Page 1

Product Line

The Insider is Belshaw’s distinctive donut frying system that

elimates the need for a standard exhaust hood. With its ability to

operate indoors, the Insider offers unique benefits:

▪ The Insider can be easily moved from one place to another.

The exhaust hood is built-in and there is no exterior ductwork.

▪ Customers in high traffic areas can watch the Insider

frying donuts automatically. The operator has only to mix

batter, fill the Donut Robot

®

hopper and bag donuts from

the Roto-Cooler, a rotating tray that collects the donuts

automatically.

▪ The Insider eliminates the purchase and installation cost of

standard ventilation and fire suppression hoods.

The Insider is designed to attract the interest of passers-by. With

its large window viewing area and attractive appearance the

Insider has great merchandising potential.

The Insider addresses fire prevention, air filtration, and sanitation

requirements. Cabinet and fryers are tested by ETL and listed to

UL-197, UL-710B, CSA C22.2 and NSF-4 standards.

COMPONENTS OF INSIDER DONUT SYSTEM

▪ Insider Clean-Air Cabinet

▪ Donut Robot

- Mark II

- Mark II GP (mini donut model)

- Mark V

- Mark V GP (mini donut model)

▪ EZMelt 18 Melter-Filter.

- The EZMelt can be placed inside the cabinet directly below

the fryer. It will quickly empty, filter and refill the shortening

in the fryer.

▪ Roto-Cooler.

- Rotating tray that collects donuts after frying.

®

Fryer, either:

INSIDER

Clean-Air Cabinet and Frying System

Insider/Mark II • Insider/Mark V

Belshaw Insider

and Roto-Cooler)

(with Donut Robot®

SPEC

INSDR/

03-2013Models

Donut Robot® Mark II / Mark II GP Donut Robot® Mark V / Mark V GP

RELATED INFORMATION

▪ Donut Robot®

▪ EZMelt18

EZ Melt 18 Roto-Cooler

▪ Roto-Cooler

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP

814 44th St NW, Suite 103

Auburn, WA 98001 USA

PART OF ALI GROUP SPA

©Belshaw Adamatic Bakery Group Product specifications may be changed without notice. Current version available at www.belshaw-adamatic.com

CONTACT

800.578.2547 (USA/CANADA)

(+1)206.322.5474 Worldwide

service@belshaw.com

WEB

www.belshaw-adamatic.com

www.belshaw.com

www.adamatic.com

SPEC

INSDR/03-2013

Page 1 of 2

Page 2

Product Line

INSIDER

Clean-Air Cabinet and Frying System

Insider/Mark II • Insider/Mark V

SPEC

INSDR/

03-2013Models

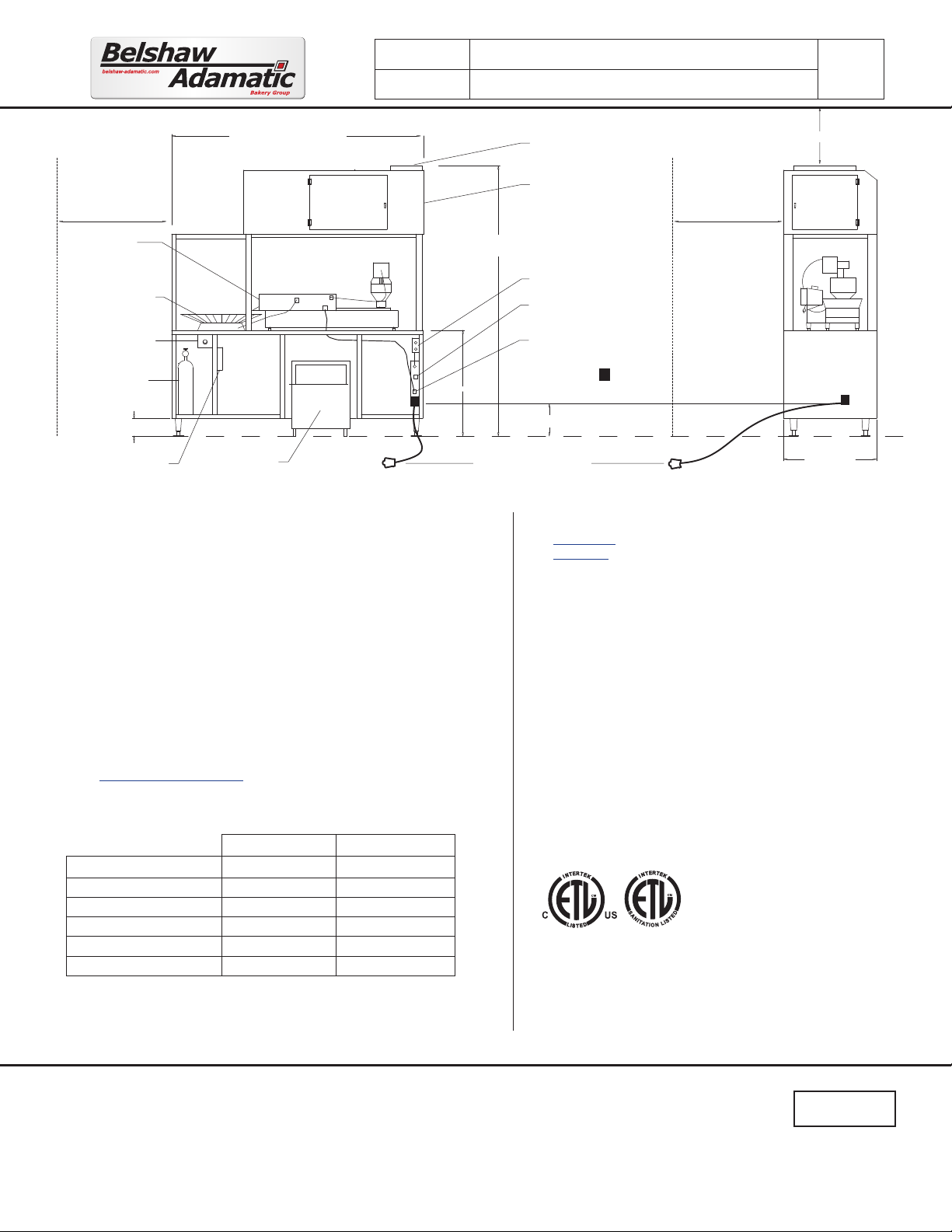

INSIDER/ MARK II: 84" (213 cm)

INSIDER/ MARK V: 96" (244 cm)

DONUT ROBOT

ROTO COOLER

FIRE SUPPRESSION

MANUAL PULL STATION

WET FIRE

SUPPRESSION

CYLINDER

6" (15 cm)

FIRE SUPPRESSION

CONTROL BOX

,

P

EZMELT 18

MELTER FILTER

OVERALL HEIGHT:

35" (89 cm)

PLUG NEMA #14-50 (1-PHASE)

STANDARD FEATURES - INSIDER CABINET

▪ Air recycling system, with fan-assisted grease filter, electronic filter, and odor

filters.

▪ Interlock system to ensure ventilation is active. Fryer is otherwise shut down or

unable to start.

▪ Fire suppression system (Pyro-Chem Kitchen Knight II, PLC-240/300).

Operates automatically, also manually from a pull station.

▪ Stainless steel, plated steel and aluminum construction

▪ Removable clear polycarbonate viewing windows.

▪ Heavy Duty 4" casters (feet optional)

COMPATIBILITY WITH DONUT ROBOT® FRYERS

Insider is compatible only with Donut Robot® Mark II, Mark II GP, Mark V, or Mark

V GP

▪ For standard size donuts, use Donut Robot

®

Mark II or Mark V

▪ For mini donuts, use Donut Robot® Mark II GP or Mark V GP

▪ To make standard size AND mini donuts, use Donut Robot® Mark II or Mark V,

along with Mini Donut Hopper/Plunger Kit, Part #MK-1502-1

▪ See Donut Robot Mark II/Mark V spec sheet for specifications

▪ Insider is not compatible with Donut Robot® Gas Mark II/Mark II GP

DONUT ROBOT® FRYERS – CAPACITY ESTIMATES

Standard Donuts Mini Donuts

Mark II

Mark II GP –

Mark II with Minidonut Kit

Mark V

Mark V GP –

Mark V with Minidonut Kit

Estimates are based on full capacity at frying times of 95 seconds for standard donuts

and 60 seconds for mini donuts.

37 Dozen/hour –

153 Dozen/hour

37 Dozen/hour 109 Dozen/hour

56 Dozen/hour –

226 Dozen/hour

56 Dozen/hour 163 Dozen/hour

AIR DISCHARGE

HOOD/CLEAN AIR ASSEMBLY

90" (229 cm)

STOP/START SWITCH

FILTRATION RECEPTACLE

FRYER RECEPTACLE

12" (30 cm)

POWER CORD 72" (183 cm)

NEMA #6-50P (3-PHASE)

OTHER EQUIPMENT

(Optional unless included in Insider Donut System package)

▪ Roto-Cooler for cooling and collecting donuts

▪ EZ Melt 18 melter-filter system

ELECTRICAL INFORMATION

▪ Single power connection.

▪ 208-240V, 50/60hz, 1ph

- Insider with Donut Robot

- Insider with Donut Robot

▪ Contact factory for 3-phase and other voltage options. In some

cases these options may not be ETL certified

INSTALLATION

Installation and usage may require approval by local jurisdictions.

(Customer is responsible for such approval)

Clearance

▪ 36" (92 cm) space at rear to allow room for operator, and to

allow EZMelt 18 Melter Filter to roll out

▪ 36" (92 cm) at left side (viewed from rear) for operator access

to the left and rear of the unit

▪ 36" (92 cm) above Insider for air discharge

STANDARDS CERTIFICATION

UL197

UL710B

Certified by ETL to UL-197, UL-710B, NSF-4 and CSA C22.2

standards. (ETL Control #68183)

P

POWER

CONNECTION

NSF STD 4

CSA C22.2

Clearance 36" (92 cm)

Clearance 36" (92 cm) Clearance 36" (92 cm)

REAR

31" (79 cm)

®

Mark II/Mark II GP: up to 36 Amps

®

Mark V/Mark V GP: up to 50 Amps

FRONT

P

90 Years of Quality Donut & Bakery Equipment

BELSHAW ADAMATIC BAKERY GROUP

814 44th St NW, Suite 103

Auburn, WA 98001 USA

PART OF ALI GROUP SPA

©Belshaw Adamatic Bakery Group Product specifications may be changed without notice. Current version available at www.belshaw-adamatic.com

CONTACT

800.578.2547 (USA/CANADA)

(+1)206.322.5474 Worldwide

service@belshaw.com

WEB

www.belshaw-adamatic.com

www.belshaw.com

www.adamatic.com

SPEC

INSDR/03-2013

Page 2 of 2

Loading...

Loading...