Page 1

AD-4412-CW

Weighing Indicator

CONNECTION SETTING EXAMPLE

1WMPD4004155

Page 2

© 2020 A&D Company, Limited. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated into any

language in any form by any means without the written permission of A&D Company, Limited.

The contents of this manual and the specifications of the instrument covered by this manual are

subject to change for improvement without notice.

Page 3

This section shows descriptions from connection to basic settings for using the AD-4412-CW as a weight checker.

Setting flow Instruction manual

“ ” shows the instruction

manual section referenced..

Connecting

Configuring settings

for the indicator

Configuring settings

for theproducts

Connecting to the indicator

Connecting to external

equipment

Setting the weighing unit, decimal

point position and division

Setting the weighing capacity

Adjusting the weight

Setting the conveyer length

Setting the photo eye sensor

Setting the speed

Setting the product length

Setting the detect basis

Setting the DO and DI

Refer to "3. Installing the

Weighing Indicator" for

details of connection.

Refer to "11. Interface" for

other external equipments.

Refer to "6.1. Calibrating the

Indicator using a Weight",

"9.12.Weighing" and "9.13.

Cal (Calibration)" for details

of scale settings.

Refer to "9.1. Product name/

product code" to "9.7. Tare"

for details of product settings.

Refer to "5.6.2. Settings of

Threshold Values ( Target,

HiHi Limit, Hi Limit, Lo Limit,

LoLo Limit )" and

"9.2. Detect basis" for

details of detect basis.

Refer to "5.6.4. Setting the

Digital Output (DO)",

"9.4.DO Map (Digital Output

Map)" and "9.5.Control I/O

(Part of Digital Output) " for

details of DO settings.

Refer to "9.18.Control I/O

(Part of Digital Input)" for

details of DI settings.

AD4412-CW 3

Page 4

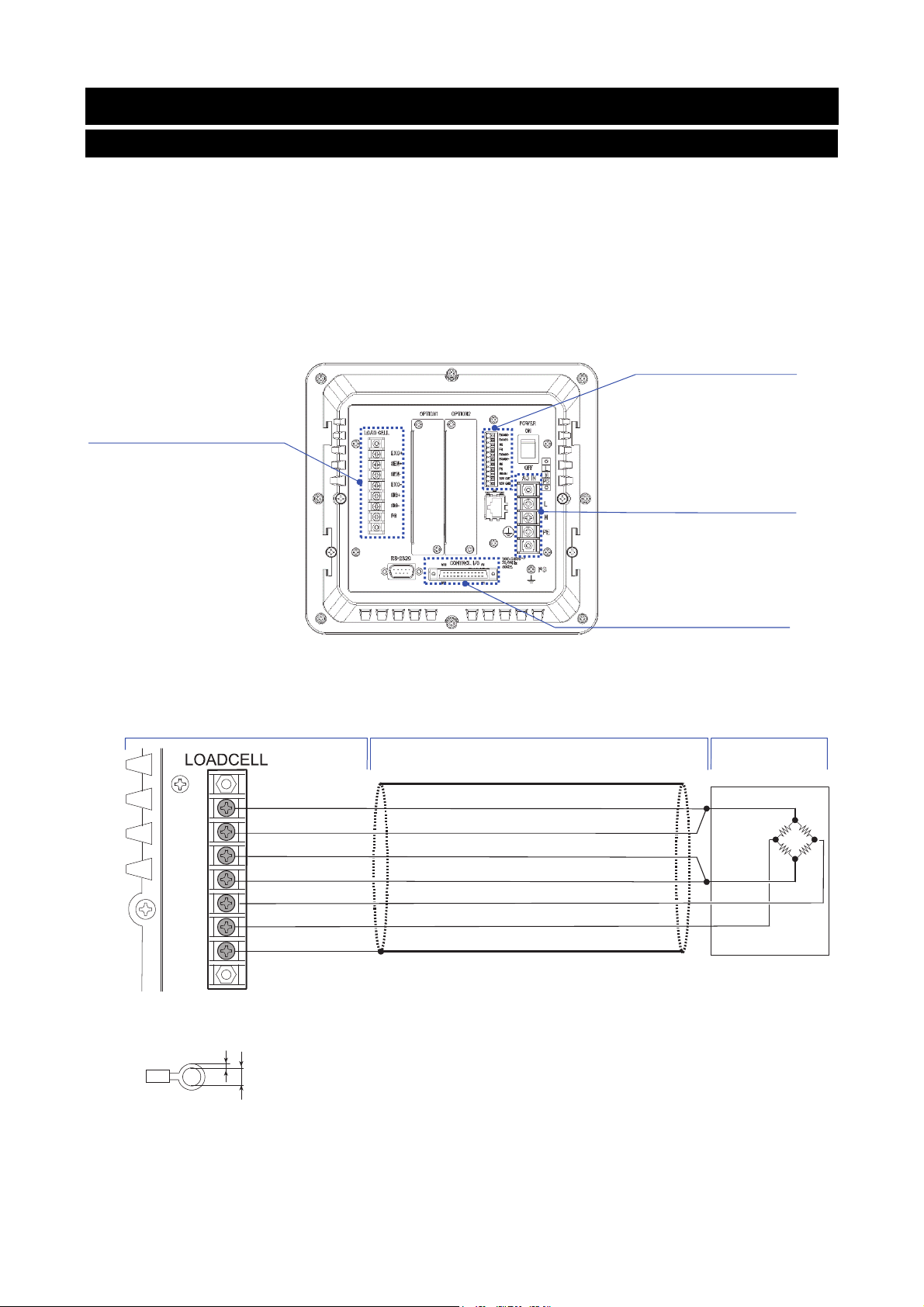

1. Connecting

1.1. Connecting to the indicator

The following describes how to connect the indicator to the load cell.

Follow the procedure below for the indicator connection.

1. Connect the load cell cable to the “LOAD CELL” terminal (Fig. 2), the indicator’s power cable to the “AC IN” terminal

(Fig. 3), both located on the rear panel of the indicator. (Refer to “3.4. Connecting Load Cell Cables” and “3.5.

Connecting Power Lines” in the instruction manual.)

2. When using the photo eye sensor, connect it to the “I/F” terminal on the rear panel of the indicator. (Refer to

“Connection of Photo eye Sensor” of “11. Interface” in the instruction manual.)

I/F terminal

Load cell terminal

Power terminal

Control I/O

• AD-4412-CW 6-wire shielded load cell cable Load cell

1 EXC+ Positive power supply to load cell EXC+

2 SEN+ Positive sense input

3 SEN- Negative sense input

4 EXC- Negative power supply to load cell EXC-

5 SIG+ Positive input from load cell SIG+

6 SIG- Negative input from load cell SIG-

7 SHLD Shield

Fig. 1 Rear panel

Usable Compression Terminal Parts (M3)

1.0

3.2

Fig. 2 Standard connection method for load cell (6-wire)

4 AD4412-CW

Page 5

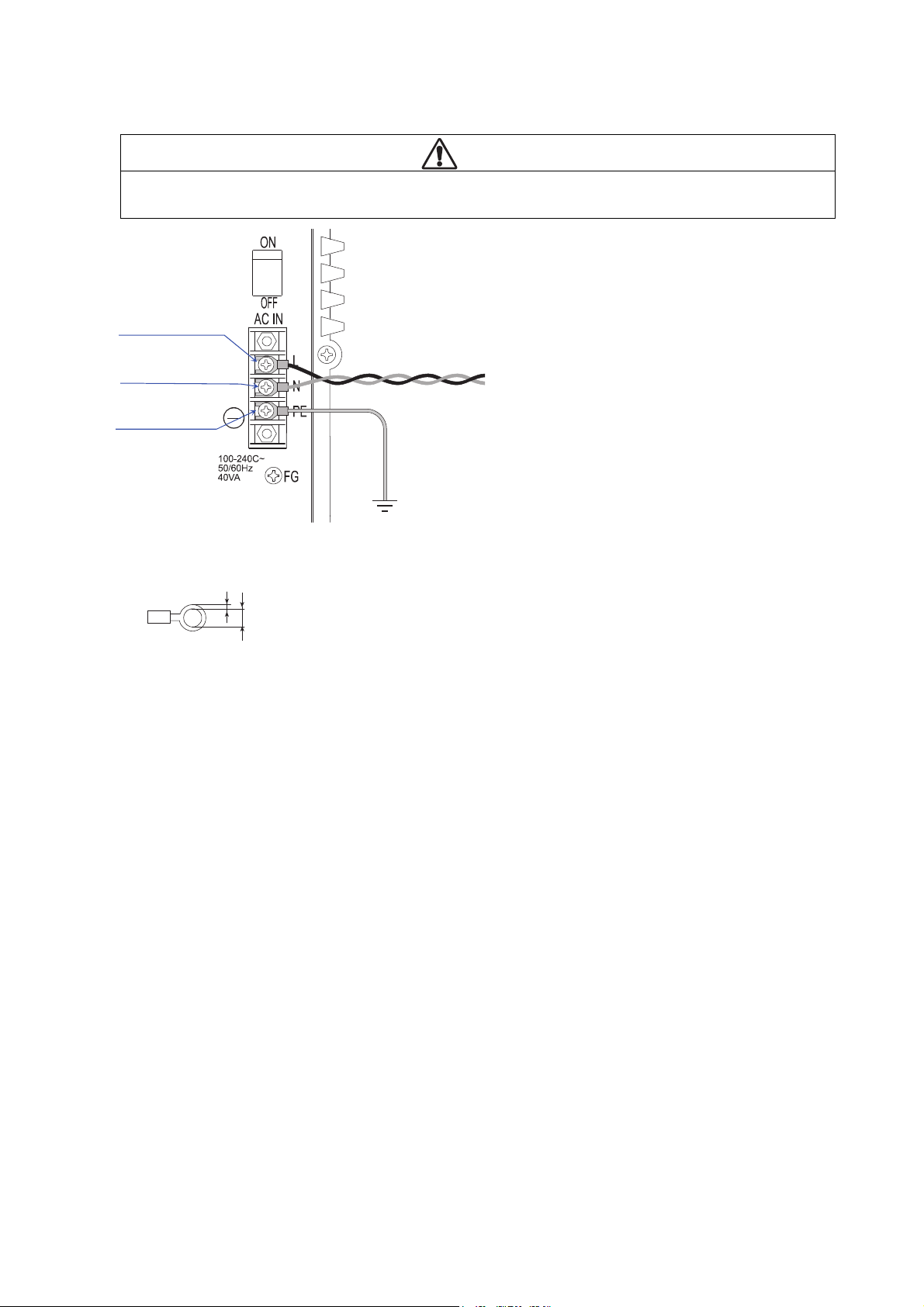

Warning

Ground the indicator to avoid an electric shock or operation error. If the indicator is not grounded, it may cause an

electric shock or malfunction due to discharge of static electricity.

Live terminal

Neutral terminal 100-240 V

PE terminal

Ground

~

, 50Hz or 60Hz

Noiseless stable single phase power source

Usable Compression Terminal Parts (M4)

1.0

4.3

Fig. 3 Connecting power lines

AD4412-CW 5

Page 6

y

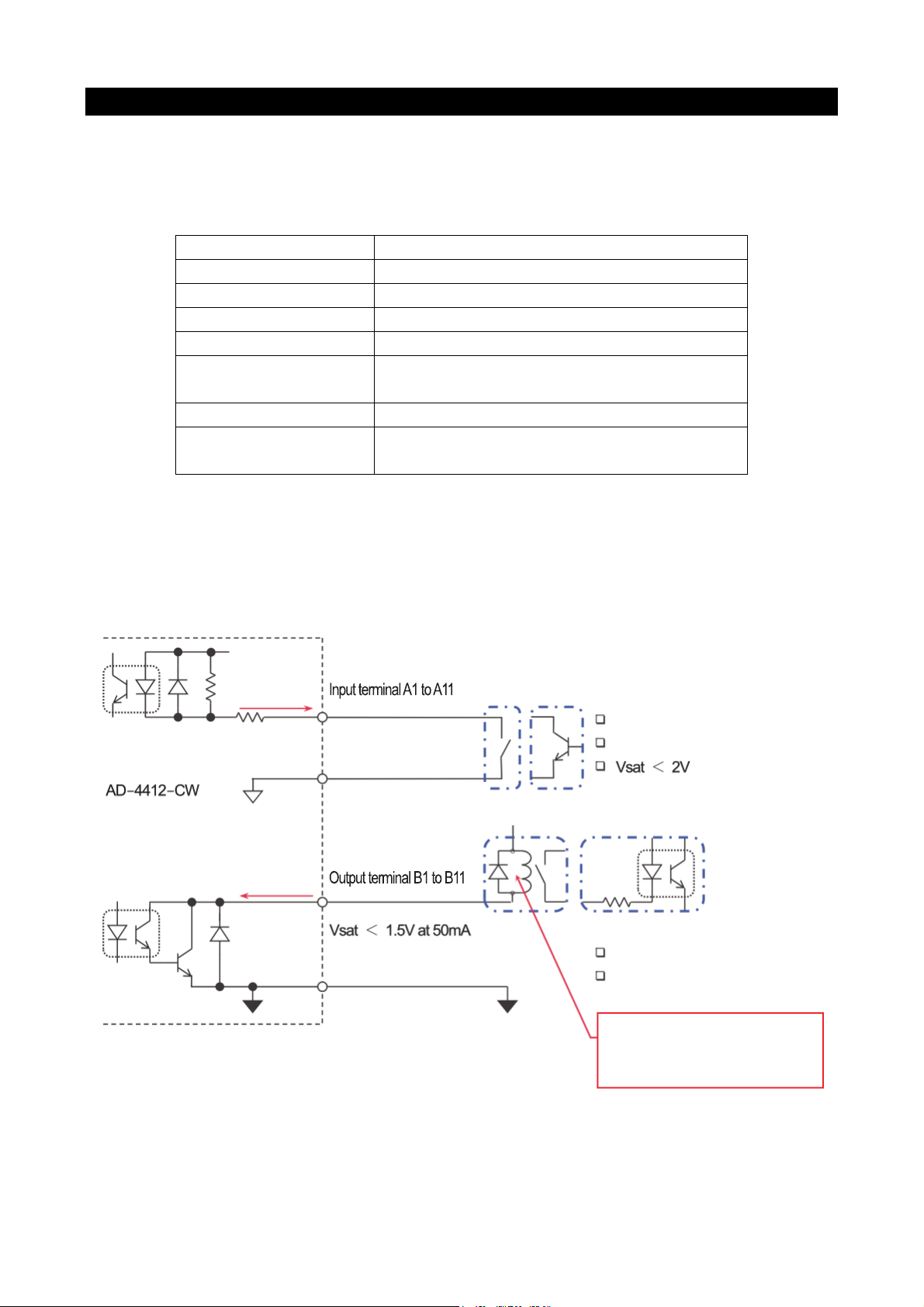

1.2. Connecting the external equipment

This section describes the specifications and connection examples for control I/O.

Control I/O specifications

Control I/O has DO11 points, DI11 points, and the following specifications.

Ta b l e 1 Control I/O Interface specifications

Input circuit (DI) method Non-voltage input/open collector drive

Input terminal open valtage 7 to 11 V

Input circuit drive current 5 mA (max.)

Max. residual voltage 2V (max.)

Output circuit (DO) method Open collector

Output circuit withstand

voltage

Max. drive current 50 mA

Output terminal residual

voltage

Connecting the control I/O

Refer to the following figure for connecting the control I/O.

internal circuit

Max. drive current 50 mA

Max. 5 mA

Input common A12

Output common B12

Fig. 4 Input and output circuit of control I/O

DC 40 V

1.5 V (at drive current 50 mA)

Max. DC 40 V

Recommended drive circuit

Mechanical relay

Open collector

Recommended drive circuit

Relay (with protection diode)

Photo coupler

Be sure to attach protection

diode to inductive loads such as

rela

and solenoid coil.

6 AD4412-CW

Page 7

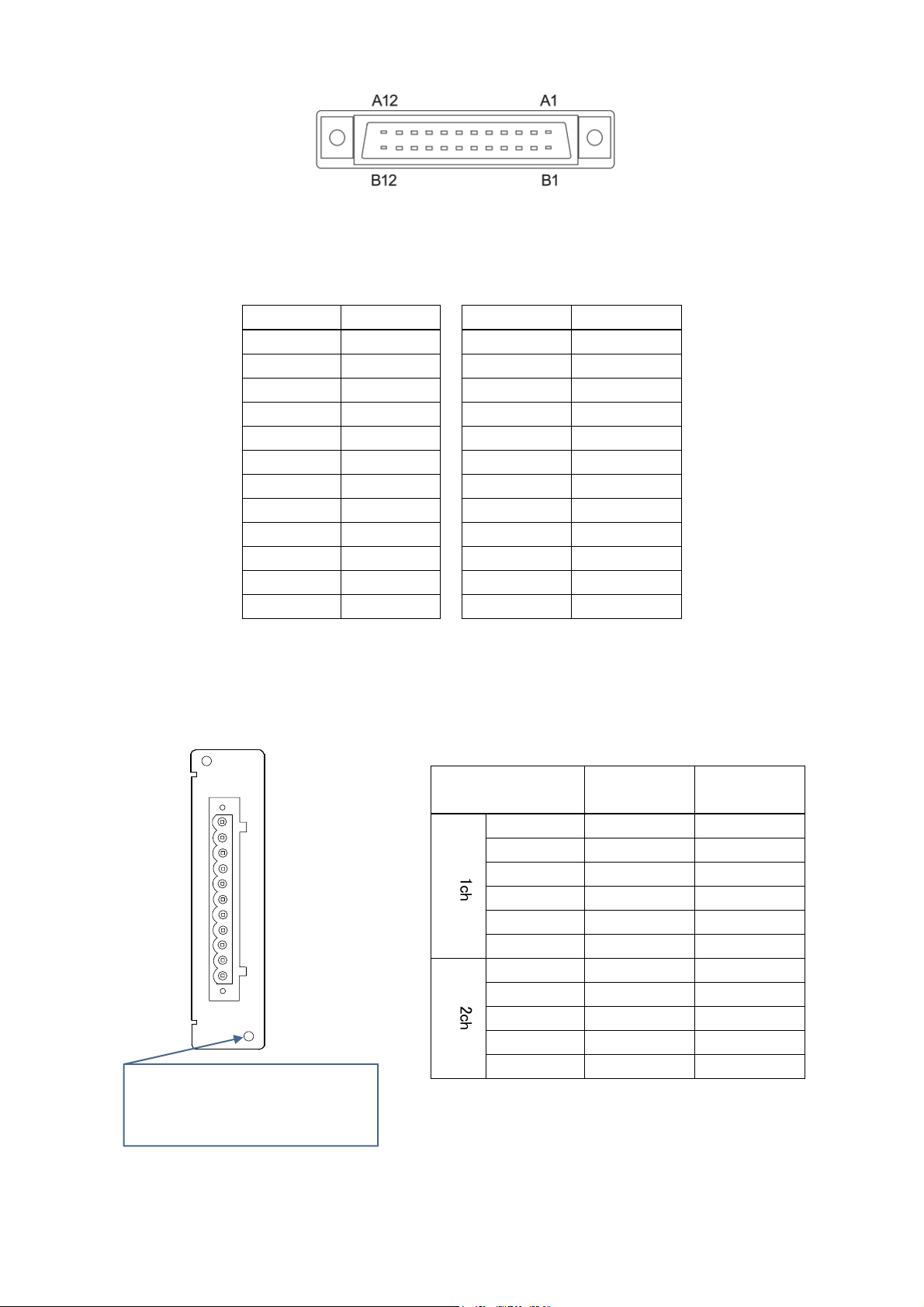

* Optional OP-02 Relay output and OP-05 parallel I/O can be installed in the indicator for a total of up to two units.

However, corresponding numbers for the DI/DO vary depending on the slot installed to.

Installing the OP-02 Relay output into optional slot 1 allows use of DO12 to DO20. Installing the OP-02 Relay output into

optional slot 2 allows use of DO28 to DO36. (Refer to “11.5. OP - 02 Relay output” in the instruction manual for details.)

Table 3 Correspondence table of OP-02 and DO

Screw hole

When installing the OP-02 to the

indicator, be sure that the screws are

firmly tightened.

Fig 1 OP-02 connector terminal

Input terminal DI number

A1 DI 1

A2 DI 2

A3 DI 3

A4 DI 4

A5 DI 5

A6 DI 6

A7 DI 7

A8 DI 8

A9 DI 9

A10 DI 10

A11 DI 11

A12

OP-02

2ch 1ch

Fig. 5 Terminal numbers of control I/O connector

Ta b l e 2 Correspondence table of control I/O and DI/DO

Output terminal DO number

B1 DO 1

B2 DO 2

B3 DO 3

B4 DO 4

B5 DO 5

B6 DO 6

B7 DO 7

B8 DO 8

B9 DO 9

B10 DO 10

B11 DO 11

(

input common)

B12

Output terminal

1

c

h

2

c

h

(

output common)

DO number

( optional slot 1)

1 DO 12 DO 28

2 DO 13 DO 29

3 DO 14 DO 30

4 DO 15 DO 31

5 DO 16 DO 32

(

6

output common

7 DO 17 DO 33

8 DO 18 DO 34

9 DO 19 DO 35

10 DO 20 DO 36

(

11

output common

DO number

( optional slot 2)

) (

output common

) (

output common

)

)

AD4412-CW 7

Page 8

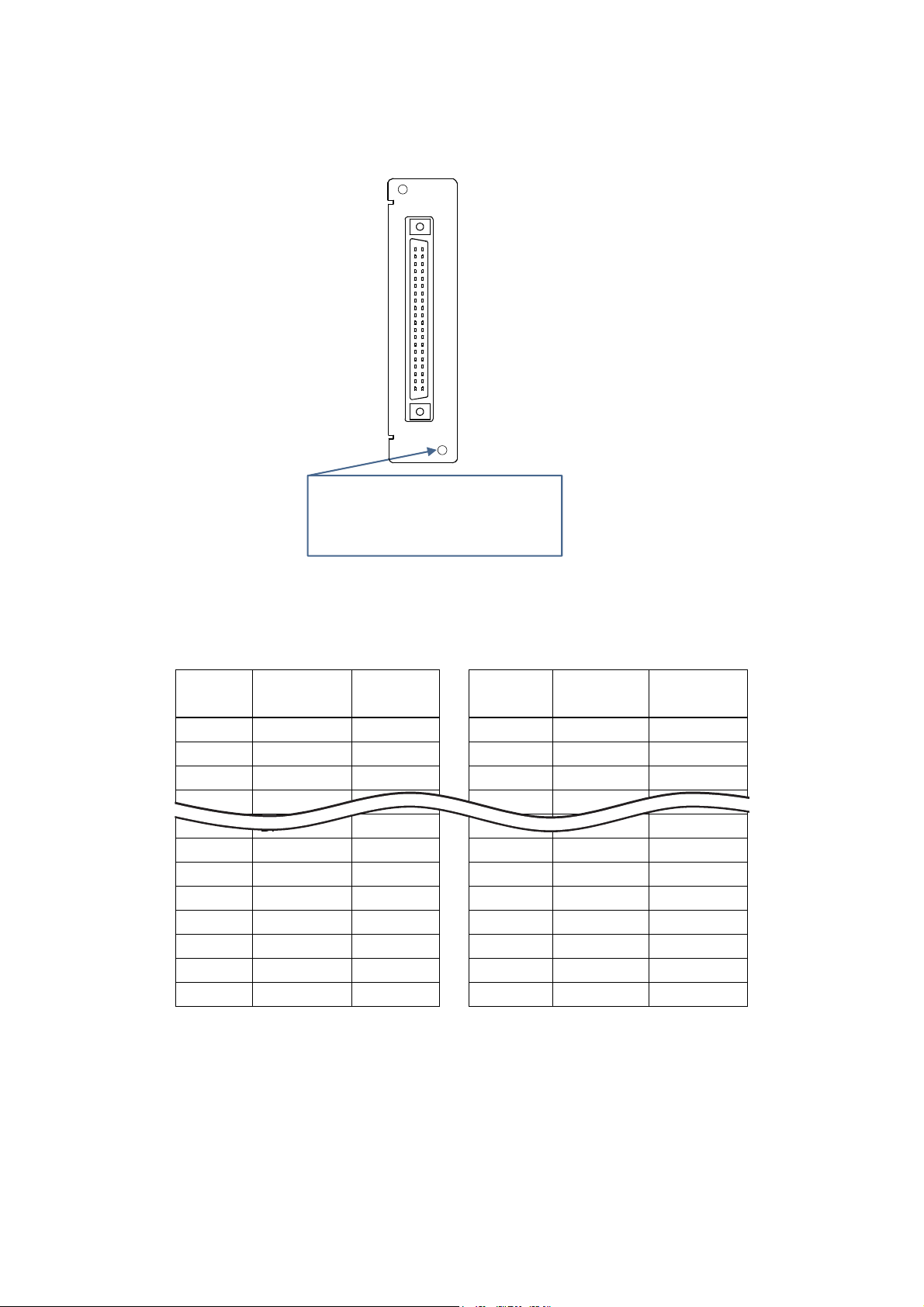

Installing the OP-05 Parallel I/O to optional slot 1 allows use of DI12 to DI27 and DO12 to DO27. Installing the OP-05

Parallel I/O to optional slot 2 allows use of DI28 to DI43 and DO28 to DO43.

(Refer to “11.6. OP - 05 Parallel Input/Output” in the instruction manual for details.)

OP-05

A1 A20

B1 B20

Screw hole

When installing the OP-05 to the

indicator, be sure that the screws are

firmly tightened.

Fig 2 OP-05 Connector terminal number

Ta b l e 4 Correspondence table of OP-05 and DI/DO

Input

terminal

A1 DI 12 DI 28

A2 DI 13 DI 29

A3 DI 14 DI 30

A4 DI 15 DI 31

A13 DI 24 DI 40

A14 DI 25 DI 41

A15 DI 26 DI 42

A16 DI 27 DI 43

A17

A18

A19

DI number

(optional slot 1)

(

input common) (input common)

(

input common) (input common)

(

input common) (input common)

DI number

(optional slot 2)

Output

terminal

B1 DO 12 DO 28

B2 DO 13 DO 29

B3 DO 14 DO 30

B4 DO 15 DO 31

B13 DO 24 DO 40

B14 DO 25 DO 41

B15 DO 26 DO 42

B16 DO 27 DO 43

B17

B18

B19

DO number

(optional slot 1)

(

output common) (output common)

(

output common) (output common)

(

output common) (output common)

DO number

(optional slot 2)

A20 (FG) (FG) B20 (FG) (FG)

8 AD4412-CW

Page 9

A

Connection example

The following shows a general connection example for the indicator. The following settings are described based on this

example.

DO2 DO1

Relay

Othrer specifications

- Scale weighing capacity: 1000 g

- Conveyer length : 300 mm

- Conveyer speed : 80 m/min

To w er li ght

Conveyer

Photo eye sensor

Load cell

D-4412-CW

B2 B1

Fig. 8 Connection example

AD4412-CW 9

Page 10

2. Setting the indicator

By changing the factory settings for the indicator, it can be changed to have the appropriate settings for your scale.

The parameters set are maintained in the memory even after shutting down the power of the indicator until the

indicator is initialized or those settings are changed. The following settings require quality manager or higher

permissions. (Refer to “5.5 Managing User Level for Logging In” of the instruction manual for setting the management

level.)

2.1. Weighing unit, decimal point position and division

1. Touch the Setting key on the weighing screen to display the setting screen.

2. Touch the Weighing button on “Balance” tab and set the weighing unit, decimal point position and division for

weighing products into the each field on “Weighing Setting 1” tab.

Fig. 10 Setting the weighing unit, decimal point position and division

Fig. 9 Setting screen

10 AD4412-CW

Page 11

2.2. Weighing capacity

1. Touch the Setting key on the weighing screen to display the setting screen.

2. Touch the Weighing button on the “Balance” tab and enter an appropriate capacity (rated capacity) for your load cell

into the field “Capacity” on the “Weighing Setting 1” tab. (Example below is when the 1000 g is entered as capacity.)

Fig. 11 Setting screen

Fig. 12 Setting the capacity

AD4412-CW 11

Page 12

2.3. Adjusting the weight

1. Touch the Setting key on the weighing screen to display the setting screen.

2. Touch the Cal button on the “Balance” tab to display the weight adjustment screen.

Fig. 13 Setting screen

Fig. 14 Weight adjustment screen

12 AD4412-CW

Page 13

3. Touch the Adjust Cal button to calibrate the zero point. Touch the OK button after confirming that nothing is

placed on the load cell. To proceed to span calibration in the next step without calibrating the zero point, touch the

Cancel button

Fig. 15 Zero point calibration

4. The “Weight value enter” screen is displayed after finishing zero point calibration. Enter a mass for the weight to

be used for calibration. (The weight value can be set between 0 g and capacity (g) of the load cell.)

Fig. 16 Weight value enter screen

5. The “Span calibration” screen is displayed after you have finished entering the weight value. Place a weight of

the mass entered on the load cell. Wait until the numerical value is stabilized, and then perform the span

calibration.

Fig. 17 Span calibration screen

AD4412-CW 13

Page 14

2.4. Conveyer length

By changing the factory settings for the indicator connected to the weight checker, settings can be changed to those

appropriate for your weight checker. The parameters set are maintained in the memory even after shutting down the

power of the indicator until the indicator is initialized or those settings are changed. The following settings require

quality manager or higher permissions.

1. Touch the Setting key on the weighing screen to display the setting screen.

2. Touch the Main Unit button on the “System 1” tab to display the main unit setting screen.

Fig. 18 Setting screen

Fig. 19 System setting screen

14 AD4412-CW

Page 15

3. Set the length for your conveyer in the field “Conveyer Length” on the“Main Unit 1” tab. (The indicator must be

restarted to enable those settings.)

Fig. 20 Setting the conveyer length

AD4412-CW 15

Page 16

2.5. Photo eye sensor

Setting the photo eye sensor

1. After connecting the photo eye sensor to the I/F terminal, touch the Setting key on weighing screen to display the

setting screen. Touch the Main Unit button on “System 1” tab to display main unit setting screen.

2. Set the “Curb Chattering”, ”Photo Eye Sensor Polarity” and ”Photo Eye Sensor Timeout” on the “Main Unit 2” tab.

Fig. 21 Setting screen / System 1 screen

Fig. 22 Setting the photo eye sensor

16 AD4412-CW

Page 17

3. Settings for products

When using the indicator as weight checker, it requires settings according to the type of products to be conveyed in

order to detect and reject properly.

The parameters set are maintained in the memory even after shutting down the power of the indicator until the

indicator is initialized or those settings are changed. The following settings require quality manager or higher

permissions.

3.1. Speed

1. Touch the Product key on weighing screen to display the product screen.

2. Touch the Edit key on the product screen to display the product edit screen.

Fig. 23 Product screen

Fig. 24 Product edit screen

AD4412-CW 17

Page 18

3. Touch the Detect Parameter button on the “Detect Function” tab to display the weighing parameter setting screen.

Fig. 25 Detect parameter setting screen

4. Enter an appropriate speed for your belt conveyor in the field “Speed” on the “Weighing Parameter Setting 1” tab. (The

speed for the belt conveyor must be calibrated beforehand.)

Fig. 26 Selecting the speed

18 AD4412-CW

Page 19

3.2. Product length

1. Display the product edit screen in the same way as “3.1. Speed” described previously, and then touch the Detect

Parameter button on the “Detect Function” tab to display the weighing parameter setting screen.

2. Set an appropriate length for products to be conveyed in the field “Product Length” on the “Weighing Parameter

Setting 1” tab.

The product length is used for continuous unsplit detection. (Setting it to a value longer or shorter than the products to

be conveyed may cause a detecton error.)

Fig. 27 Detect parameter setting screen

Fig. 28 Setting the product length

AD4412-CW 19

Page 20

3.3. Detect basis

1. Display the product edit screen in the same way as “3.1. Speed” described previously, and then touch the Detect

Basis button on “Detect Function” tab to display the detect basis setting screen.

2. By setting “Target”, “Hi Limit” and “Lo Limit” on the “Detect Basis Setting 1” tab, the indicator detects weighing values

that exceed the upper limit (Hi Limit) as being overweight and weighing values below the lower limit as being

underweight.

(When setting the reject stage to stage 5, the upper-upper limit (Hi Hi Limit) value detects very overweight and lower-

lower limit (Lo Lo Limit) detects very underweight by adding upper-upper limit and lower-lower limit to those settings.)

Those detections can also be used as output conditions of the DO/DI. Refer to “3.4 Setting the DI/DO” for details of

the setting method.

3. Refer to “5.7. Summary of Weighing Result” in the instruction manual for details of summary of weighing results using

the detect basis described above.

Fig. 29 Detect basis setting screen

Fig. 30 Detect basis settings

20 AD4412-CW

Page 21

3.4. Setting the DO/DI

Setting the DO is described using the connection example shown in “1.2. Connecting the external equipment”.

The example below is when an output to the conveyer is set to DO1 and an output to the tower light is set to DO2.

(DO number is a number set by yourself at connection.)

DO2 DO1

Relay

Setting the DO

1. Touch the Product key on the weighing screen to display the product screen. Then, touch the Edit key on the product

screen to display the product edit screen.

To w er li ght

Conveyer

Load cell

-

Fig. 31 Connection example

Fig. 32 Product screen / Product edit screen

-

Photo eye sensor

AD4412-CW 21

Page 22

2. Touch the DO button on the “Detect Function” tab to display the DO setting screen.

Fig. 33 DO selection screen

3. Touch the DO Map button to display the DO map screen.

Fig. 34 DO seting screen

4. The example is when “○” is placed in the field “Belt Running” for “DO1” to operate the belt conveyer while weighing.

“○”is placed in the field “HiHi” and “LoLo” for “DO2” to reject products using the rejecter at upper-upper (HiHi) detection

or lower-lower (LoLo) detection.

Fig. 35 Setting the DO1 / Setting the DO2

22 AD4412-CW

Page 23

5. Return to the DO setting screen and touch the AD-4412-CW button to display the DO operation setting screen.

Fig. 36 DO setting screen

6. In this example, DO does not need to be set for the belt conveyor and tower light. However, when using a flipper, etc,

set the delay time as “the time until the weighing product reaches the rejecter after detecting it at the end of the

conveyer” plus "the swing time for the flipper of the rejecter”.

(However, the swing time for the flipper of the rejecter varies depending on settings for the cushion needle of the air

cylinder. So, fine adjustment is required for it.)

Fig. 37 DO2 operation setting screen

7. Hold time is the time to output the signal. There is a possibility that a jitter of about 50msec is generated at the hold

time. So, it must be set with sufficient leeway.

If DI connection is made for other external equipment, see "9.13. DI (Digital Input)" in the instruction manual.

AD4412-CW 23

Page 24

3.5. For additional usage

This application note shows descriptions from connecting the indicator to basic setting. Since those descriptions are only

for basic connection methods and functions, the indicator can also be

described in this document, such as providing feedback to the packing machine or charging machine (“9.10. Feedback

Control (FC)” in the instruction manual). Refer to the instruction manual for details of descriptions.

practially used by adding functions or options not

24 AD4412-CW

Loading...

Loading...