Page 1

ОМПГ^Щ©ТГО©М ffiQÄMMÄlL

owners-AD-8118A-V.3.a 90.11.14

A&D Company, Limited

Page 2

Table of Contents

Warranty..................................................................................................... Page 3

Compliance with FCC Rules...................................................................Page 3

Introduction

Welcome.....................................................................................................Page 4

Features..................................................................................................... Page 4

Specifications

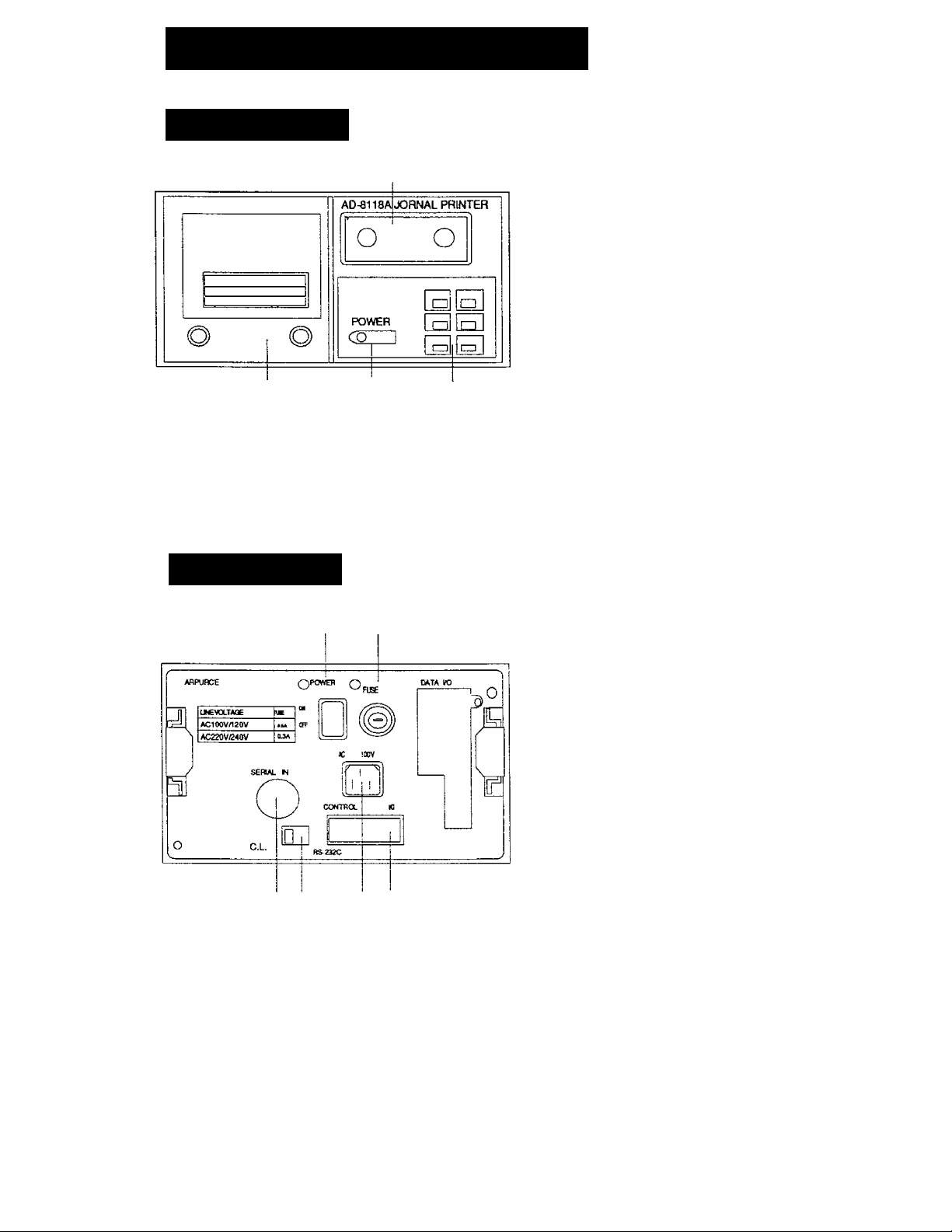

Description of Paneis

Front Panel.................................................................................................Page 6

Rear Panel.................................................................................................Page 6

Accessories................................................................................................Page 7

Installation

Best Conditions for Installation..................................................................Page 8

Connection of Power Supply/Ground..

Connection of Serial Input...................................................................... Page 8

Serial Input Connection Table

Connection of Control I/O..........................................................................Page 10

Control I/O Connection Table....................................................................Page 10

Replacing the Printing Paper

Replacing the Ink Ribbon..........................................................................Page 12

............

...........................................................................Page 5

......................................................

...............................................................

....................................................................

Page 8

Page 9

Page 11

Setting

Setting the DIP Switches...........................................................................Page 13

Function Setting Mode..............................................................................Page 14

Time Setting Mode....................................................................................Page 16

Date Formatting Mode..............................................................................Page 17

Operation

Operating the Switch Keys........................................................................Page 18

Operating the Control I/O..........................................................................Page 19

Others.......................................................................................................Page 21

©A&D Co., Ltd..international DivisIon{1990)

AD-81 ISAJounal Printer Instruction Manual v.3.a

11/13/90 JCK

Page 3

Printing

Nornnal Characters....................................................................................Page 22

Enlarged Characters..................................................................................Page 23

Applications

Serial Inputs...............................................................................................Page 26

Connection to an Industrial Scale..............................................................Page 26

■>

Connection to an Electronic Balance.........................................................Page 27

Connection to Peripheral Devices.......................................................... Page 27

Connection to Other Devices.....................................................................Page 28

Dimensions

..........................................................!................................

Page 29

Appendix

Character Code Table

...............................................................................

Page 30

Page 2

owners-AD-8118A-V.3.3

Page 4

Warranty

Warranty rights vary from country to country but it is the general intention of

A&D Co., Ltd., to offer customers a one year warranty on this product from the

day it is purchased. In some countries consumer protection legislation states

that your dealer is responsible for offering a warranty and under these

circumstances please ^efer to your local dealer.

in the U.S.A. the product (if defective) should be returned, freight prepaid by

the customer, to A&D Engineering Inc. in California and in Europe the product

can be returned freight prepaid to A&D Instruments GmbH in Frankfurt, West

Germany. Elsewhere the product can be returned to A&D Co., Ltd. in Japan.

In any event please contact your nearest A&D office before shipping, to

confirm that the product is covered by this warranty. Simple repairs can be

carried out by your local dealer under warranty and this may be the fastest

method of solving your problem.

This warranty only applies to product failures due to defective materials and/or

workmanship. This warranty will be rendered invalid if, upon inspection, it is

found that the product was: Abused; used for a purpose for which it was not

designed: mishandled; placed in a hostile environment; repaired by

unauthorized personnel; improperly installed or not adjusted in accordance

with instructions given in this manual.

ij^i

If repair under warranty is confirmed by A&D, then the product will be repaired

(or replaced, at the discretion of A&D) and then returned to the customer at no

extra cost.

Compliance with FCC Rules

Please note that this equipment generates, uses and can radiate radio

frequency energy. This equipment has been tested and has been found to

comply with the limits of a Class A computing device pursuant to Subpart J of

Part 15 of FCC rules. These rules are designed to provide reasonable

protection against interference when equipment is operated in a commercial

environment. If this unit is operated in a residential area it might cause some

interference and under these circumstances the user would be required to

take, at his own expense, whatever measures are necessary to eliminate the

interference.

(FCC = Federal Communications Commissbn in the U.S.A.)

owners-AD-8118A“V.3.a Page 3

Page 5

Introduction

Welcome!

Thank you for your

This is an Instruction Manual for the AD-8118 A Journal printer. The

AD-8118A is a product of years of design, development, and in-field

testing. It is designed to withstand harsh environmental conditions - and

each printer is subjected to several levels of quality control before it leaves

the factory. Every care has been taken during the manufacturing process

of this printer to ensure that it will perform accurately and reliably for

many years,

The AD-8118A Journal Printer is mainly for use with A&D's industrial scales

and electronic balances. A highly reliable printer mechanism is perfect for

industrial use, a watchdog circuit prevents malfunctioning and the AD8118A is built solid to protect against noise influence. Easy to operate, the

Journal Printer provides fast dependable printing.

purchase

Features

□ Dot impact printing mechanism.

□ Can print 24 columns per line.

□ Easy connection to serial input cable.

□ Small DIN size body can be mounted on panel.

□ Cumulative total function by code.

□ Calendar/clock function.

□ A lithium battery provides cumulative total and calendar back-up

without AC power for approximately 6 years.

□ 60 mm paper used for large printing capacity.

Page 4

owners-AD-8118A-v.3.a

Page 6

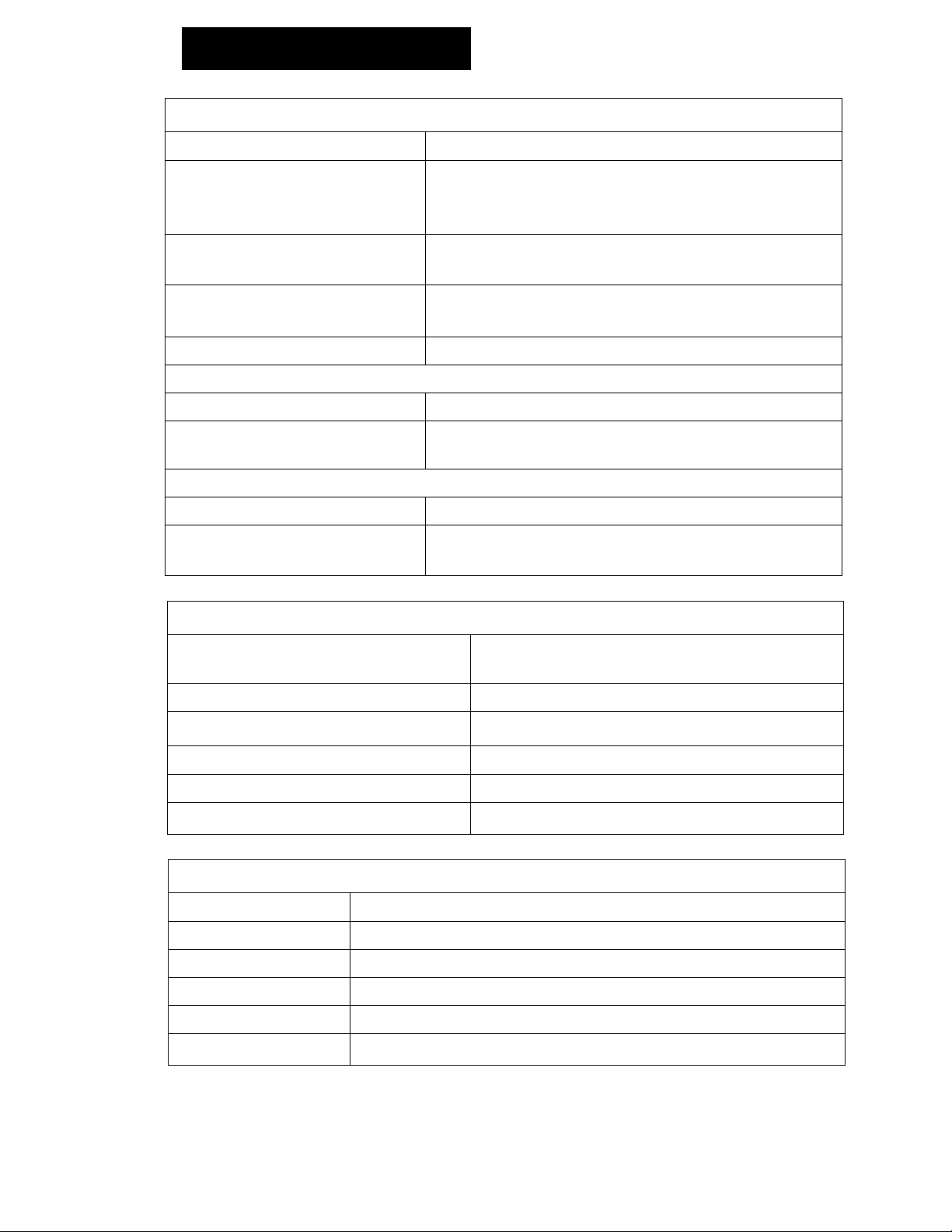

Specifications

Printer Specifications

Printing system

Printing width

>

Printing speed

Dimensions of character

Reiiability 1,000,000 lines

ink ribbon (ERC-09)

Color of character

Life

Printing paper (PP-137)

External dimensions 57.5 (W) X 60 (diameter) mm

Length

Mechanical type dot impact printer

24 columns/iine for 5 x 7 dot character

12 columns/Iine for 10 x 7 dot character

(enlarged character)

Approximately 1.7 iine/second

(internal processing time excluded)

1.7(W)x2.6 (H) mm

3.4 (W) X 2.6 (H) mm (enlarged character)

Purple

250,000 characters (varies depending on

environment)

Approximately 30m (an ending mark

appears approximately 1 m from the end.)

Generai Specifications

Power supply

Weight

Operating temperature range

Maximum humidity 80 %RH (non-condensating)

Physical dimensions

Dimensions of panel cut

100, 117, 220, 240V AC +10% / -15%,

50/60 Hz

Approximately 3 kg

-5°C to 40^C(23^F to 104^F)

192 (W)x185 (D)x96 (H) mm

186 +1.0/-0 X 92 +0.8/-0 mm

Input Specifications

Method

Baud rate

Data bits

Parity bit

Stop bit

Codes used

EIA RS-232C or 20 mA current loop (PASSIVE)

2400/600 bps

7/8 bits

1 (EVEN)/0

1

ASCII or JIS

owners-AD-8118A-v.3,a

Page 5

Page 7

Description of Panels

Front Panel

© Cover for setting section

Remove this cover and use

the DIP switches to set,

otherwise keep it attached to

prevent dust from getting

inside.

@ Printer cover

Remove this cover to change

printing paper and/or ink

ribbon,

@

<D POWER indicator

This lights up when the power

is on.

® Operation keys

For operation, refer to

"Operating the Switch Keys," .

Rear Panel

Connector for power cable

Refer to "Connection of Power

Supply/Ground," .

© ®

(D ©

© POWER switch

Turn OFF when not using.

© Fuse

0.5A 100V to 120V{blow)

0.3A 200V to 240V(blow)

@ Standard serial input

connector

Input of RS-232C or current

loop for data.

Refer to "Connection of Serial

Input,".

® Select switch for input mode

This switch is used to select

RS-232C or current loop for

serial inputs. Refer to "Serial

Inputs,".

® Connector for control I/O

This is the I/O area that

controls the printer. Refer to

"Connection of Control I/O,".

Page 6

owners-AD-8118A-V.3.3

Page 8

Accessories

AC cable

Fuse

0.5A lOOVtO 120V{blow)

0.3A 200V to 240V(blow)

1

1

Printing paper (PP-137)

Ink ribbon (ERC-09 by Epson)

I/O connector

DIN connector

Rubber legs

1

1

1

1

4

owners-AD-8118A-v.3.a

Page 7

Page 9

Installation

Best Conditions for installation

Be careful when handling this unit because it is a precision electronic

device.

1) Don't install the AD-8118A in direct sunshine. Avoid places where

there are sudden temperature changes, vibrations, strong winds and

excessive moisture or dirt.

Also, keep away from conductive substances such as carbon powder.

If these substances get inside the unit errors can occur.

2) The best temperature setting is about 20°C (68*^ F) at 50% relative

humidity.

3) Be careful not to expose the unit to excessive noise or static electricity,

this may cause malfunctioning.

Connection of Power Supply/Ground

Earth the AD-8118A via the power cable to the rear terminal of your

1)

scale or balance. Don't plug it in directly to any other equipment. Do

not use it commonly with power devices.

If the local AC electricity supply fluctuates by more than ±10% an AC

2)

regulator must be used to stabilize the power supply. Do not use a

common source for the power lines.

NOTE: Do not turn ON the power at this time. Connect the power

plug after all other connections have been made.

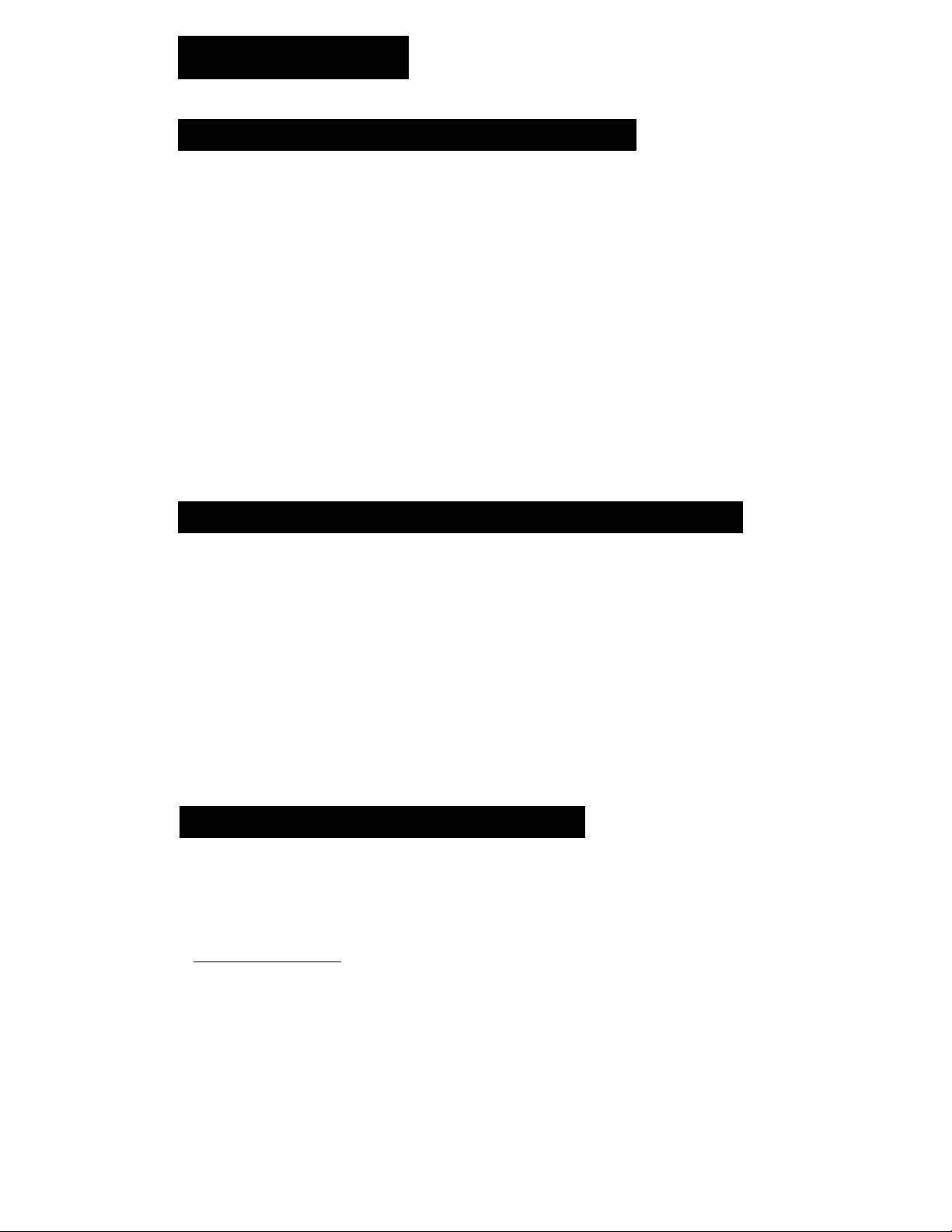

Connection of Serial lnp>ut

The Serial input on the rear panel can be connected with either the RS232C input or the current loop input. Select the appropriate input with the

slide switch also located on the rear panel.

Direct Connection

The Serial Input can be connected with a standard serial output or current

loop on A&D Weighing Indicators.(ex. AD-4322A, AD-4323, AD-4324,AD4325A)

Page 8

owners-AD-8118A-v.3.a

Page 10

Using the Optional Interface

The Serial input can be connected with a RS-232C input or current loop

input using an RS-232C optional interface. This can be done with the FX,

FY, FR, FV, FW and AD-4316 or AD-4321. (If the option is provided with a

current loop output, it can be used as well.)

Note that these units^are equipped with outputs that can be connected to

the AD-8917, AD-8918, AD-8117 and AD-8118A externally.

Serial Input Connection Table

Pin No.

1

2

3

4

5

6

7

O The Serial Input is commonly used for the RS-232C and the current

loop. On a RS-232C connection, pin No. 5 Is used as the signal

ground; connect the shield to pin No. 2.

O Signal lines using a twist-pair shielded cable should work better. This

is diagrammed below:

Abbreviation

C.LOUT

F.G

Ser. m+ Serial input + (TxD) /

GND

Ser.lN-

I.C

I.C

AD-8117, 8118A, 8917, 8918 etc.

Description

Current loop output ^

Frame ground /o 0\

Signal ground 1 J

Serial input - (SG)

For internal use

For internal use Viewed from rear panel

owners-AD-8118A-v.3.a

Page 9

Page 11

Connection of Control I/O

+v

Input

□ This is the interface circuit of the Control I/O .

□ Please use an optical isolator or relay.

□ The extension, or driving capacity of these relays is 24V 50mA DC

maximum.

□ The width of these inputs are at least 100msec.

Control I/O Connection Table

Pin No.

A 1

1 ■—1

2

2 2

3 4

4 8

5

10 5

6 20 6

7

40 7

8 80 “ 8

9 Printing command input

10

Paper feed command input 10

11

Addition command input

12

Subtotal printing command input

Description

Code input (BCD)

Pin No.

B 1

3

4

9

11

12

Grand total printing command input

Delete command input

Cumulative total delete command input

Input for disable printing time

Busy output

Printing announcement

N.C.

Output common

For internal use

Input common

Input common

F.G.

The Pins to change the Control I/O specifications are located on the rear

panel. See drawing below:

12

DODDODDOQDDD

D D D D D D D D D a D Q

/

Viewed from the rear panel

1

\

The inputs are operated by shortcircuits.The input is a pulse that has a coded

A

input. These pulse widths are 100 msec, or

B

longer.

The output is operated by the output

transistor turnnig ON.

Description

/h Note The data will only print when the "Input for disable printing time"

Pin # B-4 is shorted.

Page 10

owners-AD-8118A-v.3.a

Page 12

Replacing the Printing Paper

1, First, turn the power OFF.

I

----

1

o

0

j] Paper Roli

r

Front View

Side View

Side View

Front of Printer

Loosen the screws on the printer cover and

2.

draw out the printer unit.

Peel off the adhesive tape on the printing

3.

paper (PP-137) completely, insert the shaft

provided as an accessory and set the

paper. (Be careful of the Erection of the

paper.)

After setting the paper to the holder, take

4.

out the paper and insert it into the opening

labeled "A" on the printer through the lower

side of the roller, as shown to the left.

With the paper inserted, turn the right knob

5.

of the printer unit in the direction of the

arrow shown to the left; the paper should

come out the front.

oi.

Side of Printer

!f the paper fails to come out, check for a

bend or fold in the paper. If it is difficult to

insert, fold the top over a few centimeters.

If the ink ribbon needs adjusting turn the

knob of the ink ribbon to give tension to it.

Return the unit to its original position and tighten the screws on the

6.

printer cover.

Note 1: Do not apply excessive force to the printer unit. If normal, it

can be drawn out easily. If it is hard to take out return it once and draw

it out again. The guide may be damaged if excessive force is applied

vertically or horizontally.

Note 2: The printer is made of precision components and could be

damaged if metallic powder, water or other foreign substance get inside

the printer. Also be careful of static electricity when the printer is drawn

out..

If dust and other foreign substance get inside the unit, blow it out with

clean air. If the unit is used in a dusty environment consider using a

dust cover or air purge when not in use.

Note 3: A red mark will be printed approximately 1m before the end

of the roll of paper; replace the paper when you see this mark.

owners-AD-8118A-v.3.a

Page 11

Page 13

Replacing the Ink Ribbon

1. First, turn the power OFF.

2. Loosen the screws on the printer cover and draw out

the printer unit. Remove the printing paper. (Refer to

Front of Main Unit

"Replacing the Printing Paper," p. 10.)

3. Remove the printer cover carefully: it can be

detached from the unit by lightly lifting up.

Side of Main Unit

4. Remove the old ink ribbon by lifting it up when the

arrow position of the printer unit is pushed.

5. Set the new ink ribbon in place being careful not to

—TTT

À

__

Front of Printer

roll the ribbon. After the ribbon is in place, turn the

right knob of the ink ribbon in the direction of the

arrow shown in the figure to the left.

6. Reattach the printer cover by setting the bosses and

sliding the cover down.

7. Set the printing paper, see page 11.

8. Return the unit to its original position and tighten the

Printer Unit

screws on the printer cover.

Note 1 : Do not apply excessive force to the printer unit. If normal, it can

be drawn out easily. If it is hard to take out return it once and

draw it out again. The guide may be damaged if excessive force

is applied vertically or horizontally.

Note 2: The printer is made of precision components and could be

damaged if metallic powder, water or other foreign substance get

inside the printer. Also be careful of static electricity when the

printer is drawn out.

If dust and other foreign substance get inside the unit, blow it out

with clean air. If the unit is used in a dusty environment consider

using a dust cover or air purge when not in use.

Page 12

owners-AO-8118A-v.3.a

Page 14

Settings

Setting the DIP Switches

The DIP switches control the conditions of printing. Open the cover on the

front panel (refer to “Front Panel,“ p. 6) and set the DIP switches. The DIP

switch options are as follows:

Switch No.

1 Baud rate

Contents

2 Data bit

3

Printing mode Dump print

4 Printing form

5* Minus/unstabie Accepted

6

7

8

Printing characters Standard characters

Key input

Setting mode

2400bps

7bit (even parity check) 8bit (no parity)

Normal characters

Enabled

Normal mode

OFF

600bps

Standard format

Inverted characters

Not accepteddata

Enlarged characters

Disabled

Setting modechange

All switches are turned OFF without No.3 when shipped from our factory so

make changes according to your needs. Note that switch #5 is available only

in the standard format.

n

start M

LSS

0

1 2

3

data bit parity bit stop bit

4 5

MSB

6

ON

The DIP switch explanations are described beginning below:

Baud rate Switch #1

Baud rate is the speed of transmitting data, it can be changed by the DIP

switch #1. Choose either a faster 2400bps or normal 600bps speed.

Choose 600bps to avoid errors caused by the expansion of the cable.

Data bit Switch #2

Data bits are the bits used to transfer one character of data; 7 bits or 8

bits are available. Even parity is performed on 7bit data.

Printing mode Switch #3

Dumb printing is simply having al! print formatting controlled by an

external device. All function keys and inputs are disabled except for the

FEED key.

owners-AD-8118A-v.3.a

Page 13

Page 15

The Standard format results in data after the output from an A&O

industrial scale or electronic balance is internally processed and

formatted. Printing timing, cumulative total, etc. are taken, (For the input

data of the standard format, refer to "Applications," p. 21.)

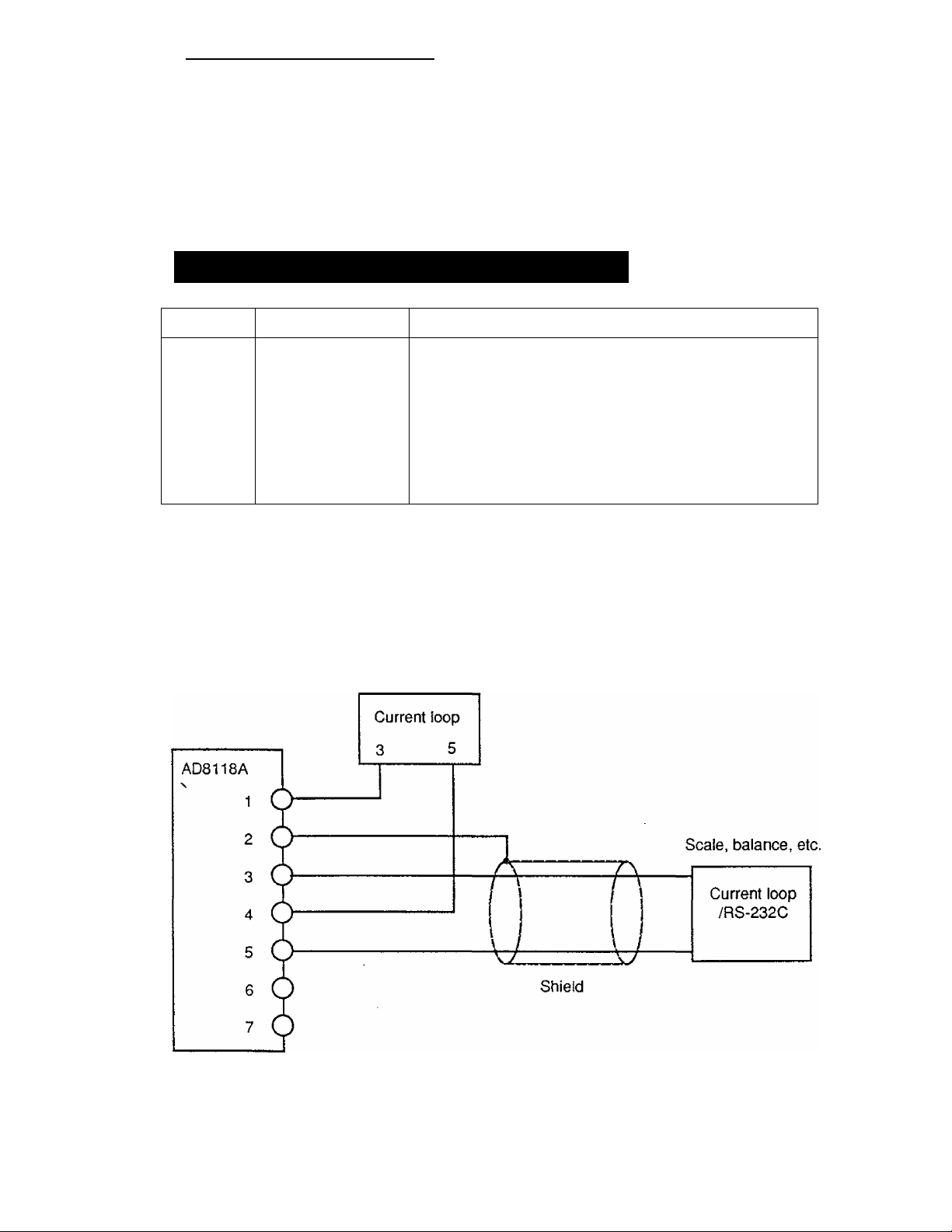

Printing form

Switch #4

Select the printing direction.

12/31/99 11:59 PM

600.0kg

Normal character Printing direction

inverted character Printing direction

When Normal characters are selected they seem to be inverted during

printing, but the printing process is the same as the input data process.

Inverted characters selected seem to be normal, but the printing process is

the opposite of the input data process.

Status printing Switch #5

Changes over to enable/disable the data at minus/unstable.

Printing character Switch #6

Choose either standard character size (5x7 dots) or

enlarged (10 x 7).

Key input

Switch #7

Enable or disable the key inputs from the front panel.

Setting mode change Switch #8

if this DIP switch is selected the unit is in the setting mode explained below.

Function Setting Mode

Setting mode can only be accessed when DIP switch #8 is turned ON.

Then, while pressing the SET UP key, press the M+.PRT.key at the same

time. The following message is printed:

FUNCTION 1 1

You are now in the Function mode, press the TOTAL key to change the

Function No, and same format used for printing. Press the M+.PRT. key to

increase the function level, press the CLEAR key to decrease the function

level.

Page 14

owners-AD-8118A-v.3.a

Page 16

The FEED key will advance the paper by one line and the PRINT key will

print the function message and the data currently in the setting format.

Press and immediately release the SET UP key to update and escape the

Function mode. The functions will be printed and the unit will return to

setting mode.

F1-1,F2-2,F3-1,F4-1

FUNCTION SET END

Function Mode Options

F1-Printing Mode

There are two types of FI printing modes:

(1) The Auto mode prints input data automatically. The printing

timing can be controlled either manually or by using the auto

printing mode.

(2) The Manual mode only prints when the PRINT key is pressed

or a command is input. The printing timing can be controlled on

the main unit if the device connected is set to stream.

Set value of FI

FI -1

Printing mode

Manual printing 1

Description

Adds and prints at addition printing,

(initial setting)

FI -2

Manual printing 2-

Adds only at addition printing.

FI -3 Auto printing Prints the data.

FI -4

Auto addition

Adds the data.

FI -5 Auto addition/printing Adds and prints the data.

F2- Lines to feed

Sets the number of feeding lines after printing the data or the

cumulative total by a number from 0 to 9. default is "2".

F3- Input mode

Select either gross weight, net weight, tare weight, or ail three. This

function is used when connecting a weighing indicator {ex. AD-4322,

AD-4323, AD-4325A) to several peripheral devices (external indicator,

etc.) (refer to ’‘Connection to Peripheral Devices,"). Otherwise, set to "1

(All enable)."

Set value of F3

F3-1 All enable (initial setting)

F3-2

F3-3

F3-4

owners-AD-8118A-v.3.a

input mode

Gross weight

Net weight

Tare weight

Page 15

Page 17

F4- Statistics mode

This mode can get maximum data .minmum data ,average data

.standard deviation, sample range of cumulated data and prints out

these. The Statistics caluclates all data no concernning with code

data.

Set value of F4

F4-0

F4-1

No caluclation of statistics (initial setting)

Sample deviation (an-i)

mode

F4-2 Standard deviation (an)

Time Setting Mode

Press the TOTAL key while at the same time pressing the SET UP key.

Now change the date and time to their correct settings. You will be

prompted with the following screen:

10/26/90 2:35 PM

A

To set the date and time use the following keys:

TOTAL key

M+.PRT key

Shifts the mark to the right, the mark indicates

which input can be changed.

Increases the number.

CLESR key

SET UP key

Decreases the number.

Press the SET UP key when done. This stores the date

and time to memory and the following message is

printed:

10/26/90 7:35 AM

CLOCK SET END

If any set value is wrong a message is printed, the value is not stored and

the unit remains in the time setting mode. Set the value again.

10/66/90 7:35 AM

A

CLOCK SET ERROR

Page 16

owners-AD-8118A-v.3.a

Page 18

Date Formatting Mode

You can select from the following date formats:

American type:

European type:

Japanese type:

6/22/90 10:47 AM

22/6/90 10:47 AM

90*6*22* 10*47* AM

To change date format:

Step 1

Step 2

Turn off the power switch on the rear panel.

Turn back on the power switch while pressing the SET UP

key and M+.PRT key at the same time.

Step 3

Press the CLEAR key to rotate through the three types. The

type selected will be printed as the CLEAR key is pressed.

American type

European type

Japanese type

<or>

<or>

U.S.A.

EUROP

JAPAN

Step 4 Turn off the power switch.

Step 5 Everything in Setting Mode has been saved,

switch #8 to the OFF position.

Return DIP

owners-AD-8118A-v.3.a

Page 17

Page 19

Operation

Operating the Switch Keys

PRINT FEED

SET UP M+.PRT

TOTAL CLEAR

□

CLEAR key

FEED key

PRINT* key

M+.PRT* key

Press M+.PRT key while pressing the this key to delete

the last data from the cumulative total. The following is

printed;

Press TOTAL key while pressing the this key to clear the

cumulative total and number; the following is printed:

Press this key to advance one line.

Hold it pressed to feed continuously.

Press this key to print a line of data

input. If no data is input within 3

seconds, "T ERROR" will be printed. If

the format does not match, "F ERROR"

will be printed.

Press this key to add an input data

before printing. If no data is input within

3 seconds a "T ERROR" is printed. If

the format does not match, "F ERROR"

is printed.

^CANCEL

^CLEAR

TOTAL key

SET UP key Press this key to set functions, etc. in the setting mode.

The keys marked with "*" are disabled in Auto printing mode. In Dump

Press this key to print the cumulative total (grand total)

separating the total weight by code and the gross total

weight.

Refer to "Function Setting Mode," p. 14 for details.

printing ail functions, other than the FEED key and the

SET UP key, are disabled.

Page 18

owners-AD-8118A-v.3.a

Page 20

Operating the Control I/O

Inputs

Code

Print

command*

Paper feed command

Addition print command *

Subtotal

printing

command

Grand total

printing

command

The value is printed on the left side of the paper when

addition printing is done. This value is stored with the

we^ht value and can be retrieved by code as well.

This code is not printed if the value is "00," only

numbers from 01 to 99 can be used.

When this input is negative low (short), the first data

input within 3 seconds is printed.

This command advances the paper one line, negative

low(short).

When this input is negative low(short), the first data

input within 3 seconds is added and printed.

This command prints the subtotal value and clears after

printing.

This command prints the grand total value and does not

clear the subtotal or grand total after printing.

Delete

command

Cumulative

total delete

command

Input for

disable

printing time

Outputs Busy

Printing This output is turned ON when the unit is printing,

announcement Control inputs are not accepted during this time.

This command deletes the last added data from the

cumulative total value and then prints the message

"^CANCEL". It is unable to perform this command if

there is no cumulative total value.

This command deletes the cumulative total value and

then prints the message "¥CLEAR". It is unable to

perform this command if there is no cumulative total

value.

Time printing is disabled while this input is ON. Once

OFF, the time printing is preformed once more on the

next printing time. In cumulative total printing, time

printing is preformed regardless of the input.

This output is turned ON when the data buffer exceeds

75 lines.

Therefore, enter the control input when this output is

OFF.

owners-AD-8118A-v.3.a

Page 19

Page 21

The inputs marked with are disabled in Auto printing mode. In Dump

printing, all functions except paper feed are disabled.

Each command input is judged at the negative edge and actuated only

when it is turned ON.

Input is accepted when turned ON (short-circuited) continuously for 100 ms

or longer.

Page 20

owners-AD-8118A“V.3.a

Page 22

others

Printing buffer

This unit has a printing buffer of 80 lines. If data can not be printed the

data is stacked in this buffer and cleared as the printing progresses. If

this buffer exceeds 75 lines the "Busy Output" from the I/O is turned ON.

"B ERROR" is printed^ once when the buffer exceeds 80 lines. The

printing speed is 1.7 iines/sec, do not input the data faster than this

speed.

Error printing

This unit recognizes the foilowing errors and prints them;

Error printing

T ERROR

U ERROR M

S ERROR *2

O ERROR

F ERROR

I ERROR

B ERROR

R ERROR*3

*1 This message prints the weight value and accepts to the cumulative

total.

A time out in manual printing.

Appears when the unit is different than the fast data unit in

cumulative total mode

Appears when the cumulative total weight is too much.

Appears when an input is too much.

Appears when the data format does not match.

Appears when needless data (-, unstable data) is input

Appears when the printing buffer is activated.

Appears when numbers other than "00" to "99" areinput as a

code input

Description

*Z This message prints the weight value but does not add the data to

the cumulative total.

*3 This message prints the weight value and accepts to the cumulative

total as code No, 00,

Proceduer of power on

Frist plesase power on other insturments coneciing to this printer and

power on this printer, if you power on other insturments with this printer at

same time and use automatic print mode or dumb print mode, frist data

can not often caludates. In manual print mode, No problem after

inputting several data to this printer.

owners-AD-8118A-v.3.a Page 31

Page 23

Printing

Normal Characters

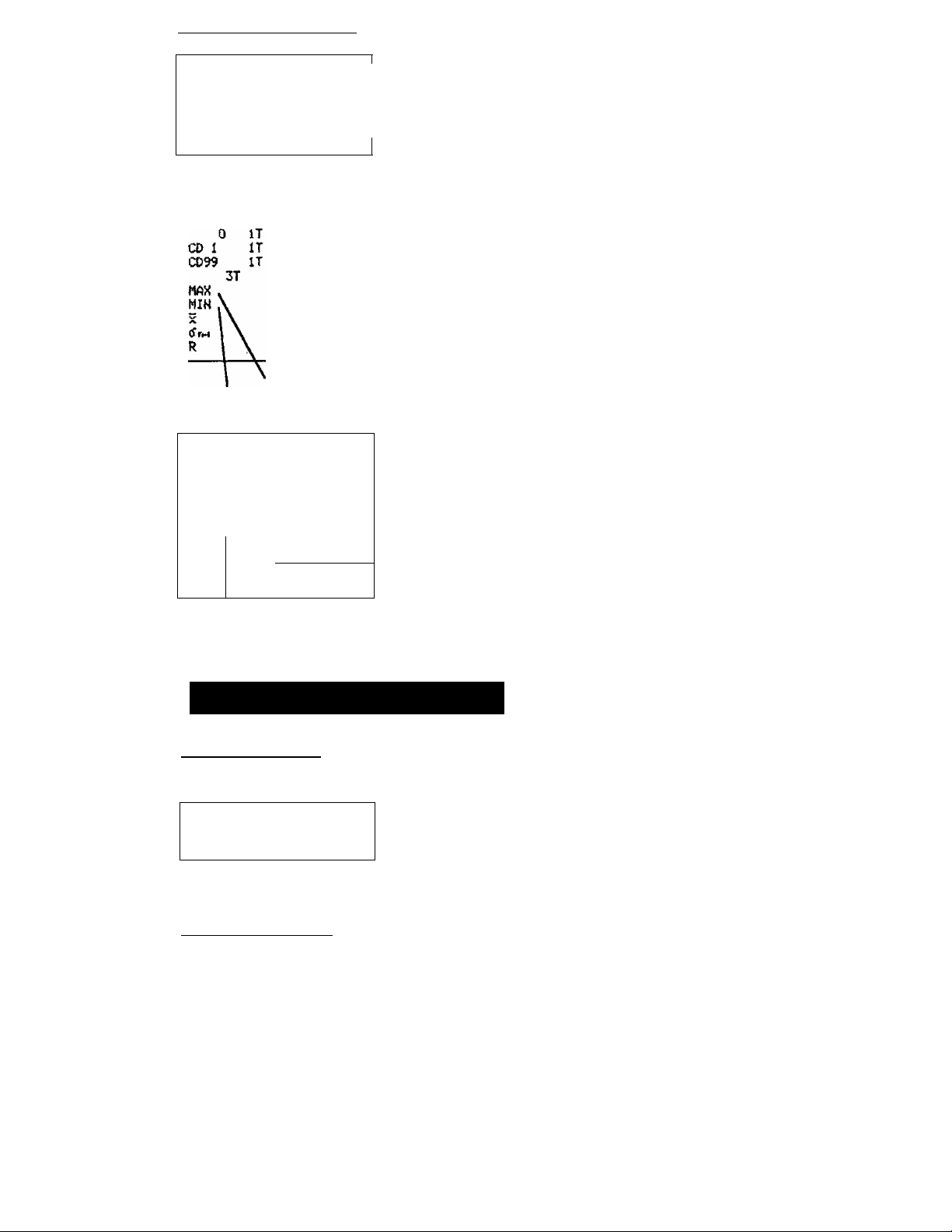

Normal printing

Greater Code

8^11/99 8S00 PiH

CD99 (3S+ 200.0kg.

Code number

-Weight value

Error code is printed from

prior Error code.

Code priority as follow :

O ERROR>S ERROR>U

ERROR>F ERROR>l ERROR

Reference page 21

Addition printing

S/n/99 8:90 AM

# ,1 CD99 9S+ 200,0kg

A

Cumulative total counting number

Subtotal printing

Error code

3U^ TOTAL

8/1 10:05 PM

0' IT 50.02kg-

CD 1 IT 3.012kg

CD99 IT 200.0kg

3T \ 253.032kg

Number of times

SUB TOTAL

8/11/99

CD 1

0)99

MAX V

MiH X 3.812kg

10:06 PM

0 IT

IT

IT

3T 253.032kg-

X \ 84.344kg_

tfn-l \ 182.S81Sk9^

R \ Vl^6.9S8kg,

50.02 kg ^

3.812kg

200.0kg>

200kg

Minimum data

SUB

8/11/99 10:07 PM

CD 1 IT

CD9.9 IT 200,0kg-

MAX V

MIH

^ w

TOTAL

0 IT

3T 253.032kg-

(1« \ X

50.02kg*

3,012kg

3.012kg

84,344kg

84.0027kg

V 196.983kg

Maximum data

Minimum data

Cumulative total by code (times : 4 digits,

cumulative total : 9 digits)

K

—Gross cumulative total (times : 6 digits,

cumulative total : 11 digits)

Pumulative total by code (times : 4 digits,

cumulative total: 9 digits)

/

Gross cumulative total (times : 6 digits,

cumulative total: 11 digits)

— Average of data

■—Sample deviation

^Range of data

Maximum data

Cumulative total by code (times : 4 digits,

cumulative total : 9 digits)

/

200kg

Gross cumulative total (times ; 6 digits,

cumulative total: 11 digits)

— Average of data

Standard deviation

Range of data

Cumulative total by Code is not

Printed, when only 'Code

No.OO' is entered, and No other

Code No is followed. (Control

I/O is not connected).

Page 22

owners-AD-8118A-v.3.a

Page 24

Grand Total printing

GRAND

9/11/99 18:05 PM

CO 1 IT 3.012k9

C099 IT

3T

GRAHD TOTAL

8/11/99 10:06 PM

TOTAL

0 IT

Maximum data

Minimum data

GRAND

8/11/99 10107 PM

0

CO 1

CD99

3T

MAX

V

MIN

\

X

\

R

A_

TOTAL

IT

IT

IT

\

Maximum data

Minimum data

(

Cumulative total by code (times : 4 digits,

50.02kg-

200.0kg-

253.032kg-

cumulative total: 9 digits)

;/■

■Gross cumulative total (times ; 6 digits,

cumulative total: 11 digits)

^Cumulative total by code (times : 4 digits,

0.02k9. /(

50

.0l2k9 f

3.

200

253.032kg—Gross cumulative total (times : 6 digits,

200kg ' ®

3.012kg

84.344kg

102.8S18kg

196.9S8kg

cumulative total : 9 digits)

cumulative total: 11 digits)

-Average of data

■Sample deviation

‘Range of data

.Cumulative total by code (times : 4 digits,

50.02kg-

3.012k9

280.0k9^

253.032kg-

200 kg

3.012kg

84.344 kg-

34.0027kg-

196,988kg-

cumulative total: 9 digits)

-Gross cumulative total (times : 6 digits,

cumulative total: 11 digits)

—Average of data

■—Standard deviation

Range of data

Enlarged Characters

Normal Printing

/Code number

8/11.^ >

GS-+-

Addition Printing

8/11

GS-*~

am

2©0.0k-3

Cumulative total counting number

00 AM

8i

COS'S«

20©.0

owners-AD-8118A-v.3.a Page 23

Page 25

Subtotal Printing

Error code

SUE/ TOTAL >

S/1l/99>

CD 1

CD33

40:05 PM X

k

D IT^ •

50- 02 kg

3- 012kg

200- 0 kg■

3T

253-032kg

3UB XOTAU

8/11/99 10!06 PM

CD 1 IT

S0. Q2 k*3

3.012

200. ©k-9

3T

253- 032 k-S

MAX

MIN

>?

CS"

102-SS10 kg

R

3-012 k^

- 34-4^ kg

133-3sakg

Number of times

IT

IT

cumulative total: 11 digits)

o IT

^Cumulative total by code (times : 4 digits,

j cumulative total: 9 digits)

IT

Gross cumulative total (times : 6 digits,

cumulative total; 11 digits)

200k-Si

Maximum data

Minimum data

Werage of data

Sample deviation

Range of data

3Ue TOTAL

3/11/99 10:07 PM

O IT

50-02kg

CD 1 IT

3-012kg

CD33 IT

200-0kgH

3T

253- 032kg

MAX

200 kg

MIN

_ 3-012kg

X

34- 344 kg

CT rt

S4-002T kg

R

136. - 333 kg

Cumulative total by code (times : 4 digits,

cumulative total: 9 digits)

r

Gross cumulative total (times : 6 digits,

y

cumulative total : 11 digits)

— Maximum data

— Minimum data

•Average of data

Standard deviation

Range of data

Page 24 owners-AD-8118A-v.3.a

Page 26

Grand Total Printing

aRAND TQTi^L.

3/n>^9 18i0S PH

CD 1 XT

O IT

•l—* K ^SmF

3-©X2k3

1T

200« ©k-g

3T

233. 032

0Ri=^HD TOTAU

S/U/9S 18:06 PH

O XT

ise . 02 k-s

CD X XT

3. 0X2k-g

XT

200.0 k-g

MAX

MIH

5<

2S3.032kg

200 kg

3. 0 12 kg

04.344kg

d" tit-i

X02-asiekg

R

X00.aaskg

Cumulative total by code (times : 4 digits,

cumulative total: 9 digits)

Gross cumulative total (times : 6 digits,

cumulative total: 11 digits)

,Cumulative total by code (times ; 4 digits,

cumulative total: 9 digits)

_l^ Gross cumulative total (times ; 6 digits,

cumulative total; 11 digits)

Maximum data

Minimum data

-Average of data

Sample deviation

Range of data

GRAf4D TOTAi»

8^'Il/99 10:07 PH

O XT

S0- 02 kg

CD 1 IT

3-012 kg

CD3S XT

200-0kg

3T

233-032kg

MAX

200 kg

MIH

_ 3-012kg

04- H 344 kg

*3"

©4-0022kg

R

X ae.seskg

^ Cumulative total by code (times : 4 digits,

I cumulative total: 9 digits)

Gross cumulative total (times : 6 digits,

cumulative total: 11 digits)

Maximum data

Minimum data

Average of data

Standard deviation

Range of data

owners-AD-8118A-v.3.a

Page 25

Page 27

Applications

Serial Inputs

The serial input can be changed through the RS-232C to current loop by

the slide switch on the rear panel. Select either one depending on the

product being connected. The power for the current loop is supplied by the

receiving side.

When using the RS-232C the following cables are useable:

For current loop (DIN7P-DIN7P) Note 1:

KO : 359- 200

KO : 359- 400

KO : 359- 600

KO : 359- 800

KO : 359-1000

KO : 359-1200

KO : 359-1400

For RS-232C (D1N7P-DSUB25P):

KO

Hint: "KO : 359-200" is a 200 cm, or 2 m cable for the current loop.

Notel: When connecting option OP-03 (RS-232C option) from a FV or

FW, use a cable for the current loop.

Set the connected instrument to stream, auto print or manual

print mode. The command mode can not be supported. In

addition, if the standard format input is set through the unit,

inputs are not accepted on rare occasions. Set the unit to

Dump print in such a case.

360- 200

Connection to an Industrial Scale

The standard format of A&D industrial scales are as follows:

AD-4316 +

AD-4321 A/B +

AD-4322A

OP-04

OP-04

(OP-04) *2

AD-4323

AD-4324

AD-4325A

FV series +

FW series +

* 1 A unit with "+OP-XX" means that it is necessary to pair this option.

Page 26

(OP-04)

(OP-04)

(OP-04)

OP-03

OP-03

owners-AD-8118A-V.3 .a

Page 28

* 2 A unit with ”(OP-xx)" can connect to the standard serial output.

Please set the DIP switches according to the specifications of these units.

When connecting to an AD-4325A, cumulative total can be started by the

codes of the AD-4325A if set to the output of format with the correct code.

Set the printer mode on DIP switch #3 to standard format.

AD-4601 has RS-232C. Set print mode of RS-232C Function . you can

input standard format data. (The flow speed can't be input; In this case ,set

dump printing mode.) >

Connection to an Electronic Balance

The standard format of A&D's electronic balances are as follows:

EP

series

ER

series +

ET

series

FX

series

FY

series

FC

series

EK

series + OP-03

FR

series + о P-03

Set the DIP switches according to their specifications.

+ OP-03

OP-03

■ + OP-03

+ OP-03

OP-03

+

+ OP-03

Connection to Peripheral Devices

This unit has the functional ability to send outputs, as well as input data,

through the current loop. This allows connection to the AD-8916, AD-8917,

AD-8918, AD-8117 and AD-8118A.

For example, if two AD-8917's are connected, the setting of gross weight,

net weight and tare weight output through the serial output of an AD-4322A,

AD-4323 or AD-4325A can be achieved. The following application will then

be realized:

AD-4323, etc.

in the above example, the gross weight is displayed in the AD-8917 "A" and

the tare in the AD-8917 "B". Then the net weight data is printed on the

AD-8118A and the cumulative total is calculated. Note that this printer can't

be connected to more than two other units.

owners-AD-8118A-v.3.a

AD-8118A

Page 27

Page 29

Connection to Other Devices

if this printer is connected to a personal computer, a sequencer or any other

unit set this unit to the RS-232C and Dump print. Set the DIP switches

appropriately. For characters to print, refer to the "Character Code Table” in

the Appendix, p. 30. This unit only receives signals, it can't output control

signals, message, etc. Note that overflow of the data buffer is valid for

control I/O only.

The following codes have meaning as control signals:

ODH

........

Moves a character point to the beginning of the next line and

clears the specification of an enlarged character.

OEH

------

An enlarged character can be used with this signal.

14H

-------

If this code is input while in the enlarged character mode it

changes back to the normal character mode. This command is

ignored when in norma! character mode.

1BH

-------

This code is used in combination with the following two

characters as an auxiliary code:

>

1BH+44H Prints the year, month and day.

1BH+54H Prints the time.

Page 28

owners-AD'8118A-v.3.a

Page 30

Il^

Dimensions

186

SIDE VIEW

+ 1.0

+0.8

0

owners-AD-8118A-v.3.a

Page 29

Page 31

Appendix

Character Code Table

KEX.N

0

1 2

0

NUL

1

2

3

4

5

6

7

8

9

A

LF

B

C

CR

D

E

F

ESC

(SP) 0

1

11

^ 2

# 3

$

%

Q

1

{

)

*

+

f

-

/

3

1

4

5

6

7

8

9

:

/

<

=

>

7

4

5 6

P

0

A

Q

B R

C S c

D T

E

u

F V

w

G

H X

I Y i

J z

K

[

L %

M

1

N

-

0

7

8 9

P

q

r

s

t

u

V

w

X

y i

z

{

1

1

}

z

■

1 r

1

I

1

1

1

+

a

b

d

e

f

g

h

j

k

1

m

n

0

A B

i*

T

-i

i-

-

-

C D

E

F

1

1

T

L

J

r

V,

J

Don't use codes AO-^FF

Page 30

owners-AD-8118A-V.3 .a

Page 32

A&D Company Limifed

Oashalsu-NIssay Ikebukuro Bldg. 5F, 3-23*14 HigashWkebukufo, Toshima-ku, Tokyo 170 Japan

Telephone: (03) 5391-6123 Fax: {03} 5391-6129 Telex: 02422816 AANOD J

A&DWGINEOTNG,1MC.

1555 McCandless Drive, Mtipilas. CA, 95035 U.SA

Telephone: (408) 263-5333- Fax; (408) 263-0119

A8tD INSTRUMENTS GmbH

Lyoner Straße 36, 0-6000 Frankfurt/Main 71. West Germany

Telephone: (069) 666-7006 Fax: (069) 566-6831 Telex: 417 0586 ANDI D

A8cD MERCURY PTY LTD.

32 Dew Street, Thebarton. South Australia 5031 Australia

Telephone: (08) 352-3033 Fax; (08) 352-7409

Loading...

Loading...