Page 1

15, 30, & 60 cfm

Compact Dehumidifying Dryers

Part Number: A0570882

Bulletin Number: SM1-690.1

Effective: 8/05/04

Write Down Your Serial Numbers Here For Future Reference:

_________________________ _________________________

_________________________ _________________________

_________________________ _________________________

We are committed to a continuing program of product improvement.

Specifications, appearance, and dimensions described in this manual are subject to change without notice.

DCN No. ____________

© Copyright 2004

All rights reserved.

Page 2

15, 30, & 60 cfm Compact Dryers ii

Shipping Information

Unpacking and Inspection

You should inspect your dryer for possible shipping damage.

Thoroughly check the equipment for any damage that might have occurred in transit, such as

broken or loose wiring and components, loose hardware and mounting screws, etc.

In the Event of Shipping Damage

According to the contract terms and conditions of the Carrier, the responsibility of the

Shipper ends at the time and place of shipment.

Notify the transportation company’s local agent if you discover damage.

Hold the damaged goods and packing material for the examining agent’s inspection. Do not

return any goods before the transportation company’s inspection and authorization.

File a claim with the transportation company. Substantiate the claim by referring to the

agent’s report. A certified copy of our invoice is available upon request. The original Bill of

Lading is attached to our original invoice. If the shipment was prepaid, write us for a

receipted transportation bill.

Advise customer service regarding your wish for assistance and to obtain an RMA (return

material authorization) number.

If the Shipment is Not Complete

Check the packing list as back-ordered items are noted on it. You should have:

˛ Dehumidifying Dryer

˛ Bill of lading

˛ Packing list

˛ Operating and Installation packet

˛ Electrical schematic and panel layout drawings

˛ Component instruction manuals

Re-inspect the container and packing material to see if you missed any smaller items during

unpacking.

If the Shipment is Not Correct

If the shipment is not what you ordered, contact the shipping department immediately. For

shipments in the United States and Canada, call 1 (414) 354-0970; for all other countries, call

our international desk at (414) 354-0970. Have the order number and item number available.

Hold the items until you receive shipping instructions.

Returns

Do not return any damaged or incorrect items until you receive shipping instructions from the

shipping department.

Page 3

15, 30, & 60 cfm Compact Dryers iii

Credit Returns

Prior to the return of any material authorization must be given by the manufacturer. A

RMA number will be assigned for the equipment to be returned.

Reason for requesting the return must be given.

ALL returned material purchased from the manufacturer returned is subject to 15% ($75.00

minimum) restocking charge.

ALL returns are to be shipped prepaid.

The invoice number and date or purchase order number and date must be supplied.

No credit will be issued for material that is not within the manufacturer’s warranty period

and/or in new and unused condition, suitable for resale.

Warranty Returns

Prior to the return of any material, authorization must be given by the manufacturer. A

RMA number will be assigned for the equipment to be returned.

Reason for requesting the return must be given.

All returns are to be shipped prepaid.

The invoice number and date or purchase order number and date must be supplied.

After inspecting the material, a replacement or credit will be given, at the manufacturer’s

discretion. If the item is found to be defective in materials or workmanship, and it was

manufactured by our company, purchased components are covered under their specific

warranty terms.

Page 4

15, 30, & 60 cfm Compact Dryers iv

Table of Contents

CHAPTER 1: SAFETY.................................................................... 6

1-1 How to Use This Manual ............................................................................................ 6

Safety Symbols Used in this Manual..................................................................... 6

Dryer Safety Tags ................................................................................................7

1-2 Warnings and Precautions ......................................................................................... 7

1-3 Responsibility............................................................................................................. 8

General Responsibility..........................................................................................8

Operator Responsibility ........................................................................................ 9

Maintenance Responsibility ................................................................................ 10

Reporting a Safety Defect...................................................................................10

1-4 Technical Specifications........................................................................................... 11

Annex B Information........................................................................................... 11

CHAPTER 2: FUNCTIONAL DESCRIPTION .............................. 12

2-1 Models Covered in This Manual ............................................................................... 12

2-2 General Description ................................................................................................. 12

What is desiccant? ............................................................................................. 13

The Process/Regeneration Cycle ....................................................................... 13

2-3 Standard Features ................................................................................................... 13

Mechanical Features .......................................................................................... 13

Electrical Features ............................................................................................. 13

Controller Features............................................................................................. 13

2-4 Options .................................................................................................................... 14

2-5 Safety Devices and Interlocks .................................................................................. 14

CHAPTER 3: INSTALLATION ..................................................... 16

3-1 Uncrating the Equipment.......................................................................................... 16

3-2 Rigging and Placing the Dryer.................................................................................. 16

Recommended Dryer Lifting Hardware ...............................................................17

3-3 Electrical Connections.............................................................................................. 18

3-4 Setup Procedures .................................................................................................... 19

Checking for Proper Blower Rotation..................................................................19

Making Dryer/Drying Hopper Process Air Connections ....................................... 19

Drying Hopper Air Trap Considerations............................................................... 20

Optional Aftercooler............................................................................................ 20

3-5 Initial Start-up........................................................................................................... 20

Pre-Startup Checks............................................................................................ 20

Starting Up the Dryer.......................................................................................... 21

Auto-Tuning the Dryer ........................................................................................ 21

Shutting Down the Dryer ....................................................................................21

CHAPTER 4: OPERATION .......................................................... 22

4-1 Start-up.................................................................................................................... 22

4-2 Controller Description and Operation........................................................................ 23

Page 5

15, 30, & 60 cfm Compact Dryers v

Identifying Control Panel Indicator Lights and Switches for the Standard

Controller ........................................................................................................... 23

Process Air Temperature Controller.................................................................... 24

Setting the Process Air Temperature ..................................................................25

Restoring the Process Air Temperature Controller (E5CN) to Factory Settings....26

Process Air Dew Point Display ........................................................................... 29

Setting the High Dew Point Alarm.......................................................................29

Restoring the Process Air Dew Point Meter (E5CK) to Factory Setup..................29

4-3 Dryer Operation Procedures..................................................................................... 30

Controller Operation ........................................................................................... 30

Alarm Display Messages .................................................................................... 32

4-4 Auto-Tuning the Dryer.............................................................................................. 33

4-5 Shutting Down the Dryer .......................................................................................... 33

CHAPTER 5: MAINTENANCE..................................................... 34

5-1 Preventative Maintenance Schedule......................................................................... 34

5-2 Preventative Maintenance........................................................................................ 35

Servicing Process Air Filters...............................................................................35

Servicing the Dew Point Monitor.........................................................................36

5-3 Corrective Maintenance ........................................................................................... 37

Symptoms of Worn Desiccant............................................................................. 37

Replacing Worn Desiccant .................................................................................38

Replacing the Process/Regeneration Heater ......................................................40

Replacing/Cleaning the Regeneration Cooling Coils ........................................... 41

CHAPTER 6: TROUBLESHOOTING........................................... 42

6-1 Introduction.............................................................................................................. 42

6-2 Determining Temperature Controller Errors or Sensor Errors.................................... 45

Using a Thermocouple .......................................................................................45

Using a Platinum Resistance Thermometer ........................................................ 45

CHAPTER 7: APPENDIX ............................................................. 46

7-1 Warranty.................................................................................................................. 46

Warranty Specifications..........................................Error! Bookmark not defined.

Warranty Restrictions .............................................Error! Bookmark not defined.

Warranty Liabilities.................................................Error! Bookmark not defined.

Customer Responsibilities ......................................Error! Bookmark not defined.

7-2 Drawings and Diagrams ........................................................................................... 47

Aftercooler Design Specifications ....................................................................... 48

Spare Parts List.................................................................................................................. 50

7-4 Dryer Identification (Serial Number) Tag................................................................... 51

7-5 Technical Assistance ............................................................................................... 51

Parts Department ...............................................................................................51

Service Department............................................................................................ 51

Sales Department .............................................................................................. 51

Contract Department .......................................................................................... 51

Page 6

15, 30, & 60 cfm Compact Dryers Chapter 1: Safety 6 of 51

Chapter 1: Safety

1-1 How to Use This Manual

Use this manual as a guide and reference for installing, operating, and maintaining your

dehumidifying dryer. The purpose is to assist you in applying efficient, proven techniques

that enhance equipment productivity.

This manual covers only light corrective maintenance. No other maintenance should be

undertaken without first contacting a service engineer.

The Functional Description section outlines models covered, standard features, and safety

features. Additional sections within the manual provide instructions for installation, preoperational procedures, operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup

of the dehumidifying dryer. We can also provide the assistance of a factory-trained technician

to help train your operator(s) for a nominal charge. This section includes instructions, checks,

and adjustments that should be followed before commencing with operation of the

dehumidifying dryer. These instructions are intended to supplement standard shop

procedures performed at shift, daily, and weekly intervals.

The Operation chapter includes a description of electrical and mechanical controls, in

addition to information for operating the dryer safely and efficiently.

The Maintenance chapter is intended to serve as a source of detailed assembly and

disassembly instructions for those areas of the equipment requiring service. Preventive

maintenance sections are included to ensure that your dehumidifying dryer provides

excellent, long service.

The Troubleshooting chapter serves as a guide for identification of most common problems.

Potential problems are listed, along with possible causes and related solutions.

The Appendix contains technical specifications, drawings, schematics, parts lists, and

available options. A spare parts list with part numbers specific to your machine is provided

with your shipping paperwork package. Refer to this section for a listing of spare parts for

purchase. Have your serial number and model number ready when ordering.

Safety Symbols Used in this Manual

The following safety alert symbols are used to alert you to potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid possible injury or death.

DANGER! DANGER indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING! WARNING indicates a potentially hazardous situation or practice that, if

not avoided, could result in death or serious injury.

Caution! CAUTION indicates a potentially hazardous situation or practice that, if

not avoided, may result in minor or moderate injury or in property damage.

Page 7

15, 30, & 60 cfm Compact Dryers Chapter 1: Safety 7 of 51

Dryer Safety Tags

Hot! Read Operation

and Installation

Manual

High Voltage Earth Ground

Inside Enclosure

PE Protected Earth

Lifting Point Ground

1-2 Warnings and Precautions

Our equipment is designed to provide safe and reliable operation when installed and operated

within design specifications, following national and local safety codes. This may include, but

is not limited to OSHA, NEC, CSA, SPI, and any other local, national and international

regulations.

To avoid possible personal injury or equipment damage when installing, operating, or

maintaining this equipment, use good judgment and follow these safe practices:

˛ Read and follow these operation and installation instructions when installing,

operating, and maintaining this equipment. If these instructions become

damaged or unreadable, additional copies are available from the manufacturer.

˛ Follow all SAFETY CODES.

˛ Wear SAFETY GLASSES and WORK GLOVES.

˛ Work only with approved tools and devices.

˛ Disconnect and/or lock out power before servicing or maintaining the equipment.

˛ Use care when LOADING, UNLOADING, RIGGING, or MOVING this

equipment.

˛ Operate this equipment within design specifications.

˛ OPEN, TAG, and LOCK ALL DISCONNECTS before working on equipment.

You should remove the fuses and carry them with you.

˛ Make sure the equipment and components are properly GROUNDED before you

switch on power.

˛ Use EXTEREME CAUTION when working with dryer. HIGH HEAT can be

dangerous. Keep body parts, tools, clothing, and debris away from dryer.

Page 8

15, 30, & 60 cfm Compact Dryers Chapter 1: Safety 8 of 51

˛ When welding or brazing in or around this equipment, make sure VENTILATION is

ADEQUATE. PROTECT adjacent materials from flame or sparks by shielding with

sheet metal. An approved FIRE EXTINGUISHER should be close at hand and

ready for use if needed.

˛ Do not restore power until you remove all tools, test equipment, etc., and the

equipment and related components are fully reassembled.

˛ Only PROPERLY TRAINED personnel familiar with the information in this

manual should work on this equipment.

We have long recognized the importance of safety and have designed and manufactured our

equipment with operator safety as a prime consideration. We expect you, as a user, to abide

by the foregoing recommendations in order to make operator safety a reality.

1-3 Responsibility

These machines are constructed for maximum operator safety when used under standard

operating conditions and when recommended instructions are followed in the maintenance

and operation of the machine.

All personnel engaged in the use of the machine should become familiar with its operation as

described in this manual.

Proper operation of the machine promotes safety for the operator and all workers in its

vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined.

All warning and danger signs must be observed and obeyed. All actual or potential danger

areas must be reported to your immediate supervisor.

General Responsibility

No mater who you are, safety is important. Owners, operators and maintenance personnel

must realize that every day, safety is a vital part of their jobs.

If your main concern is loss of productivity, remember that production is always affected in a

negative way following an accident. The following are some of the ways that accidents can

affect your production:

• Loss of a skilled operator (temporarily or permanently)

• Breakdown of shop morale

• Costly damage to equipment

• Downtime

An effective safety program is responsible and economically sound.

Organize a safety committee or group, and hold regular meetings. Promote this group from

the management level. Through this group, the safety program can be continually reviewed,

maintained, and improved. Keep minutes or a record of the meetings.

Hold daily equipment inspections in addition to regular maintenance checks. You will keep

your equipment safe for production and exhibit your commitment to safety.

Please read and use this manual as a guide to equipment safety. This manual contains safety

warnings throughout, specific to each function and point of operation.

Page 9

15, 30, & 60 cfm Compact Dryers Chapter 1: Safety 9 of 51

Operator Responsibility

The operator’s responsibility does not end with efficient production. The operator usually has

the most daily contact with the equipment and intimately knows its capabilities and

limitations.

Plant and personnel safety is sometimes forgotten in the desire to meet incentive rates, or

through a casual attitude toward machinery formed over a period of months or years. Your

employer probably has established a set of safety rules in your workplace. Those rules, this

manual, or any other safety information will not keep you from being injured while operating

your equipment.

Learn and always use safe operation. Cooperate with co-workers to promote safe practices.

Immediately report any potentially dangerous situation to your supervisor or appropriate

person.

REMEMBER:

• NEVER place your hands or any part of your body in any dangerous location.

• NEVER operate, service, or adjust the dryer without appropriate training and first

reading and understanding this manual.

• NEVER try to pull material out of the dryer with your hands while it is running!

• Before you start the dryer check the following:

• Remove all tools from the dryer;

• Be sure no objects (tools, nuts, bolts, clamps, bars) are laying in the

hopper area;

• If your dryer has been inoperative or unattended, check all settings before starting the

unit.

• At the beginning of your shift and after breaks, verify that the controls and other

auxiliary equipment are functioning properly.

• Keep all safety guards in place and in good repair. NEVER attempt to bypass, modify,

or remove safety guards. Such alteration is not only unsafe, but will void the warranty

on your equipment.

• When changing control settings to perform a different mode of operation, be sure

selector switches are correctly positioned. Locking selector switches should only be

adjusted by authorized personnel and the keys removed after setting.

• Report the following occurrences IMMEDIATELY:

• unsafe operation or condition

• unusual dryer action

• leakage

• improper maintenance

• NEVER stand or sit where you could slip or stumble into the dryer

while working on it.

• DO NOT wear loose clothing or jewelry, which can be caught while working on a

dryer. In addition, cover or tie back long hair.

Page 10

15, 30, & 60 cfm Compact Dryers Chapter 1: Safety 10 of 51

• Clean the dryer and surrounding area DAILY, and inspect the machine for loose,

missing or broken parts.

• Shut off power to the dryer when it is not in use. Turn the switch to the OFF position,

or unplug it from the power source.

Maintenance Responsibility

Proper maintenance is essential to safety. If you are a maintenance worker, you must make

safety a priority to effectively repair and maintain equipment.

Before removing, adjusting, or replacing parts on a machine, remember to turn off all electric

supplies and all accessory equipment at the machine, and disconnect and lockout electrical

power. Attach warning tags to the disconnect switch.

When you need to perform maintenance or repair work on a dryer above floor level, use a

solid platform or a hydraulic elevator. If there is a permanently installed catwalk on your

dryer, use it. The work platform should have secure footing and a place for tools and parts.

DO NOT climb on dryers, machines, or work from ladders.

If you need to repair a large component, use appropriate handling equipment. Before you use

handling equipment (portable “A” frames, electric boom trucks, fork trucks, overhead cranes)

be sure the load does not exceed the capacity of the handling equipment or cause it to become

unstable.

Carefully test the condition of lifting cables, chains, ropes, slings, and hooks before using

them to lift a load.

Be sure that all non-current carrying parts are correctly connected to earth ground with an

electrical conductor that complies with current codes. Install in accordance with national and

local codes.

When you have completed the repair or maintenance procedure, check your work and remove

your tools, rigging, and handling equipment.

Do not restore power to the dryer until all persons are clear of the area. DO NOT start and

run the dryer until you are sure all parts are functioning correctly.

BEFORE you turn the dryer over to the operator for production, verify all dryer enclosure

panels, guards and safety devices are in place and functioning properly.

Reporting a Safety Defect

If you believe that your equipment has a defect that could cause injury, you should

immediately discontinue its use and inform the manufacturer.

The principle factors that can result in injury are failure to follow proper operating procedures

(i.e. lockout/tagout), or failure to maintain a clean and safe working environment.

Page 11

15, 30, & 60 cfm Compact Dryers Chapter 1: Safety 11 of 51

1-4 Technical Specifications

Annex B Information

The following design information is provided for your reference:

1. No modifications are allowed to this equipment that could alter the CE compliance

2. Ambient temperature: 0 degrees Celsius – Maximum (104 degrees Fahrenheit)

3. Humidity range: 50% relative humidity

4. Altitude: Sea level

5. Environment: Clean, dust-free and non-explosive

6. Radiation: None

7. Vibration: Minimal, i.e. machine mounting

8. Allowable voltage fluctuation: +/- 10%

9. Allowable frequency fluctuation: Continuous +/- 1%

Intermittent +/- 2%

10. Nominal supply voltage: 115/1/60 (Verify on serial number tag)

11. Earth ground type: TN (system has one point directly earthed through a protective

conductor)

12. Power supply should include a ground connection.

13. Over-current protection is supplied in the dryer, but additional protection should be

supplied by the user.

14. The door-mounted disconnect serves as the electrical disconnect device for 3 phase

units.

15. Dryer is not equipped with local lighting.

16. Functional identification

17. Dryer is supplied with an operating manual in the language of the destination

country.

18. Cable support may be required for power cord, depending on final installation.

19. No one is required to be in the interior of the electrical enclosure during the normal

operation of the unit. Only skilled electricians should be inside the enclosure for

maintenance.

20. Doors can be opened with a screwdriver, but no keys are required.

21. Two-hand control is not required or provided.

22. All dryers should be moved around and set in a place with a lift truck or equivalent.

23. There are no frequent repetitive cycles that require manual controlærepetitive

functions are automatic while the dryer is operating.

24. An inspection report detailing the functional test is included with the dryer.

25. The machine is not equipped with cableless controls.

26. Color-coded (harmonized) power cord is sufficient for proper installation.

Page 12

15, 30, & 60 cfm Compact Dryers Chapter 2: Functional Description 12 of 51

Chapter 2: Functional Description

2-1 Models Covered in This Manual

This manual provides operation, installation, and maintenance instructions for 15, 30, and 60

cfm dehumidifying dryers. Model numbers are listed on the serial tag. Make sure you know

the model and serial number of your equipment before contacting the manufacturer for parts

or service.

Our dehumidifying mini dryers are designed to generate heated dehumidified air at carefully

controlled temperatures for use in plastic drying systems. Drying systems are sized to meet

the specific requirements stated by the Customer at the time of purchase.

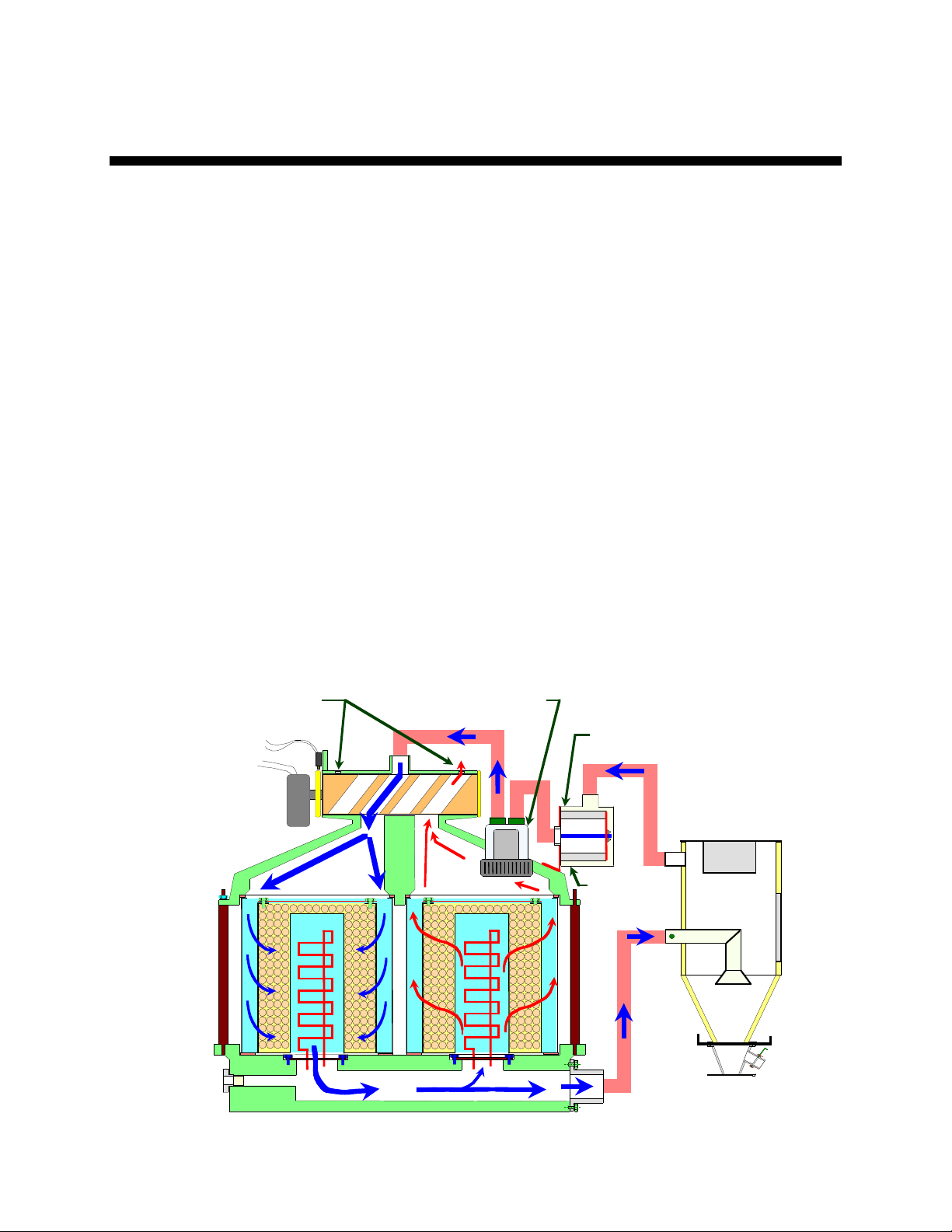

2-2 General Description

Dehumidifying dryers are used to generate very low dew point air heated to a controlled

temperature for drying plastic pellets and regrind.

Our dryers force hot, dry air through resin in a drying hopper, where air picks up moisture

from the material and draws it back to the dryer. In the dryer, a desiccant bed strips moisture

from the air. The dried process air is then re-heated and delivered back into the drying

hopper for more moisture removal.

A small amount of ambient air is introduced into the process air stream to make up for the air

lost during the bed regeneration. Because the process air is typically much drier than the

ambient air, the air mixture maintains drying efficiency at a consistently high level. To

compensate for the humidity content in the air, this dryer is supplied with the proper amount

of desiccant.

Figure 1: Typical Dryer Air Flow Schematic

Drying

Hopper

Filter

(Separates Dust )

High Pressure

Peripheral Blower

Regeneration

Make Up Air

Moisture

Exhaust

Page 13

15, 30, & 60 cfm Compact Dryers Chapter 2: Functional Description 13 of 51

What is desiccant?

Desiccant is a material that attracts and holds (absorbs) water from the air. The desiccant our

dryers use is a synthetic crystalline metal aluminosilicate blended with a clay binder and

formed into beads.

Absorbed water is driven from saturated desiccant by heating it to a high temperature

(reducing desiccant capacity to hold water) and forcing air through it. This moisture removal

process is called regeneration.

The Process/Regeneration Cycle

Our dryers have two desiccant beds. While one bed is on-line in the process air loop, the

other is off-line, being regenerated.

When a desiccant bed is on-line, it absorbs moisture from the process air. In time, the bed

becomes saturated with moisture and needs to be regenerated. The dryer automatically

redirects the process airflow to the second bed, and starts the regeneration cycle on the first

bed.

During regeneration, the dryer system heats air and forces it through the desiccant bed. The

moisture driven off the bed bleeds to the atmosphere.

2-3 Standard Features

Mechanical Features

• Dual desiccant beds

• Electrically-actuated air valve

• 13X Molecular Sieve

• Single regenerative process blower

• Drying temperature range of 180ºF to 250ºF.

Electrical Features

• Process thermocouple to be connected to drying hopper air inlet.

• Nema 12 control enclosure

• NFPA79 machinery electrical standards

• Non-fused electrical disconnect

• Branch fusing

• Mercury process heater contactor

• Regeneration temperature control

• Process high temperature alarm light

• Process/regeneration heater box

• High temperature safety system (Process/Regeneration)

Controller Features

• Mitsubishi programmable relay controller

Page 14

15, 30, & 60 cfm Compact Dryers Chapter 2: Functional Description 14 of 51

• Display of process temperature set point and actual settings

2-4 Options

Options marked with “*” indicate options that can be factory installed or retrofitted in the

field.

• Process temperature up to 400ºF (or below 180ºF), including aftercooler on back of

dryer and silicone insulated delivery hose.

Note: For below 160°F, cooler needs to be outside, between dryer and

drying hopper.

• Machine mount adapter to accommodate a dryer and corresponding hopper.

• Drawer magnet, stainless steel construction.

• Casters, two (2) fixed and two (2) swivel.

• Portable carts

• Dew point monitor

• High temperature operation up to 400ºF

• Insulated process air delivery hose

2-5 Safety Devices and Interlocks

This section includes information on safety devices and procedures that are inherent to the

Dryer. This manual is not intended to supersede or alter safety standards established by the

user of this equipment. Instead, the material contained in this section is recommended to

supplement these procedures in order to provide a safer working environment.

At the completion of this section, the operator and maintenance personnel will be able to do

the following:

• Identify and locate specific safety devices.

• Understand the proper use of the safety devices provided.

• Describe the function of the safety device.

Safety Circuit Standards

Safety circuits used in industrial systems protect the operator and maintenance personnel

from dangerous energy. They also provide a means of locking out or isolating the energy for

servicing equipment.

Various agencies have contributed to the establishment of safety standards that apply to the

design and manufacture of automated equipment. The Occupational Safety and Health

Administration (OSHA) and the Joint Industrial council (JIC) are just a few of the

organizations that have joined with the plastics industry to develop safety standards.

Every effort has been made to incorporate these standards into the design of the dryer;

however, it is the responsibility of the personnel operating and maintaining the equipment to

familiarize themselves with the safety procedures and the proper use of any safety devices.

Fail Safe Operation

If a safety device or circuit should fail, the design must be such that the failure causes a

“Safe” condition. As an example, a safety switch must be a normally open switch. The switch

Page 15

15, 30, & 60 cfm Compact Dryers Chapter 2: Functional Description 15 of 51

must be held closed with the device it is to protect. If the switch fails, it will go to the open

condition, tripping out the safety circuit.

At no time should the safety device fail and allow the operation to continue. For

example, if a safety switch is guarding a motor, and the safety switch fails, the motor should

not be able to run.

Safety Device Lock-Outs

Some safety devices disconnect electrical energy from a circuit. The safety devices that are

used on these dryers are primarily concerned with electrical power disconnection and the

disabling of moving parts that may need to be accessed during the normal operation of the

machine.

Some of the safety devices utilize a manual activator. This is the method of initiating the

safety lock out. This may be in the form of a plug, lever or a handle. Within this lockable

handle, there may be a location for a padlock. Personnel servicing the equipment should

place a padlock in the lockout handle.

In addition to the safety devices listed above, these dryers are equipped with a line cord plug.

This allows the operator or maintenance personnel to unplug the dryer from its power source

and tag it out. The plug can then be tagged with any number of approved electrical lockout

tags available at most electrical supply stores.

WARNING! Always disconnect and lockout all electrical power and pneumatic (i.e. compressed air)

sources prior to servicing or cleaning the dryer. Failure to do so may result in serious

injury. No one but the person who installed the lockout may remove it.

Page 16

15, 30, & 60 cfm Compact Dryers Chapter 3: Installation 16 of 51

Chapter 3: Installation

3-1 Uncrating the Equipment

Dehumidifying Dryers are shipped mounted on a skid, enclosed in a plastic wrapper, and

contained in a cardboard box.

1. Pry the crating away from the skid.

Note: Remove the nails holding the box to the skid and lift the box

off carefully; avoiding staples in the 1’ x 4’ wood supports.

Cut the steel banding.

2. Use a pry bar to remove the blocks securing the unit to the skid.

3. Lift unit from sides. Use a pry bar if necessary to carefully remove the

skid from the unit.

4. Lower slowly.

3-2 Rigging and Placing the Dryer

Take care when rigging and placing the dryer. Figures 1, 2 and 3 on the following pages show

a suggested safe rigging diagram. It lets you lift the dryer/hopper unit vertically for

installation on the machine throat. Adjust chain lengths at the center sling bracket before you

lift the unit. Your dryer has built-in lifting lugs.

Caution! If you are mounting a machine-mount dryer with a magnet or transition adaptor on the

machine throat, you must provide additional support to hold the dryer securely on the

machine.

Be aware that off-center static and dynamic hopper loading can occur with machine

vibration. Again, provide additional support to hold the dryer securely on the machine.

Use caution and observe safety rules when lifting and placing your dryer!

Page 17

15, 30, & 60 cfm Compact Dryers Chapter 3: Installation 17 of 51

Figure 2: Suggested Lift Rigging for Cart Mounted Dryers

Caution! Do not use a hoist to move or rig your Dryer when it is mounted on a cart!

Moving the Dryer with a hoist will cause it to become unstable and may

cause damage to the Dryer and/or injury to personnel!

Recommended Dryer Lifting Hardware

Item

Quantity

Description

Vendor

Vendor part no.

11Adjustable alloy chain sling

McMaster-Carr

33665T32

22Existing hopper lifting bracket

—

—

31Drop forged steel eye nut

McMaster-Carr

3019T15

41Chain connector

McMaster-Carr

3712T23

Figure 3: Suggested Lift Rigging for Floor Mounted Dryers

Note: Floor Mounted Dryers can be lifted by hoist or fork lift.

PROCESS

TEMPERATURE

DEW POINT

CONTROL

POWER

ON

OFF

ALARM

POWER ON

ON

OFF

PROCESS

TEMPERATURE

DEW POINT

CONTROL

POWER

ON

OFF

ALARM

POWER ON

ON

OFF

Page 18

15, 30, & 60 cfm Compact Dryers Chapter 3: Installation 18 of 51

Figure 4: Suggested Lift Rigging for Machine Mounted Dryers

Caution! When using a hoist to move a machine mounted dryer, ALWAYS attach

chains to the three (3) locations/lifting points on the unit! Moving the

Dryer without the chains attached to all of the lifting points will cause the

unit to become unstable and may cause damage to the Dryer and/or injury

to personnel!

3-3 Electrical Connections

When making electrical connections to your dryer, ensure that you take into consideration

and make arrangements for the following:

• A qualified electrician should make all electrical connections.

• Fulfill all national, state, and local safety and electrical code requirements.

• The serial tag lists voltage, phase, and amp draw information:

• Line voltage must be within plus or minus ten percent (±10%) of the

voltage listed on the serial tag, or damage may occur. Phase imbalance

must be less than two percent (2%).

• Connect main power to the dryer at the disconnect or terminals in the upper right

corner of the control enclosure.

• Install a fused disconnect with a lockout feature in the power main leading to the dryer.

• The power drop must include a ground wire.

• Make sure all electrical connections are tight.

PROCESS

TEMPERATUR

E

DEW POINT

CONT

ROL

POWE

R

ON

OFF

ALARMPOWER ON

ON

OFF

Page 19

15, 30, & 60 cfm Compact Dryers Chapter 3: Installation 19 of 51

3-4 Setup Procedures

This section provides the procedures necessary for configuring your Dehumidifying Dryer.

Configuration of your dryer includes checking for proper blower rotation, making

dryer/drying hopper process air connections and the optional aftercooler (on 15 and 30 cfm

models). We recommend that you carry out these procedures in the order given here.

Note: Before carrying out these procedures, install all equipment as

described in this section.

Checking for Proper Blower Rotation

Three-Phase Models

Caution! In three-phase models, incorrect phasing of power leads can cause

backward rotation of blower motors and CONTAMINATION OF THE

DESICCANT!

Always check blower rotation before putting material in the drying hopper!

The blower is rotating properly when air flows from the delivery outlet.

Note: Holding your hand in front of the air return will also indicate if the

blower rotates in the proper direction.

If the three-phase blower rotates improperly, reverse any two wires at the fused disconnect

outside the dryer or at the disconnect/terminal in the control enclosure. This assures that the

blower rotates in the proper direction.

Making Dryer/Drying Hopper Process Air Connections

Floor Mount Models

When making process air connections to your floor mounted dryer, ensure that you take into

consideration and make arrangements for the following:

• Use high-temperature flexible dryer hose or rigid tubing to connect the dryer to the

drying hopper.

• Keep the delivery hose to the drying hopper as short as possible to minimize heat loss.

We strongly recommend insulated hose for maximum energy savings.

• Do not use insulated hose on the return from the drying hopper.

• The return air to the blower must be 150°F (66ºC) or below. If the return air

temperature is not below this point, you should purchase and install the optional

aftercooler to remove excessive heat. Consult the manufacturer for more information.

Aftercooler considerations also apply to machine-mount models.

• Make sure that hoses are not kinked or collapsed.

• Drying hopper air inlet and outlet locations vary, but always connect hoses so the dry

process air from the dryer enters the bottom of the drying hopper and flows out the top

to return to the dryer inlet.

• Thermocouple is to be installed at drying hopper’s delivery tube.

Page 20

15, 30, & 60 cfm Compact Dryers Chapter 3: Installation 20 of 51

Drying Hopper Air Trap Considerations

Our exclusive air trap assembly on the top of the drying hopper prevents ambient air from

contaminating the material being dried. To ensure that your unit will operate at peak

efficiency, do the following:

• Keep the material level at the mid point of the air trap

This can be achieved by utilizing a hopper loader or vacuum conveying system to

supply material to the drying system.

Optional Aftercooler

Water-cooled 15 and 30 cfm models use a water-to-air heat exchanger as an aftercooler.

Cooling water is required for this design (3 gpm at 85°F or lower). Return air from the

hopper passes through the air filter to trap fines and dust before entering the heat exchanger.

Installing Water Lines

(Hose and Hose Clamp)

When installing the water lines, ensure that the aftercooler utilizes either tower, chilled or city

water up to 85°F (29°C). Recommended flow rate is three (3 gpm) gallons per minute (11

liters per minute).

3-5 Initial Start-up

Pre-Startup Checks

˛ Check the process and return hoses for tight connections.

˛ Check all companion equipment, such as the drying hopper; verify that the loading

system is ready for operation.

˛ Verify that all dryer electrical connections are tight.

Caution! Clean the rust-preventing oil from inside the drying hopper.

Failure to clean the hopper fouls the desiccant and voids your warranty!

˛ Verify that the dryer’s thermocouple is properly connected in the center of the drying

hopper’s delivery tube.

˛ Verify that the temperature control has been configured for your specified scale (ºF

or ºC).

Page 21

15, 30, & 60 cfm Compact Dryers Chapter 3: Installation 21 of 51

Starting Up the Dryer

1. Turn on (energize) the disconnect switch in your power drop, then turn on the

disconnect switch on the dryer (3 phase only).

2. Turn the system ON/OFF switch to ON to start the dryer.

3. Close the slidegate at the bottom of the drying hopper.

Make sure that the blowers turn in the right direction.

4. Fill the drying hopper with material. Dryer performance is compromised if hopper is

not full!

5. If your dryer has a water-cooled aftercooler, make sure that sufficient cooling water

(3gpm at 85°F or lower) flows properly through the coil and that you have bled any

trapped air from the system. Make sure the aftercooler has the proper supply water

temperature.

6. Set the process set point on the temperature controller.

7. After the proper pre-drying time for the initial hopper fill has elapsed, fully open the

drying hopper slide gate.

Note: To allow proper residence time during continuous processing,

maintain the material level in the hopper at the midpoint of the air trap

assembly.

Auto-Tuning the Dryer

1. For Auto-tuning, press the beige button once. The AT screen will show with the

setting OFF.

2. Press the UP arrow to change the setting to ON.

3. Press the beige button again to go back to the Temperature Screen. Your actual

temperature will start to flash for about 10-20 minutes with the temperature

fluctuating up and down during that period. After the flashing stops, it means autotuning has finished.

Shutting Down the Dryer

1. When processing is complete, close the hopper slide gate and shut down any in-line

companion equipment, such as the aftercooler.

2. Turn the Dryer ON/OFF power switch to OFF.

3. Turn the system ON/OFF switch to OFF.

4. If needed, empty the drying hopper.

5. For maintenance or a long term shutdown, open (de-energize) the electrical

disconnects at the dryer and at the power drop.

Page 22

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 22 of 51

Chapter 4: Operation

4-1 Start-up

1. Turn on (energize) the disconnect switch in your power drop, then turn on the

disconnect switch on the dryer.

2. Turn the system ON/OFF switch to ON to energize the display panel.

The process blower starts.

3. Close the slidegate at the bottom of the drying hopper.

Make sure that the blowers turn in the right direction.

4. Fill the drying hopper with material.

5. If your dryer has a water-cooled aftercooler, make sure that sufficient cooling water

(3gpm at 85°F or lower) flows properly through the coil and that you have bled any

trapped air from the system. Make sure the aftercooler has the proper supply water

temperature.

6. Set the process set point on the temperature controller.

7. After the proper pre-drying time for the initial hopper fill has elapsed, fully open the

drying hopper slide gate.

Note: To allow proper residence time during continuous processing,

maintain the material level in the hopper at the midpoint of the air trap

assembly.

Page 23

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 23 of 51

4-2 Controller Description and Operation

Identifying Control Panel Indicator Lights and Switches for the Standard

Controller

Switches

Main Power. This switch allows the dryer to receive power from the main power supply (3

phase only).

Dryer Control ON/OFF Switch. This switch energizes or de-energizes control power to the

indicator panel and starts the dryer. (The controller can be energized without the dryer

running.)

Indicator Lights

Alarm Light. This feature warns the operator of a high bed safety temperature, a

regeneration heater fault, or a blower failure.

Power On. This light illuminates when the main power switch is on, telling the user the

dryer is energized.

Dryer Operating: Indicates the process air blower is on.

Figure 5: Dryer Control Panels

Standard Controller – Standard Single Phase Control Panel shown with Optional Dew Point Monitor

Optional Controller – Optional Three Phase Control Panel shown with Optional Dew Point Monitor

Page 24

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 24 of 51

Process Air Temperature Controller

Our dryers use a microprocessor-based PID temperature controller for maintaining process air

temperature. The controller is a modular, self-contained unit you can remove from the

mounting housing. All parameters except for the process air set point are factory set and

adjusted; normally, no field adjustment to the internal controls is necessary.

Figure 6: Typical Process Air Temperature Controller

Identifying Process Air Temperature Controller LED Indicators

Indicator

Name

Description

PV

8.8.8.8

Process Value

Numeric LED

During normal operation, the process value (PV)

numeric LED indicator displays the process

temperature at the To Process thermocouple. It

also lists parameters during setup and error

messages if any errors occur.

SV

8.8.8.8

Set Value

Numeric LED

During normal operation, the set value (SV)

numeric LED indicator displays the process set

point temperature selected for the dryer. The dryer

then maintains this set point temperature. This

LED indicator also displays parameter and pre-set

function values during configuration setup.

OUT1

Out 1 LED

Lit when Control Output 1 is on. The Out1

indicator lights when the controller signals the

process heaters to be energized.

OUT2

Out 2 LED

Lit when Control Output 2 is on. Not used in

this application.

AT

AT LED

Flashes during auto-tuning in process value (PV)

screen.

PV

SV

Page 25

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 25 of 51

Indicator

Name

Description

ALARM1

ALARM 1 LED

Lights in the Operation Indicator Section when

the output function assigned to auxiliary output

1 turns on. The ALARM1 indicator lights when

the process temperature exceeds the set point

temperature by more than the alarm deviation

value. Alarm output de-energizes the heaters.

Heaters re-energize when the temperature falls

within the acceptable range.

Identifying Temperature Controller Keys

Indicator

Name

Description

Mode Key

Press the Mode key to shift the display to the next

set of parameters. The menu screen displays.

Down Key

Press the Down arrow key to lower the process air

set point temperature. During setup, it lets you

decrease the value of the parameter displayed on

the set point LED readout.

Up Key

Press the Up arrow key to raise the process air set

point temperature. During setup, it lets you

increase the value of the parameter displayed on

the set point LED readout.

Setting the Process Air Temperature

When setting the process air temperature, consult with the resin manufacture for the

recommended drying temperature.

To change the process air temperature set point with the dryer running:

• Press the Up Key to raise the set point to the temperature you want.

• Press Down Key to lower the set point to the temperature you want.

Page 26

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 26 of 51

Restoring the Process Air Temperature Controller (E5CN) to Factory Settings

If the preset parameters on the controller have been tampered with and it no longer properly

controls temperature and displays dew point, you can restore the controllers to the factory

setup. Call the Service Department for detailed instructions.

E5CN Operating Parameters

The E5CN controller has several mode selections. Within each mode are numerous

parameters that can be set.

The factory has set the security level to protect the critical parameters from being accidentally

changed. Below is an explanation of the operating modes you will have access to and on the

following page are the manufacturers’ default settings.

Available E5CN Modes

Operation Level

Indicator

Name

Description

Run/Stop Mode

(r-S)

When “RUN” is selected, the control is running.

When “STOP” is selected, the control is stopped.

When the control is stopped, the STOP display

lights. The default is set to “RUN.”

Alarm Value 1

Mode (AL-1)

This setting is used to indicate how many degrees

the process temperature will be allowed to exceed

the set point temperature. An alarm output will deenergize the heaters.

Page 27

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 27 of 51

Adjustment Level

Indicator

Name

Description

Auto-Tune Mode

(At)

See Page 19 of Chapter 3 for instructions on how

to Auto-Tune your dryer.

Note: Although the controller is calibrated at

the factory, the manufacturer

recommends that the unit be AutoTuned prior to dryer startup.

Temperature Input

Shift Mode (TnS)

This setting is used to offset an error between the

set point and the actual temperature. The entire

input range is shifted by a set figure

preprogrammed by the operator.

Proportional Band

Mode (P)

This setting controls the amount in which the

manipulated variable (MV) is proportionate to the

deviated value or controller error.

Integral Time

Mode (I)

Setting this feature, gives the control an action that

is proportionate to the time integral of the control

error. By using this setting, proportional action is

used in combination with integral action to offset

the control error and the set point will begin to

match the control temperature (PV or process

value).

Derivative Time

Mode (d)

Setting the derivative control provides the

controller with the ability to correct for a future

error in the previously set process output.

Page 28

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 28 of 51

Entering Operating Parameters to Select Modes

To enter the display:

1. Press the Mode Display key to view the Run/Stop & Alarm 1 Modes.

2. Press the Up Key and the Down Key to set the higher or lower the values of the

parameter or turn that function On or Off.

The SV readout displays the different values for the parameter within a mode.

3. To switch modes within a level, press and hold the Level Display key for one (1)

second.

The PV readout will display the different parameters within each mode.

4. Use short presses on the Mode Display key to display each parameter within a mode.

The SV readout displays the different values for the parameter within a mode.

5. Press the Up Key and the Down Key to set the higher or lower the values of a

parameter or turn that function On or Off.

6. Press the Level Key once to return to the Process Temperature Setting.

Figure 7: Settings for Process Temperature Controller (E5CN), Part No. A0567917

Mode

Parameter

Setting range

Default

Manuf. setting

Run/Stop

Run/Stop

Run

-

Operation

Alarm value 1

-1999 to 9999

0

25

Mode

Parameter

Setting range

Default

Manuf. setting

AT execute/cancel

ON, OFF

OFF

Various

Temperature input shift

-199.9 to 999.9

0.0

-

Proportional Band

0.1 to 999.9

8.0

Various

Integral Time

0 to 3999

233

Various

Adjustment

Derivative Time

0 to 399940Various

Page 29

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 29 of 51

Process Air Dew Point Display

Optional

The Process Air Dew Point meter indicates the current process air delivery moisture content.

Standard dryers use a microprocessor-based controller for displaying dew point air

temperature. The controller is a modular, self-contained unit removable from the mounting

housing. All parameters are factory set and adjusted; normally, no field adjustment to the

internal controls are necessary.

Figure 8: Typical Dew Point Display Monitor – Part No. A0555757

PV

SV

OUT1

OUT2 MANU STOP RMT AT SUB1

AT

E5CK

OMRON

Note: No field adjustment is required. The dew point meter is meant for

moisture indication only!

Setting the High Dew Point Alarm

The high dew point alarm setting is changed by pressing the up and down keys to input the

alarm value. The factory setting for Alarm Value 1 (AL-1) is -10°F (-23°C).

Restoring the Process Air Dew Point Meter (E5CK) to Factory Setup

If the preset parameters on the controller have been tampered with and it no longer functions

properly, call the Service Department. This controller is not meant to be modified.

Note: The dew point alarm monitors and indicates a deviation from the set

point.

Page 30

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 30 of 51

4-3 Dryer Operation Procedures

Controller Operation

1. Turn the disconnect (if applicable) on the control panel to the ON position. Power is

applied to the voltage line fuses, line side of the control power switch.

2. Turn the control power switch to the ON position. Power is applied to the

temperature control, programmable relay and dew point controller. The valve will

move to the start position as follows:

a. The valve motor rotates until the cam switch makes 2 transitions.

b. If the cam switch does not make a transition within 10 seconds, a valve

motor fault is generated. “VALVE MTR” is displayed on the relay screen,

the alarm light is activated. The valve motor, heaters, and blower shut off.

To restart the dryer, cycle control power to deactivate the alarm light and

restart the valve motor sequence.

Note: The relay screen which contains the Alarm Display Messages is located

inside the controller enclosure. For a list of Alarm Display Messages,

see Page 32.

WARNING! Do not attempt to check the Alarms on the Controller located within the

unit enclosure unless you are a qualified electrician!

c. The valve will normally complete one full cycle (revolution).

If the drying process shuts down due to an alarm, the dryer has been setup to

have the following operational features:

• The bed in process at power-down will remain in process.

• The bed in regeneration at power-down will remain in regeneration.

• The regeneration timing cycle will restart from the beginning.

3. Once the control power is on and no fault conditions exist, start the dryer as follows:

a. The process/regen blower is started.

b. The process heater is turned on and controlled by the E5CN controller.

c. The regen heater is turned on and the regeneration timing sequence is

initiated. For default timing settings for regeneration, see the table below.

Model

Heating

Cooling

15 cfm

30 cfm

15

45

60 cfm

N/A

N/A

Note: In a humid environment, you may change the setting to 20/45 for better

dew point management.

Page 31

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 31 of 51

4. If either the left or right bed safety temperature switch opens, a regen heater fault is

generated. “HIGH TEMP” is displayed on the relay screen. The alarm light is

activated. The process heater, regen heater, and process/regen blower are turned off.

5. If the process temperature controller faults or the process heater safety switch opens,

a heater fault is generated. “HIGH TEMP” is displayed on the relay screen. The

alarm light is activated. The process heater, regen heater, and process/regen blower

are turned off.

6. If the process blower overload trips, a process blower fault is generated. “PROC

BLWR” is displayed on the relay screen. The alarm light is activated. The process

heater, regen heater, and process/regen blower are turned off (3 phase only).

7. The valve position limit switch enables the right bed heater and provides an input

signal to the programmable relay when actuated by the cam lobe. When the cam lobe

position is high, the right bed is activated. When the cam lobe position is low, the

left bed is activated. Each heater is ON-OFF controlled.

8. Upon completion of the HEAT portion of the regeneration sequence, the regen

heaters are disabled by the programmable relay and the COOL time begins.

9. Once the Cool time has expired, the valve motor is turned on until the cam switch

makes a transition. Upon making a transition, the timing sequence is restarted for the

new bed.

10. When no fault conditions exist, the display reads “SYSTEM NORMAL”.

11. The top 2 lines of the display show the HEAT and COOL times (in minutes) for the

regeneration sequence. Changes to these times can be made by the operator as

follows:

a. Press the up or down arrow until the cursor is positioned at the number to be

changed.

b. Press the “+” key to increment the number, or the “-“ key to decrement the

number.

c. Press the “OK” key to accept the value and write to the relay memory.

OR

d. Press the “ESC” key to cancel the changes.

Note: A change will NOT take effect until step 11-c is done.

12. The dryer is shut off by turning the control power switch to the OFF position.

13. Refer to Schematic drawing enclosed in the control enclosure.

Page 32

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 32 of 51

Alarm Display Messages

Note: The relay screen which contains the Alarm Display Messages is located

inside the controller enclosure.

WARNING! Do not attempt to check the Alarms on the Controller located within the

unit enclosure unless you are a qualified electrician!

The following is a list of Alarm Display Messages which can be found on the relay screen:

Temperature Controller Alarm and/or

Regen Heater Temp Switch and/or

Process Heater Temp Switch and/or

Redundant Temp Safety

Valve Motor Time-Out

Multiple Alarms

No Alarms

HIGH TEMP

VALVE MTR

PROC BLWR

HIGH TEMP

VALVE MTR

HEAT 15

COOL 50

SYSTEM

NORMAL

Page 33

15, 30, & 60 cfm Compact Dryers Chapter 4: Operation 33 of 51

4-4 Auto-Tuning the Dryer

1. For Auto-tuning, press the beige button once. The AT screen will show with the

setting OFF.

2. Press the UP arrow to change the setting to ON.

3. Press the beige button again to go back to the Temperature Screen. Your actual

temperature will start to flash for about 10-20 minutes with the temperature

fluctuating up and down during that period. After the flashing stops, it means autotuning has finished.

4-5 Shutting Down the Dryer

1. When processing is complete, close the hopper slide gate and shut down any in-line

companion equipment, such as the aftercooler.

2. Turn the Dryer ON/OFF selector switch to OFF.

3. Turn the system ON/OFF switch to OFF.

4. If needed, empty the drying hopper.

5. For maintenance or a long term shutdown, open (de-energize) the electrical

disconnects at the dryer and at the power drop.

Page 34

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 34 of 51

Chapter 5: Maintenance

5-1 Preventative Maintenance Schedule

The checklist below contains a list of items which should be inspected and/or replaced to

keep your Dehumidifying Dryer operating at peak efficiency. Perform each inspection at the

regular intervals listed below.

System model #

Serial #

Every week

Date/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/ByDate/

By

Inspect all filters for

wear, replace/

clean if dirty or

worn.

Check to make

sure that all hose

conections are

air tight.

Every month

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Lock out electrical

power and inspect

electrical wiring for

integrity.

Lock out electrical

power and check

heater elements for

continuity using an

ohmmeter.

Check dew point

and temperature

tracking with an

external dew point

monitor and

pyrometer.

Visually inspect the

shifting of the

airflow valve during

one cycle.

Every year

Next scheduled

inspection

Actual inspection

Date/By

Next scheduled

inspection

Actual inspection

Date/By

Inspect desiccant. Replace

if brown or broken.

Every two years

Scheduled

replacement date

Actual replacement

Date/Work done by

Scheduled

replacement date

Actual replacement

Date/Work done by

Replace desiccant.

- Photocopy this page for your maintenance records -

Page 35

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 35 of 51

5-2 Preventative Maintenance

This section describes maintenance procedures which will increase the longevity and

efficiency of your dehumidifying dryer. Perform them at the regular intervals listed on the

dryer checklist on the previous page.

Servicing Process Air Filters

Caution! Operating the dryer without the process air filter installed voids your

warranty!

Filter cleaning is an important part of your dryer maintenance program.

Dehumidifying dryers have a single cartridge canister-type filter in the process air loop. The

filter protects blowers from plastic fines drawn in from the drying hopper and prevents the

desiccant from being contaminated. Regular filter cleaning is essential to keep your dryer

operating at peak efficiency.

You can blow or vacuum the dirt out of the filter with compressed air, but remember, it could

become damaged from high-pressure blowing.

Recommendations for Cleaning and Replacing Filters

• Turn off and/or lock out electrical power to the dryer.

• Remove the threaded fastener securing the filter access cover, then remove the cover.

• Remove the nut on the center retaining rod to remove the filter cartridge.

Figure 9: Air Filter Location and Disassembly

Process

Air

1" Wide x 1/8" Thick

Temperature

Page 36

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 36 of 51

Vacuuming

Try vacuum-cleaning a soiled filter first. Vacuuming removes most large particles and

surface contaminants, and may suffice for the first time you clean a filter. Use a commercialduty (recommended) or household vacuum cleaner. Vacuum the filter from the air intake

(dirty) side only.

Cleaning with Compressed Air

Blow clean, dry compressed air up and down the pleats, blowing out the filter

from the inside out. Remove loose dirt from the filter with compressed air or

vaccum from the outside.

Caution! DO NOT clean/wash filter with water!

After each cleaning:

• Inspect the filter element. Briefly hold a light bulb behind the element

and look for any fatigued paper or residual dirt. Inspect for holes and

tears by looking though the filter toward a bright light. Check for

damaged gaskets or dented metal parts. Do not re-use a damaged

filter!

• Check the gasket for damage. A damaged gasket allows contaminants

into the process. Replace as needed.

Servicing the Dew Point Monitor

The accuracy of the dew point monitor on mini dryer systems depends on proper operation of

the dew point sensor and the control board. The dew point sensor is in the process air stream

and is therefore susceptible to contamination.

Dew point sensor life depends on:

• Air temperature and flow passing over the sensor.

• The amount of fines (dust) in the process air.

• The amount of plasticizer vapor in the process air.

Once every six months, the dryer operator should monitor the initial dew point sensor

readings and establish a periodic replacement schedule as needed.

Caution! Do not attempt to check the continuity or resistance of the dew point

sensor.

The sensor will be destroyed!

Page 37

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 37 of 51

5-3 Corrective Maintenance

This section provides you with the information necessary to correct or repair any issues

which might appear during the normal operation of your dehumidifying dryer. Although we

have listed how to perform these procedures, it is recommended that you call the Service

Department to have any in-depth maintenance performed.

Symptoms of Worn Desiccant

The moisture absorption capacity of the desiccant used in your dehumidifying dryer degrades

after an indefinite period of time. Useful life depends on variables such as material moisture

content, plasticizer vapors in the return air, and number of regeneration cycles.

Your dryer may need new desiccant if it exhibits any of the following symptoms:

• The process air dew point measured with a portable dew point monitor

is higher than -10°F (-23ºC) throughout the process drying cycle.

• Noticeable amounts of desiccant in the beds is a medium-brown color

or darker.

If you notice any of these signs, replace the desiccant in the desiccant beds. Desiccant

replacement kits are available from the Parts Department. If you want, a technician can

repack desiccant beds at your site.

WARNING! Handling desiccant material is HAZARDOUS.

Wear an N-100 type safety filter mask or equivalent to avoid prolonged

breathing of desiccant dust. Wear safety goggles and gloves to avoid

contact with eyes and skin.

• Handle with adequate ventilation.

• Wash hands thoroughly after handling.

: FIRST AID :

In case of eye contact, immediately flush eyes

with plenty of water for at least 15 minutes.

SEE A PHYSICIAN IMMEDIATELY IF IRRITATION PERSISTS.

Page 38

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 38 of 51

Replacing Worn Desiccant

Caution! DESICCANT BEDS ARE HOT DURING OPERATION.

To avoid burn hazard, make sure desiccant beds are sufficiently cool

before replacing worn desiccant.

To access the Desiccant Bed:

1. Disconnect electrical power to the dryer.

2. Using a 1/8” Allen wrench, remove the 10-24 button head screws holding the top,

back and side panels to the frame and back of the dryer.

3. Disconnect the three (3) plugs for the valve motor, switch, and blower (15 cfm only)

4. Remove four (4) nuts at each corner of the top casting.

5. Disconnect all hoses and dew point air lines.

6. Pickup and place the top casting in a safe place.

7. Using a 1/8” Allen wrench, remove the four (4) 10-32 button screws holding the

desiccant cover to the canister.

8. Remove the cover.

9. Pickup the desiccant can and turn it upside down over an empty container to remove

all desiccant.

10. Dispose of properly using MSDS sheet.

Page 39

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 39 of 51

Figure 10: Desiccant Bed Location and Disassembly

Caution! You should properly dispose of any discarded desiccant.

Consult local disposal regulations for more information.

11. Inspect each desiccant screen for tears or holes where desiccant burned-through.

Replace desiccant can if needed.

12. After cleaning each chamber, add the full amount of bead desiccant specified per bed.

Amounts are listed in the Desiccant Amounts Table below. Tap on side of tank to

settle desiccant. Smooth the top level, and finally add another layer of the remaining

bead desiccant to the top. Make sure this layer is level and smooth.

13. Repeat the previous step for the other bed.

14. Inspect the gaskets. Replace if necessary.

15. Re-install all components and reconnect all of the wiring and hoses.

Figure 11: Required Desiccant Amounts (13X Type)

Dryer

8 x 12 bead Total

Model

Part no.

lbs.

Kg

15 cfm

6.5

2.9

30 cfm

9.7

4.4

60 cfm

W00018051

13.5

6.1

Valve & Air

Manifold Casting

Desiccant

Assembly Rod

Regeneration

Heater

Wire Conduit

Assembly

Lower Air Manifold Casting

Gasket

Hollow

Desiccant

Tank

Page 40

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 40 of 51

Replacing the Process/Regeneration Heater

The dehumidifying dryers utilize a single-phase Calrod-type heater element. This heater

element is mounted in the center compartment in the desiccant beds. Although the

replacement procedure is the same for each heater, the wattage varies by model, voltage,

temperature range, etc.

WARNING! Hazardous electrical current present.

Disconnect and lock out power before you replace heater elements!

Figure 12: Process/Regeneration Heater Location and Disassembly

Valve & Air

Manifold Casting

Desiccant

Assembly Rod

Regeneration

Heater

Wire Conduit

Assembly

Lower Air Manifold Casting

Gasket

Hollow

Desiccant

Tank

Page 41

15, 30, & 60 cfm Compact Dryers Chapter 5: Maintenance 41 of 51

Procedures

1. Disconnect electrical power to the dryer.

2. Using a 1/8” Allen wrench, remove the 10-24 button head screws holding the top,

back and side panels to the dryer frame.

3. Disconnect the plug for the valve motor, valve switch, and blower (15 only).

4. Remove the four (4) nuts at each corner of the top casting.

5. Pickup and place the top casting in a safe place.

6. Pickup the desiccant can to reveal the heater.

7. Using a 1/8” Allen wrench, remove the four (4) 10-32 screws on the heater plate.

8. Remove the wires to the heater plate assembly being removed or replaced.

9. Remove the two (2) 4-40 screws for the temperature switch.

10. Inspect temperature switch with voltmeter. (Normally closed, ohms). Replace if

faulty.

11. Re-install the heater and heater plate assemblies in reverse order. Install new heater

gaskets and securely tighten all fasteners.

Caution! Heater loops should not touch each other.

“Hot spots” lead to premature heater failure!

Replacing/Cleaning the Regeneration Cooling Coils

Figure 13: Cooling Coil Location and Disassembly

To clean the cooling coil, use compressed air or a steam cleaner to blow the dust off or clean

any oily residue on the coil.

Undo (4) 10-32 Button

Head Screws using 1/8

Allen Wrench

Use compressed air or a steam

cleaner to blow the dust off or clean

any oily residue on the coil.

1" Wide x 1/8" Thick High

Temperature Gasket

Page 42

15, 30, & 60 cfm Compact Dryers Chapter 6: Troubleshooting 42 of 51

Chapter 6: Troubleshooting

6-1 Introduction

The utmost in safety precautions should be observed at all times when working on or around

the machine and the electrical components. All normal trouble-shooting must be

accomplished with the power off, line fuses removed, and with the machine tagged as out of

service.

The use of good quality test equipment cannot be over-emphasized when troubleshooting is