Page 1

SV-A series

-Stand Type-

SV-H series

-Portable Type-

Vibro Viscometer

INSTRUCTION MANUAL

1WMPD4001459A

Page 2

© 2008 A&D Company Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated

into any language in any form by any means without the written permission of A&D

Company Ltd.

The contents of this manual and the specifications of the instrument covered by this

manual are subject to change for improvement without notice.

Page 3

CONTENTS

1. INTRODUCTION .............................................................................................................................3

1-1 Compliance......................................................................................................................................... 3

Compliance with FCC Rules ................................................................................................................. 3

Compliance with Council Directives...................................................................................................... 3

1-2 Features ............................................................................................................................................. 5

2. UNPACKING THE VISCOMETER ..................................................................................................7

2-1 Part names for the SV-A series (Stand type)...................................................................................... 7

2-2 Part names for the SV-H series (Portable type)............................................................................... 13

3. CHANGING TYPE ..........................................................................................................................16

3-1 Changing from SV-A (Stand type) to SV-H (Portable type).....................................................................16

3-2 Changing from SV-H (Portable type) to SV-A (Stand type)..................................................................... 17

4. DISPLAY AND KEYS ....................................................................................................................20

4-1 Display.............................................................................................................................................. 20

4-2 Keys (For all models)........................................................................................................................ 21

4-3 Displaying the Viscosity Values ........................................................................................................ 22

4-3-1 SV-1A/SV-1H ............................................................................................................................. 22

4-3-2 SV-10A/SV-10H......................................................................................................................... 23

4-3-3 SV-100A/SV-100H ..................................................................................................................... 23

5. PRECAUTIONS ............................................................................................................................24

5-1 General Precautions (For all models)............................................................................................... 24

5-2 Precautions for an Acurate Measurment (Only for the SV-H series)................................................ 24

5-3 During Use (For all models) ............................................................................................................. 25

5-4 After Use (For all models)................................................................................................................. 26

5-5 Measuring the Absolute Value of Viscosity (For all models) ..................................................................... 27

5-5-1 At Measurement ........................................................................................................................ 27

5-5-2 At Calibration ............................................................................................................................. 27

6. MEASUREMENT ..........................................................................................................................28

6-1 Preparing the Sample (For the SV-A series) .................................................................................... 29

6-2 Basic Measurement Procedure (For the SV-A series) ..................................................................... 32

6-3 Basic Measurement Procedure (For the SV-H series)..................................................................... 33

6-4 Changing Units (For all models)....................................................................................................... 36

7. USING THE WATER JACKET ......................................................................................................37

7-1 . Introduction..................................................................................................................................... 37

7-2 . Installation ...................................................................................................................................... 38

7-3 . How to Use ..................................................................................................................................... 40

7-4 . Measuring the Absolute Value of Viscosity Using the Small Sample Cup.................................................. 41

7-5 . Maintenance ................................................................................................................................... 41

7-6 . Specifications.................................................................................................................................. 41

1

Page 4

8. VISCOSITY CALIBRATION (FOR ALL MODELS) .......................................................................42

8-1 Notes on Viscosity Calibration (For all models)................................................................................ 43

8-2 Calibration Procedure (For all models)............................................................................................. 44

8-2-1 One-point Calibration................................................................................................................. 45

8-2-2 Two-point Calibration................................................................................................................. 46

8-2-3 Simplified Calibration Using Purified Water (SV-1A/1H/10A/10H) ............................................ 48

9. FUNCTION SETTING (FOR ALL MODELS) ................................................................................50

9-1 Operation (For all models)................................................................................................................ 50

9-2 Details of the Function Items (For all models).................................................................................. 52

9-3 Description of Items (for all models) ................................................................................................. 54

9-4 Data Output Format Examples (For all models)............................................................................... 64

9-4-1 A&D Standard Format................................................................................................................ 64

9-4-2 D.P. Format ................................................................................................................................ 66

9-4-3 CSV Format ............................................................................................................................... 67

9-4-4 RsVisco Format ......................................................................................................................... 71

10. CONNECTION TO A PERSONAL COMPUTER.........................................................................74

10-1 Introduction ..................................................................................................................................... 74

10-2 Installation of WinCT-Viscosity ....................................................................................................... 74

10-3 Connection to a personal computer................................................................................................ 75

10-4 Configuration of the COM port........................................................................................................ 76

10-5 Controlling the measurement using a personal computer.............................................................. 77

11. CONNECTION TO A PRINTER (FOR ALL MODELS)................................................................78

12. RS-232C SERIAL INTERFACE (FOR ALL MODELS) ............................................................... 79

13. COMMAND LIST (FOR ALL MODELS)......................................................................................80

14. TROUBLESHOOTING (FOR ALL MODELS) .............................................................................81

14-1 When measurement values do not become stable (For all models)........................................................ 81

14-2 When measurement values are not correct (For all models)............................................................ 83

14-3 When more precise measurement is required: (For all models) ........................................................... 84

14-4 When the temperature values are not correct (For all models)............................................................. 84

14-5 When water viscosity is to be measured (Only for SV-1A/1H/10A/10H)........................................................... 84

15. ERROR DISPLAY (FOR ALL MODELS) ....................................................................................85

16. SPECIFICATIONS.......................................................................................................................86

17. OPTIONAL ACCESSORIES.......................................................................................................88

18. EXTERNAL DIMENSIONS .........................................................................................................98

2

Page 5

1. INTRODUCTION

This manual describes how the SV-A/SV-H series viscometer works and how to get the most out of it

in terms of performance.

Read this manual thoroughly before using the viscometer and keep it at hand for future reference.

The SV-A series uses a stand. In a laboratory, quality control room etc, you can make accurate

measurements using the stand set, the sample cup set and the software set provided.

The SV-H series uses a handle only. While at a manufacturing location, you can make a

measurement easily. If you buy the accessories, the SV-H series functions the same as the SV-A

series.

1-1 Compliance

Compliance with FCC Rules

Please note that this device generates, uses and can radiate radio frequency energy. This

device has been tested and has been found to comply with the limits of a Class A computing

device pursuant to Subpart J of Part 15 of FCC rules. These rules are designed to provide

reasonable protection against interference when this device is operated in a commercial

environment. If this unit is operated in a residential area, it may cause some interference and

under these circumstances the user would be required to take, at his own expense, whatever

measures are necessary to eliminate the interference.

(FCC = Federal Communications Commission in the U.S.A.)

Compliance with Council Directives

This device features radio interference suppression and safety regulation in compliance with

the following Council Directives

Council directive 89/336/EEC EN61326 EMC directive

Council directive 73/23/EEC EN60950

EN61326 Emission and Immunity.

Note

The CE mark is an official mandatory European marking.

Please note that any electronic product must comply with local laws and regulations when

sold or used anywhere outside Europe.

Safety of Information Technology Equipment

3

Page 6

4

Page 7

1-2 Features

High accuracy

The Vibro Viscometer adopting the sine-wave vibration technique (SV type), achieves a high

measurement accuracy of 1%*

*1 With the SV-H series, when using the AX-SV-51 stand set (sold separately).

Refer to "16. SPECIFICATIONS" on page 86.

Measurement of a small amount of sample

The SV-1A can measure with a 2 mL sample (minimum amount), and the standard X-Y-Z

stage can position the sample container easily.

When using the accessory items (sold separately), the SV-1H can measure with stability a 2

mL sample (minimum amount). For details, refer to "17. OPTIONAL ACCESSORIES"

With the SV-H series, you can measure the viscosity at the manufacturing location by using

the standard carrying case.

The sensor plates are made of corrosion resistant titanium. Although titanium is a chemically

stable material, it is corroded by some liquid such as sulfuric acid. So, handle it with much

care.

Wide range continuous measurement

Continuous measurement over the whole measuring range is possible, without replacing the

viscosity detection sensor plates.

Standard temperature sensor

The temperature sensor to measure the sample temperature is installed as standard. With

SV-1A/1H, the temperature sensor is located behind the two sensor plates. With the

SV-10A/10H/100A/100H, the temperature sensor is located between the two sensor plates. So,

the accurate detection of the relation between temperature and viscosity is possible.

1

(repeatability) over the full range.

Accurate measurement

Due to the low heat capacity of the viscosity detection unit (sensor plates and temperature

sensor), the time required for temperature equilibrium is short. Thus, the sample viscosity can

be measured accurately in a short time.

Long continuous measurement time

The sensor plates, with a low frequency of 30 Hz and an amplitude of less than 1 mm, apply

very little load to the sample. So, the viscometer can continuously obtain stable viscosity

values without causing a temperature rise or damaging the sample. With the SV-H series, use

the AX-SV-53 Software set-WinCT Viscosity (sold separately).

Measurement of a non-Newtonian fluid/foaming sample

The thin sensor plates allow little deformation of the sample texture. Thus, non-Newtonian fluid

can be measured in a stable way. And, foaming samples can be measured without breaking

minute foam particles and with less influence scattering large foam particles.

When measuring tap water, bubbles may accumulate on the sensor plates, increasing the

viscosity.

Viscosity measurement of a flowing sample

The two sensor plates oscillate in the opposite direction. So, even when a sample is in motion,

errors are eliminated. This allows measurement of a sample while being stirred. Therefore, the

viscometer can be used for a continuously flowing product line, which enables field

management with identical data used at the laboratories.

5

Page 8

Calibration

The viscometer can be calibrated using a standard viscosity fluid or a sample of a known

viscosity. Calibration allows the viscometer to maintain the accuracy constantly.

In case of a Newtonian fluid, by calibrating an actual sample, using the viscosity value

obtained by another type of viscometer as a correction value, the measurement data obtained

by the SV-A/SV-H series viscometer can be combined into those obtained by the other type of

viscometer.

The vibro viscometer and the

capillary viscometer and the rotational viscometer are a type of

calibration equipment for viscosity measurement by JCSS standard (Japan Calibration Service

System).

Simplified calibration when measuring the viscosity near 1 mPa⋅s (Only for SV-1A/1H/

10A/10H)

Simplified calibration using purified water is a one-key operation. The SV-1A/1H/10A/10H has

a built-in function to measure the temperature of the purified water using the temperature

sensor and calculates the viscosity value of the purified water at that temperature.

At this time, be careful not to influence the viscosity value by generating bubbles.

Standard windows communication tools WinCT-Viscosity (With the SV-A series, it is standard

accessory. With the SV-H series, it is sold separately (AX-SV-53-EX))

Windows communication tools WinCT-Viscosity (CD-ROM) is provided as standard. The

CD-ROM contains the graphing program RsVisco, which imports the data into a personal

computer and displays the results as a graph in real time. With RsVisco, changes in viscosity

over time and temperature dependency of viscosity can be observed easily and the obtained

data can be saved in files.

When using the accessory serial / USB converter, the personal computer can input the data

using the personal computer’s USB port. (With the SV-A series, it is standard accessory. With

the SV-H series, it is sold separately (AX-SV-53-EX))

The cup, that the sample is to be measured in, can be the plastic sample cup and the glass

sample cup. When measuring an organic solvent, use the glass sample cup.

Use the carrying case only for carrying the viscometer. Do not transport the viscometer using

the carrying case. Doing so may cause damage to the viscometer. When transporting the

viscometer, be sure to use the original packing material.

6

Page 9

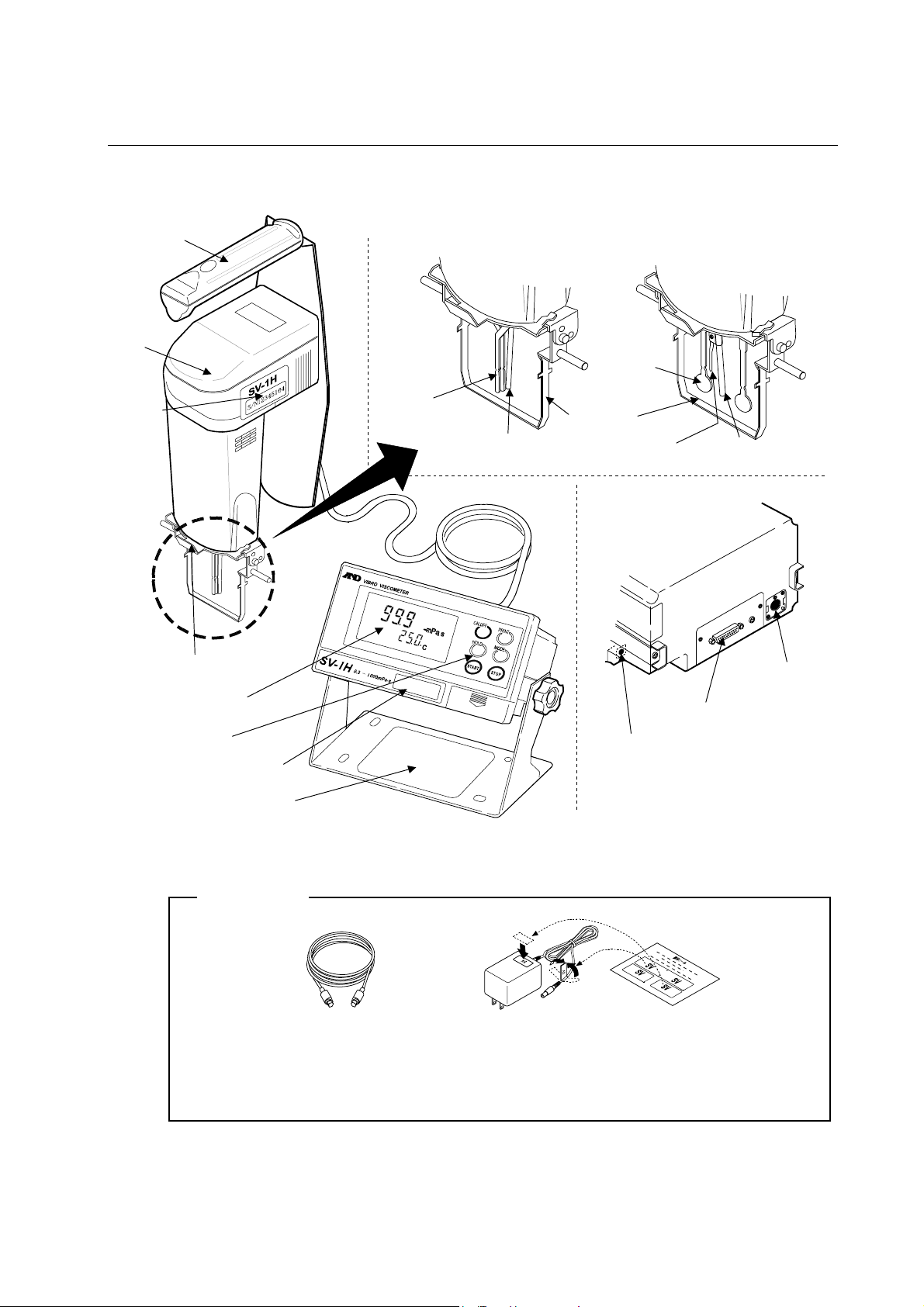

2. UNPACKING THE VISCOMETER

The viscometer is a precision instrument. Unpack the viscometer carefully. Keep the packing

material to be used for transporting the viscometer in the future.

2-1 Part names for the SV-A series (Stand type)

*The illustration below is after assembling.

Sensor unit

Sensor protective

cover

Sample cup

knob

Ta bl e

Guides

Right and left

direction

Cap

Grip

Lever

Supporting

post

Serial number

Sensor

plate

Temperature sensor

SV-1A

Leveling foot

Protector

Sensor

plate

Surface locator

plate

Temperature sensor

SV-10A/SV-100A

knob

Back and forth

direction

(Height direction)

knob

Main unit

Serial number

Reference card

Keys

S

/

N

1

2

3

4

5

Display unit

Display

Connection

cable jack

1

6

4

AC adapter jack

RS-232C serial interface

Display unit

rear side

7

Page 10

Accessories for SV-1A

Connection cable (1 pc)

Sample cup (Lid attached)

(

Polycarbonate,

10 pcs)

Capacity: 2 mL,

Sample cup

(

Polycarbonate,

5 pcs)

Capacity: 45 mL,

AC adapter (1 pc) AC adapter label

See the note below.

Glass sample cup

(Capacity: 2 mL, 10 pcs)

* The lid for the sample cup

(2 mL) does not fit this cup.

Sample cup stand

(

2 mL capacity, 1 pc)

For

Square glass sample cup

(

10 mm x10 mm x 45 mm

Can be used for

optical measuring devices

Sample cup holder

(

Polycarbonate, For

Transparent: 3 pcs, Black: 2 pcs)

2 mL capacity,

)

Water jacket (1 pc)

Windows communication tools

WinCT-Viscosity(CD-ROM) (1 pc)

Stand for securing the sensor unit (1 pc)

RS-232C cable (1 pc)

25P-9P for modem

X-Y-Z stage (1 pc)

Serial-USB converter (1 pc)

Screwdriver (1 pc)

Note

Please confirm that the AC adapter type is correct for

your local voltage and receptacle type.

8

Page 11

Accessories for SV-10A / SV-100A

A

Connection cable (1 pc)

Sample cup

(

Polycarbonate,

5 pcs)

Glass sample cup

(Capacity: 13 mL, 2 pcs)

AC adapter (1 pc) AC adapter label

Capacity: 45 mL,

Small sample cup

(

Polycarbonate,

5 pcs)

Glass sample cup holder

(1 pc)

Capacity: 10 mL,

Note

Please confirm that the

C adapter type is correct

for your local voltage and

receptacle type.

Small sample cup cover

(

Polycarbonate, 5

pcs)

Water jacket (1 pc)

The position about 25 mm

above the cup bottom

indicates 13 mL.

Windows communication tools

WinCT-Viscosity(CD-ROM) (1 pc)

Stand for securing the sensor unit (1 pc)

RS-232C cable (1 pc)

25P-9P for modem

X-Y-Z stage (1 pc)

Serial-USB converter (1 pc)

Screwdriver (1 pc)

.

9

Page 12

Unpacking

Display

Connection

cable

Stand

AC adapter

Knobs for securing

the display

Instruction

manual

X-Y-Z stage

Protector

Supporting post

Slider

Sensor unit

Handle the sensor plate

with care.

Glass sample

cup[2ml] (10 pcs)

Lid

(2 pcs)

Square glass sample cup

(2 pcs)

Screwdriver

Lid

(10 pcs)

Sample cup

[2ml] (10 pcs)

Water jacket

(1 pc)

Base

Sample cup holder

[For 2ml] ( 5 pc s) *

Sample cup

[45ml] ( 5 pc s )

Small sample

c u p [10ml] ( 5 p c s )

Sample cup

[45ml] ( 5 pc s)

Small sample

c u p cover ( 5 p c s )

Glass sample

cup holder

[For 13ml] ( 1 p c )

Glass sample

cup

[13ml] ( 2 pc s )

Water jacket

(1 pc)

Sample cup

stand (1 pc)

SV-1A

* Transparent-3 pcs,

Black-2 pcs

SV-10A / SV-100A

10

Page 13

Assembling

Note: When assembling, handle the sensor plates

with care.

When removing or tightening the screws

located on the rear side of the sensor unit’s

handle, use the screwdriver that is provided

with the viscometer.

1 Remove the two screws from the bottom of the

supporting post. Install the supporting post onto

the base. From the underside of the base, secure

the post using the two screws previously

removed.

2 Remove the attachment screw from the base.

Install the X-Y-Z stage along the guide ribs from

forward of the base. Secure the X-Y-Z stage using

the screw removed. (Confirm the direction of the

X-Y-Z stage’s knobs.)

Supporting post

Base

Screws

X-Y-Z stage

Screw

3 Install the protector on the sensor unit of the

SV-1A/SV-10A/ SV-100A.

Insert the protector’s rotational axis into the

sensor unit’s hole.

(Refer to the figure at the right.)

4 Remove the four screws from the

rear side of the sensor unit’s handle.

Using the four screws removed,

attach the sensor unit to the slider.

Tighten the screws completely, using

the screwdriver provided with the

viscometer, so that there will be no

measurement error due to movement

of the head.

Install from forward

Sensor unit

Example: SV-1A

Sensor

plate

1

Screws

Rotational

axis

3

3

Rotational

axis

1

2

Protector

Screwdriver

Slider

11

Page 14

Lever

r

y

5 Raise the lever and install the sensor unit along

the guide channels of the supporting post’s

sides.

At an appropriate height, secure the sensor unit

to the supporting post by lowering the lever.

6 Confirm that the stand’s mounting holes and the

display’s mounting holes match up. Secure both

sides of the display with the knobs.

Cap

Serial number

Guide channel

Handle the sensor

plates with care.

Knob for securing

the display

Display

Knob for

securing

the display

7 Connect the display unit to the main unit using the

connection cable.

8 Insert the AC adapter plug into the AC

from the display unit

(Connect as shown)

adapter jack located on the rear side of the

display unit. Insert the other end of the AC

adapter plug into an electrical outlet.

Note:

Display unit

• Confirm that the adapter type is correct fo

rear side

• The main unit and the display unit have been

Connection cable

from the main unit

(Connect as shown)

Serial number

Connection cable

Stand

Main unit

the local voltage and power receptacle type.

adjusted in pairs. For accurate viscosit

measurement, before use, confirm that the

main unit and the display unit have the same

serial number.

AC adapter cable

12

Page 15

2-2 Part names for the SV-H series (Portable type)

A

r

r

r

p

A

p

Handle

Senso

unit

Serial

number

Main

unit

Senso

late

SV-1H SV-10H/SV-100H

Sensor

late

Protector

Temperature

sensor

Surface

locator plate

Temperature

sensor

Sensor protective

cove

Display

Keys

Serial number

Reference card

ccessories

Note

Please confirm that the AC adapter type is correct for your local

voltage and receptacle type.

S

/

N

1

2

3

4

5

1

6

4

RS-232C serial interface

C adapter jack

Display unit

rear side

Display unit

Connection cable (1 pc) AC adapter (1 pc) AC adapter label

Connection

13

Page 16

Unpacking / Assembling

Note: When assembling, handle the sensor plates with care.

1 Unpack the parts from the carrying case.

Display

Connection

cable

AC adapter

Instruction

manual

Stand

Knobs for securing

the display

Protector

2 Install the protector on the sensor unit of the SV-1H/SV-10H/SV-100H.

Insert the protector’s rotational axis into the sensor unit’s hole.

Sensor unit

Example: SV-1H

(Refer to the figure at the right.)

3 Connect the display unit to the main unit using the connection

Sensor

plate

3

cable.

Note

1

The main unit and the display unit have been adjusted in

pairs. For accurate viscosity measurement, before use,

confirm that the main unit and the display unit have the

same serial number.

Serial number

Sensor unit

Handle the sensor plates

with care.

Rotational

axis

3

Rotational

axis

1

2

Protector

Sensor plate

Connection cable

from the display unit

(Connect as shown)

14

Page 17

4 Confirm that the stand’s mounting holes and the

display’s mounting holes match up. Secure both

sides of the display with the knobs.

Knob for securing

the display

5 Insert the AC adapter plug into the AC adapter

jack located on the rear side of the display unit.

Insert the other end of the AC adapter plug into

an electrical outlet.

Serial number

Display

Knob for

securing

the display

Stand

AC adapter cable

Note

Confirm that the adapter type is correct for the

local voltage and power receptacle type.

Display unit

rear side

Connection cable

from the main unit

(Connect as shown)

15

Page 18

3. CHANGING TYPE

r

3-1 Changing from SV-A (Stand type) to SV-H (Portable type)

In the case that you have purchased an SV-A series (stand type), and you need to use it as a

portable type, make the following changes.

Note: When removing or tightening the screws,

use the screwdriver that is provided

with the viscometer.

1 Remove the four screws from the

rear side of the sensor unit’s slider.

Using the four screws removed,

attach the sensor unit to the handle.

Change the function setting of

* Even if the function setting of

the portable functions, H-fnc, 5t-b, Hld-t, Cp, bep, Cp Hi and Cp lo will not be available.

“5vtyp” from “atype” to“Htype”as follows:

“5vtyp” is not changed, you can still use the viscometer. However,

Screws

Screwdriver provided

with the viscomete

Handle

Screws

2 Insert the AC adapter plug into the AC adapter

jack located on the rear side of the display unit.

Insert the other end of the AC adapter plug into an

electrical outlet.

3 Press the ON:OFF key to turn the power on.

4 While in the standby mode, press and hold the MODE

key for two or more seconds. The viscometer will

enter the function mode 5vtyp .

Display unit

rear side

AC adapter cable

(Standby mode)

Press and

hold

5 Press the PRINT key to select this item.

Continued on next page

16

Page 19

6 Press the START or HOLD key to display

Htype .

7 Press the PRINT key to store the setting.

After the viscometer displays end , it display the

next item of the function setting.

From the previous page

or

8 Press the STOP key to return to the standby mode.

If you need other functions of the portable type, refer to

“9. FUNCTION SETTING”.

3-2

In the case that you have purchased an SV-H series (portable type), and you need to use it with the

stand set, prepare the following accessories and make the following changes.

Changing from SV-H (Portable type) to SV-A (Stand type)

- AX-SV-51 Stand set

- AX-SV-53-EX Software set

- AX-SV-54 Sample cup set (10 mL/13 mL/45 mL)

- AX-SV-55 Sample cup set (2 mL) Only for SV-1A/SV-1H

Note: When removing or tightening the screws located on the rear side of the sensor unit’s

Next item of

function setting

(Standby mode)

handle, use the screwdriver that is provided with the viscometer.

1 Remove the two screws from the bottom of

the supporting post. Install the supporting

post of the stand set onto the base. From the

underside of the base, secure the post using

the two screws previously removed.

Supporting post

Base

Screws

17

Page 20

2 Remove the attachment screw from the

base. Install the X-Y-Z stage along the guide

X-Y-Z stage

Screw

ribs from forward of the base. Secure the

X-Y-Z stage using the screw removed.

(Confirm the direction of the X-Y-Z stage’s

knobs.)

Install from forward

3 Remove the four screws from the

rear side of the sensor unit’s

handle.

Using the four screws removed,

attach the sensor unit to the slider.

Screws

Screwdriver

4 Raise the lever an d install the sensor unit along

the guide channels of the supporting post’s

sides.

At an appropriate height, secure the sensor

unit to the supporting post by lowering the

lever.

Serial number

Handle the sensor

plate with care.

Change the function setting of

“5vtyp” from “Htype” to “atype” as follows:

Slider

Lever

Guide channel

* Even if the setting of

“5vtyp” is not changed, you can still use the viscometer. However, the

portable functions, H-fnc, 5t-b, Hld-t, Cp, bep, Cp Hi and Cp lo remain available.

18

Page 21

5 Insert the AC adapter plug into the AC adapter

jack located on the rear side of the display unit.

Insert the other end of the AC adapter plug into

an electrical outlet.

6 Press the ON:OFF key to turn the power on.

7 While in the standby mode, press and hold the MODE

key for two or more seconds. The viscometer will enter

the function mode 5vtyp .

Display unit

rear side

AC adapter cable

(Standby mode)

Press and

hold

8 Press the PRINT key to select the item.

9 Press the START or HOLD key to display atype .

10 Press the PRINT key to store the setting.

After the viscometer displays end , it displays the

next item of the function setting.

11 Press the STOP key to return to the standby mode.

or

Next item of

function setting

(Standby mode)

Now the portable functions H-fnc, 5t-b, Hld-t, Cp, bep, Cp Hi, Cp lo are not available.

19

Page 22

4-1 Display

4. DISPLAY AND KEYS

Name Description

Standby mode Displays [- - - - -].

Viscosity display

Viscosity units Displays the unit of viscosity.

Temperature display

Temperature units Displays the unit of temperature.

Processing indicator

Hold indicator Illuminates while the viscometer is in the data hold mode.

RsVisco link indicator

Calibration indicator Displays " C " in the calibration mode.

Calibration mode ID

indicator

Measurement mode

Data hold mode

Standby mode

Measurement mode

Data hold mode

Blinks while the measurement is being performed. (While the

sensor plates are in vibrating motion)

Illuminates while measurement is performed using RsVisco, the

graphing program contained in the WinCT-Viscosity (CD-ROM).

At one-point calibration Blank display [ ]

At two-point calibration

Displays the viscosity value in real

time.

Freezes the display of the viscosity

value.

Displays the temperature value in

real time.

Freezes the display of the

temperature value.

Inputting

first point

Inputting

second point

Displays [ - - ].

Displays [ - - ].

20

Page 23

4-2 Keys (For all models)

Key Description

ON:OFF

Power

START

Start

measurement

STOP

Stop

measurement

HOLD

Data hold

MODE

Change units

PRINT

Output data

Turns the power on and off.

When the power is turned on, the viscometer enters the standby

mode ( [- - - - -] is displayed.)

Start a measurement. (The processing indicator blinks.)

Displays the viscosity and temperature values in real time during

measurement.

If the display is set to HOLD, release it by pressing the START key.

Stops the measurement (The processing indicator is off) and freezes

the display of the viscosity and temperature values at the time the

STOP key is pressed during measurement.

When the STOP key is pressed again, the viscometer enters the

standby mode.

Freezes temporarily the display of the measurement data (viscosity

and temperature) at the time the HOLD key is pressed during

measurement. (The hold indicator is on.)

In the above condition, the measurement is continued. (The processing

indicator blinks.)

Pressing the HOLD key again releases the data hold mode. ∗1

Changes viscosity units. ∗2

(By the function setting "fnc 1", the measurement elapsed time can

be displayed.)

Outputs the measurement data.

∗1 While data are being output continuously (function setting "prt 2" or SIR command), the

data hold mode using the HOLD key is not available.

∗2 While the measurement is being performed using the graphing program RsVisco, the

data hold mode using the HOLD key and unit changes using the MODE key are not

available. RsVisco is contained in the Windows communication tools of the CD-ROM,

WinCT-Viscosity.

With the SV-A series, the CD-ROM is a standard accessory.

With the SV-H series, use the AX-SV-53-EX (software set, sold separately).

21

Page 24

4-3 Displaying the Viscosity Values

The viscosity values are displayed as below, depending on the unit selected and the viscosity range.

The correlation of the units are as follows: 1 mPa⋅s = 0.001 Pa⋅s = 1 cP =0.01 P

4-3-1 SV-1A/SV-1H

Use the MODE key to switch between mPa⋅s (Millipascal second) and Pa⋅s (Pascal second), or

between cP (Centipoise) and P (Poise).

The unit selected at the factory before shipment is mPa⋅s.

When the viscosity unit is mPa⋅s or Pa⋅s:

Viscosity

measured

mmPa⋅s

0.30 0.0003

1 1.00 0.0010

|

9.99

10 10.0 0.0100

|

99.9

100 100 0.100

|

999

1000

Display

⏐

1.00 0.01

mmPa⋅s Pa⋅s

Minimum

display

0.01

0.1

1

When the viscosity unit is cP or P:

Viscosity

measured

mmPa⋅s

0.30 0.0030

| |

1 1.00 0.0100

| |

9.99

10 10.0 0.100

| |

99.9

100 100 1.00

| |

999

1000 1 0.0 0.1

Display

Minimum

CcP P

display

0.01

0.1

1

Unit selected

Unit Remarks Display

mmPa⋅s

Pa⋅s

Switches

to

Pa⋅s

0.0099

0.0999

0.999

1.00

Unit selected

Unit Remarks Display

CcP

P

Switches

to P

10.0 0.1

0.0999

0.999

9.99

Minimum

display

0.0001

0.0001

0.001

0.01

Minimum

display

0.0001

0.001

0.01

Unit Remarks

Digit

indicating

0.01 mPa⋅s is

not displayed

Pa⋅s

Unit Remarks

P

22

Page 25

4-3-2 SV-10A/SV-10H

Use the MODE key to switch between mPa⋅s (Millipascal second) and Pa⋅s (Pascal second), or

between cP (Centipoise) and P (Poise).

The unit selected at the factory before shipment is mPa⋅s.

When the viscosity unit is mPa⋅s or Pa⋅s:

Unit selected Viscosity

measured

MmPa⋅s Display

0.30 0.0003

⏐

1 1.00 0.0010

|

9.99

10 10.0 0.0100

|

99.9

100 100 0.100

|

999

1000 1.00 1.00

| |

10000 10.00

mmPa⋅s Pa⋅s

Minimum

display

0.01

Unit Remarks Display

0.0099

Minimum

mPa⋅s

0.1

0.0999

1

0.999

0.01

Pa⋅s Switches

Pa⋅s

to

10.00

display

0.0001

0.0001

0.001

0.01

Unit Remarks

Digit

indicating

0.01 mPa⋅s is

not displayed

Pa⋅s

When the viscosity unit is cP or P:

Viscosity

measured

MmPa⋅s Display

0.30 0.0030

| |

1 1.00 0.0100

| |

9.99

10 10.0 0.100

| |

99.9

100 100 1.00

| |

999

1000 1.00 10.0

| |

10000 100.0

Minimum

CcP P

display

0.01

Unit Remarks Display

CcP

0.1

1

0.1

P

Unit selected

Switches

to P

Minimum

display

0.0001

0.0999

0.001

0.999

0.01

9.99

0.1

100.0

4-3-3 SV-100A/SV-100H

Use the MODE key to switch between Pa⋅s (Pascal second) and P (Poise).

The unit selected at the factory before shipment is Pa⋅s.

Unit Remarks

P

measured

Unit selected Viscosity

Pa⋅s P

Pa⋅s Display

1 1.00 10.0

| |

9.99

10 10.0 100

| |

99.9 999

100 100.0

Minimum

display

0.01

0.1

Display

99.9

1000

Minimum

display

0.1

1

23

Page 26

5. PRECAUTIONS

To get the optimum performance from the viscometer and acquire accurate measurement data, note

the following:

5-1 General Precautions (For all models)

For accurate measurement, use care with the following conditions.

Install the viscometer in an environment where the temperature and humidity are not excessive.

The best operating temperature is 25°C±2°C at 45-60% relative humidity.

For precise measurement, install the viscometer where there are no great changes in

temperature and humidity.

Install the viscometer where it is free of dust.

The viscometer uses the Tuning-fork Vibration Method. So, use much care to avoid external

vibration, especially when measuring low viscosity.

Places where the viscometer is prone to vibration are:

Second or higher floor, soft ground, near busy highways or rail lines.

Avoid these places as a measuring site. If measurement is to be performed in such a place, use

an anti-vibration table that is available as an option (AD-1685).

Do not measure where heaters or air conditioners can affect the measurement.

Do not measure where direct sunlight can affect the measurement.

Install the viscometer away from equipment which produces magnetic fields.

Protect the internal parts from liquid spills and excessive dust.

Do not disassemble the viscometer.

When precise measurement is required, acclimatize the viscometer to the measuring

environment. After installation, plug in the AC adapter and warm up the viscometer for one hour

or more.

5-2 Precautions for an Accurate Measurment (Only for the SV-H series)

With the SV-H series, when you need to make an accurate measurement, adjust the height of

the sample surface and sensor plates correctly by using the AX-SV-51 stand set. The

specification values are when using the stand set.

24

Page 27

5-3 During Use (For all models)

The SV-A/SV-H series viscometer, designed for very accurate measurement, is sensitive to

vibration or shock during transportation, as that may cause a display value error. Before

measurement, calibrate the viscometer using the sample cup that will be used for measurement.

To level the surface of the sample, adjust the leveling feet. (Height adjustment of the right and left

leveling feet.)

(With SV-10A, the center of the narrow part of the right and left sensor plates is on the liquid

surface.)

* With the SV-H series, use the AX-SV-51 (stand set, sold separately).

The viscosity of a liquid is temperature dependent and changes by negative 2 to negative 10

percent, per degree Celsius. Take changes in the liquid temperature into consideration for an

accurate measurement.

Be sure to calibrate using the standard viscosity fluid or purified water before measurement.

In a measurement that takes a long time, perform calibration periodically, as necessary.

Ensure a stable power source when using the AC adapter.

Placing the sensor plates and the temperature sensor in the sample may change the sample

temperature. For precise measurement, leave the sample as is for a while, after placing the

sensor plates and the temperature sensor, to ensure no changes to the sample temperature.

And then, start a measurement.

Use only your finger to press the keys. Using a sharp instrument such as a pen may damage

keys.

Handle the sensor plates with care.

If the sensor plates, or the protector, touch the inner wall of the sample cup, it may cause

measurement error. When measuring, be sure to adjust the spacing between the sensor

plates and the inner walls of the sample cup.

The sample cups are made of polycarbonate (PC) or glass. When using organic solvents, we

recommend the use of the glass sample cup (accessory or sold separately) or a commercially

available glass beaker.

Raise or remove the protector if necessary.

How to remove the protector:

Press the left and right side frames lightly in the direction indicated as 1 to remove the

rotational axis. Pull the protector in the direction indicated as 2 to remove.

Protector

1

Rotational

axis

1

Protector

2

25

Page 28

5-4 After Use (For all models)

r

Remove any residual sample material from the sensor plates, temperature sensor and

protector using alcohol. Using the sensor plates, temperature sensor and protector with

residue of an old sample left on will cause a measurement error.

Clean the sensor plates carefully to avoid bending them.

The sensor plates and the temperature sensor are made of titanium.

How to clean the sensor plates and temperature sensor

SV-1A/SH-1H

Hold the sensor plates with folded tissue paper.

Move the tissue paper upward and downward to

remove the sample. Pushing strongly on the

sensor plates when moving the tissue upward, may

cause the sensor plates to bend.

Clean the temperature sensor in the same way.

Then, use tissue paper moistened with alcohol,

to remove any residual sample material.

SV-10A/SV-10H/SV-100A/SV-100H

Hold the sensor plate or temperature sensor with

tissue paper. Move the tissue paper downward to

remove the sample.

Then, use tissue paper moistened with alcohol,

to remove any residual sample material.

Sensor plate

Sensor plate

Temperature

senso

Temperature

sensor

Clean the sample cup as necessary.

Unlock the cable connector before disconnecting the connection the cable.

How to unlock the cable connector

26

Page 29

5-5 Measuring the Absolute Value of Viscosity (For all models)

The SV-A/SV-H Series Sine-wave Vibro Viscometer, as a measuring principle, detects the product of

viscosity and density.

Displayed viscosity value = Viscosity × Density ⋅ ⋅ ⋅ ⋅ ⋅ [1]

While the displayed value has a unit of mPa⋅s, it indicates the product of viscosity and density.

Example (1) When a sample has an absolute value of viscosity of 2.00 mPa⋅s and density of 1.000:

Displayed value = 2.00 [mPa⋅s] × 1.000

= 2.00 [mPa⋅s]

(2) When a sample has an absolute value of viscosity of 2.00 mPa⋅s and density of 0.800:

Displayed value = 2.00 [mPa⋅s] × 0.800

= 1.60 [mPa⋅s]

Note

The density can be measured, using the density determination kit, AD-1653 in

combination with a balance.

To obtain the absolute viscosity value precisely, do as follows:

5-5-1 At Measurement

Divide the displayed viscosity value by the sample density to obtain the absolute value of viscosity.

Example (1) Measure the sample and confirm the displayed viscosity value.

Here, 736 mPa⋅s as an example.

(2) Check the sample density at the temperature when the sample is measured.

Here, 0.856

(3) Divide the displayed viscosity value by the sample density to obtain the absolute value

of viscosity.

Here, 860 mPa⋅s is obtained as the absolute viscosity value.

Absolute value of viscosity =

as an example.

Displayed viscosity value

Sample density

736

= ≅ 860 mPa⋅s

0.856

27

Page 30

5-5-2 At Calibration

When calibrating, enter the product of the absolute viscosity value and the density of the standard

viscosity fluid used for calibration, as a correction value.

The standard viscosity fluid has the calculation sheet of kinetic viscosity and viscosity at various

temperatures attached. To obtain the correction value using this sheet, do as follows:

Kinetic viscosity = From this, Density = ⋅ ⋅ ⋅ ⋅ ⋅ [2]

Correction value = Viscosity × Density ⋅ ⋅ ⋅ ⋅ ⋅ [3]

When substituting [2] for the density in [3], the following equation is obtained.

Correction value = ⋅ ⋅ ⋅ ⋅ ⋅ [4]

Example 1: To calibrate the viscometer using a standard viscosity fluid:

Using the calculation sheet, calculate the value used for calibration.

Viscosity

Density

Viscosity2

Kinetic viscosity

Viscosity

Kinetic viscosity

(1) Check the kinetic viscosity and the viscosity at the temperature when the calibration is

performed.

2

Here, 1011 mm

/s for the kinetic viscosity and 889 mPa⋅s for the viscosity at 20°C

as an example.

(2) Substitute the values above into equation [4].

8892

≅781

1011

781 mPa⋅s is obtained as a correction value used for calibration.

(3) After calibration, measure the viscosity of the standard viscosity fluid used and confirm

that the viscometer displays the similar value as the correction value, 781 mPa⋅s in

this example. This completes the calibration procedure.

Example 2: To calibrate using a standard viscosity fluid with known values of viscosity and density.

In this example, a standard viscosity fluid with a viscosity of 889 mPa⋅s at 20°C is used.

(1) Check the viscosity value and the density of the standard viscosity fluid at the

temperature when the calibration is performed..

Here, 889 mPa⋅s for the viscosity and 0.878 for the density at 20°C as an example.

(2) Substitute the values above into equation [3].

889 × 0.878 ≅ 781

781 mPa⋅s is obtained as a correction value used for calibration.

(3) After calibration, measure the viscosity of the standard viscosity fluid used and confirm

that the viscometer displays the similar value as the correction value, 781 mPa⋅s in

this example. This completes the calibration procedure.

28

Page 31

6. MEASUREMENT

6-1 Preparing the Sample (For the SV-A series)

* Vibration or shock during transportation may cause a display value error. Before measurement,

calibrate the viscometer using the sample cup that will be used for measurement. For calibration

with purified water, refer to “8-2-3 Simplified Calibration Using Purified Water”. (Only for SV-1A/10A)

Model: SV-1A

1 Pour the sample into the cup until its surface is between the level

gauges.

- With the 2 mL sample cup, the lower level gauge indicates 1.8

mL, the upper level gauge indicates 2 mL.

- With the 45 mL sample cup, the lower level gauge indicates 35

mL, the upper level gauge indicates 45 mL.

*The glass sample cup does not have level gauges.

2 Attach the cup on the table along the guides.

- With the 2 mL sample cup, place the sample cup in the sample

cup holder (For 2 mL), and set it into the 45 mL sample cup.

* When using the sample cup holder,

holder or the black holder, depending on the sample color.

3 Confirm that the protector is in the position as shown in the

figure.

Raise the lever to release the sensor unit.

select either the transparent

Sample cup

(2 mL)

Guides

Protector

Sensor

plate

Sensor unit

Level

gauges

Sample cup

<2 mL>

Sample cup

holder

<For 2 mL>

Sample cup

<45 mL>

Grips

4 Pinch the grips, support the front side of the sensor unit and

gently lower the sensor plates above the sample surface.

Adjust the X-Y-Z stage if necessary.

5 Lower the lever to secure the sensor unit.

6 Confirm that the positioning of the sensor plates is in center of

the sample cup by adjusting the X-Y-Z stage.

- When using the 2 mL sample cup, raise the protector.

29

Lever

Page 32

7 Turn the knob (Height direction) so as to

adjust the sample surface to the center of

the narrow part of the sensor plates.

Confirm that the sample surface is between

the upper and lower triangular marks.

Sensor protective

cover

Protector

Sample

surface

adjustment

position

Note

•When using the 2 mL sample cup, raise

the protector.

• Adjust the height of the sample surface

correctly, otherwise it may cause a

measurement error.

(Height direction)

Knob

Model: SV-10A / SV-100A

1 Pour the sample into the cup until its surface is between the

level gauges.

- With the 45 mL sample cup, the lower level gauge indicates

35 mL, the upper level gauge indicates 45 mL.

- The 13 mL glass sample cup does not have level gauges.

The position approximately 25 mm above the cup bottom

indicates 13 mL.

2 Attach the cup on the table along the guides.

3 Confirm that the protector is in the position as shown in the

figure.

Level gauges

Sample cup (45 mL)

Approx. 25cm

Glass sample cup (13 mL)

Guides

Raise the lever to release the sensor unit.

4 Pinch the grips, support the front side of the sensor unit and

gently lower the sensor plates above the sample surface.

5 Lower the lever to secure the sensor unit.

30

Sensor

plate

Protector

Page 33

6 Confirm that the positioning of the sensor plates is in center of

the sample cup by adjusting the X-Y-Z stage.

7 Turn the knob (Height direction) so

as to adjust the sample surface to

(Shaded portion)

Surface

locator plate

the center of the narrow part of the

sensor plates. At this time, use the

surface locator plate as a guide. The

surface locator plate has been

secured in position so that the tip of

the surface locator plate comes into

contact with the sample surface.

Sensor protective

cover

Sample

surface

adjustment

position

(Height direction)

Knob

Note

• Adjust the height of the sample surface correctly, otherwise it may cause a

measurement error.

• With SV-10A/SV-100A, the surface locator plate can be attached or removed by loosening the

screw.

• With SV-10A/SV-100A, before removing the sensor protective cover, remove the

surface locator plate.

• Removing and reattaching the surface locator plate will cause the position (Height) of

the sensor plates and the sample surface to change. Therefore, it is recommended

that calibration be performed using a standard viscosity fluid before measurement.

Note

Use the protector in the position as shown on the left below. If the protector is not used, a

measurement error may occur, especially in measuring a viscosity over 5000 mPa⋅s.

NO

When the position of the sensor plates in the liquid is not at the same level, level the

viscometer using the leveling feet so that the liquid surface will be leveled.

31

Page 34

6-2 Basic Measurement Procedure (For the SV-A series)

1 With the power turned off, press the ON:OFF

key.

When the display is in the standby mode, press

the START key. *1

After about 15 seconds, the measurement

values are displayed.

2 During measurement, press the

HOLD key as necessary, to freeze

the display temporarily.

To release the data hold mode,

press the HOLD or START key

again. *2

Below is an example of the SV-10A at shipment.

3 Press the STOP key to stop

the measurement. The

measurement results freeze

and are displayed.

4 To stop the measurement,

press the STOP key.

To go on to the next

measurement, set the sample

and press the START key.

When the viscosity value is below the measuring range, Sl TOP is displayed.

When the viscosity value exceeds the measuring range, SH TOP is displayed.

If the sensor plates are not in vibrating motion for about 20 seconds, for example, when

the sample coagulates, the measurement will stop automatically.

∗1 When the graphing program RsVisco is used, click the START button on the RsVisco to

start a measurement.

∗2 While the measurement is being performed using the graphing program RsVisco or data

are being output continuously (function setting "prt 2" or SIR command), the data hold

mode using the HOLD key is not available.

32

Page 35

6-3 Basic Measurement Procedure (For the SV-H series)

1 Pour the sample into the beaker (500ml) etc.

Beaker

2 With the power turned off, press the ON:OFF key.

When the display is in the standby mode, the SV-H

can measure.

3 Hold the SV-H handle firmly in your hand. Prepare to

insert the sensor plates in the sample.

(Standby mode)

Sample

4 Press the START key. Insert the sensor plates into the sample.

The measurement time is about 15 seconds. After inserting the sensor plates in the sample,

maintain the height of the sensor plates.

l is displayed when the sensor plates do not touch the liquid.

Right after the sensor plates touch the liquid, l will be still displayed. Continue the

measurement with this state. After stabilizing, the viscometer displays the viscosity value.

[Precautions when inserting the sensor plates into the sample]

Confirm that the protector is in the position as shown in the figure, and then insert the sensor

plates into the sample.

Confirm that the sample surface and the center of the narrow part of the sensor plates match up.

Keep the SV-H at this position (Height).

Sensor plates

Protector

At this time

- With SV-1H, there are the triangular marks on the sensor plate. Confirm that the sample

surface is between the upper and lower triangular marks.

33

Page 36

r

S

t

- With SV-10H/100H, use the surface locator plate as a guide. The surface locator plate has

Sample

surface

been secured in position so that the tip of the surface locator plate comes into contact with the

sample surface.

Surface

Sensor

protective

cover

Sample

surface

adjustment

position

locator plate

(Shaded portion)

SV-10H/SV-100H

Sample

surface

Sensor

protective

cove

ample

surface

adjustmen

position

Note

Use the protector in the position as shown on the left below. If the protector is not used,

be careful that the sensor plates do not touch the inner wall of the beaker etc. With the

SV-10H, when the protector is removed, a measurement error may occur, especially in

measuring a viscosity over 5000 mPa⋅s.

SV-1H SV-10H/SV-100H

No

Protector

Note

• Adjust the height of the sample surface correctly, otherwise it may cause a

measurement error.

• When you need a more accurate measurement, use the stand set (AX-SV-51, sold

separately).

• With SV-10H/SV-100H, the surface locator plate can be attached or removed by loosening the

screw.

• With SV-10H/SV-100H, before removing the sensor protective cover, remove the

surface locator plate.

• Removing and reattaching the surface locator plate will cause the position (Height) of

the sensor plates and the sample surface to change. Therefore, it is recommended

that calibration be performed using a standard viscosity fluid before measurement.

34

Page 37

Below is an example of the SV-10H at shipment.

5 After measurement, the buzzer sounds and the displayed

value blinks, then holds.

Note

When the values do not stabilize because of hand

movement, set the condition function that levels the

large variation in digits (refer to page 54) and the

function that do not display the large variation in digits

(refer to page 55) if necessary.

With the portable type, you can use the auto hold

function and timer mode function (refer to page 57).

6 To stop the measurement, press the STOP key.

(Standby mode)

(Measurement mode)

To go on to the next measurement, set the sample and press

the START key.

(Data hold

after measurement)

When the viscosity value is below the measuring range, Sl TOP is displayed.

When the viscosity value exceeds the measuring range, SH TOP is displayed.

If the sensor plates are not in vibrating motion for about 20 seconds, for example, when

the sample coagulates, the measurement will stop automatically.

∗1 When using the graphing program RsVisco, of the AX-SV-53-EX software set, click the

START button of the RsVisco program to start a measurement.

∗2 While the measurement is being performed using the graphing program RsVisco of the

AX-SV-53-EX software set or data are being output continuously (function setting "prt 2"

or SIR command), the data hold mode using the HOLD key is not available.

35

Page 38

6-4 Changing Units (For all models)

The units of viscosity available are: mPa⋅s (millipascal second),

Pa⋅s (Pascal second),

cP (Centipoise),

P (Poise).

The correlation of the units are as follows: 1 mPa⋅s = 0.001 Pa⋅s = 1 cP =0.01 P

The units of temperature available are: °C (Celsius) and °F (Fahrenheit).

The unit selected upon power-on depends on the function setting. The unit selected at the factory

before shipment is as shown below.

Model Viscosity Temperature

SV-1A/SV-1H

SV-10A/SV-10H

SV-100A

SV-100H

Use the MODE key to change units. Each time the MODE key is pressed, units are switched as below:

Note that the unit of temperature is fixed in the function setting.

mmPa・s

°C

Pa・s

SV-1A/SV-1H/ SV-10A/SV-10H

In the function setting, mPa⋅s or Pa⋅s is selected:

In the function setting, cP or P is selected:

SV-100A/SV-100H

Note

•While the measurement is being performed using the graphing program RsVisco, unit

changes using the MODE key is not available.

•With the function setting "fnc 1", pressing the MODE key during measurement will display

the measurement elapsed time.

36

Page 39

7. USING THE WATER JACKET

7-1. Introduction

The water jacket, is used with the SV-A Series Vibro Viscometer, to maintain the sample temperature

constant or to measure the viscosity when the sample temperature is changed. The operating

temperature range is 0°C to 100°C

The water jacket consists of the following:

Water jacket 1 pc (Main body: PC (Polycarbonate), Packing: Silicone rubber, Washer: Nylon)

Screw 1 pc (Screw: POM (Polyacetal), Washer: Nylon)

Note

• As a heating medium, use water, isopropyl alcohol (IPA), mixture of water and IPA, or

silicone oil, which does not erode the materials described above. Using the heating

medium other than these may damage the water jacket.

• When using the water jacket, make sure that no inner pressure is exerted in the water

jacket due to the kinked or blocked tubes, as that could exert the pressure in the water

jacket, causing it to break.

• To control the temperature, a commercially available constant temperature bath is

required separately.

• With the SV-H Series, the water jacket is part of the option AX-SV-54 (Cup set, sold

separately, capacity: 10 mL・13 mL・45 mL) or option AX-SV-55 (Cup set, sold separately,

capacity: 2 mL, only for the SV-1A/ SV-1H). At this time, use the optional AX-SV-51 stand

set (sold separately) if necessary. If you use the optional AX-SV-53-EX software set (sold

separately), you can easily understand the graphing data and sample characteristics in

real time.

37

Page 40

7-2. Installation

A

With the SV-1A, as the viscometer, the sample cup holder and the sample cup (capacity: 2 mL)

provided or the glass sample cup (capacity: 2 mL) also provided, is used.

With the SV-10A/100A, as the viscometer, the small sample cup (capacity: 10 mL) provided or the

glass sample cup (capacity: 13 mL) also provided, is used.

To circulate the heating medium into the water jacket, a commercially available constant temperature

bath is required.

1 Using silicone tubes with an inside diameter of 8 mm, make a connection between the "OUT"

connector of the bath and the lower nozzle of the water jacket indicated as 1 in the illustration,

and then, between the "IN" connector and the upper nozzle indicated as 2.

dd approximately 11 mL of

water as the heating medium.

3

Tubing clamp

(Commercially available)

IN

2

1

Water jacket assembly

Constant temperature bath

(Commercially available)

OUT

2 Pour the heating medium into the water jacket indicated as 3. An appropriate sample amount is

approximately 11 mL.

The heating medium conducts the heat of the water jacket to the sample cup.

Note: When the levels of the sample surface and the heating medium surface are the

same and hard to distinguish the positioning of the sensor plates, change the

amount of the heating medium.

3 When the sample cup (capacity: 2 mL) is used, pour the sample into the cup and

Level

gauges

confirm that the sample surface is between the 1.8 mL line and the 2 mL line.

When the small sample cup (capacity: 10 mL) is used, pour the sample

up to the 10 mL line.

Sample cup (2 mL)

38

Page 41

r

p

4 Model: SV-1A

Insert the sample cup into the sample cup holder, ant then into the water jacket indicated as 3.

When the specific gravity of the sample liquid is small and the sample cup floats, secure lightly

the front side of the cup to the water jacket using the screw provided.

Model: SV-10A/SV-100A

Insert the small sample cup into the water jacket indicated as 3.

When the specific gravity of the sample liquid is small and the small sample cup floats, secure

lightly the front side of the cup to the water jacket using the screw provided.

Use the small sample cup cover for volatile samples.

Glass sample cup

(Capacity: 2 mL)

Sample cu

(Capacity: 2 mL)

Sample cup holder

(For 2 mL)

Screw

Small sample cup cove

Small sample cup

(Capacity: 10 mL)

Glass sample cup

(Capacity: 13 mL)

If the handles of the sample cup holder or the small sample cup interfere with the

measurement, they can be removed.

Apply force in the up and down directions slowly as shown in the illustration, to break the

handle off.

Water jacket

Circulation nozzle

Sample cup holder Small sample cup

39

Page 42

7-3. How to Use

pp

r

S

1 Attach the water jacket on the table along the guides.

Make sure that the water jacket is slid furthest along

the guides until stopped.

2 When the water jacket is used, be sure to raise or

remove the protector.

Slide furthest

until sto

Guide

Protector

Raise or remove

the protector

ed

Guide

3 Use much care so that the sensor plates and the

temperature sensor do not come into contact with the

inner wall of the sample. If they are in contact, a

measurement error may occur.

4 Be sure to adjust the sample surface to the center of the narrow part of the sensor plates.

Sample

surface

Sensor

protective

cover

Sample

surface

adjustment

position

Surface

locator plate

(Shaded portion)

SV-10A/SV-100A

Sample

surface

Sensor

protective

cove

ample

surface

adjustmen

t position

SV-1A SV-10A/SV-100A

40

Page 43

7-4. Measuring the Absolute Value of Viscosity Using the Small Sample Cup

The SV-10A/100A has been calibrated using the accessory sample cup (45 mL) when shipped. The

distance between the inner wall and the sensor plates when the accessory sample cup is used,

differs from the distance when the small sample cup (10 mL) is used. This causes a difference in the

sensor plate's detection capability, thus causing a difference in the viscosity measured.

Therefore, to measure the absolute value of viscosity using the small sample cup (10 mL), it is

recommended that calibration be performed using a fluid with a known viscosity value which is close to

the sample viscosity. (Refer to "8. VISCOSITY CALIBRATION" of the viscometer instruction manual.)

7-5. Maintenance

Clean the sample cup as necessary. If cleaning is not sufficient, a measurement error may occur due

to contamination.

7-6. Specifications

Operating temperature: 0°C to 100°C

Circulation nozzle outside diameter: 10.5 mm

Recommended hose: Silicone tube with an inside diameter of 8 mm

When a stirrer is attached at the bottom of the water jacket, the sample viscosity can be

measured while the sample is being stirred. The maximum viscosity value which can be

measured is 1000 mPa⋅s.

Stirrer: VARIOMAG MICRO manufactured by H+P Labortechnik AG

Note

•Use a rotator with a size of 6 mm (length) x 4 mm (diameter).

•Attach the stirrer to the bottom of the water jacket, using an M4 screw from below.

•When the rotator is used, make sure that the rotator will not touch the temperature

sensor or the sensor plates. If it does, increase the sample amount so that the rotator will

be farther away from the sensor plates.

•Use the stirrer with a revolution speed which will not cause ripples in the sample surface.

Stirrer

M4 screw

41

Page 44

8. VISCOSITY CALIBRATION (FOR ALL MODELS)

With the SV-H series, when calibration is needed, use the stand set (AX-SV-51, sold

separately)

Viscosity calibration is to correct the viscosity value.

Two calibration methods are available: one-point calibration and two-point calibration, using

standard viscosity fluids.

It is recommended that calibration be performed using a fluid with a known viscosity value

which is close to the sample viscosity.

When the measuring range is great, perform two-point calibration. Two-point calibration

requires two standard viscosity fluids (high viscosity and low viscosity) that are appropriate for

the measuring range.

When measuring the viscosity near 1 mPa⋅s, simplified calibration using purified water, which

is a one-key operation, is available. The SV-1A/1H/10A/10H/ has a built-in function to perform

an automatic temperature compensation on the viscosity value, based on the temperature of

the purified water used.

In one-point and two-point calibration, the viscosity of a fluid with a known value, such as a

standard viscosity fluid, is measured, displayed, corrected digitally and saved in memory.

To obtain the absolute viscosity value precisely, use the correction value as described in

"5-5-2 At Calibration".

If the wrong calibration data such as a correction value have been entered, the viscometer

condition can be restored. For details, refer to "Initialization (Clr)" of the function setting.

42

Page 45

8-1 Notes on Viscosity Calibration (For all models)

Pay close attention to the liquid temperature at calibration. Be sure to enter the temperature

corrected viscosity value of the liquid at calibration. Even a standard viscosity fluid has a

viscosity change of -2%/°C to -10%/°C, and purified water, a viscosity change of -2%/°C, when

the room temperature changes.

The temperature of the standard viscosity fluid must be the same as the temperature of the

sensor plates and the temperature sensor. Allow the displayed temperature to stabilize before

calibration.

Be sure to adjust the sample surface to the center of the narrow part of the sensor plates.

Otherwise, a measurement error may occur.

In the calibration mode, the unit of viscosity for the SV-1A/1H/10A/10H is mPa⋅s, the unit of

viscosity for the SV-100A/100H is Pa⋅s. The unit of temperature is fixed to °C.

Influence caused by the sample cup

The viscometers have been calibrated with the following cups when shipped. When using

another cup, use that cup to measure viscosity only after calibrating with it.

SV-1A/SV-1H Sample cup (Capacity: 2 mL)

SV-10A/SV-10H/SV-100A/SV-100H Sample cup (Capacity: 45 mL)

Note

Models SV-10A/SV-10H/SV-100A/SV-100H, have been calibrated with the protector

attached when shipped. Please note that the value, obtained when the viscometer is

calibrated without the protector, may be different from that upon shipment.

If water other than purified water (such as pressurized tap water) is used for simplified

calibration, or the water temperature is different from the ambient temperature, bubbles may

accumulate on the sensor plates and cause a measurement error. Allow the sample to adjust

to the ambient temperature and remove any accumulated bubbles before calibration.

If the measured viscosity of the water is 3.00 mPa⋅s or greater, it is contaminated and

simplified calibration can not be performed using it. Replace the water.

43

Page 46

8-2 Calibration Procedure (For all models)

Note

As to the correction value used for one-point calibration and two-point calibration, enter the

product of the absolute viscosity value and the density of the standard viscosity fluid. For

details, refer to "5-5-2 At Calibration".

After calibration, check the values, comparing the product described above with the

displayed value.

Kinetic viscosity = From this, Viscosity × Density =

Example 1: To calibrate the viscometer using a standard viscosity fluid:

(1) Check the kinetic viscosity and the viscosity at the temperature when the calibration is

Viscosity

Density

Viscosity2

Kinetic viscosity is obtained.

Using the calculation sheet, calculate the value used for calibration.

performed.

2

Here, 1011 mm

/s for the kinetic viscosity and 889 mPa⋅s for the viscosity at 20°C

as an example.

Viscosity

2

(2) Substitute the values above to obtain the value for .

8892

Kinetic viscosity

≅781

1011

781 mPa⋅s is obtained as a correction value used for calibration.

Example 2: To calibrate using a standard viscosity fluid with known values of viscosity and density.

In this example, a standard viscosity fluid with a viscosity of 889 mPa⋅s at 20°C is

used.

(1) Check the viscosity value and the density of the standard viscosity fluid at the

temperature when the calibration is performed..

Here, 889 mPa⋅s for the viscosity and 0.878 for the density at 20°C as an example.

(2) Substitute the values above to obtain the value for Viscosity × Density.

889 × 0.878 ≅ 781

781 mPa⋅s is obtained as a correction value used for calibration.

44

Page 47

8-2-1 One-point Calibration

1 In the standby mode, press and hold

the HOLD key to enter the

calibration mode. " Cal " appears.

Below is an example of the SV-10H.

(Standby mode)

2 Select one-point calibration (Cal-1)

and press the PRINT key to confirm.

The standby mode of the one-

calibration mode appears.

Use the MODE key to switch

between the calibration modes,

one-point calibration (Cal-1) or

two-point calibration (Cal-2).

* Press the STOP key to exit the

calibration mode. The display

returns to the standby mode.

3 Place the standard viscosity fluid in

the sample cup. Press the START

key to start a measurement.

4 After the measurement, wait for the

display to become stable and press

the PRINT key. The measurement

value blinks and is ready to be

corrected.

5 Correct the value using the following keys:

MODE key Switches the blinking digits.

Press and hold

(One-point calibration)

(One-point calibration

standby mode)

Set standard viscosity fluid

(Measurement mode)

When the data

is stabilized

START key Changes the setting of a

blinking digit.

STOP key Moves the decimal point.

6 Press the PRINT key to confirm the correction value.

7 To exit the calibration mode:

With " end " being displayed, press the PRINT

key again to return to the standby mode.

To correct the value:

With " end " being displayed, press the

STOP key and correct the value.

8 Measure the viscosity of the

standard viscosity fluid used.

Confirm that the viscometer displays

the similar value as the entered

correction value.

(Confirm the value)

(Correct the value)

To c o rr e ct

(End of one-point calibration)

(Standby mode)

45

Page 48

8-2-2 Two-point Calibration