Page 1

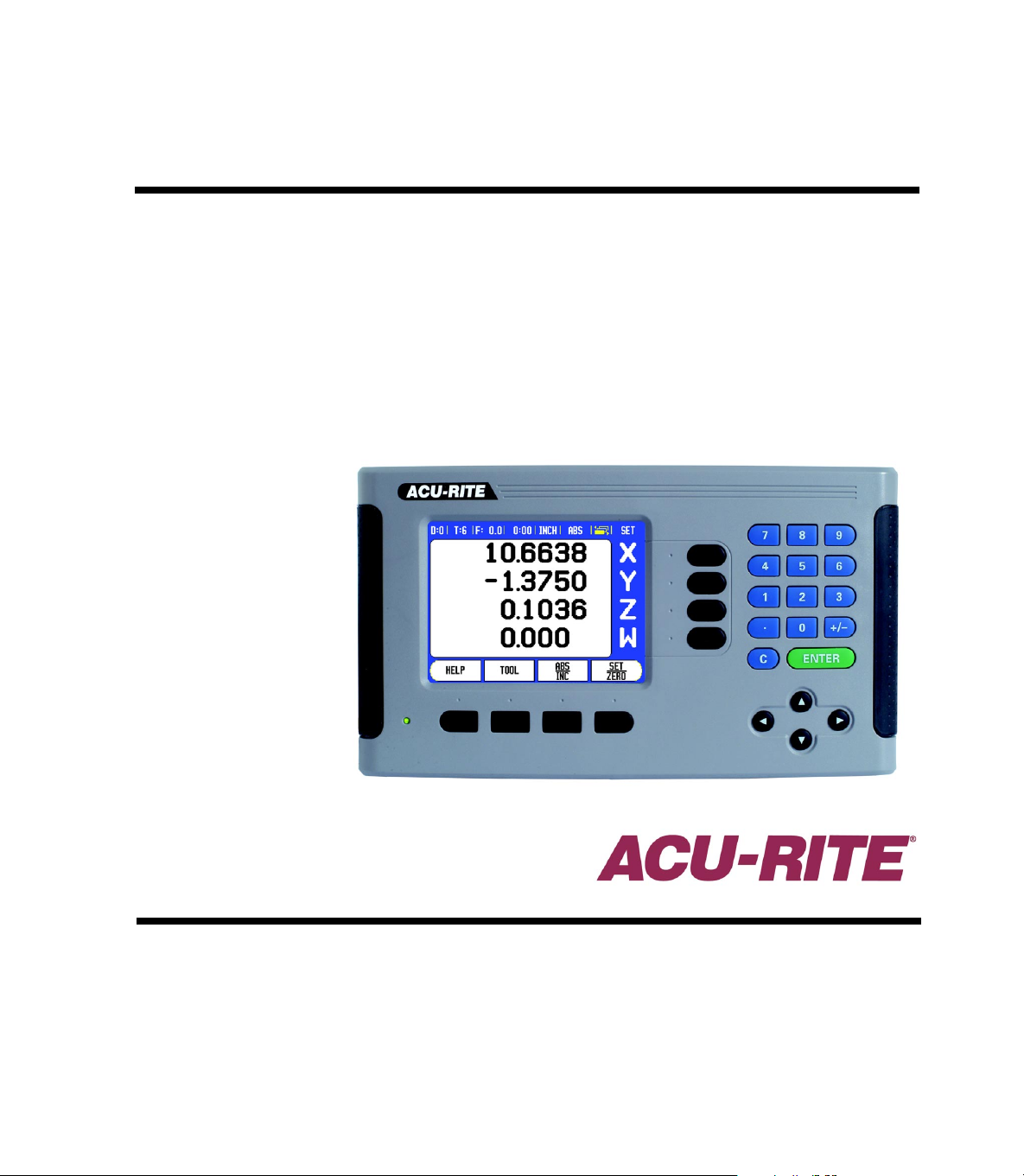

300S R

EADOUTS

REFERENCE MANUAL

Page 2

Page 3

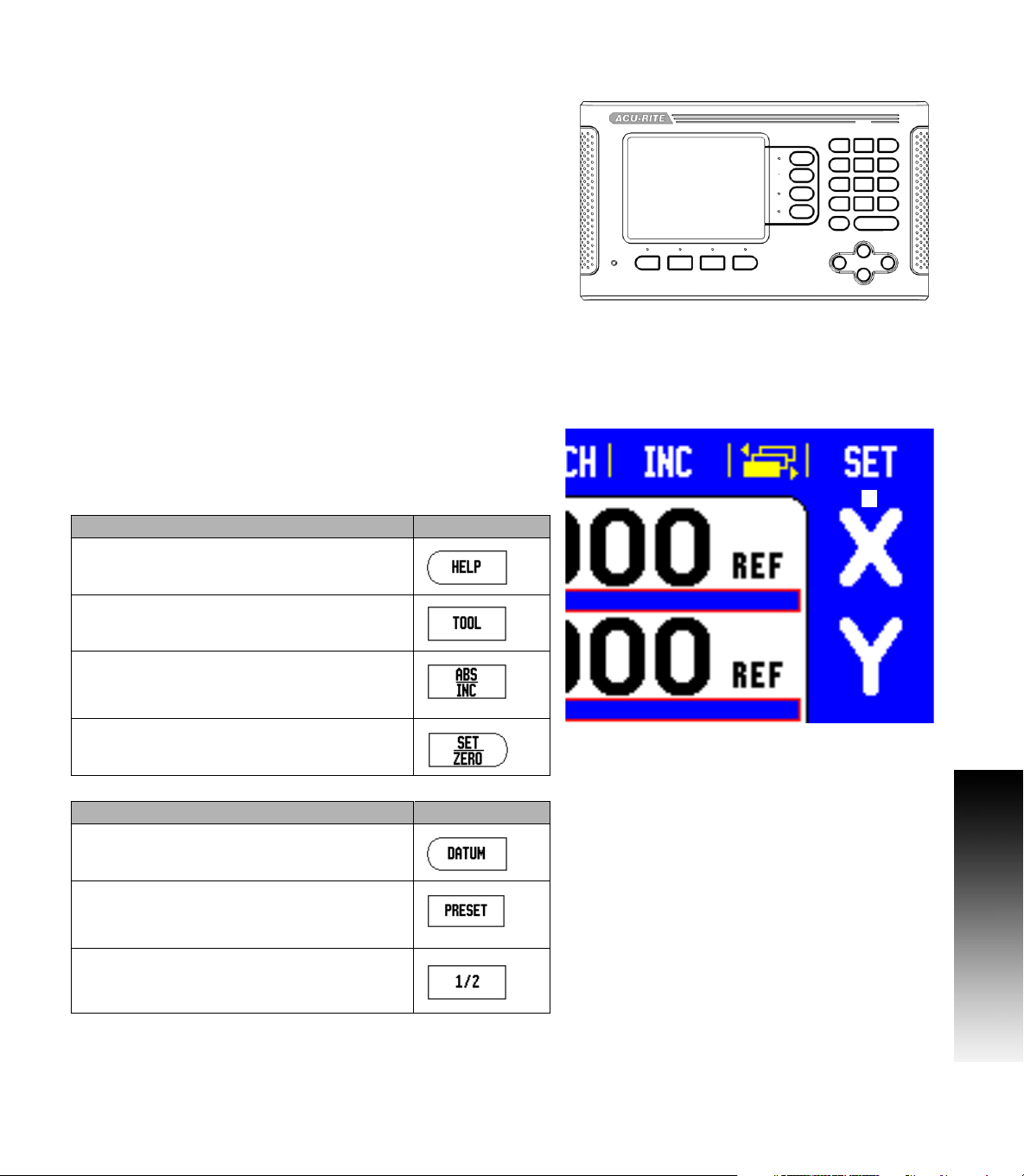

300S Key Layout

1

1

121

41516

1

7

1

8

3

1

1

2

1

1 Display Area

2 Soft keys

3 Power Indicator light

4 Arrow Keys: Use the UP/DOWN keys to adjust the

screen contrast.

5 Axis Keys

6 Numeric Keypad

7 ENTER key

8 CLEAR key

300S Soft keys

There are multiple pages of soft key functions to select from the

operating modes. Use the LEFT/RIGHT arrow keys [4] to cursor

through each page. The page indicator in the Status Bar will show the

page orientation. The darkened page indicates the page you are

currently on.

1 Page Indicator

2 Set Zero Indicator

Soft Key function (Page 1) Soft key

Opens on-screen help instructions.

Opens the Tool Table. Page 22 for Milling, and

page 51 for Turning.

Switches display between operating modes

Actual Value (Absolute) / Distance-to-Go

(incremental). See page 12.

Toggles between Set/Zero functions. Used

with individual axis keys (page 20).

Soft Key function (Page 2a) Soft key

Opens the Datum form to set the datum for each axis

(

page 28).

Opens the Preset form. This form is used to set a

nominal position. This is a Distance-To-Go

(Incremental) function (

Used to divide the current position by two (

page 33).

page 36).

300S i

Page 4

Soft Key function (Page 2a) Soft key

Press to select the Circle Pattern, Linear Pattern,

Incline Mill, or Arc Mill table (

This soft key toggles between radius and diameter

displays. This function is for Turning applications only

(

page 56).

page 38).

Soft Key function (Page 2b) Soft key

Opens the Job Setup menu and provides access to

the Installation Setup soft key (

page 13).

Press when ready to identify a reference mark (

10

).

Opens the Calculator functions for standard math,

trigonometry, RPM, and Taper for Turning functions.

The

CALC key is also available on input forms

where calculations may be required while

page

inputting data.

Toggles between inch and millimeter units (page

).

13

Soft Key function (Page 3) Soft key

Selects the Program Mode (page 66).

ii

Page 5

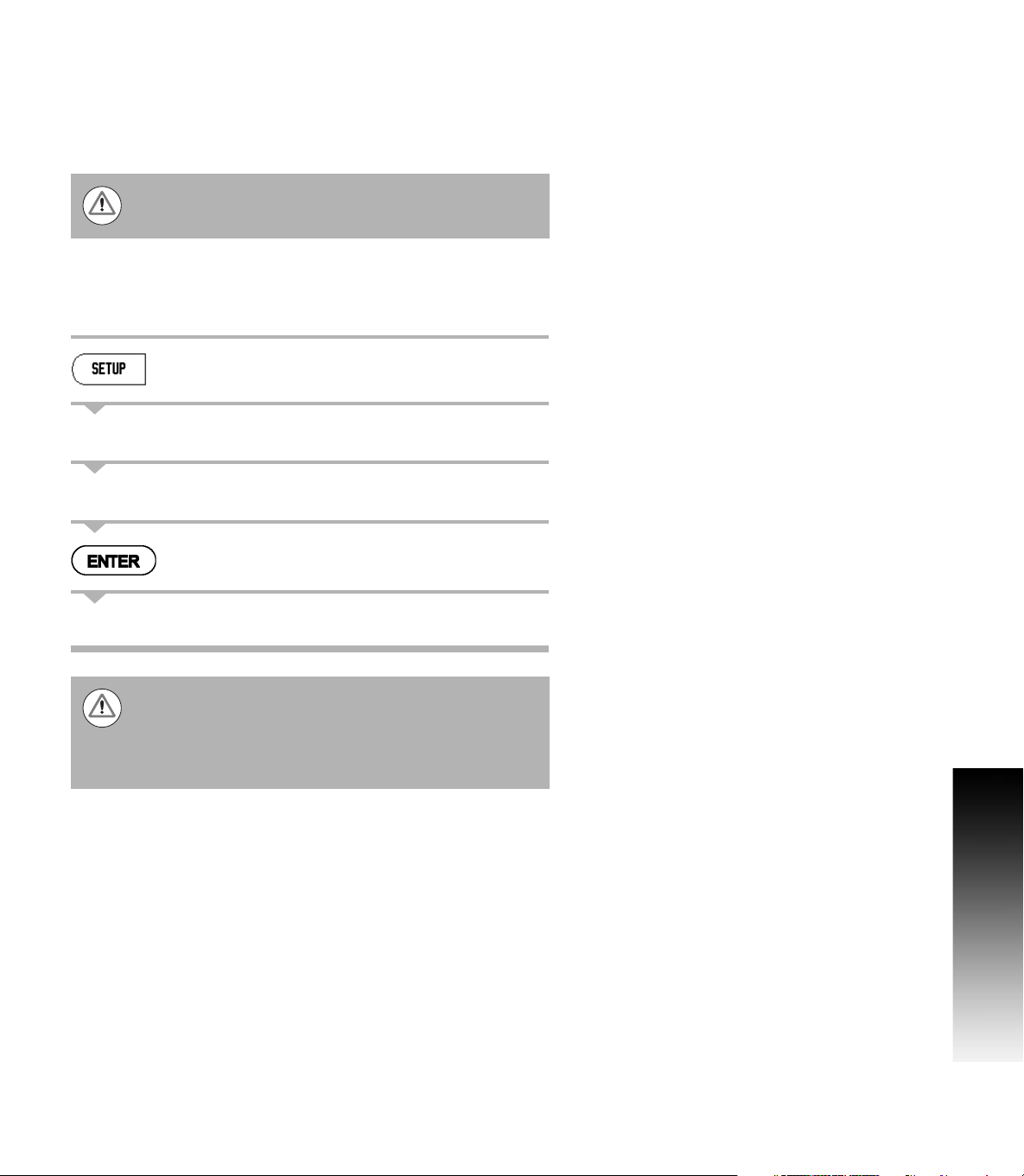

Readout Parameter Access Code

An access code must be entered before machine-related installation

parameters can be set or changed. This prevents inadvertent

adjustments to the installation setup parameters.

IMPORTANT!

The access code is 8891.

Access to Machine Parameter Operations

Refer to the Setup section also.

Begin by pressing the SETUP soft key.

Press the soft key INSTALLATION SETUP.

Press the access code numbers 8891 using the numeric key pad.

Press the ENTER key

The readout is now ready for machine parameter setting operations.

IMPORTANT!

To prevent setup parameters from being changed, remove

this page from the Reference Manual after initially setting

up the readout system. Retain this information in a safe

place for future use.

Readout Parameter Access Code

300S iii

Page 6

Readout Parameter Access Code

iv

Page 7

Introduction

Software Version

The software version is shown on the initial power up screen.

This User's Manual covers the functions of the 300S for

both milling, and turning applications. Operational

information is arranged in three sections: General

Operations, Mill Specific Operations, and Turn

Specific Operations.

300S

DRO axis availability.

The 300S Color DRO is available in two, three, and four

axis form. The 4 axis 300S DRO is used through out this

manual for illustration, and description of function keys.

Symbols within Notes

Every note is marked with a symbol on the left indicating to the

operator the type, and/or potential severity of the note.

General Information

e.g. on the behavior of the 300S.

Introduction

Warning

e.g. when a special tool is required for a function.

Damage - Risk of electric shock

e.g. when opening a housing.

300S Fonts

The following shows how soft keys, and hard keys are represented

within the text of this manual:

Soft keys - SETUP soft key

Hard keys - ENTER hard key

300S v

Page 8

Introduction

vi

Page 9

Warranty

Go to www.acu-rite.com for warranty information.

300S vii

Page 10

viii

Page 11

Table of Contents

300S Key Layout........................................................................................................i

300S Soft keys...........................................................................................................i

Readout Parameter Access Code

Access to Machine Parameter Operations .............................................................. iii

Introduction

Software Version ......................................................................................................v

300S..........................................................................................................................v

Symbols within Notes...............................................................................................v

300S Fonts................................................................................................................v

Warranty

Warranty ................................................................................................................. vii

I - 1 Fundamentals of Positioning

Datums .................................................................................................................... 2

Actual Position, Nominal Position, and Distance-To-Go........................................... 2

Absolute Workpiece Positions ................................................................................. 3

Incremental workpiece positions............................................................................. 3

Zero Angle Reference Axis ...................................................................................... 4

Reading head position ............................................................................................. 4

Encoder Reference Marks ....................................................................................... 5

I - 2 General Operations for 300S

Screen Layout ......................................................................................................... 6

General Navigation................................................................................................... 7

General Overview .................................................................................................... 7

Graphic Positioning Aid ....................................................................................... 7

Help Screen ............................................................................................................. 8

Data Input Forms ..................................................................................................... 9

Instruction Box messages .................................................................................. 9

Error Messages................................................................................................... 9

Power Up............................................................................................................... 10

Reference Mark Evaluation.................................................................................... 10

Working without reference mark evaluation..................................................... 10

Enable/Disable Ref function................................................................................... 11

Operating Modes................................................................................................... 12

Setup .................................................................................................................... 12

300S ix

Page 12

Job Setup Parameters ........................................................................................... 13

Units ................................................................................................................. 13

Scale Factor ...................................................................................................... 13

Mirror ................................................................................................................ 14

Edge Finder (milling applications only).............................................................. 14

Diameter Axes .................................................................................................. 14

Measured Value Output.................................................................................... 15

Near Zero Warning............................................................................................ 15

Status Bar Settings ........................................................................................... 15

Job Clock .......................................................................................................... 15

Skew Compensation (Milling applications only)............................................... 16

Remote Switch ................................................................................................. 17

DRO View Settings........................................................................................... 17

Console Adjustment ......................................................................................... 19

Language .......................................................................................................... 19

Import/Export.................................................................................................... 19

Set/Zero Soft Key Details.................................................................................. 20

Calc Soft Key .................................................................................................... 20

RPM Calculator ................................................................................................. 21

I - 3 Milling Specific Operations

Soft Key Functions Detailed .................................................................................. 22

Tool Soft Key .................................................................................................... 22

Tool Table ......................................................................................................... 22

Import/Export.................................................................................................... 23

Tool Radius Compensation feature................................................................... 24

Sign for the length difference

Entering tool data................................................................................................. 25

Calling the Tool from the Tool Table ................................................................. 28

Datum Soft Key ................................................................................................ 28

Probing Functions for Datum Setting ............................................................... 28

Probing with a Tool ........................................................................................... 31

Example: Probe workpiece edge and set edge as datum ................................ 32

Presets.............................................................................................................. 33

Absolute Distance Preset ................................................................................. 33

Incremental Distance Preset ............................................................................ 35

1/2 Soft Key ...................................................................................................... 36

Features (Milling) ................................................................................................... 37

Circle, and Linear Patterns..................................................................................... 38

Soft key Functions ............................................................................................ 38

Circle, and Linear Pattern Table Entry............................................................... 39

Circle, and Linear Pattern Soft keys.................................................................. 40

Circle, or Linear Pattern Execution ................................................................... 41

Example: Enter data and execute a circle pattern. .......................................... 42

Incline, and Arc Milling........................................................................................... 44

Soft Key Functions............................................................................................ 44

Incline, and Arc Milling Table Entry................................................................... 45

ΔL ...................................................................... 24

x

Page 13

Incline, and Arc Milling Table Entry................................................................... 46

Arc Milling......................................................................................................... 47

Incline, and Arc Mill Execution.......................................................................... 48

Z/W Coupling ......................................................................................................... 50

Enabling Z/W Coupling...................................................................................... 50

Disabling Z/W Coupling..................................................................................... 50

I - 4 Turning Specific Operations

Tool Display Icon............................................................................................... 51

Tool Table.......................................................................................................... 51

Datum Setting................................................................................................... 53

Taper Calculator Soft Key.................................................................................. 55

Presets.............................................................................................................. 56

Radius/Diameter Soft Key................................................................................. 56

Vectoring........................................................................................................... 57

Z Coupling......................................................................................................... 57

Disabling Z0, and Z Coupling............................................................................ 58

Thread Cycle .......................................................................................................... 59

Soft Key Functions............................................................................................ 59

Running the Thread Cycle Program .................................................................. 64

I - 5 Programming 300S

Overview ............................................................................................................... 66

Program Mode Soft key functions.................................................................... 67

View Soft Key ................................................................................................... 68

Feature Soft Key functions ............................................................................... 69

Program Function Soft keys .................................................................................. 71

Step Function Soft keys......................................................................................... 72

Editing, and moving through a program............................................................ 73

I - 6 Executing a Program

Run Soft Keys ................................................................................................... 74

Executing Steps..................................................................................................... 74

II - 1 Installation Setup

Installation Setup Parameters ................................................................................ 78

Encoder Setup ....................................................................................................... 79

Thread Cycle Setup:............................................................................................... 80

Display Configuration............................................................................................. 81

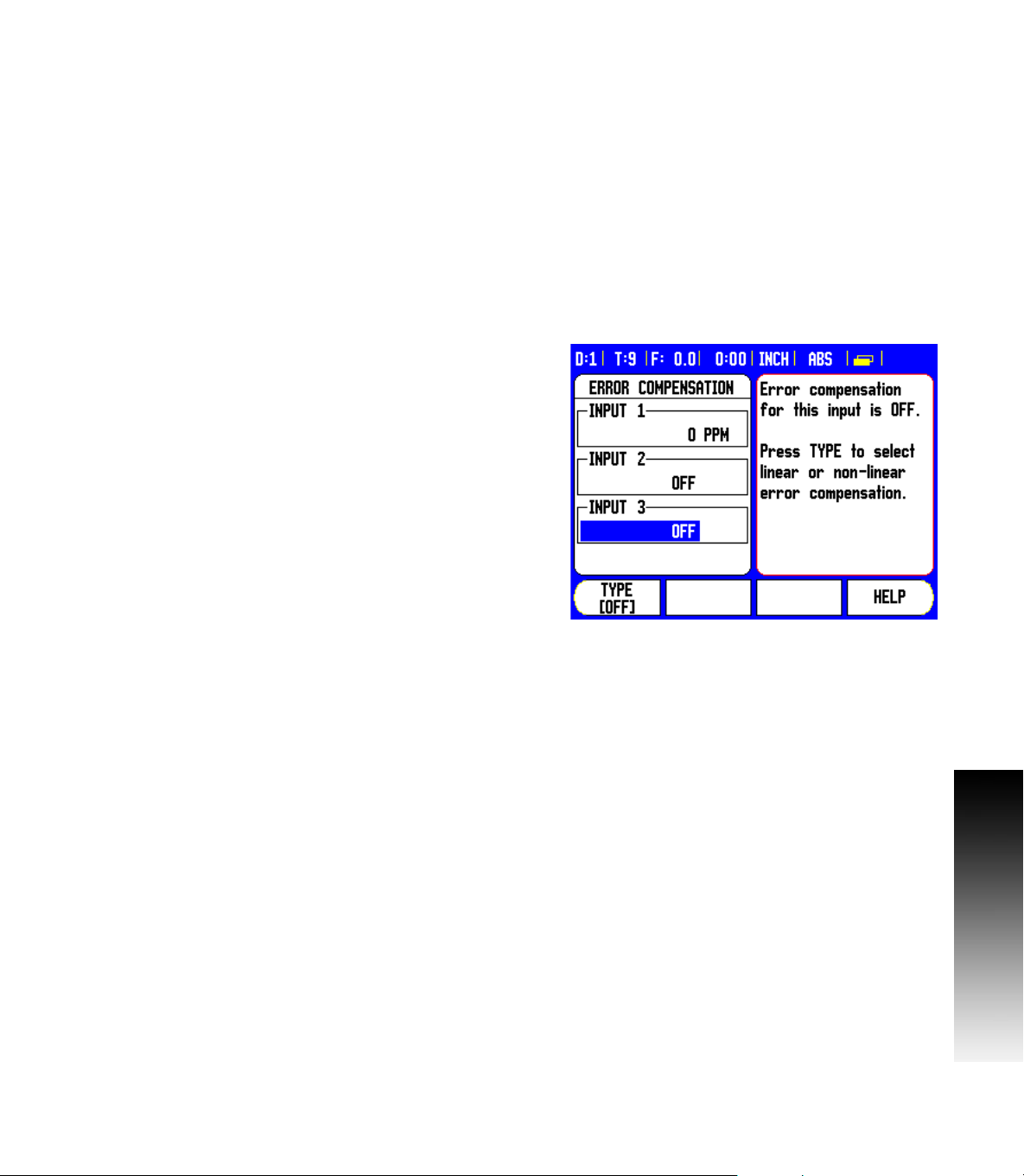

Error Compensation............................................................................................... 81

Linear Error Compensation ............................................................................... 82

Automatic Linear error compensation..................................................................... 82

Non-Linear Error Compensation............................................................................. 83

Setup procedure for Non-linear Error................................................................ 83

300S xi

Page 14

Starting a Non-Linear Error Compensation Table

Configuring the Compensation Table ............................................................... 85

Automatic Non Linear error compensation....................................................... 85

Backlash Compensation ........................................................................................ 87

Counter Settings.................................................................................................... 87

Diagnostics ............................................................................................................ 88

Keypad Test ...................................................................................................... 88

Edge Finder Test............................................................................................... 88

Display Test ...................................................................................................... 88

..................................................... 84

II - 2 Data Interface

Serial Port .............................................................................................................. 90

II - 3 Installation and Electrical Connections

Installation.............................................................................................................. 91

Electrical requirements ..................................................................................... 91

Environmental................................................................................................... 91

Preventative maintenance ................................................................................ 91

II - 4 I/O Connections

Wiring the Serial communication cable ................................................................. 93

II - 5 Remote Switch Data Output

Data output using external signals.................................................................... 94

Data output using Edge Finder ......................................................................... 96

II - 6 Error Messages

............................................................................................................................... 99

II - 7 Dimensions

DRO Dimensions ................................................................................................. 102

xii

Page 15

Operating Instructions

300S 1

Page 16

I - 1 Fundamentals of Positioning

Datums

The workpiece drawing identifies a certain point on the workpiece

(example: “a corner”) as the absolute datum, and perhaps one, or

more other points as relative datums.

The datum setting procedure establishes these points as the origin of

the absolute, or relative coordinate systems. The workpiece, which is

aligned with the machine axes, is moved to a certain position relative

to the tool. The display is set either to zero, or to another appropriate

value (e.g., to compensate for tool radius).

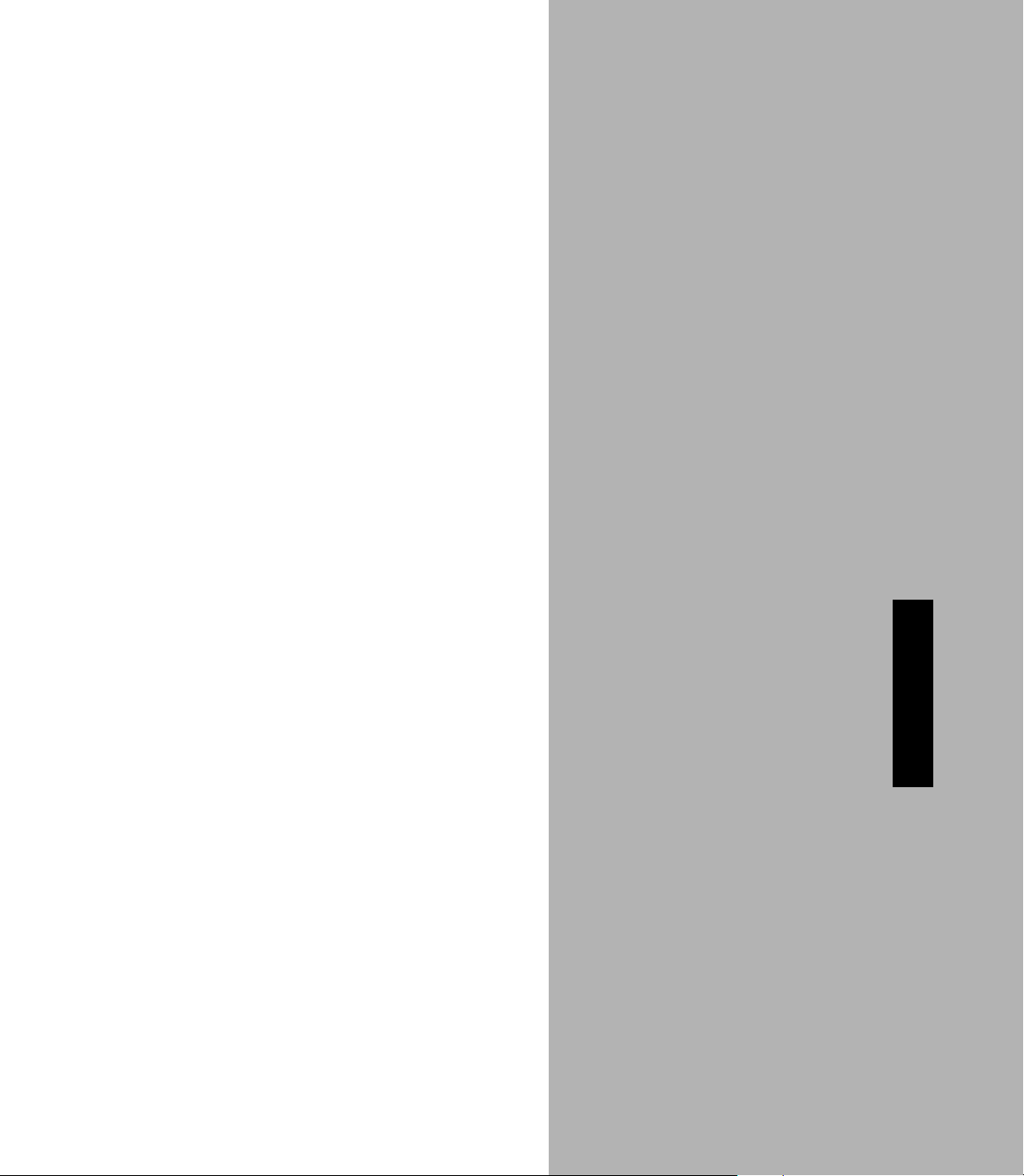

Actual Position, Nominal Position, and Distance-To-Go

The position of the tool at any given moment is called the ACTUAL

POSITION I, while the position that the tool is to move to is called the

NOMINAL POSITION S. The distance from the nominal position to

the actual position is called the DISTANCE-TO-GO R.

I - 1 Fundamentals of Positioning

2 I

Page 17

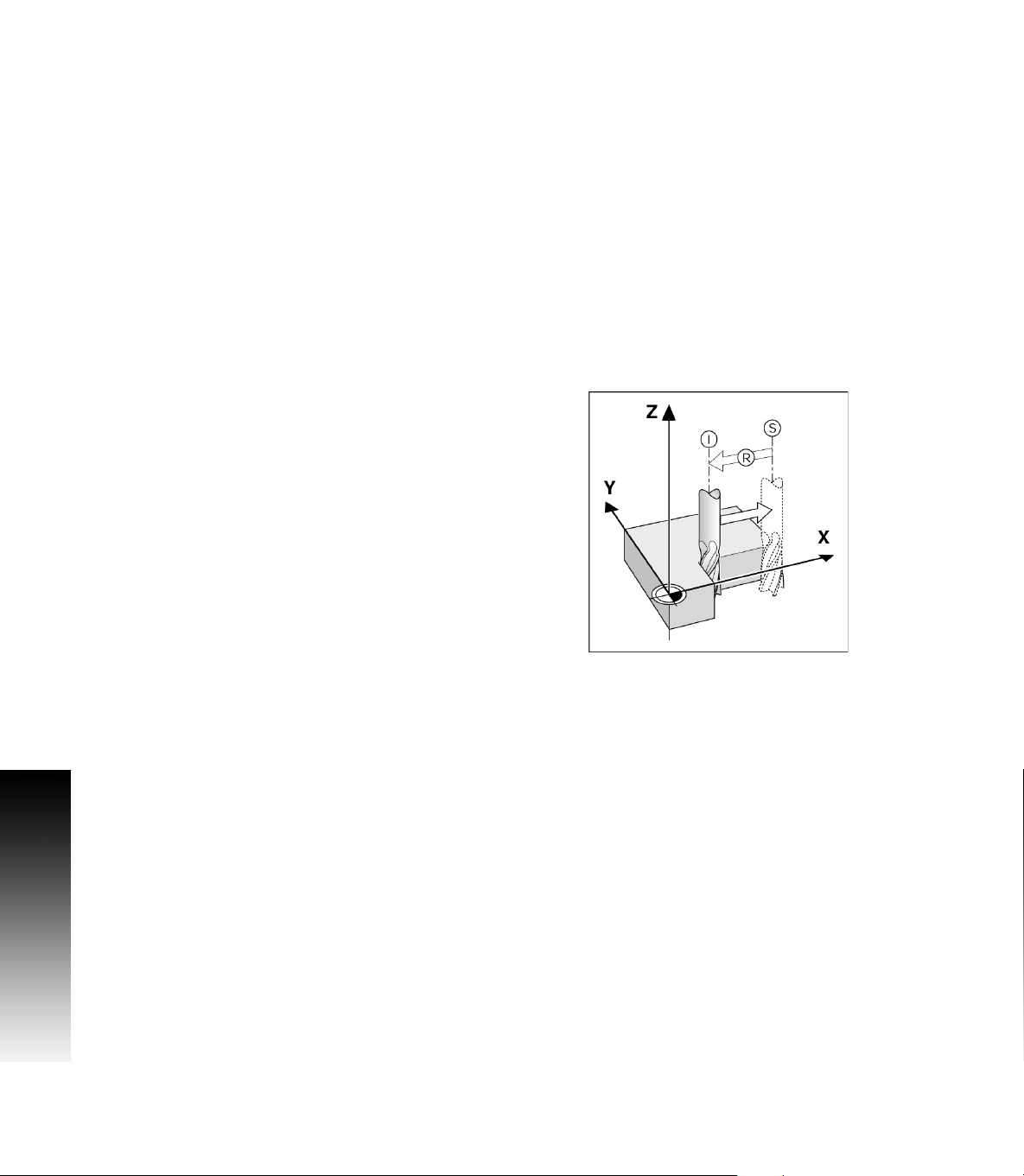

Absolute Workpiece Positions

Each position on the workpiece is uniquely identified by its

absolute coordinates.

Example: Absolute coordinates of position 1:

X = 20 mm

Y = 10 mm

Z = 15 mm

If you are drilling, or milling a workpiece according to a workpiece

drawing with absolute coordinates, the tool is moving to the value of

the coordinates.

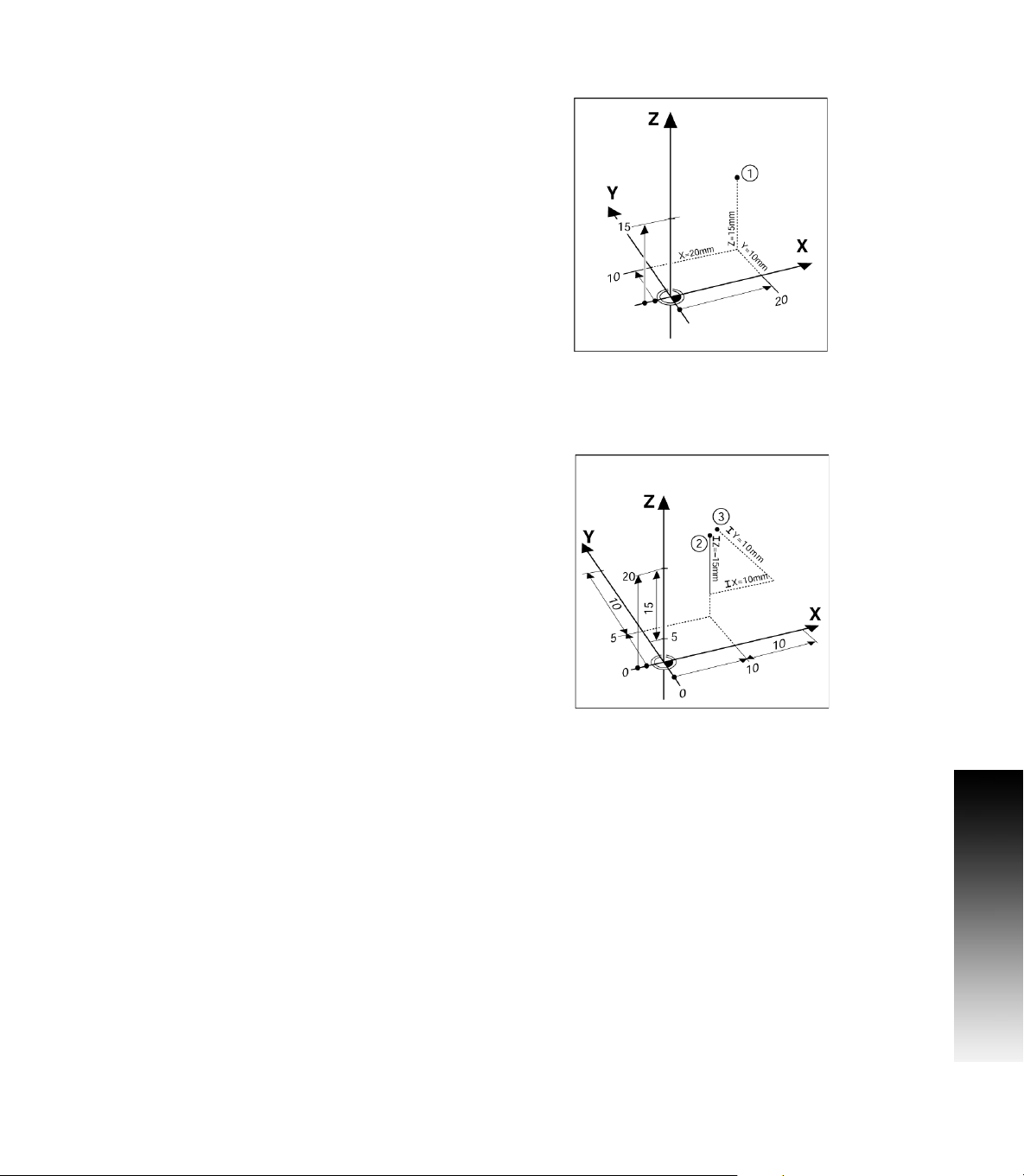

Incremental workpiece positions

A position can also be referenced to the preceding nominal position.

In this case the relative datum is always the last nominal position.

Such coordinates are referred to as incremental coordinates

(increment = increase). They are also called incremental, or chain

dimensions, since the positions are defined as a chain of dimensions.

Incremental coordinates are designated with the prefix I.

Example: Incremental coordinates of position 3 referenced

to position 2.

Absolute coordinates of position 2:

X = 10 mm

Y = 5 mm

Z = 20 mm

Incremental coordinates of position 3:

IX = 10 mm

IY = 5 mm

IZ = 20 mm

If you are drilling, or milling a workpiece according to a drawing with

incremental coordinates, you are moving the tool by the value of

the coordinates.

I - 1 Fundamentals of Positioning

300S 3

Page 18

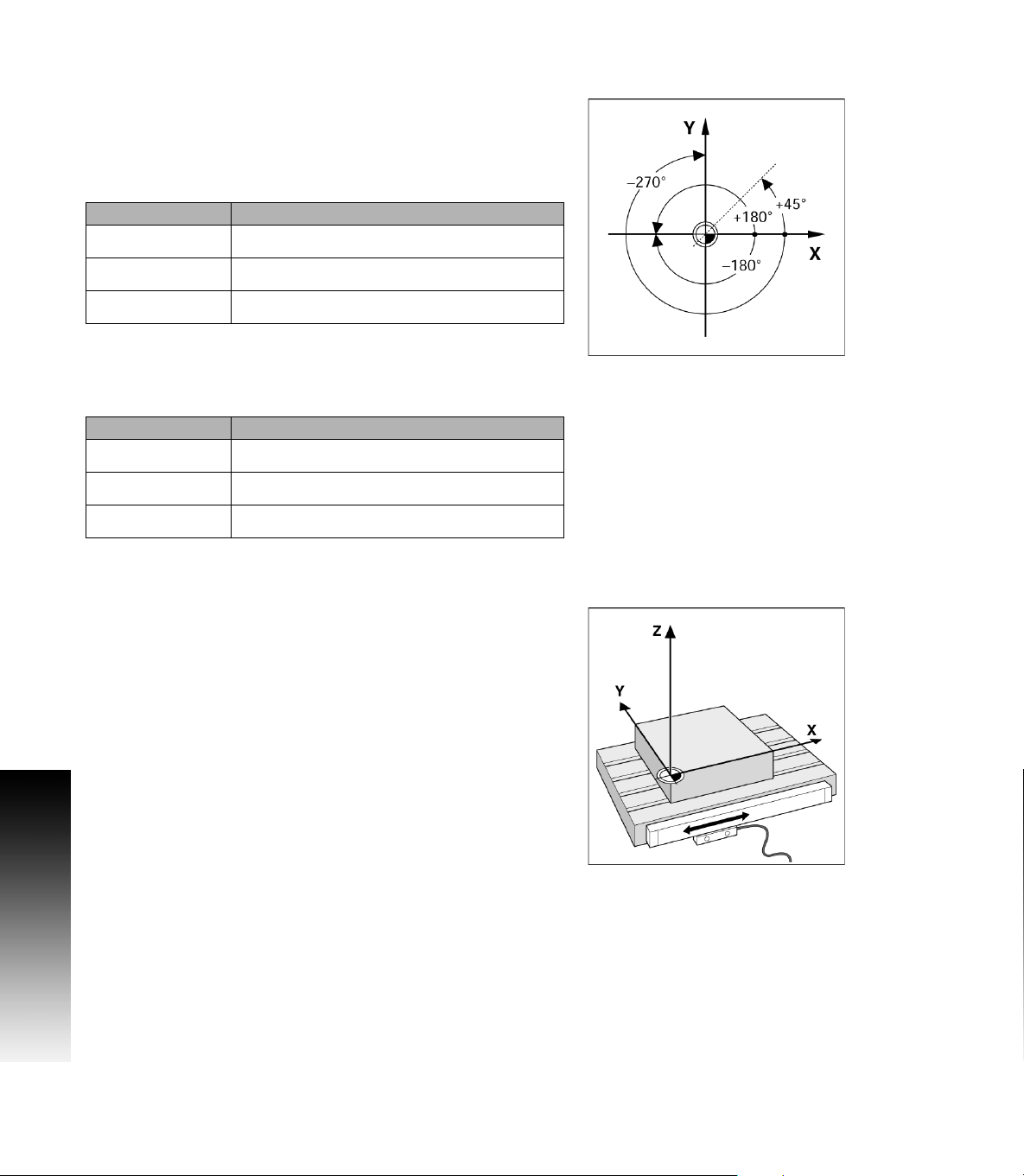

Zero Angle Reference Axis

The Zero Angle Reference Axis is the 0.0° position. It is defined as

one of the two axes in the plane of rotation. The following table

defines the Zero Angle where the position of the angle is zero for the

three possible planes of rotation.

For angular positions, the following reference axes are defined:

Plane Zero Angle Reference Axis

XY +X

YZ +Y

ZX +Z

Positive direction of rotation is counterclockwise if the working plane

is viewed in the negative tool axis direction.

EXAMPLE: Angle in the working plane X / Y

Plane Zero Angle Reference Axis

+ 45° ... bisecting line between +X and +Y

I - 1 Fundamentals of Positioning

+/- 180° ... negative X axis

- 270° ... positive Y axis

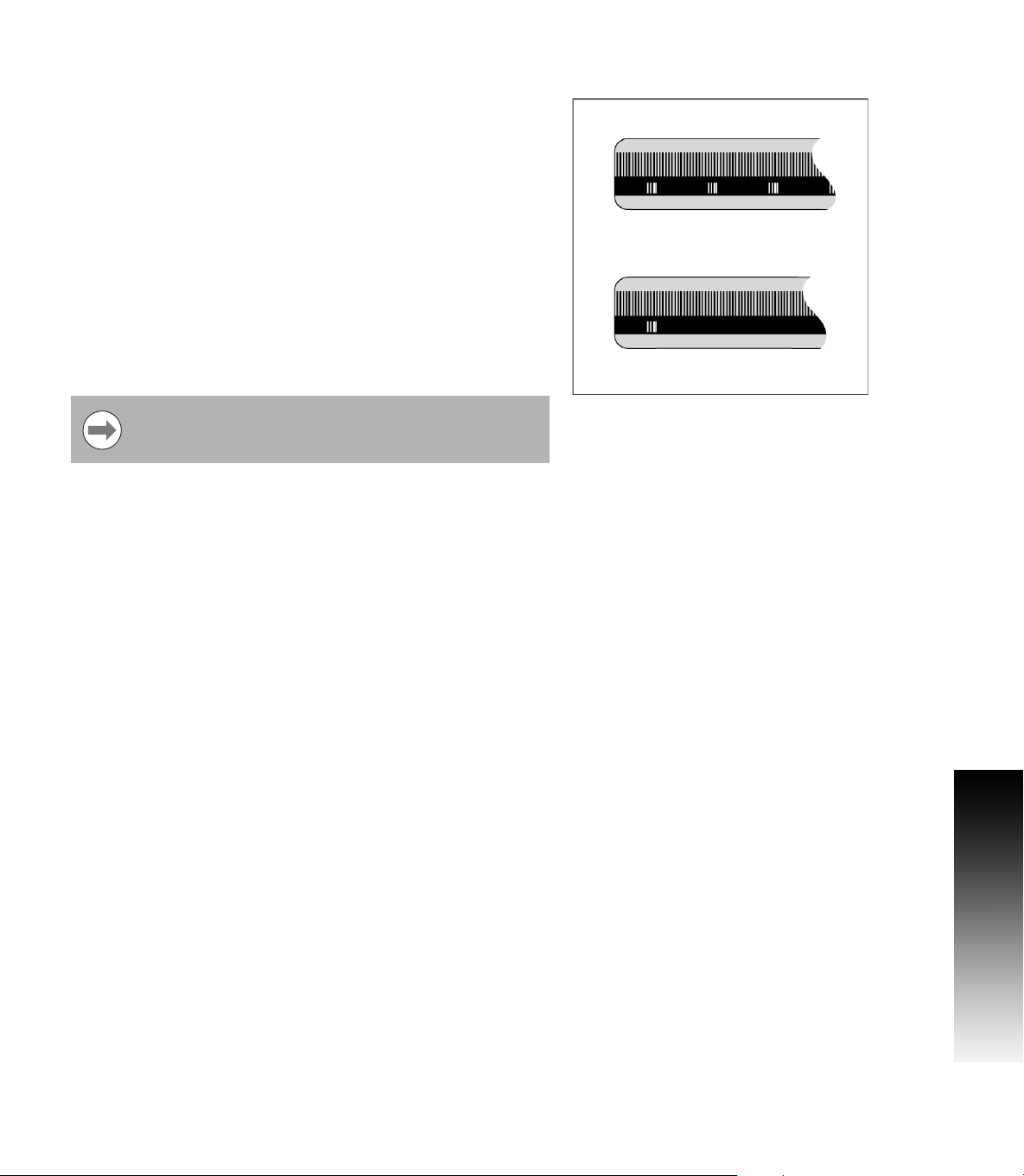

Reading head position

The reading head position provides feed back to the 300S that

converts the movement of the machine axes into electrical signals.

The 300S constantly evaluates these signals, and calculates the actual

positions of the machine axes, which it displays as a numerical value

on the screen.

If there is an interruption in power, the calculated position will no

longer correspond to the actual position. When power is restored, you

can re-establish this relationship by using the reference marks on the

provided on the scale. The 300S provides the Reference Mark

Evaluation feature (REF).

4 I

Page 19

Encoder Reference Marks

Encoders normally contain one or more reference marks which the

300S Reference Mark Evaluation feature uses to re-establish datum

positions after a power interruption. There are two main options

available for reference marks; fixed and distance-coded.

Position Trac (Distance-coded reference marks): Encoders that have

marks separated by a specific encryption pattern allows the 300S to

use any two pair of marks along the length of the encoder to reestablish the prior datums. This configuration means that the operator

only has to travel less than two inches any where along the encoder,

to re-establish the datums when the 300S is turned back on.

Fixed reference marks: Encoders that have one or more marks on

fixed intervals, have to re-establish the datums correctly. It is

necessary to use the same exact reference mark, during the

Reference Mark Evaluation routine, that was used when the datum

was first established.

The established datums’ cannot be restored from one

power cycle to the next if the reference marks were not

crossed before the datums were set

I - 1 Fundamentals of Positioning

300S 5

Page 20

I - 2 General Operations for 300S

9

10

4

5

1

678

2

11112

13

3

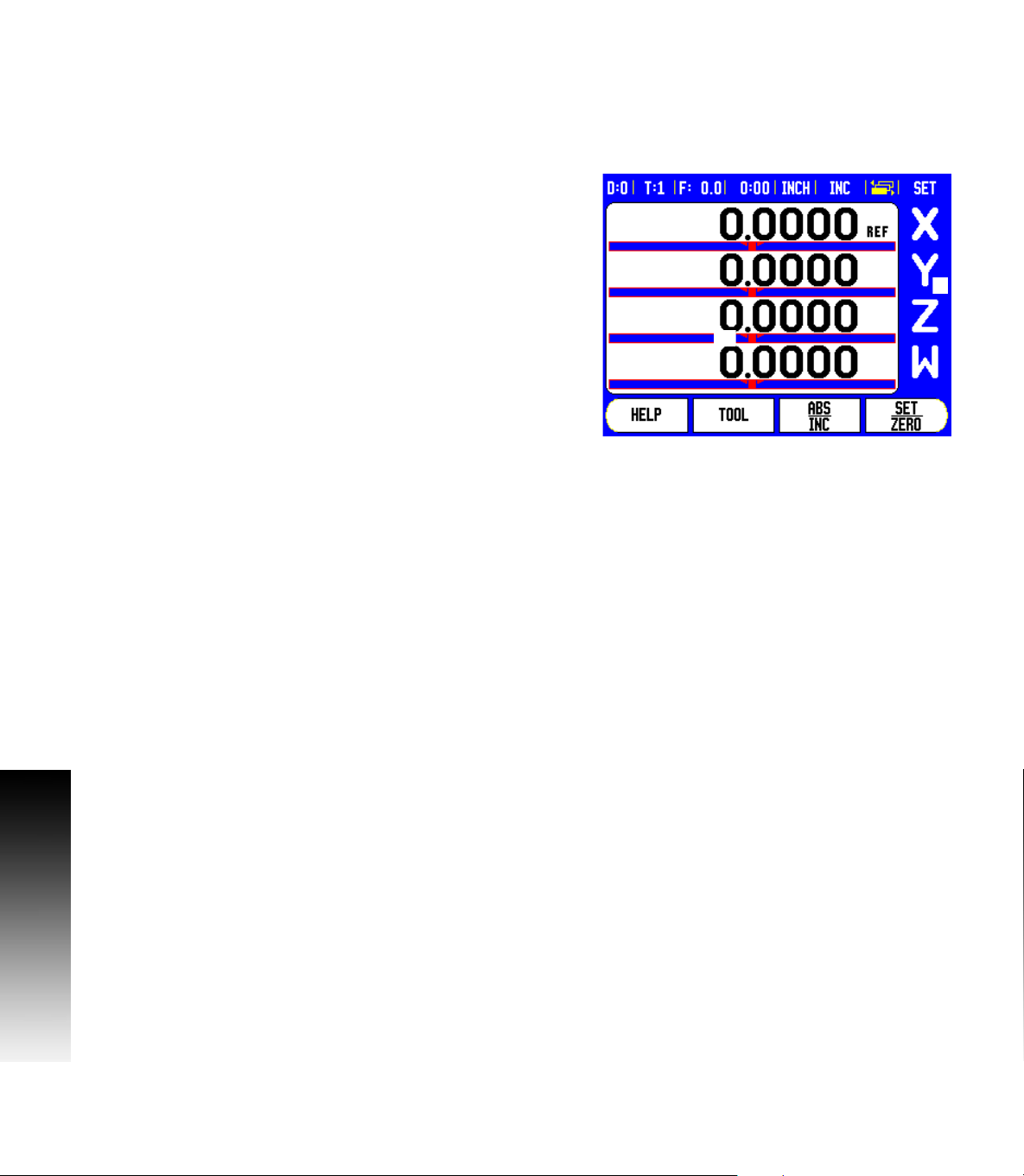

Screen Layout

1 Datum

2 Tool

3 Feed Rate

4 Job Clock

5 Unit of Measure

6 Operating Modes

7 Page Indicator

8 Set/Zero

9 Axis Labels

10 Ref Symbol

11 Soft key Labels

12 Display Area

13 Near Zero Warning (In Distance-To-Go mode only)

The ACU-RITE 300S color readout provides application-specific

I - 2 General Operations for 300S

features that allows you to obtain the most productivity from your

manual machine tools.

Status Bar - This displays the current datum, tool, feed rate, job

clock time, unit of measure, operating mode status, page indicator,

and set/zero. See Job Setup for details on setting up the Status

Bar parameters.

Display Area - Indicates the current position of each axis. Also

shows forms, fields, instruction boxes, error messages and

help topics.

Axis Labels - Indicates axis for corresponding axis key.

Ref Symbols - Indicates current reference mark status.

Soft key Labels - Indicates the various milling or turning functions.

6 I

Page 21

General Navigation

Use key pad to enter numeric values within each field.

The ENTER key will confirm the entry within a field, and return to the

previous screen.

Press the C key to clear entries, and error messages, or return back

to the previous screen.

SOFT KEY labels show the various milling, or turning functions.

These functions are selected by pressing the corresponding soft key

directly below each soft key label. There are 3 pages of selectable

soft key functions. These are accessed using the LEFT or RIGHT

arrow keys as indicated below.

LEFT or RIGHT arrow keys move through pages 1-3 of soft key

selectable functions. The current page will be highlighted in the

Status bar at the top of screen.

Use the UP, or DOWN arrow keys to move between fields within a

form, and list boxes within a menu. The orientation of the cursor is

such that it will return to the top once it has reached the bottom of

a menu.

General Overview

Graphic Positioning Aid

When traversing to display value zero (in the Distance-To-Go mode),

300S displays a graphic positioning aid.

300S displays the graphic positioning aid in a narrow rectangle

underneath the currently active axis. Two triangular marks in the

center of the rectangle symbolize the nominal position.

A small square symbolizes the axis slide. An arrow indicating the

direction appears in the square while the axis is moving towards, or

away from the nominal position. Note that the square does not begin

to move until the axis slide is near the nominal position. Setting up the

graphic positioning aid, see "Status Bar Settings" on page 15 under Job

Setup.

I - 2 General Operations for 300S

300S 7

Page 22

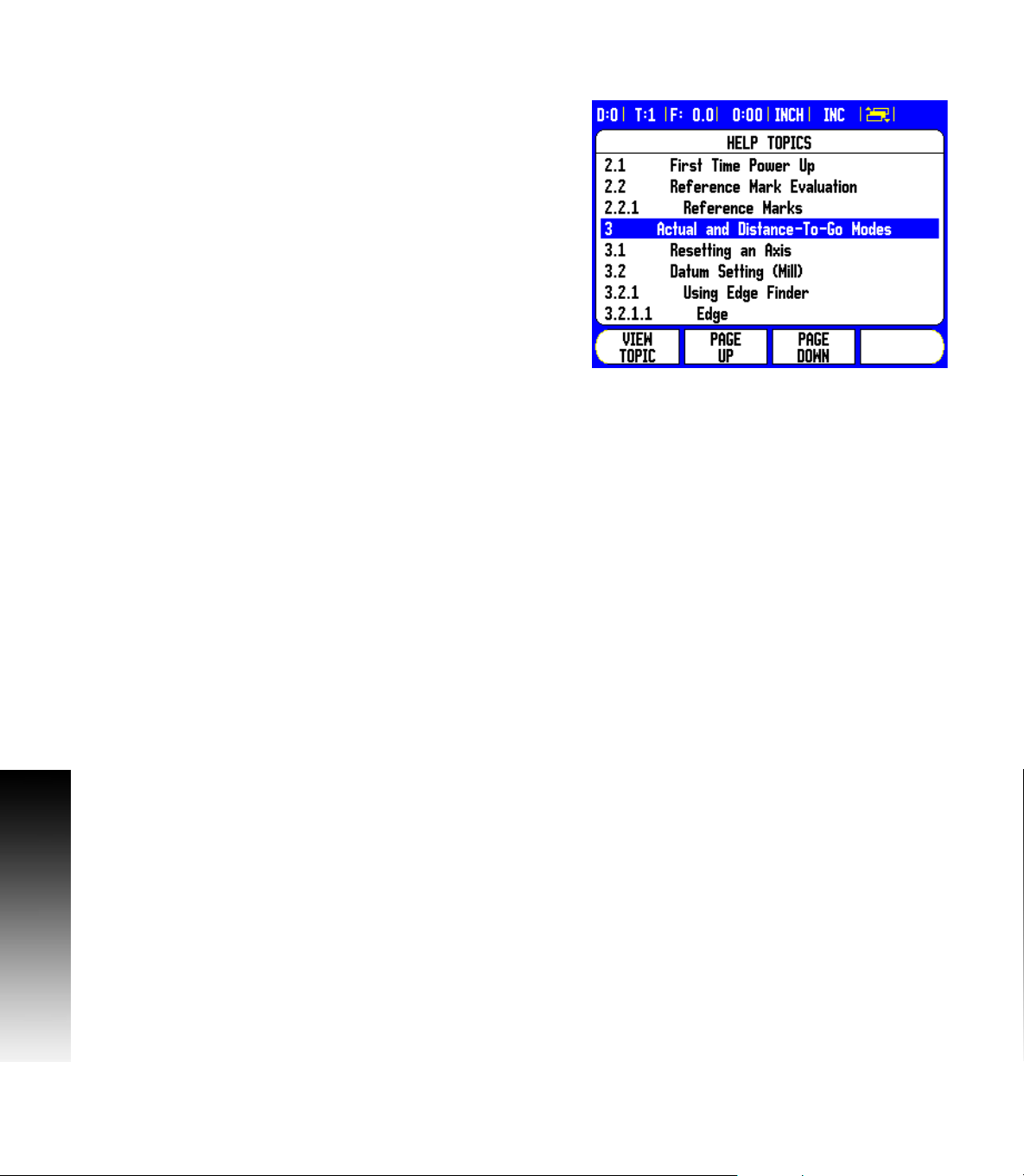

Help Screen

The integrated operating instructions provide information and

assistance in any situation.

To call the operating instructions:

8 Press the HELP soft key.

8 Information relevant to the current operation will be displayed.

8 Use the UP/DOWN arrow keys if the explanation is spread over

more than one screen page.

To view information on another topic:

8 Press the LIST OF TOPICS soft key.

8 Press the UP/DOWN arrow keys to scroll through the index.

8 Press the ENTER key to select the item you need.

To exit the operating instructions:

8 Press the C key.

I - 2 General Operations for 300S

8 I

Page 23

Data Input Forms

Information required for various operational functions and setup

parameters are entered through a data input form. These forms will

appear after selecting features that require any additional information.

Each form provides specific fields for entering the required

information.

Changes must be confirmed by pressing the ENTER key for them to

become effective. If you do not want to save your changes, press the

C key to return to the previous screen without saving changes.

In some cases such as the Tool Table, the C key is used in place of the

ENTER key.

Instruction Box messages

Whenever a Menu, or Form is opened, an instruction box will also

open immediately to the right of it. This message box will provide

information for what the chosen function does, and present

instructions for available options.

I - 2 General Operations for 300S

Error Messages

If an error occurs while working with the 300S, the message will

appear on the display, and provide an explanation of what caused the

error. See "Error Messages" on page 99.

To clear the error message:

8 Press the C key.

Error message will be cleared, and normal operation can be

continued.

300S 9

Page 24

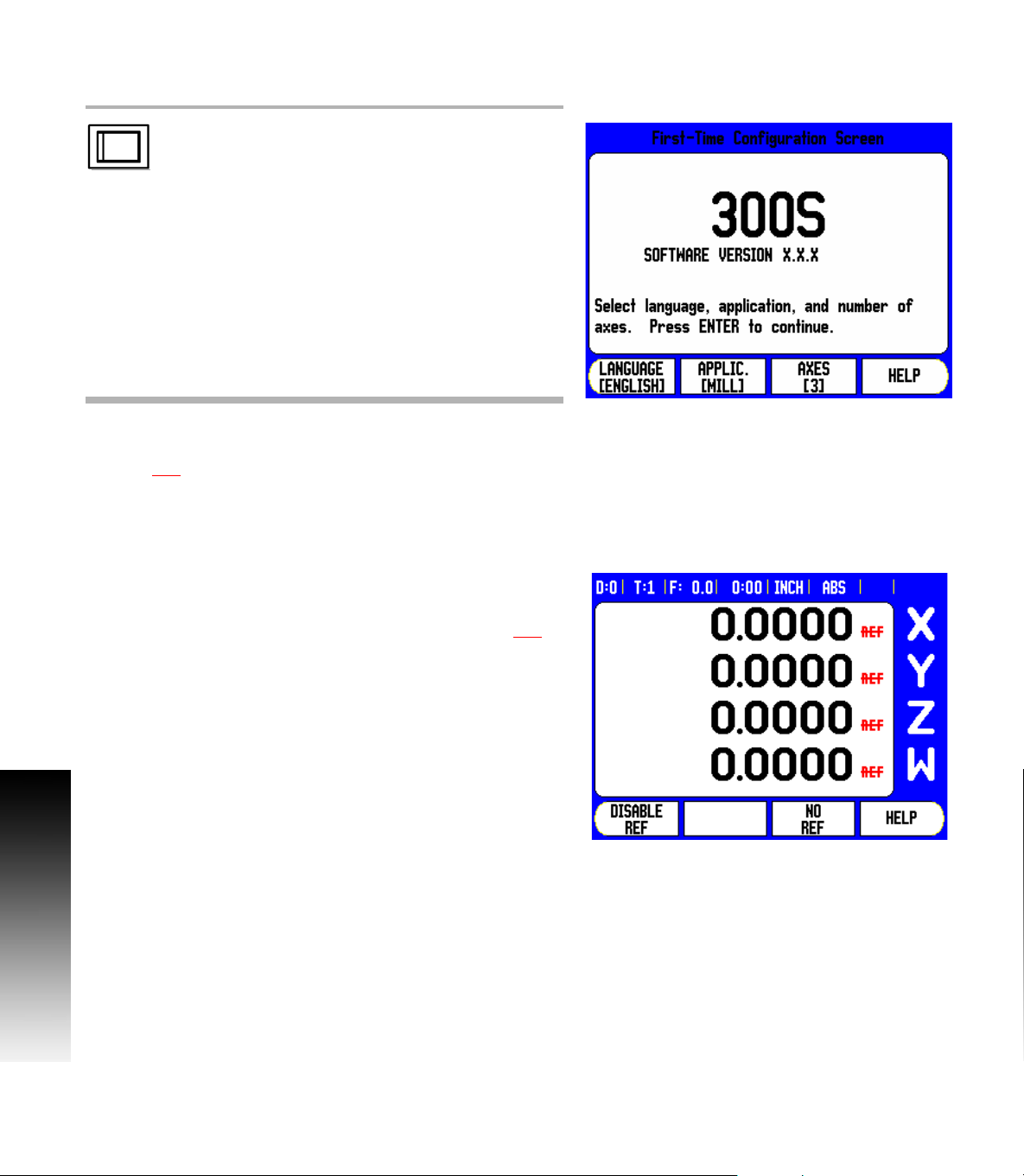

Power Up

(1)

Switch on the power (located on the back). The initial

screen will appear. This screen will only appear the

very first time the unit is powered up. The following

steps may have already been completed by

the installer.

Select the proper language by pressing the LANGUAGE soft key.

Choose your application of either MILL or TURN. The APPLIC.

[MILL/TURN] soft key toggles between these two settings.

Next, select the number of axes required. When complete, press

the ENTER hard key.

If necessary, you can change the application later in Installation Setup

under Counter Settings.

The 300S is now ready for the remaining setup requirements. It is

now in the operating mode “Absolute”. Each active axis will have a

flashing “REF” sign next to it. The following section, “Reference

I - 2 General Operations for 300S

Mark Evaluation”, describes setting up this feature.

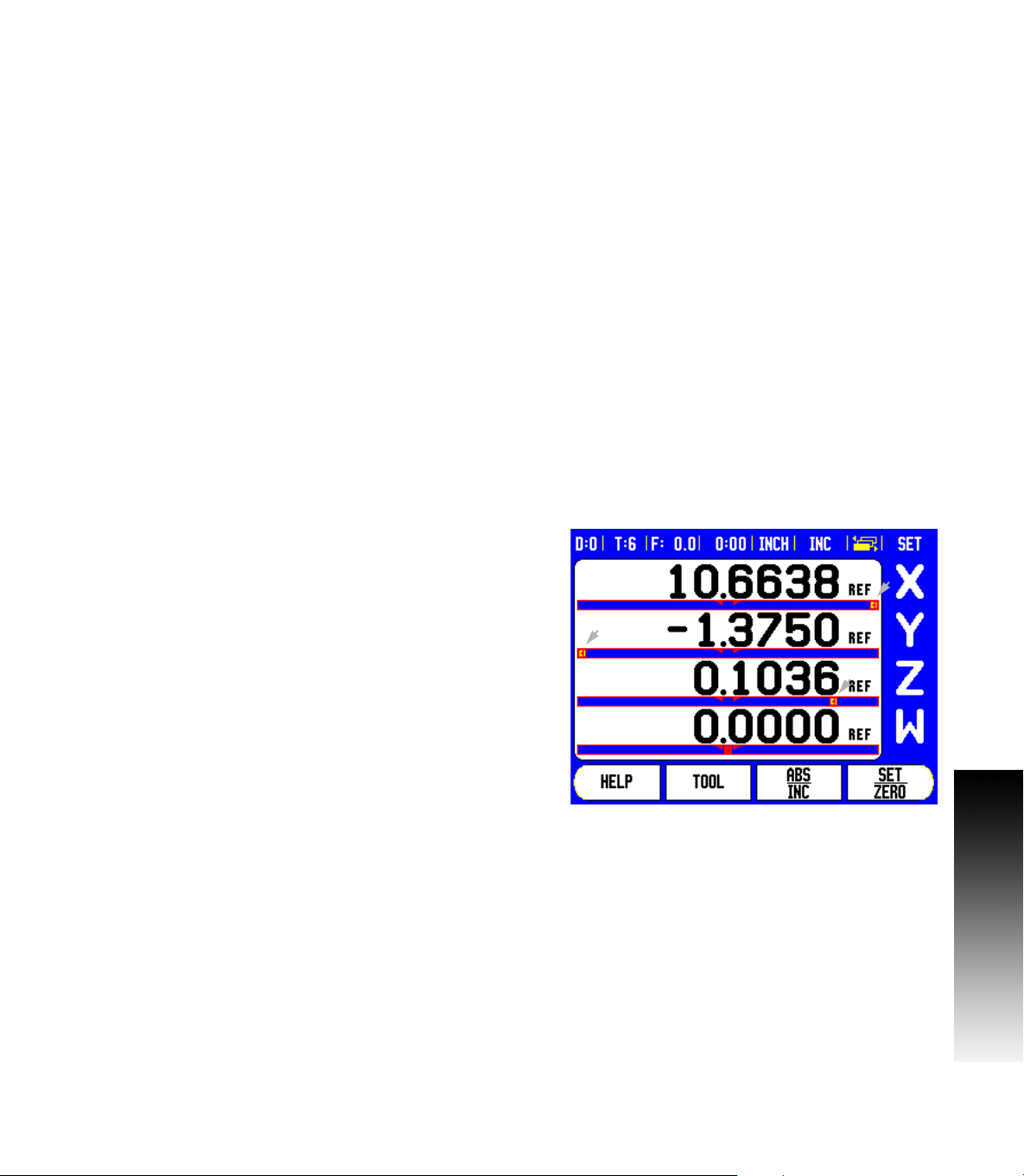

Reference Mark Evaluation

The 300S reference mark evaluation feature (1), automatically

re-establishes the relationship between axis slide positions and

display values that was last defined by setting the datum.

For each axis with an encoder that has reference marks, the “REF

indicator will flash for that axis. After crossing over the reference

marks, the indicator will stop flashing and change to a non-flashing

“REF” indicator.

Working without reference mark evaluation

The 300S can also be used without crossing over the reference marks.

8 Press the NO REF soft key to exit the reference mark evaluation

routine, and continue.

”

10 I

Page 25

The 300S can still cross over reference marks at a later time. Such as

if it becomes necessary to define a datum that can be re-established

after a power interruption.

8 Press the ENABLE REF soft key to activate the position recovery

routine. Press the RIGHT / LEFT arrow key if the soft key is not

shown on current screen.

If an encoder is setup without reference marks, then the

REF indicator will not be displayed, and a datum set from

any axis will be lost once power is turned off.

Enable/Disable Ref function

The ENABLE/DISABLE soft key, that is present during the position

recovery routine, allows the operator to select a specific reference

mark on an encoder. This is important when using encoders with

Fixed Reference Marks (instead of ones with Position-Trac™ feature).

When the DISABLE REF soft key is pressed, the recovery routine is

paused and any reference marks that are crossed during encoder

movement are ignored. When the ENABLE REF soft key is then

pressed, the recovery routine once again becomes active and the next

crossed reference mark will be selected.

Not all reference marks have to be crossed over on each encoder, only

those that are needed.

8 Once reference marks for all desired axes are established, press the

NO REF soft key to cancel out of the routine. If all reference marks

have been found, the 300S will return to the DRO display

screen automatically.

I - 2 General Operations for 300S

300S 11

Page 26

Operating Modes

The 300S has two operating modes: Distance-To-Go

(INCREMENTAL), and Actual Value (ABSOLUTE). The Actual Value

mode always displays the current actual position of the tool, relative

to the active datum. In this mode, all moves are done by traveling until

the display matches the nominal position that is required. The

Distance-To-Go feature enables you to approach nominal positions by

traversing to display value zero. When working within the DistanceTo-Go mode you can enter nominal coordinates as either absolute or

incremental dimensions.

Milling applications have only the tool length offsets active while in the

Actual Value Mode. In the Distance-To-Go mode, both the diameter

and length offsets are used to calculate the amount of “distance-togo” required to get to the desired nominal position. This is relative to

the edge of the tool that will be doing the cutting.

Turning applications have both diameter and length offsets in both the

Actual Value and Distance-To-Go modes.

Press the ABS/INC soft key to toggle between these two modes. To

view other soft key functions in either Actual Value or Distance-To-Go

mode, use the LEFT/RIGHT arrow keys.

The Milling application provides a quick method for coupling the Z and

I - 2 General Operations for 300S

W axes position on a 4 axis system. For more information, see "Z/W

Coupling (4 axes Milling)" on page 50.

The Turning application provides a quick method for coupling the Z

axes positions on a 3 axis system. For more information, see "Z

Coupling" on page 57.

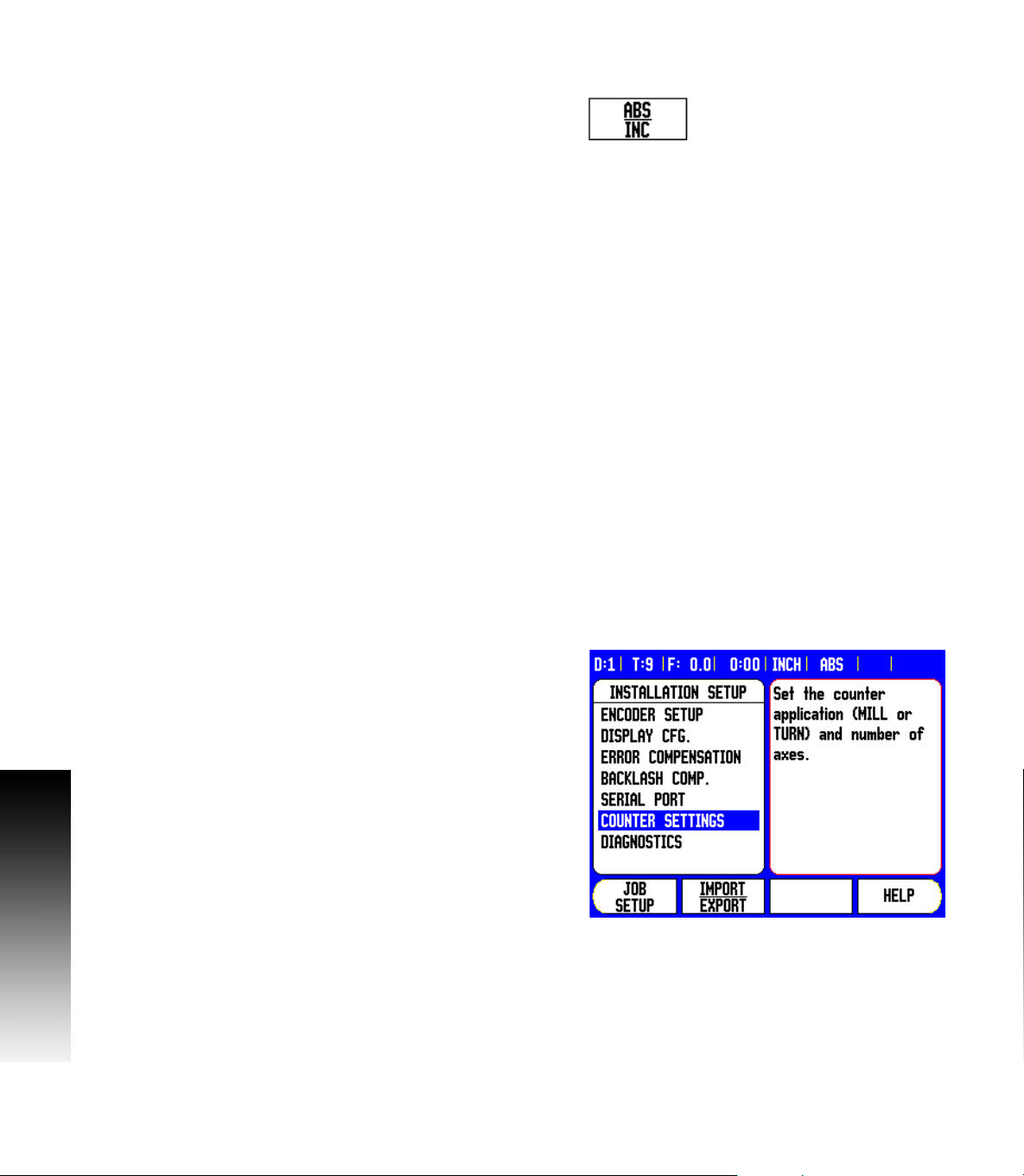

Setup

300S offers two categories for setting up operating parameters. These

categories are: Installation Setup and Job Setup. The Job Setup

parameters are used to accommodate specific machining

requirements for each job. Installation Setup is used to establish

encoder, display and communication parameters.

The Installation Setup menu is accessed by pressing the SETUP soft

key, then the INSTALLATION SETUP soft key. When in the Installation

Setup menu, the following soft keys will be available:

JOB SETUP: Press to begin accessing the Job Setup parameters.

IMPORT/EXPORT: Press to begin importing or exporting operating

parameters. See "Import/Export" on page 19.

HELP: Will open on-line help.

8 To view, and change Installation Setup parameters, first press the

SETUP soft key, then the INSTALLATION SETUP soft key.

8 Use the UP/DOWN arrow keys to highlight the parameters

of interest.

8 press the ENTER key.

12 I

Page 27

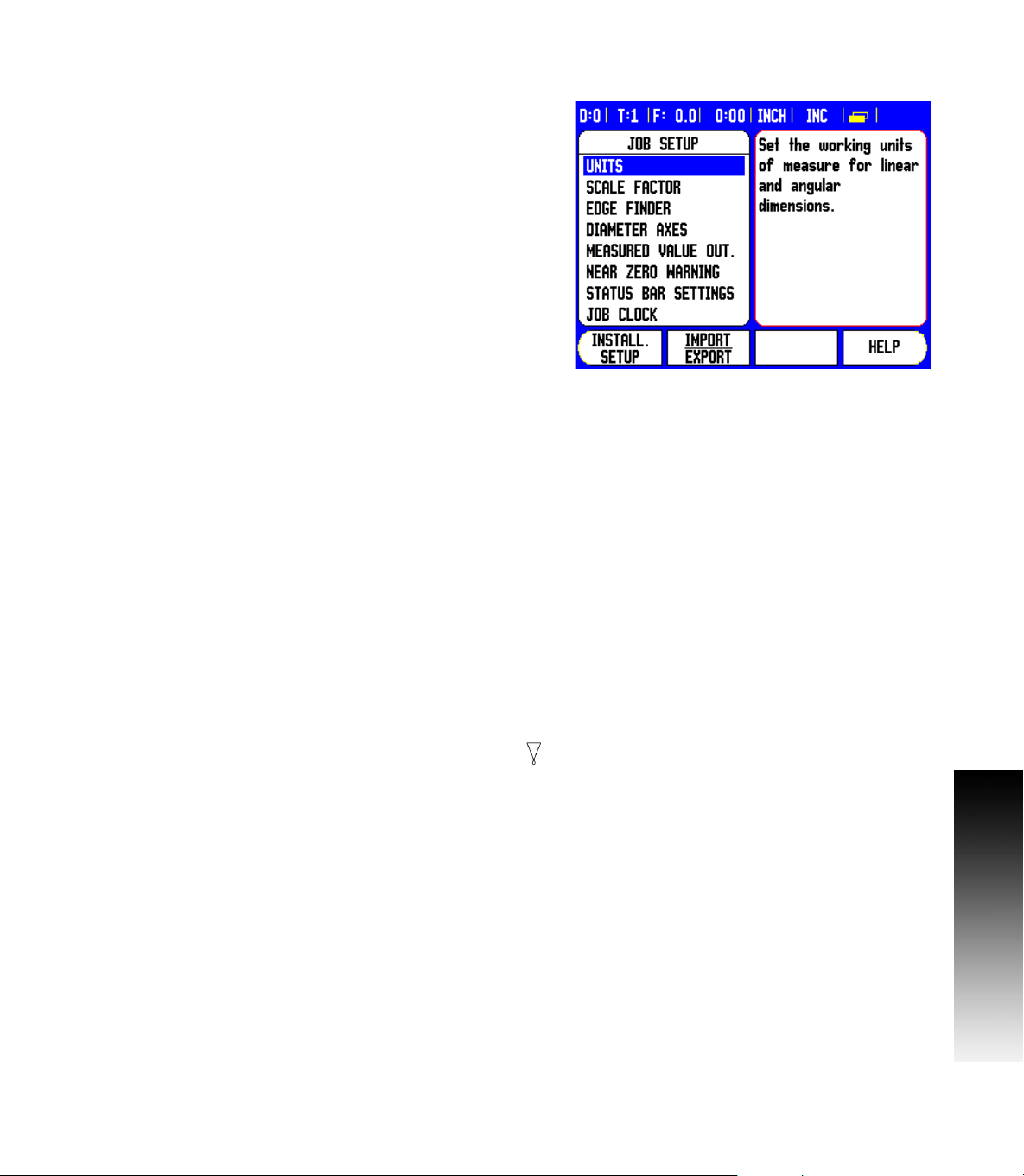

Job Setup Parameters

8 To view and change Job Setup parameters, first press the SETUP

soft key. This is the screen that will now be on the DRO.

8 Use the UP/DOWN arrow keys to highlight the parameters

of interest.

8 press the ENTER key.

The Job Setup Data can be imported, or exported using the

IMPORT/EXPORT soft key

Exporting the current Job Setup:

8 Press the SETUP soft key.

8 Press the IMPORT/EXPORT soft key.

8 Press the EXPORT soft key.

Importing a new Job Setup Table

8 Press the SETUP soft key.

8 Press the IMPORT/EXPORT soft key.

8 Press the IMPORT soft key.

Units

The Units form is used to specify the preferred display units and

format. You can also select the unit of measure by pressing the

INCH/MM soft key in either Actual Value or Distance-To-Go mode.

Scale Factor

The scale factor may be used to scale the part up or down. A scale

factor of 1.0 creates a part with the exact size as dimensioned on the

print. A scale factor >1 “grows” the part, and <1 “shrinks” the part.

The numeric keys are used to enter a number greater than zero. The

number range is 0.1000 to 10.000. A negative value may also

be entered.

The scale factor settings will be retained on a power cycle.

When the scale factor is a value other than 1, the scaling symbol

is shown on the axis display.

The ON/OFF soft key is used to disable the current scale factors.

I - 2 General Operations for 300S

300S 13

Page 28

Mirror

A scale factor of -1.00 will produce a mirror image of the

part. You can both mirror and scale a part at the same time.

Edge Finder (milling applications only)

The diameter, length offset and units of the edge finder are set in this

form. Both values are in the units indicated in the form. Please see

"Probing Functions for Datum Setting" on page 28 for details on using

Edge Finder functions.

The numeric keys are used to enter values of diameter and length.

The diameter must be greater than zero. The length is a sign value

(negative, or positive).

A soft key is provided to indicate the units of measure for the

edge finder.

The edge finder values will be retained on a power cycle.

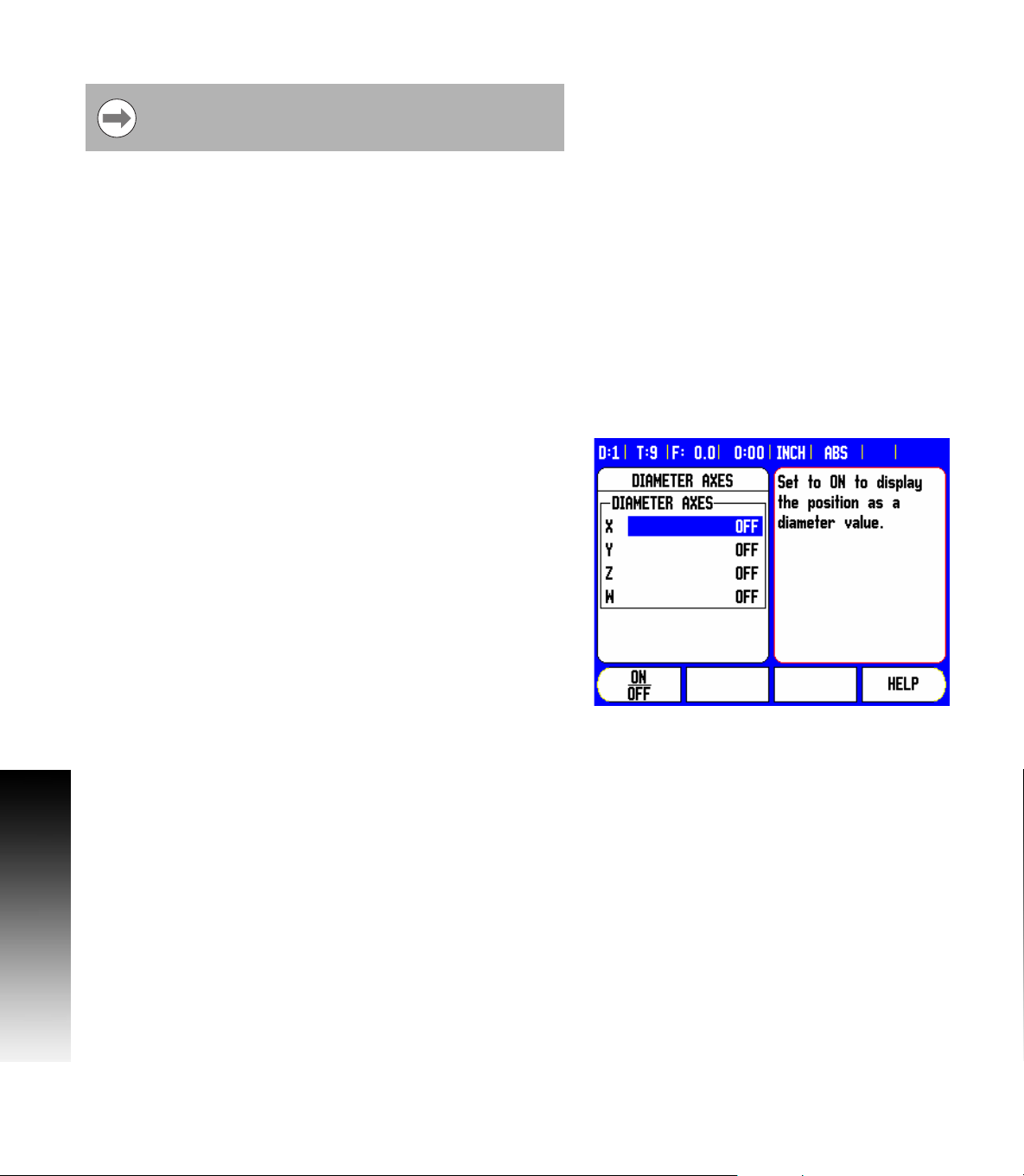

Diameter Axes

Select Diameter Axes to bring up the diameter screen shown here to

set which axes can be displayed in either radius or diameter values.

ON indicates that the axis position will be displayed as a diameter

I - 2 General Operations for 300S

value. When OFF, the Radius/Diameter feature does not apply. For

turning applications see "Radius/Diameter Soft Key" on page 56 for the

Radius/Diameter feature.

8 Cursor to Diameter Axes, and press ENTER.

8 The cursor will be in the X axis field. Depending on the parameter

you need for that axis press ON/OFF soft key to turn feature on

or off.

8 Press ENTER.

14 I

Page 29

Measured Value Output

With the measured value output feature, probe measurement values

can be sent over the serial port. Also output of the current display

positions is activated via a command (Ctrl B), sent to the 300S over the

serial port.

The Measured Value Output form is used to set data output during

probing operations.

Data Output Probing (Milling Only), may be set to either On, or Off.

When On, the measurement data is output when the probe

operation is completed.

Refer to chapter "II - 5 Remote Switch Data Output on page 94” for

information on the format of the output data.

Near Zero Warning

The Near Zero Warning form, is used to configure the bar graph. This

is shown below the axes’ display in Distance-To-Go mode. Each axis

has its own range.

8 Press the ON/OFF soft key to enable, or begin entering values using

the numeric keys. The current position box will begin moving when

the position is within range.

Status Bar Settings

The Status Bar is the segmented bar at the top of the screen which

displays current datum, tool, feed rate, job clock and page indicator.

8 Press the ON/OFF soft key for each setting you want to

see displayed.

Job Clock

The job clock shows the hours (h), minutes (m), seconds (s). It

operates like a stop watch showing elapsed time. The clock starts

timing from 0:00:00.

The elapsed time field shows the total accumulated time from

each interval.

8 Press the START/STOP soft key, the status field will read

RUNNING. Press it again to stop time from elapsing.

I - 2 General Operations for 300S

300S 15

Page 30

8 Press RESET to reset the elapsed time. Resetting will stop the

clock if it is running.

Pressing the Decimal key while in operating mode, will also

stop and start the clock. Pressing the Zero key will reset

the clock.

Skew Compensation (Milling applications only)

Skew compensation allows the user to drill holes on a workpiece

without aligning the workpiece on the machine. Use this feature only

for drilling holes.

The Skew Compensation setup form is found under Job Setup. The

form is used to turn skew compensation on, or off; to set, or learn the

skew angle; and to set the datum.

8 In the Status Field, press the ON/OFF soft key, turn skew

compensation on, or off.

8 In the Angle Field, enter the skew angle if known. To learn the

angle, use the edge finder (or a tool) to touch off the part.

The skew angle is learned by touching off two points along

one side. When using the edge finder, the location of the

edge is captured automatically.

I - 2 General Operations for 300S

8 When using a tool, touch the tool to the edge of the part, and press

the TEACH soft key.

Setting the datum

After learning the angle, the datum may be set to the corner of the

part by touching off one point along the other side see "Datum

Soft Key" on page 28. In the datum calculation, the system

compensates for the radius of the edge finder (or current tool).

The readout automatically compensates for the misaligned workpiece

on the machine when running a program, a hole pattern, or preset.

Move the machine until the X axis and the Y axis indicate zero.

When skew compensation is activated, the skew icon is

displayed on the right side of the axis display.

16 I

Page 31

Remote Switch

The remote switch sets the parameters so the external switch

(pendant, or foot switch) can be enabled to perform any or all of the

following functions: Data Output; Zero, and Next Hole. Refer to

Section II for information on connecting remote switches via

Grounding Edge Finder input.

Data Output - to send position information out of the serial port or to

print the current position.

Zero - to zero one or more axes. In Distance-To-Go mode, it will zero

the Distance-To-Go display. In Actual Value mode, it will zero the

datum).

Next Hole key press will move to the next hole within a pattern (i.e.

Hole Pattern).

8 While in the Data Output Field, press the ON/OFF soft key to ON

to send the current position over the serial port when the switch

is closed.

8 While in the Zero Field, press the appropriate axis keys to enable

or disable zeroing of the axis display positions when the switch is

closed.

8 While in the Next Hole Field, press the ON/OFF soft key to ON to

move to the next hole within a pattern.

DRO View Settings

The 300S has the ability to define up to two DRO display

configurations (views). Each view defines which axes displays appear

on the screen when the view is selected.

With two views available, one may be set to all available axes, and the

other may be a subset of the axes.

I - 2 General Operations for 300S

300S 17

Page 32

When two DRO views are configured, the DRO mode includes a VIEW

soft key which is used to toggle between DRO 1 and DRO 2 views.

The current view (1 or 2) is indicated on the soft key.

To setup the DRO views, press SETUP, cursor to DRO view settings,

and press ENTER. The configuration form will open.

Press the axis key to turn that axis display on. If an axis key is pressed

on an axis that is already on, it will turn off. The default configuration

is that all available axes are on for DRO 1, and all axes are off for

DRO 2. The 300S requires that at least one axis must be turned on at

all times. Axis view settings are remembered when power is cycled.

Multiple DRO views are only available when the full screen DRO is

displayed. In screens where the small DRO is displayed, all axes

positions are displayed and multiple DRO views are not available.

When running a program or a single cycle pattern, the large DRO uses

the current DRO view that is selected. The view with the graphic and

I - 2 General Operations for 300S

small DRO will show all available axes.

The size of the position values, and the axis labels are

adjusted based on the number of axes being displayed.

Smallest at 4 axes, largest at 1, or 2 axis display.

Axis keys correspond to the axes being displayed in the

current DRO view. If only two axes are being displayed,

and there are more axis keys (3 or 4), then only the top two

keys will function. Unmatched keys are ignored.

18 I

Page 33

Console Adjustment

The LCD’s brightness and contrast can be adjusted either by using the

soft keys in this form, or by using the UP/DOWN arrow keys on the

keypad in either operating mode. The settings of brightness, and

contrast may need to be adjusted due to variations in ambient lighting,

and operator preference. This form is also used to set the display

saver’s idle time-out. The display saver setting is the amount of time

the system is idle before the LCD is turned off. The idle time may be

set from 30 to 120 minutes. The display saver can be disabled during

the current power cycle.

Language

The 300S supports multiple languages. To change the

language selection:

8 Press the LANGUAGE soft key until the desired language selection

appears on the soft key, and the form.

8 Press ENTER to confirm your selection.

Import/Export

Job, and Installation Setup parameters can be imported or exported

using the serial port. See "Data Interface" on page 89.

8 Press the IMPORT/EXPORT soft key in the Setup screen.

8 Press IMPORT to download operating parameters from a PC.

8 Press EXPORT to upload the current operating parameters to a PC.

8 Press the C key to exit.

I - 2 General Operations for 300S

300S 19

Page 34

Set/Zero Soft Key Details

The SET/ZERO soft key is a key that determines the effect of pressing

an Axis key. This key is a toggle key, switching the functionality

between Set, and Zero. The current state is indicated in the Status Bar

shown as “SET” in this view.

When the state is Set, and the 300S is in Actual Value mode, selecting

an Axis key opens the Datum form for the selected axis. If the 300S

is in Distance-To-Go mode, a Preset form opens.

When the state is Zero, and the 300S is in Actual Value mode,

selecting an Axis key sets the current datum for that axis to zero, at

the current position. If it is in Distance-To-Go mode, the current

Distance-To-Go value is set to zero.

If the 300S is in Actual Value mode and the state of

Set/Zero is zero, pressing any Axis key resets the current

datum to zero at the current location for that axis.

Calc Soft Key

300S’s calculator is capable of handling everything from simple

arithmetic to complex trigonometry and RPM calculations.

Press the CALC soft key to access the STANDARD/TRIG and RPM

soft keys. The CALC soft key is also available on input forms where

I - 2 General Operations for 300S

preforming calculations may be required while inputting data.

When you need to enter more than one calculation into a

numeric field, the calculator will perform multiplication and

division before it performs addition and subtraction. If you

were to enter 3 + 1 ÷ 8, 300S will divide one by eight, then

add three for an answer of 3.125.

Trig functions contain all trig operators as well as, square and square

root. Whenever you're calculating the SIN, COS or TAN of an angle,

enter the angle first and then press the appropriate soft key.

Angle values use the current angle format selection of

decimal degrees, or radians.

20 I

Page 35

RPM Calculator

The RPM calculator is used to determine the RPM (or surface cutting

speed) based on a specified tool (part, for turning applications)

diameter. The values shown in this Figure are only an example.

Consult your tool manufacturer’s manual to verify spindle speed

ranges per tool.

8 Press CALC.

8 Press the RPM soft key to open the RPM Calculator form.

8 The RPM calculator requires a tool diameter. Use the numeric hard

keys to enter a diameter value. The diameter value will default to the

current tool’s diameter. If there is no last value entered in this power

cycle, the default value is 0.

8 If a surface speed value is required, enter the value using the

numeric hard keys. When a surface speed value is entered, the

associated RPM value will be calculated.

When in the Surface Speed field, a soft key is available for opening online help. The table may be consulted for a recommended range of

surface speeds for the material being machined.

8 Press the UNITS soft key to show the units as inch or millimeter.

8 The RPM Calculator form is closed by pressing the C key saving

current data.

I - 2 General Operations for 300S

300S 21

Page 36

I - 3 Milling Specific Operations

This section discusses operations and soft key functions specific to

milling applications only.

Soft Key Functions Detailed

Tool Soft Key

This soft key opens the tool table and provides access to the Tool form

for entering a tool’s parameters (a soft key is used on a one axis

readout). The 300S can store up to 99 tools within the tool table.

Tool Table

The 300S tool table provides a convenient way to store diameter and

length offset information for each of the tools that may be commonly

used, up to 99 tools. An example of the Tool Table screen is

shown here.

The following soft keys are also available while in the Tool Table form

or in the individual tool data form:

Function Soft key

I - 3 Milling Specific Operations

Use this key to select which axis all the tool

length offsets will affect. The tool’s diameter

values will subsequently be used to offset the

remaining two axes.

Press to automatically enter the tool offset

length. This key is only available in the TOOL

LENGTH field.

The Tool Types form is opened using this key,

and is only available in the Type field.

To remove a tool from the table, use the CLEAR

TOOL key.

To use a tool from the table, highlight the tool,

and press the USE TOOL key.

Press access available help files.

22 I

Page 37

Import/Export

Tool Table information can be imported, or exported over the serial

port.

8 IMPORT, and EXPORT soft keys are available in the Tool Table

screen.

8 Press IMPORT to download a Tool Table from a PC.

8 Press EXPORT to upload the Tool Table to a PC.

8 To exit, press the C key.

I - 3 Milling Specific Operations

300S 23

Page 38

Tool Radius Compensation feature

This allows you to enter workpiece dimensions directly from the

drawing. R represents the tool radius, and examples of the R values

are shown in this figure. The displayed distance to go is then

automatically lengthened R+, or shortened R- by the value of the tool

radius. For more information see "Presets" on page 33.

The length offset may be entered as a known value or the 300S may

determine the offset automatically. The tool length is the difference in

length ΔL between the tool and the reference tool. The length

difference is indicated with the “Δ”symbol. The reference tool is

indicated by T1.

Sign for the length difference ΔL

If the tool is longer than the reference tool: ΔL>0(+).

If the tool is shorter than the reference tool:ΔL<0(–).

I - 3 Milling Specific Operations

The length offset may be entered as a known value, or the 300S may

determine the offset automatically. To have the 300S determine a

tool’s length offset involves touching the tip of each tool to a common

reference surface. This allows the 300S to determine the difference

between the length of each tool.

Move the tool until it’s tip is touching the reference surface. Press the

TEACH LENGTH soft key. The 300S will calculate an offset relative to

this surface. Repeat the procedure for each additional tool using the

same reference surface.

Only the tools set using the same reference surface may be

changed without having to reset the datum.

24 I

Page 39

Entering tool data

8 Choose TOOL soft key.

8 Cursor to the desired tool and press ENTER. The Tool Description

form will appear.

8 Enter the tool diameter.

8 Enter the tool length or press TEACH LENGTH.

8 Enter the tool units (inch/mm).

8 Enter the tool type.

8 Spindle data is not required unless the Spindle Speed Control has

been installed. If installed, then refer to the CSS I/O User’s Manual.

8 Press C to return to the tool table. Press C to exit.

Tool Table Usage

Example: Entering the tool length and diameter into the tool table.

Tool diameter 2.00

Tool length: 20.000

Tool unit: mm

Tool type: flat end mill

I - 3 Milling Specific Operations

It is also possible to have 300S determine the length of an

offset. See - ALTERNATIVE METHOD -.

Spindle Speed Control information is only required when

CSS I/O option box is installed. Refer to the CSS I/O User

Manual if this has been installed.

300S 25

Page 40

Entering a tool:

8 Press the TOOL. soft key. The cursor will default to the Tool Table

form.

8 Cursor to the tool you want to define or enter the tool number. Press

ENTER.

8 Enter the tool diameter, for example (2).

8 Press the DOWN ARROW key.

8 Enter the tool length, for example, (20).

8 Press the DOWN ARROW key.

-ALTERNATIVE METHOD -

It is also possible to have 300S determine an offset. This method

involves touching the tip of each tool to a common reference surface.

This allows 300S to determine the difference between the length of

each tool.

8 Move the tool until its tip is touching the reference surface.

8 Press the TEACH LENGTH soft key. 300S will calculate an offset

relative to this surface.

8 Repeat the procedure for each additional tool using the same

I - 3 Milling Specific Operations

reference surface.

8 Press ENTER.

26 I

Page 41

Only the tools set using the same reference surface may be

changed without having to reset the datum.

If the tool table already contains tools in which the length

has been set, the reference surface should first be

established using one of them. If not, you will not be able

to switch between the new tools and the existing tools

without having to re-establish the datum. Before adding the

new tools, select one of the tools from the tool table. Touch

the tool to a reference surface and set the datum to 0

TOOL UNIT

8 Enter the tool unit (inch/mm).

8 Cursor to the Tool Type field.

TOOL TYPE

8 Press TOOL TYPES soft key.

8 Press ENTER.

I - 3 Milling Specific Operations

300S 27

Page 42

Calling the Tool from the Tool Table

Before you start machining, select the tool you are using from the tool

table. 300S then takes into account the stored tool data when working

with tool compensation.

Tool call

8 To call a tool, press the TOOL soft key.

8 Use the UP/DOWN arrow keys to cursor through the selection of

tools (1-99). Highlight the tool you want.

8 Verify the proper tool has been called, and press the TOOL, or C key

to exit.

Datum Soft Key

Datum settings define the relationships between the axis positions,

and the display values.

Setting datum points is done by using the 300S probing functions

either with a tool, or with an edge finder.

Probing Functions for Datum Setting

An electronic Edge Finder can be connected through the edge finder

input. The 300S also supports a grounding type edge finder connected

via the 3.5mm Phono Jack on the back of the unit. Both types of edge

I - 3 Milling Specific Operations

finders operate the same way.

The following probing soft key functions are available:

Workpiece edge as datum: EDGE soft key.

Centerline between two workpiece edges: CENTER LINE soft key.

Center of a hole or cylinder: CIRCLE CENTER soft key.

In all probing functions, 300S takes into account the probes’s entered

tip diameter. During probing functions, with an electronic, or

grounding edge finder, the display freezes with the location of the

edge, centerline, or circle center.

8 To abort the probing function while it is active, press the C key.

To perform probing, the probe’s dimensional

characteristics must first be entered into Job Setup. See

"Job Setup Parameters" on page 13..

28 I

Page 43

Example: Set centerline between two workpiece edges as datum

0 is offered as a default value for the coordinate. Enter the desired

coordinate for the workpiece edge. For this example Y = 0.0, set the

coordinate as a datum for this workpiece.

8 Press the ENTER hard key.

The position of the centerline M is determined by probing the edges

1, and 2.

The centerline is parallel to the Y axis.

Desired coordinate of the centerline: X = 0.0

Spacing between edges is displayed on the message box

when using the probe centerline feature.

I - 3 Milling Specific Operations

300S 29

Page 44

8 Press the DATUM soft key.

8 Press the DOWN arrow key to select the item you need.

8 Press the PROBE soft key.

Probe the 1st edge X

8 Move the edge finder toward workpiece edge 1 until the LEDs in the

edge finder light up.

Probe the 2nd edge in X

8 Move the edge finder toward workpiece edge 2 until the LEDs in the

edge finder light up. The distance between the edges is displayed

on the message box.

8 Retract the edge finder from the workpiece.

Enter the value for X

8 Enter coordinate (X = 0.0), and transfer coordinate as datum for the

centerline.

8 Press the ENTER hard key.

Example: Probe the center of a hole with an edge finder, and set the datum 2.00 from the circle’s center

X coordinate of the circle center: X = 2.00”

I - 3 Milling Specific Operations

Y coordinate of the circle center: Y = 0.00”

8 Press the DATUM soft key.

8 Press the DOWN arrow key to select the item you need.

8 Press the PROBE soft key.

8 Press the CIRCLE CENTER soft key.

8 Move the edge finder toward the first point 1 on the circumference

until the LEDs in the edge finder light up.

8 Probe two additional points on the circumference in the same

manner. Further instructions appear on the screen. See Instruction

Box for the measured diameter.

Enter center point X X = 2.00”

8 Enter the first coordinate (X = 2.00”).

8 Press the DOWN arrow hard key.

Enter center point Y Y = 0.00”

8 Accept default entry Y = 0.00”.

8 Press the ENTER hard key.

30 I

Page 45

Probing with a Tool

If using a tool, or non-electrical edge finder to set datum points, the

300S probing functions can still be used.

Datum points can be set by touching the edges of a workpiece, one

after the other with a tool, and then manually entering the tool’s

position as datum points.

I - 3 Milling Specific Operations

300S 31

Page 46

Example: Probe workpiece edge and set edge as datum

8 Preparation: Set the active tool to the tool that will be used to set

the datum. An end mill is shown in this example, along with the Set

Datum screen.

Datum axis: X =0

Tool diameter D = 0.25”

8 Press DATUM.

8 Press the Down arrow key until the X axis field is highlighted.

8 Press PROBE soft key.

8 Press EDGE soft key.

8 Touch workpiece edge.

8 Press the TEACH soft key to store the current absolute value while

the tool is in contact with the workpiece edge. The location for the

touched edge will take into account the diameter of the tool in use

(T:1, 2...), and the last direction the tool was moved prior to pressing

the TEACH soft key.

8 Retract the tool from the workpiece and enter 0” and then

press ENTER.

I - 3 Milling Specific Operations

32 I

Page 47

Presets

The Preset function allows the operator to indicate the nominal (target)

position for the next move. Once the new nominal position

information is entered the display will switch to Distance-To-Go mode

and show the distance between the current position and the nominal

position. The operator now only needs to move the table until the

display is zero and he will be at the required nominal position. The

information for the location of the nominal position can be entered as

an absolute move from the current datum zero or as an incremental

move from the current nominal position.

Presetting also allows the operator to indicate which side of the tool

will be doing the machining at the nominal position. The R+/- soft key

in the Preset form defines the offset that will be in effect during the

move. R+ indicates that the center line of the current tool is in a more

positive direction than the edge of the tool. R- indicates that the

center line is in a more negative direction than the edge of the current

tool. Using R+/- offsets automatically adjusts the distance-to-go value

to account for the diameter of the tool.

Absolute Distance Preset

Example: Milling a shoulder by traversing to display value zero using

absolute position.

The coordinates are entered as absolute dimensions; the datum is the

workpiece zero. Using this figure example:

Corner 1: X = 0 / Y = 1

Corner 2: X = 1.50 / Y = 1

Corner 3: X = 1.50 / Y = 2.50

Corner 4: X = 3.00 / Y = 2.50

I - 3 Milling Specific Operations

Press the PRESET soft key, then an axis key to recall the

last entered preset value for that axis.

300S 33

Page 48

Preparation:

8 Select the tool with the appropriate tool data.

8 Pre-position the tool to an appropriate location (such as X = Y = -1”).

8 Move the tool to milling depth.

8 Press the PRESET soft key.

8 Press the Y axis key

-ALTERNATIVE METHOD -

8 Press the SET/ZERO soft key so that you are in Set mode.

8 Press the Y axis key.

8 Enter nominal position value for corner point 1: Y = 1”, and select

tool radius compensation R + with R+/- soft key. Press until R+ is

shown next to axis form.

8 Press ENTER.

8 Traverse the Y axis until the display value is zero. The square in the

near zero warning is now centered between the two

triangular marks.

8 Press the PRESET soft key.

8 Press the X axis key.

I - 3 Milling Specific Operations

-ALTERNATIVE METHOD -

8 Press the SET/ZERO soft key so that you are in Set mode.

8 Press the X axis key.

8 Enter nominal position value for corner point 2: X = 1.5” select tool

radius compensation R - with R+/- soft key. Press twice until R- is

shown next to axis form.

8 Press ENTER.

8 Traverse the X axis until the display value is zero. The square in the

near zero warning is now centered between the two

triangular marks.

8 Presets can be entered in the same manner for corners 3, and 4.

34 I

Page 49

Incremental Distance Preset

Example: Drilling by traversing to display value zero with

incremental positioning.

Enter the coordinates in incremental dimensions. These

are indicated in the following (and on the screen) with a

preceding I (Incremental). The datum is the

workpiece zero.

Hole 1 at: X = 1” / Y = 1”

Distance from hole 1 to hole 2: XI = 1.5” / YI = 1.5”

Hole depth: Z = –0.5”

Operating mode: DISTANCE-TO-GO (INC)

8 Press the PRESET soft key.

8 Press the X axis key.

8 Enter nominal position value for hole 1: X = 1” and ensure no tool

radius is active. Note that these presets are Absolute Presets.

8 Press the DOWN arrow key.

8 Enter nominal position value for hole 1: Y = 1”.

8 Ensure no tool radius compensation is showing.

8 Press the DOWN arrow key.

8 Enter the nominal position value for the hole depth: Z = -0.5”. Press

ENTER hard key.

8 Drill hole 1: Traverse the X, Y and Z axis until the display value is

zero. The square in the near zero warning is now centered between

the two triangular marks. Retract the drill.

I - 3 Milling Specific Operations

300S 35

Page 50

To preset the location for Hole 2:

8 Press the PRESET soft key.

8 Press the X axis key.

8 Enter nominal position value for hole 2: X = 1.5”, mark your input as

an incremental dimension, press the I soft key.

8 Press the Y axis key.

8 Enter nominal position value for hole 2: Y = 1.5”, mark your input as

an incremental dimension, press the I soft key.

8 Press ENTER.

8 Traverse the X and Y axes until the display value is zero. The square

in the near zero warning is now centered between the two

triangular marks.

8 To preset the Z axis:

8 Press the PRESET soft key.

8 Press the Z axis key.

8 Press the ENTER key (use last entered preset).

8 Drill hole 2: Traverse Z axis until the display value is zero. The

square in the near zero warning is now centered between the two

triangular marks.

I - 3 Milling Specific Operations

8 Retract the drill.

1/2 Soft Key

The 1/2 hard key is used to find the centerline (or midpoint) between

two locations along a selected axis of a workpiece. This can be

performed in either Actual Value or Distance-To-Go mode.

This feature will change datum locations when in Actual

Value mode.

36 I

Page 51

Features (Milling)

Pressing the FEATURES soft key will provide access to the Circle

Pattern, Linear Pattern, Incline Mill, and Arc Mill milling features.

The 300S provides one user definable pattern each of these features.

They can be recalled, and executed from the DRO anytime

during operation.

The following soft keys are available while in the Milling Feature table.

Function Soft key

Press to access the circle pattern table.

Press to access the linear pattern table.

Press to access the Incline Mill entry form.

Press to access the Arc Mill entry form.

The Circle Pattern, and Linear Pattern features provide ways to

calculate, and machine various hole patterns. The Incline, and Arc

milling features provide ways to machine a flat diagonal surface

(incline milling), or a rounded surface (arc milling) using a

manual machine.

I - 3 Milling Specific Operations

Defined Circle, Linear, Incline, and Arc patterns are

remembered when power is cycled

300S 37

Page 52

Circle, and Linear Patterns

This section describes the Circle, and Linear pattern tables, and

capabilities. The 300S provides storage of 10 user definable patterns

each for Circle, and Linear. Once patterns are defined, they are

remembered when power is cycled. They can be recalled, and

executed from the DRO, or from a program.

The View Graphic enables verification of the hole pattern before you

start machining. It is also useful when selecting holes directly,

executing holes separately, and skipping holes.

To access the Circle Pattern Table, or Linear Pattern Table, press the

FEATURES soft key. The CIRCLE PATTERN, and LINEAR PATTERN

soft keys are shown. Pressing one of these soft keys will open the

corresponding hole pattern table.

Soft key Functions

The following soft keys are available while in the Circle, and Linear

Pattern Milling feature.

Function Soft key

Press to access the FEATURES soft keys.

I - 3 Milling Specific Operations

Press to access the circle pattern table.

Press to access the linear pattern table.

Press to create a new circle, or linear pattern.

Press to edit an existing pattern.

Press CLEAR to delete an existing pattern.

Press RUN to execute a pattern.

Press HELP for additional information about

the pattern.

38 I

Page 53

Circle, and Linear Pattern Table Entry

The Circle, or Linear Pattern Table is used to define up to 10 different

circle hole patterns (Full, or Segment), and 10 different linear hole

patterns (Array, or Frame).

8 Access the Pattern Table from the DRO soft key menu by pressing

the FEATURES soft key.

8 Press the CIRCLE PATTERN, or LINEAR PATTERN soft key.

The Pattern Table will show all of the patterns that have been

previously defined.

8 Press the UP/DOWN arrow keys to define a new pattern, or edit an

existing pattern.

8 Highlight the table entry, press the NEW, or EDIT soft key (or

press ENTER).

A Circle, or Linear Pattern form is opened.

8 Enter the information to define the pattern, then press ENTER.

The pattern will be entered into the appropriate table. It can now

be modified, executed, or referred to from a program.

8 To delete a pattern from the table press the CLEAR soft key. Press

YES to confirm deletion from the table.

The pattern table, and its entries are saved to memory.

They will stay in memory until deleted, or changed, and are

not affected by a power cycle.

I - 3 Milling Specific Operations

300S 39

Page 54

Circle, and Linear Pattern Soft keys

The following additional soft keys are available while in the Circle, and

Linear Pattern Milling feature.

Function Soft key

Press to execute the circle or linear pattern.

Press to use the current absolute position.

Press to open the Calculator for standard math, and

trigonometry functions.

Circle Pattern Information Required

Type: type of pattern, FULL, or SEGMENT.

Holes: number of holes in the pattern.

Center: location of the center of the hole pattern.

I - 3 Milling Specific Operations

Radius: radius of the pattern.

Start Angle: angle between X axis and the first hole.

End Angle: angle between X axis and the last hole.

Depth: the target depth for drilling in the tool axis.

Linear Pattern Information Required

Type: type of pattern, ARRAY or FRAME.

First Hole: location of the first hole of the pattern.

Holes per Row: number of holes in each row of a pattern.

Angle: the angle, or rotation of the pattern.

Depth: the target depth for drilling in the tool axis.

Number of Rows: the number of rows in the pattern.

Row Spacing: the spacing between each row of the pattern.

40 I

Page 55

Circle, or Linear Pattern Execution

8 To execute a circle, or linear pattern, highlight the pattern to be

executed in the table.

8 Press the RUN soft key.

The 300S then calculates the positions of the holes. It can also

provide a graphical view of the hole pattern.

The following soft keys are available while running a Circle, or

Linear Pattern

Function Soft key

Press to select the graphic view of the pattern.

Available in both incremental DRO, or

absolute DRO.

Press to select the previous hole in the pattern.

Press to select the next hole in the pattern.

Press to end execution of the pattern.

Press the VIEW soft key to toggle the views between

distance-to-go positions, graphic view, and

absolute positions.

I - 3 Milling Specific Operations

300S 41

Page 56

Example: Enter data and execute a circle pattern.

1st step: Enter data

8 Press FEATURES soft key.

8 Press CIRCLE PATTERN soft key.

8 Press UP/DOWN hard keys to select pattern 1.

8 Press ENTER hard key.

8 Press FULL/SEGMENT soft key until FULL is selected.

8 Press DOWN ARROW hard key to move to the next field.

8 Enter 4 for the number of holes.

8 Enter X= 2.0”, Y= 1.5” for the circle pattern center location.

8 Enter 5” for the radius of the circle pattern.

8 Enter 25° for the start angle.

8 The end angle is 295°, and can not be changed because the pattern

I - 3 Milling Specific Operations

is full.

8 Enter depth of -.25”.

The depth of the hole is optional, and may be left blank.

8 Press ENTER

42 I

Page 57

The Circle Pattern table now shows the pattern that was just defined

as pattern 1.

2nd step: Execute circle pattern

8 Press the RUN soft key.

The distance-to-go view is displayed.

8 Move to the hole, move the X, and Y axis until their display values

show 0.0.

8 Drill (Z depth): If a depth was entered into the pattern, move Z until

it’s display value shows 0.0. Otherwise, drill to the desired depth.

8 Press the NEXT HOLE soft key.

8 Continue to drill the remaining holes in the same manner.

When the pattern is complete, press the END soft key.

I - 3 Milling Specific Operations

300S 43

Page 58

Incline, and Arc Milling

The incline and arc milling features provide ways to machine a flat

diagonal surface (incline milling) or a rounded surface (arc milling)

using a manual machine.

The 300S provides storage of up to 10 user definable Incline Mill

features, and 10 Arc Mill features. Once the features are defined, they

are stored in memory and can be recalled at anytime. They can be

executed from the DRO, or from the operating program. All defined

features will stay in memory until removed, regardless if the power

has been cycled.

To access the Incline or Arc Mill Table, press the FEATURE soft key,

then press the INCLINE MILL, or ARC MILL soft key to open the

corresponding mill table.

Soft Key Functions

The following soft keys are available while in the Milling Feature table.

Function Soft key

Press to access the Incline Mill Table.

I - 3 Milling Specific Operations

Press to access the Arc Mill Table.

Press to create a new milling feature.

Press to edit and existing milling feature.

Press to delete and existing milling feature.

Press to execute the milling feature.

Press for additional information about the

milling feature.

44 I

Page 59

Incline, and Arc Milling Table Entry

The Incline or Arc Mill Table is used to define the milling features. To

access either Mill Table:

8 Press the FEATURES soft key.

8 Press the INCLINE MILL, or ARC MILL soft key.

To define a new milling feature:

8 Press the UP/DOWN ARROW hard keys to highlight a blank feature.

8 Press the NEW soft key, or press ENTER.

To edit an existing feature:

8 Press the UP/DOWN ARROW hard keys to highlight the table entry.

8 Press the EDIT, soft key, or press ENTER.

To execute a milling feature:

8 Highlight the table entry, and press the RUN soft key.

See “Incline, & Arc Mill Execution” for more information.

To delete an existing feature:

8 Highlight the table entry.

8 Press the CLEAR soft key.

8 Press YES to confirm deletion.

I - 3 Milling Specific Operations

300S 45

Page 60

Incline, and Arc Milling Table Entry