Page 1

Weighing Indicator

for Check Weighing Scales

1WMPD4002313

Page 2

This Manual and Marks

All safety messages are identified by the following, “WARNING” or “CAUTION”,

of ANSI Z535.4 (American National Standard Institute: Product Safety Signs and

Labels). The meanings are as follows:

WARNING

CAUTION

A potentially hazardous situation which, if not avoided,

could result in death or serious injury.

A potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

This is a hazard alert mark.

Note This manual is subject to change without notice at any time to improve the

product. No part of this manual may be photocopied, reproduced, or translated

into another language without the prior written consent of the A&D Company.

Product specifications are subject to change without any obligation on the part

of the manufacture.

Copyright 2011

Page 3

Contents

1. COMPLIANCE ................................................................................................. 2

2. INTRODUCTION .............................................................................................. 3

3. UNPACKING .................................................................................................... 4

4. INSTALLATION and PRECAUTIONS ............................................................. 5

4-1. Precautions for Installing the Indicator ...................................................... 5

4-2. Load Cell Connections .............................................................................. 5

4-3. Verifying Load Cell Output and Input Sensitivity........................................ 6

4-4. Setting Up the Indicator............................................................................. 7

4-5. Parameter Settings and Calibration .......................................................... 7

5. NAMES AND FUNCTIONS .............................................................................. 8

6. FUNCTION PARAMETER SETTINGS........................................................... 10

6-1. The procedure for setting parameters ..................................................... 10

6-2. Function list ..............................................................................................11

7. CALIBRATION ............................................................................................... 12

7-1. Calibration using a weight ....................................................................... 12

7-2. Gravity acceleration correction................................................................ 13

8. AUTO-TARE FUNCTION ............................................................................... 14

9. ADDITIONAL INFORMATION........................................................................ 15

9-1. F-Function list.......................................................................................... 15

9-2. OP-03 RS-232C ...................................................................................... 15

9-3. OP-04 RS-422 / 485................................................................................ 17

10. ERROR MESSAGES ................................................................................... 18

11. SPECIFICATIONS........................................................................................ 19

11-1. Capacity and minimum display.............................................................. 19

11-2. Specifications ........................................................................................ 19

11-3. Options.................................................................................................. 20

11-4. Dimensions............................................................................................ 20

1

Page 4

1. COMPLIANCE

Compliance with FCC rules

Please note that this equipment generates, uses and can radiate radio frequency

energy. This equipment has been tested and has been found to comply with the

limits of a Class A computing device pursuant to Subpart J of Part 15 of FCC rules.

These rules are designed to provide reasonable protection against interference

when equipment is operated in a commercial environment. If this unit is operated in

a residential area it might cause some interference and under these circumstances

the user would be required to take, at his own expense, whatever measures are

necessary to eliminate the interference.

(FCC = Federal Communications Commission in the U.S.A.)

Classification of protection provided by enclosures

The equipment is designed to comply with the IP Code of IEC 60529.

The “IP65” is explained as follows:

“IP” International Protection.

“6” Against ingress of solid foreign objects.

Dust-tight. No ingress of dust.

“5” Against ingress of water with harmful effects.

Protected against water jets (no powerful jets). Water projected in jets

against the enclosure from any direction shall have no harmful effects.

2

Page 5

2. INTRODUCTION

This manual describes how this product works and how to get the most out of it in

terms of performance.

The FS-D weighing indicator is used to build high performance check weighing

scales. It has similar specifications and functions as an indicator of the FS-i series.

Please refer to the instruction manual for the FS-i supplied with the FS-D.

The FS-D indicator has the following features.

The indicator can be used to build platform scales from 6 kg (15 lb) capacity to 1500

kg (3500 lb) capacity.

The indicator can drive up to 4 x 350 Ω load cells.

Three weight display resolutions are available, 1/3,000, 1/6,000 (~1/7,500) and

1/12,000 (~1/15,000) to cover various applications.

Weighing units are kg (kilogram), g (gram), lb (pound), oz (ounce), and lb-oz

(pound and ounce). However, the FS-D set to a capacity higher than 30 kg (70 lb)

does not have all of them. Refer to “11-1. Capacity and minimum display” in detail.

Waterproof to IP-65 specifications.

Constructed from stainless steel for harsh working environments.

Large liquid crystal display with back lighting and analog sweep display of 60

segments with back lighting.

AC power source (100V ~ 240V), and an optional SLA (sealed lead acid) battery is

available for operation where AC power is not available.

Built in comparator lights with large and bright red, green and yellow LEDs for better

visibility.

Two modes of comparator operation, Target weight setting and Upper / Lower limits

setting.

Take-away check weighing with auto-tare function.

Optional serial data and comparator relay interface.

3

Page 6

(

(

r

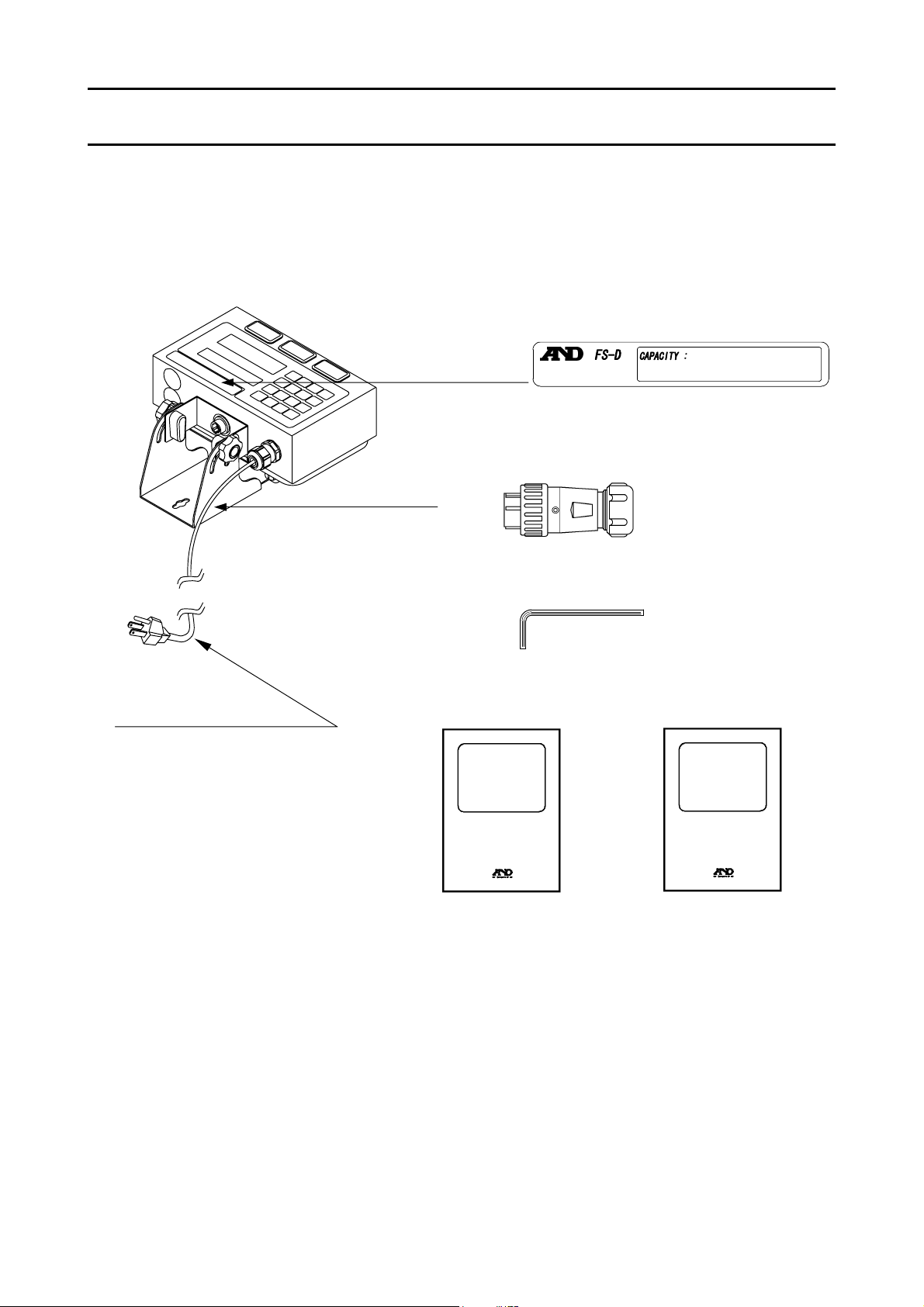

3. UNPACKING

Unpack the indicator carefully and keep the packing material if you are likely to

transport the indicator again in the future.

When unpacking, check whether all of the following items are included:

Main power cord

Please confirm that the main

power type is correct for you

local voltage and receptacle.

Indicator

Display stand

To be attached.

Connector plug

(1JMNJW-165-PM7)

Hexagonal wrench

1.27 mm / 0.05 inch)

Set Up Instruction

(this manual)

FS-D

SET UP INSTRUCTION

Model label

1083014607)

Instruction manual

FS-i series

FS-i series

INSTRUCTION MANUAL

4

Page 7

4. INSTALLATION and PRECAUTIONS

4-1. Precautions for Installing the Indicator

Ground the indicator so that the user will not be subjected an electric shock.

Do not handle the main power cord with wet hands.

The AC plug is not water-resistant. Install it in an area where it does not get wet.

Do not install the indicator where there is flammable or corrosive gas present.

Do not install the indicator under water.

Do not pull, fold or arrange cables forcibly.

Use shielded cables for all connections.

Ground the platform to be connected to the indicator to avoid a risk of electric shock.

Read the section “CAUTION” in the instruction manual of the FS-i to

understand the conditions and precautions for installation, operation and

cleaning the indicator.

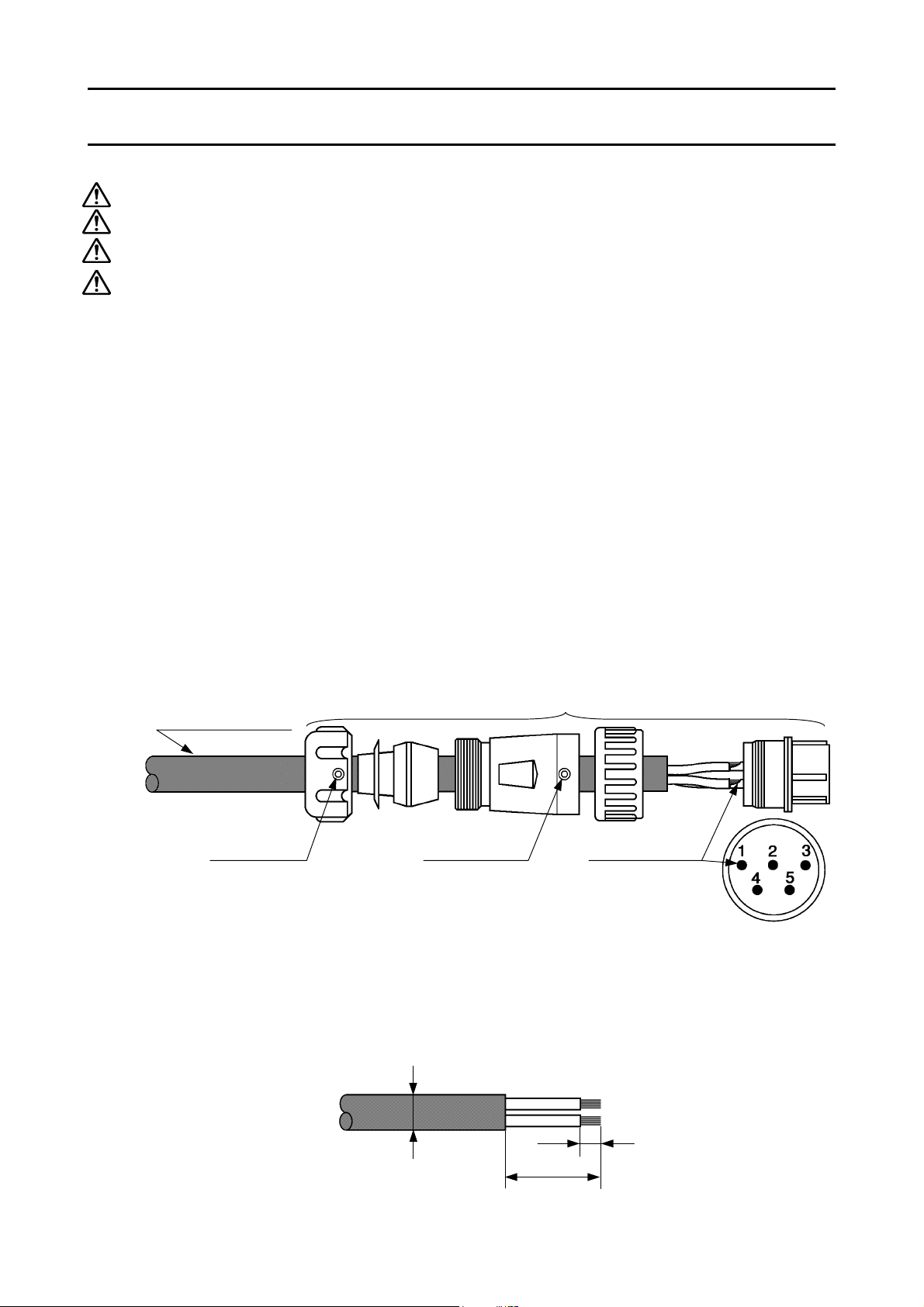

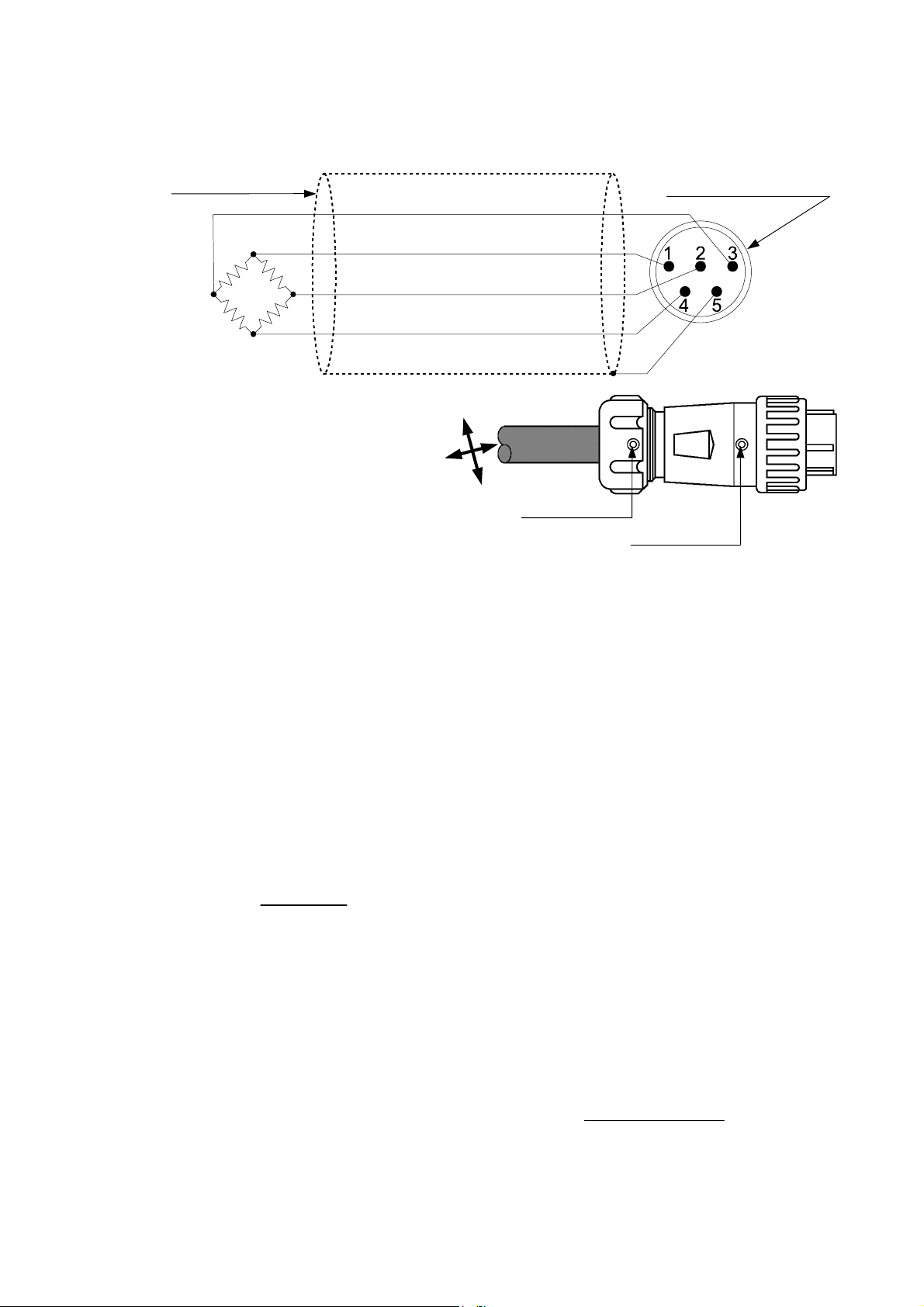

4-2. Load Cell Connections

Solder the load cell cable to the connector plug (1JMNJW-165-PM7) provided with

the FS-D and connect it to the connector on the bottom of the FS-D.

1. Use the supplied hexagonal wrench (1.27 mm / 0.05 inch) to loosen the setscrews A

and B to disassemble the connector plug.

Load cell cable

2. Put the load cell cable through each parts of the connector taking care of their order

and directions.

3. Remove the sheath and wire covering of the load cell cable referring to the drawing

below.

The external diameter of the applicable load cell cable is Ø5.7 ~ Ø6.8 mm.

Setscrew B

Load cell cable

Ø5.7 ~ Ø6.8 mm

Connector plug (1JMNJW-165-PM7)

Setscrew A Pin contacts

3.2 mm

16 mm

5

Page 8

×

4. Solder the wires to the pin contacts of the connector.

A 5 m or less load cell cable is recommended as the

FS-D uses a 4 wire system (no remote sensing).

5. Reassemble the connector plug

6. Move the load cell cable back

7. Connect the connector plug to the

Load cell cable

Load cell

and tighten the setscrew A.

and forth and around, and tighten

each parts again. Finally, tighten

the setscrew B.

load cell connector on the bottom

of the display pod.

SIG-

Load cell connector

EXC+

SIG+

EXC-

Shield

Setscrew B

Setscrew A

4-3. Verifying Load Cell Output and Input Sensitivity

The input sensitivity is 0.2 µV/division or more. When designing a weighing scale, the

load cell output voltage should satisfy the input sensitivity of the indicator. Or the scale

should be designed so that the following calculating formula is satisfied.

In order to achieve a scale with stable performance, select the input sensitivity as

large as possible.

Calculating formula:

A : Rated capacity of load cell (kg)

dBE

≤0.2

××

nA

×

Example of calculation:

In the case of designing a scale with a capacity of 60 kg, using a load cell with a

rated capacity of 100 kg and rated output of 1 mV/V:

Load cell capacity: A = 100 kg

Rated output: B = 1 mV/V

Set function setting C02-3, then

Min. display (smallest): d = 0.005 kg

Excitation voltage: E = 5000 mV

Number of load cell: n = 1

B : Rated output (mV/V)

d : Min. display (smallest of kg) / scale division

E : Excitation voltage (mV) = 5000 mV for FS-D

n : Number of load cells

005.015000

×

1100

×

2.025.0

>=

6

Page 9

4-4. Setting Up the Indicator

Clamp

Clamp

Display stand

Earth terminal

Connect the main power cord to an outlet that has an earth ground terminal. You

may use the earth terminal on the rear side of the display to ground the indicator.

If necessary, adjust the viewing angle of the display by loosening the 2 clamps,

changing the angle and re-tightening the clamps.

The Display stand can be secured on a table or flat surface using screws (not

supplied). It can be also used as a wall-mounting bracket. See “11-3. Dimensions”

about the dimensions of the mounting holes.

Earth

terminal

To the wall

Display stand

(Wall-mounting bracket)

4-5. Parameter Settings and Calibration

When a platform scale is initially set up, it is necessary to set some parameters and

calibrate it using a calibration weight.

See “6. FUNCTION PARAMETER SETTINGS” to set parameters and “7. CALIBRATION”

to calibrate the scale.

7

Page 10

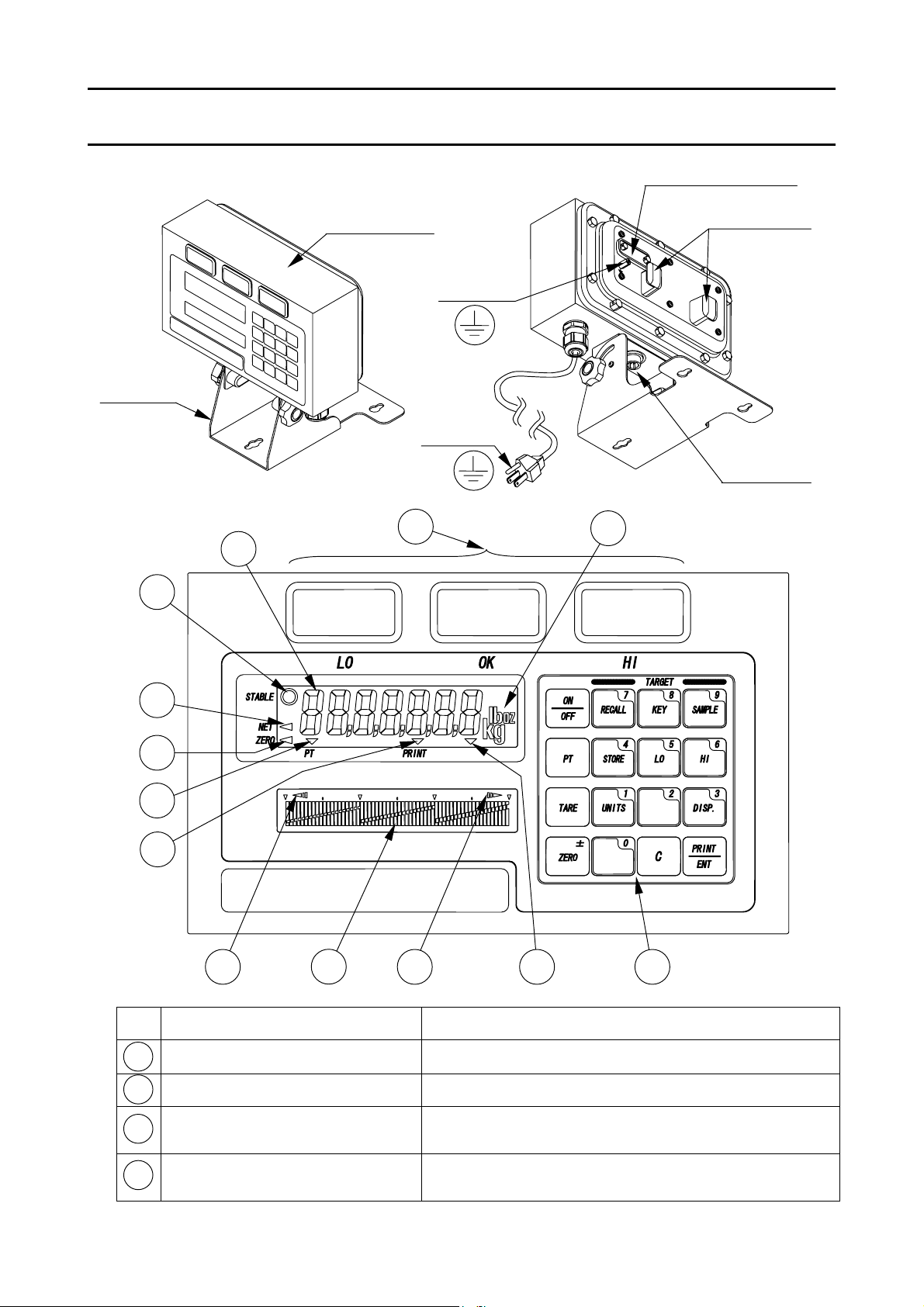

5. NAMES AND FUNCTIONS

Display

stand

6

8

7

9

10

Display pod

1

4 4

3

Earth

terminal

Earth

terminal

5

11

CAL switch cover

Load cell

connector

2

12

No. NAMES FUNCTIONS / OPERATION

1

WEIGHT DATA DISPLAY

2

WEIGHING UNIT INDICATOR

3

ANALOG WEIGHT DISPLAY

4

OVER RANGE INDICATORS

8

Indicates the weight data.

Indicates the weighing unit in use.

Indicates zero to full scale or comparison limits

and results.

Turns ON when the weight is outside the range of

the analog sweep display.

Page 11

No. NAMES FUNCTIONS / OPERATION

5

COMPARISON INDICATORS

6

STABLE ANNUNCIATOR

7

ZERO ANNUNCIATOR

8

NET ANNUNCIATOR

9

PT ANNUNCIATOR

10

PRINT ANNUNCIATOR

PRECAUTION AGAINST

11

LOW BATTERY

12

ON/OFF Key

ZERO / ± Key

TARE Key

Indicates the results of the weight comparison

LO (RED), OK (GREEN) and HI (YELLOW).

Turns ON when the weight reading is STABLE.

Turns ON when the weight is in the center of

ZERO range.

Turns ON when the display shows the NET

weight.

Turns ON when the display shows the preset tare

weight.

Turns ON for a moment when the weight data is

sent by the PRINT/ENT or auto-printing.

Turns ON when the optional battery is getting

close to low battery.

Turns the power on or off. When turned on,

the power-on zero will work.

Zeroes the indicator when the weight is stable.

Or the key switches the sign “+” & “-”.

Zeroes the display and switches to net weight

mode when the weight is plus and stable.

PT Key

SAMPLE / 9 Key

KEY / 8 Key

RECALL / 7 Key

HI / 6 Key

LO / 5 Key

STORE / 4 Key

DISP. / 3 Key

UNITS / 1 Key

PRINT / ENT Key

The key is used to enter a tare weight via the

10-key pad.

To register the sample weight as a target.

Or the numeric key 9 in the data entry.

To enter a target weight via the 10-key pad.

Or the numeric 8 in the data entry.

To recall target weight and/or HI/LO limits.

Or the numeric 7 in the data entry.

To enter comparator HI limit via the 10-key pad.

Or the numeric 6 in the data entry.

To enter comparator LO limit via the 10-key pad.

Or the numeric 5 in the data entry.

To store target weight and/or HI/LO limits.

Or the numeric 4 in the data entry.

Switches the analog sweep display modes.

Or the numeric 3 in the data entry.

To select the desired weighing unit.

Or the numeric 1 in the data entry.

To send a data string through the optional

interface. Or to ENTER the numeric data.

C Key

0 and 2 Keys

The key to clear an incorrect data entry from the

numeric keypad.

The numeric keys 0 and 2.

9

Page 12

r

r

6. FUNCTION PARAMETER SETTINGS

To design a platform scale, set the capacity, weighing

unit and other functions according to the specifications

of the scale.

Normally, end users do not have to set these function

parameters and these setting can be sealed together

with the calibration switch.

-C01-00

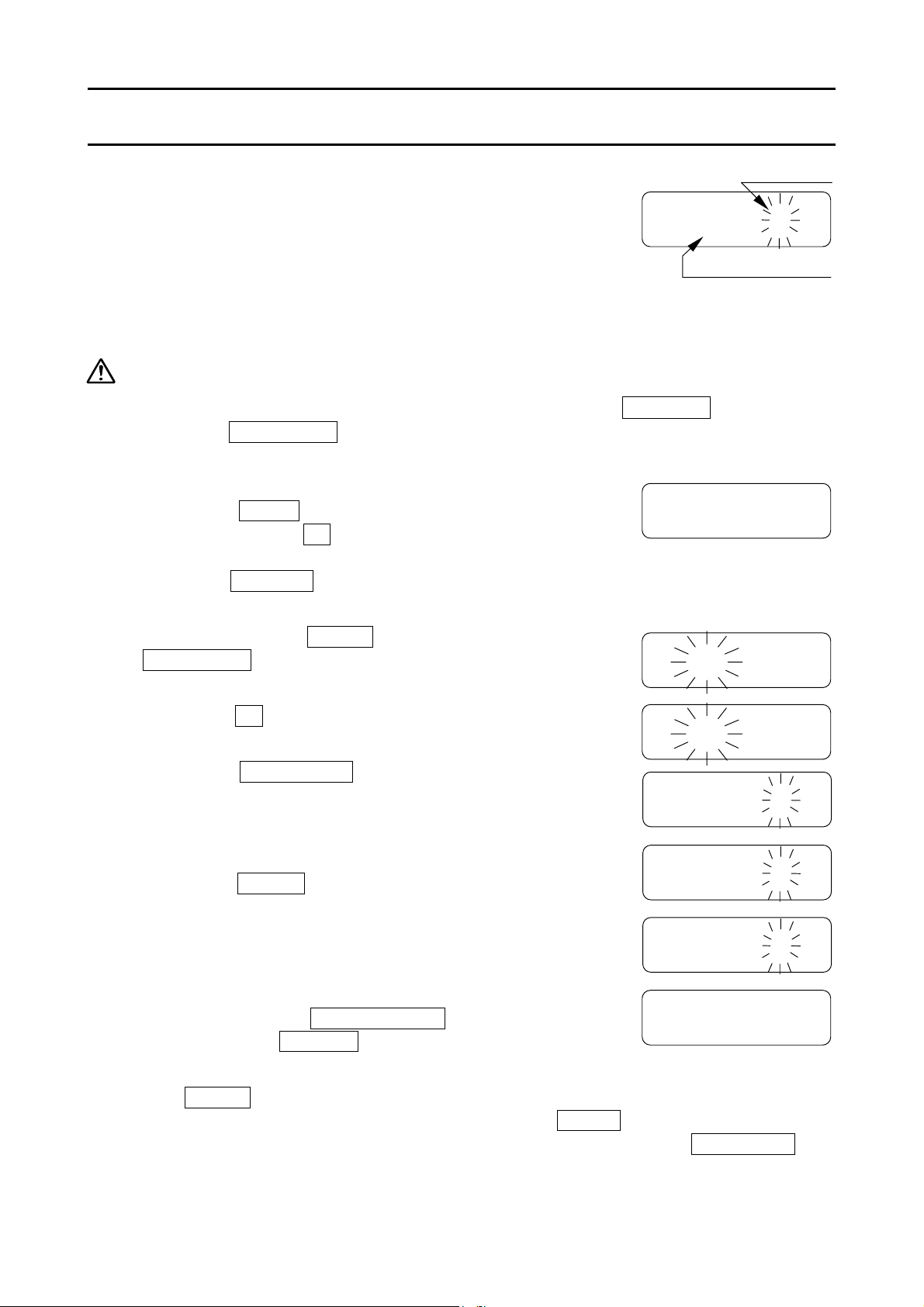

6-1. The procedure for setting parameters

Do not set “C01-1”. Once set, the indicator cannot get into the parameter

setting procedure again.

When turning the power on and the indicator may display ------- ,

press the PRINT/ENT key to proceed to the weighing mode.

See “7. CALIBRATION” as for the location of the calibration (CAL) switch.

1. In the weighing mode, press and hold the calibration (CAL)

switch until Cal appears. Then, release the switch.

Press and hold the 0 key for about 5 seconds, then you

can also enter the calibration mode (when “C01-0” is set).

Press the ON/OFF key or (CAL) switch to stop the

setting procedure.

-00Cal00

Function numbe

Paramete

2. Press and hold the ZERO key and press the

PRINT/ENT key. Then the first function number is

displayed.

3. Press the 2 key to enter into the “C02 Capacity”

setting.

4. Press the

stored appears.

5. Enter the parameter value for the capacity using the

10-key pad.

6. Press the ZERO key to go to the next function

number “C03 Weighing display unit”.

7. Set C03 “0” (metric unit), or “1” (non-metric unit).

8. The settings C02 and C03 are minimum requirements

to design a platform scale. To finalize the settings, be

sure to press the

display shows end for a few seconds and

returns to weighing mode.

PRINT/ENT key. Then the parameter

PRINT/ENTER key. Then, the

-C01-01

-C02-01

-C02-00

-C02-02

-C03-01

-00end00

The ZERO key increments the function number as in the step 6 above, but note

that all of the new parameters are not stored until end is displayed.

To exit with nothing changed, turn the power off without pressing the PRINT/ENT key.

Set the other parameters according to the specifications required.

10

Page 13

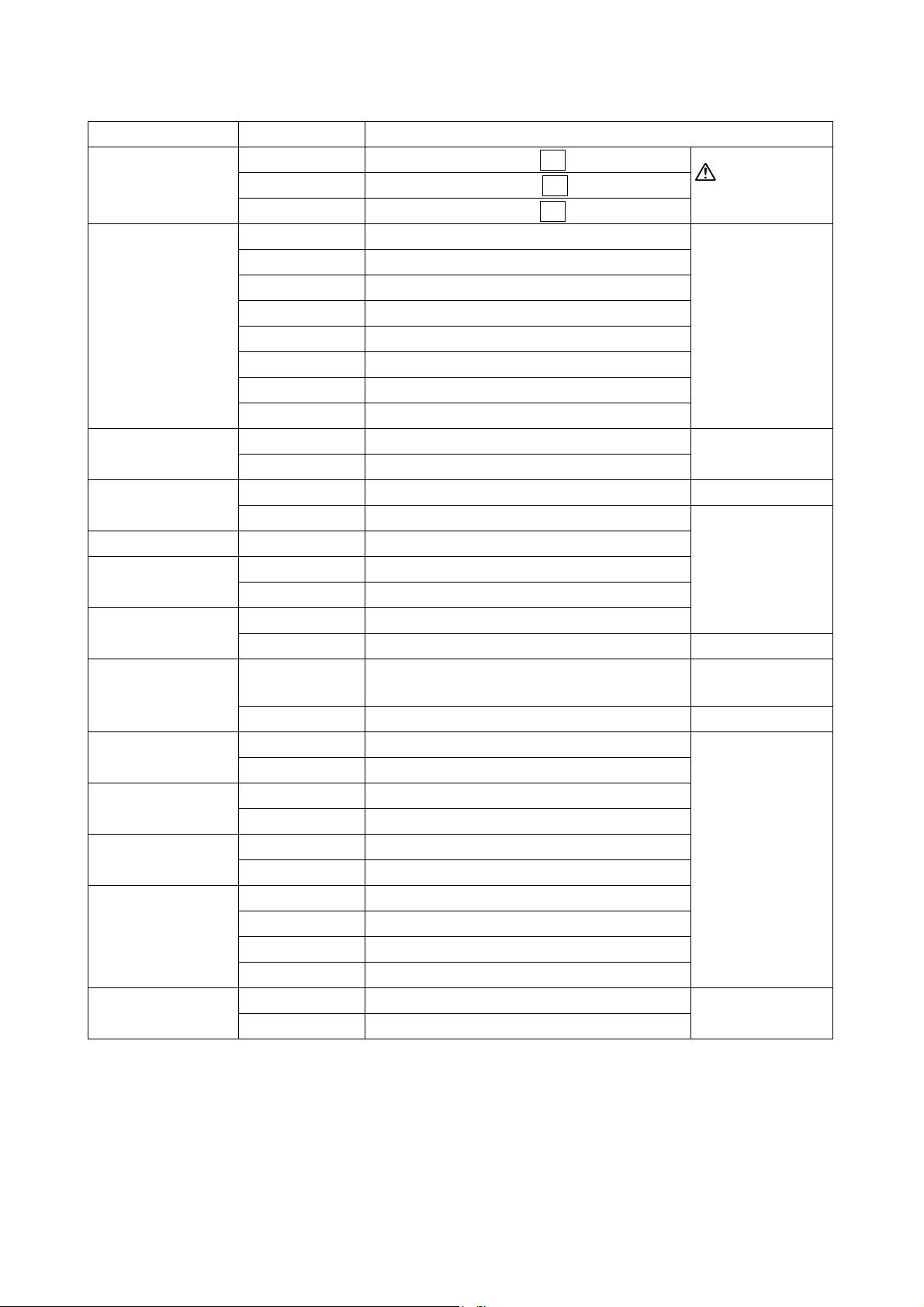

6-2. Function list

Item

Function number

Description

C01- 0 CAL switch enabled, 0 key enabled

Calibration

C01- 1 CAL switch disabled, 0 key disabled

Do not set

“C01-1”

C01- 2 CAL switch enabled, 0 key disabled

C02- 0 6 kg (15 lb)

C02- 1 15 kg (35 lb)

C02- 2 30 kg (70 lb)

Capacity

C02- 3 60 kg (150 lb)

C02- 4 150 kg (350 lb)

C02- 5 300 kg (700 lb)

C02- 6 600 kg (1500 lb)

C02- 7 1500 kg (3500 lb)

Weighing display

unit

Power-on-zero

range

C03- 0 kg, g

C03- 1 kg, g, lb, oz, lb-oz

See “11-1.

Capacity ...”.

C04- 0 ±10% of the capacity OIML R76 / NTEP

C04- 1 ±50% of the capacity

Internal use C05- 0 Do not change.

Decimal

separator

Tare clear by

ZERO operation

Tare operation

(Net weight

calculation)

Preset tare

function

lb-oz unit

C06- 0 . (point)

C06- 1 , (comma)

C07- 0 ZERO does not clear tare weight

C07- 1 ZERO clears tare weight OIML R76

C08- 0

Tare weight is rounded to the weight

display count

C08- 1 Internal count is used for TARE weight. OIML R76

C09- 0 Function disabled

C09- 1 Function enabled

C10- 0 lb-oz disabled

NTEP

C10- 1 lb-oz enabled

ZERO operation

range

C11- 0 ±2% of the capacity

C11- 1 Up to the capacity

C12- 0 “f02” setting specifies the resolution.

Display resolution

C12- 1 Fixed to “f02-0” (1/3,000~1/3,500)

C12- 2 Fixed to “f02-1” (1/6,000~1/7,500)

C12- 3 Fixed to “f02-2” (1/12,000~1/15,000)

Auto-tare function

C13- 0 Function disabled

C13- 1 Function enabled

C13-0 deletes

“f21” ~ “f23”.

Factory setting

11

Page 14

r

7. CALIBRATION

This function adjusts the scale (indicator) for accurate weighing.

Calibration must be done when the FS-D is initially connected to a load cell (base unit).

Calibration may also be required according the changes in the environment.

When the scale (indicator) has been moved.

When the ambient environment has

significantly changed.

For regular calibration.

Loose the lock screws on the rear side of the

display pod, and remove the (CAL) switch

cover. The calibration switch inside.

7-1. Calibration using a weight

1. Warm up the indicator with a weighing platform connected for at least half an hour.

Change the user function setting “f01” or place something on the platform to

disable the auto power-off function.

When turning the power on and the indicator may display ------- ,

press the PRINT/ENT key to proceed to the weighing mode.

CAL switch cove

Calibration (CAL) switch

2. Press and hold the calibration (CAL) switch until

Cal appears, and release the switch.

Press and hold the 0 key for about 5 seconds, then you

can also enter the calibration mode (when “C01-0” is set).

Press the ON/OFF key or (CAL) switch to exit without

calibration.

3. Press the PRINT/ENT key, then the gravity

acceleration value will be displayed.

It is not necessary to set the gravity acceleration value

when calibrating the indicator with a calibration weight

at the place where it is to be used. (See the next

section about the gravity acceleration correction.)

4. Press the PRINT/ENT key, then Cal 0 will be

displayed.

5. Make sure that there is nothing on the platform, and wait

until the STABLE indicator turns on.

6. Press the PRINT/ENT key. The indicator inputs the

zero point, and the display shows 5pn 1 and the

weight value for calibration (SPAN calibration).

The weight value is equal to the capacity. When you

enter with “kg” or “g” mode, then the value is “kg”.

Entering with “lb” or “oz”, then “lb”.

-00Cal00

-009.7985

-00Cal00

-05pn010

-00030.00

12

Page 15

If you need ZERO calibration but do not need SPAN

calibration, turn the power off to exit from the calibration

procedure.

7. To calibrate with a different weight, change the

displayed value using the 10-key pad.

If you enter the wrong number, press the C key. The

value returns to the capacity and enter the number again.

8. Place a calibration weight on the platform with the same

value as displayed, and wait until the STABLE indicator

turns on.

9. Press the PRINT/ENT key. The indicator calibrates

SPAN and end will appear. Remove the weight

from the platform, and turn the power off.

Note

The value set in step 7 will be cleared after the power is switched off.

If the indicator will be moved to another location, set the gravity

acceleration value for the current location and calibrate the indicator

according to the procedure above. See the next section to set the value.

-00020.00

-00end00

7-2. Gravity acceleration correction

When the indicator will be moved to different place from the calibration location, it

should be calibrated using a calibration weight.

But if a calibration weight is not available, the gravity acceleration correction will

compensate the indicator. To use this function, set the gravity acceleration value to the

value of the location where the calibration will be done. Refer to the gravity

acceleration map appended to the instruction manual of the FS-i series.

1. At step 3 of the previous section “7-1. Calibration using

a weight”, enter a new value using 10-key pad.

The integral part “9” is fixed, enter the value after the

decimal point.

If you hit the wrong number, press the C key. The

value returns to the original number. Enter the number

again.

2. Press the PRINT/ENT key, then Cal 0 will be

displayed.

3. Go to step 5 of “7-1. Calibration using a weight”.

-009.8050

-00Cal00

13

Page 16

8. AUTO-TARE FUNCTION

The FS-D has an auto-tare function to be used with the comparator function enabled.

If the weight value is within the OK range and stable for a preset time, then the

indicator will automatically tare the weight and show zero. The Function “f22”

designates the timing to tare automatically. See “9. ADDITIONAL INFORMATION”

about the added F-Function settings related to the auto-tare function.

To use the auto-tare function, set the function settings below.

f08-1: Compare all weighing data (other settings may be used depending on

the application).

f21-1: Auto-tare function enabled.

f22-0 ~ 9: Select the timing to tare automatically to avoid the wrong tare

operation, for example; too early to tare, to take a longer time to go to

the next weighing and so on.

Take-away check weighing:

Take-away check weighing (negative comparison) is the way to compare the

negative weight taking away material from a container. Set the Function “f24-1”

together with the auto-tare function enabled “f21-1”. In this operation mode, the

indicator operates as “take-away the material” Æ “OK and stable” Æ “auto-tare” Æ

“take-away the material” Æ ······.

In this setting, the polarity of the target weight and the upper / lower limit weight are

ignored and the indicator shows the comparator results as below.

f07-1: -(|Target|+HI limit) -(|Target|-LO limit)

f07-0: -|Upper limit| -|Lower limit|

Negative value Net 0 Weight display

Note To start the take-away check weighing, be sure to use the TARE key to tare

When the Function “f23-1 Tares the initial (container) weight.” is set:

To start the auto-tare function application, usually the container (filled with material) will

be placed on the weighing pan and its weight must be tared using the TA R E key.

When the Function “f23-1” is set, the indicator will tare the initial (container) weight

automatically.

Remove all load on the weighing pan to return to the zero point, the tare weight will be

automatically cleared. If the indicator could not return to the zero point because of a

zero shift, press the ZERO key to clear the tare weight.

If the indicator is equipped with the optional RS-232C interface, the OK weighing data

only can be sent out automatically. Set the Function setting “f06-7 Auto-print mode

+/- data”.

HI OK LO

the weight of the container filled with material. The ZERO key may zero the

display, and the indicator goes below the zero point by taking out the material.

Then, the auto-tare function does not work.

14

Page 17

9. ADDITIONAL INFORMATION

This section describes the additional functions and corrections to the instruction manual of

FS-i series (WM+PD4001332 and 1WMPD4001368) which are common to the FS-D.

9-1. F-Function list

The following function settings are added (“11-2. Function list” in WM+PD4001332).

Item

Serial interface

Data output

mode

Zero tracking

Auto-tare

function

Auto-tare timing

Auto-tare for the

initial weight

Normal/Negative

comparison

Function number

f06- 5

f06- 6 Auto-print mode + data & OK

f06- 7 Auto-print mode +/- data & OK

f13- 0 Zero tracking OFF

f13- 1 Zero tracking ON, 0.5d/sec

f13- 2 Zero tracking ON, 1.0d/sec

f13- 3 Zero tracking ON, 2.0d/sec

f21- 0 Auto-tare function disabled.

f21- 1 Auto-tare function enabled.

f22- 0 Immediately after OK and stable

f22- 1 0.5 sec. after OK and stable

f22- 2 1.0 sec. after OK and stable

f22- 3 1.5 sec. after OK and stable

f22- 4 2.0 sec. after OK and stable

f22- 5 2.5 sec. after OK and stable

f22- 6 3.0 sec. after OK and stable

f22- 7 4.0 sec. after OK and stable

f22- 8 5.0 sec. after OK and stable

f22- 9 6.0 sec. after OK and stable

f23- 0 Function disabled

f23- 1 Tares the initial (container) weight.

f24- 0 Normal comparison

f24- 1 Negative comparison for take-away

Multi-connection with print key mode

(RS-422/485)

Description

The UFC format

is applicable to

f06-2 to 4.

Setting C04-0,

f13-2 and 3

cannot be set.

Timing to tare

automatically

after the comp.

OK and weight

stable.

To be used with

f21-1.

Automatic

operation.

Factory setting

9-2. OP-03 RS-232C

The followings are the corrections and the additional information for the optional

interface (“2-2. OP-03 Specifications” and “2-3. Command Mode” in 1WMPD4001368).

Circuit diagram

15

4 Signal ground SG

5 Shield

6 Frame ground FG

4 Signal ground SG

5 Frame ground FG

6 Shield

Page 18

The frame ground and the shield are connected internally and there is no difference

between them in use.

Data format

Example of data

Out of range “kg” (+)

Out of range “kg” (+)

O L

O L

,

+999999 9 9 _ k g CRL

,

+9999.9 9 9 _ k g CRL

The position of decimal point is different according to the model and/or “f02”.

Example for the weighing unit “lb-oz” (added)

Weighing data “lb-oz” (+)

S T

,

+001L01.6 _ o z C

Data output mode (f06)

The commands can be used in all data output modes (f06-1 is command mode only).

The new modes f06-5, f06-6 and f06-7 are added to the Function “f06”.

Auto-print Mode + data and OK (f06-6)

Data is sent if the weight display is stable at +5d (d = weighing display division) and

above, and the comparator result OK in addition. The next transmission cannot

occur until after the weight display falls below +5d.

Auto-print Mode +/- data and OK (f06-7)

Data is sent if the weight display is stable at ±5d (d = weighing display division) and

above/below, and the comparator result OK in addition. The next transmission

cannot occur until after the weight display falls between –5d and +5d.

F

F

RLF

Multi-connection with Print key mode (RS-422/485) (f06-5)

This is one of the applications when a PC and more than one FS-D (RS-422/485

installed) are connected. Refer to “Multi-connection with Print key mode” in detail.

(In “2-3. Command Mode”)

Examples of command and reply (“

_

” shows “Space” (20H).)

There are corrections to the instruction manual 1WMPD4001368.

Set a HI limit value or upper limit weight. (No reply for f20-1.)

When f07-0 or f07-1 is set, the

command should have “+” and 6

digit number without decimal point.

When f07-0 or f07-1 is set, the command

should have “+/-” (“+” only for f07-1) and 6

digit number without decimal point.

Set a LO limit value or lower limit weight. (No reply for f20-1.)

When f07-0 or f07-1 is set, the

command should have “+” and 6

digit number without decimal point.

When f07-0 or f07-1 is set, the command

should have “+/-” (“+” only for f07-1) and 6

digit number without decimal point.

When f07-2 is set, the command should have “+” and 5 digit number without

decimal point.

16

Page 19

Command H I , + 0 0 1 0 0 CRL

Reply H I , + 0 0 1 0 0 CRL

F

F

Assume 2 decimal place number.

1.00% will be set as LO limit %.

Command

Reply

L O

L O

,

+ 0 0 1 0 0 C

,

+ 0 0 1 0 0 C

RLF

RLF

Assume 2 decimal place number.

1.00% will be set as LO limit %.

Store the comparator limits into the specified memory number. (No reply for f20-1.)

Reply

H I

,

0 1 , +001200,+000 9 0 0 C

RLF

Reply

M L

,

0 1 , +001200,+000 9 0 0 C

RLF

9-3. OP-04 RS-422 / 485

The followings are the corrections and the additional information for the optional

interface. (“3-2. OP-04 Specifications” in 1WMPD4001368).

Circuit diagram

The frame ground and the shield are connected internally and there is no difference

between them in use.

Multi-connection with Print key mode (new function)

This is one of the applications when a PC and more than one FS-D are connected.

The indicator will prepare the weighing data by pressing the PRINT key first and will

send out the prepared data after receiving a command from the PC.

5 Shield

6 Frame ground FG

5 Frame ground FG

6 Shield

1. Set the Function “f06-5” for all of the indicators.

2. Weigh something and wait for the STABLE indicator to turn on (the indicator having

f18-##).

3. Press the

PRINT key, the indicator will temporarily store the weight data and turn

the PRINT indicator on.

The indicator does not accept the

PRINT key while the PRINT indicator on.

4. Send the “@##S” command to the indicators from the PC.

5. The indicator (f18-##) will respond to the command to send the weight data in

memory and turn the PRINT indicator off.

The address ## = 23 (f18-23).

A request for weight data.

Command

Reply

Reply

@ 2 3 S C

@ 2 3 S T , +0012.345_kg C

@ 2 3 I C

R LF

R LF

R LF

The indicator does not have any stored data to send.

While the PRINT indicator is on, the indicator will send back “@##I” to commands

other than “@##S” command.

17

Page 20

10. ERROR MESSAGES

Overload error

Warning to indicate that an object beyond the weighing

----e---

Power-on error

--------

Low battery

---lb1--

CAL error

---Cal-e

Other errors

---err-#

When the indicator does not recover from errors or shows other errors, contact your

local A&D dealer.

capacity has been placed on the weighing pan. Remove

the object from the weighing pan.

Warning to indicate that an object beyond the power-on

zero range (50% of the weighing capacity or 10%) is

placed on the weighing platform. Remove the object from

the weighing pan.

Pressing the PRINT/ENT key, the indicator will show

the weight value without zeroing the indicator.

Warning to show that the OP-02 battery is discharged.

Immediately connect the power cord to the AC power

source to charge the battery. The indicator can be used

while the battery is charging (except when the OP-04 is

installed).

Warning to indicate that the calibration has been

canceled because the calibration weight is too light.

Check if the calibration weight is correct.

Showing errors inside the indicator. Check the

connection between the indicator and platform, and turn

the power off and on with nothing on the weighing

platform. (# signifies an error number.)

18

Page 21

11. SPECIFICATIONS

11-1. Capacity and minimum display

C02- setting 0* 1 2 3 4 5 6 7

Capacity 6 15 30 60 150 300 600 1500

kg

Min. display

Capacity 6000 15000 30000

g

Min. display

Capacity 15 35 70 150 350 700 1500 3500

lb

Min. display

Capacity 240 560 1120 2400 5600 11200

oz

Min. display

Capacity 15 35 70

lb-

oz

Min. display 0.1 0.1 0.1

0.002* 0.005 0.01 0.02 0.05 0.1 0.2 0.5

0.001 0.002 0.005 0.01 0.02 0.05 0.1 0.2

0.0005 0.001 0.002 0.005 0.01 0.02 0.05 0.1

2* 5 10

NA NA NA NA NA

1 2 5

0.5 1 2

0.005* 0.01 0.02 0.05 0.1 0.2 0.5 1

0.002 0.005 0.01 0.02 0.05 0.1 0.2 0.5

0.001 0.002 0.005 0.01 0.02 0.05 0.1 0.2

0.1* 0.2 0.5 1 2 5

NA NA

0.05 0.1 0.2 0.5 1 2

0.02 0.05 0.1 0.2 0.5 1

NA NA NA NA NA

*: Factory setting NA: Not Available

11-2. Specifications

Input sensitivity 0.2 µV / d (d: the smallest Min. display of kg)

Input signal range 0 mV ~ 13 mV

Load cell excitation

voltage

Load cell drive capacity Up to 4 x 350 ohm load cells

Temperature

coefficient

Non-linearity ±0.01 % of full scale

Display

Display update Approximately 20 times per second

Operating temp. -10°C ~ 40°C / 14°F ~ 104°F, less than 85% R.H.

Power supply AC main (100V ~ 240 V, 50/60 Hz) or SLA Battery (option)

Dimension 250 (W) x 202 (D) x 266 (H) mm / 9.8 (W) x 8.0 (D) x 10.5 (H) in.

Zero ±(0.2 µV ±0.001% of zero adjustment voltage) / °C (typ.)

Span ±0.001% / °C of reading (typ.)

5 V DC ±5% (no remote sensing)

7 segment LCD display (Character height 18.6 mm) with backlight

60 segment analog sweep display with backlight

Weight Approximately 2.7 kg

19

Page 22

11-3. Options

OP-02 (HC-02i) SLA Battery (Yuasa Battery NP4-6 recommended.)

OP-03 (FS-03i) RS-232C + Comparator Relay Output (See note.)

OP-04 (FS-04i) RS-422/485 + Comparator Relay Output (See note.)

Note OP-03 and OP-04 cannot coexist.

11-4. Dimensions

Unit: mm

20

Page 23

Page 24

3-23-14 Higashi-Ikebukuro, Toshima-ku, Tokyo 170-0013 JAPAN

Telephone: [81] (3) 5391-6132 Fax: [81] (3) 5391-6148

A&D ENGINEERING, INC.

1756 Automation Parkway, San Jose, California 95131 U.S.A.

Telephone: [1] (408) 263-5333 Fax: [1] (408)263-0119

A&D INSTRUMENTS LIMITED <UK Office>

Unit 24/26 Blacklands Way, Abingdon Business Park, Abingdon, Oxfordshire OX14 1DY United Kingdom

Telephone: [44] (1235) 550420 Fax: [44] (1235) 550485

A&D INSTRUMENTS LIMITED <German Sales Office>

Große Straße 13 b 22926 Ahrensburg Deutschland

Telefon: [49] (0) 4102 459230 Telefax: [49] (0) 4102 459231

A&D Australasia Pty Ltd.

32 Dew Street, Thebarton, South Australia 5031 AUSTRALIA

Telephone: [61] (8) 8301-8100 Fax: [61] (8) 8352-7409

A&D KOREA Limited 한국에이.엔.디(주)

대한민국 서울시 영등포구 여의도동 36-2 맨하탄 빌딩 8층

( 8th Floor, Manhattan Bldg. 36-2 Yoido-dong, Youngdeungpo-ku, Seoul, KOREA )

전화: [82] (2) 780-4101 팩스: [82] (2) 782-4280

A&D RUS CO., LTD. Компания ЭЙ энд ДИ РУС

121357, Российская Федерация, г.Москва, ул. Верейская, дом 17

( Bldg. 17, Vereyskaya st., Moscow, 121357 RUSSIAN FEDERATION )

тел.: [7] (495) 937-33-44 факс: [7] (495) 937-55-66

A&D Instruments India Private Limited

( 509, Udyog Vihar, Phase-

: 91-124-4715555

, Gurgaon - 122 016, Haryana, India )

: 91-124-4715599

BackCover 1WMPD4000058J

Loading...

Loading...