Page 1

HCB J Precious Metals and Density

Balance

(P.N. 308660002 Revision D1, June 2013)

Adam Equipment

Software 4.2 and above

© Adam Equipment Company 2013

Page 2

© Adam Equipment Company 2013

Page 3

CONTENTS

1.0 INTRODUCTION .......................................................................................................2

2.0 SET UP......................................................................................................................2

2.1 HCB J123, SETTING UP YOUR BALANCE.........................................................2

2.2 HCB J302, J1002 and J2002 SETTING UP YOUR BALANCE ............................6

2.3 PREPARING FOR USE........................................................................................10

2.4 KEYPAD / DISPLAY FUNCTION..........................................................................12

2.5 REAR PANEL.......................................................................................................13

2.6 INTERNAL RECHARGEABLE BATTERY............................................................13

3.0 LOCATING AND PROTECTING YOUR BALANCE.................................................14

4.0 BASIC OPERATION................................................................................................15

4.1 TURNING ON THE BALANCE.............................................................................15

4.2 ZEROING / TARE.................................................................................................15

4.3 WEIGHING...........................................................................................................15

4.4 WEIGHING UNITS ...............................................................................................15

5.0 DENSITY FUNCTION..............................................................................................16

5.1 WEIGHING A SAMPLE........................................................................................16

5.2 DISPLAY DENSITY..............................................................................................17

6.0 DENSITY PARAMETERS........................................................................................19

6.1 SELECTING THE ALLOY TO TEST.....................................................................19

6.2 TEST OPTIONS ...................................................................................................19

6.3 LIQUID AND TEMPERATURE PARAMETERS...................................................19

6.4 ALLOY PARAMETERS ........................................................................................20

7.0 PARAMETERS........................................................................................................23

7.1 ENABLING WEIGHING UNITS, F1 Unt.................................................................24

7.2 HOLD FUNCTION, F2 Hld .....................................................................................26

7.3 BACKLIGHT, F3 bL................................................................................................27

7.4 PRINTING PARAMETERS, F4 Ser .......................................................................27

7.5 AUTO POWER OFF, F5 OFF..................................................................................29

7.6 INTERNAL OR EXTERNAL CALIBRATION, F6 ICE ..............................................29

7.7 ADJUST THE VALUE OF THE INTERNAL MASS, F7 CA ......................................30

7.8 USER TECHNICAL PARAMETERS, F8 SEt ..........................................................31

8.0 USER CALIBRATION..............................................................................................32

9.0 SERIAL INTERFACE SPECIFICATIONS................................................................34

10.0

REMOTE DISPLAY..............................................................................................36

11.0

TEMPERATURE SENSOR ..................................................................................36

12.0

TROUBLE SHOOTING.........................................................................................37

12.1 ERROR MESSAGES ........................................................................................37

12.2 REPLACEMENT PARTS AND ACCESSORIES ...............................................38

13.0

SPECIFICATIONS................................................................................................39

13.1 TECHNICAL SPECIFICATIONS .......................................................................39

13.2 COMMON SPECIFICATIONS...........................................................................39

14.0

WARRANTY INFORMATION...............................................................................40

1

© Adam Equipment Company 2013

Page 4

1.0 INTRODUCTION

Thank you for purchasing your new HCB J Precious Metals and Density Balance. As

with our popular HighlandTM series of balances the HCB J has all the features you

really need: DC adapter with internal rechargeable battery, HandiCalTM calibration,

backlit display, and ShockProtectTM with overload indicator. With the RS-232

interface for communication with printers and computers, splash-proof keypad, and

sturdy plastic construction, the HCB J will be a balance you can rely upon. We hope

that you enjoy using your new balance.

2.0 SET

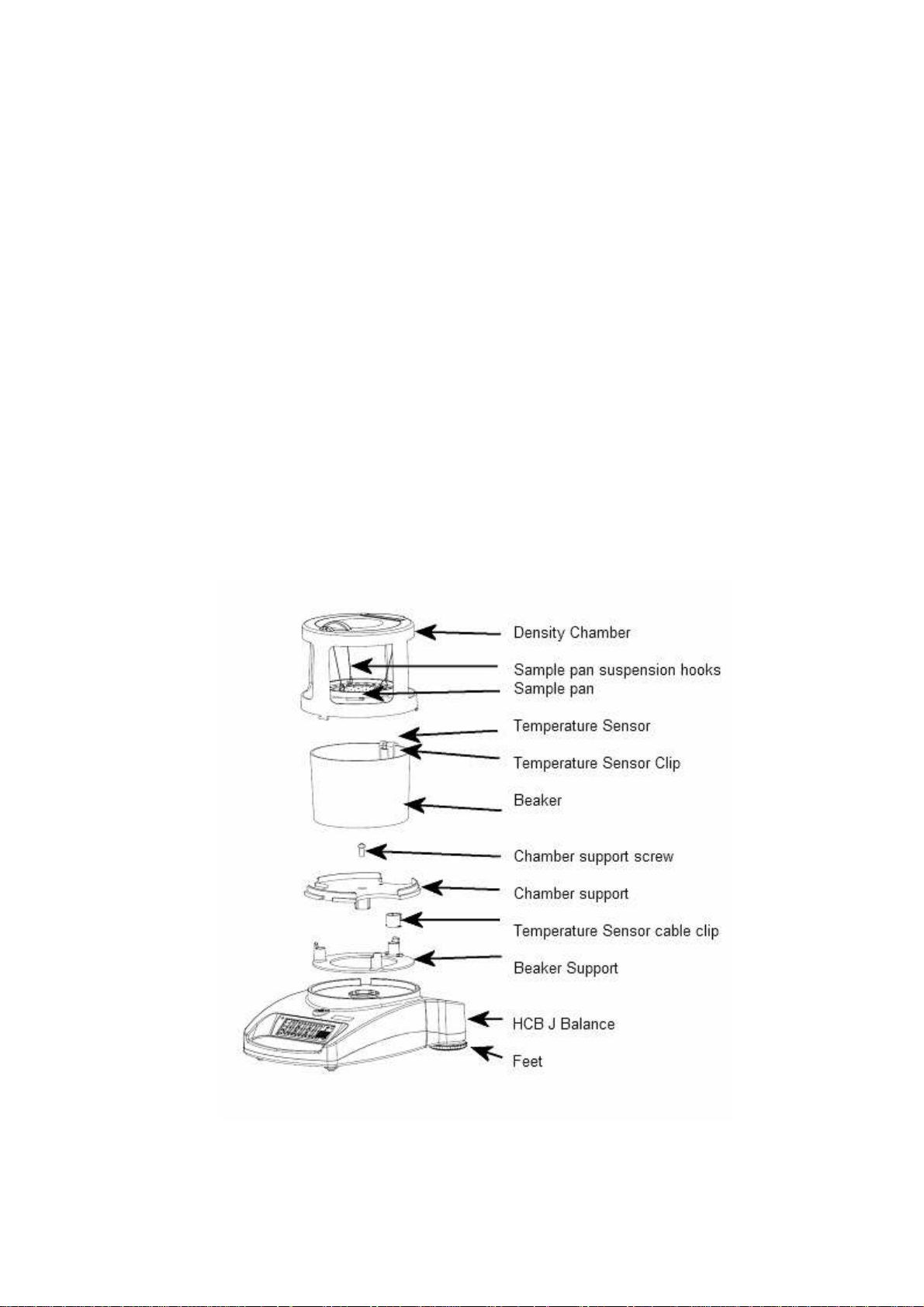

2.1 HCB

UP

J123,

SETTING UP YOUR BALANCE

1) Remove the balance and all accessories from the packaging

2

© Adam Equipment Company 2013

Page 5

2) Remove the shipping protection screw and transit disc from the top of the

balance

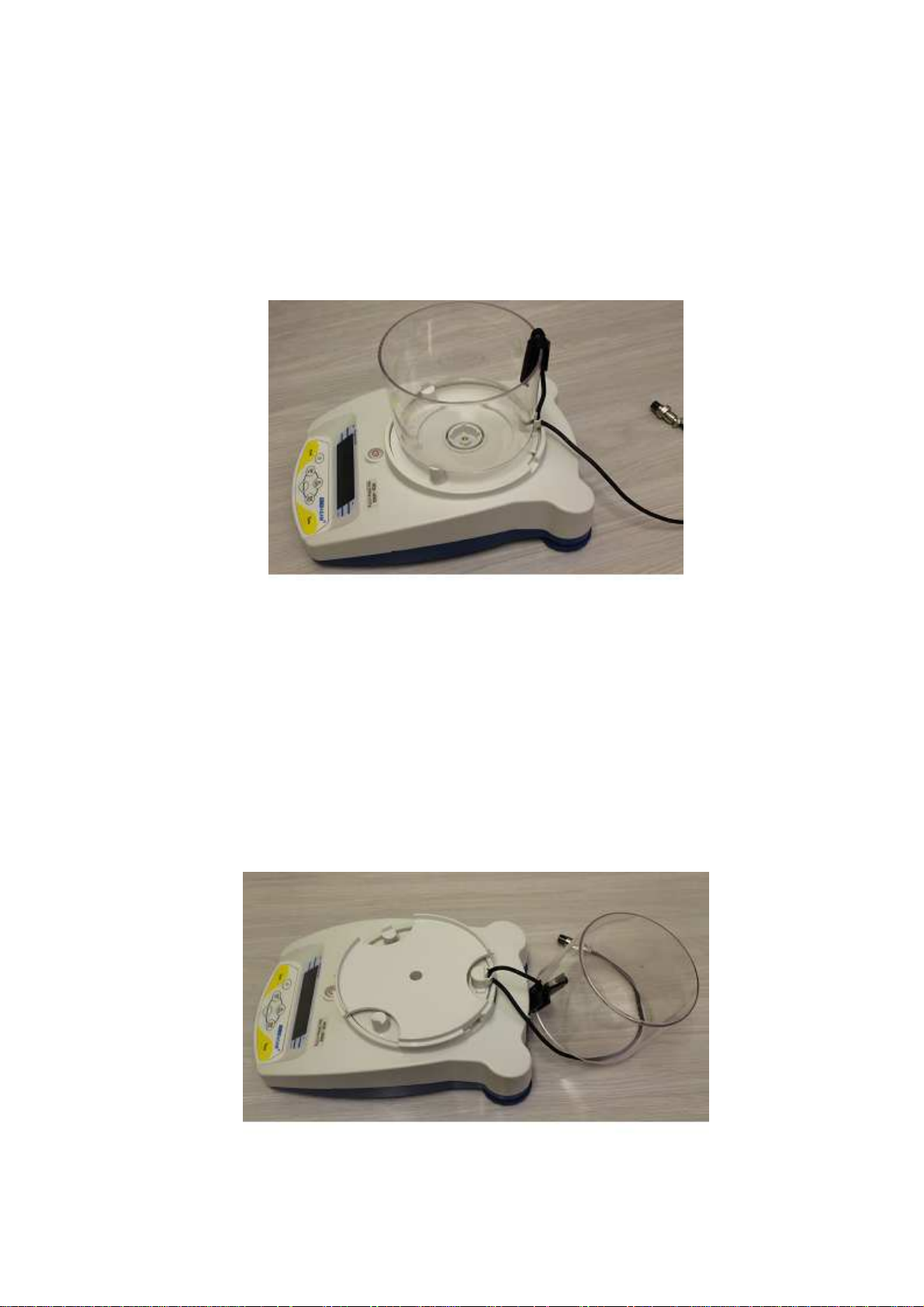

3) Place the Beaker Support assembly onto the top housing with the

Temperature Sensor cable running down the back of the balance.

4) Lift the beaker away to the rear and locate the Density Chamber support into

the receptacle with the arrow facing the rear of the balance. Press gently to

insert it then secure the support in the center using the M4 x 20mm screw

which is packed in the accessory bag. Tighten only enough to secure the pan

support so that it does not rock in the receptacle.

3

© Adam Equipment Company 2013

Page 6

5) Replace the beaker onto the beaker support and pull the Temperature Sensor

cable through the clip to take up any slack or loose amount of cable.

6) Place the Density Chamber over the beaker with the handle of the lid at the

front and allowing for the sample pan to hang freely inside it. Secure the

Chamber to the support by rotating it gently clockwise and locking into the 3

tabs. Take care not to push down or use excessive force on the Chamber

when fixing as damage can be caused.

4

© Adam Equipment Company 2013

Page 7

7) Plug the Temperature sensor into the 5 pin connector, and the remote

Indicator into the 6 pin connector at the rear of the balance.

8) Make sure again that the cable from the Temperature Sensor is tightly pulled

down through the clip and that it does not interfere or sit close to the Density

Chamber or Chamber support. If the cable is touching against any of these

parts it will result in incorrect weighing and karat calculations.

Position the balance and Remote Indicator in a convenient place and adjust the

feet to show a level state.

Switch on the balance whilst using battery power or connect the adaptor to the

mains supply.

5

© Adam Equipment Company 2013

Page 8

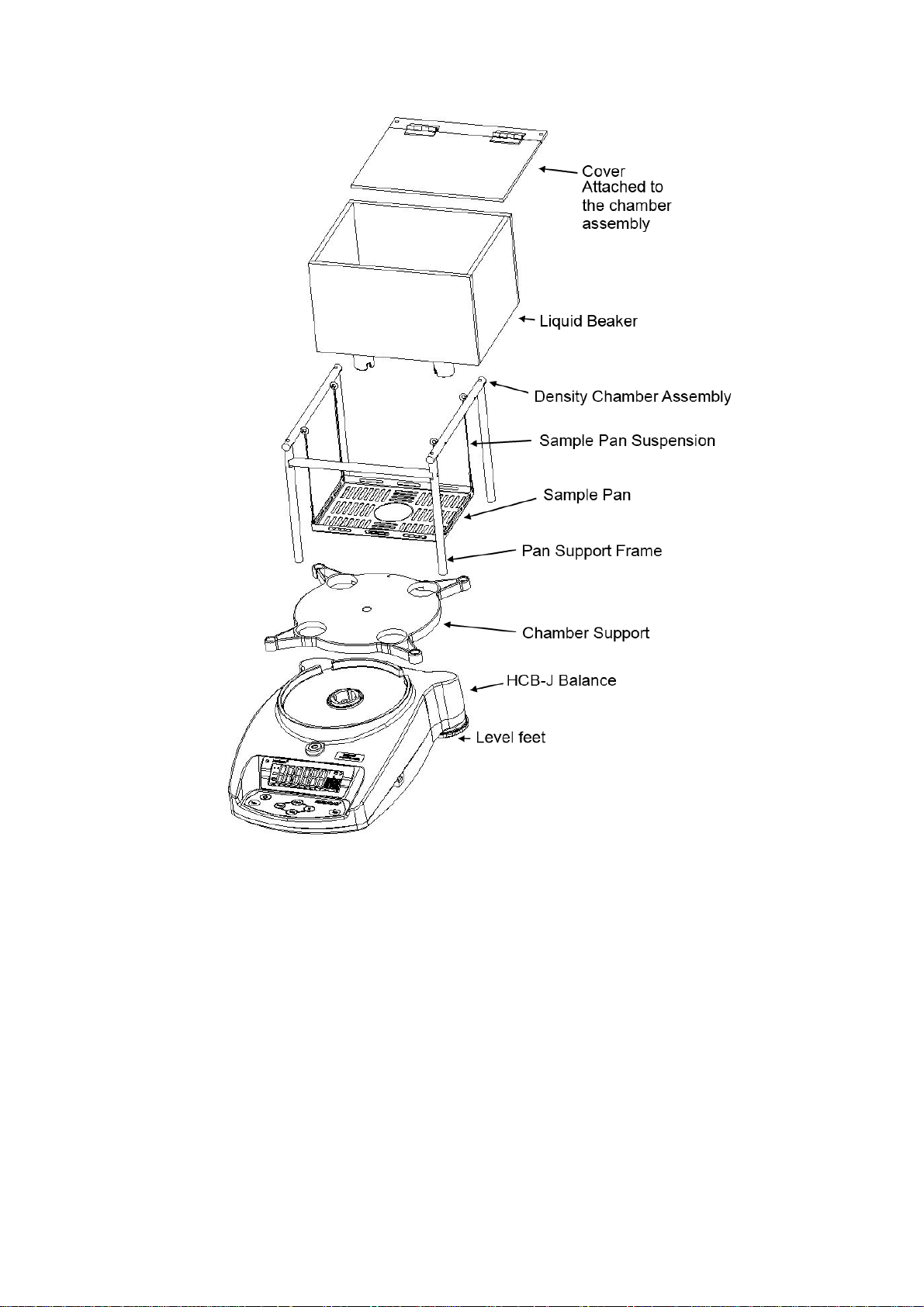

2.2 HCB

J302, J1002

AND

J2002 SETTING UP YOUR BALANCE

1) Remove the balance and all accessories from the packaging

2) The following items are included:

HCB J balance body

Power Supply

Weighing Chamber Assembly that includes

Sample Pan with suspension wires

Chamber Cover

Chamber Support

Liquid Beaker

Temperature Sensor

Temperature Sensor Clip

Remote Display

1ea M3 x 20 hex screw for Chamber Support Mounting

6

© Adam Equipment Company 2013

Page 9

7

© Adam Equipment Company 2013

Page 10

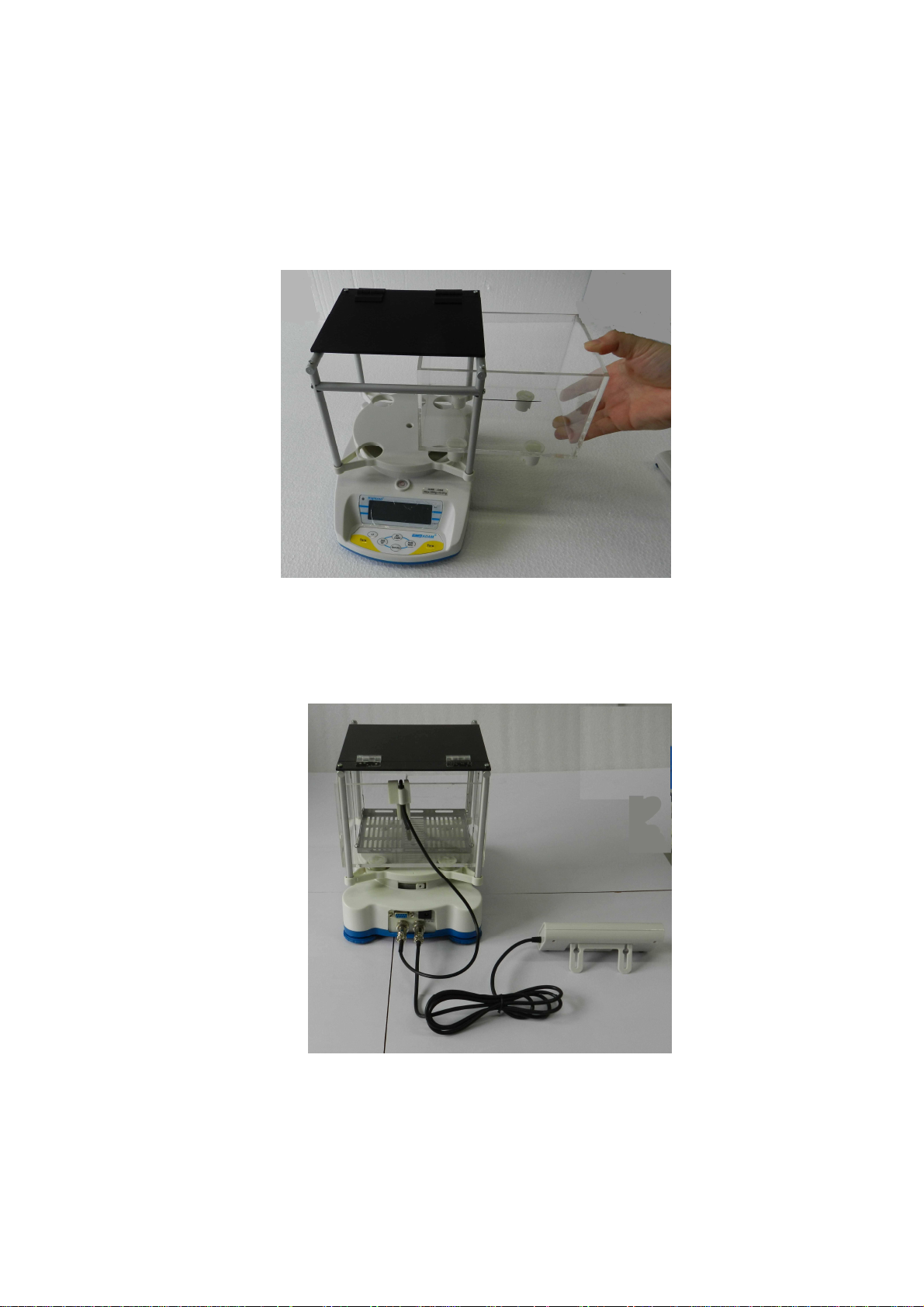

3) Remove the shipping protection screw and transit disc from the top of the

balance.

4) Place the Chamber Support assembly onto the top housing. Press gently to

insert it then secure the support in the center using the M4 x 20mm screw

which is packed in the accessory bag. Tighten only enough to secure the pan

support so that it does not rock in the receptacle.

8

© Adam Equipment Company 2013

Page 11

5) Place the liquid chamber onto the support. Ensure the line marking the water

level is to the front.

6) Place the temperature sensor onto the rear panel of the chamber. Pull the

Temperature Sensor cable through the clip to take up any slack or loose

amount of cable.

9

© Adam Equipment Company 2013

Page 12

7) Position the sample pan in the beaker area and connect the 4 suspension

wires to the rings in the support frame.

8) Plug the Temperature sensor into the 5 pin connector, and the remote

Indicator into the 6 pin connector at the rear of the balance.

9) Make sure again that the cable from the Temperature Sensor is tightly pulled

down through the clip and that it does not interfere or sit close to the Density

Chamber or Chamber support. If the cable is touching against any of these

parts it will result in incorrect weighing and karat calculations.

2.3 PREPARING

FOR USE

Position the balance and Remote Indicator in a convenient place and adjust the

feet to show a level state.

Switch on the balance whilst using battery power or connect the adaptor to the

mains supply.

10

© Adam Equipment Company 2013

Page 13

When you are preparing to do a Density Test it will be necessary to fill the

chamber with liquid. The choice of the type of liquid will be left for the user to

decide, however some solvents may not be compatible with the Polycarbonate of

the chamber or ABS of the Sample Pan. Test a small sample of the liquid on the

plastics before filling the beaker if unsure.

Fill the chamber with liquid lift the Chamber lid, or remove the Density Chamber

from its support and pour through a funneled container. The beaker should be

filled no higher than the maximum filling mark and needs to cover the metal part

of the Temperature Sensor cable. If the Chamber is removed refit the Chamber

once finished as described earlier. Care should be taken to not spill any liquid

onto or inside the balance as damage may occur which is not covered under the

normal warranty terms.

To fill the chamber whilst it is away from the balance it will be necessary to

remove the Temperature Sensor and clip from the chamber which then allows it

to be removed from the support. The cable will need to be pulled gently upwards

from below the Temperature Sensor clip to allow easy removal of the clip. When

re-fitting the Temperature Sensor and clip follow the previous instructions

ensuring the cable is pulled down into a tight position and lifted away from the

Chamber.

If water is used a few drops of liquid detergent may be added to the water to

improve the wetting ability and avoid trapped bubbles of air on the sample being

tested. Stir well to distribute the soap evenly.

When removing samples from the chamber use a towel to dry the samples so

the water does not splash onto the balance.

11

© Adam Equipment Company 2013

Page 14

Zero

Stable

Capacity tracker

Weighing digits

Low battery indicator

Hold symbol

Weight in Air

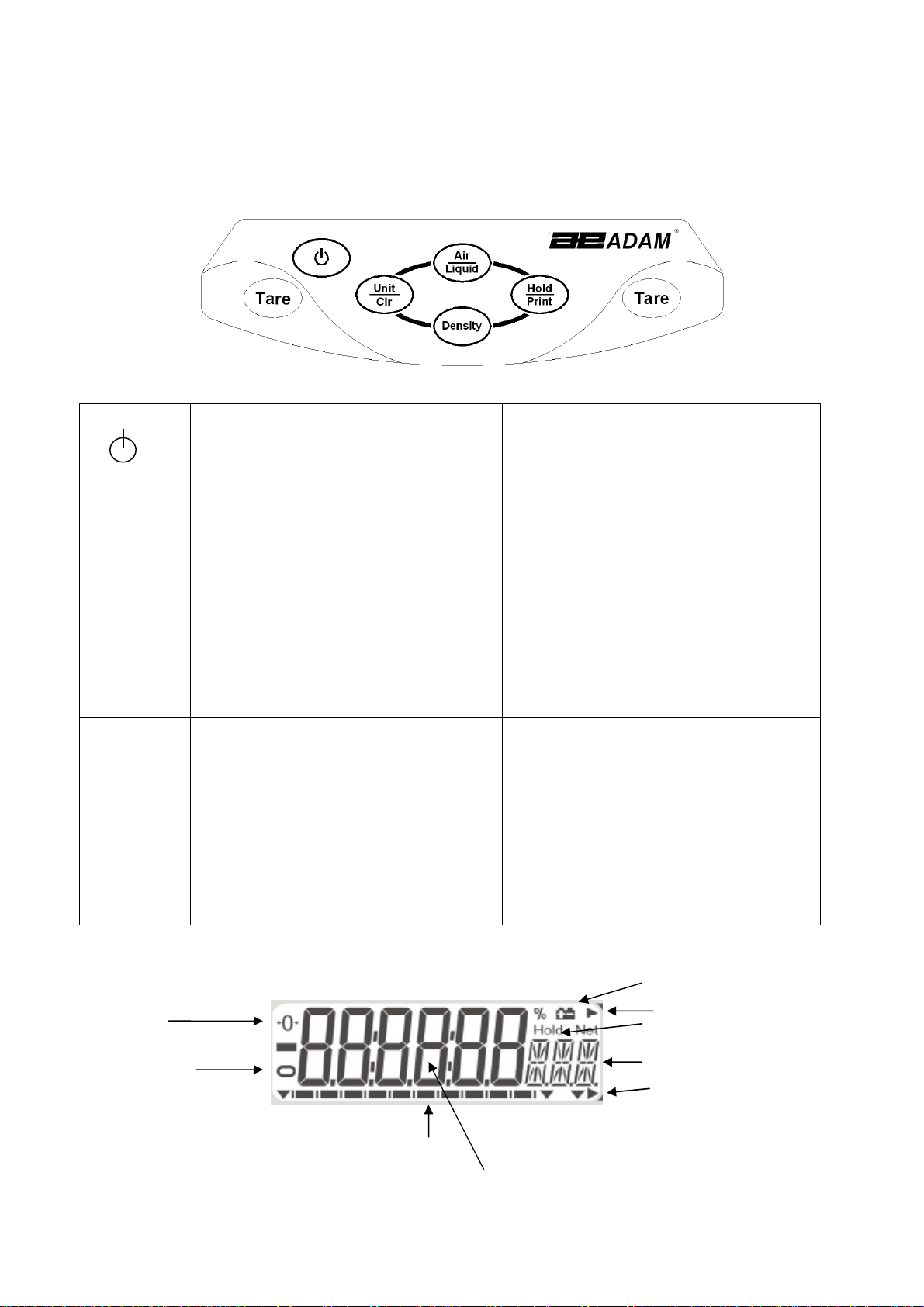

2.4 KEYPAD

/

DISPLAY FUNCTION

The keypad and display have a number of features as shown and explained below:

KEYS PRIMARY FUNCTION SECONDARY FUNCTION

To turn the balance On or Off. ----

[On/Off]

[Tare]

[Hold/Print] Will set the current weight to be held

[Unit/Clr] Pressing this key will cycle through the

[Density] Pressing after the weights in the air

[Air/Liquid] Stores the current weight into the

Tares the balance and shows the net

weight value. Pressing the [Tare] again

will reset another tare value

on the display and will also send the

current weight data to the RS232

interface. When displaying the results

of the density test pressing

[Hold/Print] will send the results to

the interface.

weighing units which are enabled

and in the liquid have been stored will

show the density and karat results.

memory for density determination.

A secondary function of "Enter" is for

setting parameters or other functions.

When setting some parameters this key

will move the flashing digit to the right.

When in density mode pressing the

[Unit/Clr] will return the display to

normal weighing mode.

Whilst setting parameters it will show

the previous option, or decrease the

value of the flashing digit.

Whilst setting parameters it will show

the next option, or increase the value

of the flashing digit.

Alpha numeric display

Weight in Liquid

12

© Adam Equipment Company 2013

Page 15

2.5 REAR

PANEL

The rear panel has connectors for the power, RS232, remote display and

temperature sensor. For connections to these see the relevant sections.

2.6 INTERNAL

RECHARGEABLE BATTERY

The balance can be operated from the internal rechargeable battery or using an

adapter. The battery life is approximately 24 hours with the backlight off. Depending

on the usage of the backlight the lifetime of the battery will reduce and using the

remote display will lessen the battery life considerably.

The display will show an indication when the battery needs to be charged. To charge

the battery plug the adapter into the POWER socket at the back of the balance and

connect it to the mains power supply. The charging indicator at the left top corner of

the LCD will be on to show it is charging and will turn green when the battery is fully

charged.

13

© Adam Equipment Company 2013

Page 16

3.0 LOCATING

AND PROTECTING YOUR BALANCE

In order to keep your balance functioning at its best we suggest that you do the

following:

Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

Make sure the balance is located on a strong table

and free from vibration.

Avoid unstable power sources. Do not use near large

users of electricity such as welding equipment or

large motors. Do not let the balance battery go flat.

If you are not using it for a long time you should

charge the battery periodically to make sure the

battery does not lose its charge.

Keep free from vibration. Do not place near heavy or

vibrating machinery.

Avoid high humidity that might cause condensation.

Keep away from direct contact with water. Do not

spray or immerse the balance in water.

Do not place near open windows, air-conditioning

vents or fans that may cause a draft and unstable

readings.

Keep the balance clean. Do not stack material on the

balance / balance pan when it is not in use.

14

© Adam Equipment Company 2013

Page 17

4.0 BASIC

4.1 TURNING

OPERATION

ON

THE BALANCE

Plug in the unit using the adapter or use the internal rechargeable battery. It is

recommended that you charge the battery for at least 8 hours before first use.

1) To turn on press the [On/Off] key once and release. The balance will show the

software revision and the battery voltage then self-test before showing the

current temperature as measured or defined by the user. The balance will

show the stable sign and zero weight on the display and is now ready to use.

2) To turn the balance off after use press the [On/Off] key again. There is an

auto power-off function that will automatically turn the unit off if not used for

a period of time; this can be set in the parameters section.

4.2 ZEROING

/

TARE

You can press the [Tare] key to set a new zero point and show a zero reading. This

may be necessary if the weight reading is not indicating zero with nothing on the

pan. The zero indicator will show up in the upper left corner of the LCD.

If you are using a container whilst weighing then you can place this on the weighing

pan and press the [Tare] key. Providing the container weight is more than 4% of the

maximum capacity of the balance the display will show a zero reading and NET will

light up on the display. You can then weigh your sample in the container. Taring a

container will reduce the maximum weighing capacity available of the balance.

4.3 WEIGHING

To determine the weight of a sample place the sample in the container. The display

will show the weight of the sample and the unit of weight currently in use. The

stable indicator will light up when the reading is stable.

4.4 WEIGHING

UNITS

To change the weighing units press [Unit/Clr] which will cycle through the options of

units that are enabled. See Parameters 7.1 Enabling Weighing Units to enable or

disable the weighing units.

15

© Adam Equipment Company 2013

Page 18

5.0 DENSITY

FUNCTION

Once the HCB J is prepared for a density test and the parameters have been set for

doing the Density Determination (see section 6) the following procedure is used to

weigh the sample in air, and then again in water or another liquid, allowing you to

determine the density of the sample and if applicable a determination of the purity

(karat) of the gold in the sample.

The Hold function must be enabled (see section 7.2) for the Density function to

operate correctly. The Density parameters (see Section 6.0) should be checked

before doing a test as the results are dependent on the liquid and alloy settings.

NOTE: To perform a density only test set the parameters for density test (Section 6)

to Silver (Ag), Set Hold to Automatic (Hd Au), Select water for the liquid (H2O) and

automatic temperature detection (Auto tmP). Then when doing the density test only

the density of the sample will be displayed.

5.1 WEIGHING

A

SAMPLE

Place the sample to be weighed in air on top of the lid of the Density Chamber and

allow the weight displayed to become stable. If the Hold function is set to manual

press the [Hold/Print] key. The capacity tracker at the bottom of the display will

move from right to left and when ready the display will show “HOLD”. If the Hold

function is set to automatic you are not required to press the [Hold/Print] key once

the weighing in air becomes stable.

After the Hold symbol is shown press the [Air/Liquid] key to store this value. Wait

for the Weight in Air indicator to be displayed before you proceed to the next step.

Remove the sample and ensure the balance returns to zero. If necessary press the

[Tare] key to zero the display.

Open the lid of the Density Chamber and carefully place the sample in the liquid on

the suspended pan. It may be helpful to shake the sample gently to dislodge any air

bubbles.

Close the lid of the Density chamber and allow the weight displayed to become

stable. If the Hold function is set to manual press the [Hold/Print] key. The capacity

tracker at the bottom of the display will move from right to left and when ready the

16

© Adam Equipment Company 2013

Page 19

display will show “HOLD”. If the Hold function is set to automatic you are not

required to press the [Hold/Print] key once the weighing in liquid becomes stable.

After the Hold symbol is shown press the [Air/Liquid] key to store this value. The

Weight in Liquid indicator will be shown at which point the sample can be removed.

If when weighing in air the weighing unit starts to flash a message of “ADD”, this

informs you that the weight of the sample may not be enough to give accurate

calculations and therefore it is recommended that a larger sample weight is used.

At this point the USER can add more weight to the lid until the flashing stops which

signifies that the minimum sample weight required has been met.

Once the flashing stops remove the sample from the lid of the chamber, press the

[Unit/Clr] key and make sure the display shows zero, place the sample back onto

the lid to start the process again.

Minimum sample weights are as follows:

HCB J123 – 2g

HCB J302 – 2g

HCB J1002 – 5g

HCB J2002 – 10g

* Please note that if extra weight is not added to meet the minimum sample weight

requirements when the message “ADD” is being displayed, the balance will continue

to calculate based on the sample weight at that time.

5.2 DISPLAY

DENSITY

Press the [Density] key to display the density of the sample, ie- “14.2 den”

Press the [Density] key a second time to display the Karat value for the sample. For

example if gold with silver is selected the display would show “ 14

for other display options the display might show “ 14

KCu

” for gold with copper, “ 14

KAg

”. Like wise

K11

” for gold with silver and copper in a 1:1 ratio, “ 14

and “ 14

K o

” for other density of alloys that might be used. See section 6.2 for

KMn

” for a ratio other than 1:1

details of setting the alloy options.

Press the [Density] key a third time to display the content of gold determined during

the test, ie- “583 Cnt”. If the density value is outside of the expected range (see

17

© Adam Equipment Company 2013

Page 20

table below), the karat value and content value will not be displayed. An error

message will be shown. Only the density value will be available.

To return to normal weighing press the [Unit/Clr] key. To run another test ensure

all weight is removed from the pan support in the water and from the Density

Chamber.

Gold Density values used for Karat determination for silver and copper alloys.

GOLD

KARAT

7K 292/1000 12.14(12.01-12.27) 10.60(10.46-10.73) 11.32(11.18-11.45)

8K 333/1000 12.42(12.28-12.55) 10.89(10.74-11.03) 11.60(11.46-11.74)

9K 375/1000 12.70(12.56-12.84) 11.19(11.04-11.34) 11.90(11.75-12.04)

10K 417/1000 13.00(12.85-13.14) 11.51(11.35-11.67) 12.21(12.05-12.36)

11K 458/1000 13.31(13.15-13.46) 11.85(11.68-12.02) 12.54(12.37-12.70)

12K 500/1000 13.64(13.47-13.80) 12.22(12.04-12.40) 12.89(12.71-13.06)

13K 542/1000 13.98(13.81-14.15) 12.61(12.41-12.80) 13.26(13.07-13.44)

14K 584/1000 14.34(14.16-14.52) 13.02(12.81-13.22) 13.65(13.45-13.84)

15K 625/1000 14.72(14.53-14.91) 13.46(13.23-13.68) 14.06(13.85-14.27)

16K 667/1000 15.12(14.92-15.32) 13.93(13.69-14.16) 14.50(14.28-14.72)

17K 708/1000 15.54(15.33-15.75) 14.43(14.17-14.69) 14.97(14.73-15.20)

18K 750/1000 15.99(15.76-16.21) 14.98(14.70-15.25) 15.47(15.21-15.72)

19K 792/1000 16.46(16.22-16.70) 15.56(15.26-15.86) 16.00(15.73-16.27)

20K 834/1000 16.97(16.71-17.22) 16.19(15.87-16.51) 16.57(16.28-16.86)

21K 875/1000 17.50(17.23-17.77) 16.88(16.52-17.23) 17.18(16.87-17.49)

22K 917/1000 18.07(17.78-18.36) 17.63(17.24-18.01) 17.84(17.50-18.18)

23K 958/1000 18.68(18.37-19.16) 18.44(18.02-19.09) 18.55(18.19-19.12)

24K 1000/1000 19.32(19.17-19.48) 19.32(19.10-19.54) 19.32(19.13-19.51)

Typical

CONTENT

SILVER(Ag) COPPER(Cu) Ag:Cu=1:1

Platinum Density Values used for determination of Platinum purity

Pt Content

1000 1000/1000(975-1025)

950 950/1000(925-975) 20.04(19.40-20.72) 20.64(20.26-21.04) 20.34(19.82-20.88)

900 900/1000(875-925) 18.8(18.24-19.40) 19.88(19.54-20.26) 19.33(18.87-19.82)

850 850/1000(825-875) 17.71(17.21-18.24) 19.18(18.86-19.54) 18.42(18.00-18.87)

800 800/1000(775-825) 16.73(16.29-17.21) 18.53(18.24-18.86) 17.6(17.21-18.00)

750 750/1000(725-775) 15.86(15.46-16.29) 17.92(17.65-18.24) 16.84(16.48-17.21)

700 700/1000(675-725) 15.08(14.71-15.46) 17.37(17.10-17.65) 16.14(15.82-16.48)

650 650/1000(625-675) 14.37(14.03-14.71) 16.83(16.58-17.10) 15.5(15.20-15.82)

600 600/1000(575-625) 13.72(13.42-14.03) 16.33(16.09-16.58) 14.91(14.63-15.20)

550 550/1000(525-5750 13.13(12.85-13.42) 15.86(15.63-16.09) 14.37(14.11-14.63)

500 500/1000(475-525) 12.58(12.33-12.85) 15.41(15.20-15.63) 13.86(13.62-14.11)

Nickel(Ni) Palladium(Pa) Ni:Pa=1:1

18

© Adam Equipment Company 2013

Page 21

6.0 DENSITY

PARAMETERS

To use the density function it is necessary to set parameters describing the liquid

used and the alloy being tested. These parameters can be set when the balance is in

the normal weighing mode.

6.1 SELECTING

THE ALLOY TO TEST

The HCB J allows the alloy to be tested to be selected by the user. Select either Gold

(Au), Platinum (Pt), Silver (Ag) or disable the alloy selection and show the weight

only.

When displaying the weight press the [Air/Liquid] key to select the alloy to be

tested. The display will show the last alloy selected i.e. “ ON Au”

Select a new alloy by pressing the [Air/Liquid] or [Density] key to show “On Au” for

gold, “ON Pt” for Platinum, “ON Ag” for silver or “ON WEI” to display the weight

only.

Press the [Unit/CLR] key to return to weighing with the alloy selected active.

6.2 TEST

OPTIONS

During normal weighing with the display showing zero weight, press the [Density]

key. If the display does not change to show Liquid check the parameter for the Hold

Function (section 7.2). If it has been set to off “Hd Off”, density is disabled and this

section will not operate. Set to Hold On, “Hd On”, or Hold Automatic, “Hd AU”, to

enable the density function.

The display will show Liquid to identify the section for setting parameters associated

with the liquid used.

Press [Tare] to enter this section or press [Air/Liquid] to view the Alloy parameters.

When Alloy is displayed press [Tare] to enter this section or press [Air/Liquid] to

return to the Liquid parameters.

6.3 LIQUID

AND TEMPERATURE PARAMETERS

The parameters available are water (H2O) and any other user definable liquid. If

water is used and selected the next parameter will ask to determine the

19

© Adam Equipment Company 2013

Page 22

temperature of the water, selections are either using the automatic temperature

sensor or to manually input the temperature.

If another liquid is used then the user must set the density of that liquid.

The display will show Liquid, Press [Tare] to enter this section.

Press [Air/Liquid] or [Density] to select H2O or Define den. Press [Tare] to select the

setting or press [Unit/Clr] to return to the Liquid display.

If H2O is selected the display will show the current setting for the temperature

determination, either Auto tmp, or Set tmp.

Press [Air/Liquid] or [Density] to select the option, then press [Tare] to store the

selection.

If Auto tmp is selected the display will show the current temperature measured by

the external temperature probe. Press [Tare] to accept the value and return to

Liquid.

If Set tmp was selected the display will show the temperature last set by the user i.e.

24 °C tmp . To change the current setting press the [Air/Liquid] or [Density] key to

increase or decrease the value. Press [Tare] when the correct value is shown.

The display will return to show Liquid. Press [Unit/Clr] to return to weighing or press

[air/Liquid] or [Density] to change the display to set the Alloy parameters.

If Define den was selected for setting the density of another liquid press [Tare] and

the display will show the current valued stored. Enter the value for the density of

the liquid you are using (in g/cc3) by using the [air/Liquid] or [Density] keys to

change the value of the flashing digit on the display, and the [Hold/Print] key to

change the flashing digit position. Press [Tare] when the correct value is shown.

The display will return to show Liquid. Press [Unit/Clr] to return to weighing or press

[air/Liquid] or [Density] to change the display to set the Alloy parameters.

6.4 ALLOY

PARAMETERS

If Gold (Au) has been selected for the alloy to test the balance will compute the

density based on the weight values recorded. The value for purity (karats) and

content will be computed depending on the alloy selected by the user. The alloy

20

© Adam Equipment Company 2013

Page 23

options are Silver (Ag), Copper (Cu), Silver: Copper in a 1:1 ratio (AG:CU 1-1), Silver:

Copper in a user settable ratio (Ag:Cu: M-N) or a user defined density (Define den).

When the display shows Alloy, press the [Tare] key to enter this section.

The display will show the current setting for the alloy as above.

Press the [air/Liquid] or [Density] key to change the display to another setting, then

press [Tare] to select the setting.

When the sample is gold mixed with an alloy the user needs to select the option that

describes the alloy used. If the alloy is Silver (Ag), Copper (Cu) or Silver plus Copper

in a 1:1 ratio (AG:CU 1-1) select the option shown and press [Tare] to store the

selection. The display will return to show Alloy. Press [Unit/Clr] to return to

weighing or select the Liquid setting as above.

If the alloys are in another known ratio of Silver to Copper (Ag:Cu: M-N), or the alloy

is another metal of known density (Define den) then following pressing [Tare] the

display will show the current value stored for each option. To set the ratio or density

use the [Air/Liquid] or [Density] keys to change the flashing digit, and the

[Hold/Print] key to move the flashing digit to the right. Once the value is set, press

the [Tare] key to store the value. The display will return to show Alloy. Press

[Unit/Clr] to return to weighing whereupon you are now ready to proceed as

section 5 to perform density testing.

If Platinum (Pt) has been selected for the alloy to test the balance will compute the

density based on the weight values recorded. The value for purity (karats) and

content will be computed depending on the alloy selected by the user. The alloy

options are Nickel (NI), Palladium (PA), Nickel:Palladium in a 1:1 ratio (Ni:PA 1-1),

Nickel:Palladium in a user settable ratio (Ni:PA M-N) or a user defined density (Define

den).

When the display shows Alloy, press the [Tare] key to enter this section.

The display will show the current setting for the alloy as above.

Press the [Air/Liquid] or [Density] key to change the display to another setting, then

press [Tare] to select the setting.

21

© Adam Equipment Company 2013

Page 24

When the sample is Platinum mixed with an alloy the user needs to select the option

that describes the alloy used. If the alloy is Nickel (Ni), Palladium (PA) or Nickel plus

Palladium in a 1:1 ratio (Ni:PA 1-1) select the option shown and press [Tare] to store

the selection. The display will return to show Alloy. Press [Unit/Clr] to return to

weighing or select the Liquid setting as above.

If the alloys are in another known ratio of Nickel plus Palladium (Ni:PA M-N), or the

alloy is another metal of known density (Define den) then following pressing [Tare]

the display will show the current value stored for each option. To set the ratio or

density use the [Air/Liquid] or [Density] keys to change the flashing digit, and the

[Hold/Print] key to move the flashing digit to the right. Once the value is set, press

the [Tare] key to store the value. The display will return to show Alloy. Press

[Unit/Clr] to return to weighing whereupon you are now ready to proceed as

section 5 to perform density testing.

If Silver (Ag) has been selected for the alloy to test the balance will compute the

density based on the weight values recorded. There are no options for setting the

composition of the silver, only the density will be shown.

22

© Adam Equipment Company 2013

Page 25

7.0 PARAMETERS

The balance has 8 parameters that can be set by the user.

FUNCTION SECTION DESCRIPTION

F1 Unt

F2 HLd

F3 bL

F4 SEr

F5 OFF

See section 7.1 Sets the units to be used

g, ct, GN, dwt, oZt, Oz, Lb, MM, t, tLH, tLS, tLT, tLJ

See section 7.2 Sets the operation of the Hold function

On HD: Manual hold the weight whit the [Hold/Print] key

Auto HD: Weight held automatically when stable

OFF HD: Hold function Off, Density function disabled

See section 7.3 Sets the backlight

on BL

AU BL

oFF BL:

See section 7.4 Sets the print parameters

See section 7.5 Sets the auto power-off parameter

: backlight always on

: backlight automatically turns on when a weight is

placed on the pan or a key is pressed

backlight always off

F6 ICE

F7 CA

F8 SEt

tECH

See section 7.6 Selects Internal or external calibration mode

See section 7.7 Calibration mass value fine adjustment

See section 7.8 User Parameters for auto zero, filter and stability

Technical parameters setting mode / factory setting

23

© Adam Equipment Company 2013

Page 26

7.1 ENABLING

WEIGHING UNITS,

F1

F1 UUUU

F1F1

NNNNTTTT

You can enable and disable the weighing units available to the user when they press

the [Unit/Clr] key as described in section 4.4 Weighing Units.

1) Switch on the balance then press and hold the [Unit/Clr] key during the self-

checking test of the display.

2) After a few seconds, the display will show the first function F1 Unt.

3) When F1 Unt is displayed you can press the [Unit/Clr] key to return to normal

weighing or press [Air/Liquid] to go to the next function.

4) When F1 Unt is displayed you can press the [Tare] key to view the current

setting for the weighing units.

5) Press [Unit/Clr] at any time to return to the parameter heading.

6) Pressing the [Hold/Print] key will cycle through the other units along with

their current settings. For example, if oFF is displayed with the weighing unit

Carats, the user will not be able to use this unit while weighing.

7) Pressing the [Air/Liquid] key will change the setting of a particular unit. For

example, to enable the weighing unit Carats, change the setting to on by

pressing the [Air/Liquid] key.

8) Note that grams will always be enabled.

24

© Adam Equipment Company 2013

Page 27

The following table shows different units which are available to the user and the

conversion factors for each.

Name of the

Units

Grams A standard metric unit 1.0 g

Carats Used for weighing jewelry and gems, etc. 5.0 ct

Grains A basic weighing unit in the imperial

Pennyweight Pennyweight was the weight of a silver

Ounce Troy Troy ounce- used for weighing gold, silver

Ounce Avoirdupois ounce.

Pounds Standard weighing unit in UK/USA. 0.0022046 Lb

Mommes A weighing unit used in Japan to weigh

Tola An Asian weighing unit 0.085735 t

Description Conversion

Factor

15.43236 GN

system. Used to weigh gun powder.

0.6430149 dwt

penny in medieval England. Equals to 1/20th

of an Ounce Troy.

0.03215075 oZt

and in pharmacy.

0.035274 oZ

16 ounces make a pound.

0.266667 MM

pearls.

Display

Symbol

Taels Hk Hong Kong Taels 0.026717 tL H

Taels S Singapore Taels 0.026455 tL S

Taels T Taiwan Taels 0.026667 tL T

Taels J Japan Taels 0.026659 tL J

After setting the units to on or off, press [Unit/Clr] or [Tare] to return to the

function menu.

25

© Adam Equipment Company 2013

Page 28

7.2

HOLD FUNCTION,

F2

F2

F2F2

HHHH

LLLLDDDD

The hold function may be set to automatic, manual or off by the user. If the hold

function is disabled the density function will not work. If it is set to auto the balance

will hold the weight display when it becomes stable. If it is set to manual the user

must press the [Hold/Print] key to set the hold function.

AU Hd

Off Hd

On Hd

Sets the hold function to operate automatically when a weight is

stable.

Sets the hold function to off. The Density function will not

operate. The [Hold/Print] key will function only as a print key.

Sets the hold function to be on when the user presses the

[Hold/Print] key.

1) Switch on the balance then press and hold the [Unit/Clr] key during the self-

checking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Press the [Air/Liquid] key to select F2 Hld .

4) Press the [Tare] key to view the current setting for the hold function.

5) To change the setting press the [Air/Liquid] key to scroll through and select a

new setting as shown above.

6) Press [Tare] to confirm and move to the next setting.

7) When F3 bL is displayed press the [Tare] key to enter the parameter, the

[Unit/Clr] key to return to weighing, or press [Air/Liquid] to go to the next

function.

26

© Adam Equipment Company 2013

Page 29

7.3 BACKLIGHT,

F3

F3

F3F3

bbbbLLLL

The backlight may be enabled or disabled by the user. If the backlight is disabled the

battery life will be greater. The following settings are available:

AU bL

On bL

Off bL

Sets the backlight to operate automatically when a weight is

placed on the balance or a key is pressed.

Sets the backlight to be on at all times.

Sets the backlight to be off at all times.

1) Switch on the balance then press and hold the [Unit/Clr] key during the selfchecking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Press the [Air/Liquid] key to select F3 bL .

3) Press the [Tare] key to view the current settings for the backlight.

4) To change the setting press the [Air/Liquid] key to scroll through and select a

new setting as shown above.

5) Press [Tare] to confirm and move to the next setting.

6) When F4 Ser is displayed press the [Tare] key to enter the parameter, the

[Unit/Clr] key to return to weighing, or press [Air/Liquid] to go to the next

function.

7.4 PRINTING

PARAMETERS,

F4

F4

F4F4

SSSSeeeerrrr

1) Switch on the balance then press and hold the [Unit/Clr] key during the self-

checking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Keep pressing the [Air/Liquid] key until F4 SEr is displayed.

4) Press the [Tare] key to view the current setting.

27

© Adam Equipment Company 2013

Page 30

5) The following options are available for setting the serial output functions:

Mode Print Feature

Auto Mod

Set Mod

After density is tested it will automatically send data for

the test results to the printer as shown in section 9.

After density is tested and during the time the results

are displayed press [Hold/Print] to send the data to the

printer. This allows the user to print only when they are

ready. Pressing [Hold/Print] a second time will send the

data again.

Press the [Air/Liquid] key to change the setting. Press [Tare] to confirm and

move to the next setting.

6) Setting the baud rate. This is the transmission speed for communication with

printers and computers. The selected rate must match that of the other

device for communications to work.

The following settings are available:

2400 bPS

4800 bPS

9600 bPS

7) Press the [Air/Liquid] key to change the setting.

7) Press [Tare] to confirm and move to the next setting.

8) When F5 oFF is displayed press the [Tare] key to enter the parameter, the

[Unit/Clr] key to return to weighing, or press [Air/Liquid] to go to the next

function.

*Please see section 9 for more printing details

28

© Adam Equipment Company 2013

Page 31

7.5 AUTO

POWER OFF,

F5

F5

F5F5

OF

OFFFFF

OFOF

The auto power off function helps conserve power by automatically turning the

balance off when it is not in use. The Auto power off time can be set by the user in

minutes, or to not be in operation (OFF).

1) Switch on the balance then press and hold the [Unit/Clr] key during the self-

checking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Keep pressing the [Air/Liquid] key until F5 OFF is displayed.

4) Press the [Tare] key to view the current setting.

5) Press [Air/Liquid] to change the setting to (Off, 5, 10, 20 or 30 minutes).

6) Press [Tare] to confirm and move to the next setting.

7) When F5 oFF is displayed press the [Tare] key to enter the parameter, the

[Unit/Clr] key to return to weighing, or press [Air/Liquid] to go to the next

function.

7.6 INTERNAL

OR

EXTERNAL CALIBRATION,

F6

F6

F6F6

IIIICE

CE

CECE

You can select to use the internal mass or an external mass to calibrate the balance.

1) Switch on the balance then press and hold the [Unit/Clr] key during the self-

checking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Keep pressing the [Air/Liquid] key until F6 ICE is displayed.

4) Press the [Tare] key to view the current setting.

5) To change the setting press the [Air/Liquid] key to select either Int

CAL

(internal calibration) or Etl

CAL

(external calibration).

6) Press [Tare] to confirm and move to the next setting.

7) When F7 CA is displayed press the [Tare] key to enter the parameter, the

[Unit/Clr] key to return to weighing, or press [Air/Liquid] to go to the next

function.

29

© Adam Equipment Company 2013

Page 32

7.7 ADJUST

THE VALUE OF THE INTERNAL MASS,

F7

F7

F7F7

CCCCAAAA

The internal mass value stored in memory can be adjusted if required.

1) Switch on the balance then press and hold the [Unit/Clr] key during the self-

checking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Press the [Air/Liquid] key until F7 CA is displayed.

4) Press the [Tare] key to view the current setting.

5) The display will show the current value with the first digit

flashing. To change the flashing digit position press the

[Hold/Print] key. Press the [Air/Liquid] key to increase the value

or the [Density] key to decrease the value. The internal

calibration weight should only change between 95.00 and 105.00 grams or

495.00 and 505.00 grams (depending upon the model).

6) Press [Tare] to confirm and move to the next setting.

7) When F8 SEt is displayed press the [Tare] key to enter the parameter, the

[Unit/Clr] key to return to weighing, or press [Air/Liquid] to go to the next

function.

*Changing the value of the internal mass will affect the weighing readings following

an internal calibration. To check if your internal mass value is correct you should

only use high quality weights that are accurate to the readability of the balance.

30

© Adam Equipment Company 2013

Page 33

7.8 USER

TECHNICAL PARAMETERS,

F8

F8

F8F8

SSSSEt

Et

EtEt

The balance has a number of technical parameters the user can adjust.

Display Description Default Value

Filter settings - 1 to 3

n FIL

1 FIL

1 will allow the display to update at it’s fastest

The Automatic Re zero range - 1 to 7

n ZEO

4 ZEO

1 is the minimum A/Z range and 7 is the maximum

Stability symbol range - 1 to 6

n STA

2 STA

1 is the smallest stability range and 6 is the largest.

1) Switch on the balance then press and hold the [Unit/Clr] key during the selfchecking test of the display.

2) After a few seconds, the display will show the first function F1 UNT.

3) Keep pressing the [Air/Liquid] key until F8 SET is displayed.

4) Press the [Tare] key to view the current setting.

5) To change the settings press the [Air/Liquid] key. Press the [Tare] key to store

the setting and advance to the next parameter. When complete the display will

show the TECH parameter.

The display will now show TECH. This parameter is for qualified technicians only and

requires entry via a pass code. Press the [Unit/Clr] key to return to weighing or

press [Air/Liquid] to go to the first function again.

31

© Adam Equipment Company 2013

Page 34

8.0 USER

CALIBRATION

The Highland series of balances comes standard with HandiCalTM internal calibration

to make calibrating the balance quick and easy. However you can also calibrate the

balance using an external verification weight if needed. The HandiCal method is the

default but if you would like to use external calibration then you must first enable

this via the parameter (section 7.6 Selecting the Internal or External Calibration).

Install the handle for the calibration as shown below. To calibrate the balance the

handle is pushed to the side which will lower the calibration mass.

Internal Calibration using HandiCal

1) Press and hold the [Air/Liquid] and [Density] keys at the same time and

power on the balance.

2) Release both keys when the display shows unload.

3) Remove any weight from the pan assembly and press the [Tare] key when the

stable sign is shown.

4) The display will show C Int. Press the [Tare

]

key and the display will show

LoAd.

5) Move the handle fully across as shown above which will lower the internal

calibration mass onto the pan assembly inside the balance. Press the [Tare]

key once the stable sign is shown.

6) The display will show PASS if the calibration is successful. Move the handle

back to its original position and the display will show zero.

32

© Adam Equipment Company 2013

Page 35

External Calibration

1) Press and hold the [Air/Liquid] and [Density] keys at the same time and

power on the balance.

2) Release both keys when the display shows unload.

3) Remove any weight from the pan assembly and press the [Tare] key when the

stable sign is shown.

4) The display will show an acceptable mass that can be used to calibrate the

unit. You can change this value by pressing the [Air/Liquid] key to match the

calibration mass you may have.

5) The calibration masses that can be used are as follows:

Model # HCB J123 HCB J302 HCB J1002 HCB J2002

Weight 1 50g 100g 500g 500g

Weight 2 70g 200g 700g 1000g

Weight 3 100g 300g 1000g 2000g

6) Once the calibration weight has been selected press the [Tare] key

7) The display shows LoAd. Place your weight on the pan. Press the [Tare] key

after the stable sign is shown.

8) The display will show PASS if the calibration is successful.

9) Remove the weight and the display will show zero.

NOTE: If the calibration fails try doing the calibration again. The calibration must

agree with the factory calibration within ±5%.

The balance will show FAllllL H (when the weight is higher) or FAllllL L (when the weight

is lower). Repeat the process using the correct calibration weight.

33

© Adam Equipment Company 2013

Page 36

<cr><lf>

9.0 SERIAL

INTERFACE SPECIFICATIONS

The balance comes equipped with an RS-232 Serial Interface.

The connector is a DE-9P female fitting with the following connections.

Pin 2 TXD Transmitted data

Pin 3 RXD Received data

Pin 5 GND Signal ground

Data Format for the printout is described below. All lines end with a carriage return

<cr> and a line feed <lf>, (0dH and 0aH in ASCII).

Format Output:

The lines will include a heading for each line then the value. A typical output when

weighing is shown below. 8 lines of data are printed including one blank line at the

end.

Sample WT(air) : 54.00 g <cr><lf>

Sample WT(liquid): 50.00 g <cr><lf>

Liquid Density : 0.997 g/cm3<cr><lf>

Sample Volume : 4.010 cm3 <cr><lf>

Sample Density : 13.463 g/cm3<cr><lf>

Content : 626 / 1000 <cr><lf>

Sample Karat : 15 K Cu <cr><lf>

<cr><lf>

<cr><lf>

Note: the Karat unit should reflect the setting of the Alloy parameters, K Ag, K Cu, K

1:1, K m-n or Ko Def.

If the density is of a value that does not allow the karat value to be determined the

printout should have blank values for content and karat. For example

Sample WT(air) : 58.99 g <cr><lf>

Sample WT(liquid): 50.01 g <cr><lf>

Liquid Density : 0.997 g/cm3<cr><lf>

Sample Volume : 9.004 cm3 <cr><lf>

Sample Density : 6.551 g/cm3<cr><lf>

Content : <cr><lf>

Sample Karat : <cr><lf>

<cr><lf>

34

© Adam Equipment Company 2013

Page 37

+

1

.00 g <cr><lf>

Format for simple weight only output:

Input command format:

The balance can be controlled with the following commands. The commands must

be sent in upper case letters, i.e. “T” not “t”.

T<cr><lf> Will do a combined Zero /Tare function the same as pressing the [Tare] key.

P<cr><lf>

A<cr><lf> When the weight is Held on the display this command will store the weight in

U<cr><lf> Acts in the same way the [Unit/Clr] key does. To change the weighing unit to

D<cr><lf> Acts in the same way the [Density] key does. When viewing results from a

Will perform the same functions as pressing the [Hold/Print] key.

During a density test the P command will hold the weight, allowing the

A<cr><lf> command to be used to store the value. Will print the results at

the end of the density test.

If sent whilst displaying the density results it will cause the density report to

be printed as above.

If the Hold Function (F2 HLD) is Off the command will only print the weight

readings.

memory for either weight in air or weight in liquid, the same as if the

[Air/Liquid] key is pressed.

the next available unit during normal weighing, or to return to normal

weighing if the balance is in the density section.

density test it will change to the next displayed value.

35

© Adam Equipment Company 2013

Page 38

10.0 REMOTE

DISPLAY

The remote display plugs into the 6 pin circular connector on the rear of the

balance.

Turn the balance off.

Insert the connector from the remote display into the circular connector on the rear

of the balance.

Turn the balance on. The remote display will now display the same information as

the balance display.

NOTE: Using the remote display will use more of the battery power. It is suggested

that you should use the power supply whilst using the remote display.

11.0 TEMPERATURE

SENSOR

During the density test if the balance has been set to use the auto temperature

sensor it must be plugged into the balance.

Turn the balance off.

Plug the temperature sensor into the 5 pin circular connector on the rear of the

balance.

Turn the balance back on and the sensor will now work automatically. If the sensor

becomes unplugged the display will show (0 °C au) during the power on sequence if

the automatic temperature sensor was selected in section 6.1. The balance can still

be used by setting the temperature manually as described in section 6.1. In this case

the balance after turning the power on will show the last value manually entered.

36

© Adam Equipment Company 2013

Page 39

12.0 TROUBLE

12.1 ERROR

SHOOTING

MESSAGES

If an error message is shown, repeat the step that caused the message. If the error

message is still shown then contact your dealer for support.

ERROR

CODE

Err 4

Err 5

Err 6

Err 9

Red Light

on front

panel

No Power when

DESCRIPTION POSSIBLE CAUSES

Initial Zero is

greater than

allowed (4% of

maximum capacity)

when power is

turned on)

Keyboard Error. Improper operation of the

A/D count is not

correct when

turning the balance

on.

A/D count is not

stable when

turning the balance

on.

Low Battery

indicator.

Unstable – balance

cannot get a stable

reading.

Low Battery

indicator.

turning on.

Weight on the pan when turning

on.

Internal calibration weight is in

the lowered position.

Damaged load cell.

Damaged Electronics.

balance.

Load cell damaged.

Electronics damaged.

Load cell damage.

Something touching the pan.

Air movement, vibration or

instability.

Internal battery may be flat. Charge or replace the internal

Possible damage to the

mechanics / Load cell.

Internal battery may be flat. Charge or replace the internal

Internal battery may be flat. Charge or replace the internal

SOLUTIONS

Remove the transit screw make

sure the pan is fitted correctly.

Make sure the calibration

weight is in the correct position.

Remove any weight from the

stainless steel pan.

Try recalibrating.

Turn the balance off and back

on again.

Remove any weight from the

stainless steel pan and turn the

balance off and back on again.

Try calibrating the balance.

There may be movement,

vibration or dirt on the balance

during turning on. Make sure

there is nothing touching the

pan. Make sure the internal

weight is in the up position.

Make sure the balance is level.

Try recalibrating.

rechargeable battery.

Make sure the balance is on a

flat surface and away from

vibration. Make sure the

calibration weight is in its off

position.

rechargeable battery.

rechargeable battery.

37

© Adam Equipment Company 2013

Page 40

12.2 REPLACEMENT

PARTS AND ACCESSORIES

If you need to order any spare parts and accessories contact your supplier or Adam

Equipment. A partial list of the more common items follows:

Part Number Description

3.01.4.0.11014 RS-232 to PC cable

7.00.0.0.0012 Thermal Printer

1.12.0.0.11156 ATP Printer

6.00.0.0.2028 AdamDU (Data Collection Software)

3.02.4.0.9160 AC adapter USA plug 12VDC 800mA

3.02.4.0.9156 AC adapter UK plug 12VDC 800mA

3.02.4.0.9157 AC adapter Euro plug 12VDC 800mA

3.02.4.0.9158 AC adapter SA plug 12VDC 800mA

3.02.4.0.9159 AC adapter Australian plug 12VDC 800mA

3.08.0.0.2043 Beaker

3.08.1.2.2045 Beaker Support

3.08.1.2.2046 Density Chamber

3.08.1.2.2047 Sample Pan

3.08.1.2.2048 Sample Pan Suspension Hook

3.08.0.0.2044 Temperature Sensor

3.08.1.2.2049 Temperature Sensor Support

3.08.1.2.2050 Density Chamber support

3.08.0.0.2045 Temperature Sensor Cable Clip

3.08.1.2.2044 HandiCalTM calibration handle

3.09.4.0.9012 Battery, 6V/1.3ah

38

© Adam Equipment Company 2013

Page 41

13.0 SPECIFICATIONS

13.1 TECHNICAL

SPECIFICATIONS

Model # HCB J123 HCB J302 HCB J1002 HCB J2002

Maximum Capacity 120g 300g 1000g 2000g

Readability 0.001g 0.01g 0.01 g 0.01 g

Repeatability (s.d.) 0.002g 0.01g 0.02 g 0.02 g

Linearity ± 0.003g 0.02g 0.03 g 0.03 g

Special pan assembly for Density Determination

Pan

Units of Measure g, ct, GN, dwt, oZt, Oz, Lb, MM, t, tLH, tLS, tLT, tLJ

132mm / 5.2”

diameter

160 x 165mm / 6.3” x 6.5”

13.2 COMMON

SPECIFICATIONS

Communication Interface RS-232

Stabilisation Time 2 Seconds typical

Operating Temperature 0°C to 40°C / 32°F to 104°F

Power supply (external) 12VDC 800 mA

Calibration HandiCal Internal calibration or external calibration - User selectable

Display 18mm high 6 digit LCD

Auto backlight and capacity tracker

Balance Housing ABS Plastic with Density Determination accessories

Overall Dim’s. HCB J123

(w x d x h). HCB J303/2002

Net Weight. HCB J123

HCB J303/2002

165 x 252 x 190mm / 6.5” x 9.9” x 7.5” inc Density Chamber

175 x 252 x 232mm / 6.9” x 9.9” x 9.1” inc Density Chamber

Min, 1.8 kg / 3.9 lb inc Density Chamber and Remote Indicator

Max, 2.6 kg / 5.7 lb inc Density Chamber and Remote Indicator

39

© Adam Equipment Company 2013

Page 42

14.0 WARRANTY INFORMATION

Adam Equipment offers Limited Warranty (Parts and Labour) for the components failed due to defects

in materials or workmanship. Warranty starts from the date of delivery.

During the warranty period, should any repairs be necessary, the purchaser must inform its supplier or

Adam Equipment Company. The company or its authorised Technician reserves the right to repair or

replace the components at any of its workshops depending on the severity of the problems. However,

any freight involved in sending the faulty units or parts to the service centre should be borne by the

purchaser.

The warranty will cease to operate if the equipment is not returned in the original packaging and with

correct documentation for a claim to be processed. All claims are at the sole discretion of Adam

Equipment.

This warranty does not cover equipment where defects or poor performance is due to misuse,

accidental damage, exposure to radioactive or corrosive materials, negligence, faulty installation,

unauthorised modifications or attempted repair or failure to observe the requirements and

recommendations as given in this User Manual. Additionally rechargeable batteries (where supplied)

are not covered under warranty.

Repairs carried out under the warranty does not extend the warranty period. Components removed

during the warranty repairs become the company property.

The statutory right of the purchaser is not affected by this warranty. The terms of this warranty is

governed by the UK law. For complete details on Warranty Information, see the terms and conditions

of sale available on our web-site.

40

© Adam Equipment Company 2013

Page 43

Manufacturer’s Declaration of Conformity

This product has been manufactured in accordance with the harmonised European standards, following the

provisions of the below stated directives:

Electro Magnetic Compatibility Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Adam Equipment Co.

Maidstone Road, Kingston

Milton Keynes, MK10 0BD

United Kingdom

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. The equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Shielded interconnect cables must be employed with this equipment to insure compliance with the pertinent

RF emission limits governing this device.

Changes or modifications not expressly approved by Adam Equipment could void the user's authority to

operate the equipment.

WEEE COMPLIANCE

Any Electrical or Electronic Equipment (EEE) component or assembly of parts intended to be incorporated into

EEE devices as defined by European Directive 2002/95/EEC must be recycled or disposed using techniques that

do not introduce hazardous substances harmful to our health or the environment as listed in Directive

2002/95/EC or amending legislation. Battery disposal in Landfill Sites is more regulated since July 2002 by

regulation 9 of the Landfill (England and Wales) Regulations 2002 and Hazardous Waste Regulations 2005.

Battery recycling has become topical and the Waste Electrical and Electronic Equipment (WEEE) Regulations

are set to impose targets for recycling.

© Adam Equipment Company 2013

Page 44

ADAM EQUIPMENT

experience in the production and sale of electronic weighing equipment.

Adam products are predominantly designed for the Laboratory, Educational, Health and

Fitness, retail and Industrial Segments. The product range can be described as follows:

-Analytical and Precision Balances

-Compact and Portable Balances

-High Capacity Balances

-Moisture analysers / balances

-Mechanical Scales

-Counting Scales

-Digital Weighing/Check-weighing Scales

-High performance Platform Scales

-Crane scales

is an ISO 9001:2008 certified global company with more than 35 years

- Health and Fitness Scales

-Retail Scales for Price computing

For a complete listing of all Adam products visit our website at www.adamequipment.com

© Copyright by Adam Equipment Co. Ltd. All rights reserved. No part of this publication may be

reprinted or translated in any form or by any means without the prior permission of Adam Equipment.

Adam Equipment reserves the right to make changes to the technology, features, specifications and

design of the equipment without notice.

All information contained within this publication is to the best of our knowledge timely, complete and

accurate when issued. However, we are not responsible for misinterpretations which may result from

the reading of this material.

The latest version of this publication can be found on our Website.

www.adamequipment.com

© Adam Equipment Company 2013

Loading...

Loading...