the menus. To go to the

required option, press START, and to go back, press

ESC (bottom left button).

The water levels can be varied; there are three different

settings:

1- Low (factory setting)

2- Intermediate

3- High

If the configuration is modified, this will affect all the

levels of water used. Press start and the current level is

displayed (Leu1), use the INC and DEC (∧,∨) keys to

change the level to suit your needs. Press Start again

to confirm the level selected.

5.5.3 StCL (Configuration of standard cycles)

This submenu allows you to change the length of the

different wash cycles. The standard programs are P1,

P2, P3 and P4, therefore the changes made using this

submenu will apply to these programs, but not to P5,

P6 and P7.

113687-3 17

Page 18

5.5.4 ECL (Configuration of extended cycles)

5.5.6 Cur (Currency)

Use the ECL submenu to change the length of each of

the cycles of the extended programs, P5 and P6.

The changes made will only apply to these two

programs.

The default times of each cycle and the range within

which they can be changed are as follows:

5.5.5 P7-P10 (Configuration of the OPL programs)

This option is only available when the machine is in OPL

MODE, therefore it is necessary to activate this operating

mode (see section 5.4.1).

The OPL programs are independent to the other six

programs and it is possible to change more settings in

these programs. They offer the option to add an

additional soak, prior to the prewash. In addition to the

times for each cycle, it is also possible to modify the

wash temperature and the spin speed.

The temperature of the wash cycle can be set between

cold water and 194ºF, with a default value of 104ºF.

The spin speed varies according to the type of washer

extractor: standard, rapid or high speed. Nevertheless,

it is possible to change this speed and establish a lower

speed. This change will only affect the maximum spin

cycles, as the average spin is always at 100G. The

available speeds are as follows:

SP1: 100G (standard speed)

SP2: 200G (rapid speed)

SP3: 450G (high speed) (350G EWH60)

This is only available in COIN MODE (see section 5.4.2).

This allows the currency to be selected. The default

currency of the coin slot is USD (Code 3), but it is also

possible to configure the machine for use with other

currencies. Please refer to the coin drop kit manual and

check whether the coin slot installed in your machine

accepts the currency used in your country. Allocate the

currency to the washer extractor programmer. The table

below shows the available currencies. Use code 3 for

the United States.

CODE MINIMUM PRICE

0

Token

1

Kuwait

Oman

2

Azerbaijan

Bulgaria

Bahrain

China

Fiji

Malaysia

Panama

Singapore

3

Argentina

Bermuda

Brazil

Canada

Ecuador

Egypt

Ethiopia

Guatemala

Cayman Islands

Saudi Arabia

El Salvador

Turkey

United States

4

United Arab Emirates

Bolivia

Estonia

Euro-Countries

United Kingdom

Georgia

Ghana

Croatia

Latvia

New Zealand

Qatar

Ukraine

1

0.05

0.1

0.25

0.5

18 113687-3

Page 19

5

Bosnia and Herzegovina

Bangladesh

Switzerland

Dominican Republic

Hong Kong

Israel

India

Sri Lanka

Lithuania

Morocco

Macedonia

Peru

Philippines

Poland

Russian Federation

Sweden

Slovakia

Thailand

Tunisia

Uruguay

Yugoslavia

South Africa

Australia

1

6

Czech Republic

Denmark

Kenya

Mexico

Norway

Romania

5

7

Algeria

Guyana

Hungary

Iceland

Kazakhstan

Slovenia

Taiwan

10

8

Chile

Costa Rica

Iran, Islamic Republic of

Paraguay

French Polynesia

50

9

Colombia

Indonesia

Japan

South Korea

Uganda

Venezuela

100

5.5.8 PAY (Operating mode)

This allows the machine operating mode to be changed

between CP MODE, COIN MODE & OPL MODE (see

section 5.4).

5.5.9 AVAn (Advance cycle)

This option is only available in OPL MODE. The key >

can be deactivated, to prevent the advance of a cycle

thus ensuring the wash program is completed correctly .

By default, it is ON.

NOTE: This list is continuously updated, if you cannot find your country in the

list, please ask your distributor for the latest available update.

5.5.7 TiMr (Wash time remaining)

This indicates the time remaining until the program ends.

The default setting is ON for all the programs, but if the

StOP option (Thermal stop, see section 5.5.10) is

activated, the remaining time option is automatically

deactivated.

113687-3 19

5.5.10 StOP (Thermal stop switch)

This option is only available in OPL MODE. When the

thermal stop switch is activated, the cycle time does

not start until the programmed temperature has been

reached in order to guarantee the wash cycle is correctly

completed; this switch can be deactivated so that the

time is counted from the moment the programmed level

is reached. The default setting is OFF.

5.5.11 Grd (Change between °F & °C)

This option is only available in OPL MODE. This

submenu allows you to select the temperature display

in degrees Fahrenheit (°F) or degrees Celsius (°C). The

default setting is degrees Fahrenheit.

5.5.12 Beep (Acoustic signal)

This option is only available in OPL MODE. This allows

you to switch the acoustic signals on or off. By default,

they are ON.

5.5.13 deLA (Cycle Stop Grace Period)

This option is only available in self service modes. This

allows the grace period for the cycle stop to be set. The

default time is 1 minute. The allowable range is from 0

to 9 minutes.

Page 20

5.6 Maintenance Menu

- SPd: Information about the number of times

each spin type has been run.

5.6.3 Def

To access the menu, with the washer extractor turned

on and stopped, press the INC and DEC (∧,∨) keys at

the same time for 3 seconds. With self-service washer

extractors, it is first necessary to open the lock in the

top cover, as this enables access to the menus. The

screen displays the CONF (Configuration) menu.

Use the INC & DEC (∧,∨) keys to select the MANT option

and press START.

5.6.1 In/Out (Inputs/Outputs)

This allows you to view the status of the different inputs

(IN) and outputs (OUT) of the base plate. The OUT

submenu also allows you to activate or deactivate the

plate outputs, including the water inputs, the heating

system or the inverter.

5.6.2 Std (Statistics)

This is only available to the technical service.

5.6.4 Last

This displays the last ten errors occurred in order.

5.7 Menu Mod

This is only available to the technical service

5.8 Machine operating

When the machine is running a program, the

Configuration menu is disabled, and the user is offered

certain data about the machine’s operation. This data

is only displayed if the machine is set to OPL mode

(see section 5.4.1).

To go to the menu and view the real data while the

machine is running, press INC and DEC (∧,∨) together

for 3 seconds.

The statistics submenu contains data about the

machine’s operation. The statistics available to the user

are as follows:

- CiCL: Provides information about how many

times each program has been run.

- HOUr: Gives the number of hours during

which the washer extractor has been running.

- Err: Number of times each of the errors has

occurred (see section 6.2).

The following options will be available:

PArA (Parameters): Temperature, water level and time

remaining.

In (Inputs): This is only available to the technical service.

Out (Outputs): This is only available to the technical

service.

20 113687-3

Page 21

6 MAINTENANCE

Message Possible causes Action

PWR FAUL

UAIT

This message appears on recovering the power after having been cut-off.

If the power cut occurs during the spin cycle, the message "WAIT" is

displayed. For safety reasons, wait approximately 1.5 minutes without

pressing anything until "PWR FAULT" is displayed.

Press START: the program continues to

operate in the same cycle as before the power

cut.

Press ESC: the program ends.

E2

FAULT LOCK

This message appears when it is detected that the door can not be unlocked

at the end of the program or that it has unlocked during the program.

Press ESC: the program ends.

E3

FAULT DRAIN PIPE

This message is displayed when, in spite of deactivating the emptying valve

output, the water level inside the drum has not decreased for a preestablished period of time.

Press START: the program continues.

Press ESC: the program ends.

E4

FAULT WATER INLET

This message appears when, in spite of activating the corresponding

solenoid valves' outputs, the water level inside the tub has not increased

during a certain pre-established period of time.

Press START: the program continues.

Press ESC: the program ends.

E5

HEATING FAULT

This message is shown when, in spite of activating the heating output, the

water temperature has not increased for a certain pre-established period of

time.

Press START: the program continues.

Press ESC: the program ends.

E6

MAX. TEMP

This message is displayed when the water temperature has exceeded 95 ºC.

Press START: the program continues.

Press ESC: the program ends.

E7

THERMOSTAT OPEN

This message appears when the water temperature exceeds 203ºF.

Press START: the program continues.

Press ESC: the program ends.

E9

MOTOR HEATING

This message appears when the thermal protection of the washer extractor

motor is detected to have not been activated.

Press START: the program continues.

Press ESC: the program ends.

E10

UNBALANCE

This message appears when the final spin activates the unbalance micro

three times.

Press ESC: the program ends.

E11

CLOTHES HOT

This message is displayed when a program finishes but the water

temperature inside the tub exceeds 122ºF.

Press ESC: the program ends.

E12

WATER IN TUB

This message is displayed when a program execution is finished but there is

still water inside the tub. The door can not be opened until the water is

drained from the tub.

Press ESC: the program ends.

Only qualified personnel should maintain this equipment.

6.1 Electrical and mechanical troubleshooting

Before calling the Technical Service Center, check the

following:

that power is supplied to the machine.

the condition of the fuses.

that the voltage is correct for the machine.

If the washer extractor fails to obtain the required

level of water, check:

that the water mains tap is open.

that the water inlet filter is not blocked.

that the water pressure is between 2 and 4 kg/cm2 (28

and 56 psi).

If the washer extractor vibrates excessively , check:

None of the panel screws are loose.

If a power cut occurs, check:

The tub is drained and the door is blocked. If you want

to take the clothes out of the washer extractor, unlock

the door by pulling down the belt located behind the

front panel.

6.2 Error messages

On the washer extractor screen, warning or fault

messages may be displayed during or after the

execution of a wash program. Except in the event of a

power cut, the washer extractor will be paused (drain

pipe off, motor off, etc.) awaiting user action.

If the washer extractor is set to COIN MODE or CP MODE, the door will unlock, after the safety time has elapsed, in

the event of the following errors: PWR FAUL, E2, E9

113687-3 21

Page 22

Part No. 113687 3 - 09/29/16

Loading...

Loading...