Page 1

Installation and Operation Manual

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

QC Series

Page 2

1.0 GENERAL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

1.1 PRODUCTS COVERED IN THIS MANUAL

This manual covers the AC Tech QC1000, QC2000, and QC3000 Variable Frequency Drives.

1.2 PRODUCT CHANGES

AC Technology Corporation reserves the right to discontinue or make modifications to the design of its

products and manuals without prior notice, and holds no obligation to make modifications to products sold

previously. AC Technology Corporation also holds no liability for losses of any kind which may result

from this action. Instruction manuals with the most up-to-date information are available for download

from the AC Tech website (www.actechdrives.com).

1.3 WARRANTY

AC Technology Corporation warrants the QC Series AC motor control to be free of defects in material and

workmanship for a period of eighteen months from the date of sale to the user, or two years from the date

of shipment, which ever occurs first. Any control component, which under normal use, becomes defective,

within the stated warranty time period, shall be returned to AC Technology Corporation, freight prepaid,

for examination. AC Technology Corporation reserves the right to make the final determination as to the

validity of a warranty claim, and sole obligation is to repair or replace only components which have been

rendered defective due to faulty material or workmanship. No warranty claim will be accepted for

components which have been damaged due to mishandling, improper installation, unauthorized repair

and/or alteration of the product, operation in excess of design specifications or other misuse, or

improper maintenance. AC Technology Corporation makes no warranty that its products are compatible

with any other equipment, or to any specific application, to which they may be applied and shall not be

held liable for any other consequential damage or injury arising from the use of its products.

This warranty is in lieu of all other warranties, expressed or implied. No other person, firm or

corporation is authorized to assume, for AC Technology Corporation, any other liability in

connection with the demonstration or sale of its products.

1.4 RECEIVING

Inspect all cartons for damage which may have occurred during shipping. Carefully unpack equipment and

inspect thoroughly for damage or shortage. Report any damage to carrier and/or shortages to supplier. All

major components and connections should be examined for damage and tightness, with special attention

given to PC boards, plugs, knobs and switches.

1.5 CUSTOMER MODIFICATION

AC Technology Corporation, its sales representatives and distributors, welcome the opportunity to assist

our customers in applying our products. Many customizing options are available to aid in this function.

AC Technology Corporation cannot assume responsibility for any modifications not authorized by its

engineering department.

1

Page 3

2.0 QC SERIES SPECIFICATIONS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Storage Temperature -20° to 70° C

Ambient Operating Temperature Chassis: -10 to 50° C (40° C for QC3000)

(with 8 kHz or lower carrier, Type 1 Enclosed -10 to 50° C (40° C for QC3000)

derate for higher carriers) Type 4 / 12 Enclosed -10 to 40° C

Ambient Humidity Less than 95% (non-condensing)

Altitude 3300 feet (1000 meters) above sea level without derating

Input Line Voltages 200/240 Vac, 400/480 Vac, and 480/590 Vac

Input Voltage Tolerance +10%, -15%

Input Frequency Tolerance 48 to 62 Hz

Output Wave Form Sine Coded PWM

Output Frequency 0-120 Hz Standard, 0 - 650 Hz Optional

Type 12 Enclosed -10 to 40° C

Type 4X Enclosed -10 to 40° C

Carrier Frequency 1.5, 8, 10, or 12 kHz

Frequency Stability + 0.00006% / °C

Efficiency 97% or better

Power Factor (displacement) 0.96 or better

Service Factor 1.00

Overload Current Capacity 150 % for one minute (QC1000/2000)

(based on drive output current rating) 120 % for one minute (QC3000)

Speed Reference Follower 0-10 VDC, or 4-20 mA

Control Voltage 24 VDC

Analog Outputs 0-10 VDC, 2-10 VDC, 4-20 mA

Proportional to speed or load

12 VDC Pulse Train (40-50% Duty Cycle)

Proportional to speed

Digital Outputs Form C relays: 2A at 24 VDC or 120 Vac

Open-collector output: 40 mA at 30 VDC

2

Page 4

3.0 QC SERIES MODEL DESIGNATION CODE

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The model number of a QC Series drive gives a full description of the basic drive unit (see example

below).

EXAMPLE:

Q14005HB

(QC1000, 480 Vac, 5 HP, Type 1 Enclosure with extended enclosure)

Q1 4 005 H B - XXX

Series:

Q1 = QC1000 Series - Constant Torque - NEMA 1 and Chassis

Q2 = QC2000 Series - Constant Torque - NEMA 4 / 12 & 4X

Q3 = QC3000 Series - Variable Torque - NEMA 1 and Chassis

Input Voltage:

2 = 240/200Vac (For 208 and 240 Vac; 50 or 60 Hz)

4 = 480/400Vac (For 380, 415, 440, 460 and 480 Vac; 50 or 60 Hz)

5 = 590/480Vac (For 440, 460, 480, 575 and 600 Vac; 50 or 60 Hz)

Horsepower:

001 = 1 Hp

002 = 2 Hp

003 = 3 Hp

005 = 5 Hp

008 = 7½ Hp

010 = 10 Hp

Extended Enclosures:

H = Extended enclosure.

No character indicates standard height enclosure.

Required for line reactor option. Line reactors are standard on 240 Vac models from 25 to

60 Hp, 480 Vac models from 25 to 250 Hp, and 590 Vac from 5 to 200 Hp.

Enclosure Type:

A = Chassis - Open Frame

B = NEMA 1 - General Purpose, vented: Indoor

C = NEMA 4 - Washdown: Indoor / Outdoor (NEMA 4 rating exceeds NEMA 12 rating)

D = NEMA 12 - Dust-tight and Drip-tight: Indoor

E = NEMA 4X - Washdown, Stainless steel: Indoor / Outdoor

Special Designation:

Non-standard special models have a three digit suffix.

015 = 15 Hp

020 = 20 Hp

025 = 25 Hp

030 = 30 Hp

040 = 40 Hp

050 = 50 Hp

060 = 60 Hp

075 = 75Hp

100 = 100Hp

125 = 125Hp

150 = 150 Hp

200 = 200 Hp

250 = 250 Hp

3

Page 5

4.0 QC SERIES DIMENSIONS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

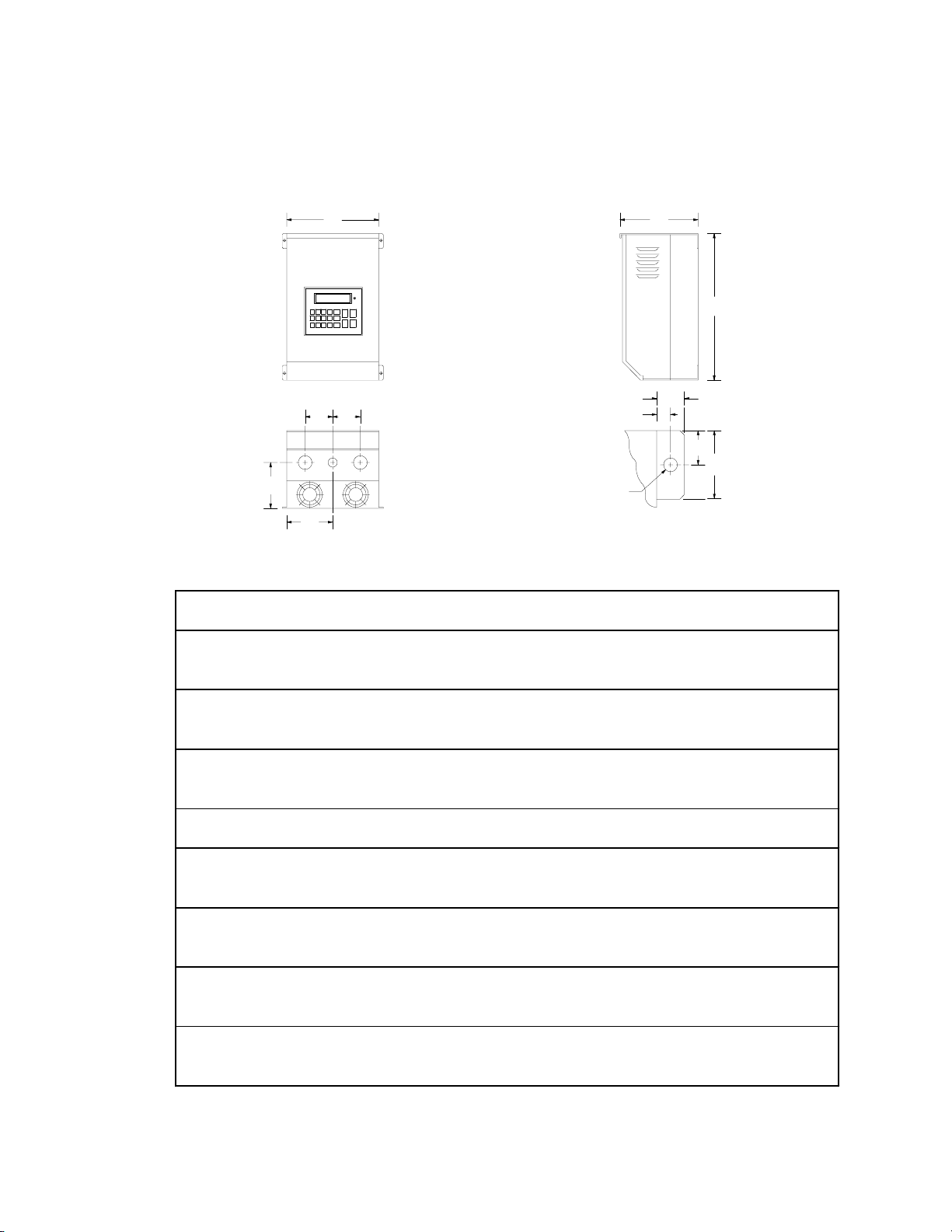

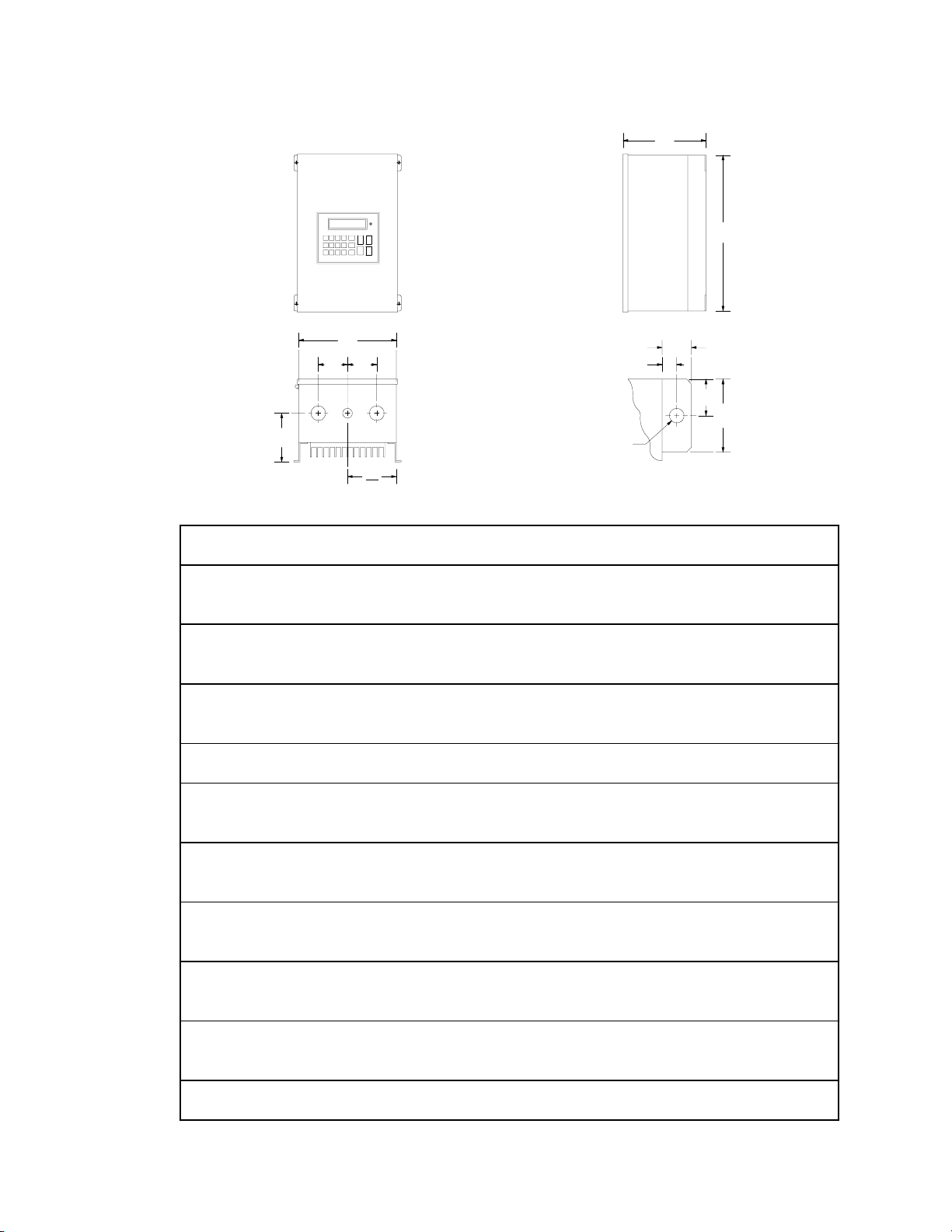

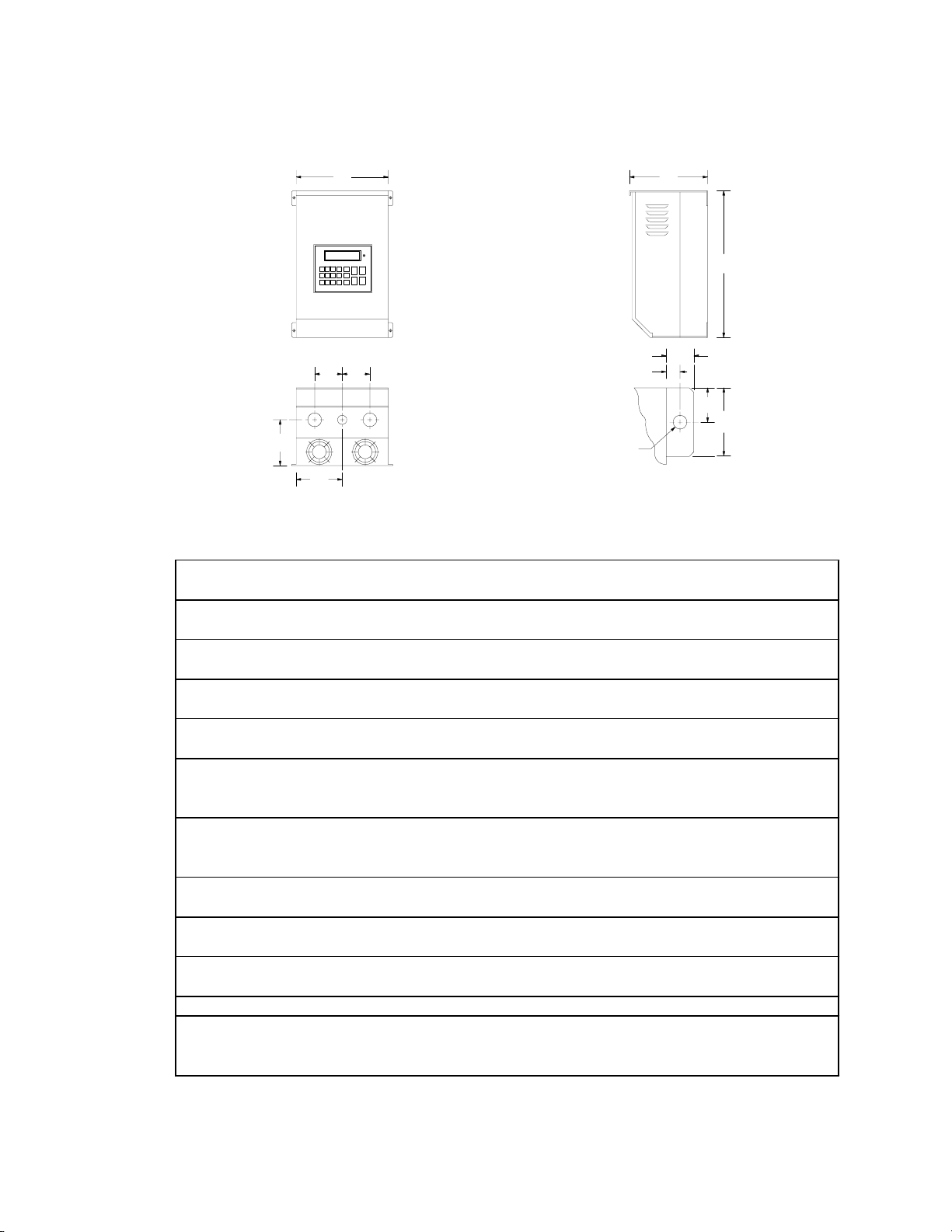

4.1 QC1000 - CHASSIS AND TYPE 1 ENCLOSED

W

Q

Q

P

N

INPUT

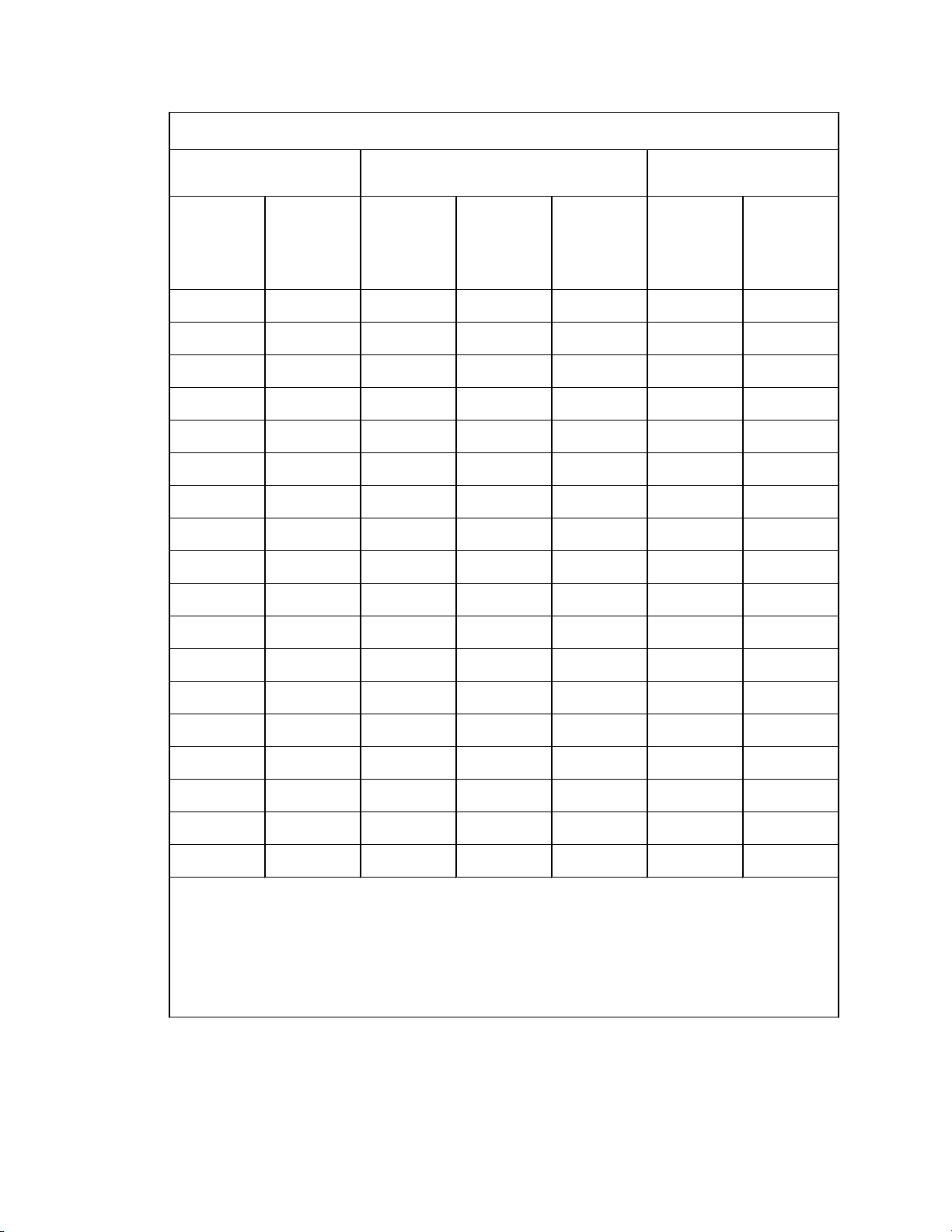

HP VOLTAGE MODEL H W D N P Q R T U V

1 240 / 200 Q12001 12.00 7.44 5.91 3.72 2.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q14001 12.00 7.44 5.91 3.72 2.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q15001 12.00 7.44 5.91 3.72 2.75 2.12 1.00 0.28 0.37 0.68

2 240 / 200 Q12002 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q14002 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q15002 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

3 240 / 200 Q12003 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q14003 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q15003 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

5 480 / 400 Q14005 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q15005 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

7.5 240 / 200 Q12008 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

480 / 400 Q14008 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q15008 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

10 240 / 200 Q12010 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

480 / 400 Q14010 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

590 / 480 Q15010 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

15 240 / 200 Q12015 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

480 / 400 Q14015 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

590 / 480 Q15015 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

20 240 / 200 Q12020 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

480 / 400 Q14020 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

590 / 480 Q15020 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

Conduit Holes:

If Q = 2.12", all = 1.13" dia.

If Q = 2.50", middle = 1.13" dia.

left & right = 1.38" dia.

D

V

U

T

Dia.

Mounting Tab Detail

H

R

2R

4

Page 6

4.1 QC1000 - CHASSIS AND TYPE 1 ENCLOSED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

W

Q

Q

P

N

INPUT

HPVOLTAGEMODELHWDNPQRTUV

25 240 / 200 Q12025 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

480 / 400 Q14025 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

590 / 480 Q15025 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

30 240 / 200 Q12030 25.00 8.88 10.50 5.56 6.50 2.50 1.50 0.36 0.37 0.68

480 / 400 Q14030 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

590 / 480 Q15030 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

40 240 / 200 Q12040 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

480 / 400 Q14040 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

590 / 480 Q15040 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

50 480 / 400 Q14050 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

590 / 480 Q15050 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

60 240 / 200 Q12060 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

480 / 400 Q14060 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

590 / 480 Q15060 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

75 480 / 400 Q14075 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

590 / 480 Q15075 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

100 480 / 400 Q14100 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

590 / 480 Q15100 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

125 480 / 400 Q14125 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

590 / 480 Q15125 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

150 480 / 400 Q14150 29.00 36.66 11.85

590 / 480 Q15150 29.00 36.66 11.85

Conduit Holes:

If Q = 2.50", middle = 1.13" dia.

left & right = 1.38" dia.

If Q = 2.62", left = 1.13" dia.

middle & right = 1.38" dia.

If Q = 3.12", left = 1.13" dia.

middle & right = 1.75" dia.

If Q = 4.50", left = 1.13" dia.

middle & right = 2.50" dia.

SEE SECTION 4.7 - PAGE 11

D

V

U

T

Dia.

Mounting Tab Detail

H

R

2R

5

Page 7

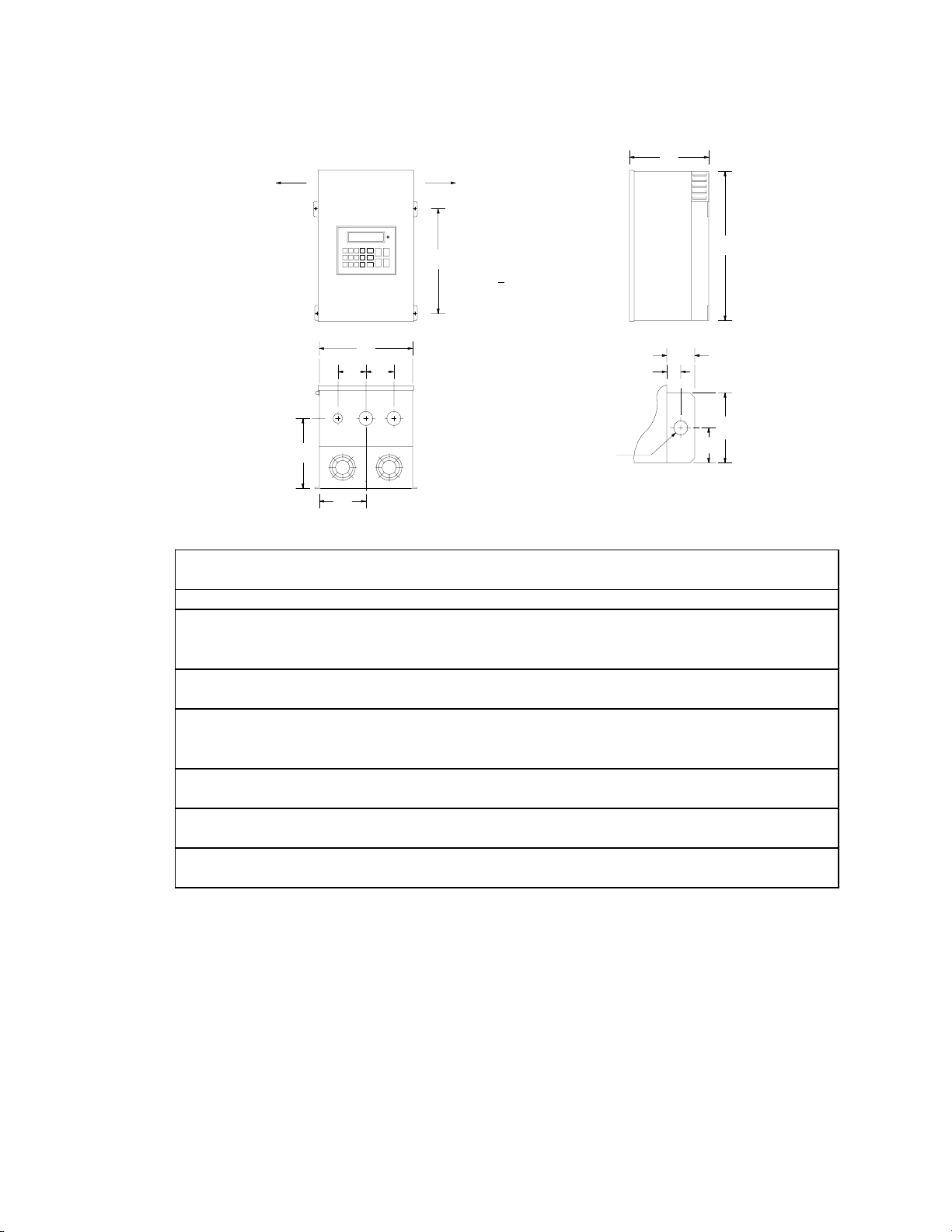

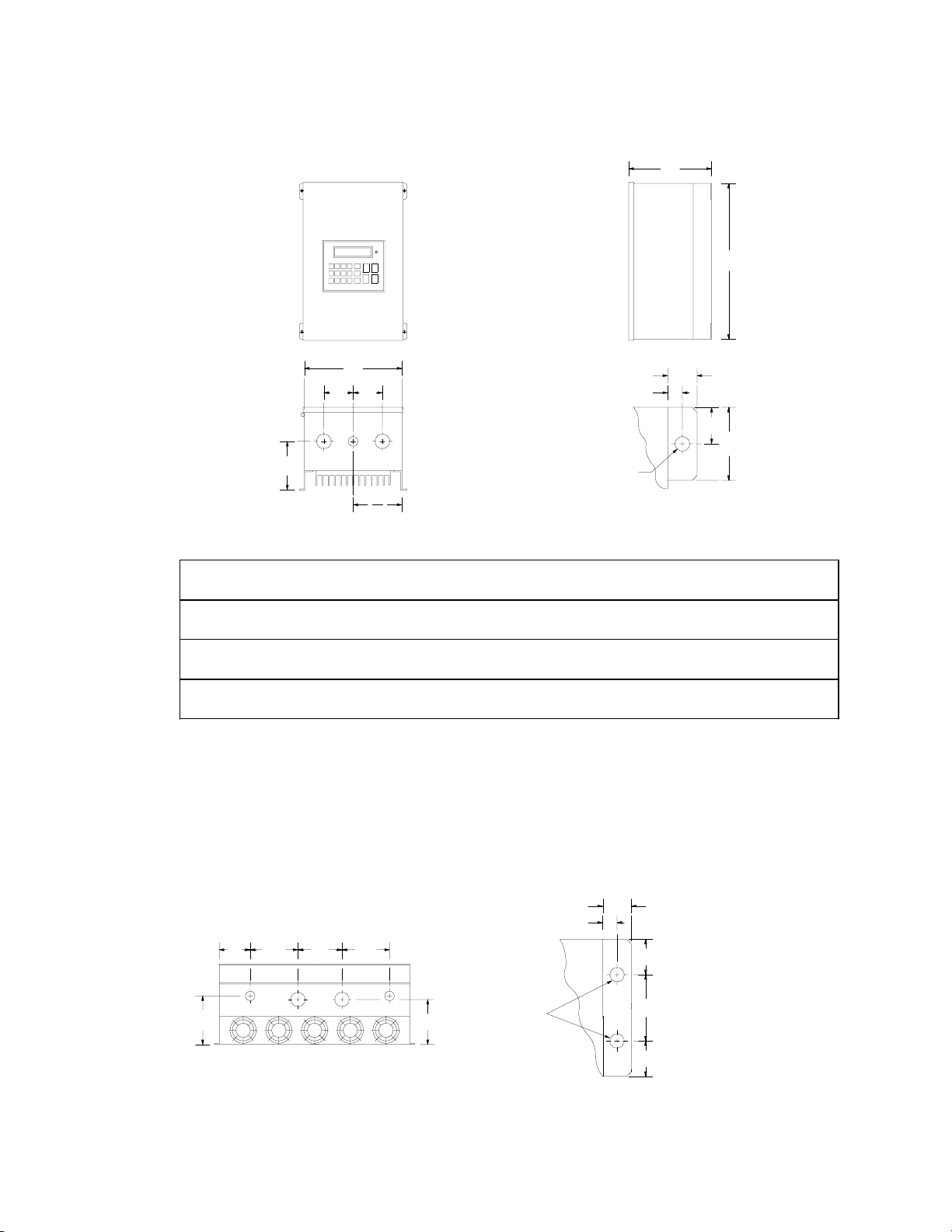

4.2 QC2000 - TYPE 4/12 AND 4X ENCLOSED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

D

H

W

QQ

Conduit Holes:

If Q = 2.12", all = 1.13" dia.

P

If Q = 2.50", middle = 1.13" dia.

left & right = 1.38" dia.

W

2

T

Dia.

V

U

R

2R

Mounting Tab Detail

INPUT

HP VOLTAGE MODEL H W D P Q R T U V

1 240 / 200 Q22001 13.00 7.88 6.19 3. 50 2.12 1.00 0.28 0.37 0.68

480 / 400 Q24001 13.00 7. 88 6.19 3.50 2. 12 1.00 0. 28 0.37 0.68

590 / 480 Q25001 13.00 7. 88 6.19 3.50 2. 12 1.00 0. 28 0.37 0.68

2 240 / 200 Q22002 13.00 7.88 7.25 4. 56 2.12 1.00 0.28 0.37 0.68

480 / 400 Q24002 13.00 7. 88 6.19 3.50 2. 12 1.00 0. 28 0.37 0.68

590 / 480 Q25002 13.00 7. 88 6.19 3.50 2. 12 1.00 0. 28 0.37 0.68

3 240 / 200 Q22003 13.00 7.88 7.25 4. 56 2.12 1.00 0.28 0.37 0.68

480 / 400 Q24003 13.00 7. 88 7.25 4.56 2. 12 1.00 0. 28 0.37 0.68

590 / 480 Q25003 13.00 7. 88 7.25 4.56 2. 12 1.00 0. 28 0.37 0.68

5 480 / 400 Q24005 16.00 9.70 7.50 4. 81 2.12 1.00 0.28 0.37 0.68

590 / 480 Q25005 16.00 9. 70 7.50 4.81 2. 12 1.00 0. 28 0.37 0.68

7.5 240 / 200 Q22008 19.00 11.38 8. 83 5.63 2.50 1. 00 0.28 0. 37 0.68

480 / 400 Q24008 16.00 9. 70 7.50 4.81 2. 12 1.00 0. 28 0.37 0.68

590 / 480 Q25008 16.00 9. 70 7.50 4.81 2. 12 1.00 0. 28 0.37 0.68

10 240 / 200 Q22010 19.00 11.38 8.83 5. 63 2.50 1.00 0.28 0.37 0.68

480 / 400 Q24010 19.00 11.38 8.83 5.63 2.50 1. 00 0.28 0.37 0.68

590 / 480 Q25010 19.00 11.38 8.83 5.63 2.50 1. 00 0.28 0.37 0.68

15 240 / 200 Q22015 19.00 11.38 8.83 5. 63 2.50 1.00 0.28 0.37 0.68

480 / 400 Q24015 19.00 11.38 8.83 5.63 2.50 1. 00 0.28 0.37 0.68

590 / 480 Q25015 19.00 11.38 8.83 5.63 2.50 1. 00 0.28 0.37 0.68

20 240 / 200 Q22020 29.00 11.74 9.78 5. 88 2.50 1.50 0.36 0.37 0.68

480 / 400 Q24020 29.00 11.74 9.78 5.88 2.50 1. 50 0.36 0.37 0.68

590 / 480 Q25020 29.00 11.74 9.78 5.88 2.50 1. 50 0.36 0.37 0.68

25 240 / 200 Q22025 29.00 11.74 10.98 7.08 2.50 1. 50 0.36 0.37 0. 68

480 / 400 Q24025 29.00 11.74 9.78 5.88 2.50 1. 50 0.36 0.37 0.68

590 / 480 Q25025 29.00 11.74 9.78 5.88 2.50 1. 50 0.36 0.37 0.68

30 480 / 400 Q24030 29.00 11.74 10.98 7.08 2.50 1. 50 0.36 0.37 0. 68

590 / 480 Q25030 29.00 11.74 10.98 7.08 2.50 1. 50 0.36 0. 37 0.68

Page 8

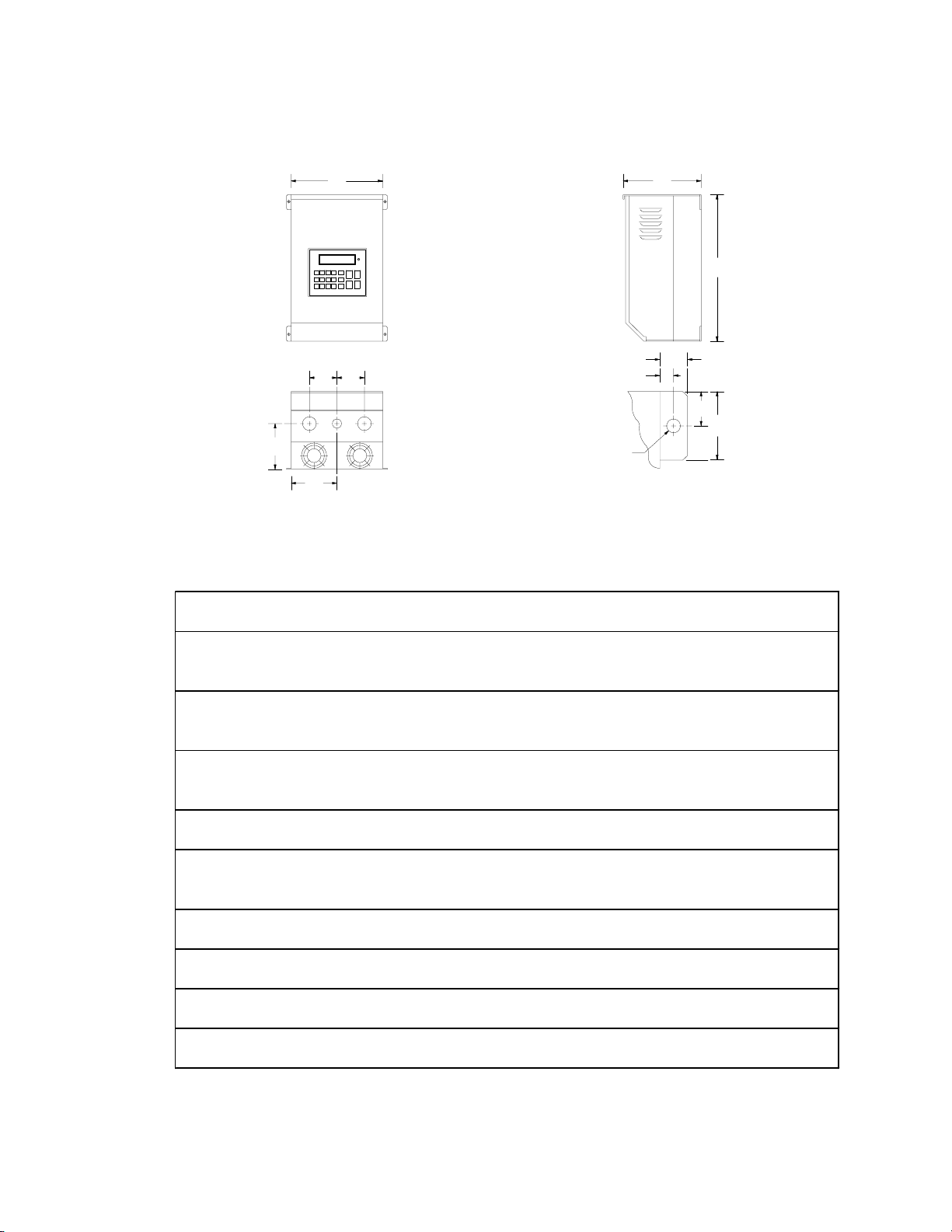

4.3 QC2000 - TYPE 12 ENCLOSED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

D

AIR FLOWAIR FLOW

If H = 31.00"

Y = 22.50"

Y

If H > 37.00"

Y = 27.00"

W

QQ

P

N

Conduit Holes:

If Q = 2.62", left = 1.13" dia.

middle & right = 1.38" dia.

If Q = 3.13", left = 1.13" dia.

middle & right = 1.75" dia.

If Q = 4.50", left = 1.13" dia.

middle & right = 2.50" dia.

T

Dia.

Mounting Tab Detail

U

H

V

2R

R

INPUT

HPVOLTAGEMODELHWDNPQRTUV

30 240 / 200 Q22030 31.00 14.00 11.86 6.00 7.50 2.62 1.50 0.36 0.37 0.68

40 240 / 200 Q22040 31.00 14.00 11.86 6.00 7.50 2.62 1.50 0.36 0.37 0.68

480 / 400 Q24040 31.00 14.00 11.86 6.00 7.50 2.62 1.50 0.36 0.37 0.68

590 / 480 Q25040 31.00 14.00 11.86 6.00 7.50 2.62 1.50 0.36 0.37 0.68

50 480 / 400 Q24050 31.00 14.00 11.86 6.00 7.50 2.62 1.50 0.36 0.37 0.68

590 / 480 Q25050 31.00 14.00 11.86 6.00 7.50 2.62 1.50 0.36 0.37 0.68

60 240 / 200 Q22060 37.00 18.00 13.30 7.50 8.00 3.13 1.50 0.49 0.50 0.92

480 / 400 Q24060 37.00 18.00 13.30 7.50 8.00 3.13 1.50 0.49 0.50 0.92

590 / 480 Q25060 37.00 18.00 13.30 7.50 8.00 3.13 1.50 0.49 0.50 0.92

75 480 / 400 Q24075 37.00 18.00 13.30 7.50 8.00 3.13 1.50 0.49 0.50 0.92

590 / 480 Q25075 37.00 18.00 13.30 7.50 8.00 3.13 1.50 0.49 0.50 0.92

100 480 / 400 Q24100 39.00 26.00 13.30 11.50 8.00 4.50 1.50 0.49 0.50 0.92

590 / 480 Q25100 39.00 26.00 13.30 11.50 8.00 4.50 1.50 0.49 0.50 0.92

125 480 / 400 Q24125 39.00 26.00 13.30 11.50 8.00 4.50 1.50 0.49 0.50 0.92

590 / 480 Q25125 39.00 26.00 13.30 11.50 8.00 4.50 1.50 0.49 0.50 0.92

7

Page 9

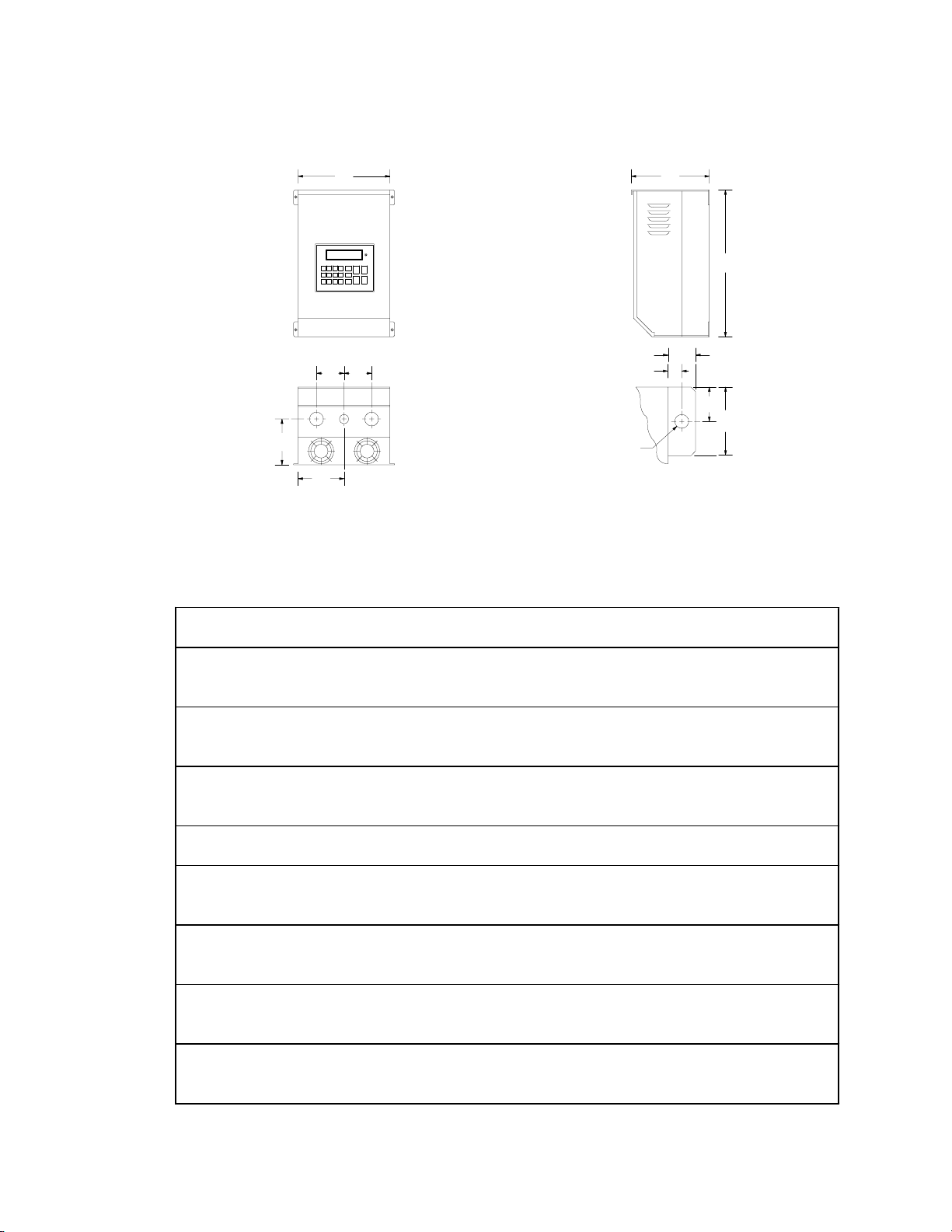

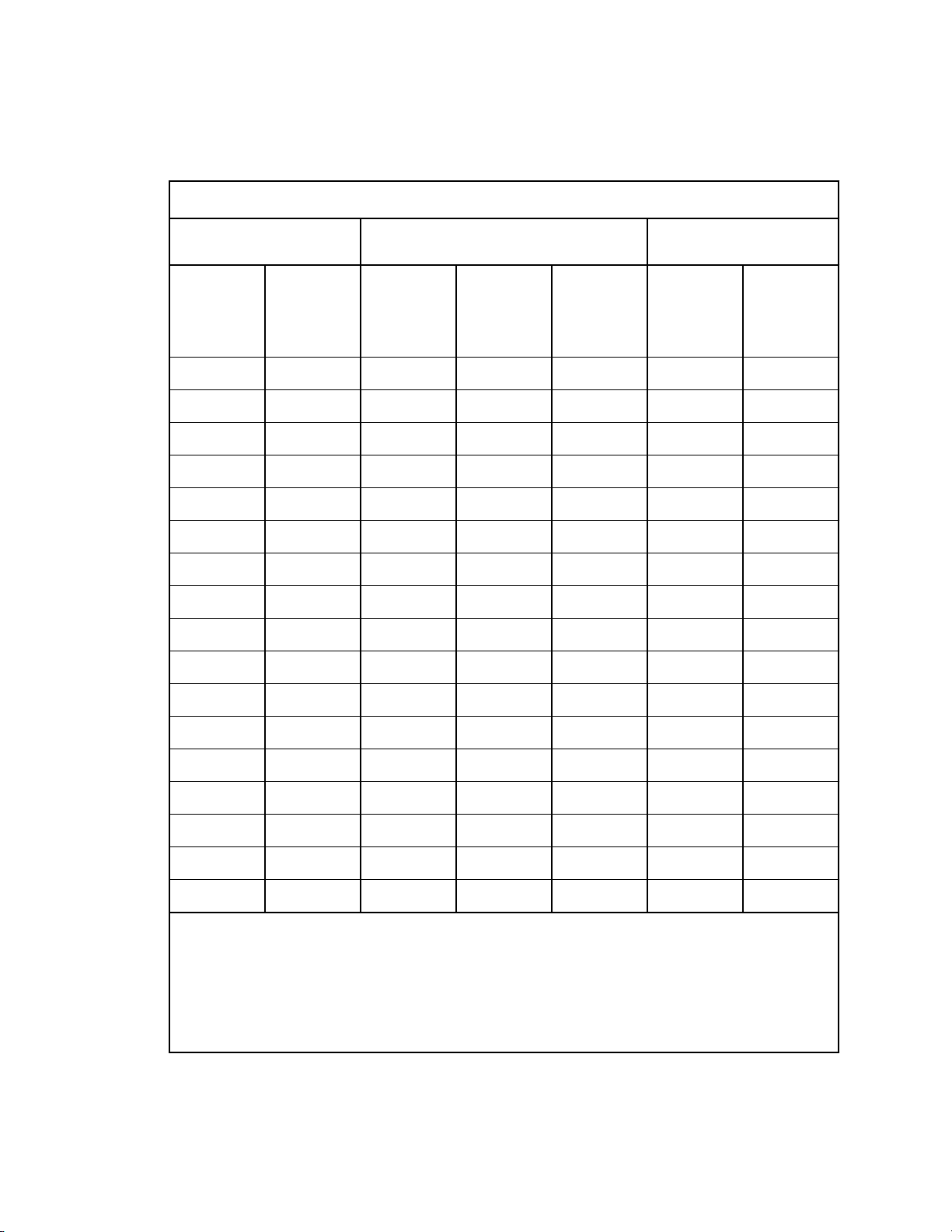

4.4 QC3000 - CHASSIS AND TYPE 1 ENCLOSED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

W

Q

Q

P

N

INPUT

HP VOLTAGE MODEL H W D N P Q R T U V

2 240 / 200 Q32002 12. 00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q34002 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q35002 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

3 240 / 200 Q32003 12. 00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q34003 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q35003 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

5 240 / 200 Q32005 12. 00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q34005 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q35005 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

7.5 480 / 400 Q34008 12. 00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q35008 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

10 240 / 200 Q32010 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

480 / 400 Q34010 12.00 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

590 / 480 Q35010 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

15 240 / 200 Q32015 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

480 / 400 Q34015 14.00 8.88 9.50 4.44 5.75 2.50 1.00 0.28 0.37 0.68

590 / 480 Q35015 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

20 240 / 200 Q32020 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

480 / 400 Q34020 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

590 / 480 Q35020 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

25 240 / 200 Q32025 25.00 8.88 10.5 4.44 6.50 2.50 1.50 0.36 0.37 0.68

480 / 400 Q34025 25.00 8.88 10.5 4.44 6.50 2.50 1.50 0.36 0.37 0.68

590 / 480 Q35025 25.00 8.88 10.5 4.44 6.50 2.50 1.50 0.36 0.37 0.68

Conduit Holes:

If Q = 2.12", all = 1.13" dia.

If Q = 2.50", middle = 1.13" dia.

left & right = 1.38" dia.

D

V

U

R

T

Dia.

Mounting Tab Detail

H

2R

8

Page 10

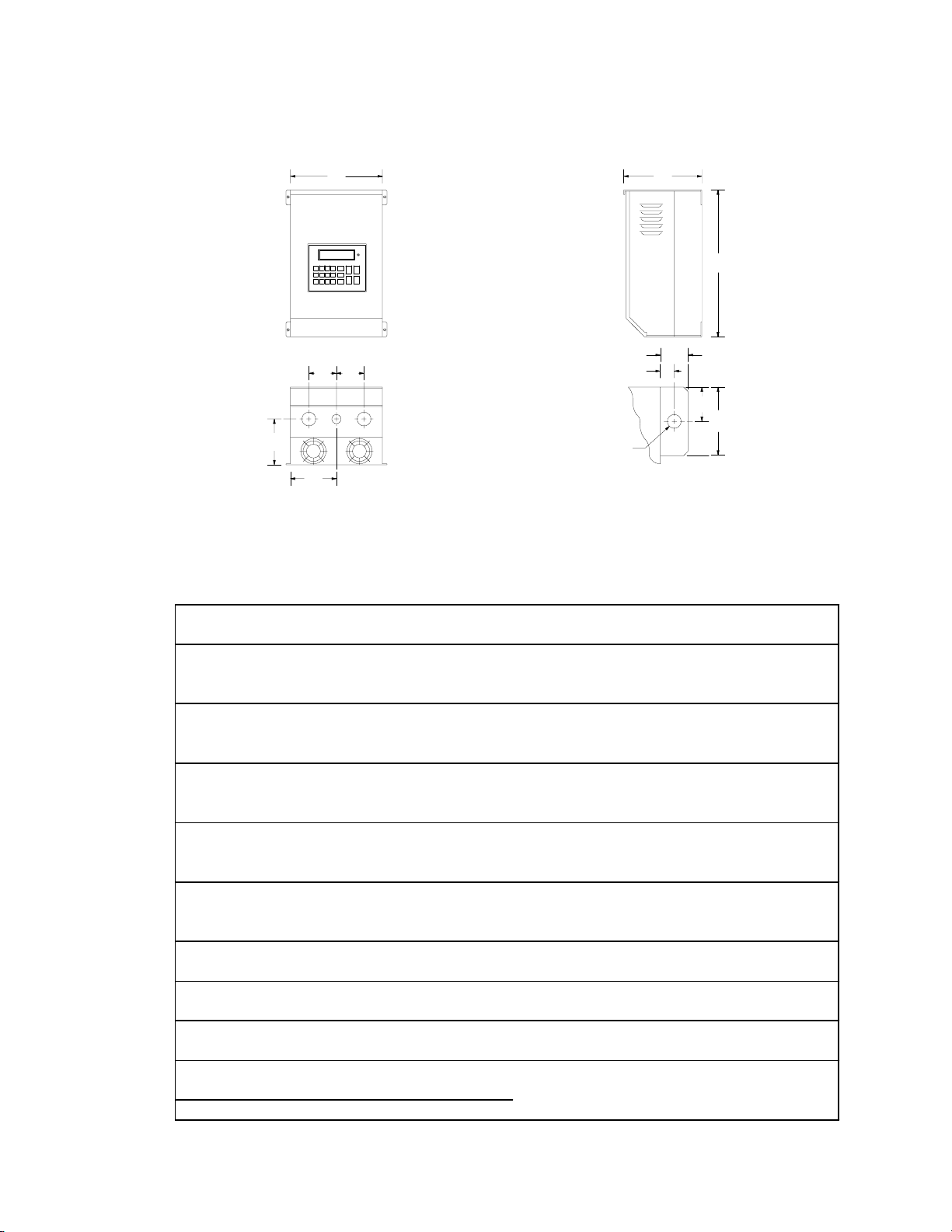

4.4 QC3000 - CHASSIS AND TYPE 1 ENCLOSED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

W

Q

Q

P

N

INPUT

HPVOLTAGEMODELHWDNPQRTUV

30 240 / 200 Q32030 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

480 / 400 Q34030 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

590 / 480 Q35030 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

40 240 / 200 Q32040 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

480 / 400 Q34040 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

590 / 480 Q35040 25.00 8.88 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

50 240 / 200 Q32050 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

480 / 400 Q34050 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

590 / 480 Q35050 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.68

60 240 / 200 Q32060 47.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

480 / 400 Q34060 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.92

590 / 480 Q35060 25.00 13.00 10.50 5.56 6.50 2.62 1.50 0.36 0.37 0.92

75 240 / 200 Q32075 47.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

480 / 400 Q34075 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

590 / 480 Q35075 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

100 480 / 400 Q34100 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

590 / 480 Q35100 29.00 16.64 11.85 7.14 6.88 3.12 1.50 0.44 0.49 0.92

125 480 / 400 Q34125 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

590 / 480 Q35125 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

150 480 / 400 Q34150 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

590 / 480 Q35150 29.00 24.42 11.85 11.12 6.50 4.50 1.50 0.44 0.49 0.92

200 480 / 400 Q34200 29.00 36.66 11.85

590 / 480 Q35200 29.00 36.66 11.85

250 480 / 400 Q34250 29.00 36.66 11.85

Conduit Holes:

If Q = 2.50", middle = 1.13" dia.

left & right = 1.38" dia.

If Q = 2.62", left = 1.13" dia.

middle & right = 1.38" dia.

If Q = 3.12", left = 1.13" dia.

middle & right = 1.38" dia.

If Q = 4.50", left = 1.13" dia.

middle & right = 2.50" dia.

SEE SECTION 4.7 - PAGE 11

D

V

U

R

T

Dia.

Mounting Tab Detail

H

2R

Page 11

4.5 QC1000 AND QC3000 - CHASSIS AND TYPE 1 EXTENDED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

W

Q

Q

P

N

INPUT

HP VOLTAGE MODEL H W D N P Q R T U V

1 240 / 200 Q12001H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q14001H 15. 50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

2 240 / 200 Q* 2002H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q*4002H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

3 240 / 200 Q* 2003H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q*4003H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

5 240 / 200 Q32005H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

480 / 400 Q*4005H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

7.5 240 / 200 Q12008H 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

480 / 400 Q14008H 15. 50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

Q34008H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

10 240 / 200 Q*2010H 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

480 / 400 Q14010H 19. 00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

Q34010H 15.50 7.44 7.91 3.72 4.75 2.12 1.00 0.28 0.37 0.68

15 240 / 200 Q*2015H 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

480 / 400 Q*4015H 19.00 8.88 9.84 4.44 6.13 2.50 1.00 0.28 0.37 0.68

20 240 / 200 Q*2020H 25.00 8.88 10. 50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

480 / 400 Q*4020H 25.00 8.88 10.50 4.44 6.50 2.50 1.50 0.36 0.37 0.68

25 240 / 200 Q*2025H 25.00 13.00 10. 50 5.56 6.50 2.50 1.50 0.36 0.37 0.68

480 / 400 Q*4025H 25.00 13.00 10.50 5.56 6.50 2.50 1.50 0.36 0.37 0.68

30 480 / 400 Q*4030H 25.00 13.00 10. 50 5.56 6.50 2.50 1.50 0.36 0.37 0.68

Conduit Holes:

If Q = 2.12", all = 1.13" dia.

If Q = 2.50", middle = 1.13" dia.

left & right = 1.38" dia.

D

V

U

T

Dia.

Mounting Tab Detail

H

R

2R

NOTE: * = 1 or 3, depending on model. See Section 3.0 for model number breakdown.

10

Page 12

4.6 QC2000 - TYPE 4/12 AND 4X EXTENDED

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

D

H

W

QQ

Conduit Holes:

If Q = 2.12", all = 1.13" dia.

P

W

If Q = 2.50", middle = 1.13"

left & right = 1.38"

2

T

Dia.

Mounting Tab Detail

V

U

R

2R

INPUT

HP VOLTAGE MODEL H W D P Q R T U V

1 240 / 200 Q22001H 16.00 9.70 7.50 4.81 2.12 1.00 0.28 0.37 0.68

480 / 400 Q24001H 16.00 9.70 7.50 4.81 2.12 1.00 0.28 0.37 0.68

2 240 / 200 Q22002H 16.00 9.70 7.50 4.81 2.12 1.00 0.28 0.37 0.68

480 / 400 Q24002H 16.00 9.70 7.50 4.81 2.12 1.00 0.28 0.37 0.68

3 240 / 200 Q22003H 16.00 9.70 7.50 4.81 2.12 1.00 0.28 0.37 0.68

480 / 400 Q24003H 16.00 9.70 7.50 4.81 2.12 1.00 0.28 0.37 0.68

4.7 MOUNTING TAB AND CONDUIT HOLE DIMENSIONS

The following diagram applies to 150 HP QC1000, 200 HP QC3000, and 250 HP QC3000 models only.

V

U

N

7.25"

Conduit Holes: Large holes = 3.00"

Small holes = 1.13"

Q

P

P

6.50"

T

Dia.

Mounting Tab Detail

1.36"

3.00"

1.36"

11

N = 7.45"

P = 9.00"

Q = 7.00"

T = 0.44"

U = 0.49"

V = 0.92"

Page 13

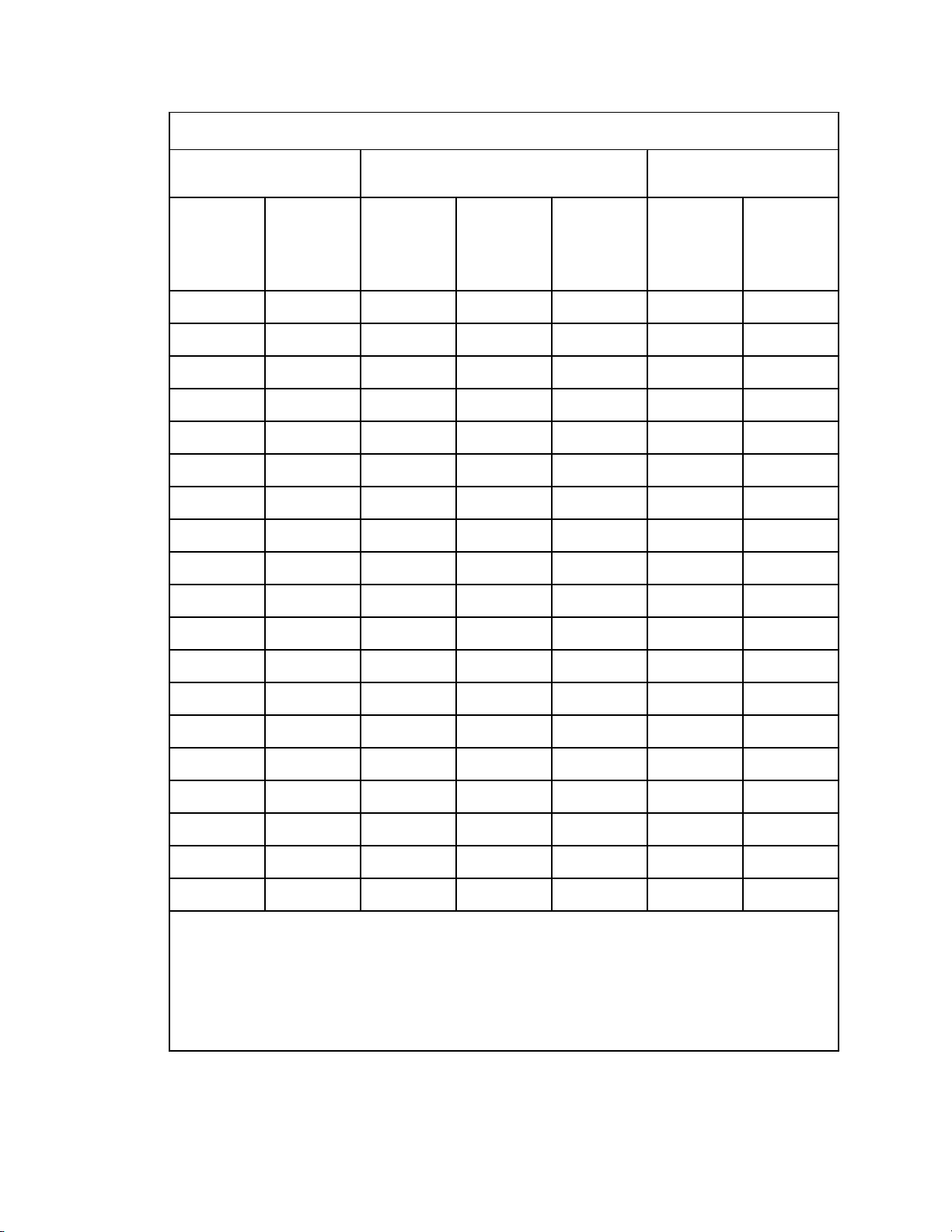

5.0 QC SERIES RATINGS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

MODEL

MODEL CURRENT NOMINA L

NUMBER RATED INPUT (AMPS) POWER CURRENT POWER

(NOT E 1)

Q*2001 1 3 4.6 1.9 4.0 1.6

Q*2001S 1 1 / 3 8.5 / 4.6 2.0 / 1.9 4.0 1.6

Q*2002 2 3 8.1 3.4 6.8 2.7

Q*2002S 2 1 / 3 14.9 / 8.1 3.6 / 3.4 6.8 2.7

Q*2003 3 3 11.3 4.7 9.6 3.8

Q*2003S 3 1 / 3 21.0 / 11.3 5. 0 / 4. 7 9.6 3.8

Q32005 5 3 17.7 7.3 15.2 6.1

HP PHASE

Q1200 , Q2200, AN D Q3200 SERIES RATING S

INPUT OUTPUT

(240 Vac, 50 - 60 Hz) (0 - 230 Vac)

NOMINA L

(NOT E 2)

(KVA) (AMPS) (KVA)

Q12008 / Q22008 7.5 3 25.0 10.5 22.0 8.8

Q*2010 10 3 32.0 13.2 28.0 11.2

Q*2015 15 3 47.6 19.8 42.0 16.7

Q*2020 20 3 61.0 25.3 54.0 21.5

Q*2025 25 3 64.0 26.6 68.0 27.1

Q*2030 30 3 76.0 31.6 80.0 31.9

Q*2040 40 3 99.0 41.0 104.0 41.4

Q32050 50 3 122.0 50.7 130.0 51.8

Q*2060 60 3 145.0 60.5 154. 0 61.3

Q*2075 75 3 182.0 75.7 192. 0 76.5

NOTE 1: See Secti on 3.0 for m odel num b er breakdow n ( * = 1, 2, or 3, depending on m odel ) .

NOTE 2: For 200 Vac input voltage on T H REE PHASE,

Q1200 AND Q2200

MODELS ONLY, mu lti pl y the input and output

curr en t ratin gs by 1.2 an d the output v ol tage by 0. 8 3.

For

thr ee pha s e models, m ult i ply the inp ut and output powe r, and output v olt a ge, by 0.83.

Q3200

Q3200 models may hav e to be oversized t o me et the c ur re nt requi r em e nts of 200 Vac appli cations.

NOTE 3 : See Sec ti on 8 .0 for rec ommended fuse type.

12

Page 14

Q1400 , Q2400, AND Q3400 SERI E S R A T INGS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

INPUT

INPUT O UTPUT

INPUTINPUT

MODEL

MODEL (480 Vac, 50 - 60 Hz) (0 - 460 Vac)

MODELMODEL

NOMINAL

MODEL CURRENT NOMINAL

NUMBER RATED INPUT (AMPS) POWER CURRENT POWER

(NOT E 1)

Q*4001 1 3 2.3 1.9 2.0 1.6

Q*4002 2 3 4.0 3.4 3.4 2.7

Q*4003 3 3 5.7 4.7 4.8 3.8

Q*4005 5 3 8.8 7.3 7.6 6.1

Q*4008 7.5 3 12.6 10.5 11.0 8.8

Q*4010 10 3 15.9 13.2 14.0 11.2

Q*4015 15 3 24 19.8 21 16.7

Q*4020 20 3 31 25.4 27 21.5

Q*4025 25 3 32 26.7 34 27.1

HP PHASE

(NOT E 2)

(KVA) (AMPS) (KVA)

OUTPUT

OUTPUTOUTPUT

Q*4030 30 3 38 31.5 40 31.9

Q*4040 40 3 49 41.0 52 41.4

Q*4050 50 3 61 50.7 65 51.8

Q*4060 60 3 73 60.5 77 61.3

Q*4075 75 3 91 75.5 96 76.5

Q*4100 100 3 116 96.4 124 98.8

Q*4125 125 3 146 121.4 156 124.3

Q*4150 150 3 168 139.7 180 143.4

Q34200 200 3 225 187.1 240 191.2

Q34250 250 3 281 233.6 302 240.6

NOTE 1: See Secti on 3.0 for m ode l num ber br eakdow n ( * = 1, 2, or 3 , dependi ng on m odel).

NOTE 2: For 400 Vac inp ut v ol tage on Q14 00 A N D Q240 0

Q14 00 AND Q2400 MODELS ONLY, m ul tip l y t he input and output c ur r ent ra tings

Q1400 AND Q2400 Q1400 AND Q2400

by 1.2 a nd the output voltage b y 0.83.

For Q3400

Q34 00 m od els, mul ti pl y the input and ou tput pow er , and output v ol tage, by 0.83.

Q3400 Q3400

Q3400 models may hav e to be oversized to meet the curre nt requi r em e nts of 400 Vac appli cation s .

NOTE 3 : See Sec ti on 8.0 for recommended fuse type.

13

Page 15

Q1500 , Q2500, AND Q3500 SERI E S R A T INGS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

INPUT

INPUT O UTPUT

INPUTINPUT

MODEL

MODEL (590 Vac, 50 - 60 Hz) (0 - 575 Vac)

MODELMODEL

NOMINAL

MODEL CURRENT NOMINAL

NUMBER RATED INPUT (AMPS) POWER CURRENT POWER

(NOT E 1)

Q*5001 1 3 1.8 1.9 1.6 1.6

Q*5002 2 3 3.3 3.4 2.7 2.7

Q*5003 3 3 4.6 4.7 3.9 3.9

Q*5005 5 3 5.8 5.9 6.1 6.1

Q*5008 7.5 3 8.6 8.8 9.0 8.9

Q*5010 10 3 10.6 10.9 11.0 11.0

Q*5015 15 3 16.4 16.7 17.0 16.9

Q*5020 20 3 21 21.3 22 21.5

Q*5025 25 3 26 26.9 27 26.9

HP PHASE

(NOT E 2)

(KVA) (AMPS) (KVA)

OUTPUT

OUTPUTOUTPUT

Q*5030 30 3 31 31.6 32 31.9

Q*5040 40 3 40 40.5 41 40.9

Q*5050 50 3 50 51.1 52 51.8

Q*5060 60 3 60 60.9 62 61.7

Q*5075 75 3 74 75.7 77 76.7

Q*5100 100 3 95 96.6 99 98.6

Q*5125 125 3 119 121.6 125 124.5

Q*5150 150 3 137 140.0 144 143.4

Q35200 200 3 183 187.0 192 191.2

NOTE 1: See Secti on 3.0 for m ode l num ber br eakdow n ( * = 1, 2, or 3 , dependi ng on m odel).

NOTE 2: For 480 Vac inp ut v ol tage on Q15 00 A N D Q250 0

Q15 00 AND Q2500 MODELS ONLY, m ul tiply the in put and outputc ur r ent ra tings

Q1500 AND Q2500Q1500 AND Q2500

by 1.23 and the output v ol tage by 0.81.

For Q3500

Q35 00 m od els, mul ti pl y the input and ou tput pow er , and t h e output v olt age, by 0.81.

Q3500 Q3500

Q3500 models may hav e to be oversized to meet the curre nt requi r em e nts of 480 Vac appli cation s .

NOTE 3 : See Sec ti on 8.0 for recommended fuse type.

14

Page 16

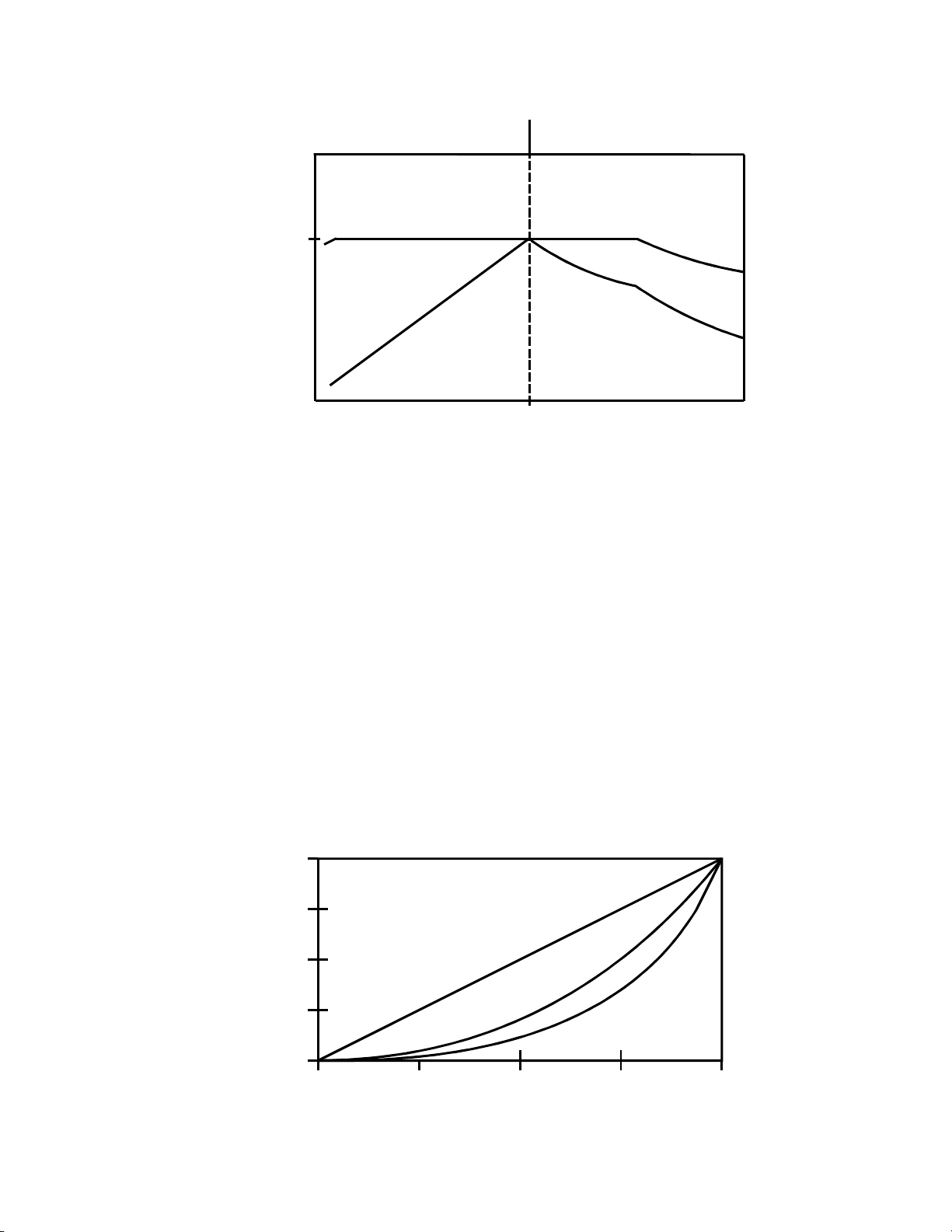

6.0 THEORY

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

6.1 DESCRIPTION OF AC MOT OR OPERATION

Three phase AC motors are comprised of two major components, the stator and th e rotor. The stator is a

set of three electrical windings held stationar y in the motor housing. The rotor is a metal cylinder, fixed

to the motor drive shaft, which rotates within the stator. The ar rangemen t of the stator coils and the

presence of three phase AC voltage give rise to a rotating magnetic field which drives the rotor. The

speed at which the magnetic field rotates is known as the synchronous speed of the motor. Syn chronous

speed is a function of th e fr equency at which the voltage is alternating and the number of poles in the

stator windings.

The following equation gives the relation between synchronous speed, frequency, and the number of

poles:

Ss = 120 f/p

Wher e: Ss = Syn chr onous speed (rpm ), f = frequency (Hz), p = nu mber of poles

In three phase induction motors the actual shaft speed differs from the synchronous speed as load is

applied. This difference is known as "slip". Slip is commonly expressed as a percentage of synchronous

speed. A typical value is three percent at full load.

The strength of the magnetic field in the gap between the r otor and stator is proportional to the amplitude

of the voltage at a given frequency. The output torque capability of the motor is, therefore, a function of

the applied voltage amplitude at a given frequency. When operated below base (rated) speed, AC motors

run in the range of "constant torque". Constant torque output is obtain ed by maintaining a constant ratio

between voltage amplitude (volts) and frequency (Hz). For 60 Hz, 230, 460, and 575 volt motors,

common values for this V/Hz ratio are 3.83, 7.66, and 9.58 respectively. Operating with these V/Hz

ratios gen erally yield optimum torque capability. Operating at lower ratios decreases tor que an d power

capability. Operating at higher ratios will cause the motor to overheat. Most standard motors are capable

of providing full torque output from 3 to 60 Hz. However , at lower speeds, where motor coolin g fan s

becom e less effective, supplemental cooling may be n eeded to operate at full torque output continuously.

If the fr equency applied to the motor is increased while the voltage remains constant, torque capability

will decrease as speed increases. This will cause the horsepower capability of the motor to remain

app roxi mate ly const ant . Motor s ru n in thi s mode wh en op erat ed above ba se speed , wher e dr ive out put

voltage is limited by the in put line voltage. This operating range is known as the "constant horsepower"

range. The typical maximum range for constant horsepower is about 2.3 to 1 (60 to 140 Hz). The

diagram below depicts the operating characteristics of a typical AC induction motor .

WARNING!

Con s ult mot or m an ufacturer befor e op e ra ting motor and/or dr iven e qui pment above r ate d spee d.

15

Page 17

CONSTANT TORQUE

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

CONSTANT HP

100

TORQUE HORSEPOWER

TORQUE (%)

HORSEPOWER

BASE FREQUENCY (%)

6.1.1 CONSTANT T ORQUE VS. VARIABLE TORQUE

Variable frequency dri ves, an d the loads they a re applied to, can generally be divided into two groups:

constant torque and variable torque. Constant torque loads include: vibrating conveyors, punch presses,

rock crushers, machine tools, and just about every other application that is not considered variable torque.

Variable torque loads include centrifugal pumps and fans, which make up the majority of HVAC

applications.

The term constant torque is not entirely accurate in terms of the torque required for an application.

Many constant torque applications have reciprocating loads, such as vibrating conveyors and punch

presses, wh ere the rotation al motion of the motor is being converted to a lin ear motion. In such cases, the

torque required can vary greatly at different poin ts in the cycle. For constant torque loads, this flucuation

in torque is not a dir ect function of speed, as it is with a variable torque load.

TORQUE

100

Variable torque loads are governed by the affinity laws, which define the relationships between speed,

flow, torque and horsepower. The diagram below illustrates these relation ships:

100%

75%

50%

% FLOW

25%

0%

0%

25% 5 0% 75% 100%

% TORQUE

% HORSEPOWER

SPEED (%)

16

Page 18

Variable torque refers to th e fact that the torque requir ed varies with the square of the speed. Also, the

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

horsepower required varies with the cube of the speed, resulting in a large reduction in horsepower for

even a small reduction in speed. It is easily seen that substantial energy savings can be achieved by

reducing the speed of a fan or pump. For example, reducing the speed to 50% results in a 50 HP motor

having to produce only 12.5% of rated horsepower, or 6.25 HP.

There are two major differences between a constant torque drive and a variable torque drive. One is that a

constant torque drive generally has a higher overload capacity rating. Constant torque loads have higher

peak torque demands, which require the ability to handle higher currents. Variable torque loads rarely

experience full load, and therefore usually have a lower overload capacity. The other difference is that

constant torque drives follow a constant V/Hz ratio to achieve maximum torque, while variable torque

drives follow a variable V/Hz ratio to optimize efficiency and energy savings.

6.2 DRIVE FUNCTION DESCRIPTION

The QC Series is a 16 bit microprocessor based, keypad programmable, variable speed AC motor drive.

There are four major sections; an input diode bridge and DC bus filter, a power board, a control board, and

an output intelligent power module.

6.2.1 DRIVE OPERATION

Incoming AC line voltage is converted to a pulsating DC voltage by the input diode bridge. The DC

voltage is supplied to the bus filter capacitors through a charge circuit which limits inrush current to the

capacitors during power-u p. The pulsating DC voltage is filter ed by the bus capacitors which re duces the

ripple level. The filtered DC voltage enters the inverter section of the drive, composed of six output

intelligent insulated gate bi-polar transistors (IGBT’s) which make up the three output legs of the drive.

Each leg has one intelligent IGBT connected to the positive bus voltage and one connected to the negative

bus voltage. Alternately switching on each leg, the intelligent IGBT produces an alternating voltage on

each of the corresponding motor windings. By switching each output intelligent IGBT at a very high

frequency (known as the carrier frequency) for varying time intervals, the inverter is able to produce a

smooth, three phase, sinusoidal output current wave which optimizes motor performance.

6.2.2 CIRCUIT DESCRIPTION

The control section consists of a control board with a 16 bit microprocessor, keypad and display. Drive

programming is accomplished via the keypad or the serial communications port. During operation the

drive can be controlled via the keypad, by control devices wired to the control terminal strip, or by the

serial communications port. The Power Board contains the control and protection circuits which govern

the six output IGBT’s. The Power Board also co ntains a charging circuit f or the bus filter capacitors, a

motor current feedback circuit, a voltage feedback circuit, and a fault signal circuit. The drive has several

built in protection circuits. These include phase-to-phase and phase-to-ground short circuit protection,

high and low line voltage protection, protection against excessive ambient temperature, and protection

against continuous excessive output current. Activation of any of these circuits will cause the drive to shut

down in a fault condition.

17

Page 19

6.2.3 QC ANALOG INPUT SIGNALS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The QC Series drive allows for three speed reference input signals: speed potentiometer (10,000 Ohm), 420 mA, or 0-10 VDC. For control by a speed pot., th e wiper lead is connected to terminal TB-5A, and the

hig h an d low end l eads ar e connected to termi nals TB-6 an d TB-2, r espectivel y. For 4-20 mA con trol,

wire the positive to terminal TB-5B and the negative to terminal TB-2. For 0-10 VDC control, wire the

positive to terminal TB-5D and the negative to terminal TB-2. See the control wir ing diagram in Section

15.0.

The input im pedance of termina l TB-5A (speed pot input) is 100 kilohms, TB-5B (4-20 m A input) is

100 ohms, and TB-5D (0-10 VDC input) is 200 kil ohm s. T erm i nal TB-2 is circuit common.

The control voltage of the microprocessor control board is 24 VDC, (Isolated, referenced to circuit

common - terminal TB-2).

6.2.4 QC ANALOG OUTPUT SIGNALS

There are four terminals that can supply a nalog output signals proportional to output frequency or load.

Terminal TB-10B can provide a 0-10 VDC signal proportiona l to frequency or load. Termi nal TB-10C

provides a 12 VDC pulse train proportional to frequency with a 40-50% duty cycle. Term inal TB-10D

can provide a 4-20 mA signal pr oportional to frequency or load, and termin al TB-10E can provide a 0-10

VDC or 2-10 VDC sign al proportional t o frequency or l oad. The 2-10 VDC signal can be converted to a

4-20 mA signal usin g a resistor in ser ies with the signal such that t he total circuit resistan ce is 500 ohm.

See Parameters: 50 - TB10B/D FUNCTION, and 53 - TB10E FUNCTION in Section 18.0 DESCRIPTION OF PARAMETERS.

6.2.5 QC ST AT US OUTPUT RELAYS

The control board has two FORM C relays at terminals TB-16, 17, 18, and TB-19, 20, 21. TB-16 and

TB-19 are normally open contacts, and TB-18 and TB-21 are normally closed contacts. TB-17 and TB-20

are common. Contacts are ra ted 2 amps at 28 VDC or 120 Vac.

Ther e i s a l so one op en -col lect or out put a t t er m inal T B-1 4. T h e open -col lect or cir cu it is a cur ren t- si n ki n g

type rated at 30 VDC and 40 mA maximum.

The FORM C relays and the open-collector output can be pr ogrammed to indicate any of the following:

NO FUNCTION, RUN, FAULT, FAULT LOCKOUT, AT SPEED, ABOVE SET SPEED, CURRENT

LIMIT, FOLLOWER PRESENT, MAINTENANCE TARGET, AUTO SPEED MODE, or START

PENDING. See Parameters: 121 - RELAY #1 FUNCTION, 122 - RELAY #2 FUNCTION, and 124 - TB14 FUNCTION, in Section 18.0 - DESCRIPTION OF PARAMETERS.

The following describes the functionality of the possible relay output settings:

NO FUNCTION This setting disables the relay output.

RUN The relay energizes when the drive is given a START command, and remains

energized until: a STOP command is given and the output frequency has

deceler ated to 0. 5 Hz, th e dri ve has "t ri pped", or th e in put volt age is removed.

Note that this relay indicates only that the drive is in the RUN mode. It does

not necessarily indicate that the motor is turnin g.

18

Page 20

FAULT The relay energizes when input voltage is applied to the drive and remains

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

energized until the drive “trips” into a fault condition, or input voltage is

removed.

FAULT LOCKOUT This relay can be used when the drive is programmed to automatically restart

after a fault. The relay energizes when input voltage is applied to the drive and

remains energized until the drive has faulted and unsuccessfully attempted the

number of restarts programmed in Parameter 72 - RESTART LIMIT, or input

voltage is removed.

AT SPEED The relay energizes when the drive reaches the commanded frequency. To avoid

a “chattering” relay (constantly energizing and de-energizing) due to small

fluctuations in speed, the relay will change states only when the speed has

changed by +

ABOVE SET SPD ABOVE SET SPEED - The relay energizes when the output frequency of the

drive exceeds the value in Parameter 123 – REL. SET SPD, and de-energizes

when the output frequency is equal to or less than REL. SET SPD.

CURRENT LIMIT The relay energizes when the drive is operating in current limit. Once the current

limit relay is energized, it remains energized for a minimum of 500ms, regardless

of whether the drive is still in current limit. At the end of the 500ms interval, the

relay will de-energize if the drive is no longer in current limit. See Parameter 1 CURRENT in Section 18.0 - DESCRIPTION OF PARAMETERS.

FOLLOWER PRES FOLLOWER PRESENT - The relay energizes when the 4-20 mA speed

reference input signal (TB-5B) is greater than 2 mA, and de-energizes when the

signal falls below 2 mA.

MAINT. TARGET MAINTENANCE TARGET - The relay energizes after the time period

programmed in Parameter 132 - MAINTENANCE TARGET has elapsed. The

relay will de-energize when a new time is programmed into Parameter 132.

AUTO SPEED MODE The relay energizes when the drive is in the AUTOMATIC MODE, and de-

energizes in the MANUAL MODE. This function is active only if Parameter 67

- AUTO/MANUAL SELECT is set to AUTO/MANUAL SPEED or

AUTO/MANUAL LOCAL. The relay will remain energized if Parameter 67 is

set to AUTO SPEED. This function will not be active if Parameter 67 is set to

MANUAL SPEED.

START PENDING The relay will energize if the drive has faulted, and is programmed for automatic

restart after a fault. START PENDING will appear on the keypad display when

the drive is in this condition. The relay will de-energize after the delay

programmed into Parameter 73 - RESTART DELAY, at which time the drive

will attempt to restart.

3 Hz.

19

Page 21

7.0 INSTALLATION

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE ENVIRONMENTAL

CONDITIONS! DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO: COMBUSTIBLE,

OILY, OR HAZARDOUS VAPORS OR DUST; EXCESSIVE MOISTURE OR DIRT; STRONG

VIBRATION; EXCESSIVE AMBIENT TEMPERATURES. CONSULT AC TECHNOLOGY FOR

MORE INFORMATION ON THE SUITABILITY OF A DRIVE TO A PARTICULAR ENVIRONMENT.

The drive should be mounted on a smooth vertical surface capable of safely supporting the unit without

vibrating. The LCD display has an optimum field of view, this should be considered when determining the

mounting position.

Chassis models must be installed in an electrical enclosure which will provide complete mechanical

protection and maintain uniform internal temperature within the drive’s ambient operating temperature

rating. All drive models MUST be mounted in a vertical position for proper heatsink cooling.

Maintain a minimum spacing around the drive of 4 inches for units rated 20 HP and below, 6 inches for

units rated 25-50 HP, and 8 inches for units rated 60 HP and above.

Fans or blowers should be used to insure proper cooling in tight quarters. Do not mount drives above other

drives or heat producing equipment that would impede the cooling of the drive. Note the ambient

operating temperature ratings for each drive model.

WARNING!

If it is necessary to drill or cu t the drive en closure or p anel, extreme care must be take n to avoid da maging

drive components or contaminating the drive with metal fragments (which cause shorting of electrical

circuits). Cover drive components with a clean cloth to keep out metal chips and other debris. Use a

vacuum cleaner to clean drive components after drilling, even if chips do not appear to be present. Do not

attempt to use positive air pressure to blow chips out of drive, as this tends to lodge debris under electronic

components. Contaminating the drive with metal chips can cause drive failure and will void the warranty.

7.1 INSTALLATION AFTER A LONG PERIOD OF STORAGE

WARNING!

Severe damage to the drive can result if it is operated after a long period of storage or inactivity without

reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding one year (due to storage,

etc), the electrolytic DC bus capacitors within the drive can change internally, resulting in excessive

leakage current. This can result in premature failure of the capacitors if the drive is operated after such a

long period of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long period of inactivity, apply

input power to the drive for 2 hours prior to actually operating the drive/motor system.

20

Page 22

7.2 EXPLOSION PROOF APPLICATIONS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Explosion proof motors that are not rated for inverter use lose their certification when used for variable

speed. Due to the many areas of liability that may be encountered when dealing with these applications,

the following statement of policy applies:

"AC Technology Corporation inverter products are sold with no warranty of fitness for a particular

purpose or warranty of suitability for use with explosion proof motors. AC Technology Corporation

accepts no responsibility for any direct, or incidenta l or consequential loss, co st, or dama ge tha t may

arise through the use of its AC inverter products in these applications. The purchaser expressly

agrees to assume all risk of any loss, cost, or damage that may arise from such application. AC

Technology Corporation or AC Technology Corporation’s engineering department will not

knowingly approve applicati ons involving explosion proof mot ors."

21

Page 23

8.0 INPUT AC POWER REQUIREMENTS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

W ARNING!

Hazard of electrical shock! Disconnect incoming power and wait three minutes before servicing the drive.

Capacitors retain charge after power is removed.

8.1 INPUT AC POWER REQUIREMENTS

8.1.1 VOLTAGE:

The system line voltage must match the drive’s input voltage rating. Voltage fluctuation must not vary by

greater than 10% overvoltage or 15% undervoltage.

NOTE: Drives with dual rated input voltage must be programmed for the proper supply voltage - see Parameter

94 - AC INPUT in Section 18.0 - DESCRIPTION OF PARAMETERS SECTION.

The drive is suitable for use on a circuit capable of delivering not more than 200,000 RMS symmetrical

amperes, at the drive’s rated voltage.

Three phase voltage imbalance must be less than 2.0% phase to phase. Excessive phase to phase imbalance

can cause severe damage to the drive’s power components.

Motor voltage should match line voltage in normal applications. The drive’s maximum output voltage will

equal the input voltage. Use extreme caution when using a motor with a voltage rating which is different from

the input line voltage.

8.1.2 kVA RATINGS:

If the kVA rating of the AC supply transformer is greater than ten times the input kVA rating of the drive, a

drive isolation transformer, or a 2 - 3% input line reactor (also known as a choke) must be added. This only

applies to 240/200 Vac and 480/400 Vac models rated 20 HP and below, and 590/480 Vac models rated 3 HP

and below, as larger units have standard built-in line reactors.

8.2 INPUT FUSING AND DISCONNECT REQUIREMENTS

A circuit breaker or a disconnect switch with fuses must be provided in accordance with the National Electric

Code (NEC) and all local codes.

The QC1000 and QC2000 drives are capable of withstanding up to 150% current overload for 60 seconds,

and the QC3000 is capable of 120% current overload for 60 seconds. Therefore, select a fuse or magnetic trip

circuit breaker rated at a maximum of 1.5 (QC1000/2000), or 1.25 (QC3000) times the input current rating of

the drive. Refer to Section 5.0 - DRIVE RATINGS.

Minimum voltage rating of the protection device should be: 250 Vac for 240/120 Vac and 240/200 Vac rated

drives, and 600 Vac for 480/400 Vac and 590/480 Vac drives.

If using fuses, current limiting fuses should be used. Select fuses with low I

Recommended fuses are Bussman type KTK-R and JJN for 240/200 Vac models, or type KTK-R and JJS for

480/400 Vac and 590/480 Vac models. Similar fuses with equivalent ratings by other manufacturers may

also be acceptable.

2

T values, rated at 200,000 AIC.

22

Page 24

9.0 VOLTAGE SELECTION

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Before applying incoming line voltage, verify that the proper voltage is selected at PL1 or PL2. FAILURE

TO PROPERLY SELECT THE INPUT VOLT AGE MAY RESULT IN DRIVE DAMAGE !

9.1 INPUT RATINGS

Q*200 drives are rated for 240/200 Vac, 50-60 Hz input. With th e proper voltage selection, the drive will

function with input power of 240 Vac (+10%, -15%) or 200 Vac (+10%, -15%), at 48 to 62 Hz.

Q*400 drives are rated for 480/400 Vac, 50-60 Hz input. With th e proper voltage selection, the drive will

function with input power of 480 Vac (+10%, -15%) or 400 Vac (+10%, -15%), at 48 to 62 Hz.

Q*500 drives are rated for 590/480 Vac, 50-60 Hz input. With th e proper voltage selection, the drive will

function with input power of 590 Vac (+10%, -15%) or 480 Vac (+10%, -15%), at 48 to 62 Hz.

WARNING!

NOTE:

NOTE:

* = 1, 2, or 3, dependin g on model. Refer to Section 3.0 for model number breakdown.

QC3000 units must be derated for operation at 200 Vac, 400 Vac, or 480 Vac (on 590 Vac

models) in put voltage. Refer to Section 5.0 for drive r atin gs.

9.2 VOLTAGE SELE CTION

To select the proper vol tage on 1, 2, and 3 HP, 240/200 Vac drives, the PL1 plug must be in the correct

position . PL1 is located in the lower right corner of the power board. Refer to the diagrams below.

For all other units, the PL2 plug is used to select the correct input voltage. Plug PL2 into the top and

middle pins to select 240, 480, or 590 Vac, or the middle a nd bottom pin s to select 200, 400, or 480 (on

Q*500 models) Vac input. PL2 is located either at the lower right corner, or upper r ight corner of the

power board, depending on h or sepower.

NOTE:

In addition to the voltage plug selection, Parameter 94 - AC INPUT must also be programmed

for the proper voltage. See Section 18.0 - DESCRIPTION OF PARAMETERS.

VOLTAGE SELECTION PLUG

PL2 PL2

PL1

208V

240V

240 Vac INPUT

1-3 HP, 240/200 Vac UNITS

PL1

208V

240V

208 Vac INPUT

MODEL

CODE

1200

1400

1500

240/480/590 Vac INPUT 200/400/480 Vac INPUT

200V

400V

480V

240V

480V

590V

MODEL

CODE

1200

1400

1500

ALL OTHER UNITS

23

200V

400V

480V

240V

480V

590V

Page 25

10.0 POWER WIRING

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

WARNING!

Hazard of electrical shock! Disconnect incoming power and wait three minutes before servicing the drive.

Capacitors retain charge after power is removed.

Note drive input and output current ratings and check applicable electrical codes for required wire type and

size, grounding requirements, over-current protection, and incoming power disconnect, before wiring the

drive. Size conservatively to minimize the voltage drop.

Input fusing and a power disconnect switch or contactor MUST be wired in series with terminals L1, L2, and

L3 (L1 and L2 if input is single phase). If one has not been supplied by AC Technology Corporation, a

disconnect means must be wired during installation. This disconnect must be used to power down the drive

when servicing, or when the drive is not to be operated for a long period of time, but should not be used to start

and stop the motor. Repetitive cycling of a disconnect or input contactor (more than once every two minutes)

may cause damage to the drive.

10.1 WIRING FOR SINGLE PHASE OR THREE PHASE INPUT

If the drive is nameplated for single phase input only, wire input to terminals L1 and L2.

If the drive is nameplated for single or three phase input, wire input to terminals L1 and L2, and jump L2 to L3

for single phase input, or wire input to L1, L2, and L3 for three phase input.

If the drive is nameplated for three phase input only, wire input to terminals L1, L2, and L3.

All three power output wires, from terminals T1, T2, and T3 to the motor, must be kept tightly bundled and

run in a separate conduit away from all other wiring.

It is not recommended to install contactors or disconnect switches between the drive and motor. Operating

such devices while the drive is running can potentially cause damage to the drive's power components. If

such a device is required, it should only be operated when the drive is in a STOP state. If there is potential for

the device to be opened while the drive is running, the drive must be programmed for COAST TO STOP (see

Parameter 65 - COAST STOP), and an auxiliary contact on the device must be interlocked with the drive's run

circuit. This will give the drive a stop command at the same time the device opens, and will not allow the

drive to start again until the devide is closed.

24

Page 26

11.0 QC SERIES POWER WIRING DIAGRAM

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

THREE PHASE

AC MOTOR

T1 T2 T3

GND

L1L2L3

GND GND

DISCONNECT

MEANS

(REQUIRED)

FUSED INPUT

VOLTAGE

WARNING!

Do not connect incoming AC power to output terminals T1, T2, or T3. Severe damage to the drive will

result.

INSTALL, WIRE, AND GROUND IN ACCORDANCE WITH ALL APPLICABLE CODES.

NOTES:

1. Wire the motor for the proper voltage per the output rating of the drive. Motor wires MUST be run in a

separate steel conduit away from control wiring and incoming AC power wiring.

2. Do not install contactors between the drive and the motor without consulting AC Technology for more

information. Failure to do so may result in drive dam a ge.

3. Remove any existing, and do not install, power factor correction capacitors between the drive and the

motor. Failure to do so will re sult in drive damage.

4. Use only UL and CSA listed and approved wire.

5. Minimum wire voltage ratings: 300 V for 120, 200 and 240 Vac systems, and 600 V for 400, 480, and

590 Vac systems.

6. Input/output wire gauge must be based on a minimum of either 150% (QC1000/2000) or 125%

(QC3000) of the rated input/output current of the drive, and a minimum 75°C insulation rating. Use

copper wire only.

7. Wire and ground in accordance with NEC or CEC, and all applicable local codes.

25

Page 27

12.0 INITIAL POWER UP

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Hazard of electrical shock! Disconnect incoming power and wait three minutes before servicing drive.

Capacitors retain charge after power is remov e d .

Before attempting to operate the drive, motor, and driven equipment be sure all procedures pertaining to

installation and wiring have been properly followed. Before powering up the drive for the first time, wire

the drive for operation via the keypad (see Section 13.0 - KEYPAD CONTROL), then follow the

procedures below.

Severe damage to the drive can result if it is operated after a long period of storage or inactivity without

reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding one year (due to storage,

etc), the electrolytic DC bus capacitors within the drive can change internally, resulting in excessive

leakage current. This can result in premature failure of the capacitors if the drive is operated after such a

long period of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long period of inactivity, apply

input power to the drive for 2 hours prior to actually operating the drive/motor system.

Disconnect the driven load from the motor. Verify that the drive input terminals (L1, L2, and L3) are

wired to the proper input voltage per the nameplate rating of the drive.

WARNING!

WARNING!

WARNING!

Incoming AC power MUST NOT be connected to output terminals T1, T2, and T3! Do not cycle input

power to the drive more than once every two minutes.

Energize the incoming power line. The LCD display should light and flash TESTING and the voltage

and horsepower rating of the drive. The display should then show the following:

STOP 20.00 HZ

0% LOAD FWD KEY

This display in dicates that the drive is stopped, the present speed setpoint is 20.00 Hz, there is no load on

the drive (because it is stopped), forward rotation is selected, an d speed contr ol is from the keypad. If the

display does not appear, remove the incoming power, wait three minutes for the bus capacitors to

discharge, and verify correct installation and wiring. If the wiring is correct, re-apply incoming power

and note the display for drive status. If the display still does not appear, refer to Section 20.0 TROUBLESHOOTING, or call the factory for assistance. If th e drive powers up correctly, follow the

procedure given below to check the motor rotation:

26

Page 28

1. Use the DOWN arrow key to decrease the speed setpoint to the minimum value allowed (0.50 Hz if

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Parameter 61 - MI NIMUM FREQ h a s not been cha nged).

2. Press the START key. The drive should indicate RUN, but if the speed setpoint is 0.50 Hz, the motor

may not rotate. Press the UP arrow key to increase the speed setpoin t until t h e motor starts to rotate.

3. If th e motor is spinning in the wrong direction, press the STOP key, remove power from the drive,

wait three minutes for the bus capacitors to discharge, and swap any two of the motor wires connected

to T1, T2, and T3.

NOTE: The dr ive is phase insen sitive with respect to incoming line voltage. Th erefore, to change the

motor rotation, the phasing must be swapped at the drive output terminals or at the motor.

27

Page 29

13.0 KEYPAD CONTROL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The d rive ca n be operated by the keypa d ( local) , by contr ol devices wi red to the t ermi nal stri p (remote) , by

serial communications, or by a combination of the terminal strip and either the keypad or serial

communications. The drive should be first operated from the keypad during initial start up. Refer to

Sections 14.0 - CONTROL WIRING, and 18.0 - DESCRIPTION OF PARAMETERS for information on

remote operation.

13.1 SETTING THE DRIVE FOR KEYPAD CONTROL

To operate by keypad control, three terminals on the main control board need to be closed to common.

Refer to the terminal strip diagram below:

15A25D5B 6 7 10B 2 22 2321

0

1. Close TB-1 to TB-2 (common) to de-activate the remote STOP in put. The remote STOP function is

always active, even in the LOCAL mode.

2. Close TB-7 to TB-2 t o select LOCAL ( k eypa d control) m od e.

3. Close TB-22 to TB-2 to de-activate the emergency stop (E-stop) input. The E-stop function is always

active, even in LOCAL mode.

13.2 KEYPAD FUNCTIONS IN LOCAL MODE

START/STOP Press the START key to start the drive, and press the STOP key to stop the

drive.

NOTE: The STOP key is active in both local and remote mode.

SPEED CONTROL The speed setpoint can be changed using either th e UP and DOWN arrow keys,

or the numeric keys. Use th e arrow keys to scroll to the desired speed setpoint,

or use the numeric keys to directly input the speed setpoint. When using the

arrow keys, the drive will begin accelerating or decelerating (if the drive is

run ni ng) as th e speed set poin t is bein g cha nged. If th e num eric keys ar e used

however, the new setpoint will not take effect until the ENTER key is pressed.

JOG To enter the keypad jog mode, press the JOG key while holding down the

STOP key, and then release both keys. "JOG" will appear in the speed

reference portion of the display. The drive will now jog when the JOG button

is pressed. The jog speed is determined by Parameter 19 - JOG SPEED. Press

any key other th an JOG to exit the jog mode.

28

Page 30

FORWARD/REVERSE To change rotation direction, press the FWD/REV key and then press the

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

ENTER key.

NOTE: Parameter 66 - FWD/REV must be set to FWD + REV for this key to

be active. The factory default setting is FWD ONLY.

SPEED REFERENCE To tog gle bet ween MANUAL s peed con tr ol an d AUTOMAT IC speed cont rol ,

press the AUTO/MAN key and then press ENTER.

NOTE: Parameter 67 - AUTO/MANUAL SEL must be set to

AUTO/MANUAL SPEED or AUTO/MANUAL LOCAL for this key to be

active. See Section 14.0 - CONTROL WIRING for information on automatic

speed r eferences.

CLEARING ERRORS Press the CLEAR key to clear any errors made wh ile entering data.

13.3 QC SERIES DISPLAY (NORMAL)

The following diagram illustrates the normal QC Series display when the drive is in the STOP mode:

DRIVE

STATUS

SPEED

SETPOINT

SPEED

UNITS

STOP 20.00 HZ

0% LOAD FWD KEY

PERCENT

LOAD

Th e disp lay sh own above in di cate s tha t th e dri ve is st opped , t he pr esen t s peed s etpoi nt is 20 Hz, t he re i s

no loa d (because it i s stopped), t he forward directi on is selected, a nd th e speed r eference sour ce is t he

keypad.

The display below shows the drive in the RUN mode. Th e drive is operating at 20 Hz, and there is now a

load on the motor. All other indications remain the same. See the tables below for the possible DRIVE

STATUS and SPEED REFERENCE SOURCE indicat i ons.

DRIVE

STATUS

DIRECTION

SPEED

SETPOINT

SPEED

REFERENCE

SOURCE

SPEED

UNITS

RUN 20.00 HZ

30% LOAD FWD KEY

PERCENT

LOAD

DIRECTION

29

SPEED

REFERENCE

SOURCE

Page 31

The following tables describes the possible DRIVE STATUS and SPEED REFERENCE SOURCE

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

indications that can appear on the display:

DRIVE S T A T US I NDI CA T IONS

DISPLAY

DISPLAY DESCRIPTION

DISPLAYDISPLAY

STOP D r ive i s in STOP mode - N o outpu t to t he m otor .

RUN Drive is in R U N mode and i s wit hi n +/- 3 H z of the speed s etpoi nt.

RUN @0 Dr i ve is in RUN m ode , wi th a 0 H z s p eed s e tpoin t.

ACCEL D r i ve is ac c eleratin g to the s peed setpoint.

DECEL D r i ve is dec el er ati ng to the s pee d set point . If DEC EL i s f las hi ng, the drive has

stopped dec e l er ati ng to av oid a HI BU S VOLTS faul t.

FAULT Drive has t r i pped into a protec ti ve FAULT. If the f ault conditi on has passed,

pressing the STOP key, or openi ng TB-1 to TB- 2 w ill clear the fault and r eturn

the dr i ve t o the ST OP mod e.

DESCRIPTION

DESCRIPTIONDESCRIPTION

FAULT The programmed nu m ber of restarts w er e attem pted, but wer e un successful.

LOCKOUT Requi re s a manual r eset as de sc r i bed above for F AU L T .

BRAKE DC BR AKE is energi z e d.

C LIM Drive i s in CUR RENT LI M IT due to an overl oa ded m otor, or AC C EL i s t o o fas t.

SPEED REFERENCE SOURCE INDI CA T IONS

DISPLAY

DISPLAY DESCRIPTION

DISPLAYDISPLAY

KEY KEYPAD - U P and D OWN arrow key s or di r ect nu m eri c entry .

JOG JOG: C los e T B- 12D to TB-2 to JOG, open to ST OP. Jog speed i s s et by

Parameter 19 - JOG SPEED.

POT SPEED POT at T B- 5A.

A-C AUTO - C URR EN T: 4- 20 m A at T B-5B.

DESCRIPTION

DESCRIPTIONDESCRIPTION

A-V AUTO - VOLTAGE: 0-10 VD C at T B-5D.

S-1 t o S-7 PRESET SPEED #1 - 7: Param eter s 11- 17 .

30

Page 32

13.4 QC SERIES DISPLAY (ACTUAL SPEED)

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The following diagram sh ows the QC Series display in the ACTUAL SPEED mode. This mode can be

activated by Parameter 133 - DISPLAY FUNCTION. In stead of displayin g the drive status, or the word

LOAD, the ACT UAL SPEED displa y will indicate the actual running speed, and whether the drive is in

LOCAL (LOC), REMOTE (REM), or SERIAL (SER) control mode.

13.5 MONITOR MODE

The QC Series MONITOR MODE allows the user to display four functions: TIME SINCE START,

TOTAL RUN TIME, TOTAL KW HOURS, and HOURS TIL MAINT.

TIME SINCE START displays the time that the drive has been run ning since the last start command.

This will reset each time the drive is given a start command, or if power is removed from the drive.

TOTAL RUN TIME displays the total elapsed time that the drive has operated since it was started the first

time. This value is non-resettable.

TOTAL KILOWATT HOURS displays the total elapsed kilowatt-hours, calculated from the total run

time, motor current, and voltage. Parameter 130 - DRIVE POWER must be set to th e drive s horsepower

rating for this function to be enabled. This value is non-resettable.

DRIVE

ST ATUS

SPEED

SETPOINT

SPEED

UNITS

20.00 20.00 HZ

30% LOC FWD KEY

PERCENT

LOAD

CONTROL

MODE

DIRECTION

SPEED

REFERENCE

SOURCE

HOURS UNTIL MAINTENANCE displays the time remaining until the MAINTENANCE TARGET

(Parameter 132) is reached. This parameter can be used to indicate when maintenance needs to be

performed on the driven equipment (gear box lubrication, replace belts, etc). Parameter 132 MAINTENANCE TARGET must be set to a val u e greater t han zero for th i s function t o be enabled.

To view the MONITOR MODE displays, press the ENTER key while viewing the operation display.

Pressing the ENTER key on ce will display TIME SINCE START. Pressing ENTER a second time will

display TOTAL RUN TIME, etc. Pressing ENTE R whi l e viewin g HOURS UNTIL MAINTENANCE will

return the user to the normal operation display. MONITOR MODE examples are shown below:

TIME SINCE START

12 : 45 HR

TOTAL KW - HOURS

49345 KWH

TOTAL RUN TIME

4500 : 55 HR

HOURS TIL MAINT

750 HR

31

Page 33

13.6 QC SERIES FAULT DISPLAY

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

When the QC Series dr ive faults, the normal oper ation display will change to a fault display that in dicates

the type of fault, the drive status at the time of the fault, and the time at which the fault occurred. This

display is part of th e MONITOR MODE (see Section 13.5), but only appears if a fault condition exists.

An example of the fault display is shown below:

Th e fau lt di spl ay above in di cat es t h at th e d ri ve t ri pp ed on a P OWE R LOSS fa ul t t h at occ ur r ed a t 837:29

on the run time meter, and the drive was in a RUN state when it faulted. Refer to Section 20.0 TROUBLESHOOTING for a list of the possible fault messages that can appear on the display.

TIME ST AMP

F AULT: 837 : 29

POWER LOSS RUN

FAUL T MESSAGE DRIVE STA TUS

There are three meth ods of cl eari ng a F AULT :

1. Press the STOP key on the keypad.

2. Open the STOP input at TB-1 on the terminal strip.

3. Remove power from the unit, wait one minute, then re-apply power.

NOTE: A FAULT can only be cleared if the condition that caused the fault has been corrected. For

example, if th e drive trips on a LOW VOLTS fault due to low input power, the fault cannot be reset until

the input power has returned to the proper level.

32

Page 34

14.0 CONTROL WIRING

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

14.1 GENERAL

14.1.1 KEYPAD CONTROL

The drive can be controlled by the keypad or by control devices wired to the terminal strip. To operate the

drive from the keypad, refer to Section 13.0 - KEYPAD CONTROL.

14.1.2 CONTROL WIRING VS. POWER WIRING

External control wiring MUST be run in a separate conduit away from all other input and output power

wiring. If control wiring is not kept separate from power wiring, electrical noise may be generated on the

control wiring that could cause erratic drive behavior, possibly resulting in damage to the drive. Use twisted

wires or shielded cable grounded at the drive chassis ONLY.

14.1.3 TB-2: CIRCUIT COMMON

The TB-2 terminals are used as circuit common for the start/stop, forward/reverse, jog, local/remote, analog

input, analog output, and E-stop functions. There are two TB-2 terminals available on the terminal strip, and

they are internally connected to each other on the main control board. If necessary TB-2 may be connected to

chassis ground.

14.1.4 SURGE SUPPRESSION ON RELAYS

Current and voltage surges and spikes in the coils of contactors, relays, solenoids, etc, near or connected to the

drive, can cause erratic drive operation. Therefore, a snubber circuit should be used on coils associated with

the drive. For AC coils, snubbers should consist of a resistor and a capacitor in series across the coil. For DC

coils, a free-wheeling or flyback diode should be placed across the coil. Snubbers are typically available from

the manufacturer of the device.

14.2 REMOTE CONTROL

14.2.1 REMOTE MODE SELECTION

To select the REMOTE mode, DO NOT close terminal TB-7 to TB-2. Closing TB-7 to TB-2 will select the

LOCAL mode.

14.2.2 TWO-WIRE START/STOP CONTROL

A two-wire (maintained contact) start/stop circuit can be accomplished by one of two methods on the QC

Series drive. Follow the appropriate procedure listed below:

FORWARD ROTATION ONLY

1. Select REMOTE mode (see above).

2. Connect a jumper between TB-12A and TB-2 to provide a permanent START command to the drive.

33

Page 35

3. Connect a jumper between TB-12B and TB-2 to select FORWARD rotation.

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

4. Wire a normally open maintained contact between TB-1 and TB-2. Close this contact to START the

drive, and open this contact to STOP the drive.

FORWARD an d REVERSE ROT A TIO N

1. Selec t REM O TE mode (see a bove ).

2. Program Parameter 66 - ROTATION to FWD + REV to allow rotation in both directions.

3. Connect a jumper between TB-12A and TB-2 to provide a permanent START command to the drive.

4. Select the desired rotation by closing the appr opriate terminal (TB-12B for forward, or TB-12C for

reverse) to TB-2. This can be don e with a toggle switch or equivalent circuit.

5. Wire a normally open maintained contact between TB-1 and TB-2. Close this contact to START the

drive, and open this contact to STOP the drive.

Refer to Section 15.2 for a diagram illustrating a typical two-wire start/stop control.

14.2.3 ALTERNATE START/STOP CONTROL METHOD

This method uses the direction selection contacts (TB-12B and TB-12C) to start and stop the drive. This

is used when only two dry contacts are available and th e user needs to con trol start/stop and direction

functions.

1. Selec t REM O TE mode (see a bove ).

2. Connect a jumper between TB- 1 and TB-2 to de-activate the S T O P inp u t.

3. Connect a jumper between TB-12A and TB-2 to provide a permanent START command to the drive.

4. ENABLE Parameter 70 - AUTO START, or Parameter 71 - RESTART ON FAULT. This will put

the drive into the RUN mode when power is applied. RUN will be flashing and three flashing

question mar ks (???) will appear in th e DIRECTION portion of the display.

5. Wire a normally open maintained con tact between TB-12B and TB-2. Close this contact to START

the drive in FORWARD, and open this contact to STOP the drive.

6. Wire a normally open maintained contact between TB-12C and TB-2. Close this contact to START

the drive in REVERSE, and open this contact to STOP the drive.

NOTE: When a connect ion is mad e between TB-2 an d eit her TB -12B (for war d), or TB- 12C ( rever se) t o

start the drive, the flashing question marks will be replaced by the selected direction indication (FWD or

REV), and the flashin g RUN will change to ACCEL as the drive accelerates t o th e speed set poin t. Wh en

the con nection is opened to stop the drive, the DRIVE STATUS indication will change to DECEL, and

the DIRECTION indication will change back to the three flashing question marks. When the drive

reaches the end of the deceleration ramp, the flashing question marks will remain, and the DRIVE

STATUS indication will return to the flashin g RUN.

Refer to Section 15.3 for a diagram illustrating the alternate start/stop control.

34

Page 36

14.2.4 THREE-WIRE START/STOP CONTROL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

A three-wire (momentary contacts) start/stop circuit can be accomplished by following the appropriate

procedure listed below:

FORWARD ROTATION ONLY

1. Selec t REM O TE mode ( s e e above).

2. Conn ect a jump er between TB-12B a nd T B- 2 to select the FO RWARD d irection .

3. Wire a n ormally closed momen tary con tact between TB-1 and TB-2. This is the STOP input. Open

this contact to STOP the drive.

4. Wire a normally open momentary contact between TB-12A an d TB-2. Close this contact to START

the drive.

FORWARD an d REVERSE RO TAT ION

1. Selec t REM O TE mode ( s e e above).

2. Program Parameter 66 - FWD / REV to FWD + REV.

3. Select the desired rotation by closing the appropriat e termina l (TB-12B for forward, or TB-12C for

reverse) to TB-2. This can be done with a toggle switch or equivalent circuit.

4. Wire a normally closed momentary con tact between TB-1 and TB-2. Open this contact to STOP the

drive.

5. Wire a normally open momentary contact between TB-12A an d TB-2. Close this contact to START

the drive.

NOTE: If the opposite direction is selected while the drive is running, the drive will deceler ate t o 0 Hz

and then accelera te back to t he speed s etpoint in the opposite directi on.

Refer to Section 15.4 for a diagram illustrating a typical three-wire star t/stop control.

14.2.5 ANALOG SPEED REFERENCE SI GNALS

The drive allows for three analog speed reference inputs: a speed potentiometer (10 kilohm), 0-10 VDC,

or 4-20 mA.

SPEED POT Connect the wiper to terminal TB-5A, and connect the high and low end leads to

terminals TB-6 and TB-2, respectively.

0-10 VDC Wire the positive to terminal TB-5D and the negative to terminal TB-2.

4-20 mA Wire the positive to terminal TB-5B and the negative to terminal TB-2.

The input impedance of terminal TB-5A (speed pot input) is 100 kilohms, terminal TB-5B (4-20 mA

input) is 100 Ohms, and termin a l TB-5D (0-10 VDC) is 200 kilohms. Termi nal TB-2 is circuit common.

35

Page 37

14.2.6 SPEED REFERENCE SELECTION