Page 1

ECOWASH

INSTALLATION MANUAL

EWH-25 / EWH-30 / EWH-40 / EWH-60

EWR-25 / EWR-30 / EWR-40 / EWR-60

EWS-25 / EWS-30 / EWS40 / EWS-60 / EWS-80

M2 and MP2 Models

Part No. 113586-4

Page 2

1. INTRODUCTION

Dear customer,

Thank you for the confidence you have placed in our product. We hope it meets your needs.

ADC products embody advanced concepts in engineering, design, and safety. If this product is properly maintained,

it will provide many years of safe, efficient, and trouble free operation.

This washer is warranted against defects in manufacturing and workmanship per the warranty sheet included with

the washer.

The warranty does not cover damage to glass components, or consumables (seals, bulbs, etc.) nor damage due to

the incorrect installation of the appliance, or to inappropriate use, inadequate maintenance or poor repair processes.

This appliance is subject to changes and modifications for its technical progress.

RETAIN THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE

ONLY qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation manual included

with the washer.

The following “FOR YOUR SAFETY” caution must be posted near the washer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflammables à proximité de cet appareil ou

de tout autre appareil.

We have tried to make this manual as complete as possible and hope you will find it useful. ADC reserves the right

to make changes from time to time, without notice or obligation, in prices, specifications, colors, and material, and to

change or discontinue models. The illustrations included in this manual may not depict your particular washer exactly.

IMPORTANT

For your convenience, log the following information:

DATE OF PURCHASE_____________________________________________ MODEL NO. _______________

RESELLER’S NAME _________________________________________________________________________

Serial Number(s) ____________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement parts from the

factory, you can FAX your order to ADC at (508) 678-9447 or telephone your order directly to the ADC Parts Department

at (508) 678-9000. Please specify the washer model number and serial number in addition to the description and

part number, so that your order is processed accurately and promptly.

2 113586-4

Page 3

2. CONTENTS

1. INTRODUCTION .................................................................................................................................................2

2. CONTENTS .........................................................................................................................................................3

3. MAIN SPECIFICATIONS .....................................................................................................................................4

4. MAIN DIMENSIONS ............................................................................................................................................6

5. IMPORTANT INSTRUCTIONS REGARDING SAFETY AND USE......................................................................8

6. STANDARDS .....................................................................................................................................................10

7. TRANSPORT.....................................................................................................................................................10

8. CHARACTERISTICS OF THE PLACE OF INSTALLATION .............................................................................. 10

9. HANDLING ........................................................................................................................................................10

10. INSTALLATION (ALL MODELS) ........................................................................................................................ 11

10.1 Water Connection ....................................................................................................................................... 11

10.2 Steam Connection....................................................................................................................................... 11

10.3 Drainage ...................................................................................................................................................... 11

10.4 Electrical Connection...................................................................................................................................12

10.5 Auxiliary Connections .................................................................................................................................. 14

10.6 Dispenser Inlet Connections ....................................................................................................................... 14

11. INSTALLATION OF GROUPS H-R-S ................................................................................................................15

11.1 Soft Washer Mounting Dimensions.............................................................................................................15

11.2 Rigid Washer Mounting Dimensions ...........................................................................................................16

11.3 Group (H) Washers .....................................................................................................................................17

11.4 Using a Steel Base ...................................................................................................................................... 18

11.5 Using an Elevated Concrete Pad ................................................................................................................18

11.5.1 Using Expansion Bolts ..........................................................................................................................19

11.5.2 Using J-bolts .........................................................................................................................................19

12. INSTALLATION OF SELF-SERVICE WASHING MACHINES (GROUP H-R-S) ...............................................20

12.1 Central Pay..................................................................................................................................................20

12.2 Card Reader ................................................................................................................................................ 20

12.3 Coin .............................................................................................................................................................20

13. WASHING MACHINE INSTALLATION AND MAINTENANCE ........................................................................... 21

113586- 4 3

Page 4

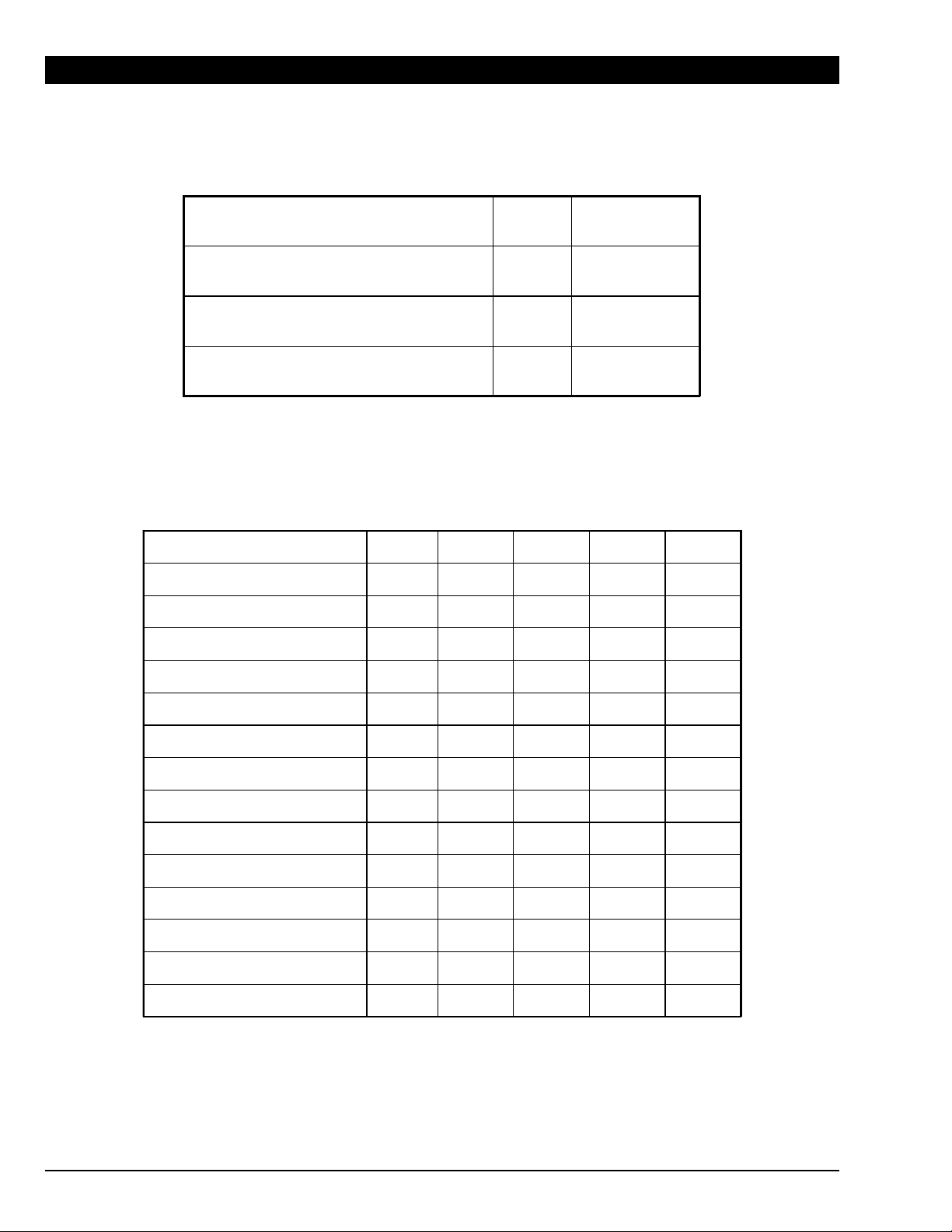

Ambient conditions

3. MAIN SPECIFICATIONS

Ambient operating temperature

Storage temperature

Maximum relative humidity

Maximum altitude

GROUP H (High spin soft mount washing machines)

MODEL EWH-25 EWH-30 EWH-40 EWH-60

Drum Volume

Maximum Load

Washer Dry Weight

Motor Power

Drain Diameter

Water Input Diameter

Optional Steam Input Diameter

Optional Steam Consumption

Static Floor Load

Maximum Dynamic Floor Load

Maximum Vertical Load

Dynamic Load Frequency

L

CuFt

Kg

Lb

Kg

Lb

kW

Hp

mm

Inc h

GHT &

BSPP

BSPP 1/2” 1/2” 1/2” 3/4”

Kg/h

Lb/h

KN

Lb

KN

Lb

KN

Lb

Hz 16.67 16.67 15.83 15.00

°C

°F

°C

°F

+5 / +41

+41 / + 106

+1 / +55

+34 / +131

%90

m

ft

94

3.3

10

25

212

467

0.75

1

76

3

3/4” 3/4” 3/4” 3/4”

7

15.5

2.08

467

0.75

169

2.83

636

130

4.6

13

30

254

560

1.1

1.5

76

3

8.5

17.7

2.49

560

1.05

236

3.54

796

1000

3280

181

6.4

18

40

348

767

2.2

3.0

76

3

12

26.5

3.41

767

1.40

315

4.81

1082

247

8.7

25

60

5002

1107

3.0

4.0

76

15

33.1

4.92

1107

1.75

393

6.67

1465

3

Maximum G Force

Maximum Noise Level

db <70 <70 <70 <70

450 450 450 350

4 113586-4

Page 5

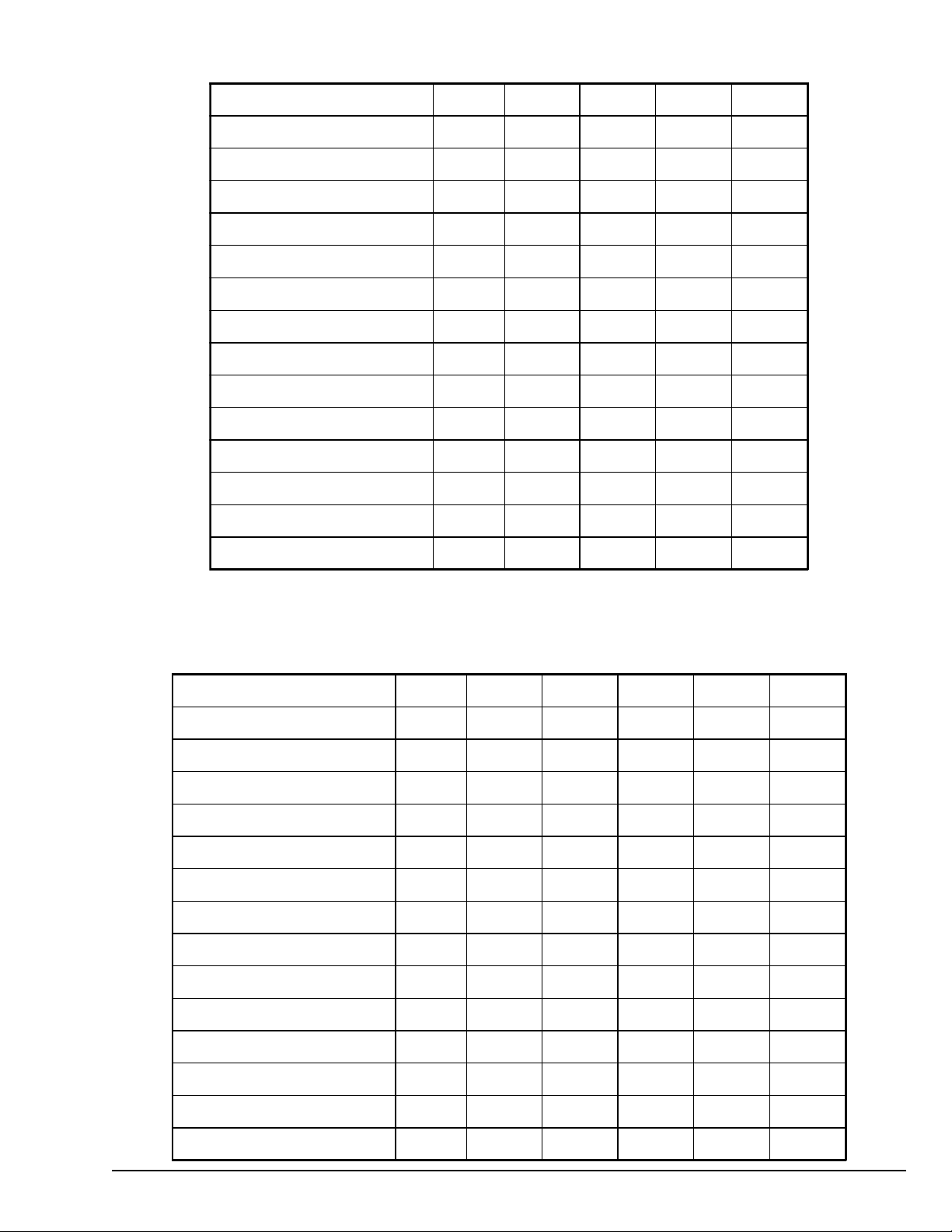

GROUP R (Rapid spin rigid mount washing machines)

MODEL EWR-25 EWR-30 EWR-40 EWR-60

Drum Volume

Maximum Load

Washer Dry Weight

Motor Power

Drain Diameter

Water Input Diameter

Optional Steam Input Diameter

Optional Steam Consumption

Static Floor Load

Dynamic Floor Load

Maximum Vertical Load

Dynamic Load Frequency

L

CuFt

Kg

Lb

Kg

Lb

kW

Hp

mm

Inc h

GHT &

BSPP

BSPP 1/2” 1/2” 1/2” 3/4”

Kg/h

Lb/h

KN

Lb

KN

Lb

KN

Lb

Hz 12.67 12.67 12.00 11.50

100

3.5

10

25

212

467

0.7

51

76

3

3/4” 3/4” 3/4” 3/4”

7

15.5

2.08

467

5.0

1124

7.08

1592

130

4.6

13

30

241

531

1.1

1.5

76

3

8.5

17.7

2.36

531

6.0

1349

8.36

1880

181

6.4

18

40

282

622

1.5

2.0

76

3

12

26.5

2.77

622

8.0

1798

10.77

2420

247

8.7

404

891

2.2

3.0

33.1

3.96

891

10.0

2248

13.96

3139

25

60

76

3

15

Maximum G Force

Maximum Noise Level

db <70 <70 <70 <70

GROUP S (Standard spin rigid mount washing machines)

MODEL EWS-25 EWS-30 EWS-40 EWS-60 EWS-80

Drum Volume

Maximum Load

Washer Dry Weight

Motor Power

Drain Diameter

Water Input Diameter

Optional Steam Input Diameter

Optional Steam Consumption

Static Floor Load

Dynamic Floor Load

Maximum Vertical Load

Dynamic Load Frequency

L

CuFt

Kg

Lb

Kg

Lb

kW

Hp

mm

Inc h

GHT &

BSPP

BSPP 1/2” 1/2” 1/2” 3/4” 3/4”

Kg/h

Lb/h

KN

Lb

KN

Lb

KN

Lb

Hz 8.93 8.93 8.42 8.02 7.58

100

3.5

10

25

2044

50

0.75

1

76

3

3/4” 3/4” 3/4” 3/4” 3/4”

7

15.5

2.00

450

3.00

674

5.00

1124

200 200 200 200

130

4.6

13

30

235

518

1.1

1.5

76

3

8.5

17.7

2.31

518

4.00

899

6.31

1417

181

6.4

18

40

268

591

1.5

2.0

76

3

12

26.5

2.63

591

5.00

1124

7.63

1715

247

8.7

25

60

360

794

2.2

3.0

76

3

15

33.1

3.53

794

6.00

1349

9.53

2143

350

12.3

35

80

468

1032

3.0

4.0

76

3

18

39.7

4.59

1032

8.00

1798

12.59

2831

Maximum G Force

Maximum Noise Level

db <70 <70 <70 <70 <70

100 100 100 100 100

113586- 4 5

Page 6

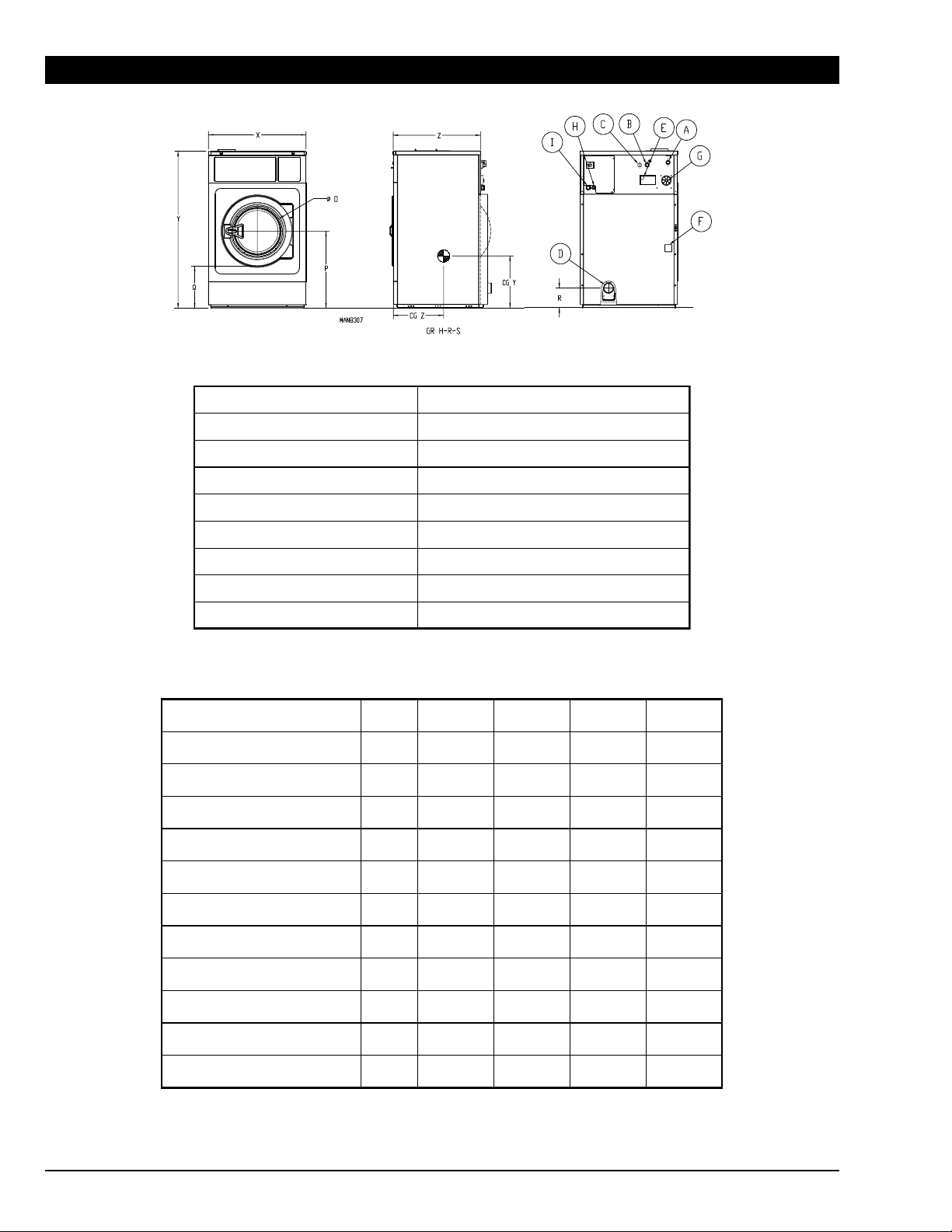

4. MAIN DIMENSIONS

A (Cold Water Inlet)

B (Hot Water Inlet)

C (Aux Water Inlet)

D (Drainage)

E (Tub Vent)

F (Steam Inlet-Optional)

G (Dispenser Inlets)

H (Ext. Dispenser Cable Inlets)

I (Main Power Cable Inlet)

GROUP H (High spin soft mount washing machines)

MODEL Unit EWH-25 EWH-30 EWH-40 EWH-60

M (Drum Diameter)

N (Drum Depth)

O (Entrance Diameter)

P (Drum Center Height)

Q (Under Door Height)

R (Drain Height)

X (Cabinet Width)

Y (Cabinet Height)

Z (Cabinet Depth)

CG Y (Center of Gravity)

CG Z (Center of Gravity)

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

mm

Inch

29-58 psi (2-4 bar)

29-58 psi (2-4 bar)

29-58 psi (2-4 bar)

29-58 psi (2-4 bar)

(7) 10 mm (3/8”) Hose, (1) 1/2” BSPP

532

21

425

16-3/4

290

11- 3/8

632

24-7/8

421

16-5/8

121

4-3/4

692

27-1/4

1162

45-3/4

791

31-1/8

424

16-3/4

577

22-3/4

620

24-3/8

430

16-7/8

373

14-5/8

689

27-1/8

432

17

126

5

788

31

1310

51-5/8

800

31-1/2

398

15-5/8

651

25-5/8

700

27-1/2

470

18-1/2

373

14-5/8

737

29

479

18-7/8

99

3-7/8

883

34-3/4

1410

55-1/2

845

33-1/4

464

18-1/4

702

27-5/8

770

30-3/8

530

20-7/8

373

14-5/8

853

33-5/8

595

23-3/8

130

5-1/8

979

38-1/2

1553

61-1/8

973

38-1/4

773

30-3/8

503

19-3/4

6 113586-4

Page 7

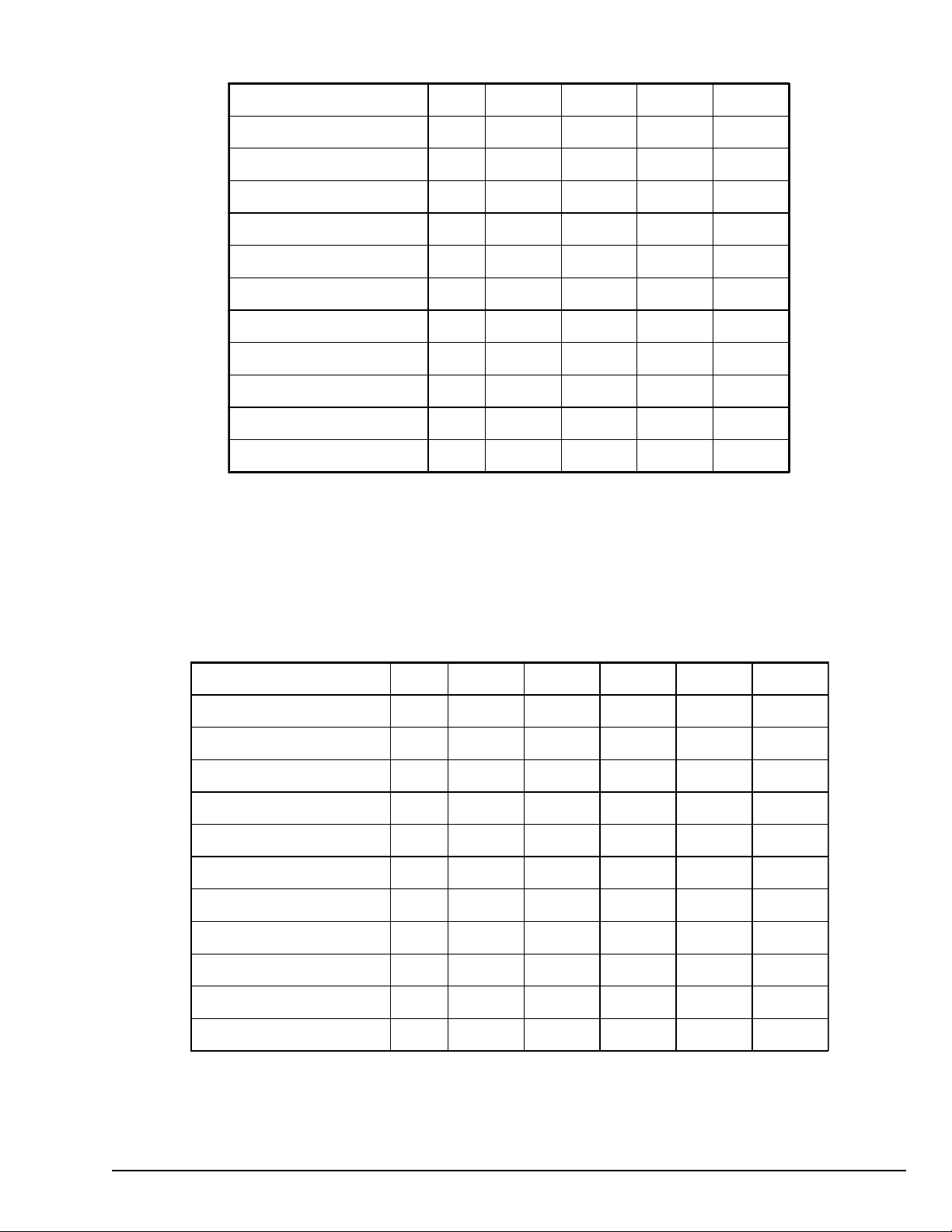

GROUP R (Rapid spin rigid mount washing machines)

MODEL Unit EWR-25 EWR-30 EWR-40 EWR-60

M (Drum Diameter)

N (Drum Depth)

O (Entrance Diameter)

P (Drum Center Height)

Q (Under Door Height)

R (Drain Height)

X (Cabinet Width)

Y (Cabinet Height)

Z (Cabinet Depth)

CG Y (Center of Gravity)

CG Z (Center of Gravity)

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

620

24-3/8

330

13

373

14-5/8

568

22-3/8

310

12-1/4

145

5-3/4

719

28-1/4

1157

45-5/8

645

25-3/8

383

15-1/8

511

20-1/8

620

24-3/8

430

16-7/8

373

14-5/8

568

22-3/8

310

12-1/4

144

5-5/8

719

28-1/4

1157

45-5/8

791

31-1/8

484

19

524

20-5/8

700

27-1/2

470

18-1/2

373

14-5/8

653

25-3/4

395

15-5/8

112

4-3/8

788

31

1307

51-1/2

800

31-1/2

479

18-7/8

546

21-1/2

770

30-3/8

530

20-7/8

373

14-5/8

691

27-1/4

433

17

150

5-7/8

884

34-3/4

1319

51-7/8

965

38

543

21-3/8

591

23-1/4

GROUP S (Standard spin rigid mount washing machines)

MODEL Unit EWS-25 EWS-30 EWS-40 EWS-60 EWS-80

M (Drum Diameter)

N (Drum Depth)

O (Entrance Diameter)

P (Drum Center Height)

Q (Under Door Height)

R (Drain Height)

X (Cabinet Width)

Y (Ca bi net Height)

Z (Cabinet Depth)

CG Y (Center of Gravity Height)

CG Z (Center of Gravity Depth)

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

620

24-3/8

330

13

373

14-5/8

568

22-3/8

310

12-1/4

145

5-3/4

719

28-1/4

1157

45-5/8

645

25-3/8

383

15-1/8

511

20-1/8

620

24-3/8

430

16-7/8

373

14-5/8

568

22-3/8

310

12-1/4

144

5-5/8

719

28-1/4

1157

45-5/8

791

31-1/8

484

19

524

20-5/8

700

27-1/2

470

18-1/2

373

14-5/8

653

25-3/4

395

15-5/8

112

4-3/8

788

31

1307

51-1/2

800

31-1/2

479

18-7/8

546

21-1/2

770

30-3/8

530

20-7/8

373

14-5/8

677

26-5/8

419

16-1/2

148

5-7/8

884

34-3/4

1307

51-1/2

965

38

591

23-1/4

543

21-3/8

860

33-7/8

602

23-7/8

560

22

733

28-7/8

373

14-5/8

149

5-7/8

979

38-1/2

1411

55-1/2

1057

41-5/8

635

25

682

26-7/8

113586- 4 7

Page 8

5. IMPORTANT INSTRUCTIONS REGARDING SAFETY AND USE

WARNING: To reduce the risk of electrical shocks or

injury when using the appliance, basic precautions

should be observed, including the following:

1- READ all the instructions prior to using the appliance

and KEEP THEM in an easily accessible place for

reference in the event of doubt.

2- This appliance must be installed by an Official or

authorized Technical Assistance Service. The

installation, incorrect adjustment, inappropriate

maintenance or use of the appliance may cause

material damages and injuries. Before

commissioning the appliance, carefully read the

instructions contained in this manual. These contain

important information about the installation of the

appliance

3- The incorrect installation, inappropriate servicing,

poor maintenance and/or cleaning and

modifications to the appliance may cause damage

to both the appliance and the users.

4- Failure to comply with the given procedures will

result in the loss of cover under guarantee.

5- Switch off the appliance in the event of breakdown

or faulty operation.

6- Do not wash clothes which have been previously

treated, washed, soaked or stained with gasoline,

dry cleaning solvents, or other inflammable or

explosive substances, as these give off vapors,

which may catch fire or explode.

7- Do not add petrol, dry cleaning solvents or other

inflammable substances to the washing water.

These substances give off vapours which could

catch fire or explode.

8- In some conditions, hydrogen gas may be produced

in a hot water system which has not been used for

more than two weeks. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for a while, before using the washing machine

turn on all the hot water taps and let the water run

for a few minutes. This will release any accumulated

hydrogen gas. As the gas is inflammable, do not

smoke or use naked flames during this operation.

9- Do NOT allow children to play in or on the appliance.

Children should be strictly supervised when in the

vicinity of a machine which is operating.

10- Remove the door from the appliance before disposal

or before leaving it out of service.

11- DO NOT TRY TO OPEN THE DOOR if the drum is

moving.

12- Do NOT install or store the appliance in the open.

13- Do NOT try to force the controls.

14- Do not repair or replace parts of the appliance or

carry out any servicing unless recommended to do

so in the User Instruction Manual. Make sure that

you fully understand the instructions and have the

necessary skills to carry out the operations

described.

15- Do NOT remove any safety device or modify any

components in the washing machine. DO NO

INSTALL components not belonging to the machine

in the appliance.

16- Failure to comply with any of the instructions given

in the Instruction Manual may result in personal

injury to the user. It is no possible to provide for all

possible situations and contingencies with warnings

about risk and hazards. Therefore, any person

involved in the transportation, installation, use or

maintenance of the machine should always employ

common sense, caution and care.

17- Do NOT use the machine unless all the covers and

guards are correctly fitted and secured.

18- The distributor (vendor) MUST correctly instruct the

user during commissioning.

19- Pour the correct doses of detergent, fabric softener

and bleach into the dispenser drawer, as indicated

by the manufacturer. Heed tips concerning the

treatment of different materials given by the

manufacturers.

20- Remove any traces of detergent or liquids from the

dispenser drawer everyday. Never use powdered

or abrasive detergents for cleaning; use only water

and soap.

21- Clean the water inlet filters and the external

dispenser conducts once a month.

8 113586-4

Page 9

22- Never clean the exterior with a pressure washer;

functional parts of the machine could be damaged.

23- If the washing machine is to be idle for long periods,

apply a coat of Vaseline oil to all its stainless steel

surfaces.

WARNING! Repairs or work carried out by personnel

not belonging to the authorised Technical Service

will void the warranty.

CAUTION! Fire protection regulations must be strictly

observed.

24- An annual general service is recommended.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE

WARNING! Before starting to connect the appliance,

check that the installation values match those given

on the appliance specification plate.

113586- 4 9

Page 10

6. STANDARDS

All models comply to standard EN ISO 10472 concerning the safety requirements for industrial laundry machinery.

2006/42/EC Machinery Safety Directive

2006/95/EC Low Voltage

2004/108/EC Electromagnetic Compatibility Directive

UL Standard for Electric Clothes Washing Machines and Extractors; UL 2157 and CSA C22.2 No. 169

For models with a drum capacity of less than 120 dm

Standards EN 60335-1 and EN 60335-2-7 concerning Electrical appliances.

Standards EN 55014, EN 61000-3-2 and EN 61000-3-3 on Electromagnetic compatibility.

For models with a larger capacity:

Standard EN 60204-1 concerning Electrical appliances.

Standards EN 61000-6-1, EN 61000-6-3 y EN 61000-3-1 on Electromagnetic compatibility.

3

(4.24 cu.ft):

7. TRANSPORT

When transporting the appliance, the following should be observed:

o

Current regulations and laws

o

Regulations concerning occupational risk prevention

o

Regulations concerning safety during transport

Check the delivery is in good condition prior to receipt.

8. CHARACTERISTICS OF THE PLACE OF INSTALLATION

In some locations, an omnipolar switch must be installed between the appliance and the mains electricity supply with

a minimum distance of 3 mm for each pole between contacts. Check your local regulations.

The washing machine must be firmly secured on the floor, which will support its weight and the dynamic force

generated while spinning.

The washing machine must be correctly leveled leaving spaces to make maintenance easier, 0.5 m on the side and

1 m at the rear.

WARNING! The stopcocks should be close to the appliance in an easily accessible location.

9. HANDLING

When handling the appliance, the following should be observed:

o

Current regulations and laws

o

Regulations concerning occupational risk prevention

-

Safety clothing and gloves must be worn for protection against cuts and knocks and safety shoes should

be used to prevent against injury as a result of falling components.

-

When handling and moving the appliance, appropriate tools and resources must be used.

-

Any work to the interior of the appliance must be carried out by qualified and skilled personnel.

CAUTION! Inappropriate handling of the appliance may result in damage or injury.

10 113586-4

Page 11

10. INSTALLATION (ALL MODELS)

10.1 Water Connection

If only cold water is available, connect as shown in figure 3. Where hot water is available, connect as shown in figure

4. If, in addition, decalcified water is available, connect as shown in figure 5. NOTE: not all washer models have a

third decalcified water valve.

A. F.

A. C.

Fig. 3

Connections on the washer are 3/4” GHT

A. F.

A. C.

Fig. 4

Fig. 5

A. D.

A. F.

A. C.

For 3/4” BSPP connection, remove the brass GHT adaptor.

A=Stopcock B=Filter C=Hose A.C.=Hot water A.F.=Cold water A.D.=Decalcified water

Water Pressure Range: 29 - 58 PSI / 2 - 4 Bar.

VERY IMPORTANT: Bleed water circuit prior to installation and fitting filters.

10.2 Steam Connection

If your washer is fitted with optional steam heat, the water in the tub can be heated by direct steam injection. The connection

diagram is shown in the figure. See the main specifications section for the connection size on your model.

Warning!

Failure to fit the filters on the water

and steam inputs will void the warranty

on the corresponding components

Steam Pressure Range: 29 - 58 PSI / 2 - 4 Bar.

VERY IMPORTANT: Bleed steam circuit prior to installation and fitting filters

After steam has been introduced into the machine for the first time, it is advisable for the steam hose nuts to be retightened.

10.3 Drainage

Fix the drainage bend pipe as shown in the figure. Be sure to check and follow any local plumbing regulations.

A=Drainage pipe bend

B=Clamp

The drain flow rate for all models is up to 47 GPM (178 LPM). Be sure that the system

is designed to handle that flow rate. If multiple washers are installed in line, be sure the

system is designed to handle the combined flow from all the washers.

113586- 4 11

Page 12

10.4 Electrical Connection

GROUP H (High Speed Soft Mount Washing Machines)

Standard or With

Optional Steam

Heating

EWH-25 3.5 15 14 3.5 15 14

EWH-30 6.8 15 14 6.8 15 14

EWH-40 10.1 15 12 10.1 15 12

EWH-60 13.7 20 12 7.9 15 14

Operating

Amperage

230V-1~ 230V-3~

FUSE

(A)

AWG

Operating

Amperage

FUSE

(A)

AWG

GROUP R-S (Rapid and Standard Speed Rigid Mount Washing Machines)

Standard or With

Optional Steam

Heating

EWS-25/EWR-25 3.5 15 14 3.5 15 14

EWS-30/EWR-30 5.0 15 14 5.0 15 14

EWS-40/EWR-40 6.8 15 14 6.8 15 14

EWS-60/EWR-60 10.1 15 12 10.1 15 12

EWS-80 13.7 20 12 7.9 15 14

Operating

Amperage

230V-1~ 230V-3~

FUSE

(A)

AWG

Operating

Amperage

FUSE

(A)

AWG

Connection to Washer

These washers were designed for direct wiring into the power supply. The washer must be electrically grounded in

accordance with all local codes or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70,

latest edition, or Canadian Electrical Code, CSA C22.1.

Direct Wire Installation:

Power supply cable must match power supply (3-wire or 4-wire) and be:

■ Flexible armored cable or nonmetallic sheathed copper cable (with grounding wire), in a flexible metallic conduit.

Flexible conduits must be used to avoid conductor breakage due to vibration. All current-carrying wires must be

insulated.

■ Copper wire of appropriate gauge for amperage requirement (see “Manufacturer’s Recommended Minimal Conductor

Section”). Stranded wire is recommended. Do not use aluminum wire.

WARNING: Risk of electrical shock

Connection is made directly to the disconnect switch on the back of the washer. To access the connections remove

the rear electric box cover. To access the heads of the connection screws, the red handle and yellow cover have to

be removed from the disconnect switch. The handle is held in place with a wedge on the switch shaft that is driven by

a Phillips head screw in the center of the handle. Loosen the screw and push in on it to release the wedge. Pull off

the handle. Note the orientation of the handle and the yellow parts so that they can be replaced in the same locations.

Check the rating plate on the washer. Make sure

that the supply phase and voltage match the rating

of the washer.

Some locations require an autonomous power

switch (I) at the current input, with a minimum of 3

mm between contacts. Fit a 300mA, type A,

immediate response differential protection. Check

your local regulations.

Insert the power cord through the large strain relief.

Connect the wiring per the correct illustration.

12 113586-4

Page 13

Multiple Single-Phase Machines in Line

When installing multiple single-phase washers into an existing 3-phase power supply, alternating the phases used as

the hot leg is recommended to evenly distribute power on the system. See illustration.

INSTRUCTIONS FOR CONNECTING THE EARTH

This appliance must be connected to an equipment grounding conductor that must run with the circuit conductors

and connected to the green and yellow terminal block inside the rear electric panel.

Connect the terminal strip and check that the connections correspond to the operating voltage. Fit a 300mA, type A,

immediate response differential protection.

The machine must be connected to earth. See the illustration on the previous page.

Equipotential Bonding:

In addition to the equipment-grounding conductor discussed earlier that runs with the circuit conductor’s and is

connected to the equipment grounding terminal, all washers or appliances in the vicinity must be permanently

interconnected with a grounded connector.

The external connection points marked on the back of the washer serve for this purpose. See illustration below.

The cross-sectional area of the conductor must be at least electrically equivalent to the cross-sectional area of the

copper conductor used to power the washer.

1.

Protective grounding structure

2.

External protective conductor connection point

3.

Protective

4.

Grounding identification

113586- 4 13

interconnecting

conductor

Page 14

10.5 Auxiliary Connections

See the figure below of the Auxiliary connections label found just outside the rear electric box on the washer. The

figure shows the locations of the connections described below.

a) The max current draw allowed on each connection is 0.5 Amps.

b) Connections 1 thru 4 are the same signal used to send water to the indicated area of the washer’s soap dispenser.

c) Connections 9-10, 11-12, 13-14 are shown on the wiring diagram. A copy of the diagram can be found in a pouch

on the back side of the hinged control door.

1: 230 V electrical signal. For dispenser 1 (prewash)

2: 230 V electrical signal. For dispenser 2 (wash)

3: 230 V electrical signal. For dispenser 3 (bleach)

4: 230 V electrical signal. For dispenser 4 (softener)

5: 230 V electrical signal. For dispenser 5 (ONLY ON MP MODELS)

6: 230 V electrical signal. For dispenser 6 (ONLY ON MP MODELS)

7: 230 V electrical signal. For dispenser 7 (ONLY ON MP MODELS)

R: (has no label) is located between terminal 7 and 9-10. This connection is a constant 230v auxiliary power source,

and has power as long as power is connected to the washer.

9-10: Active machine signal is a NO contact on the RG1 relay that powers the VFD. Contact closes when a wash

cycle is running.

11-12: This is the coin pulse signal from a central or card reader pay system.

13-14: Is a connection for an external e-stop. Remove the orange jumper and install the e-stop across this connection.

10.6 Dispenser Inlet Connections

See the figure at the top of page 6 for the location of the dispenser inlets.

There are (7) 3/8” (10mm) hose connections in a circular pattern around a central 1/2” BSPP threaded connection.

The hose connections are plugged. Before connecting a hose, drill the plug out using a 5/16” (8mm) diameter drill bit.

The threaded connection is open and has a brass cap on it. Remove the cap to connect to the port.

Port has 1/2” BSPP (G-1/2) straight thread. Sealing is achieved by a washer on the face of the port. For low pressure

applications where BSP fittings are unavailable, 1/2” NPT fittings with a thread sealant can be used.

14 113586-4

Page 15

11. INSTALLATION OF GROUPS H-R-S

11.1 Soft Washer Mounting Dimensions

MODELUnitW1W2W3W4W5W6W7W8W9

EWH-25

EWH-30

EWH-40

EWH-60

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

18-1/8

460

21-7/8

556

21-3/8

543

29-7/8

760

4-5/8

116

4-5/8

116

6-3/4

170

4-1/4

110

1-7/8

49

2

51

1-7/8

48

1-3/4

44

20-7/8

530

22-1/4

566

24-7/8

633

31-1/2

800

3-1/4

81

4-3/8

111

4-7/8

125

3-1/2

90

3-3/4

95

4-1/4

108

4-5/8

119

4-1/2

114

21-1/2

546

20-3/4

526

21-3/8

544

25-3/8

644

**

31-1/8

791

31-1/2

800

33-1/4

845

38-1/4

973

27-1/4

692

31

788

34-3/4

883

38-1/2

979

(*) Dimensions W8 and W9 refer to the washer cabinet only. They do not include any protrusions front of back.

Allow for a minimum 3/4” (19mm) side gap between adjacent washers or other machinery.

To keep the washer from moving, it’s recommended that it be lagged to the floor with 3/8” (10mm) dia screws in the

locations shown.

113586- 4 15

Page 16

11.2 Rigid Washer Mounting Dimensions

GROUP R (Fast spin rigid washing machines)

MODELUnitW1W2W3W4W5W6W7W8

EWR-25

EWR-30

EWR-40

EWR-60

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

19-11/16

500

19-11/16

500

22-1/16

560

24-7/16

620

11-7/8

301

12

305

14-1/2

368

15-1/4

387

5-7/8

149

9-1/8

232

9-1/8

232

11-11/16

300

4-5/16

110

4-5/16

110

4-1/2

114

5-3/16

132

4-3/4

121

6-1/4

158

4-13/16

122

7-7/8

200

2-7/8

73

3-11/16

93

3-1/8

77

3

76

28-1/4

719

28-1/4

719

31

788

34-3/4

884

GROUP S (Standard spin rigid washing machines)

MODELUnitW1W2W3W4W5W6W7W8

EWS-25

EWS-30

EWS-40

EWS-60

EWS-80

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

Inc h

mm

19-11/16

500

19-11/16

500

22-1/16

560

24-7/16

620

27-9/16

700

11-7 /8

301

12

305

14-1/2

368

15-1/4

387

19-5/16

490

5-7/8

149

9-1/8

232

9-1/8

232

11-11 /16

300

11-13/16

300

4-5/16

110

4-5/16

110

4-1/2

114

5-3/16

132

5-1/2

139

4-3/4

121

6-1/4

158

4-13/16

122

5-13/16

147

5-1/2

140

2-7/8

73

3-11/16

93

3-1/8

77

5-1/16

129

5

127

28-1/4

719

28-1/4

719

31

788

34-3/4

884

38-1/2

979

25-3/8

644

31

788

31-1/2

799

38

963

25-3/8

644

31

788

31-1/2

799

38

963

41-5/8

1057

(*) Dimensions W7 and W8 refer to the washer cabinet only. They do not include any protrusions front of back.

Allow for a minimum 3/4” (19mm) side gap between adjacent washers or other machinery.

16 113586-4

Page 17

Forces transmitted by the washing machine

11.3 Group (H) Washers

EWH-25 EWH-30 EWH-40 EWH-60

Static floor load (Kn - lb) 2.08 - 467 2.49 - 560 3.41 - 767 4.92 - 1107

Dinamic floor load (Kn - lb) 0.75 - 169 1.05 - 236 1.40 - 315 1.75 - 393

Maximum vertical load (Kn - lb) 2.83 - 636 3.54 - 796 4.81 - 1082 6.67 - 1465

Dynamic load frequency (Hz) 16.67 16.67 15.83 15.00

G factor 450 450 450 350

Group (R) Washers

EWR-25 EWR-30 EWR-40 EWR-60

Static floor load (Kn - lb) 2.08 - 467 2.36 - 531 2.77 - 622 3.96 - 891

Dinamic floor load (Kn - lb) 5.0 - 1124 6.0 - 1349 8.0 - 1798 10.0 - 2248

Maximum vertical load (Kn - lb) 7.08 - 1592 8.36 - 1880 10.77 - 2420 13.96 - 3139

Dynamic load frequency (Hz) 12.67 12.67 12.00 11.50

G factor 200 200 200 200

Min. Anchorage Points* 4444

Min. Concrete Thk. (mm - in) 150 - 6 150 - 6 200 - 8 200 - 8

Group (S) Washers

EWS-25 EWS-30 EWS-40 EWS-60 EWS-80

Static floor load (Kn - lb) 2.00 - 450 2.31 - 518 2.63 - 591 3.53 - 794 4.59 - 1032

Dinamic floor load (Kn - lb) 3.00 - 674 4.00 - 899 5.00 - 1124 6.00 - 1349 8.00 - 1798

Maximum vertical load (Kn - lb) 5.00 - 1124 6.31 - 1417 7.63 - 1715 9.53 - 2143 12.59 - 2831

Dynamic load frequency (Hz) 8.93 8.93 8.42 8.02 7.58

G factor 100 100 100 100 100

Min. Anchorage Points* 44444

Min. Concrete Thk. (mm - in)** 100 - 4 100 - 4 150 - 6 150 - 6 200 - 8

* The (2) anchorage points at the front must be used, (2) of the (4) anchorage points at the back must be used.

The (2) furthest to the back are preferred.

** Increasing the number of anchor points does not reduce the required concrete thickness.

WARNING! Soft and rigid mount washing machines must not be installed on non-foundation floors without

authorization from a technician familiar with the structure and resistance of the building.

Please check the weight of the machine plus the dynamic forces generated during spinning. The

manufacturer does not accept responsibility for any damage due to vibration in this type of installation.

WARNING! RIGID MACHINES MUST BE ANCHORED TO THE FLOOR. Correct construction of the anchorage

to the floor is essential to ensure the correct working of the appliance and to prevent serious damage to

the structure of the machine.

113586- 4 17

Page 18

11.4 Using a Steel Base

75 mm

F

G

F + 120 mm

Installation on a Steel Base

The steel base structure must be able to withstand the static and dynamic loads of the washer floor (see “Transmitted

Forces” chart on the previous page). The base must also allow the washer to be seated in a perfectly level manner.

Bases specifically designed for this washer are available from ADC.

11.5 Using an Elevated Concrete Pad

Installation on an Elevated Concrete Pad

Use this method if the existing floor is thinner than the

minimum in the mounting chart, or if the washer is to be

positioned above the existing floor level. The minimum height

of the elevated pad will be 4”–8” (100–200 mm) depending

on the washer model (see “Dimensions” illustration to the

right).

1. Break up and remove the existing floor down to a depth

of approx. 3” (75 mm) (see “Floor Removal” illustration

below). The hole should flare out at the bottom so that

it is about 5” (120 mm) wider at the bottom than the top.

Dimension F = W1 + 400mm, G = W2+W3+400mm

(see the “Rigid Washer Mounting Dimensions” chart).

2. Wet the complete hole and spread over with cement.

3. To increase the load-bearing capacity and reduce

possible concrete deformations, we recommend

inserting an armature into the base of the pad. For

adequate connection of the new pad with the existing

floor, insert one or more reinforcing bars.

NOTE: When inserting the reinforcing bar(s), take into

consideration the locations (and space requirements) for

drilling holes. These holes will be used for the chemical or

expansion anchor bolts.

NOTE: If casting anchor bolts into the pad, be sure to set

the bolts so that the front face of the washer is flush with the

face of the pad.

4. Pour concrete into the prepared base. Level the surface

carefully into a horizontal plane.

5. Let the concrete harden for at least two days before

installation of the washer. Wait one week before

operating the washer with a full load.

4” - 8”

(100 - 200 mm)

Dimensions

➤

➤

➤

Floor Removal

75 mm

G +120 mm

➤

➤

➤

(50 mm)

➤

➤

G+120mm

2”

➤

18 113586-4

Page 19

Installation of the rigid washer-extractor without anchorage base

11.5.1 Using Expansion Bolts

Before anchoring the machine to the floor, make sure that its minimum resistance is equal or higher than 3500 psi

(25N/mm2).

First mark the locations of the mounting holes using the dimensions specified in the “Rigid Washing Machines” chart.

Next drill the mounting holes. Follow the manufacturing installation instructions, but the holes must be at least 4

inches (100mm) deep. The holes must not go all the way through the floor. Clean the holes with compressed air.

Place the washer-extractor in position over the holes, then insert the expansion bolts in the holes. Be sure to use

5/8-11 (M16) expansion bolts, and that they protrude above the surface by 2 inches (50mm). Once in place, tighten

the bolts until the machine is securely fastened.

11.5.2 Using J-bolts

Before anchoring the machine to the floor, make sure that its minimum resistance is equal or higher than 3500 psi

(25N/mm2).

First mark the locations of the mounting holes using the dimensions specified in the “Rigid Washing Machines” chart.

Next make holes to a depth, at minimum, equal to 4 inch (100mm). Make the holes big enough to insert the J-bolt and

clean using compressed air. Insert the J-bolt s in the holes and secure using a suitable anchoring compound, ensuring

that the bolt protrudes above the surface by 2-1/2 inches (60mm). Be sure to use 5/8-11 (M16) J-bolts.

Place the washer-extractor in position above the bolts, and gradually tighten the nuts one after another until the

machine is securely fastened.

Check the condition of the J-bolts one week after installation.

113586-4 19

Page 20

12. INSTALLATION OF SELF-SERVICE WASHING MACHINES (GROUP H-R-S)

Card kit

Coin kit

Washers are delivered in the configuration ordered, and are ready for installation. Self service options are listed

below. The washer can be converted to anyone of these option. Conversion kits are available from your dealer.

12.1 Central Pay

Self-service machines with this configuration are ready for connection to a pay center. The pay center receives an

electrical signal from the washing machine informing of its availability and, at the same time, the washing machine

receives the signal that the correct money has been inserted and the programme may be run. The price and currency

settings are external to the washing machine and can therefore not be programmed. Please see the user manual for

details on the use of this self-service configuration.

12.2 Card Reader

The card reader operates in almost the same way as the central pay machine, prices and currency are programmed

on the card reader. Please see the user manual for details on the use of this self-service configuration.

12.3 Coin

On coin washers, the currency and price settings for each wash cycle are internal to the washer. Please see the user

manual for instructions on the use of this self-service configuration.

¡WARNING! The installation of the different self-service kits involves working with electrical components.

Switch off the machine before any work.

Work carried out by personnel not belonging to the authorised Technical Service will result in the loss of

warranty coverage.

20 113586-4

Page 21

13. WASHING MACHINE INSTALLATION AND MAINTENANCE

WASHING MACHINE INSTALLATION CHECKLIST

MODEL 25,30,40,60,80

Unpack removing the bag and corner pieces

Check that the specification plates correspond with the order

POSITIONING

INSTALLATION

Ensure that the floor withstands the weight and maximum force transmitted by the machine

Fit out the machine location so that it is levelled and the necessary distances are observed for maintenance

It is advisable that the floor is not slippery

Remove the transport anchors

Fixing all (Group H) washing machines to the floor is recommended

Fixing all (Group R&S) washing machines to the floor is mandatory

Flush water circuits prior to making the connectio ns

Install water hoses (a filter is required in the cold water inlet)

Ensure that the water pressure at the machine inlet is from 2 to 4 bars

STEAM machines: - installing Teflon joints on both ends of the hose is compulsory

- installing a filter in the steam electrovalve inlet is compulsory

- always open the steam cock gradually and not suddenly

- retighten the steam hose nuts

Installing a 300 mA differential switch between the wiring and the mains is recommended

Connect the mains supply. Compare mains voltage and machine voltage (observe specification plate)

Before turning the line breaker on measure voltage between phases and phase-neutral

It is advisable for the voltage between neutral and earth be equal to zero

Connect drainage pipe. Important: ensure the correct inclination for full water disposal

GENERAL

DAILY

WEEKLY

THREE-MONTHLY

WASHING MACHINE PREVENTIVE MAINTENANCE

Leaving the door open when the washing machine is not running is recommended

Put in the correct load (complete) and select the appropriate programme

At the end of the shift, clean the door seal with a damp cloth and turn the machine off

Clean the water inlet filters

Clean the detergent tray compartments so that there are no blockages

Clean the outside of the machine with a damp cloth

Clean converter ventilation filter and motor fan grille

Check belt tension

113586- 4 21

Page 22

Part No. 113586 4 - 02/01/17

Loading...

Loading...