Page 1

MCH Series

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Installation and Operation Manual

Page 2

1.0 GENERAL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

1.1 PRODUCTS COVERED IN THIS MANUAL

This manual covers the AC Tech MCH Variable Frequency Drive and optional

configurations. The main focus of this manual is the standard drive. Refer to Appendix

A for the Bypass option, or Appendix B for the Option Box.

1.2 PRODUCT CHANGES

AC Technology Corporation reserves the right to discontinue or make modifications to

the design of its products and manuals without prior notice, and holds no obligation to

make modifications to products sold previously. AC Technology Corporation also holds

no liability for losses of any kind which may result from this action. Instruction manuals

with the most up-to-date information are available for download from the AC Tech website

(www.actechdrives.com).

1.3 WARRANTY

AC Technology Corporation warrants the MCH Series AC motor control to be free of defects

in material and workmanship for a period of eighteen months from the date of sale to the user,

or two years from the date of shipment, which ever occurs first. An MCH Series control, or

any component contained therein, which under normal use, becomes defective within the

stated warranty time period, shall be returned to AC Technology Corporation, freight prepaid,

for examination (contact AC Technology Corporation for authorization prior to returning any

product). AC Technology Corporation reserves the right to make the final determination as to

the validity of a warranty claim, and sole obligation is to repair or replace only components

which have been rendered defective due to faulty material or workmanship. No warranty

claim will be accepted for components which have been damaged due to mishandling,

improper installation, unauthorized repair and/or alteration of the product, operation in

excess of design specifications or other misuse, or improper maintenance. AC Technology

Corporation makes no warranty that its products are compatible with any other equipment,

or to any specific application, to which they may be applied and shall not be held liable for

any other consequential damage or injury arising from the use of its products.

This warranty is in lieu of all other warranties, expressed or implied. No other person,

firm or corporation is authorized to assume, for AC Technology Corporation, any other

liability in connection with the demonstration or sale of its products.

1.4 RECEIVING

Inspect all cartons for damage which may have occurred during shipping. Carefully unpack

equipment and inspect thoroughly for damage or shortage. Report any damage to carrier

and/or shortages to supplier. All major components and connections should be examined for

damage and tightness, with special attention given to PC boards, plugs, switches, etc.

1.5 CUSTOMER MODIFICATION

AC Technology Corporation, its sales representatives and distributors, welcome the

opportunity to assist our customers in applying our products. Many customizing options are

available to aid in this function. AC Technology Corporation cannot assume responsibility

for any modifications not authorized by its engineering department.

1

Page 3

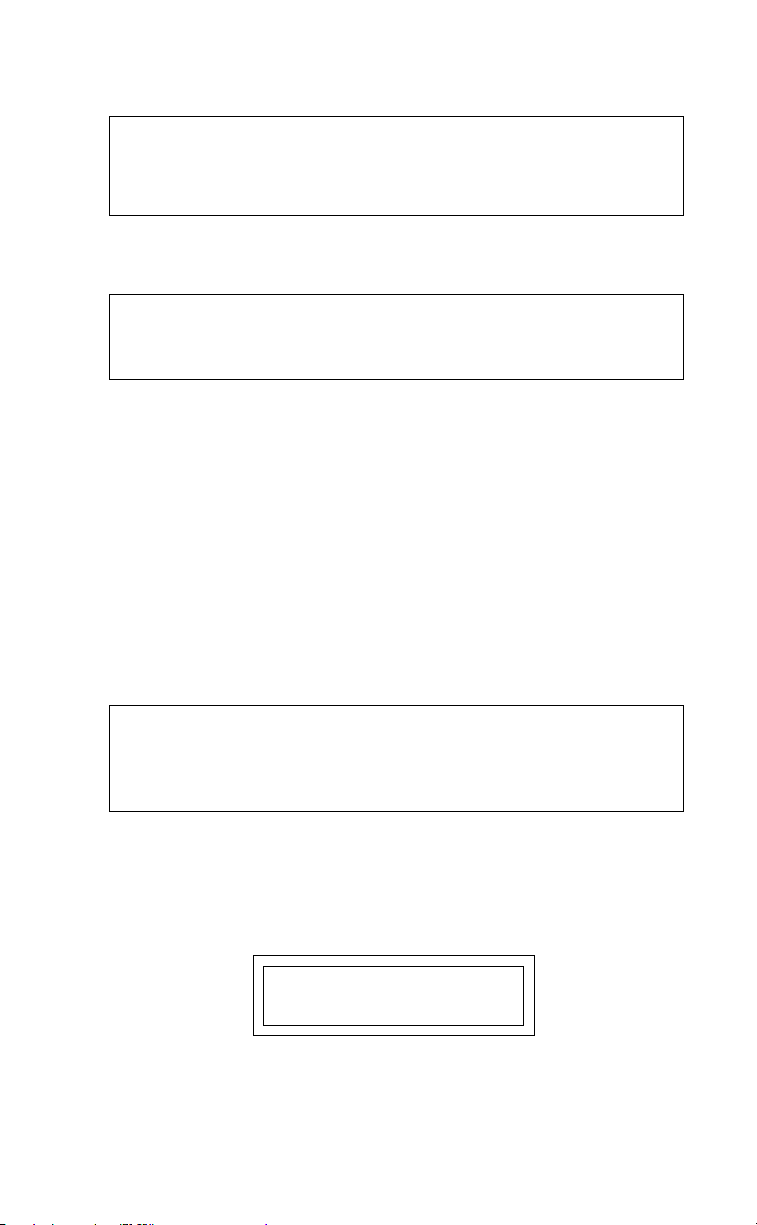

2.0 MCH SPECIFICATIONS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Storage Temperature -20° to 70° C

Ambient Operating Temperature Type 1 (IP 31) -10

(With 2.5, 6, and 8 kHz carrier,

derate for higher carriers)

Ambient Humidity Less than 95% (non-condensing)

Altitude 3300 feet (1000 m) above sea level

without derating

Input Line Voltages 240/200 Vac, 480/400 Vac, & 590/480 Vac

Input Voltage Tolerance +10%, -15%

Input Frequency Tolerance 48 to 62 Hz

Output Wave Form Sine Coded PWM

Output Frequency 0-120 Hz

Carrier Frequency 2.5 kHz to 14 kHz

Frequency Stability + 0.00006% / °C

Efficiency > 97% throughout speed range

Power Factor (displacement) > 0.96

° to 40° C

Service Factor 1.00

Overload Current Capacity 120% of output rating for 60 seconds

Speed Reference Follower 0-10 VDC, 4-20 mA

Control Voltage 15 VDC

Analog Outputs 0 - 10 VDC, or 2 - 10 VDC

Proportional to speed or load

Digital Outputs Form C relay: 2 A at 28 VDC or 120 Vac

Open-collector outputs: 40 mA at 30 VDC

2

Page 4

3.0 MCH MODEL DESIGNATION CODE

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The model number of an MCH Series drive gives a full description of the basic

drive unit (see example below).

EXAMPLE: MH450BH

(MCH, 480 Vac, 5 HP, Type 1 Enclosure, with Additional Form C Relay)

MH 4 50 B H

Series:

MH = MCH Series Variable Speed AC Motor Drive

Input Voltage:

2 = 240/200 Vac (For 208, 230, and 240 Vac; 50 or 60 Hz)

4 = 480/400 Vac (For 380, 415, 440, 460 and 480 Vac; 50 or 60 Hz)

5 = 590/480 Vac (For 440, 460, 480, 575 and 600 Vac; 50 or 60 Hz)

Rating:

10 = 1 HP (0.75 kW) 200 = 20 HP (15 kW) 1000 = 100 HP (75 kW)

20 = 2 HP (1.5 kW) 250 = 25 HP (18.5 kW) 1250 = 125 HP (90 kW)

30 = 3 HP (2.2 kW) 300 = 30 HP (22 kW) 1500 = 150 HP (110 kW)

50/51 = 5 HP (3.7 kW) 400 = 40 HP (30 kW) 2000 = 200 HP (150 kW)

75 = 7½ HP (5.5 kW) 500 = 50 HP (37.5 kW) 2500 = 250 HP (185 kW)

100 = 10 HP (7.5 kW) 600 = 60 HP (45 kW)

150 = 15 HP (11 kW) 750 = 75 HP (55 kW)

Enclosure Type:

B = NEMA 1: General Purpose, vented

C = NEMA 4: Water-tight and Dust-tight

D = NEMA 12: Oil-tight and Dust-tight

E = NEMA 4X: Water-tight, Dust-tight, and Corrosion Resistant (Stainless Steel)

Standard Options:

H = Additional Form C relay circuit board

No character when this type of option is not specified.

NOTE: Drives equipped with Bypass or the Option Box will have a modified

version of this model number format. Not all enclosure types are available when

drives are equipped with Bypass or the Option Box.

3

Page 5

4.0 MCH DIMENSIONS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

NOTE: These dimensions apply to standard MCH drives. Consult the factory

for dimensions of drives equipped with Bypass or the Option Box.

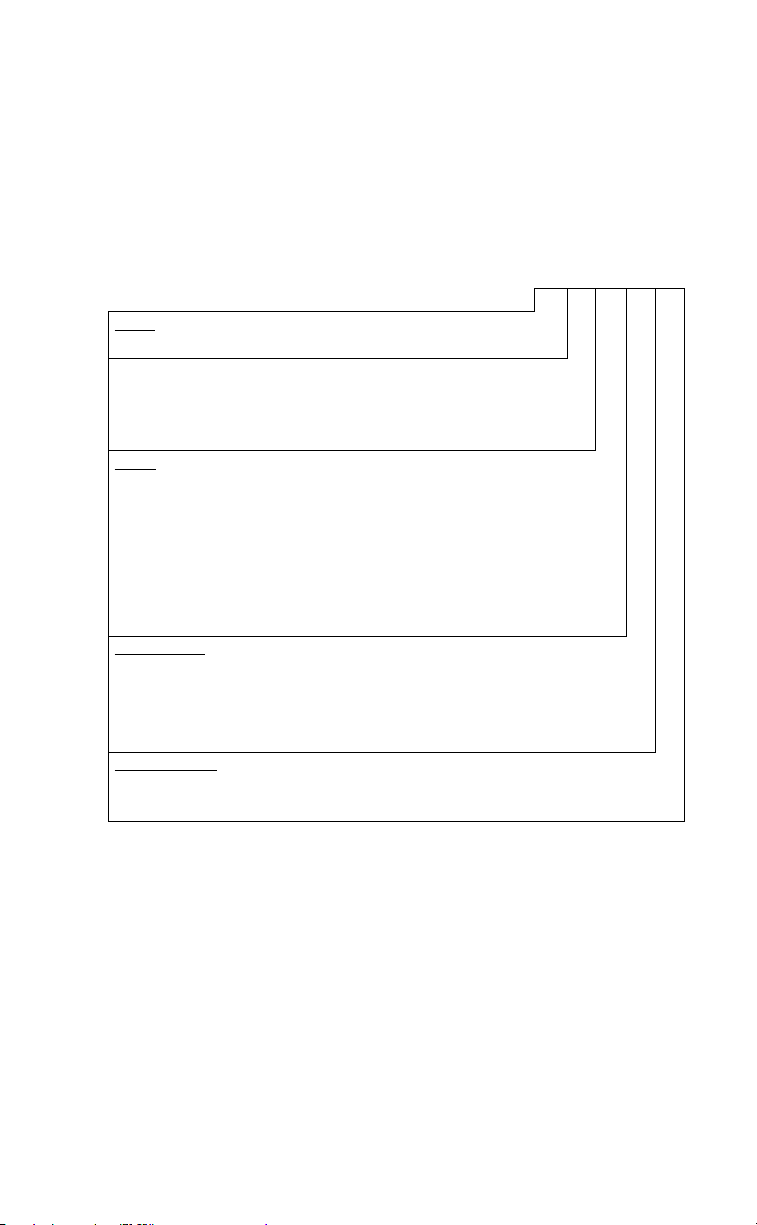

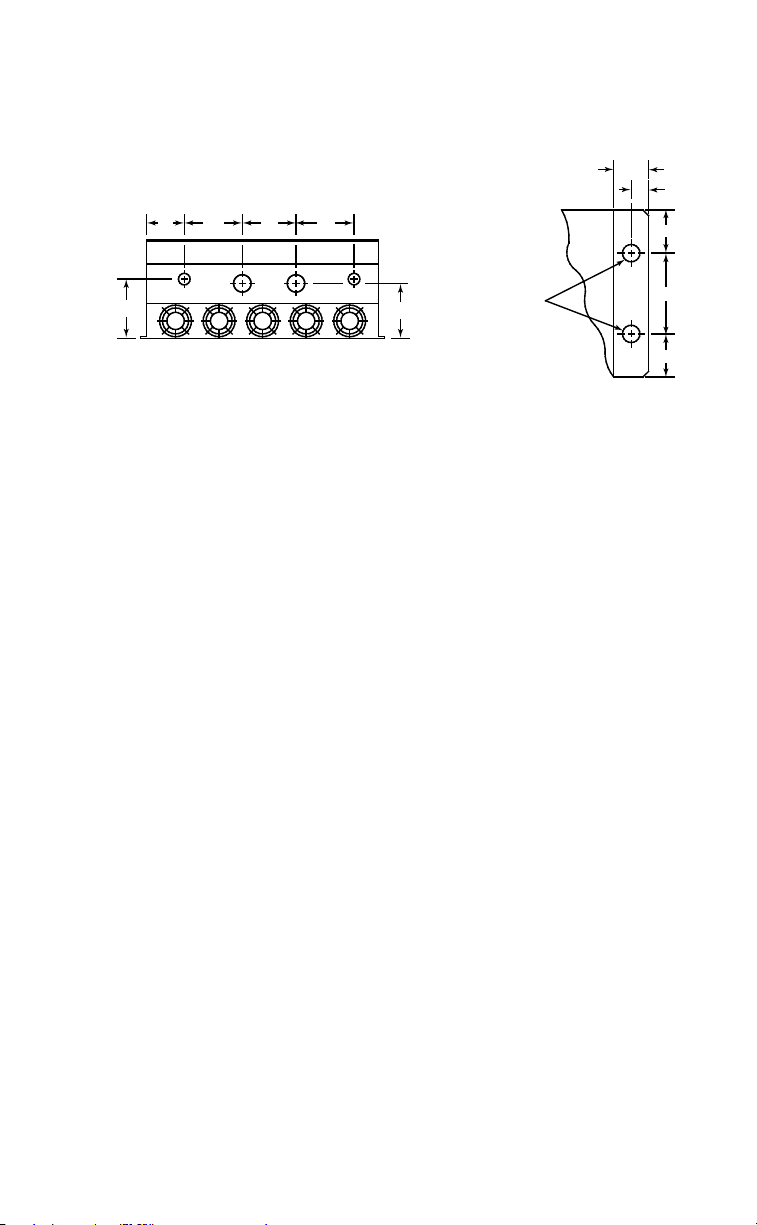

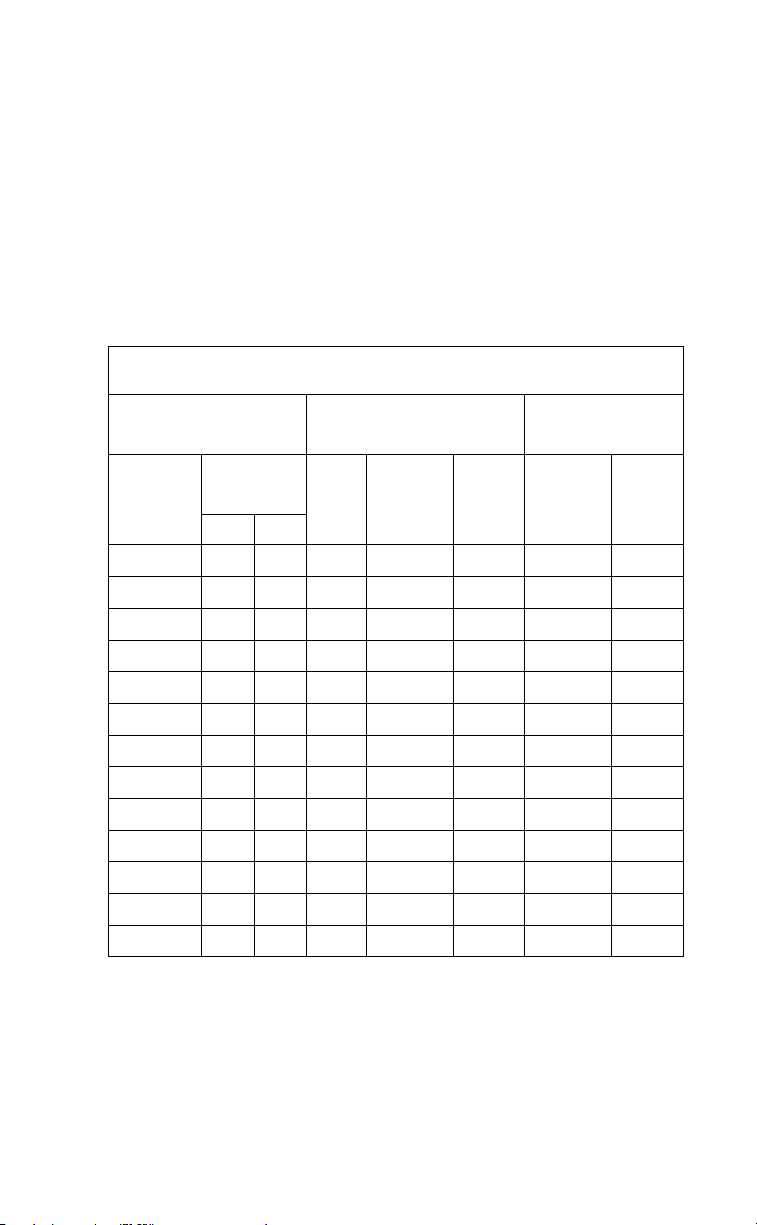

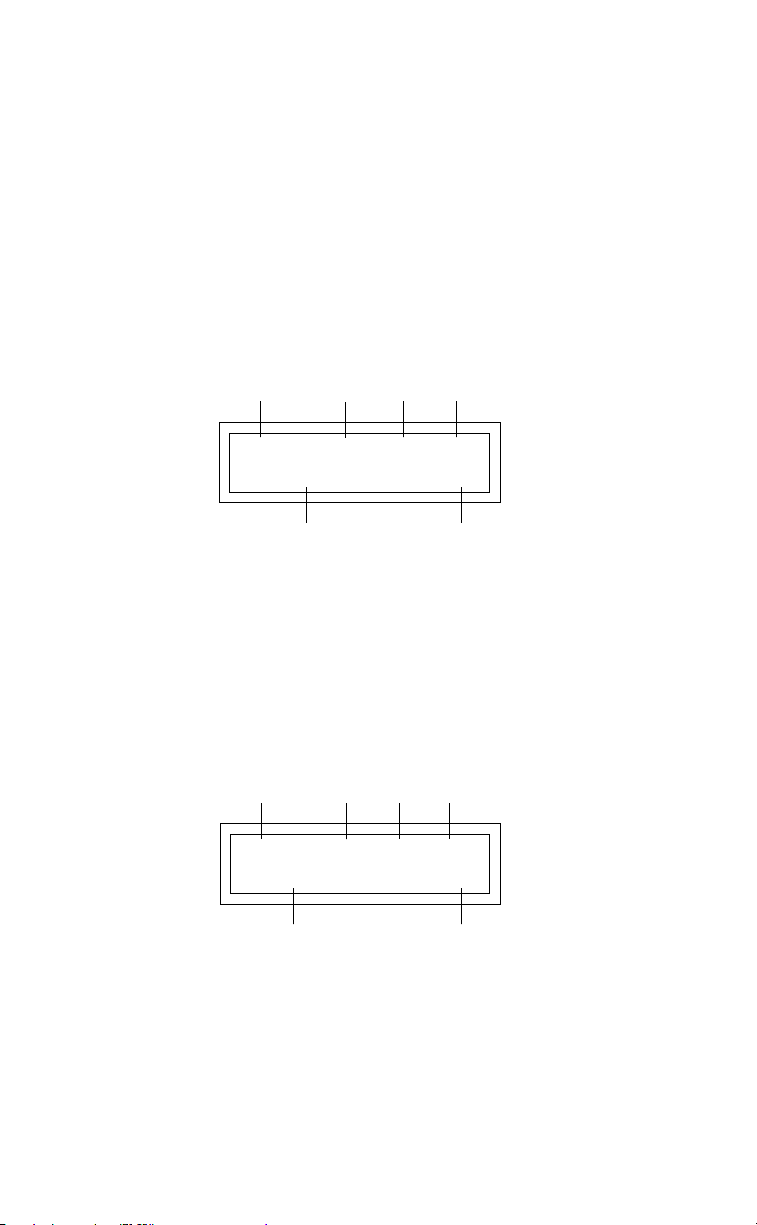

4.1 TYPE 1 DIMENSIONS FOR MODELS RATED UP TO 30 HP AT

240/200 Vac AND 60 HP AT 480/400 Vac AND 590 Vac

W

R

Q Q

P

N

HP

(kW)

(0.75)

(1.5)

(2.2)

(3.7)

(5.5)

INPUT

VOLTAGE MODEL H W D N P Q R S

240 / 200 MH210B 7.50 4.70 4.33 2.35 2.60 1.37 5.50 0.88

1

480 / 400 MH410B 7.50 4.70 3.63 2.35 1.90 1.37 5.50 0.88

590 MH510B 7.50 4.70 3.63 2.35 1.90 1.37 5.50 0.88

240 / 200 MH220B 7.50 6.12 5.12 3.77 3.30 1.37 5.50 0.88

2

480 / 400 MH420B 7.50 6.12 4.22 3.77 2.40 1.37 5.50 0.88

590 MH520B 7.50 6.12 4.22 3.77 2.40 1.37 5.50 0.88

240 / 200 MH230B 7.50 6.12 5.12 3.77 3.30 1.37 5.50 0.88

3

480 / 400 MH430B 7.50 6.12 5.12 3.77 3.30 1.37 5.50 0.88

590 MH530B 7.50 6.12 5.12 3.77 3.30 1.37 5.50 0.88

240 / 200 MH250B 7.88 7.86 5.94 5.13 3.95 1.50 5.88 1.13

5

480 / 400 MH450B 7.50 6.12 5.12 3.77 3.30 1.37 5.50 0.88

590 MH551B 7.88 7.86 5.94 5.13 3.95 1.50 5.88 1.13

240 / 200 MH275B 9.38 7.86 6.84 3.93 4.19 2.00 5.88 1.13

7.5

480 / 400 MH475B 9.38 7.86 6.25 5.13 3.95 1.50 7.38 1.13

590 MH575B 9.38 7.86 6.25 5.13 3.95 1.50 7.38 1.13

Conduit Holes:

S Dia.

0.88" Dia.

S Dia.

Dia. Slot

D

W

U

V

T

Mounting Tab Detail

H

1.00"

R

IF W < 7.86"

T = 0.20"

U = 0.34"

V = 0.19"

IF W = 10.26"

T = 0.28"

U = 0.44"

V = 0.24"

4

Page 6

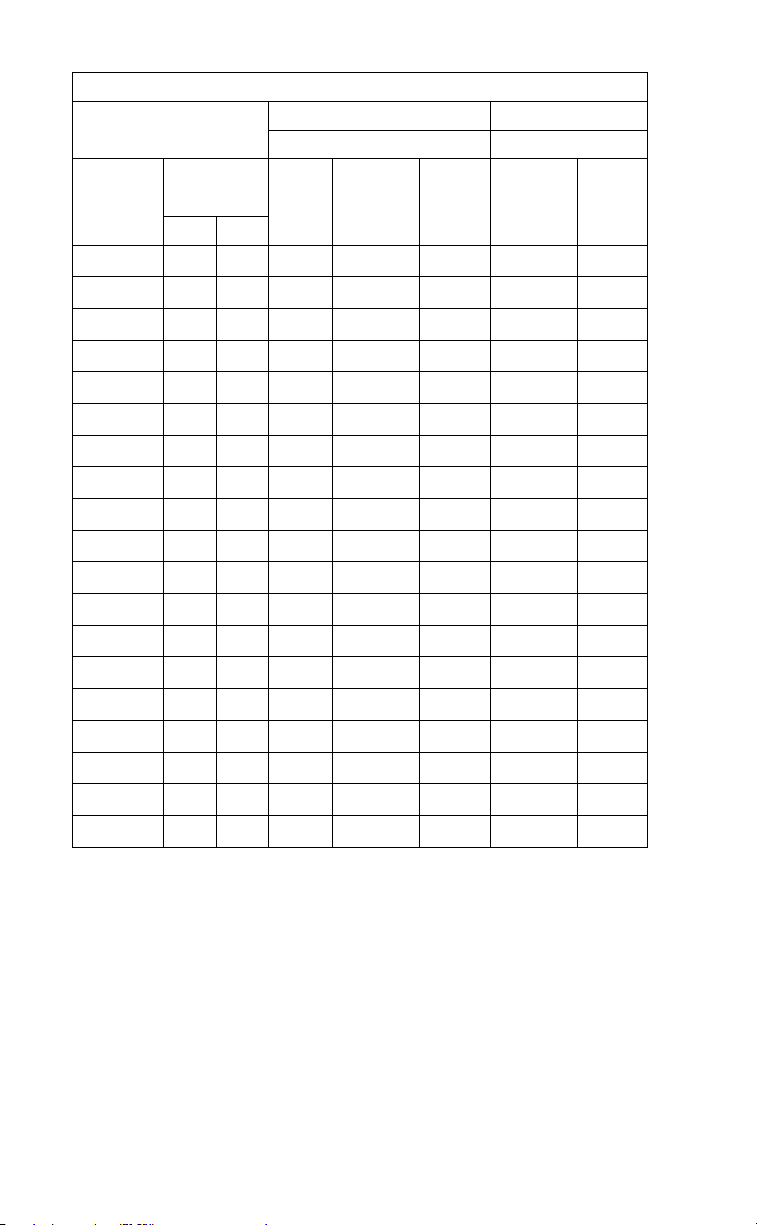

TYPE 1 DIMENSIONS (continued)

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

HP

(kW)

(7.5)

(11)

(15)

(18.5)

(22)

(30)

(37.5)

(45)

INPUT

VOLTAGE MODEL H W D N P Q R S

240 / 200 MH2100B 11.25 7.86 6.84 3.93 4.19 2.00 7.75 1.38

10

480 / 400 MH4100B 9.38 7.86 6.84 3.93 4.19 2.00 5.88 1.13

590 MH5100B 9.38 7.86 7.40 3.93 4.19 2.00 5.88 1.13

240 / 200 MH2150B 12.75 7.86 6.84 3.93 4.19 2.00 9.25 1.38

15

480 / 400 MH4150B 11.25 7.86 6.84 3.93 4.19 2.00 7.75 1.38

590 MH5150B 12.75 7.86 6.84 3.93 4.19 2.00 9.25 1.38

240 / 200 MH2200B 12.75 10.26 7.74 5.13 5.00 2.50 9.25 1.38

20

480 / 400 MH4200B 12.75 7.86 6.84 3.93 4.19 2.00 9.25 1.38

590 MH5200B 12.75 7.86 7.40 3.93 4.19 2.00 9.25 1.38

240 / 200 MH2250B 15.75 10.26 8.35 5.13 5.00 2.50 12.25 1.38

25

480 / 400 MH4250B 12.75 10.26 7.74 5.13 5.00 2.50 9.25 1.38

590 MH5250B 12.75 10.26 7.74 5.13 5.00 2.50 9.25 1.38

240 / 200 MH2300B 15.75 10.26 8.35 5.13 5.00 2.50 12.25 1.38

30

480 / 400 MH4300B 12.75 10.26 7.74 5.13 5.00 2.50 9.25 1.38

590 MH5300B 12.75 10.26 8.25 5.13 5.00 2.50 9.25 1.38

480/400 MH4400B 15.75 10.26 8.35 5.13 5.75 2.50 12.25 1.38

40

590 MH5400B 15.75 10.26 8.35 5.13 5.75 2.50 12.25 1.38

480 / 400 MH4500B 19.75 10.26 8.55 5.13 5.75 2.50 16.25 1.75

50

590 MH5500B 19.75 10.26 8.55 5.13 5.75 2.50 16.25 1.75

480 / 400 MH4600B 19.75 10.26 8.55 5.13 5.75 2.50 16.25 1.75

60

590 MH5600B 19.75 10.26 8.55 5.13 5.75 2.50 16.25 1.75

5

Page 7

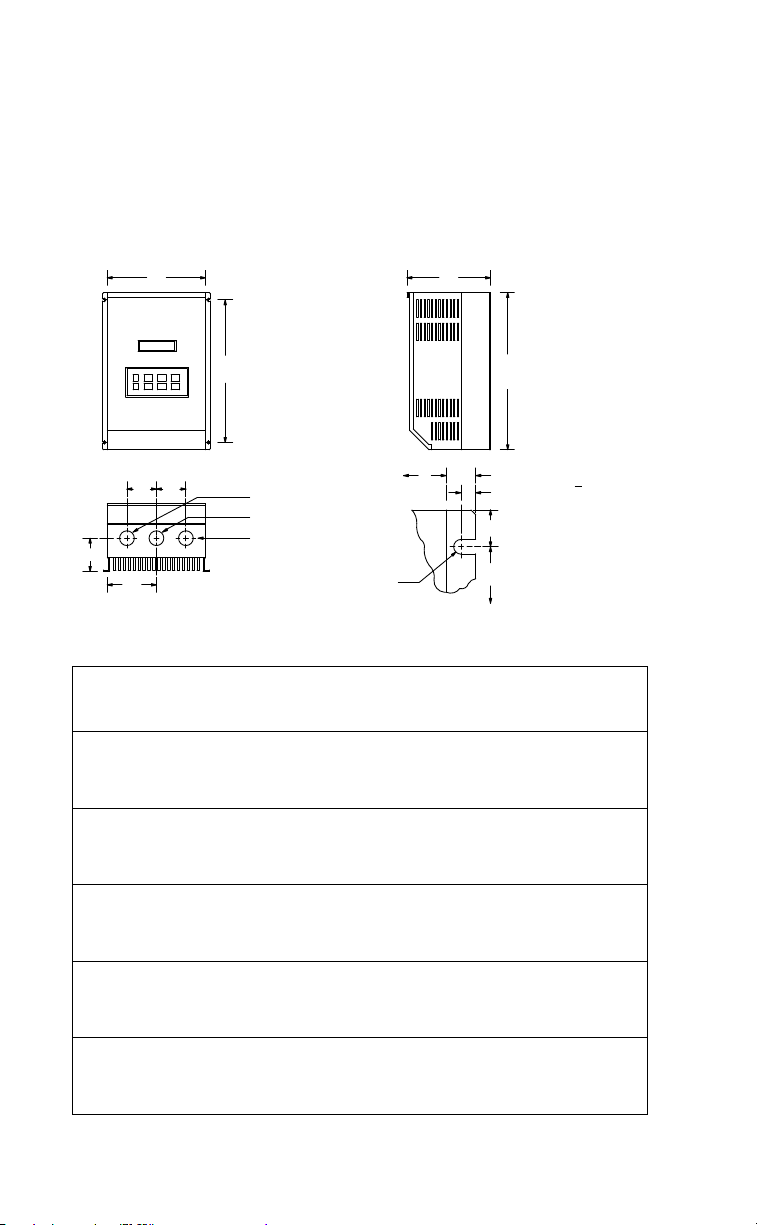

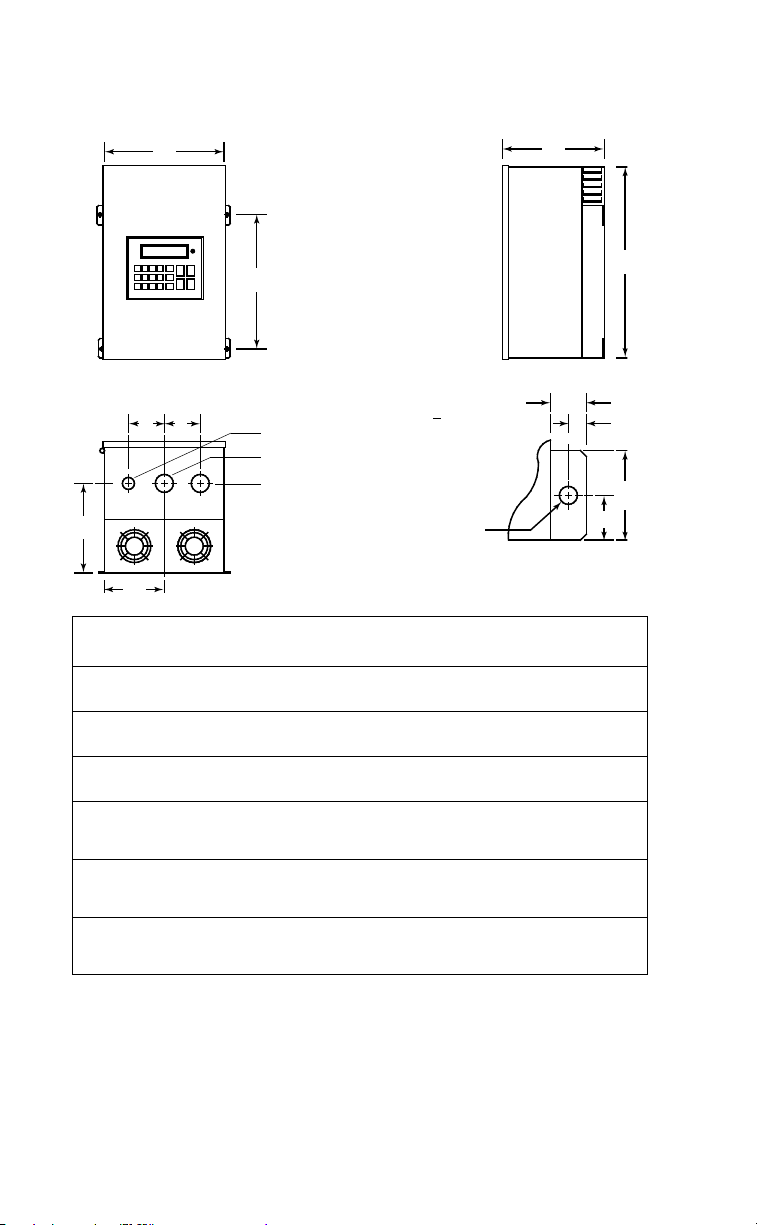

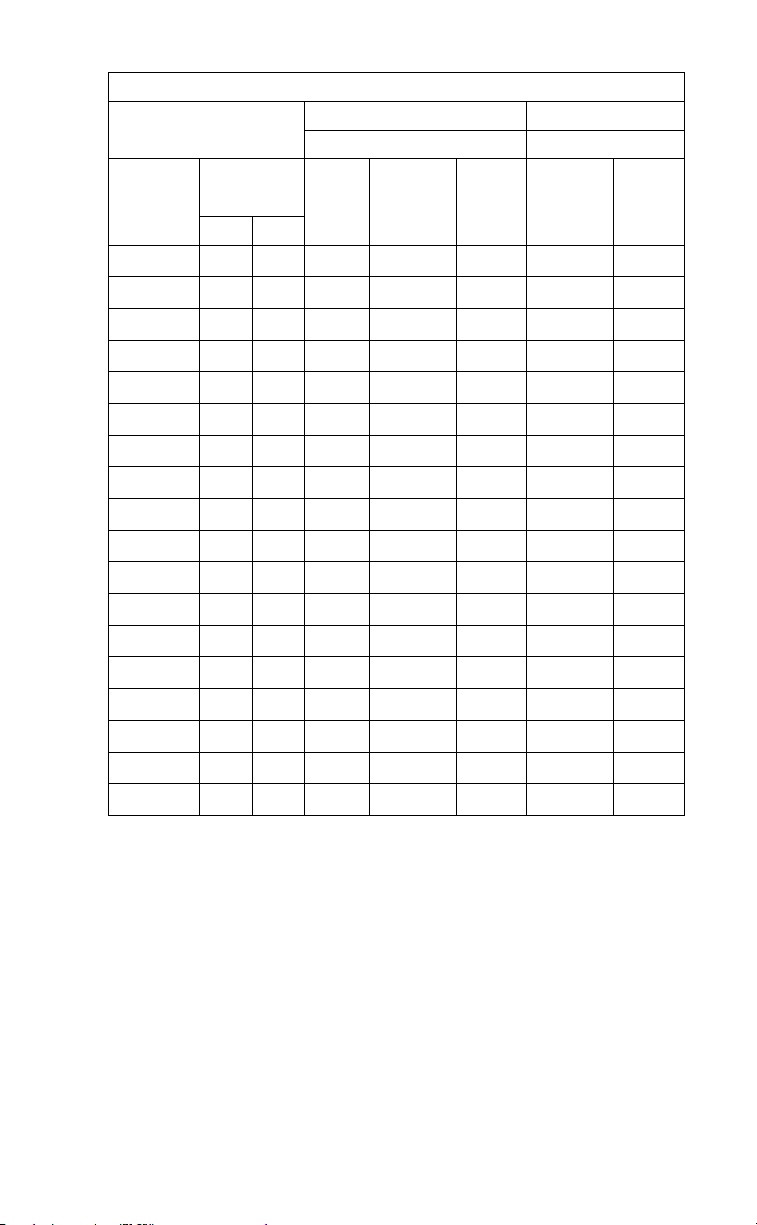

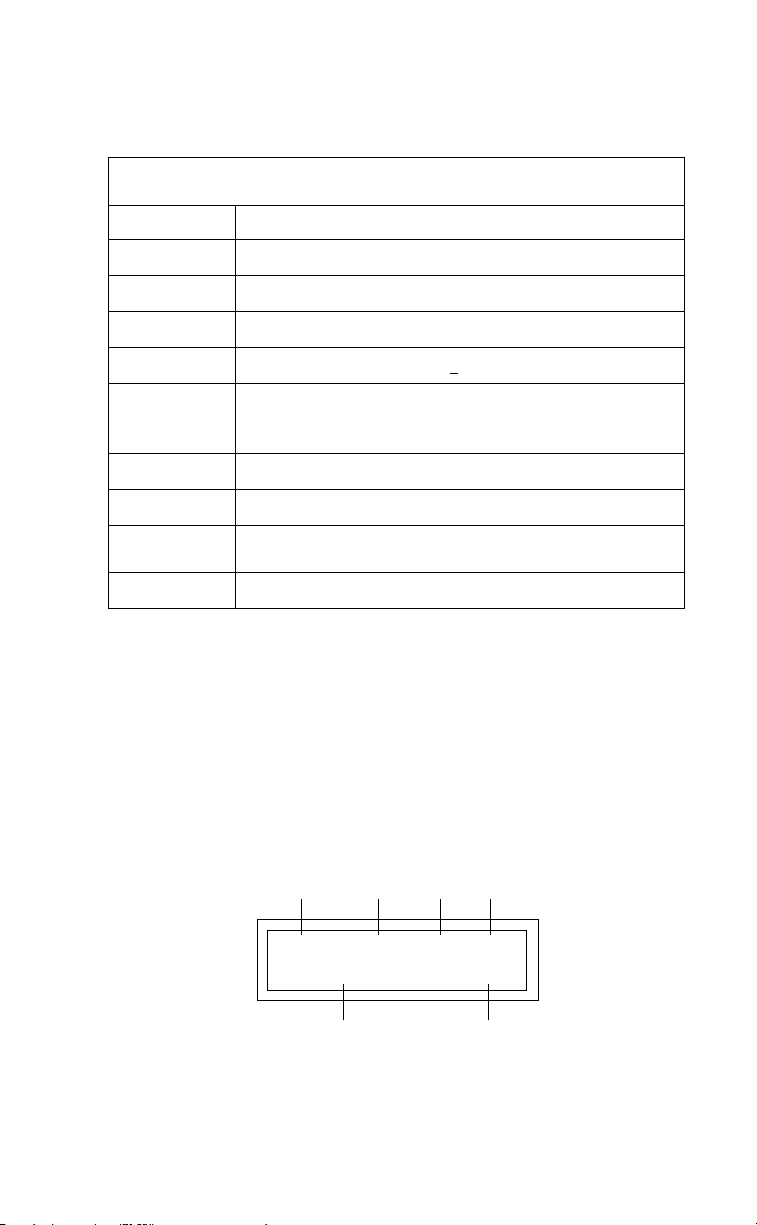

4.2 TYPE 1 DIMENSIONS FOR MODELS RATED ABOVE 30 HP AT

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

240/200 Vac AND 60 HP AT 480/400 Vac AND 590 Vac

W

R

Q

Q

P

N

HP

INPUT

(kW)

VOLTAGE MODEL H W D N P Q R S

40

240 / 200 MH2400B 25.00 13.00 10.50 5.56 6.50 2.62 22.00 1.38

(30)

50

240 / 200 MH2500B 25.00 13.00 10.50 5.56 6.50 2.62 22.00 1.38

(37.5)

60

240 / 200 MH2600B 47.00 16.64 11.85 7.14 6.88 3.12 N/A 1.75

(45)

75

480 / 400 MH4750B 29.00 16.64 11.85 7.14 6.88 3.12 N/A 1.75

(55)

100

(75)

125

(90)

150

(110)

200

(150)

250

(185)

590 MH5750B 29.00 16.64 11.85 7.14 6.88 3.12 N/A 1.75

480/400 MH41000B 29.00 16.64 11.85 7.14 6.88 3.12 N/A 1.75

590 MH51000B 29.00 16.64 11.85 7.14 6.88 3.12 N/A 1.75

480 / 400 MH41250B 29.00 24.42 11.85 11.12 6.50 4.50 N/A 2.50

590 MH51250B 29.00 24.42 11.85 11.12 6.50 4.50 N/A 2.50

480 / 400 MH41500B 29.00 24.42 11.85 11.12 6.50 4.50 N/A 2.50

590 MH51500B 29.00 24.42 11.85 11.12 6.50 4.50 N/A 2.50

480 / 400 MH42000B 29.00 36.66 11.85

590 MH52000B 29.00 36.66 11.85

480 / 400 MH42500B 29.00 36.66 11.85

Conduit Holes:

1.13" Dia.

S Dia.

S Dia.

IF W = 13.00"

T = 0.36"

U = 0.68"

V = 0.31"

IF W > 16.64"

See Mounting

Tab Detail in

Section 4.3

T

Dia.

Mounting Tab Detail

See Section 4.3

D

H

U

V

1.50"

3.00"

6

Page 8

4.3 CONDUIT HOLES AND MOUNTING TAB DETAIL FOR MODELS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

MH42000B, MH52000B, AND MH42500B

P

N

7.25"

Conduit Holes: Large holes = 3.00"

Small holes = 1.13"

N = 7.45"

P = 9.00"

6.50"

Q = 7.00"

0.44"

Dia.

Mounting Tab Detail

Q

P

0.92"

0.43"

1.36"

3.00"

1.36"

7

Page 9

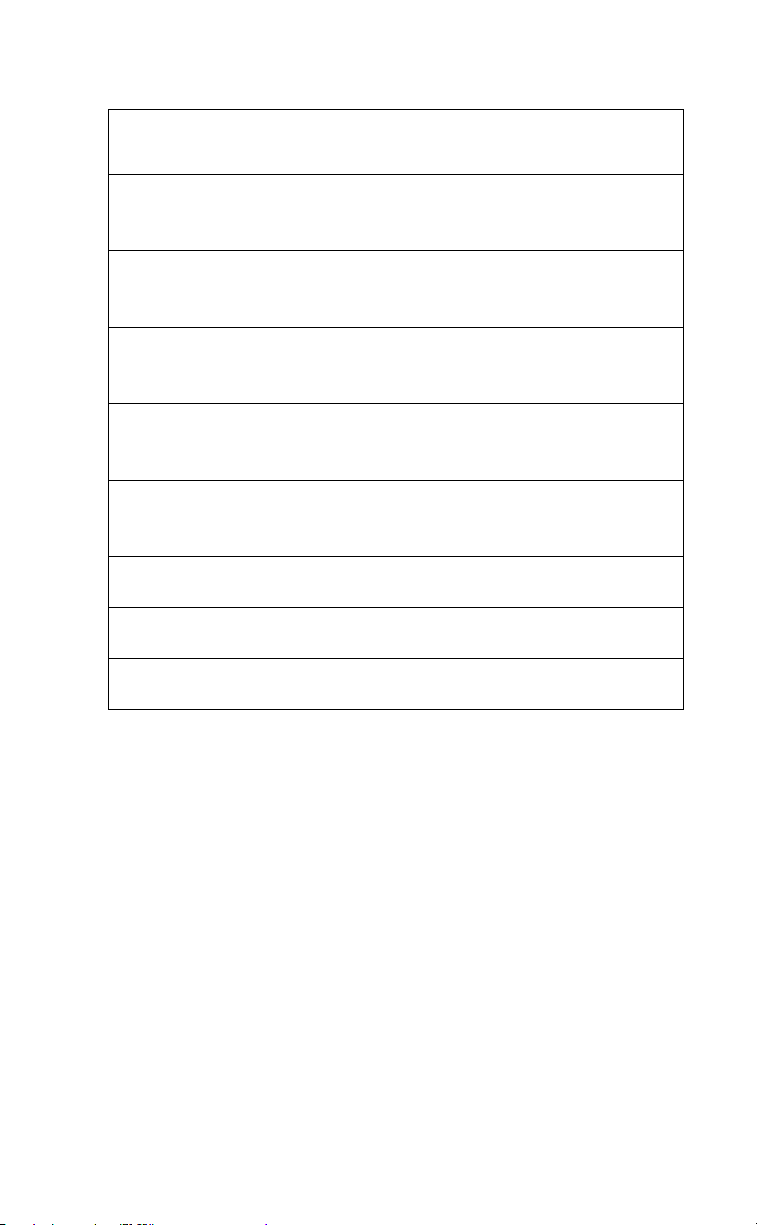

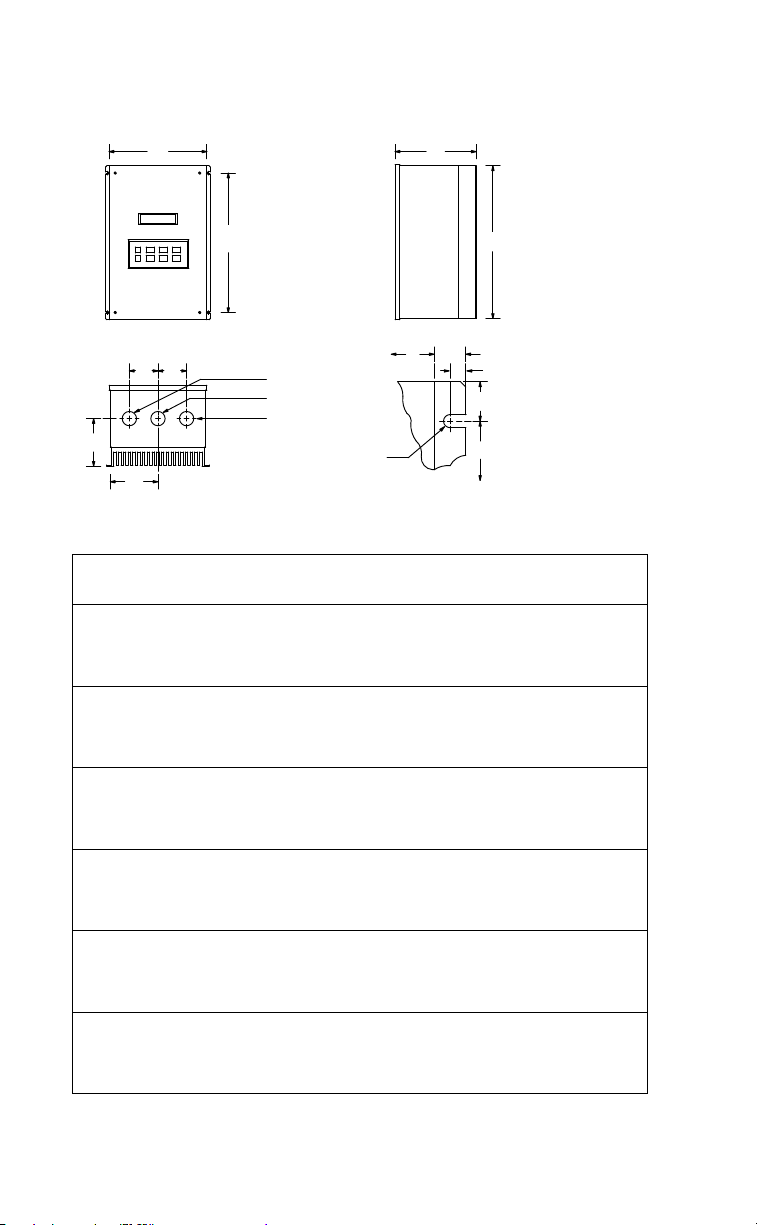

4.4 TYPE 4, 4X, AND 12 DIMENSIONS FOR MODELS RATED UP TO

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

30 HP AT 240/200 Vac AND 60 HP AT 480/400 Vac AND 590 Vac

W

R

Q Q

P

N

HP

INPUT

(kW)

VOLTAGE MODEL* H W D N P Q R S

1 240 / 200 MH210 7.88 6.12 4.35 3.06 2.70 1.37 5.88 0.88

(0.75) 480 / 400 MH410 7.88 6.12 4.35 3.06 2.70 1.37 5.88 0.88

590 MH510 7.88 6.12 4.35 3.06 2.70 1.37 5.88 0.88

2 240 / 200 MH220 7.88 7.86 4.90 4.80 3.25 1.37 5.88 0.88

(1.5) 480 / 400 MH420 7.88 7.86 4.90 4.80 3.25 1.37 5.88 0.88

590 MH520 7.88 7.86 4.90 4.80 3.25 1.37 5.88 0.88

3 240 / 200 MH230 7.88 7.86 5.90 4.80 4.25 1.37 5.88 0.88

(2.2) 480 / 400 MH430 7.88 7.86 4.90 4.80 3.25 1.37 5.88 0.88

590 MH530 7.88 7.86 4.90 4.80 3.25 1.37 5.88 0.88

5 240 / 200 MH250 9.75 10.26 7.20 5.13 5.25 2.00 7.75 1.13

(3.7) 480 / 400 MH450 7.88 7.86 5.90 4.80 4.25 1.37 5.88 0.88

590 MH550 7.88 7.86 5.90 4.80 4.25 1.37 5.88 0.88

7.5 240 / 200 MH275 11.75 10.26 8.35 5.13 5.75 2.00 9.75 1.13

(5.5) 480 / 400 MH475 9.75 10.26 7.20 5.13 5.25 2.00 7.75 1.13

590 MH575 9.75 10.26 7.20 5.13 5.25 2.00 7.75 1.13

10 240 / 200 MH2100 13.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

(7.5) 480 / 400 MH4100 11.75 10.26 8.35 5.13 5.75 2.00 9.75 1.13

590 MH5100 11.75 10.26 8.35 5.13 5.75 2.00 9.75 1.13

Conduit Holes:

S Dia.

0.88" Dia.

S Dia.

Dia. Slot

D

W

U

V

T

Mounting Tab Detail

1.00"

R

H

IF W = 7.86"

T = 0.20"

U = 0.34"

V = 0.19"

IF W = 10.26"

IF W = 13.72"

T = 0.28"

U = 0.44"

V = 0.24"

8

Page 10

TYPE 4, 4X, AND 12 DIMENSIONS (continued)

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

HP

INPUT

(kW)

VOLTAGE MODEL* H W D N P Q R S

15 240 / 200 MH2150 15.75 10.26 8.35 5.13 5.75 2.00 13.75 1.38

(11) 480 / 400 MH4150 13.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

590 MH5150 13.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

20 240 / 200 MH2200D 15.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

(15) 480 / 400 MH4200 15.75 10.26 8.35 5.13 5.75 2.00 13.75 1.38

590 MH5200 15.75 10.26 8.35 5.13 5.75 2.00 13.75 1.38

25 240 / 200 MH2250D 20.25 10.26 8.35 5.13 5.75 2.00 16.25 1.38

(18.5) 480 / 400 MH4250D 15.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

590 MH5250D 15.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

30 240 / 200 MH2300D 20.25 10.26 8.35 5.13 5.75 2.00 16.25 1.38

(22) 480 / 400 MH4300D 15.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

590 MH5300D 15.75 10.26 8.35 5.13 5.75 2.00 11.75 1.38

40 480 / 400 MH4400D 20.25 10.26 8.35 5.13 5.75 2.00 16.25 1.38

(30) 590 MH5400D 20.25 10.26 8.35 5.13 5.75 2.00 16.25 1.38

50 480 / 400 MH4500D 21.00 13.72 8.35 5.13 6.10 2.00 16.25 1.38

(37.5) 590 MH5500D 21.00 13.72 8.35 5.13 6.10 2.00 16.25 1.38

60 480 / 400 MH4600D 21.00 13.72 8.35 5.13 6.10 2.00 16.25 1.38

(45) 590 MH5600D 21.00 13.72 8.35 5.13 6.10 2.00 16.25 1.38

* MODELS WITH BLANK ENCLOSURE DESIGNATION ARE AVAILABLE IN NEMA 4

(INDICATED BY “C”) OR 4X STAINLESS STEEL (INDICATED BY “E”).

9

Page 11

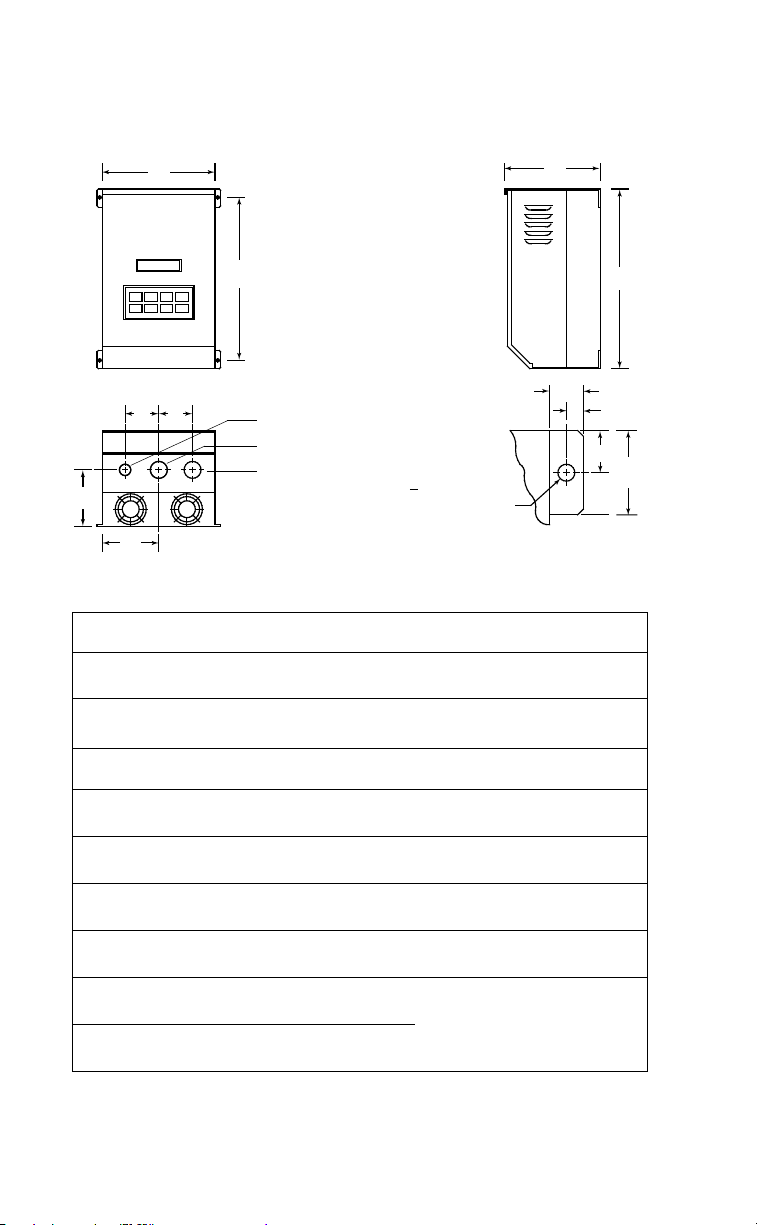

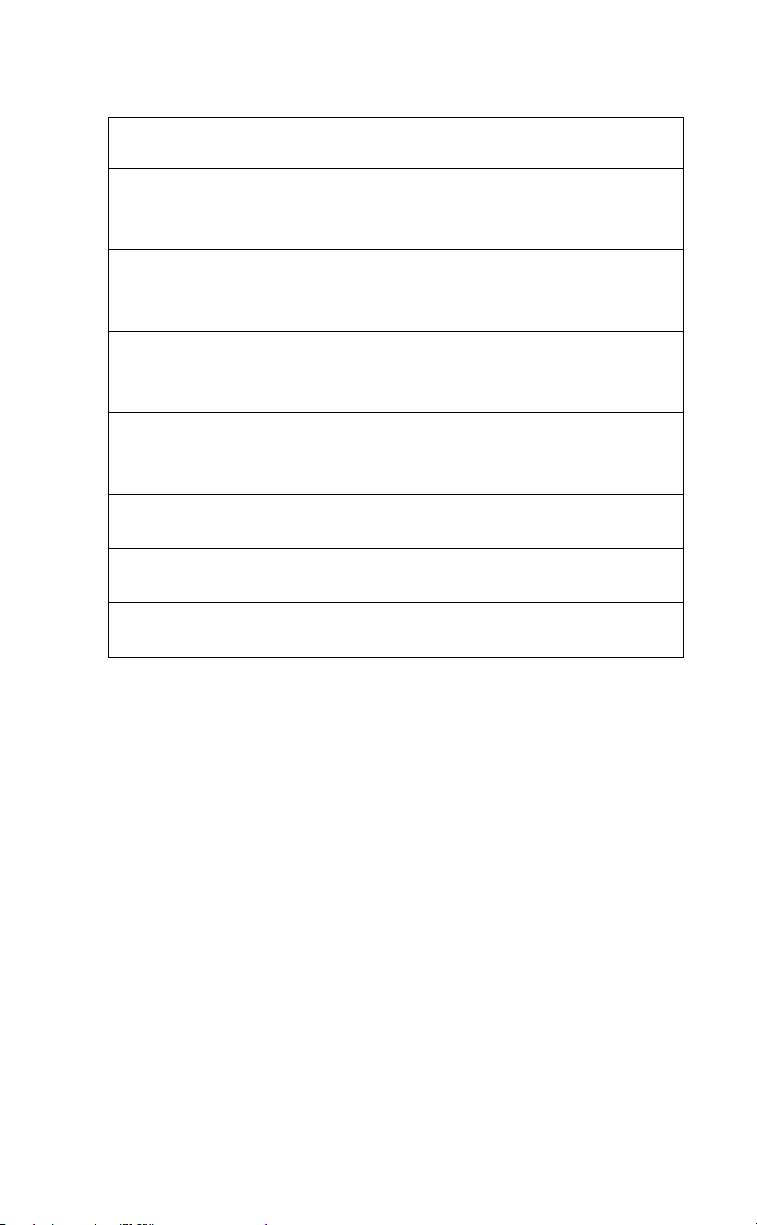

4.5 TYPE 12 DIMENSIONS FOR MODELS RATED ABOVE 30 HP AT

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

240/200 Vac AND 60 HP AT 480/400 Vac AND 590 Vac

P

(37.5)

W

R

QQ

N

HP

(kW)

(30)

(45)

(55)

100

(75)

125

(90)

INPUT

VOLTAGE MODEL H W D N P Q R S

40

240 / 200 MH2400D 31.00 14.00 11.86 6.00 7.50 2.62 22.50 1.38

50

240 / 200 MH2500D 31.00 14.00 11.86 6.00 7.50 2.62 22.50 1.38

60

240 / 200 MH2600D 37.00 18.00 13.30 7.50 8.00 3.13 27.00 1.75

480 / 400 MH4750D 37.00 18.00 13.30 7.50 8.00 3.13 27.00 1.75

75

590 MH5750D 37.00 18.00 13.30 7.50 8.00 3.13 27.00 1.75

480 / 400 MH41000D 39.00 26.00 13.30 11.50 8.00 4.50 27.00 2.50

590 MH51000D 39.00 26.00 13.30 11.50 8.00 4.50 27.00 2.50

480 / 400 MH41250D 39.00 26.00 13.30 11.50 8.00 4.50 27.00 2.50

590 MH51250D 39.00 26.00 13.30 11.50 8.00 4.50 27.00 2.50

Conduit Holes:

1.13" Dia.

S Dia.

S Dia.

IF W > 14.00"

T = 0.36"

U = 0.68"

V = 0.31"

T

Dia.

Mounting Tab Detail

D

H

U

V

3.00"

1.50"

10

Page 12

5.0 MCH RATINGS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The following tables indicate the input and output ratings of the MCH Series

drive.

NOTE: The output current ratings are based on operation at carrier frequencies

of 8 kHz and below. At full ambient temperature, operation at carrier frequencies

above 8 kHz require derating the drive by multiplying the output current rating

by the following factors: 0.94 at 10 kHz, 0.89 at 12 kHz, and 0.83 at 14 kHz.

Refer to Parameter 23 - CARRIER FREQ in Section 18.0 - DESCRIPTION OF

PARAMETERS.

MH200 SERIES RATINGS

MODEL

MODEL FOR MOTORS NOMINAL NOMINAL

NUMBER RATED INPUT CURRENT POWER CURRENT POWER

(NOTE 1) HP kW PHASE (AMPS) (KVA) (AMPS) (KVA)

MH210 1 0.75 3 5.5 / 4.8 2.0 4.6 / 4.0 1.6

MH220 2 1.5 3 9.3 / 8.1 3.4 7.8 / 6.8 2.7

MH230 3 2.2 3 13.0 / 11.3 4.7 11.0 / 9.6 3.8

MH250 5 3.7 3 20 / 17.7 7.4 17.5 / 15.2 6.1

MH275 7.5 5.5 3 30 / 26 10.6 25 / 22 8.8

MH2100 10 7.5 3 37 / 32 13.2 32 / 28 11.2

MH2150 15 11 3 55 / 48 19.8 48 / 42 16.7

MH2200 20 15 3 70 / 61 25.3 62 / 54 21.5

MH2250 25 18.5 3 89 / 77 32.0 78 / 68 27.1

MH2300 30 22 3 104 / 90 37.6 92 / 80 31.9

MH2400 40 30 3 99 / 99 41.0 104 / 104 41.4

MH2500 50 37.5 3 122 / 122 50.7 130 / 130 51.8

MH2600 60 45 3 145 / 145 60.5 154 / 154 61.3

(200/240 Vac, 50 - 60 Hz) (0 - 200/230 Vac)

INPUT OUTPUT

NOTE 1: See Section 3.0 for model number breakdown.

NOTE 2: See Section 8.0 for recommended fuse type.

11

Page 13

MH400 SERIES RATINGS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

MODEL

MODEL

NUMBER

(NOTE 1)

MH410 1 0.75 3 2.8 / 2.4 2.0 2.3 / 2.0 1.6

MH420 2 1.5 3 4.7 / 4.1 3.4 3.9 / 3.4 2.7

MH430 3 2.2 3 6.6 / 5.7 4.7 5.5 / 4.8 3.8

MH450 5 3.7 3 10.2 / 8.9 7.3 8.7 / 7.6 6.1

MH475 7.5 5.5 3 14.7 / 12.8 10.6 12.6 / 11.0 8.8

MH4100 10 7.5 3 18.3 / 15.9 13.2 16.0 / 14.0 11.2

MH4150 15 11 3 28 / 24 19.8 24 / 21 16.7

MH4200 20 15 3 36 / 31 25.3 31 / 27 21.5

MH4250 25 18.5 3 44 / 38 31.9 39 / 34 27.1

MH4300 30 22 3 52 / 45 37.6 46 / 40 31.9

MH4400 40 30 3 68 / 59 49.0 60 / 52 41.4

MH4500 50 37.5 3 85 / 74 61.5 75 / 65 51.8

MH4600 60 45 3 100 / 87 72.3 88 / 77 61.3

MH4750 75 55 3 91 / 91 75.5 96 / 96 76.5

MH41000 100 75 3 116 / 116 96.4 124 / 124 98.8

MH41250 125 90 3 146 / 146 121.4 156 / 156 124.3

MH41500 150 110 3 168 / 168 139.7 180 / 180 143.4

MH42000 200 150 3 225 / 225 187.1 240 / 240 191.2

MH42500 250 185 3 281 / 281 233.6 300 / 300 240.6

NOTE 1: See Section 3.0 for model number breakdown.

NOTE 2: See Section 8.0 for recommended fuse type.

FOR MOTORS

RATED CURRENT POWER CURRENT POWER

HP kW (AMPS) (KVA) (AMPS) (KVA)

(400/480 Vac, 50 - 60 Hz) (0 - 400/460 Vac)

INPUT

PHASE

INPUT OUTPUT

NOMINAL NOMINAL

12

Page 14

MH500 SERIES RATINGS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

MODEL

MODEL

NUMBER

(NOTE 1)

MH510 1 0.75 3 1.9 / 1.9 1.9 1.6 / 1.6 1.6

MH520 2 1.5 3 3.3 / 3.3 3.4 2.7 / 2.7 2.7

MH530 3 2.2 3 4.6 / 4.6 4.7 3.9 / 3.9 3.9

MH551 5 3.7 3 7.1 / 7.1 7.3 6.1 / 6.1 6.1

MH575 7.5 5.5 3 10.5 / 10.5 10.7 9.0 / 9.0 8.8

MH5100 10 7.5 3 12.5 / 12.5 12.8 11.0 / 11.0 11.0

MH5150 15 11 3 19.3 / 19.3 19.7 17.0 / 17.0 16.9

MH5200 20 15 3 25 / 25 25.4 22 / 22 21.5

MH5250 25 18.5 3 31 / 31 31.2 27 / 27 26.9

MH5300 30 22 3 36 / 36 37.1 32 / 32 31.9

MH5400 40 30 3 47 / 47 47.5 41 / 41 40.8

MH5500 50 37.5 3 59 / 59 60.3 52 / 52 51.8

MH5600 60 45 3 71 / 71 72.5 62 / 62 61.7

MH5750 75 55 3 74 / 74 75.7 77 / 77 76.7

MH51000 100 75 3 95 / 95 96.6 99 / 99 98.6

MH51250 125 90 3 119 / 119 121.6 125 / 125 124.5

MH51500 150 110 3 137 / 137 140.0 144 / 144 143.4

MH52000 200 150 3 183 / 183 187.0 192 / 192 191.2

NOTE 1: See Section 3.0 for model number breakdown.

NOTE 2: See Section 8.0 for recommended fuse type.

FOR MOTORS

RATED CURRENT POWER CURRENT POWER

HP kW (AMPS) (KVA) (AMPS) (KVA)

(480/590 Vac, 50 - 60 Hz) (0 - 460/575 Vac)

INPUT

PHASE

INPUT OUTPUT

NOMINAL NOMINAL

13

Page 15

6.0 THEORY

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

6.1 DESCRIPTION OF AC MOTOR OPERATION

Three phase AC motors are comprised of two major components, the stator and

the rotor. The stator is a set of three electrical windings held stationary in the

motor housing. The rotor is a metal cylinder, fixed to the motor drive shaft, which

rotates within the stator. The arrangement of the stator coils and the presence

of three phase AC voltage give rise to a rotating magnetic field which drives the

rotor. The speed at which the magnetic field rotates is known as the synchronous

speed of the motor. Synchronous speed is a function of the frequency at which

the voltage is alternating and the number of poles in the stator windings.

The following equation gives the relation between synchronous speed, frequency,

and the number of poles:

Ss = 120 f/p

Where: Ss = Synchronous speed (rpm ), f = frequency (Hz),

p = number of poles

In three phase induction motors the actual shaft speed differs from the synchronous

speed as load is applied. This difference is known as “slip”. Slip is commonly

expressed as a percentage of synchronous speed. A typical value is three percent

at full load.

The strength of the magnetic field in the gap between the rotor and stator is

proportional to the amplitude of the voltage at a given frequency. The output

torque capability of the motor is, therefore, a function of the applied voltage

amplitude at a given frequency. When operated below base (rated) speed, AC

motors run in the range of “constant torque”. Constant torque output is obtained

by maintaining a constant ratio between voltage amplitude (Volts) and frequency

(Hertz). For 60 Hz motors rated at 230, 460, and 575 Vac, common values for

this V/Hz ratio are 3.83, 7.66, and 9.58 respectively. Operating with these V/Hz

ratios generally yields optimum torque capability. Operating at lower ratio values

results in lower torque and power capability. Operating at higher ratio values will

cause the motor to overheat. Most standard motors are capable of providing full

torque output from 3 to 60 Hz. However, at lower speeds, where motor cooling

fans become less effective, supplemental cooling may be needed to operate at full

torque output continuously.

14

Page 16

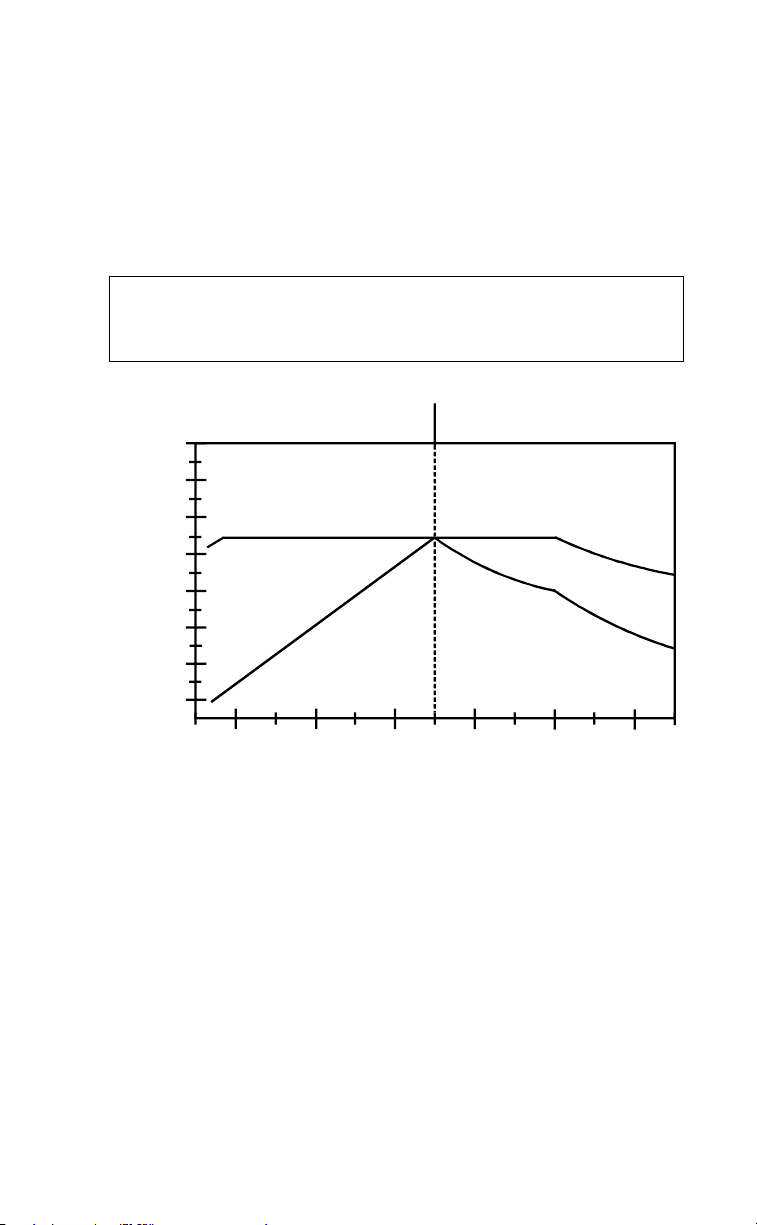

If the frequency applied to the motor is increased while the voltage remains

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

constant, torque capability will decrease as speed increases. This will cause the

horsepower capability of the motor to remain approximately constant. Motors

run in this mode when operated above base speed, where drive output voltage is

limited by the input line voltage. This operating range is known as the “constant

horsepower” range. The typical maximum range for constant horsepower is about

2.3 to 1 (60 to 140 Hz). The diagram below depicts the characteristics of a typical

AC induction motor with a 60 Hz base speed.

WARNING!

Consult motor manufacturer before operating motor and/or driven equipment

above base speed.

150

130

110

90

70

50

TORQUE (%)

30

10

CONSTANT TORQUE

TORQUE HORSEPOWER

HORSEPOWER

20 40

60 80 100 120

CONSTANT HP

TORQUE

FREQUENCY (Hz)

6.1.1 VARIABLE TORQUE VS. CONSTANT TORQUE

Variable frequency drives, and the loads they are applied to, can generally be

divided into two groups: constant torque and variable torque. Constant torque

loads include: vibrating conveyors, punch presses, rock crushers, machine tools,

and just about every other application that is not considered variable torque.

Variable torque loads include centrifugal pumps and fans, which make up the

majority of HVAC applications.

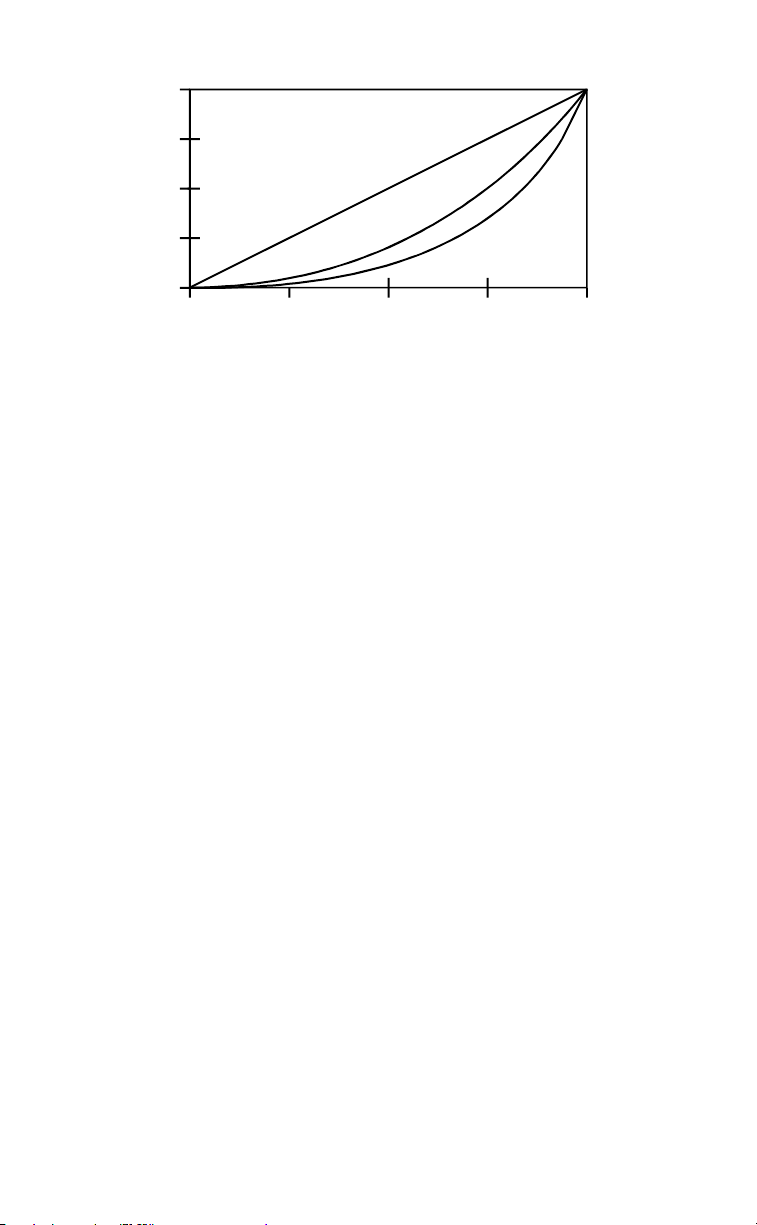

Variable torque loads are governed by the affinity laws, which define the

relationships between speed, flow, torque and horsepower. The diagram below

illustrates these relationships:

15

Page 17

100%

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

75%

50%

25%

0%

% FLOW

% TORQUE

% HORSEPOWER

100%75%50%25%0%

% SPEED

“Variable torque” refers to the fact that the torque required varies with the square

of the speed. Also, the horsepower required varies with the cube of the speed,

resulting in a large reduction in horsepower for even a small reduction in speed.

It is easily seen that substantial energy savings can be achieved by reducing the

speed of a fan or pump. For example, reducing the speed to 50% results in a

50 HP motor having to produce only 12.5% of rated horsepower, or 6.25 HP.

Variable torque drives usually have a low overload capacity (110% - 120% for

60 seconds), because variable torque applications rarely experience overload

conditions. To optimize efficiency and energy savings, variable torque drives are

usually programmed to follow a variable V/Hz ratio.

The term “constant torque” is not entirely accurate in terms of the actual torque

required for an application. Many constant torque applications have reciprocating

loads, such as vibrating conveyors and punch presses, where the rotational motion

of the motor is being converted to a linear motion. In such cases, the torque required

can vary greatly at different points in the cycle. For constant torque loads, this

fluctuation in torque is not a direct function of speed, as it is with a variable torque

load. As a result, constant torque drives typically have a high overload rating

(150% for 60 seconds) in order to handle the higher peak torque demands. To

achieve maximum torque, constant torque drives follow a constant V/Hz ratio.

The MCH Series has an overload capacity of 120% for one minute, indicating

that it is meant for variable torque loads.

6.2 DRIVE FUNCTION DESCRIPTION

The MC Series is a microprocessor based, keypad programmable, variable speed

AC motor drive. There are four major sections: an input diode bridge and filter,

a power board, a control board, and an output intelligent power module.

16

Page 18

6.2.1 DRIVE OPERATION

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Incoming AC line voltage is converted to a pulsating DC voltage by the input

diode bridge. The DC voltage is supplied to the bus filter capacitors through a

charge circuit which limits inrush current to the capacitors during power-up. The

pulsating DC voltage is filtered by the bus capacitors which reduces the ripple

level. The filtered DC voltage enters the inverter section of the drive, composed

of six output intelligent insulated gate bi-polar transistors (IGBTs) which make up

the three output legs of the drive. Each leg has one intelligent IGBT connected to

the positive bus voltage and one connected to the negative bus voltage. Alternately

switching on each leg, the intelligent IGBT produces an alternating voltage on

each of the corresponding motor windings. By switching each output intelligent

IGBT at a very high frequency (known as the carrier frequency) for varying time

intervals, the inverter is able to produce a smooth, three phase, sinusoidal output

current wave which optimizes motor performance.

6.2.2 CIRCUIT DESCRIPTION

The control section consists of a control board with a microprocessor, keypad

and display. Drive programming is accomplished via the keypad or the serial

communications port. During operation the drive can be controlled via the

keypad, by control devices wired to the control terminal strip, or by the the serial

communications port. The Power Board contains the control and protection

circuits which govern the six output IGBTs. The Power Board also contains a

charging circuit for the bus filter capacitors, a motor current feedback circuit, a

voltage feedback circuit, and a fault signal circuit. The drive has several built

in protection circuits. These include phase-to-phase and phase-to-ground short

circuit protection, high and low line voltage protection, protection against excessive

ambient temperature, and protection against continuous excessive output current.

Activation of any of these circuits will cause the drive to shut down in a fault

condition.

6.2.3 MCH INPUTS & OUTPUTS

The drive has two analog inputs (0-10 VDC and 4-20 mA) that can be used for

speed reference, PID setpoint reference, or PID feedback. A speed potentiometer

(10,000 Ohm) can be used with the 0-10 VDC input.

There are also two analog outputs: one is proportional to speed (frequency), and

the other is proportional to load.

The standard MCH drive has three programmable outputs for status indication:

one Form C Relay and two open-collector outputs.

Refer to Sections 14.0 - CONTROL WIRING and 15.0 - MCH CONTROL

WIRING DIAGRAMS for more information.

17

Page 19

7.0 INSTALLATION

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

WARNING!

DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE

ENVIRONMENTAL CONDITIONS! DRIVES MUST NOT BE INSTALLED

WHERE SUBJECTED TO: COMBUSTIBLE, OILY, OR HAZARDOUS

VAPORS OR DUST; EXCESSIVE MOISTURE OR DIRT; STRONG

VIBRATION; EXCESSIVE AMBIENT TEMPERATURES. CONSULT AC

TECHNOLOGY FOR MORE INFORMATION ON THE SUITABILITY OF

A DRIVE TO A PARTICULAR ENVIRONMENT.

The drive should be mounted on a smooth vertical surface capable of safely

supporting the unit without vibrating. The LCD display has an optimum field of

view, this should be considered when determining the mounting position.

Maintain a minimum spacing around the drive as follows:

SPACING REQUIREMENTS

HP

0.25 - 5 2 50

7.5 - 25 4 100

30 - 60 6 150

75 - 250 8 200

SPACING

INCHES mm

All drive models MUST be mounted in a vertical position for proper heatsink

cooling. Fans or blowers should be used to insure proper cooling in tight quarters.

Do not mount drives above other drives or heat producing equipment that would

impede the cooling of the drive. Note the ambient operating temperature ratings

for each drive model.

If it is necessary to drill or cut the drive enclosure or panel, extreme care must be

taken to avoid damaging drive components or contaminating the drive with metal

fragments (which cause shorting of electrical circuits). Cover drive components

with a clean cloth to keep out metal chips and other debris. Use a vacuum cleaner

to clean drive components after drilling, even if chips do not appear to be present.

Do not attempt to use positive air pressure to blow chips out of drive, as this tends

to lodge debris under electronic components. Contaminating the drive with metal

chips can cause drive failure and will void the warranty.

18

Page 20

7.1 INSTALLATION AFTER A LONG PERIOD OF STORAGE

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

WARNING!

Severe damage to the drive can result if it is operated after a long period of

storage or inactivity without reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding

three years (due to storage, etc), the electrolytic DC bus capacitors within the drive

can change internally, resulting in excessive leakage current. This can result in

premature failure of the capacitors if the drive is operated after such a long period

of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long

period of inactivity, apply input power to the drive for 8 hours prior to actually

operating the motor.

7.2 EXPLOSION PROOF APPLICATIONS

Explosion proof motors that are not rated for inverter use lose their certification

when used for variable speed. Due to the many areas of liability that may be

encountered when dealing with these applications, the following statement of

policy applies:

“AC Technology Corporation inverter products are sold with no warranty

of fitness for a particular purpose or warranty of suitability for use with

explosion proof motors. AC Technology Corporation accepts no responsibility

for any direct, incidental or consequential loss, cost, or damage that may

arise through the use of its AC inverter products in these applications. The

purchaser expressly agrees to assume all risk of any loss, cost, or damage that

may arise from such application.”

19

Page 21

8.0 INPUT AC REQUIREMENTS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

WARNING!

Hazard of electrical shock! Disconnect incoming power and wait three minutes

before servicing the drive. Capacitors retain charge after power is removed.

8.1 INPUT AC POWER REQUIREMENTS

8.1.1 VOLTAGE

Th e input vo ltage mu st matc h the driv e ’s namepl ate volt age rat i ng.

Voltage fluctuation must not vary by greater than 10% overvoltage or 15%

undervoltage.

NOTE: Drives with dual rated input voltage must be programmed for the

proper supply voltage. Refer to Parameter 0 - LINE VOLTS in Section 18.0

- DESCRIPTION OF PARAMETERS.

The drive is suitable for use on a circuit capable of delivering not more than

200,000 RMS symmetrical amperes, at the drive’s rated voltage.

Three phase voltage imbalance must be less than 2.0% phase to phase. Excessive

phase to phase imbalance can cause severe damage to the drive’s power

components.

Motor voltage should match line voltage in normal applications. The drive’s

maximum output voltage will equal the input voltage. Use extreme caution

when using a motor with a voltage rating which is different from the input line

voltage.

8.1.2 SUPPLY TRANSFORMER kVA RATINGS

If the kVA rating of the AC supply transformer is greater than ten times the input

kVA rating of the drive, a drive isolation transformer, or a 2 - 3% input line reactor

(also known as a choke) must be added.

8.2 INPUT FUSING AND DISCONNECT REQUIREMENTS

A circuit breaker or a disconnect switch with fuses must be provided in accordance

with the National Electric Code (NEC) and all local codes.

The MCH drive is capable of withstanding up to 120% current overload for 60

seconds. Select a fuse or magnetic trip circuit breaker rated at 1.25 times the input

current rating of the drive (the minimum size should be 10 amps, regardless of

input current rating). Refer to Section 5.0 – MCH RATINGS.

Minimum voltage rating of the protection device should be 250 Vac for 240/200

Vac rated drives, and 600 Vac for 480/400 Vac and 590/480 Vac drives.

20

Page 22

Current limiting type fuses should be used when input fusing is required. Select

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

fuses with low I

Bussman type KTK-R, JJN, and JJS. Similar fuses with equivalent ratings by

other manufacturers may also be acceptable.

2

T values, rated at 200,000 AIC. Recommended fuses are

9.0 VOLTAGE SELECTION

MH200 Series drives are rated for 240/200 Vac, 50-60 Hz input. The drive will

function with input voltages of 200 to 240 Vac (+ 10%, - 15%), at 48 to 62 Hz.

MH400 Series drives are rated for 480/400 Vac, 50-60 Hz input. The drive will

function with input voltages of 400 to 480 Vac (+ 10%, - 15%), at 48 to 62 Hz.

MH500 Series drives are rated for 590/480 Vac, 50-60 Hz input. The drive will

function with input voltages of 480 to 590 Vac (+ 10%, - 15%), at 48 to 62 Hz.

10.0 POWER WIRING

WARNING!

Hazard of electrical shock. Disconnect incoming power and wait three minutes

before servicing the drive. Capacitors retain charge after power is removed.

Note drive input and output current ratings and check applicable electrical codes

for required wire type and size, grounding requirements, overcurrent protection,

and incoming power disconnect, before wiring the drive. Size conservatively to

minimize voltage drop.

Input fusing and a power disconnect switch or contactor MUST be wired in series

with terminals L1, L2, and L3. If one has not been supplied by AC Technology

Corporation, a disconnect means must be wired during installation. This disconnect

must be used to power down the drive when servicing, or when the drive is not

to be operated for a long period of time, but should not be used to start and stop

the motor.

Repetitive cycling of a disconnect or input contactor (more than once every

two minutes) may cause damage to the drive.

All three power output wires, from terminals T1, T2, and T3 to the motor, must

be kept tightly bundled and run in a separate conduit away from all other power

and control wiring.

Do not install contactors between the drive and motor without consulting AC

Technology Corporation for more information. Operating such devices while the

drive is running can potentially cause damage to the drive's power components.

If such a device is required, it should only be operated when the drive is in a

STOP state.

21

Page 23

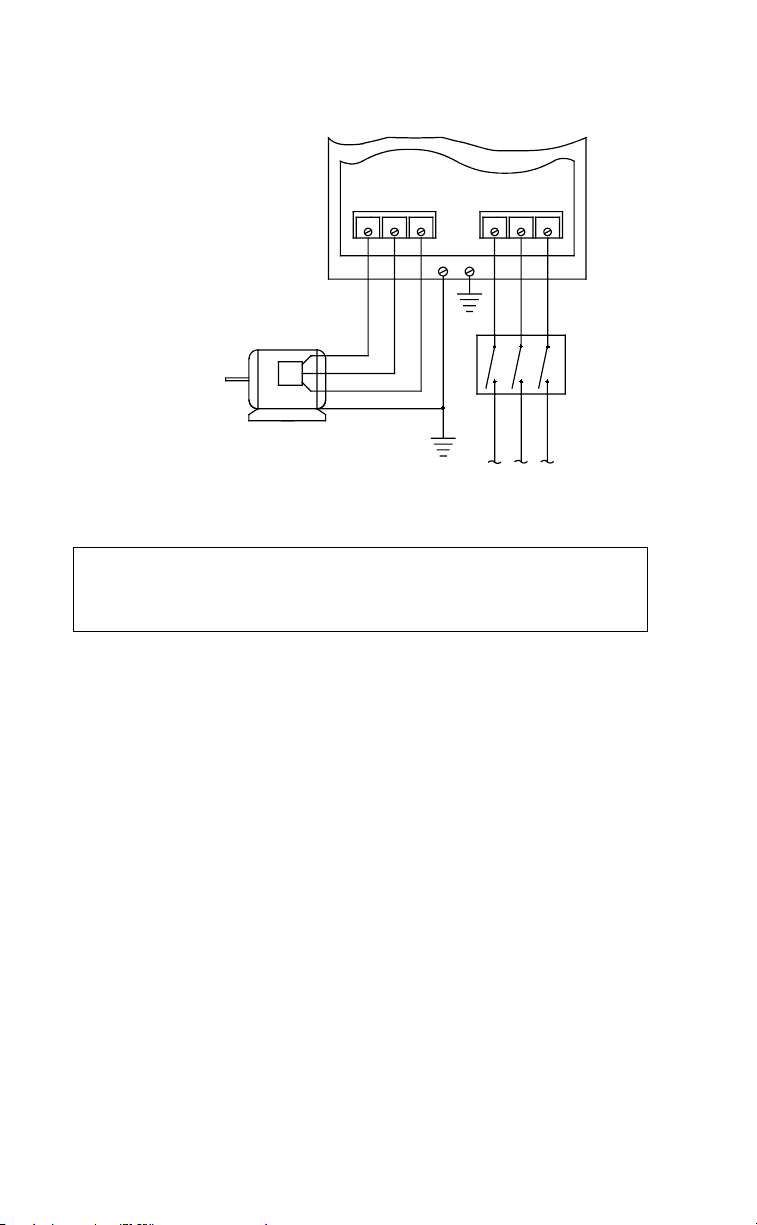

11.0 MCH POWER WIRING DIAGRAM

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

This diagram applies to

standard MC H d r i v e s .

Refer to Appendix A for

Bypass power wiring, or

Appendix B for Option

Box power wiring.

THREE PHASE

AC MOTOR

Do not connect incoming AC power to output terminals T1, T2, or T3. Severe

damage to the drive will result.

T1 T2 T3 L1 L2 L3

GND

WARNING!

GNDGND

DISCONNECT

MEANS

(REQUIRED)

FUSED INPUT

VOLTAGE

IN S TA L L , WI R E , AND GR O U ND IN AC C ORDANCE WITH ALL

APPLICABLE CODES.

NOTES:

1. Wire the motor for the proper voltage per the output rating of the drive. Motor

wires MUST be run in a separate steel conduit away from control wiring and

incoming AC power wiring.

2. Do not install contactors between the drive and the motor without consulting

AC Technology for more information. Failure to do so may result in drive

damage.

3. Remove any existing, and do not install, power factor correction capacitors

between the drive and the motor. Failure to do so will result in drive

damage.

4. Use only UL and CSA listed and approved wire.

5. Minimum wire voltage ratings: 300 V for 200 and 240 Vac systems, and 600

V for 400, 480, and 590 Vac systems.

6. Wire guage must be based on a minimum of 125% of the rated output current

of the drive, and a minimum 75°C insulation rating. Use copper wire only.

7. Wire and ground in accordance with NEC or CEC, and all applicable local

codes.

22

Page 24

12.0 INITIAL POWER UP

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

WARNING!

Hazard of electrical shock! Wait three minutes after disconnecting incoming

power before servicing drive. Capacitors retain charge after power is

removed.

Before attempting to operate the drive, motor, and driven equipment be sure all

procedures pertaining to installation and wiring have been properly followed.

WARNING!

Severe damage to the drive can result if it is operated after a long period of

storage or inactivity without reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding

three years (due to storage, etc), the electrolytic DC bus capacitors within the drive

can change internally, resulting in excessive leakage current. This can result in

premature failure of the capacitors if the drive is operated after such a long period

of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long

period of inactivity, apply input power to the drive for 8 hours prior to actually

operating the motor.

Disconnect the driven load from the motor. Verify that the drive input terminals

(L1, L2, and L3) are wired to the proper input voltage per the nameplate rating

of the drive.

WARNING!

DO NOT connect incoming AC power to output terminals T1, T2, and T3! Do

not cycle input power to the drive more than once every two minutes. Damage

to the drive will result.

Energize the incoming power line. The LCD display should light and flash

“TESTING” and then show the voltage and horsepower rating of the drive. The

display should then look like the example display below, which indicates that

the drive is in a STOP state, the speed setpoint is 20.00 Hz, and there is no load

(because it is not running):

KSTOP > 20.00 HZ

0 % LOAD OFF

NOTE: If the drive is equipped with Bypass, the drive will not power up unless

the Drive Mode/Off/Bypass Mode switch is in the Drive Mode position, or the

Drive Test/Off/Drive Normal switch is in the Drive Test position.

23

Page 25

If the display does not appear, remove the incoming power, wait three minutes for

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

the bus capacitors to discharge, and verify correct installation and wiring. If the

wiring is correct, re-apply incoming power and note the display for drive status.

If the display still does not appear call the factory for assistance.

Follow the procedure given below to check the motor rotation:

1. Use the key to decrease the speed setpoint to the minimum value allowed

(0.50 Hz if Parameter 10 - MIN FREQ has not been changed).

2. Press the HAND (START) key. The drive should indicate RUN, but if the speed

setpoint is 0.50 Hz, the motor may not rotate. Press the key to increase the

speed setpoint until the motor starts to rotate.

3. If the motor is rotating in the wrong direction, press the OFF (STOP) key

and remove power from the drive. Wait three minutes for the bus capacitors

to discharge, and swap any two of the motor wires connected to T1, T2, and

T3.

NOTE 1: The drive is phase insensitive with respect to incoming line voltage.

Therefore, to change the motor rotation, the phases must be swapped at the drive

output terminals or at the motor.

NOTE 2: If the drive is equipped with the Bypass option, motor rotation must

be checked in both drive mode and bypass mode:

To check rotation in Drive mode:

1. Select Drive Mode using the Drive Mode/Off/Bypass Mode switch.

2. Select Drive Normal using the Drive Test/Off/Drive Normal switch.

3. Select HAND using the HAND/OFF/AUTO switch. The drive should start,

allowing the motor rotation to be checked.

To check rotation in Bypass mode:

1. Select Bypass Mode using the Drive Mode/Off/Bypass Mode switch.

2. Select Drive Normal using the Drive Test/Off/Drive Normal switch.

3. Momentarily put the Hand/Off/Auto switch into Hand to "bump" the motor

so rotation can be checked.

If rotation is incorrect in both modes, swap any two motor leads at the output

terminals (thermal overload terminals).

If rotation is correct in drive mode, but incorrect in bypass mode, swap any two

leads at the main input power terminals.

If rotation is incorrect in drive mode, but correct in bypass mode, swap any two

leads at the main input terminals AND any two leads at the output terminals

(thermal overload terminals).

24

Page 26

13.0 KEYPAD CONTROL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The drive can be operated in a number of different ways: keypad (HAND),

control devices wired to the terminal strip (AUTO), serial communications

(SERIAL), or combinations of each. The drive should first be operated in HAND

mode during initial start-up. Refer to Sections 14.0 - CONTROL WIRING, and

18.0 - DESCRIPTION OF PARAMETERS for information on remote (AUTO)

operation.

13.1 KEYPAD FUNCTIONS (in Keypad H/O/A mode)

HAND (START) To start the drive, press the HAND (START) key.

OFF (STOP) To stop the drive, press the OFF (STOP) key.

NOTE: The OFF (STOP) key is active in both HAND

and AUTO modes.

AUTO (START) Puts the drive into AUTO mode.

Close TB-1 to TB-2 to start the drive.

Open TB-1 to TB-2 to stop the drive.

SPEED SOURCE Selects the speed reference source. Press this key to

select the desired speed reference, and then press the

ENTER key within three seconds to confirm the change.

The choices are described below:

HAND ONLY: Drive speed is determined by the setting

of Parameter 29 - HAND SOURCE.

AUTO ONLY: Drive speed is determined by the setting

of Parameter 24 - AUTO SOURCE.

NORM SRC: In HAND mode, speed is determined by

the setting of Parameter 29 - HAND SOURCE.

In AUTO mode, speed is determined by the setting of

Parameter 24 - AUTO SOURCE.

SPEED SETPOINT To increase the speed setpoint, press the key. To

decrease the speed setpoint, press the key.

NOTE: The and keys are only active if another

speed reference source is not selected.

FAULT RESET Use the OFF (STOP) key to reset a fault. If the fault

condition has passed, pressing the STOP key will clear

the fault and return the drive to a STOP condition.

NOTE: If an OUTPUT fault occurs, there will be a 30

second delay before the fault can be cleared using the

STOP key.

25

Page 27

13.2 MCH DISPLAY

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The following describes the possible display configurations for the MCH Series

drive when operating as a standard drive (without PID control). Refer to Section

19.0 - MCH PID SETPOINT CONTROL for a complete description of drive

operation when using PID control.

13.2.1 MCH DISPLAY IN STOP MODE

When the drive is in the STOP mode, there are two possible displays: load

and motor voltage. The standard display indicates % LOAD, which is shown

DRIVE

STATUS

DIRECTION

(FORWARD)

SPEED

SETPOINT

SPEED

UNITS

KSTOP > 20.00 HZ

0 % LOAD OFF

LOAD

METER

NOTE: See Parameter 31 - UNITS for the SPEED UNITS display options.

Pressing the ENTER key will change the display from the % LOAD indication

to the VAC (motor voltage) indication:

DRIVE

STATUS

DIRECTION

(FORWARD)

HAND/OFF/AUTO

SPEED

SETPOINT

STATUS

SPEED

UNITS

KSTOP > 20.00 HZ

0 VAC OFF

MOTOR

VOLTAGE

HAND/OFF/AUTO

STATUS

Pressing ENTER again will change the display back to the % LOAD indication.

26

Page 28

The following table shows the possible DRIVE STATUS indications that can

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

appear on the drive display:

DRIVE STATUS TABLE

DISPLAY DESCRIPTION

KSTOP KEYPAD STOP - The drive was stopped using the OFF (STOP) key.

RSTOP REMOTE STOP - The drive was stopped by opening TB-1 to TB-2.

SSTOP SERIAL STOP - The drive was stopped through the serial link.

RUN Drive is in RUN mode and is within + 0.5 Hz of the speed setpoint.

Drive has shut down due to a FAULT condition. If the fault condition has

FAULT

LOCK Drive is in FAULT LOCKOUT after five unsuccessful restart attempts.

BRAKE DC BRAKE is energized.

LIMIT

F DEC Drive is in DECEL FREEZE because DECEL is set too fast.

passed, pressing the HAND (OFF) key will clear the fault and return the

drive to the STOP mode.

Drive is in CURRENT LIMIT due to an overloaded motor, or ACCEL is set

too fast.

13.2.2 MCH DISPLAY IN RUN MODE

When the drive is in the RUN mode, the default display will look like this:

DRIVE

STATUS

DIRECTION

(FORWARD)

SPEED

SETPOINT

SPEED

UNITS

RUN > 60.00 HZ

86 % LOAD HAND

LOAD

METER

HAND/OFF/AUTO

STATUS

27

Page 29

As in the STOP mode, the ENTER key can be used to toggle the display from %

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

LOAD to VAC (motor voltage):

DRIVE

STATUS

DIRECTION

(FORWARD)

SPEED

SETPOINT

SPEED

UNITS

RUN > 60.00 HZ

460 VAC HAND

MOTOR

VOLTAGE

NOTE: During acceleration and deceleration to the SPEED SETPOINT, the

DRIVE STATUS will show the actual drive speed. When the SPEED SETPOINT

is reached, the DRIVE STATUS will change to RUN (or STOP if the drive is

decelerating to a STOP).

HAND/OFF/AUTO

STATUS

13.2.3 MCH DISPLAY IN FAULT MODE

When the drive trips on a fault, the display will automatically change to the FAULT

display, which indicates the FAULT MESSAGE:

DRIVE

STATUS

DIRECTION

(FORWARD)

SPEED

SETPOINT

SPEED

UNITS

FAULT > 60.00 HZ

OVERLOAD HAND

FAULT

MESSAGE

HAND/OFF/AUTO

STATUS

In FAULT mode, the ENTER key will toggle the display between three screens:

FAULT, % LOAD and VAC. The DRIVE STATUS for these displays will be

FAULT. An example is shown below of the drive in the FAULT mode displaying

% LOAD:

DRIVE

STATUS

DIRECTION

(FORWARD)

SPEED

SETPOINT

SPEED

UNITS

FAULT > 60.00 HZ

0 % LOAD HAND

FAULT

MESSAGE

NOTE: To clear a FAULT, press the OFF (STOP) key, issue a remote STOP

command at TB-1, or use TB-13D (refer to Parameter 50 - TB13D INPUT).

HAND/OFF/AUTO

STATUS

28

Page 30

13.2.4 MCH DISPLAY IN AUXILIARY MODE

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

If the ENTER key is held down, the display will enter the auxiliary mode and

cycle between two displays: a CONTROL display that indicates the H/O/A source

(keypad or terminal strip), speed reference source, and the setting of the SPEED

SOURCE key on the keypad; and a TIME/kWh display that indicates total elapsed

run time and kilowatt hours. When the ENTER key is released, the display will

return to the previous screen. Examples of theses displays are shown below:

H/O/A

SOURCE

KEYPAD HOA - KEY

SRC=NORM

SPEED SOURCE

KEY SETTING

CONTROL DISPLAY

SPEED

REFERENCE

TIME: 4872.7 HRS

KWH: 49345

TIME / KWH DISPLAY

The table below shows the possible SPEED REFERENCE SOURCE indications

for the CONTROL display in the auxiliary mode:

SPEED REFERENCE SOURCE TABLE

DISPLAY DESCRIPTION

KEY

VDC

IDC

KEYPAD -

0 - 10 VDC analog input at TB-5A (In PID mode, this indicates that the

SETPOINT reference is a 0-10 VDC signal).

4 - 20 mA analog input at TB-5B (In PID mode, this indicates that the

SETPOINT reference is a 4-20 mA signal).

and keys.

SP#1 - SP#4 PRESET SPEED #1 - PRESET SPEED #4

MKB

AKB

MANUAL KEYBOARD - The

control. This occurs in PID mode when the drive is put into HAND

(open-loop) mode.

AUTO KEYBOARD - The

SETPOINT reference. This occurs in PID mode when the drive is put

into AUTO (closed-loop) mode.

and keys are used for speed

and keys are used as the PID

29

Page 31

14.0 CONTROL WIRING

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

14.1 GENERAL

This section describes control wiring for standard MCH drives. Refer to

Appendix A for control wiring for the Bypass option, or Appendix B for

control wiring for the Option Box.

14.1.1 KEYPAD CONTROL

The drive can be controlled by the keypad or by control devices wired to the terminal

strip. The drive will run from the keypad “out of the box”, requiring no connections

to the terminal strip. Refer to Section 13.0 - KEYPAD CONTROL.

14.1.2 CONTROL WIRING VS. POWER WIRING

External control wiring MUST be run in a separate conduit away from all other

input and output power wiring. If control wiring is not kept separate from power

wiring, electrical noise may be generated on the control wiring that will cause

erratic drive behavior. Use twisted wires or shielded cable grounded at the drive

chassis ONLY. Recommended control wire is Belden 8760 (2-wire) or 8770 (3wire), or equivalent.

Torque the control terminals to 2 lb-in (0.2 Nm). Be careful not to overtorque

the terminals, as this will cause damage to the terminal strip. This is not covered

under warranty and can only be repaired by replacing the control board.

14.1.3 TB-2: CIRCUIT COMMON

The TB-2 terminals are used as circuit common for the start/stop, input select,

analog input, and analog output functions. There are three TB-2 terminals available

on the terminal strip, and they are all internally connected to each other on the

main control board. If necessary TB-2 may be connected to chassis ground.

NOTE: TB-2 MUST be connected to chassis ground when using serial

communications.

14.1.4 SURGE SUPPRESSION ON RELAYS

Current and voltage surges and spikes in the coils of contactors, relays, solenoids,

etc, near or connected to the drive, can cause erratic drive operation. Therefore,

a snubber circuit should be used on coils associated with the drive. For AC coils,

snubbers should consist of a resistor and a capacitor in series across the coil.

For DC coils, a free-wheeling or flyback diode should be placed across the coil.

Snubbers are typically available from the manufacturer of the device.

30

Page 32

14.2 START/STOP AND SPEED CONTROL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

14.2.1 START/STOP CONTROL IN KEYPAD H/O/A MODE

In Keypad H/O/A mode, the HAND (START) and AUTO (START) keys on the

keypad are used to select HAND and AUTO modes. When the HAND (START)

key is pressed, HAND mode is selected and the drive starts immediately. When the

drive is put into AUTO mode, it will respond to an external start/stop command.

This is done as follows:

1. Press the AUTO key on the keypad. The H/O/A STATUS portion of the display

will indicate AUTO.

2. Wire a normally open maintained contact between TB-1 and TB-2 on the

terminal strip. Close the contact to start the drive, and open the contact to

stop the drive.

Refer to the wiring diagram in Section 15.2.

14.2.2 START/STOP CONTROL IN REMOTE H/O/A MODE

In Remote H/O/A mode, the terminal strip is used to select HAND and AUTO

modes. This is done as follows:

1. Program TB-13C (Parameter 49) to HAND. Once this is done, the HAND

(START) and AUTO (START) keys on the keypad will be disabled.

2. Wire a contact between TB-13C and TB-2. Close this contact to select HAND

mode.

NOTE: When HAND mode is selected, TB-1 must be closed to TB-2 to allow

the drive to run. Therefore, when TB-13C is closed to TB-2, TB-1 must also

be closed to TB-2 by some means (another set of contacts, etc).

3. Wire a contact between TB-12A and TB-2. Close this contact to select AUTO

mode.

4. Wire a normally open maintained contact between TB-1 and TB-2. In AUTO

mode (TB-12A closed to TB-2), close this contact to start the drive and open

this contact to stop the drive.

Refer to the wiring diagram in Section 15.3.

NOTE: If the drive is operating in Remote H/O/A mode, and the OFF (STOP)

key on the keypad is used to stop the drive (instead of using the OFF position of

the remote H/O/A switch), the HAND (START) or AUTO (START) key must be

pressed to cancel the keypad stop and allow the drive to start again.

31

Page 33

14.2.3 SPEED REFERENCE SIGNALS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The drive allows for three analog speed reference inputs: a speed potentiometer

(10,000 Ohm), 0-10 VDC, or 4-20 mA.

SPEED POT Connect the wiper to terminal TB-5A, and connect the high and

low end leads to terminals TB-6 and TB-2, respectively.

0-10 VDC Wire the positive to terminal TB-5A and the negative to terminal

TB-2. TB-5A input impedance is 200 kilohms.

4-20 mA Wire the positive to terminal TB-5B and the negative to terminal

TB-2. TB-5B input impedance is 100 Ohms.

14.2.4 SPEED REFERENCE SELECTION

In HAND mode, the speed reference source will be determined by the setting of

Parameter 29 - HAND SOURCE.

In AUTO mode, the speed reference source will be determined by the setting of

Parameter 24 - AUTO SOURCE.

The SPEED SOURCE key on the keypad can be used to change the speed reference

source. When NORM SRC is selected, the above statements are true. However,

the SPEED SOURCE key can also be used to select HAND ONLY or AUTO

ONLY, which forces the drive speed to be controlled from the HAND SOURCE

(Parameter 29) or the AUTO SOURCE (Parameter 24), regardless of whether the

drive is in HAND or AUTO mode.

Speed references can also be selected using TB-13A, 13B, and 13C on the terminal

strip. If HAND SOURCE and/or AUTO SOURCE are set to SELECTED, the

speed source will be whatever speed reference is selected using TB-13A, 13B, or

13C (0-10 VDC, 4-20 mA, preset speeds, etc). Refer to Parameters 47, 48, and

49 in Section 18.0 - DESCRIPTION OF PARAMETERS.

0 - 10 VDC and 4 - 20 mA INPUT SIGNALS

HAND SOURCE (Parameter 29) and AUTO SOURCE (Parameter 24) can be set

for 0-10 VDC or 4-20 mA.

If HAND SOURCE and/or AUTO SOURCE are set to SELECTED, TB-13A,

TB-13B, and TB-13C can all be used to select 0-10 VDC or 4-20 mA input.

32

Page 34

PRESET SPEEDS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

HAND SOURCE (Parameter 29) and AUTO SOURCE (Parameter 24) can be set

to PRESET #1 - PRESET #4.

If HAND SOURCE and/or AUTO SOURCE are set to SELECTED, TB-13A

can be programmed to select PRESET #1, TB-13B to select PRESET #2, and

TB-13C to select PRESET #3. Closing any two of these terminals to TB-2 will

select PRESET #4. Refer to Parameters 1-4: PRESET #1 - #4 in Section 18.0

- DESCRIPTION OF PARAMETERS.

MOP - MOTOR OPERATED POT

MOP allows the drive speed to be adjusted using contact closures (one for increase

and another for decrease).

HAND SOURCE (Parameter 29) and AUTO SOURCE (Parameter 24) can be set

to MOP. This requires that TB-13A (Parameter 47) be set to DECREASE FREQ,

and TB-13B (Parameter 48) be set to INCREASE FREQ. Close TB-13A to TB-2

to decrease the drive speed, and close TB-13B to TB-2 to increase the drive speed.

Once the desired speed is reached, release the contact, and the drive speed will

hold at that value. The DECREASE FREQ function will work when the drive is

in a STOP or RUN mode. The INCREASE FREQ function will only work while

the drive is in a RUN mode.

If HAND SOURCE and/or AUTO SOURCE is set to SELECTED, TB-13A and

TB-13B can be programmed for this function. Program TB-13A (Parameter 47)

to DECREASE FREQ, and TB-13B (Parameter 48) to INCREASE FREQ. Refer

to the description of operation above .

NOTE: If TB-13A, TB-13B, and TB-13C are all programmed to select speed

references, and two or three of the terminals are closed to TB-2, the higher terminal

has priority and will override the others. For example, if TB-13A is programmed

to select 0-10VDC, and TB-13C is programmed to select PRESET #3, closing

both terminals to TB-2 will cause the drive to respond to PRESET #3, because

TB-13C overrides TB-13A.

14.2.5 ANALOG OUTPUT SIGNALS

There are two terminals that can supply analog output signals proportional to

output frequency and load. Terminal TB-10A can provide a 0-10 VDC or a 210 VDC signal proportional to output frequency, and TB-10B can provide the

same signals proportional to load. The 2-10 VDC signals can be converted to a

4-20 mA signal using a resistor in series with the signal such that the total circuit

resistance is 500 Ohms. See Parameters: 42 - TB10A OUTPUT, 43 - TB10A

SCALING, 44 - TB10B OUTPUT, and 45 - TB10B SCALING in Section 18.0

- DESCRIPTION OF PARAMETERS.

33

Page 35

14.2.6 DRIVE STATUS OUTPUTS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The control board has one Form C relay at terminals TB-16, TB-17, and TB-18.

Contacts are rated 2 amps at 28 VDC or 120 Vac.

There are also two open-collector outputs at terminals TB-14 and TB-15. The opencollector circuit is a current-sinking type rated at 30 VDC and 40 mA maximum.

A power supply (30 VDC max) must be used to power the open-collector outputs.

The standard drive does not have a power supply (a 24 VDC power supply is

optional when the drive is equipped with the Bypass option).

The Form C relay and open-collector outputs can be programmed for many

different status indications. See Parameters 52 - TB14/RELAY #2, 53 - TB15/

RELAY #3, and 54 - RELAY #1.

NOTE: The Bypass option includes two Form C relays and a third is optional

(refer to Appendix A). When the drive is equipped with the Option Box, there are

two Form C relays and two open-collector outputs (refer to Appendix B).

34

Page 36

15.0 MCH CONTROL WIRING DIAGRAMS

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The following wiring diagrams apply to standard MCH drives. Refer to

Appendix A for control wiring for the Bypass option, or Appendix B for

control wiring for the Option Box.

15.1 MCH TERMINAL STRIP

Shown below is the terminal strip on the main control board, along with a brief

description of the function of each terminal.

FORM C

The TB-2 terminals are internally tied together

RELAY

1 2 5A 5B 6

RUN / STOP

0-10 VDC SPEED REFERENCE INPUT

CIRCUIT COMMON

10A 12A RXA TXB10B 2 13A 13B

10 VDC SUPPLY FOR SPEED POT

0-10 OR 2-10 VDC OUTPUT: FREQUENCY

4-20 mA SPEED REFERENCE INPUT

0-10 OR 2-10 VDC OUTPUT: LOAD

AUTO MODE SELECT

CIRCUIT COMMON

TB-13A FUNCTION SELECT

13C

TB-13B FUNCTION SELECT

TB-13C FUNCTION SELECT

15 2

13D 14

TB-13D FUNCTION SELECT

CIRCUIT COMMON

OPEN-COLLECTOR OUTPUT

OPEN-COLLECTOR OUTPUT

COMMUNICATIONS

16 17 18

RS-485 SERIAL

NOTE: The function of terminals TB-10A, TB-10B, TB-13A, TB-13B, TB-13C,

TB-13D, TB-14, TB-15, TB-16, and TB-18 are dependent on the programming

of certain parameters. In most cases, the name of the parameter matches the

number of the terminal, allowing quick and easy programming of the terminals

to suit the application. The exception is TB-16 and TB-18, which are governed

by Parameter 54 - RELAY.

A complete description of operating the drive in the AUTO mode can be found in

Section 14.2. The following diagrams provide a quick reference to wire the drive

for the most common configurations.

35

Page 37

15.2 KEYPAD H/O/A

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

When the drive is in Keypad H/O/A mode, the AUTO (START) key on the keypad

is used to put the drive into AUTO mode. The drive will then respond to start/stop

commands from the terminal strip. The start/stop circuit is wired as shown below.

Also shown is the wiring for a 4-20 mA or 0-10 VDC speed reference signal.

FORM C

The TB-2 terminals are internally tied together

RELAY

1 2 5A 5B 6

CIRCUIT COMMON

RUN / STOP

4-20 mA INPUT

0-10 VDC INPUT

MAINTAINED

RUN/STOP

CONTACT

10A 12A RXA TXB10B 2 13A 13B

CIRCUIT COMMON

13C

13D 14

NOTES:

1. Close TB-1 to TB-2 to RUN, and open to STOP.

15 2

16 17 18

2. When the drive is put into AUTO mode, the speed reference will be determined

by AUTO SOURCE (Parameter 24). In the example above, the AUTO speed

reference is either a 4-20 mA or 0-10 VDC signal.

3. When HAND mode is selected, the drive starts immediately. TB-1 has no

effect.

36

Page 38

15.3 REMOTE H/O/A

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

Shown below is the wiring diagram for selecting H/O/A from the terminal strip.

Also shown is the wiring for a 0-10 VDC or 4-20 mA speed reference signal. In

HAND mode, TB-1 must be closed to TB-2 in order to start the drive. In AUTO

mode, close TB-1 to TB-2 to RUN, and open to STOP

FORM C

The TB-2 terminals are internally tied together

RELAY

1 2 5A 5B 6

CIRCUIT COMMON

RUN / STOP

4-20 mA INPUT

0-10 VDC INPUT

MAINTAINED

RUN/STOP CONTACT

(AUTO MODE ONLY)

10A 12A RXA TXB10B 2 13A 13B

CIRCUIT COMMON

AUTO MODE SELECT

13C

HAND MODE SELECT

OFF

AUTO

HAND

OFF

AUTO

13D 14

HAND

15 2

CIRCUIT COMMON

16 17 18

NOTES:

1. Program TB-13C (Parameter 49) to HAND. This forces TB-12A to act as

AUTO.

2. In AUTO mode (TB-12A closed to TB-2), close TB-1 to TB-2 to RUN, and

open to STOP. The speed reference will be determined by AUTO SOURCE

(Parameter 24).

3. When HAND mode is selected (TB-13C closed to TB-2), TB-1 must also be

closed to TB-2 in order to RUN. The speed reference will be determined by

HAND SOURCE (Parameter 29).

37

Page 39

15.4 SPEED POT AND PRESET SPEED CONTROL

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

In this example, the drive is in Keypad H/O/A mode. In HAND mode, speed is

controlled from the speed pot. In AUTO mode, speed is controlled by the selected

PRESET SPEED.

FORM C

The TB-2 terminals are internally tied together

RELAY

1 2 5A 5B 6

CIRCUIT COMMON

RUN / STOP

0-10 VDC INPUT

MAINTAINED

RUN/STOP

CONTACT

10A 12A RXA TXB10B 2 13A 13B

10 VDC SUPPLY

SPEED POT

(10 K)

CIRCUIT COMMON

PRESET SPEED #1

PRESET SPEED #2

13C

13D 14

PRESET SPEED #3

15 2

CIRCUIT COMMON

NOTES:

1. Program the PRESETS (Parameters 1-4) to the desired values.

16 17 18

2. Program TB-13A to PRESET #1, TB-13B to PRESET #2, and TB-13C to

PRESET #3 (Parameters 47-49). Close any two to select PRESET #4.

3. Program HAND SOURCE (Parameter 29) to 0-10 VDC. In HAND mode,

the speed will be controlled by the speed pot.

4. Program AUTO SOURCE (Parameter 24) to SELECTED. In AUTO mode,

the speed will be controlled by the preset speeds.

38

Page 40

16.0 PROGRAMMING THE MCH DRIVE

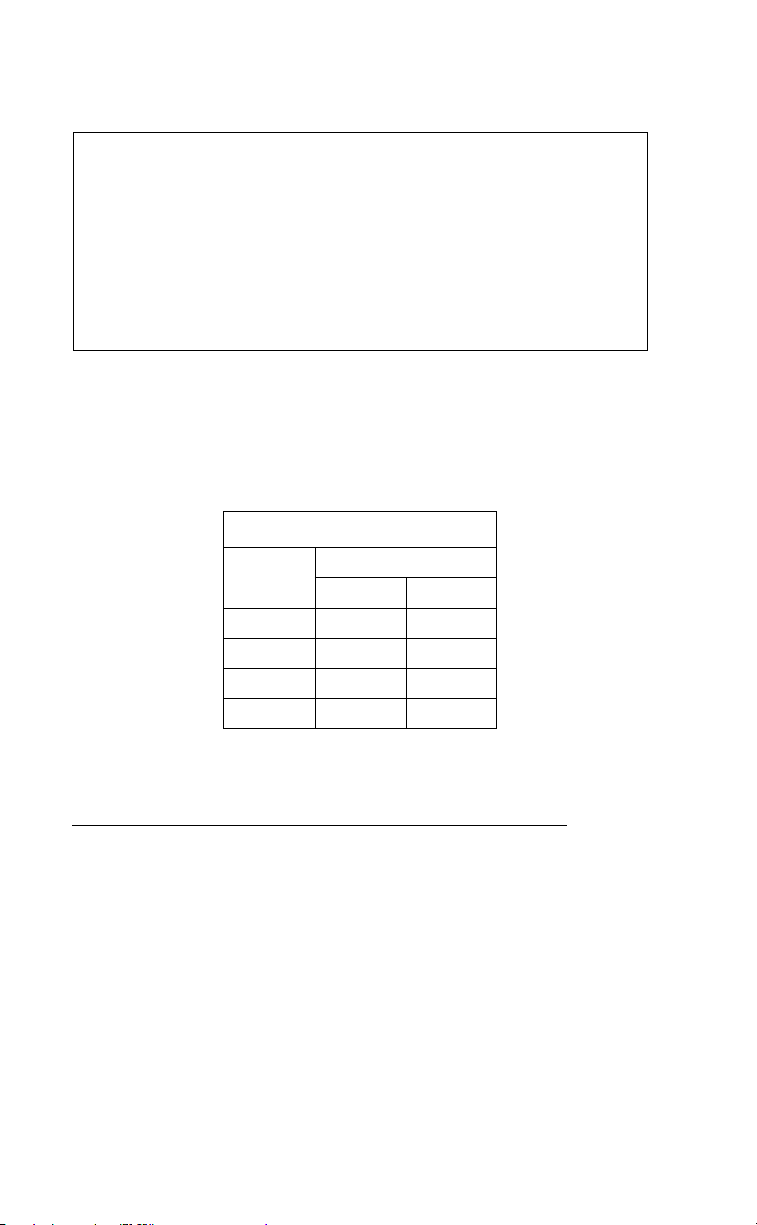

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

The MCH keypad serves two purposes: operating the drive when in the LOCAL

mode, and programming the parameters for particular applications. The keypad

is shown below, along with the display that should appear when the drive is first

powered up:

STOP > 20.00 HZ

0 % LOAD OFF

PROG

RUN

ENTER

AUTO

(START)

SPEED

SOURCE

HAND

(START)

OFF

(STOP)

To program the drive, the PROGRAM mode must be entered by pressing the

PROG/RUN button. If the password protection is disabled, pressing the PROG/

RUN button will result in direct entry into the PROGRAM mode. If the password

protection is enabled, the PASSWORD prompt will appear when an attempt is made

to enter the PROGRAM mode. The PASSWORD prompt appears as follows:

PASSWORD

0000

CURSOR

To enter the password, use the

and keys to scroll to the password value, and

then press the ENTER key.

NOTE: The factory default password is 0019.

39

Page 41

Once the correct password is entered, the PROGRAM mode will be entered and

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

the first parameter will be displayed, which is Parameter 0 - LINE VOLTS. This

is shown below:

PARAMETER

NUMBER

PARAMETER

NAME

PARAMETER

VALUE

0 LINE VOLTS

AUTO

CURSOR

To scroll through the parameters, use the

and keys on the keypad. When

the desired parameter is found, press the ENTER key to shift the cursor from the

parameter name to the parameter value. In this example, the cursor shifts from

LINE VOLTS to AUTO:

PARAMETER

NUMBER

PARAMETER

NAME

PARAMETER

VALUE

0 LINE VOLTS

AUTO

CURSOR

The parameter value can then be changed using the and keys. If the parameter

has a numerical value, the key will increase the value and the key will

decrease the value. If the parameter has specific choices that can be selected, the

and keys will scroll through the list of possible settings. When the desired

value or option is selected, press the ENTER key to store the new setting. If the

new setting is not ENTERED, it will not take effect and the old setting will still

be valid.

If the PROG/RUN key is pushed while the cursor is highlighting the parameter

value, the value will change back to the original setting (if it had been changed, but

not ENTERED), and the cursor will shift back to the parameter name. Pressing

PROG/RUN again will exit the PROGRAM mode. If the PROGRAM mode is

entered again within two minutes, the last parameter that was viewed, or changed,

will come up on the display. After two minutes has elapsed, the password will

have to be entered again when attempting to access the PROGRAM mode.

40

Page 42

17.0 PARAMETER MENU

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

PARAMETER MENU

PARAM.

NUMBER

0 LINE VOLTS HIGH, LOW, AUTO AUTO

1 PRESET #1 (NOTE 1) 20.00 Hz

2 PRESET #2 (NOTE 1) 20.00 Hz

3 PRESET #3 (NOTE 1) 20.00 Hz

4 PRESET #4 (NOTE 1) 20.00 Hz

5 SKIP FREQ #1 .00 Hz - MAXIMUM FREQ .00 Hz

6 SKIP FREQ #2 .00 Hz - MAXIMUM FREQ .00 Hz

7 BANDWIDTH .00 - 10.00 Hz 1.00 Hz

8 ACCEL RATE (NOTE 1) 30.0 SEC

9 DECEL RATE (NOTE 1) 30.0 SEC

10 MINIMUM FREQ .00 - MAXIMUM FREQ .50 Hz

11 MAXIMUM FREQ MINIMUM FREQ - 120.0 Hz 60.00 Hz

12 DC BRAKE VOLT (NOTE 1) .0 VDC

13 DC BRAKE TIME .0 - 999.9 SEC .0 SEC

14 DYNAMIC BRAKE OFF, ON OFF

PARAMETER

NAME

RANGE OF

ADJUSTMENT

FACTORY

DEFAULT

16 CURRENT LIMIT 25 - 120 % 120 %

17 MOTOR OVRLOAD 25 - 100 % 100%

18 BASE FREQ 20.00 - 360.0 Hz 60.00 Hz

19 FIXED BOOST .0 - 30.0 % (NOTE 1)

22 TORQUE

23 CARRIER FREQ 2.5, 6, 8, 10, 12, 14 kHz 2.5 kHz

NOTE 1: REFER TO SECTION 18.0 - DESCRIPTION OF PARAMETERS.

CONSTANT, VARIABLE,

CONST / NO COMP

CONSTANT

41

Page 43

PARAMETER MENU

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

PARAM.

NUMBER

24 AUTO SOURCE

25 START METHOD

26 STOP METHOD RAMP, COAST COAST

28 SPEED SRC KEY ENABLED, DISABLED ENABLED

29 HAND SOURCE

30 CONTROL

31 UNITS

32 HZ MULTIPLIER .10 - 650.0 1.00

33 UNITS DECIMAL

34 LOAD MULTIPLY 95 - 139 % 100%

35 LCD CONTRAST LOW, MED, HIGH MED

36 SLEEP THRSHLD .00 - 360.0 Hz .00 Hz

37 SLEEP DELAY .0 - 300 SEC 30.0 SEC

38 SLEEP BANDWID FB @ MIN - FB @ MAX 0%

39 TB5 MIN FREQ .00 - 360.0 Hz .00 Hz

40 TB5 MAX FREQ .00 - 360.0 Hz 60.00 Hz

41 AN INPUT FLTR 0.01 - 10.0 SEC 0.02 SEC

42 TB10A OUTPUT NONE, 0-10V, 2-10V NONE

PARAMETER

NAME

RANGE OF

ADJUSTMENT

KEYPAD, 0-10 VDC, 4-20 MA,

PRESET #1, PRESET #2,

PRESET #3, PRESET #4,

MOP, SELECTED

NORMAL, POWER UP,

AUTO 1, AUTO 2, AUTO 3

KEYPAD, 0-10 VDC, 4-20 MA,

PRESET #1, PRESET #2,

PRESET #3, PRESET #4,

MOP, SELECTED

NORMAL, NORM NO HAND,

SERIAL AUTO, S AUTO/NO HND

speed: HERTZ, RPM, % HZ,

/SEC, /MIN, /HR, GPH, NONE

speed: HERTZ

pid: %, PSI, FPM, CFM, GPM, IN,

FT, /SEC, /MIN, /HR, F, C, MPM, GPH

XXXXX, XXX.X, XX.XX,

X.XXX, .XXXX

FACTORY

DEFAULT

4-20 MA

NORMAL

KEYPAD

NORMALSERIAL SPEED, S SPD/NO HAND,

XXXXX

42

Page 44

PARAMETER MENU

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

PARAM.

NUMBER

43 TB10A SCALING 3.00 - 360.0 Hz 60.00 Hz

44 TB10B OUTPUT NONE, 0-10V, 2-10V NONE

45 TB10B SCALING 10 - 200 % 125 %

47 TB13A INPUT

48 TB13B INPUT

49 TB13C INPUT

50 TB13D INPUT

52 TB14/RELAY #2 CURRENT LIMIT, AUTO/HAND

53 TB15/RELAY #3 SRC, FOLLOWER PRES, NONE

54 RELAY #1 MIN/MAX ALARM, INV MIN/MAX A,

55 TB5B LOSS FAULT, PRESET #3 FAULT

56 SERIAL LOSS FAULT, AUTO FAULT

57 SERIAL

58 SERIAL ADDRES 1 - 247 30

61 PASSWORD 0000 - 9999 0019

63 SOFTWARE VERS (VIEW - ONLY) (N/A)

64 MONITOR MODE OFF, ON ON

PARAMETER

NAME

RANGE OF

ADJUSTMENT

NONE, 0-10VDC, 4-20MA,

FREQ, REVERSE

NONE, 0-10VDC, 4-20MA,

PRESET #2, INCREASE FREQ

NONE, 0-10VDC, 4-20MA,

PRESET #3, HAND, REVERSE

EXTERN FAULT,

EXTERN FAULTEXTERN /FAULT,

EXTERN CLEAR

NONE, RUN, FAULT, INVERSE

FAULT, FAULT LOCKOUT,

AT SPEED, ABOVE PRSET #3,

MIN ALARM, INV MIN ALARM,

MAX ALARM, INV MAX ALARM,

RUN REVERSE

DISABLED, WITH TIMER,

W/O TIMER

FACTORY

DEFAULT

NONEPRESET #1, DECREASE

NONE

NONE

DISABLED

43

Page 45

PARAMETER MENU

Phone: 800.894.0412 - Fax: 208.368.0415 - www.ctiautomation.net - e.mail: info@ctiautomation.net

PARAM.

NUMBER

65 PROGRAM

66 CLEAR HISTORY MAINTAIN, CLEAR MAINTAIN

70 PID MODE OFF, NORMAL, REVERSE OFF

74 PID FEEDBACK TB-5A, TB-5B TB-5A

75 FEEDBACK @ MIN -32500 to 32500 0.0%

76 FEEDBACK @ MAX -32500 to 32500 100.0%

77 PROPOR. GAIN 0.0 - 999.9% 5.00%

78 INTEGRAL GAIN 0.0 - 10.0 SEC 0.0 SEC

79 DIFF. GAIN 0.0 - 10.0 SEC 0.0 SEC