Acer PD523PD, PD527D Schematic

PD527D & PD523PD

Service Guide

Service guide files and updates are available

on the AIPG/CSD web; for more information,

please refer to http://csd.acer.com.tw

PRINTED IN TAIWAN

Revision History

Please refer to the table below for the updates made on PD527D & PD523PD service guide.

Date Chapter Updates

II

Copyright

Copyright © 2005 by Acer Incorporated. All rights reserved. No part of this publication may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language or computer language, in

any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without

the prior written permission of Acer Incorporated.

Disclaimer

The information in this guide is subject to change without notice.

Acer Incorporated makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranties of merchantability or fitness for any particular

purpose. Any Acer Incorporated software described in this manual is sold or licensed "as is". Should the

programs prove defective following their purchase, the buyer (and not Acer Incorporated, its distributor, or its

dealer) assumes the entire cost of all necessary servicing, repair, and any incidental or consequential

damages resulting from any defect in the software.

Acer is a registered trademark of Acer Corporation.

Intel is a registered trademark of Intel Corporation.

Pentium 4 and Celeron are trademarks of Intel Corporation.

Other brand and product names are trademarks and/or registered trademarks of their respective holders.

III

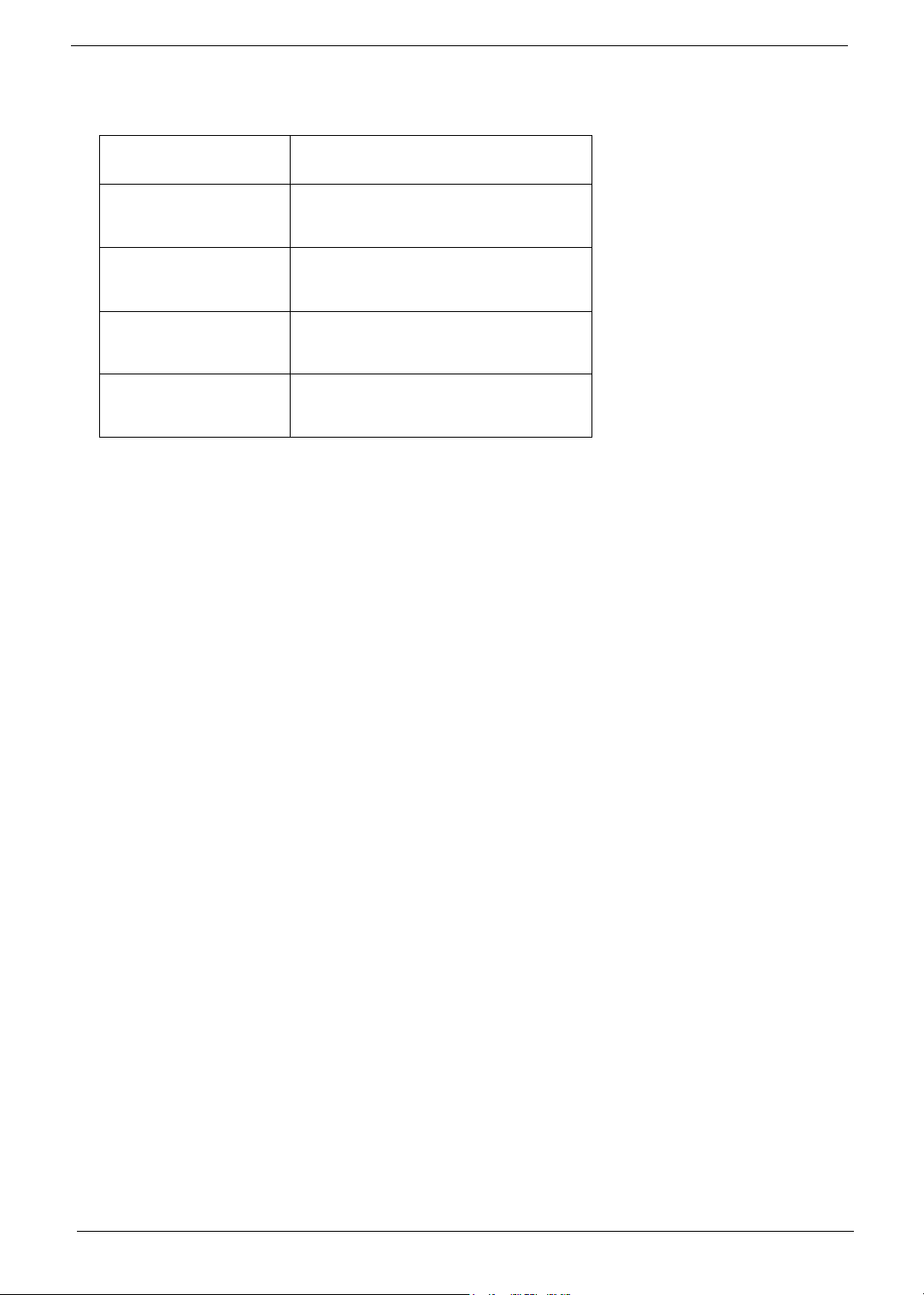

Conventions

The following conventions are used in this manual:

Screen messages

NOTE Gives bits and pieces of additional

WARNING Alerts you to any damage that might

CAUTION Gives precautionary measures to

IMPORTANT Reminds you to do specific actions

Denotes actual messages that appear

on screen.

information related to the current

topic.

result from doing or not doing specific

actions.

avoid possible hardware or software

problems.

relevant to the accomplishment of

procedures.

IV

Preface

Before using this information and the product it supports, please read the following general information.

1. This Service Guide provides you with all technical information relating to the BASIC CONFIGURATION

decided for Acer's "global" product offering. To better fit local market requirements and enhance product

competitiveness, your regional office MAY have decided to extend the functionality of a machine (e.g.

add-on card, modem, or extra memory capability). These LOCALIZED FEATURES will NOT be covered

in this generic service guide. In such cases, please contact your regional offices or the responsible

personnel/channel to provide you with further technical details.

2. Please note WHEN ORDERING FRU PARTS, that you should check the most up-to-date information

available on your regional web or channel. If, for whatever reason, a part number change is made, it will

not be noted in the printed Service Guide. For ACER-AUTHORIZED SERVICE PROVIDERS, your Acer

office may have a DIFFERENT part number code to those given in the FRU list of this printed Service

Guide. You MUST use the list provided by your regional Acer office to order FRU parts for repair and

service of customer machines.

V

1 Chapter 1

System Introduction (PD527D)

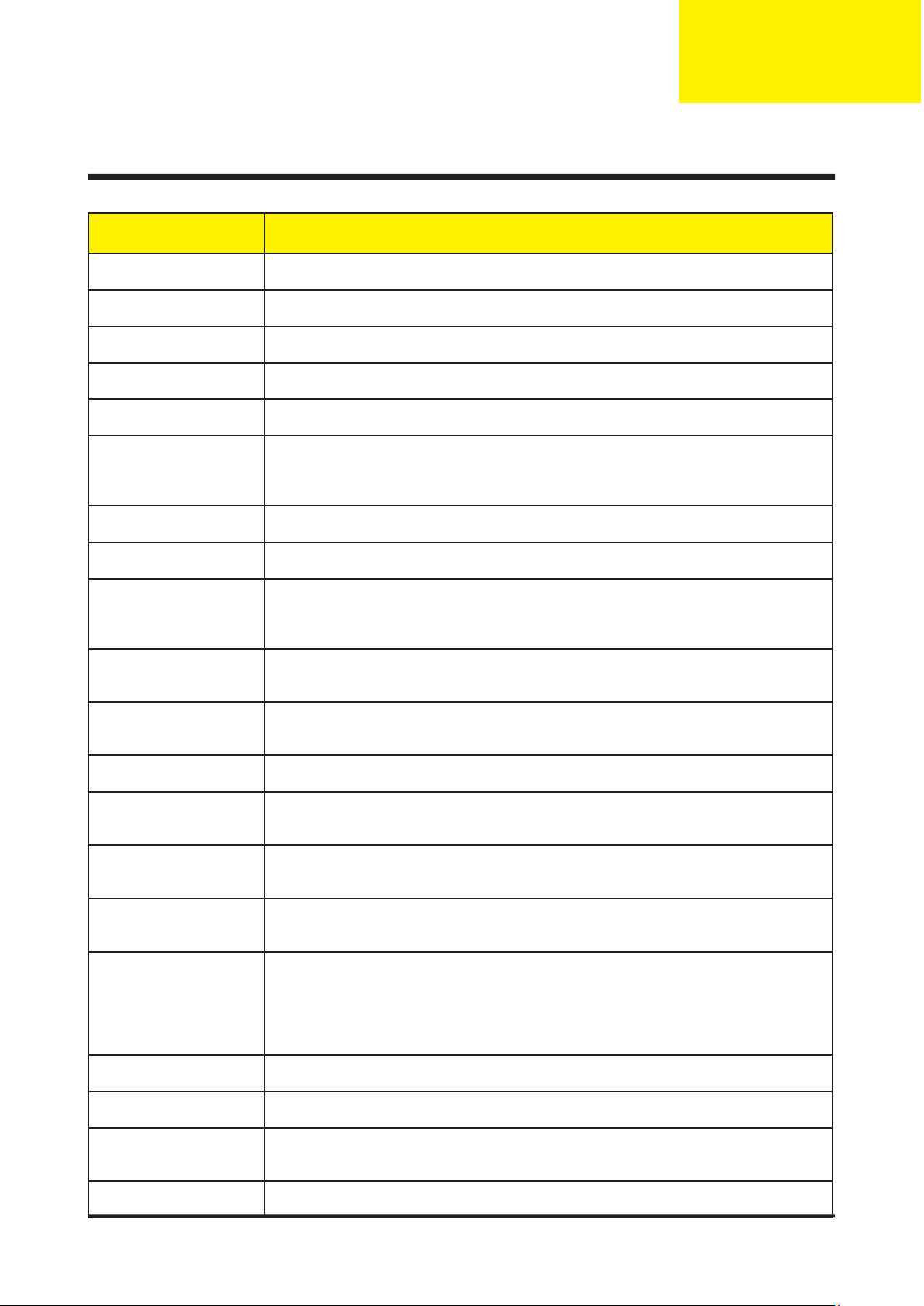

Technical Specifi cation

Item Description

Dimensions (LxWxH) 256 x 283 x 104 mm

Weight

Approx. 6.0 lbs (2.7 Kg)

Tilt Angle

7 degree with elevator mechanism

Keystone correction +/-16 degree (32 degree) (Horizontal)

Lamp Door Projection Lamp power supply shut off automatically when door open

Power Supply

- Universal AC 100-240V ~ 50-60Hz with PFC input

- 230W for OSRAM Lamp @ normal operation

- Variance FAN speed control (Depends on temperature variant)

Projection Lens f=28.04mm~33.59mm@2.4m, F/2.4~2.65@2.4m, 1.2X Mechanical Zoom Lens

Throw Distance 1.5m - 12m (Mechanical Travel)

Brightness

- 2550 ANSI Lumens (Typical; Full Power Mode)

- 2040 ANSI Lumens (Typical; Eco Mode)

- 1600 ANSI Lumens (Engineering Minimum; Full Power Mode)

Contrast

- 1000 : 1 Full White and Black (Minimum; Full Power Mode)

- 1500 : 1 Full White and Black (Typical; Full Power Mode)

Uniformity

- 70% Japan standard (Minimum; Full Power Mode)

- 85% Japan standard (Typical; Full Power Mode)

Temperature

Opterating : 5~35oC Storage : -20~60oC

Maximum Humidity Operating : 5~35oC, 80%RH (Max.), non-condensing

Storage : -20~60oC, 80%RH (Max.), non-condensing

Acoustic noise level 36 dB(A) (Typical, Under 23 +/- 20C; Full Power Mode)

33 dB(A) (Typical, Under 23 +/- 20C; Eco Mode)

Lamp Life 2000 hours min, 50% survival rate (Full Power Mode)

2500 hours min, 50% survival rate (Eco Mode)

Altitude

Operating : 0~2,500 ft for 5 oC~35oC

2,500~5,000 ft for 5 oC~30oC

5,000~10,000 ft for 5 oC~25oC

Storage : 40,000 ft (Max.)

MTBF Operating more than 12,000 hours (90% Confi dence Level)

XGA / Compression

Color Wheel

- Four segments (W110/R92/G83/B75)

- 7200 rpm

DMD Chip

- 0.7” 12

o

DDR XGA Digital Mirror Device

Chapter 1

Chapter 1 2

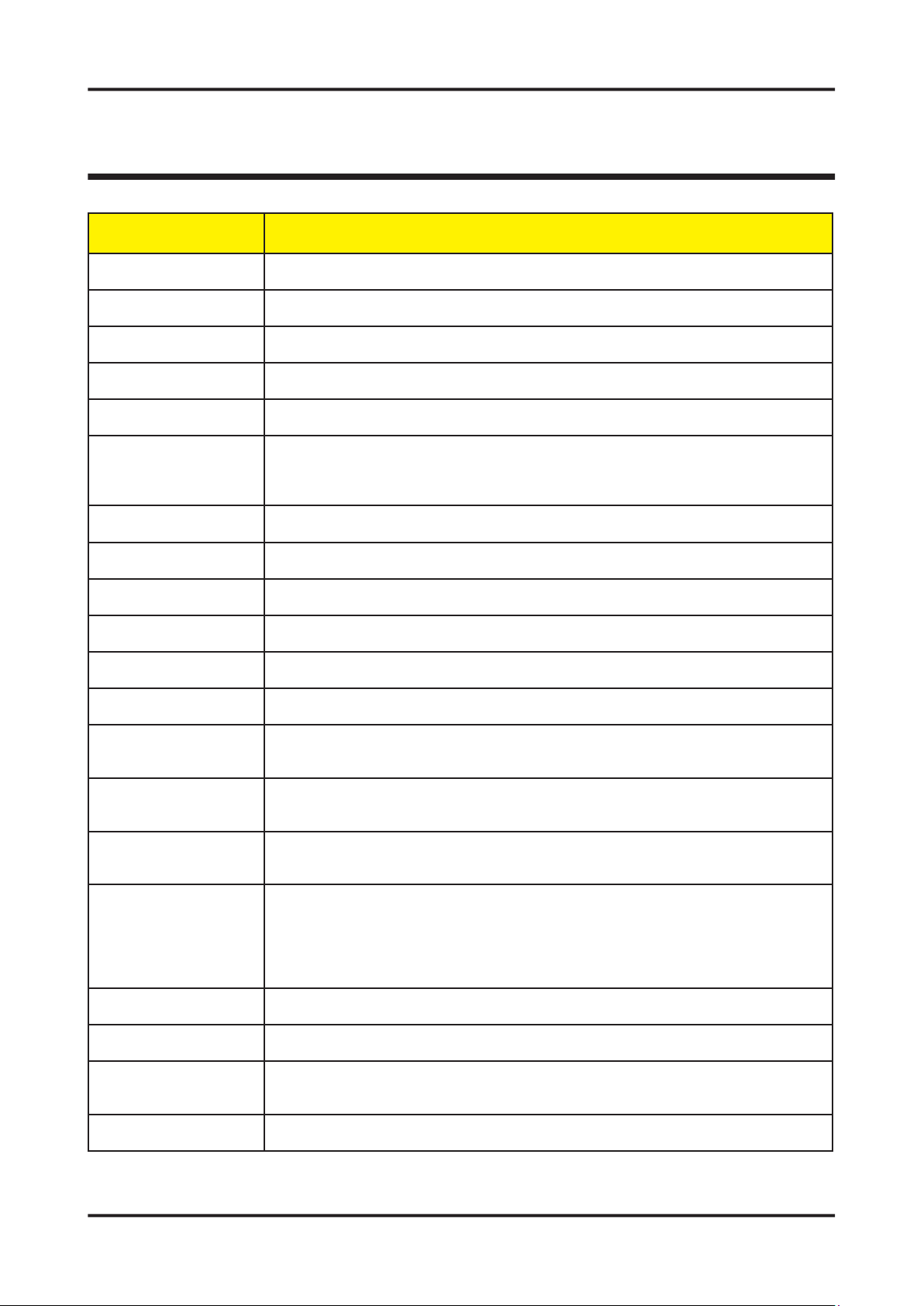

System Introduction (PD523PD)

Technical Specifi cation

Item Description

Dimensions (LxWxH) 256 x 283 x 104 mm

Weight

Approx. 6.0 lbs (2.7 Kg)

Tilt Angle

7 degree with elevator mechanism

Keystone correction +/-16 degree (32 degree) (Horizontal)

Lamp Door Projection Lamp power supply shut off automatically when door open

Power Supply

- Universal AC 100-240V ~ 50-60Hz with PFC input

- 230W for OSRAM Lamp @ normal operation

- Variance FAN speed control (Depends on temperature variant)

Projection Lens f=28.04mm~33.59mm@2.4m, F/2.4~2.65@2.4m, 1.2X Mechanical Zoom Lens

Throw Distance 1.5m - 12m (Mechanical Travel)

Brightness - 1564 Lumens (Engineering Minimum; Full Power Mode)

Contrast - 1000 : 1 Full White and Black (Minimum; Full Power Mode)

Uniformity - 70% Japan standard (Minimum; Full Power Mode)

Temperature

Opterating : 5~35oC Storage : -20~60oC

Maximum Humidity Operating : 5~35oC, 80%RH (Max.), non-condensing

Storage : -20~60oC, 80%RH (Max.), non-condensing

Acoustic noise level 36 dB(A) (Typical, Under 23 +/- 20C; Full Power Mode)

33 dB(A) (Typical, Under 23 +/- 20C; Eco Mode)

Lamp Life 2000 hours min, 50% survival rate (Full Power Mode)

2500 hours min, 50% survival rate (Eco Mode)

Altitude

Operating : 0~2,500 ft for 5 oC~35oC

2,500~5,000 ft for 5 oC~30oC

5,000~10,000 ft for 5 oC~25oC

Storage : 40,000 ft (Max.)

MTBF Operating more than 12,000 hours (90% Confi dence Level)

XGA / Compression

Color Wheel

- Four segments (W110/R92/G83/B75)

- 7200 rpm

DMD Chip - 0.55” 12o DDR XGA Digital Mirror Device

3 Chapter 1

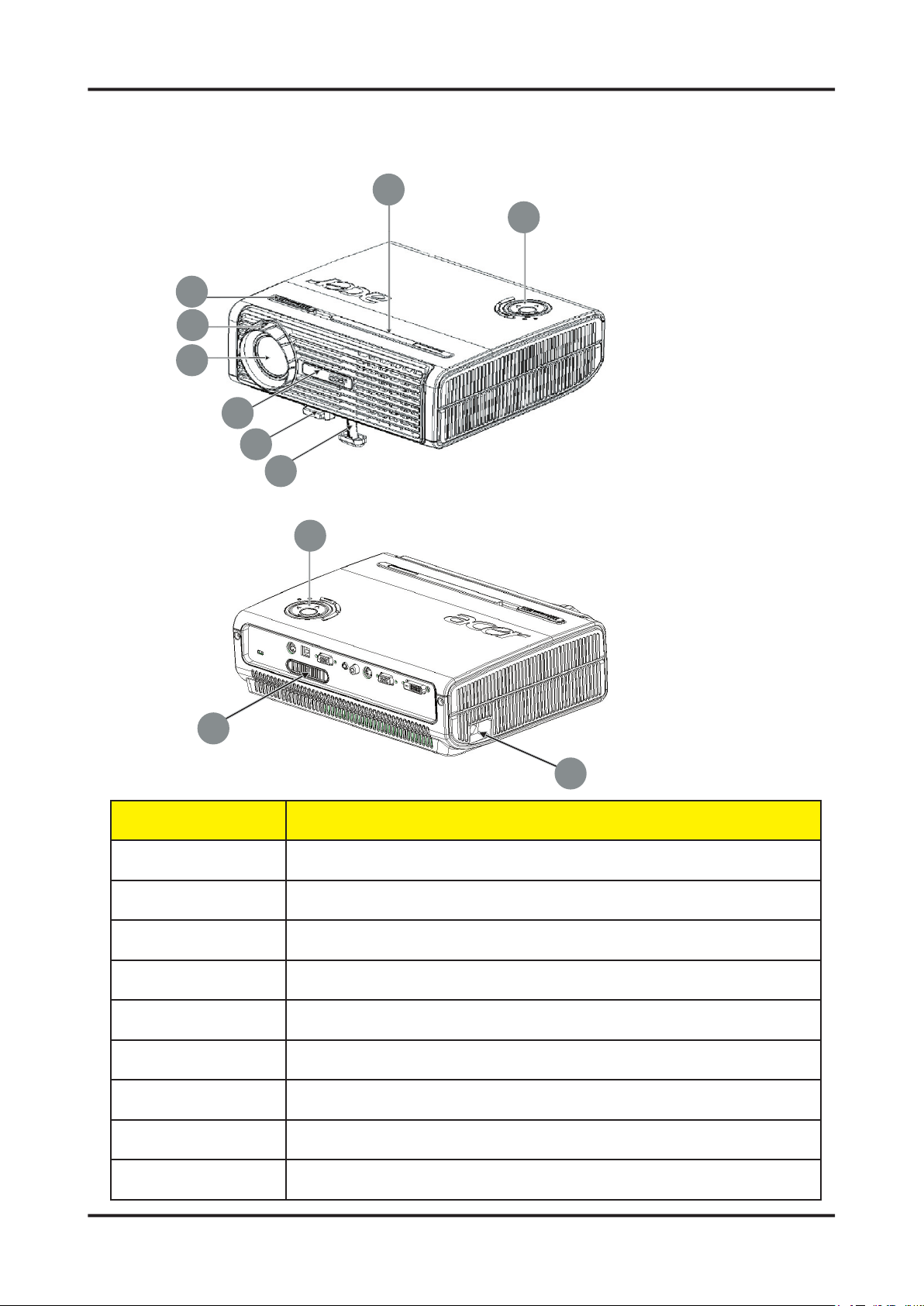

Product Overview

Main Unit

Item Description

1 Focus Ring

2 Zoom Ring

3 Zoom Lens

4 Remote Control Receiver

5 Elevator Button

6 Elevator Foot

7 Connection Ports

8 Power Socket

9 Control Panel

1

2

3

6

7

9

9

8

4

5

4

Chapter 1 4

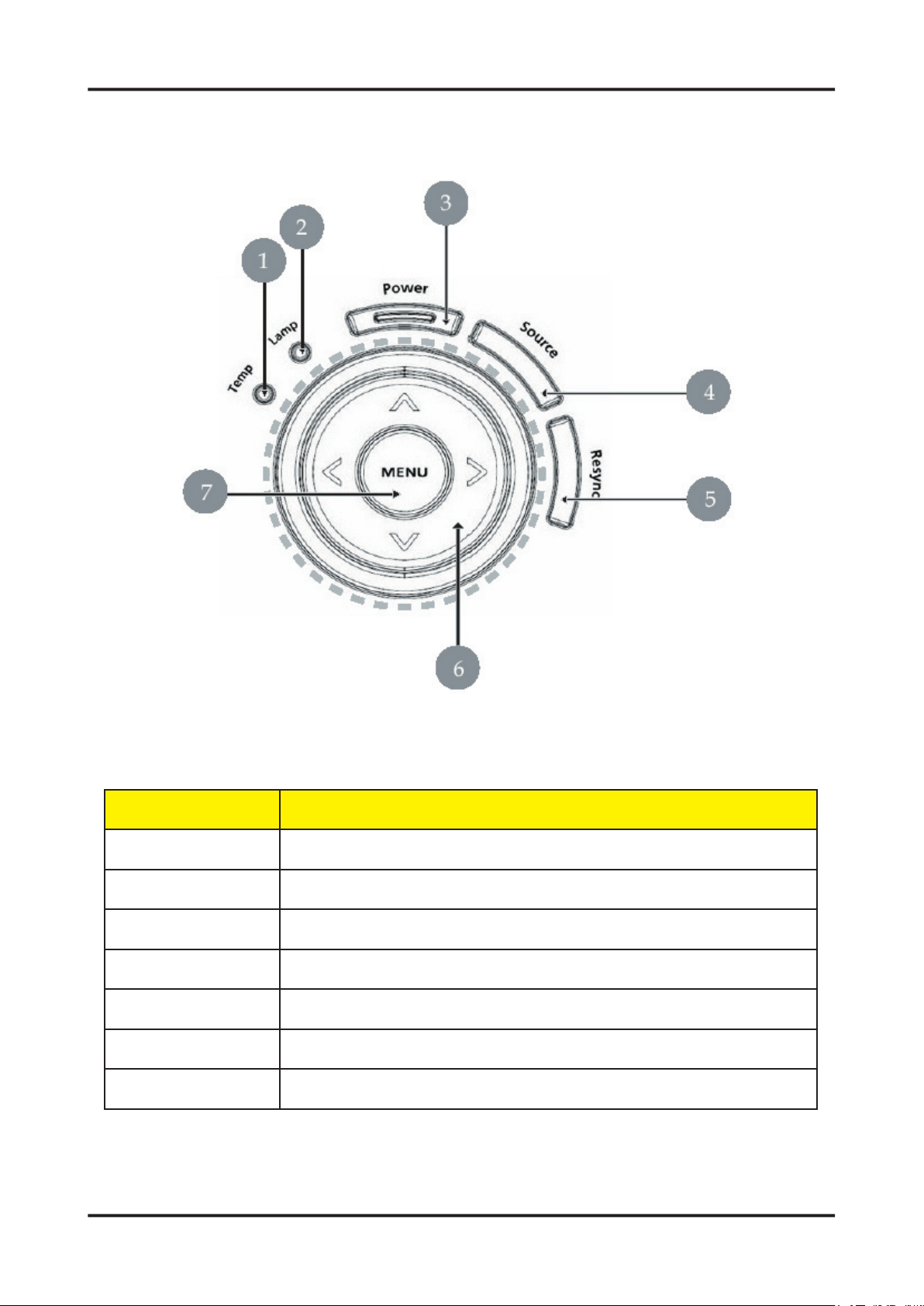

Control Panel

Item Description

1 Temp Indicator LED

2 Lamp Indicator LED

3 Power and Indicator LED (Power LED)

4 Source

5 Resync

6 Four Directional Select Keys

7 Menu

5 Chapter 1

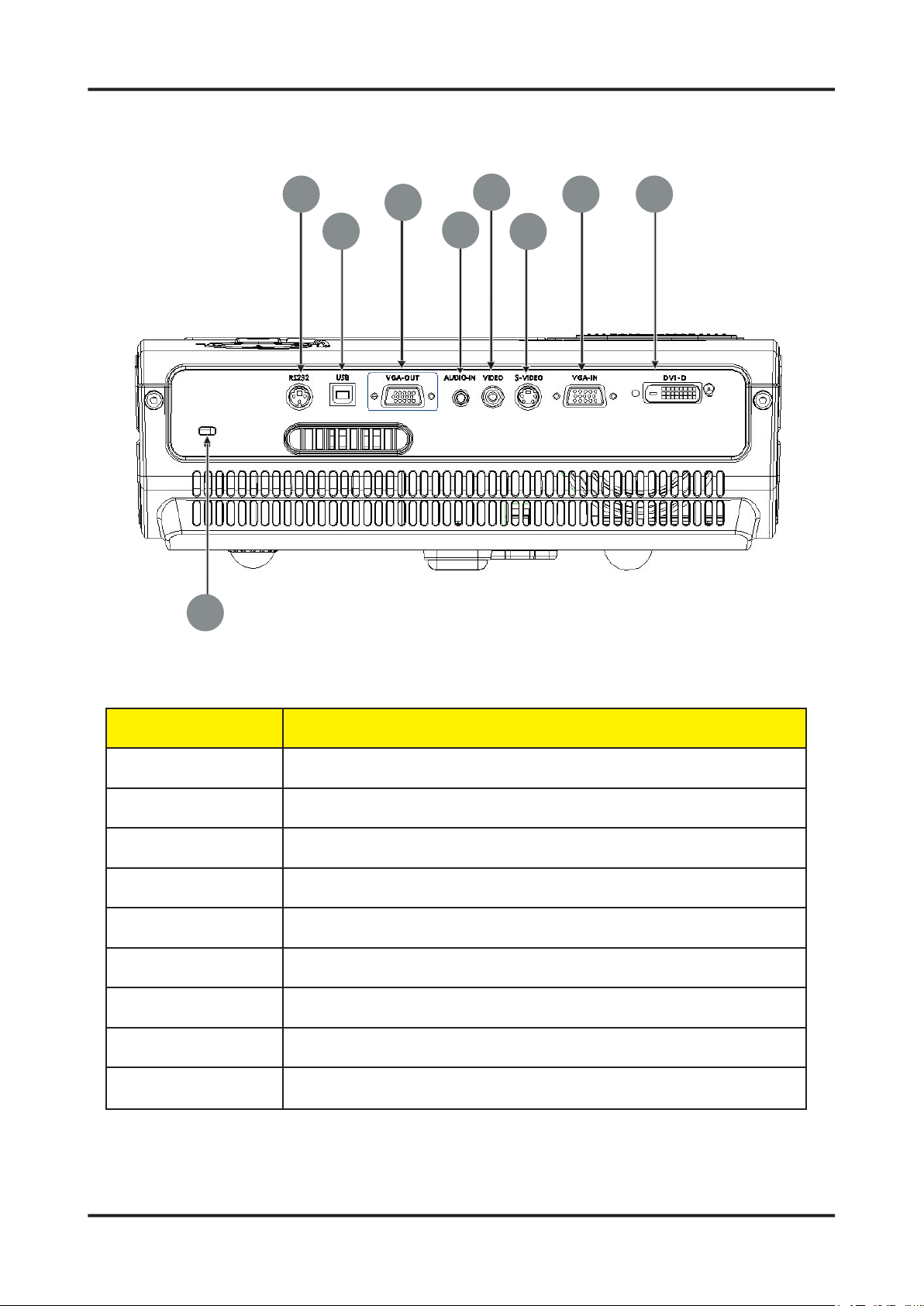

Connection Ports

Item Description

1 RS232 Connector

2 USB Connector

3 Monitor Loop-through Output Connector (VGA-Out)

4 Audio Input Connector

5 Composite Video Input Connector

6 S-Video Input Connector

7

PC Analog Signal / HDTV / Component Video Input Connector

8

DVI Input Connector (for Digital signal with HDCP function) (Optional)

9 KensingtonTM Lock Port

1

6

2

5

3

4

7

9

8

Chapter 1 6

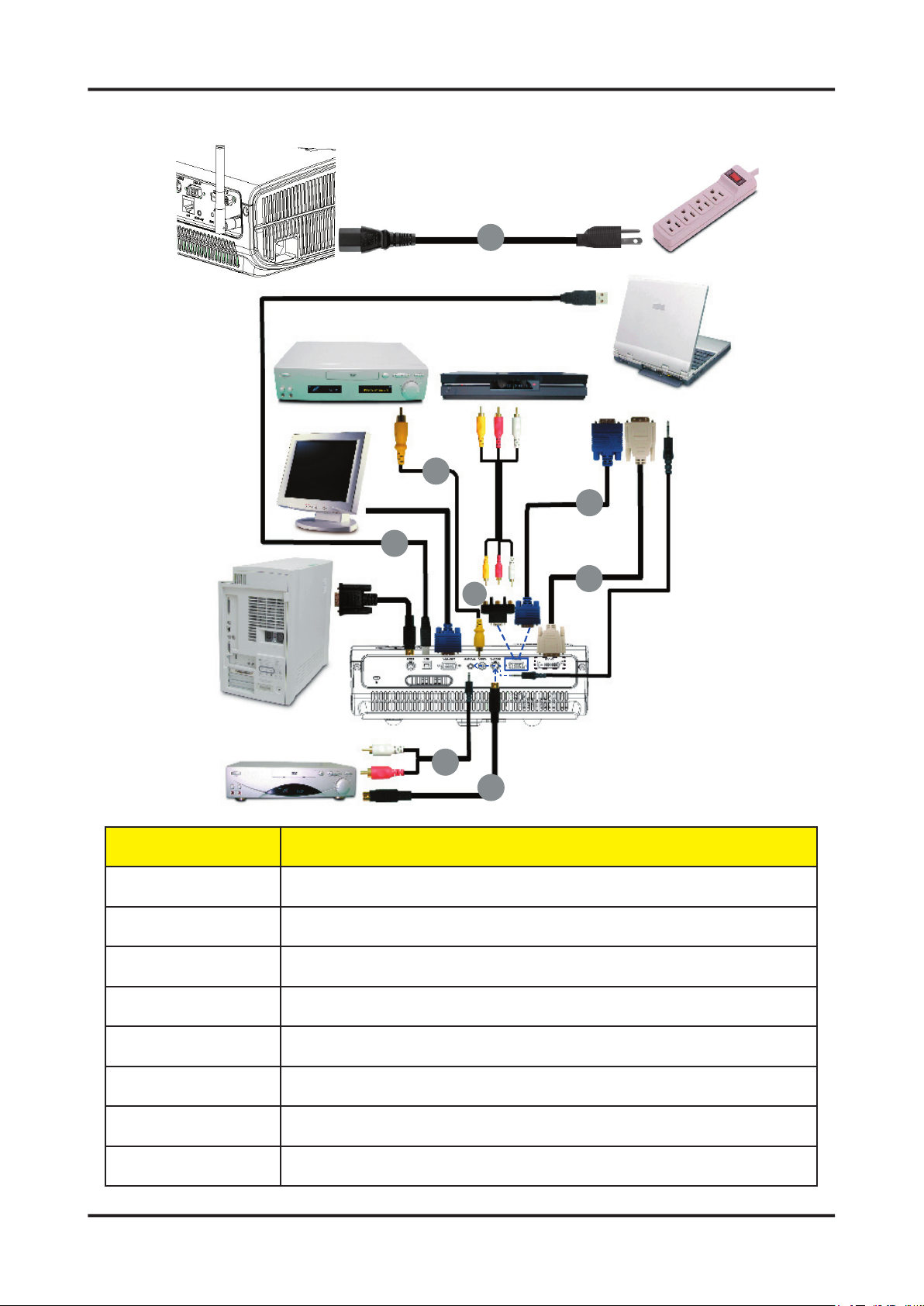

Item Description

1 Power Cord

2 VGA Cable

3 Composite Video Cable

4 USB Cable

5 VGA to Component / HDTV Adapter

6 S-Video Cable

7 Audio Cable Jack / Jack

8 DVI Cable (Optional Accessory)

Connecting the Projector

Video Output

DVD Player, Settop Box,

HDTV receiver

4

2

3

6

7

DVI

RGB

USB

5

S-Video Output

8

1

RS232

5

+3.3V/1.3A (1.5A Max)

LVPS

+5.0V/3.2A (3.5A Max)

+13.0V/0.4A (1.0A Max)

+385V/0.62A (0.65A Max)

LPF

LPF

8

/

2

/

2

/

2

/

2

/

3

/

3

/

2

/

2

/

1

/

2

/

2

/

DVI EDID

EDID R/W I2C

VGA EDID

VGA RGB

WS RGB

VGA HVSync

WS HVSync

SCART Sync

AMP

TMDS IN

D D

DVI

IN

VGA

OUT

VGA

IN

S-Video

IN

C C

CVBS

IN

USB

IN

Audio

IN

DVI RS-232

DDC I2C

DDC I2C

VGA RS-232

VGA RGB

VGA HV

H

1

/

R/L

RGB Out

HV Out

2

/

2

/

LPF

SPKout

B B

Wireless

Rear IR

TOP IR

Front IR

A A

PC

RS-232

WS RS-232

Rear IR Data

TOP IR Data

Front IR Data

UART1

2

/

FAN 1

System

2

/

DAC

FAN 2

Blower

FAN 3

System

RGB

HV

RGB

S-Video

CVBS

VOL_PWM

BEEP

2

I2C Bus

/

4

DVI HDCP

SiI169 /

SiI1169

2

/

2

/

3

/

ADC

9883A

2

/

3

/

Video

Decoder

SAA7117A

DVI RS-232

WS RS-232

VGA RS-232

LAMP RS-232

FAN 4

Blower

3

DRCG

24

/

3

/

2

/

3

Sync

/

ALF HV

24

/

Digital RGB

RDRAM

/ 24

Image Processor

8

/

8

/

4

/

Title

Size Document Number Rev

B

Date: Sheet

Motor

Driver

CW

Motor

Digital UV

Digital Y

Ctrl/CLK

USB D+/D-

2

/

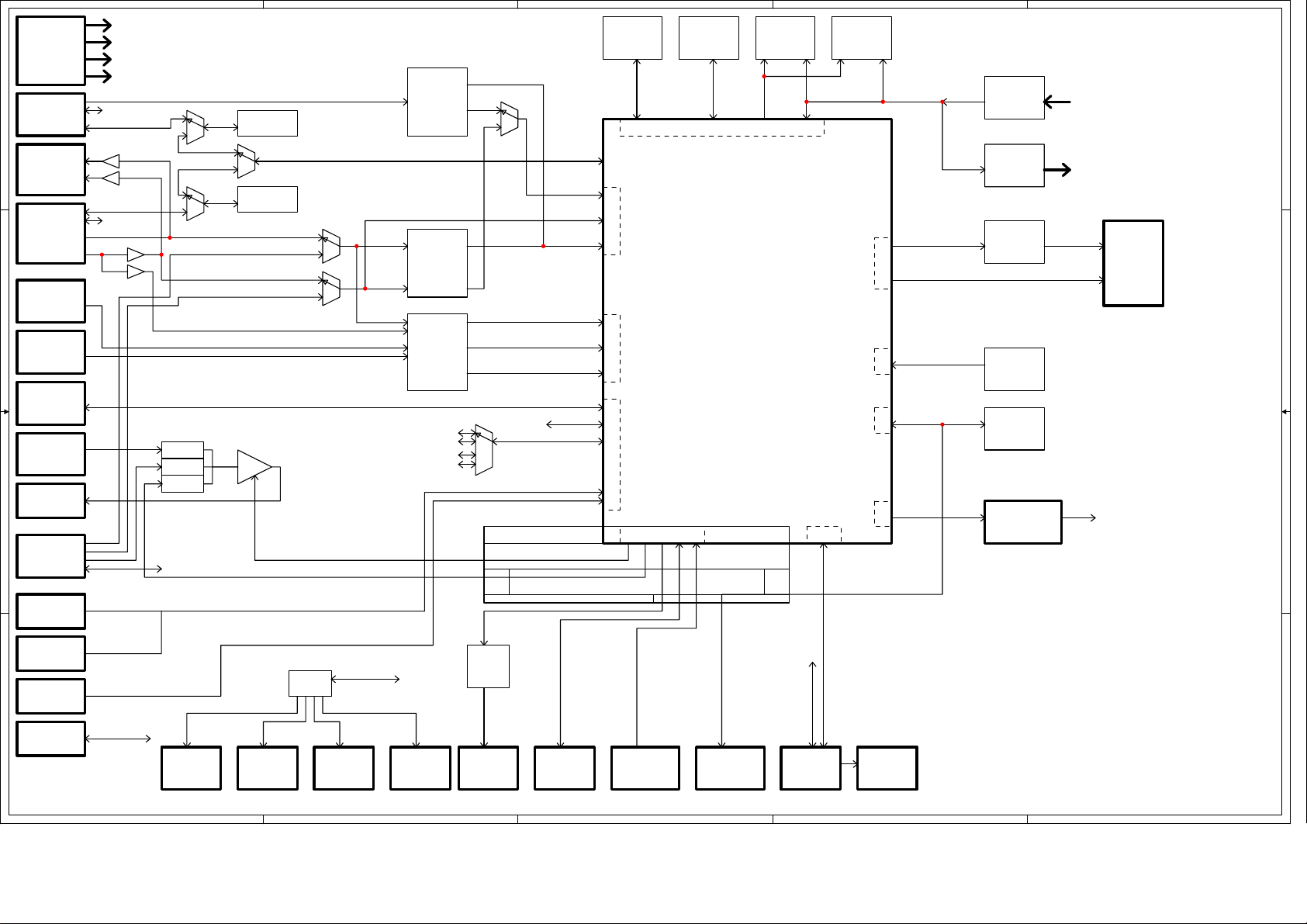

BLOCK DIAGRAM

PD523PD 527D SCHEMATIC B

UART1

UART0

RIR DAT

FIR DAT

Photo

Sensor

PWM0

PWM1

PWM3

CWINDEX

THER_ERR

Thermal

Switch

DDP2000

I2C Bus

118Thursday, November 10, 2005

of

Thermal

Sensor

SDRAM

(Optioin)

PMADR

21

/

16

/

PMDAT

LAMP RS-232

Lamp

Driver

FLASH

ROM

2

/

LAMP

2

PMDAT

Ctrl & Reset

DDR Data

Power Sense

I2C Bus

LEDs

4

/

GPI

Expander

GPO

Expander

DAD1000

Reset IC

NVRAM

KEYPAD

16

/

16

/

23

/

64

/

8

/

16 Bits

16 Bits

1

DMD

CHIP

(DDR)

GPI Expander

5

4

3

2

1

of

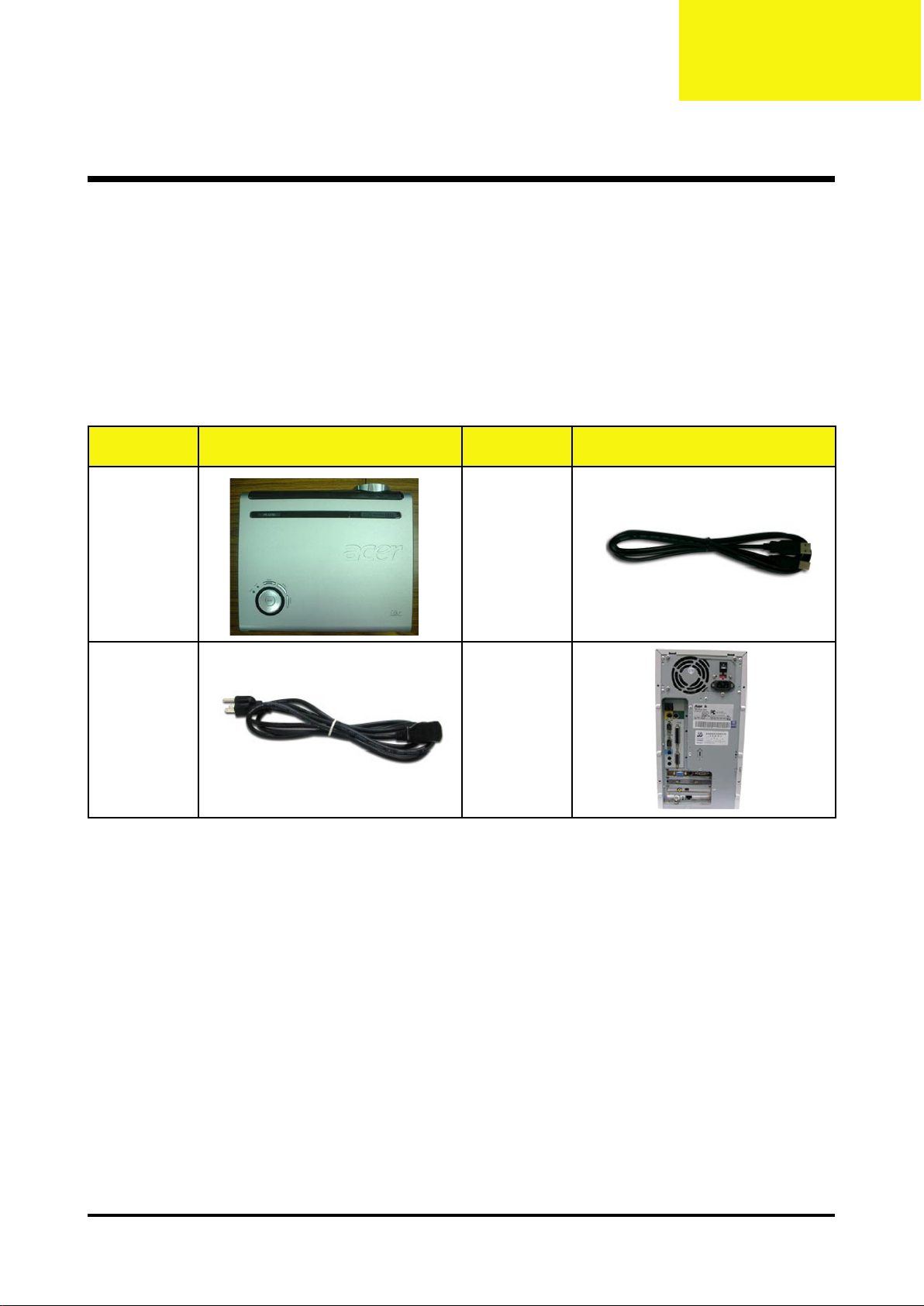

Firmware Upgrade

Equipment Needed

Software : (DDP 2000- USB)

- DLP Composer

- Firmware Files (PD527D or PD523PD)

Hardware :

Item Photo Item Photo

Chapter 2

Projector USB Cable

Power Cord

PC or Laptop

Chapter2 8

Installation Procedure

DLP Composer Lite Setup Procedure

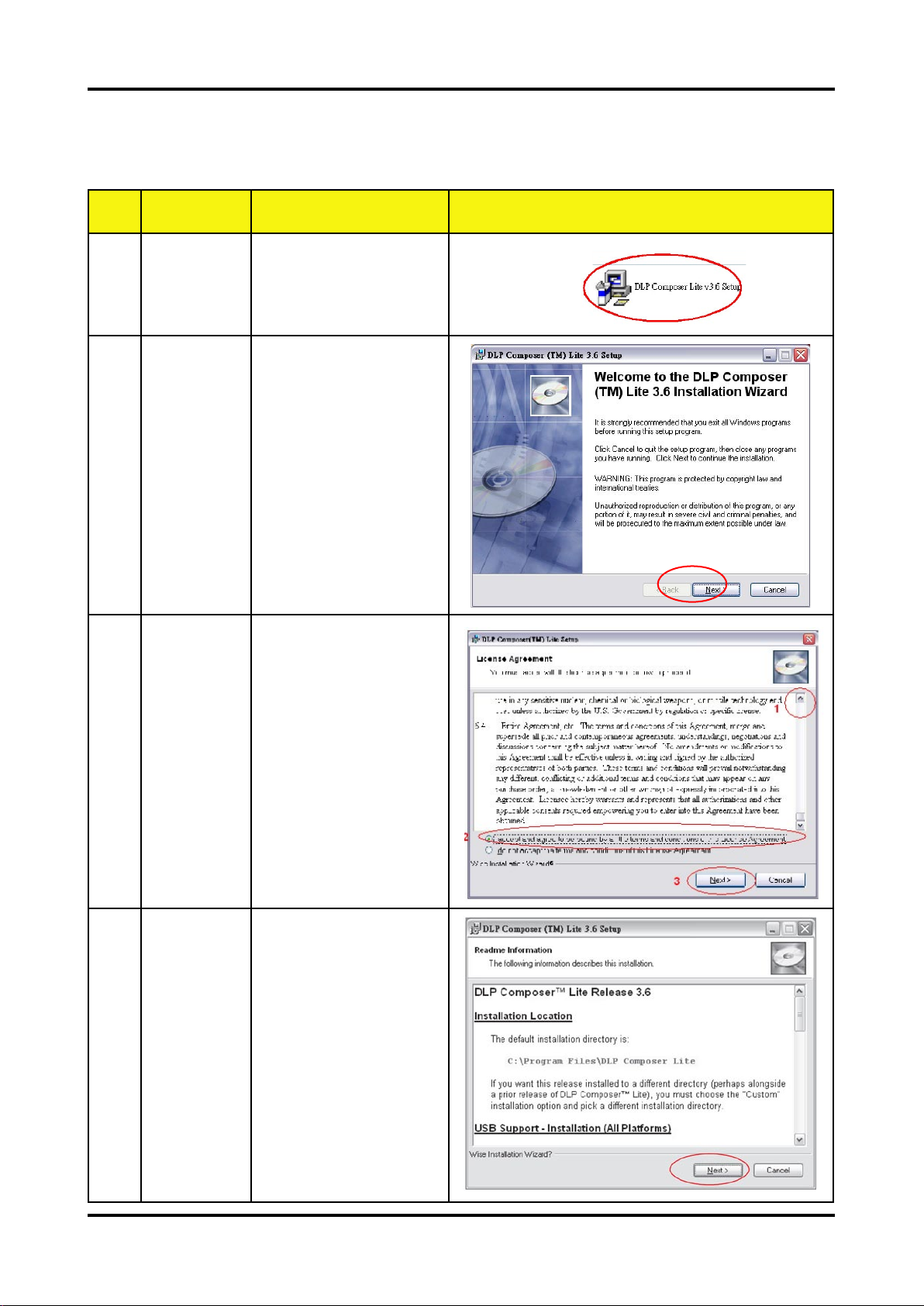

No Step Procedure Photo

1 Execute

FW program

2 Next

3 Next

Choose

“DLP Composer Lite

v3.6 Setup” program.

Click “Next” button.

1. Reading the “License

Agreement” rules.

2. Choose “I accept and

agree to be bound by

all the terms and

conditions of this

License Agreement”

icon.

3. Click “Next” button.

4 Next

9 Chapter 2

Click “Next” button.

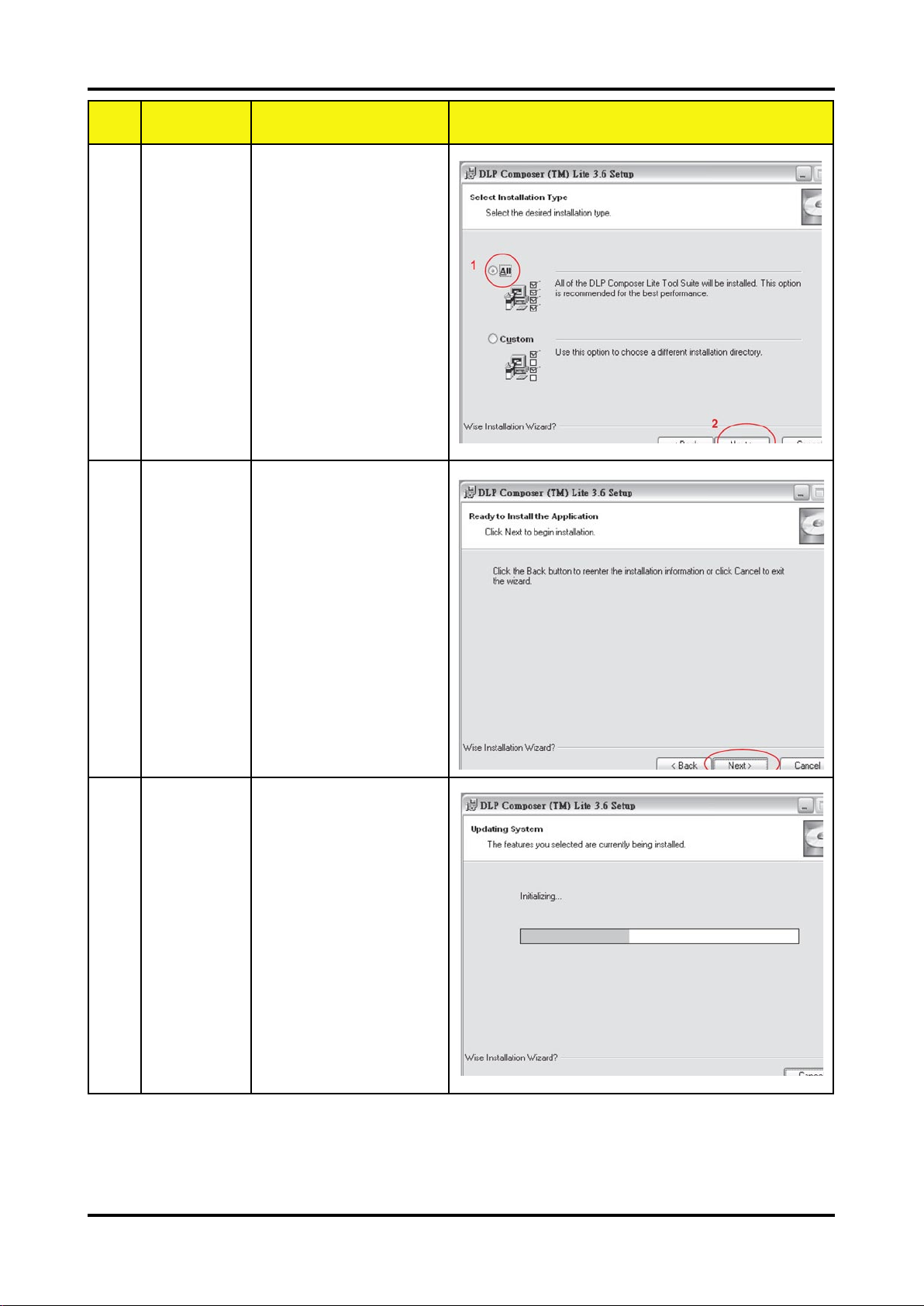

No Step Procedure Photo

5 Next

6 Next

1. Choose “All” icon.

2. Click “Next” button.

Click “Next” button.

7 Process-

ing

Chapter2 10

The program is executing “Initializing” status.

USB Driver Upgrade Procedure

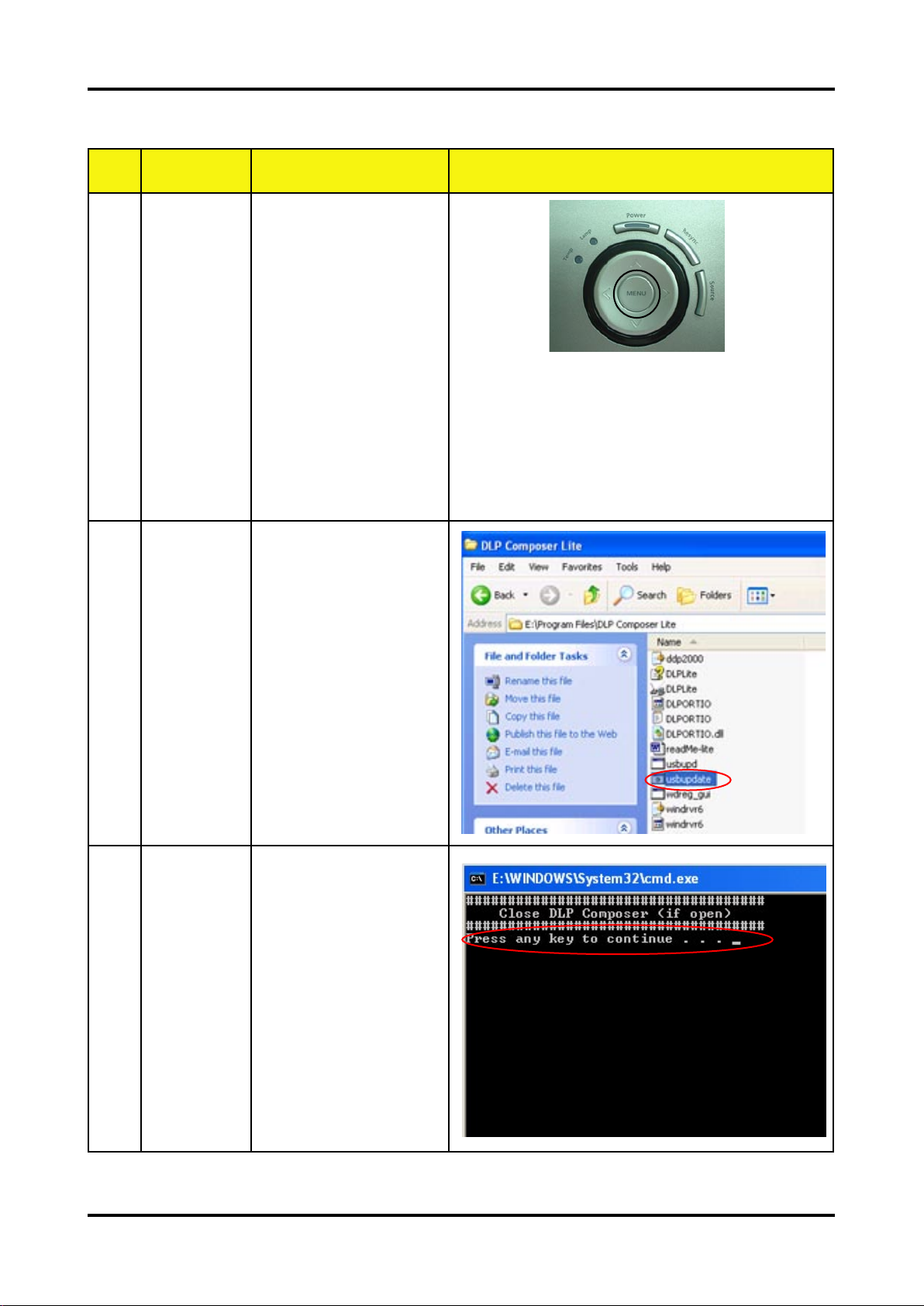

No Step Procedure Photo

1 Set-up

2 Execute

Program

1. Hold on “Menu” button

and plug in Power

Cord while holding on

“Menu”.

2. Wait for about 5 secs.

3. Once Power, Lamp,

Temp LED lights up,

plug in USB Cable

into the Projector.

(Note: The system fan

will not function. The

light will not function as

well.)

Execute the C:\Program

files\DLP Composer\usbupdata.cmd

(Note: The “DLP Composer” program must be

closed first.)

3 Type any

key to

continue

11 Chapter 2

Press any key to continue. Then, wait for about

1 minute.

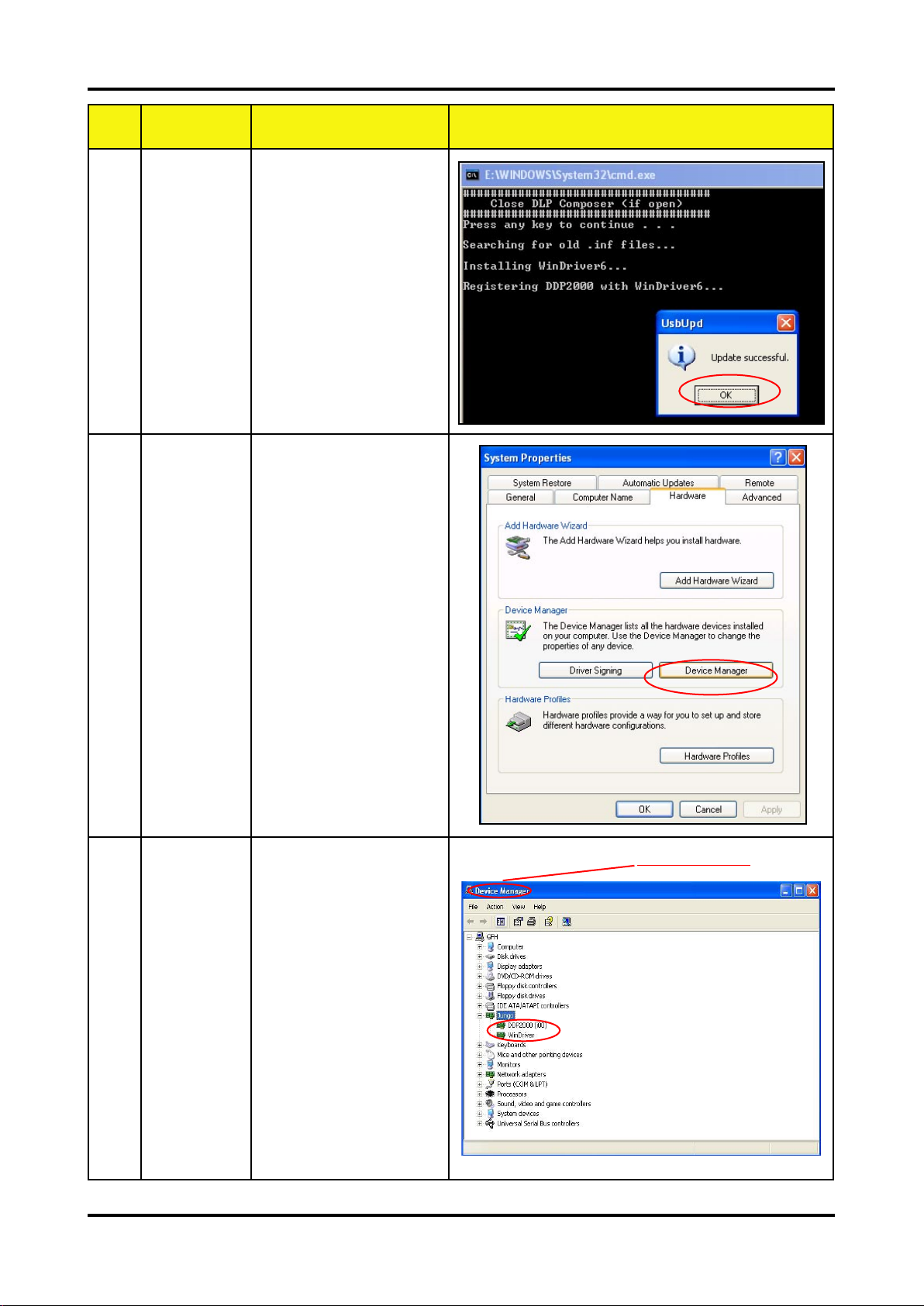

No Step Procedure Photo

4 Update

Successfully

5 Device

Manager

Click “OK”. The USB

driver is updated successfully.

1. Right click “My

computer” on the

desktop.

2. Select “Properties”

on the popup menu

to launch the “System

Properties” window.

3. Choose “Hardware”

and then click “Device

Manager”.

Ensure

6

“DDP2000”

& “WinDriver” are

properly

installed

Chapter2 12

Click “Jungo” to ensure

“DDP2000” and “Windriver” are properly

installed. If not, repeart

Step 1~5.

Device Manager

Firmware Upgrade Procedure

No Step Procedure Photo

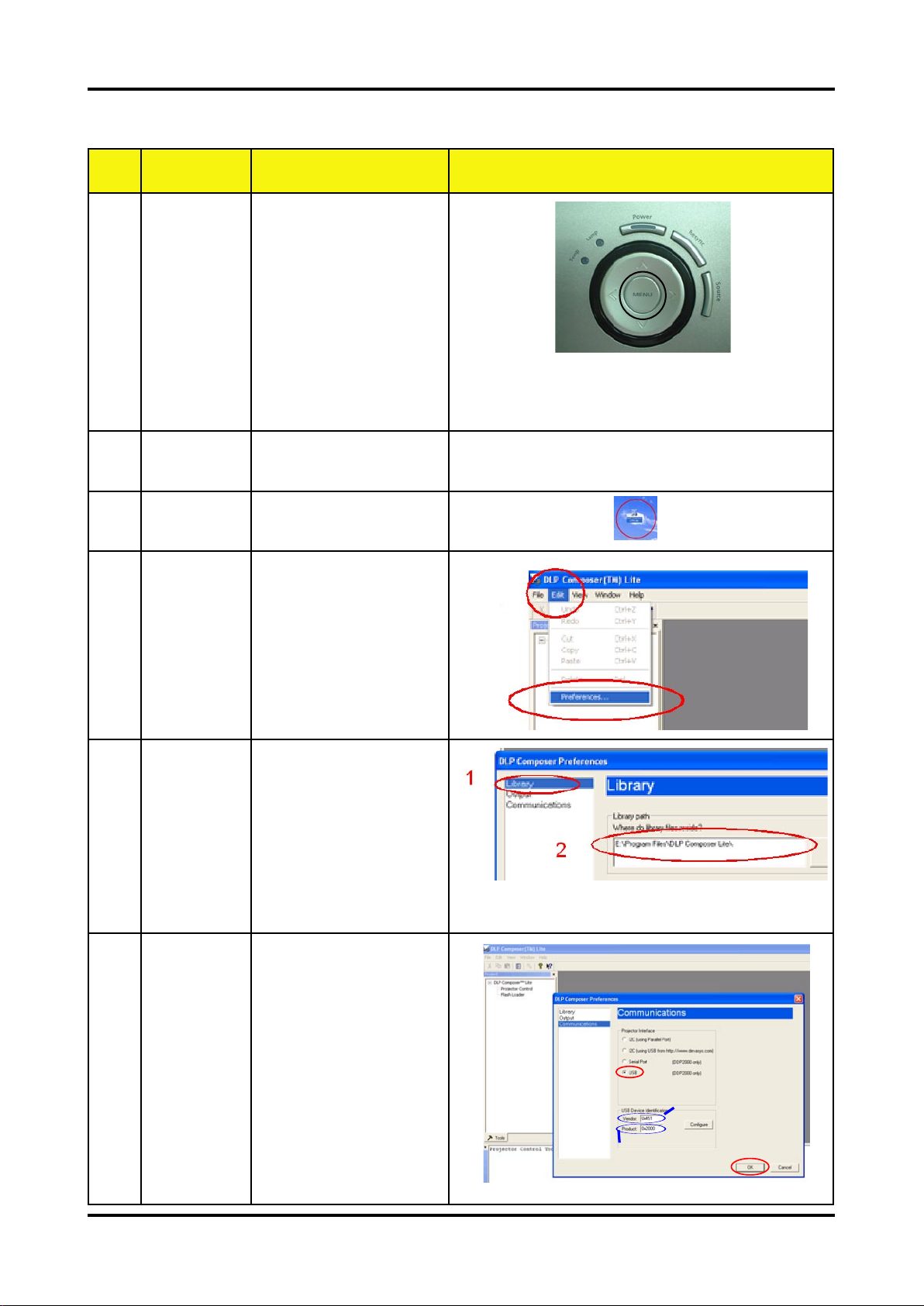

1 Set-up

2 Set-up

3

4

1. Hold on “Menu” button and

plug in Power Cord while

holding on “Menu”.

2. Wait for about 5 secs.

3. Once Power, Lamp, Temp

LED lights up, plug in USB

Cable into the Projector.

(Note: The system fan will not

function. The light will not

function as well.)

Link PC USB and projector

Execute the “DLP Com-

TM”

pose

file.

.

Click “Edit” and “Preferences”.

1

2

5

6

1. Click “Library”.

2. The library path

located in the default

installation directory

is C:\Program Files\

DLP Composer.

If not, press “Browse” to

select the right path.

1. Select “Edit\Prefer

ences\Communi

cations” and choose

“USB”.

2. Click “OK”.

1

USB

Vendor: 0x451

Product: 0x2000

2

OK

13 Chapter 2

No Step Procedure Photo

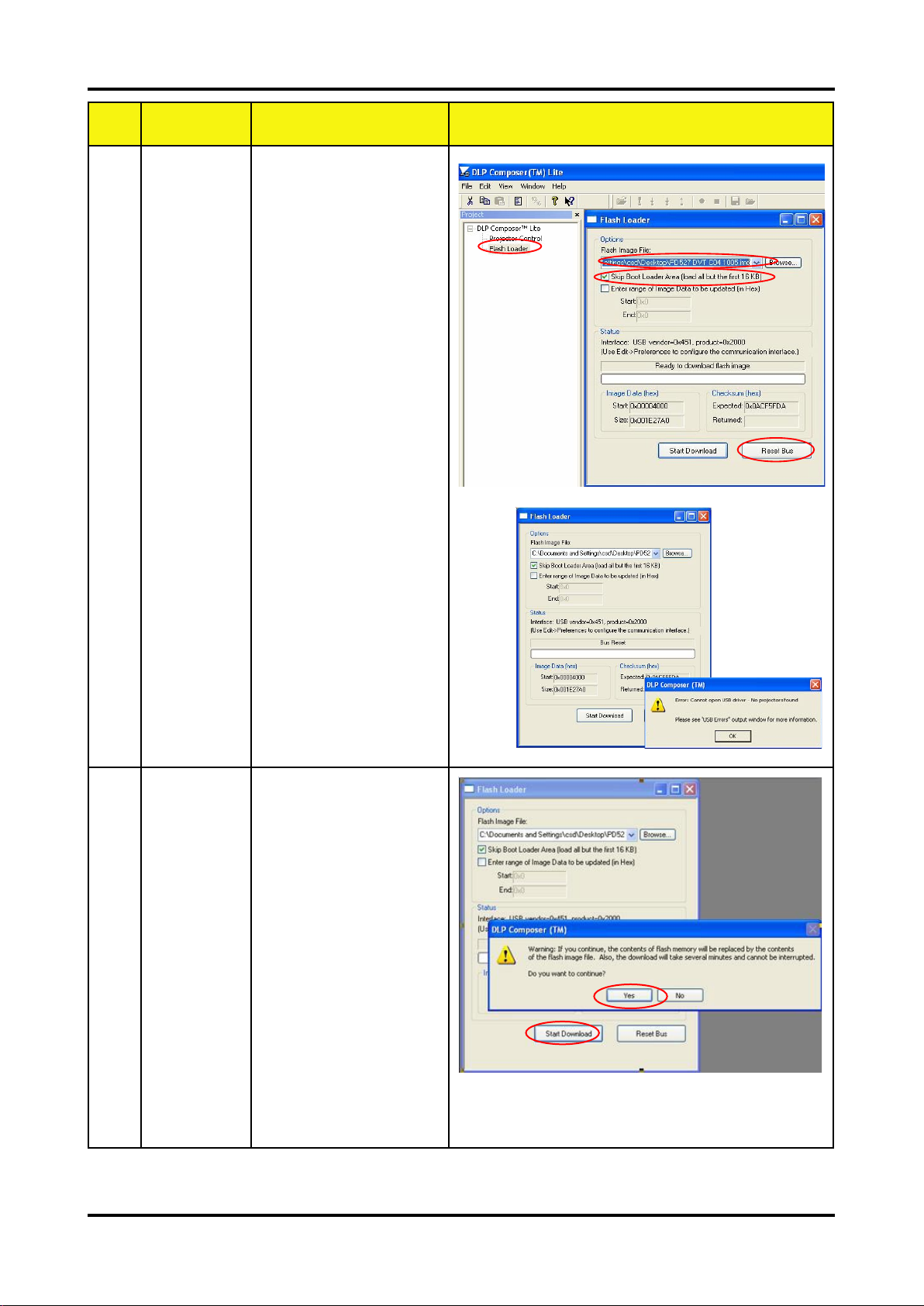

7

1. Choose “Flash

Loader”

2. Click “Browse” to

search the firmware

file. (PD527D or

PD523PD)

3. Select the item “Skip

Boot Loader Area

(load all but the first

16KB).”

4. Click “Reset Bus” to

erase the flash

memory.

(Note: If the error message “cannot open USB

driver - No projectors

found” appears, please

unplug the USB Cable &

Driver and replug, then

re-do 4. Click “Reset

Bus” to erase the flash

memory.)

1

2

3

4

Note:

8

1. If the firmware is

ready, click “Start

Download” to process

the firmware upgrade.

2. Click “Yes” to erase

the flash memory.

2

1

Chapter2 14

No Step Procedure Photo

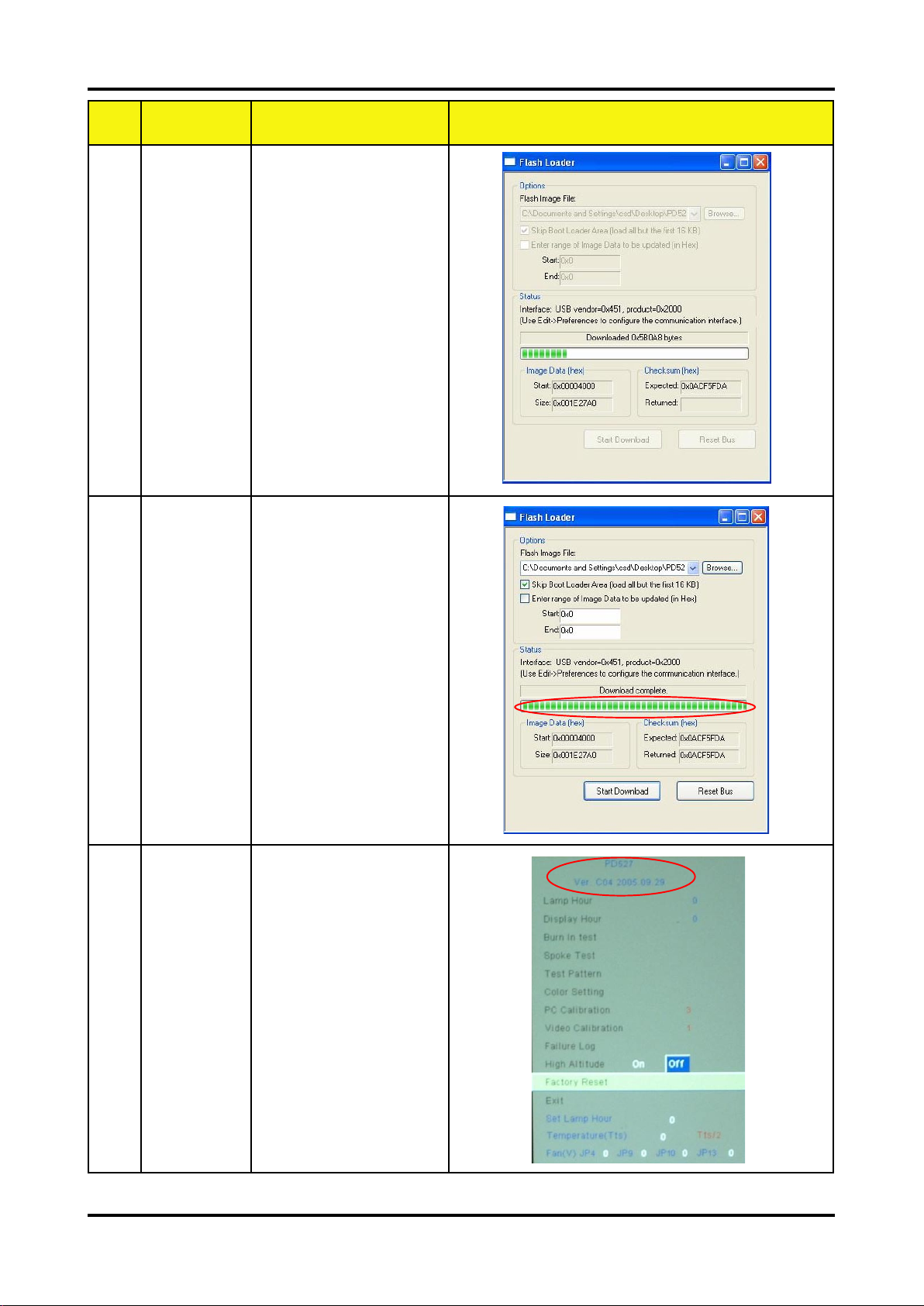

9 Proceed-

ing

10

Proceeding Picture

1. When Firmware

Upgrade Process is

finished, the LED

power flashs.

2. Unplug USB Cable

and Power Cord.

Re-plug in Power

Cable.

11 Check

Firmware

15 Chapter 2

Restart the unit and

enter the Service Mode

to check the Firmware

Version.

(For entering Service

Mode, please refer to

Chapter 4 Function Test

and Alignment Procedure.)

EDID Upgrade

EDID Introduction

Extended Display Identification Data is a VESA standard data format that contains

basic information about a display device and its capabilities, including vendor information,

maximum image size, color characteristics, factory pre-set timings, frequency range limits,

and character strings for the model name and serial number.

The information is stored in the display and is used to communicate with the system

through a Display Data Channel (DDC), which sites between the display device and the PC

graphics adapter. The system uses this information for configuration purposes, so the unit

and system can work together.

Note:

If a display device has digital input ports, like DVI or HDMI, but without EDID in its

main board, the display device will show no image while the input source is digital signal.

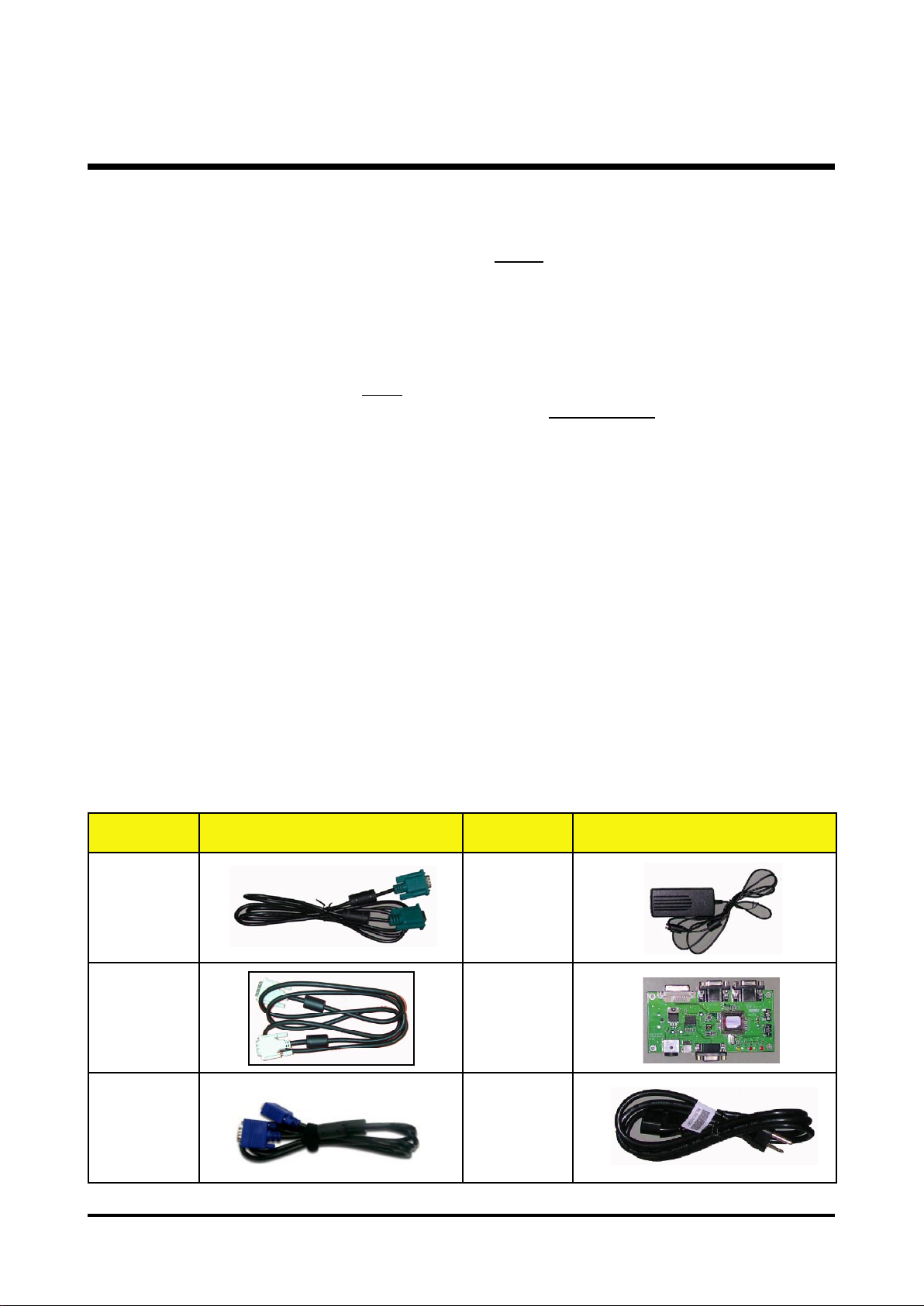

Equipment Needed

Software:

- EDID Software (Generic V0.51)

- EDID Tables (*.ini) -- PD527D or PD523PD

Hardware:

- V3 Fixture for EDID Key-in

(Fixture: JP3 must be closed)

Item Photo Item Photo

RS-232

Cable

(F - M)

DVI Cable

Power

Adapter for

Fixture

Generic

Fixture

VGA Cable Power Cord

Chapter2 16

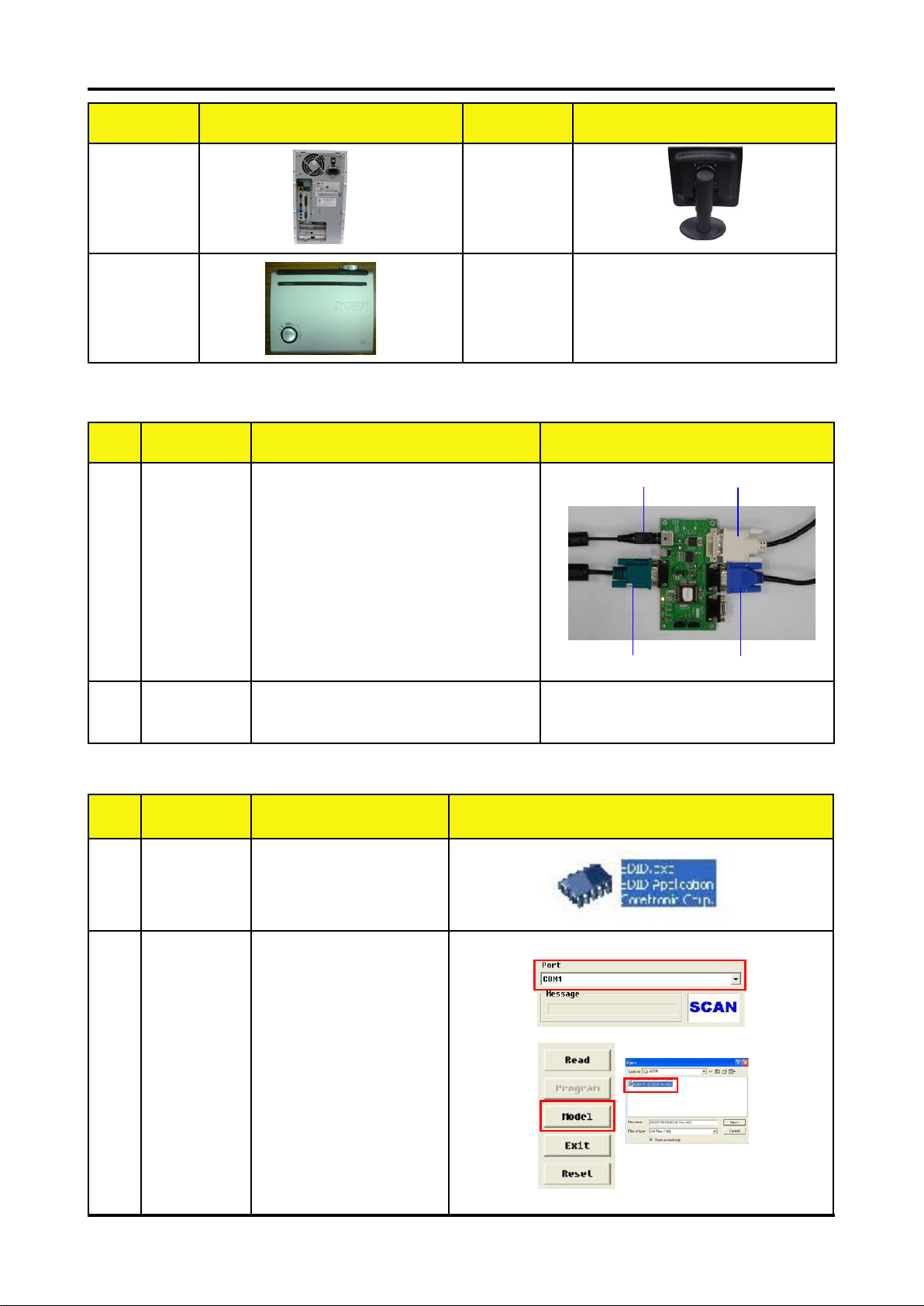

Item Photo Item Photo

One additional

PC

Projector

monitor (for

checking the pro-

gram execution)

Setup Procedure

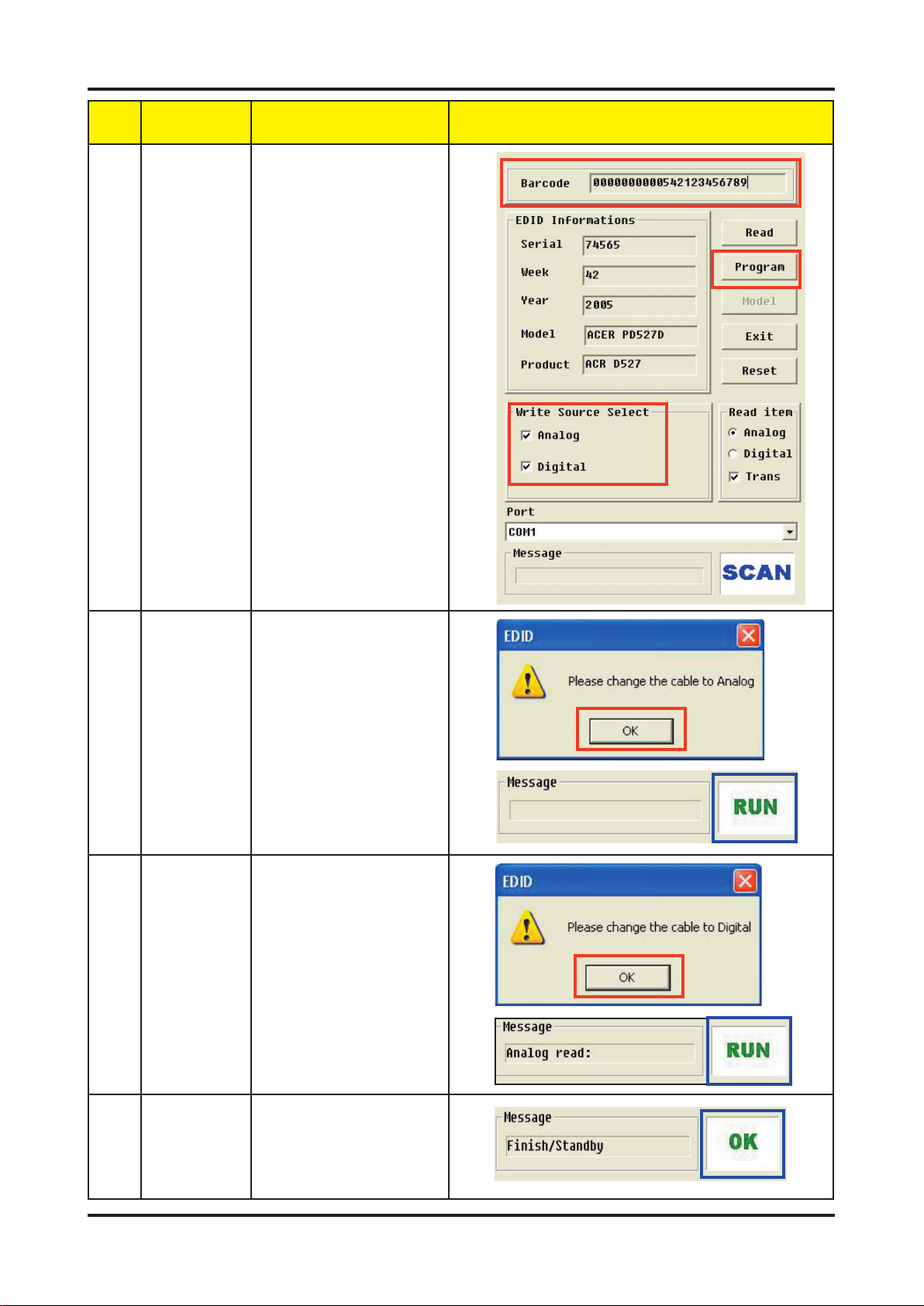

No Step Procedure Photo

1 C o n n e c t

All Ports

2 Power On

1. Power Adapter to Fixture JP1

2. Fixture P1 to PC COM1 Port

3. Fixture P2 to Projector Analog Port

4. Fixture P3 to Projector Digital Port

RS-232 Cable

Power on Fixture

Fixture

EDID Key-In Procedure

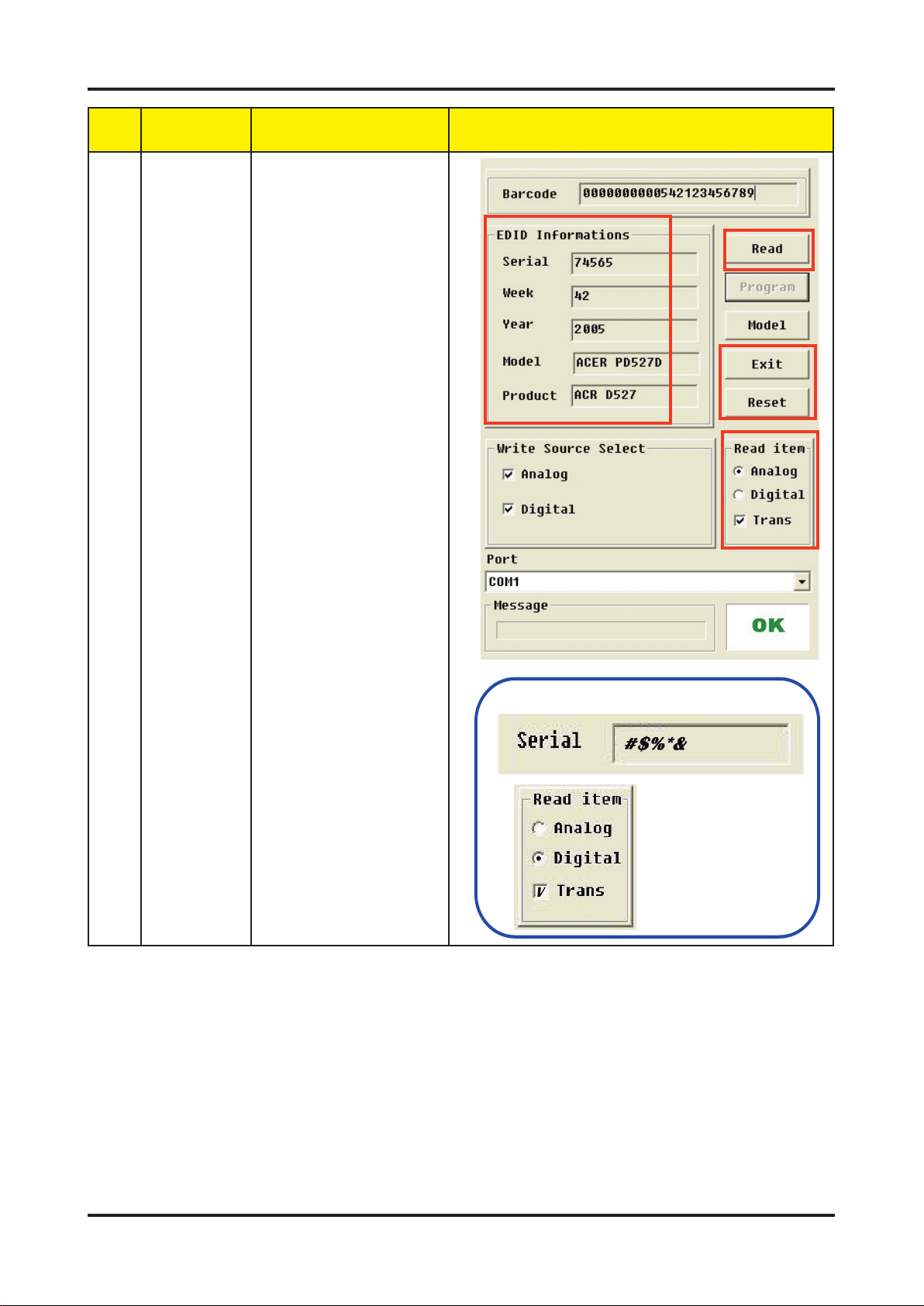

No Step Procedure Photo

1 Execute

EDID

Program.

Click on “EDID” to execute EDID Program.

JP1

P1

To Digital PortAdapter

P3

P2

To Analog Port

2 Choose

Model

17 Chapter 2

1. In the Port Selection

Bar, please choose

the Port that you use.

Ex: If you use “COM

1”, choose COM 1 in

the Port selection.

2. Click on “Model”.

(PD527D or PD523PD)

3. Choose the EDID that

responses to the

model that you

choose.

1

32

No Step Procedure Photo

3 Key in

Serial

Number

1. Key in the Serial

Number into the

Barcode blank space.

2. In “Write Source

Select”, make a check

in “VGA” and “DVI”.

3. Click “Program”.

1

3

2

4 Change

Cable to

Analog

5 Change

Cable to

Digital

“Please change the

Cable to Analog” message is shown on the

screen, then click “OK”.

(Note: “RUN” message will appear on the

screen.)

“Please change the

Cable to Digital” message is shown on the

screen, then click “OK”.

(Note: “RUN” message will appear on the

screen.)

6 Finished

Chapter2 18

When the EDID program

is completed, the message, “OK”, will appear

on the screen.

No Step Procedure Photo

7 Check

the whole

process

1. In the “Read Item”

Selections, choose

the Port that you use.

Ex: If you use the

Analog Port, choose

“Analog” in the “Read

Item”.

2. Click on “Read” to

read EDID

information.

3. The “EDID

Informations” will

show the result.

(Note: After pressing “Read”, if the code

in the Serial Blank is

scrambled, please make

a check in “Trans”.)

4. Click “Reset” to do the

next unit or “Exit” to

close the EDID

program.

3

2

4

1

Note

PS.

Both Analog and Digital are needed to be

checked.

19 Chapter 2

Chapter 3 20

Mechanical Disassembly & Reassembly

This section provides disassembly & Reassembly procedures for PD527D Micro Portable XGA

DMD Projector (As a sample model). Before you begin any of these procedures, be sure to

turn off the power, computer system, and other attached devices; then disconnect the power

cable from the electrical outlet. Moreover, when you disassemble the projector, be sure to

put the screws in a safe place and separate them according to their category.

(For PD523PD, you can refer to this sample disassembly & reassembly procedures for

instructions.)

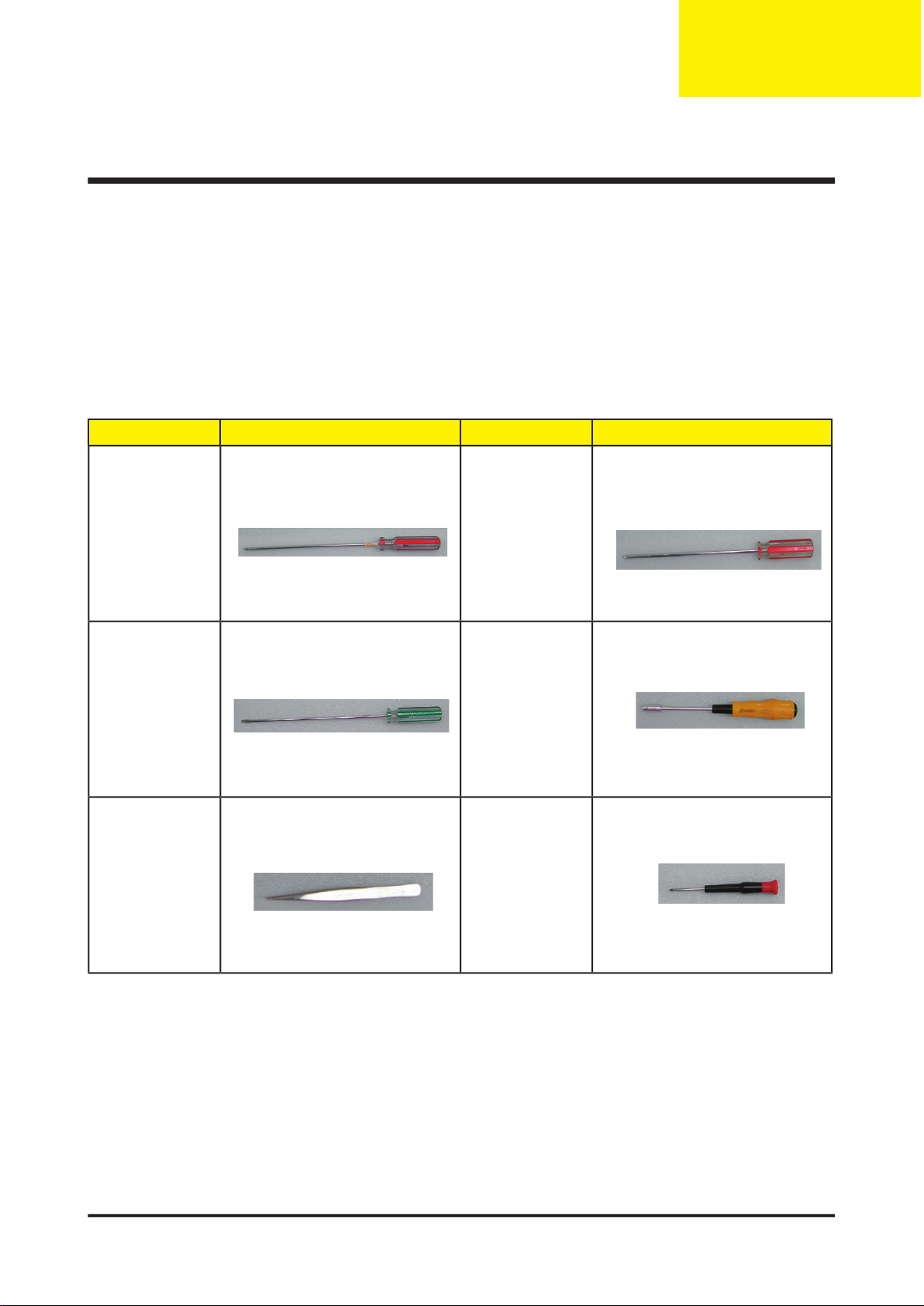

Equipment Needed

Chapter 3

General Information

Before You Begin

Before proceeding with the disassembly procedure, make sure that you do the following

procedures:

1. Turn off the power of the system and all the peripherals.

2. Unplug the AC adapter and all power and signal cables from the system.

3. Anti-static wrist strap.

Item Photo Item Photo

Philips (+) : 107 Philips (+) : 102

Screw Bit

Hex Screw :

5mm

Tweezers

Screw Bit

21 Chapter 3

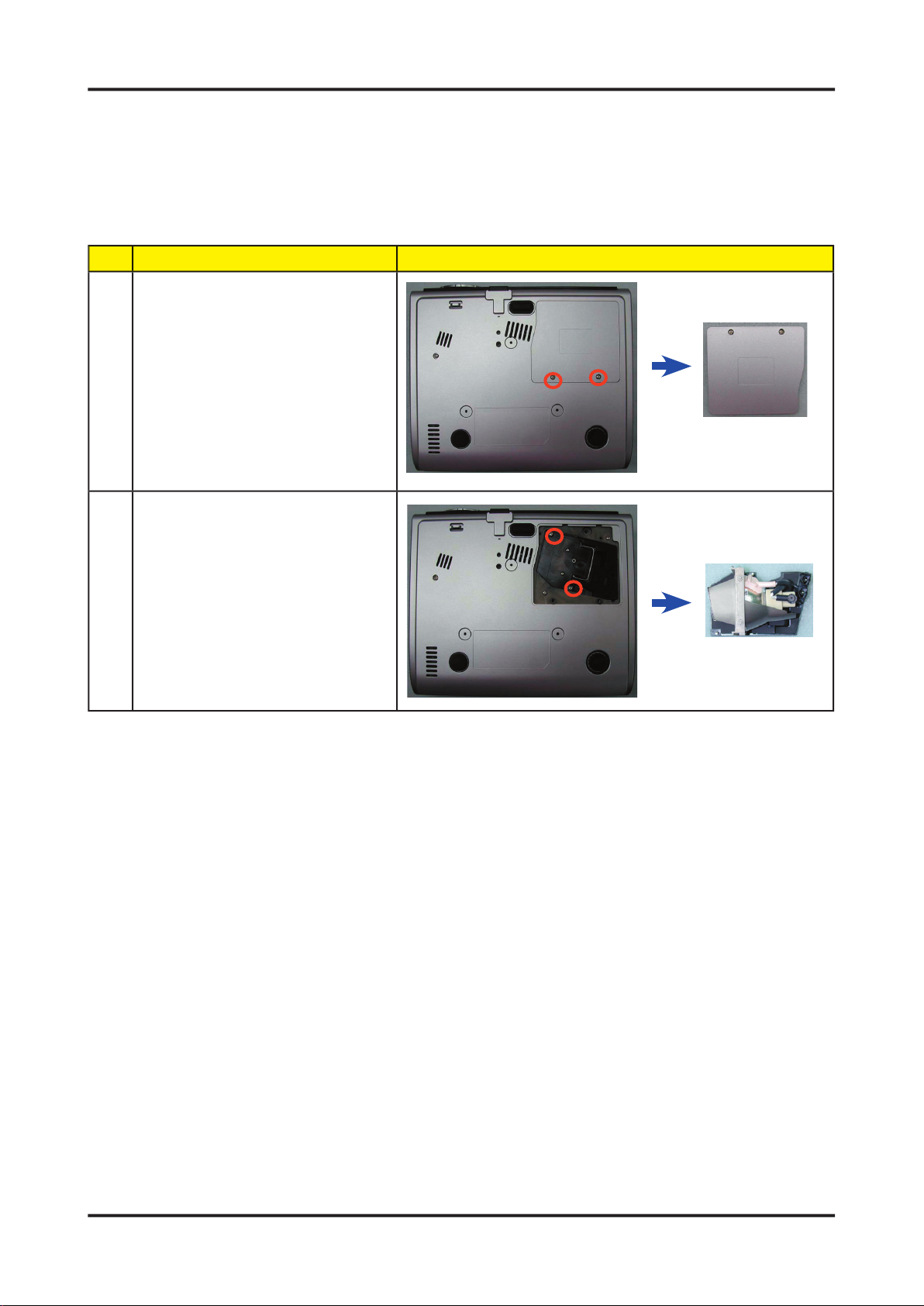

No Procedure Photo

1 Unscrew 2 screws to remove

the Lamp Cover.

2 Unscrew 2 screws to remove

the Lamp Module.

1. Remove Lamp Module

Mechanical Disassembly Procedure

Chapter 3 22

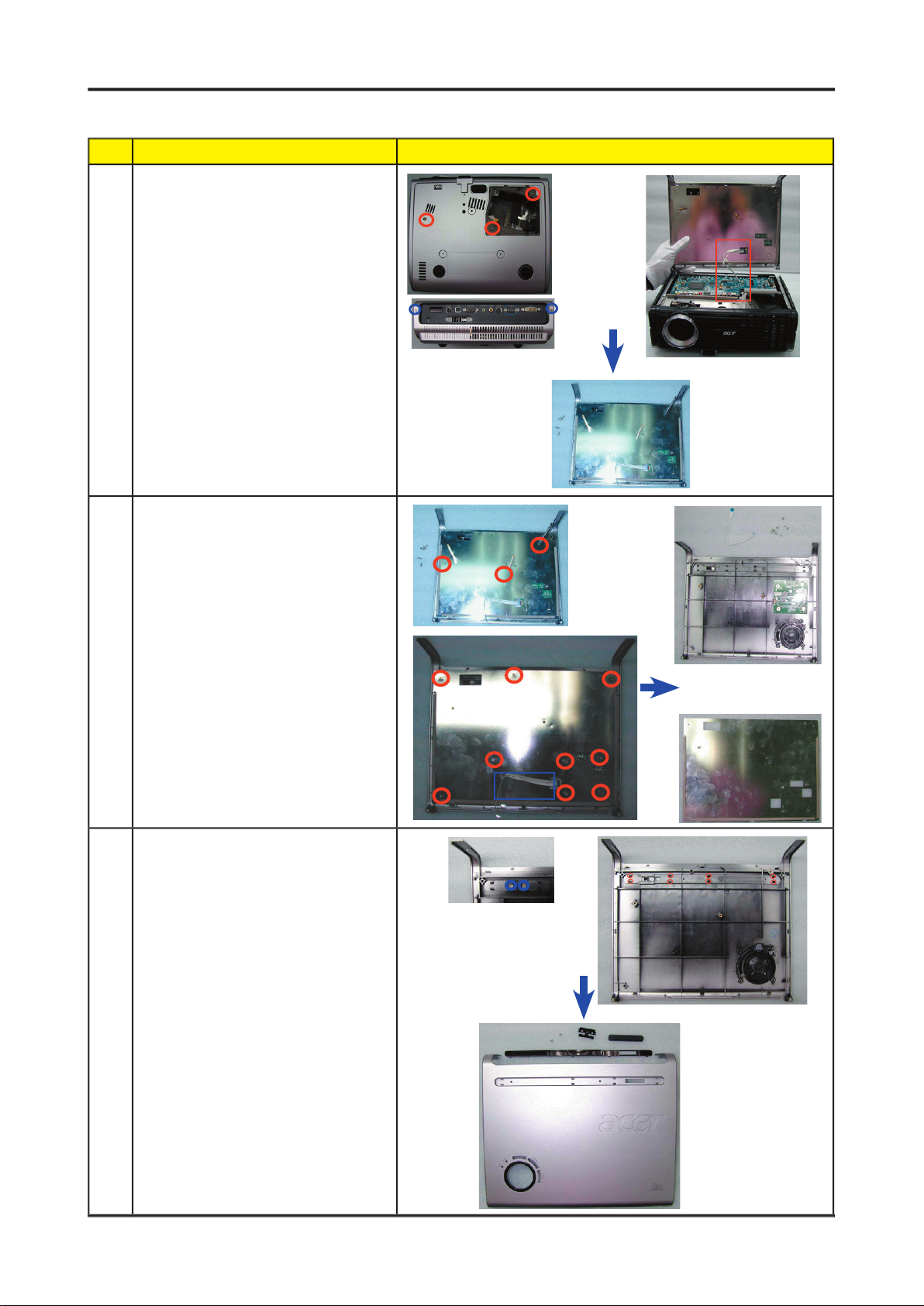

No Procedure Photo

1 Unscrew 3 screws in the

Bottom Cover, 2 screws in

the IO Cover and 1 FPC

connector to remove Top

Cover Module.

2 Disassemble Top Cover /

Keypad BD / Main Button:

(1) Unscrew 3 hex spacers

(2) Unplug 1 FPC connector

(3) Unscrew 9 screws to

remove Top Shelding.

3 Disassemble Model Plate:

(1) Unscrew 2 screws

(2) Loosen 8 tenons to

remove Model Plate

2. Remove Top Cover / Keypad Board / Main Button

23 Chapter 3

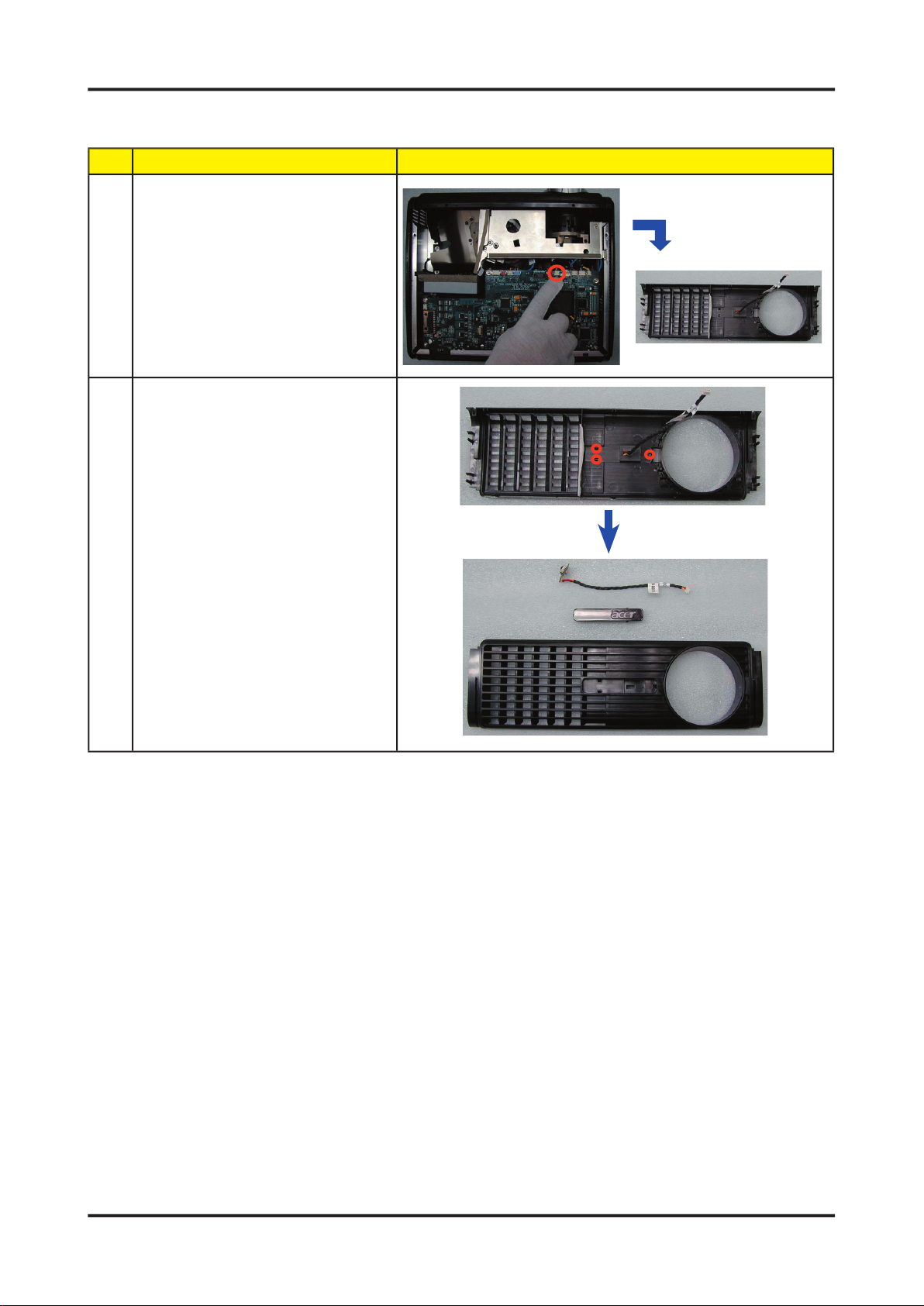

3. Remove Front Cover / IR Sensor Board

No Procedure Photo

1 Unplug IR Receivers and

remove Front Cover directly.

2 Loosen 3 tenons to remove IR

Sensor Board.

Chapter 3 24

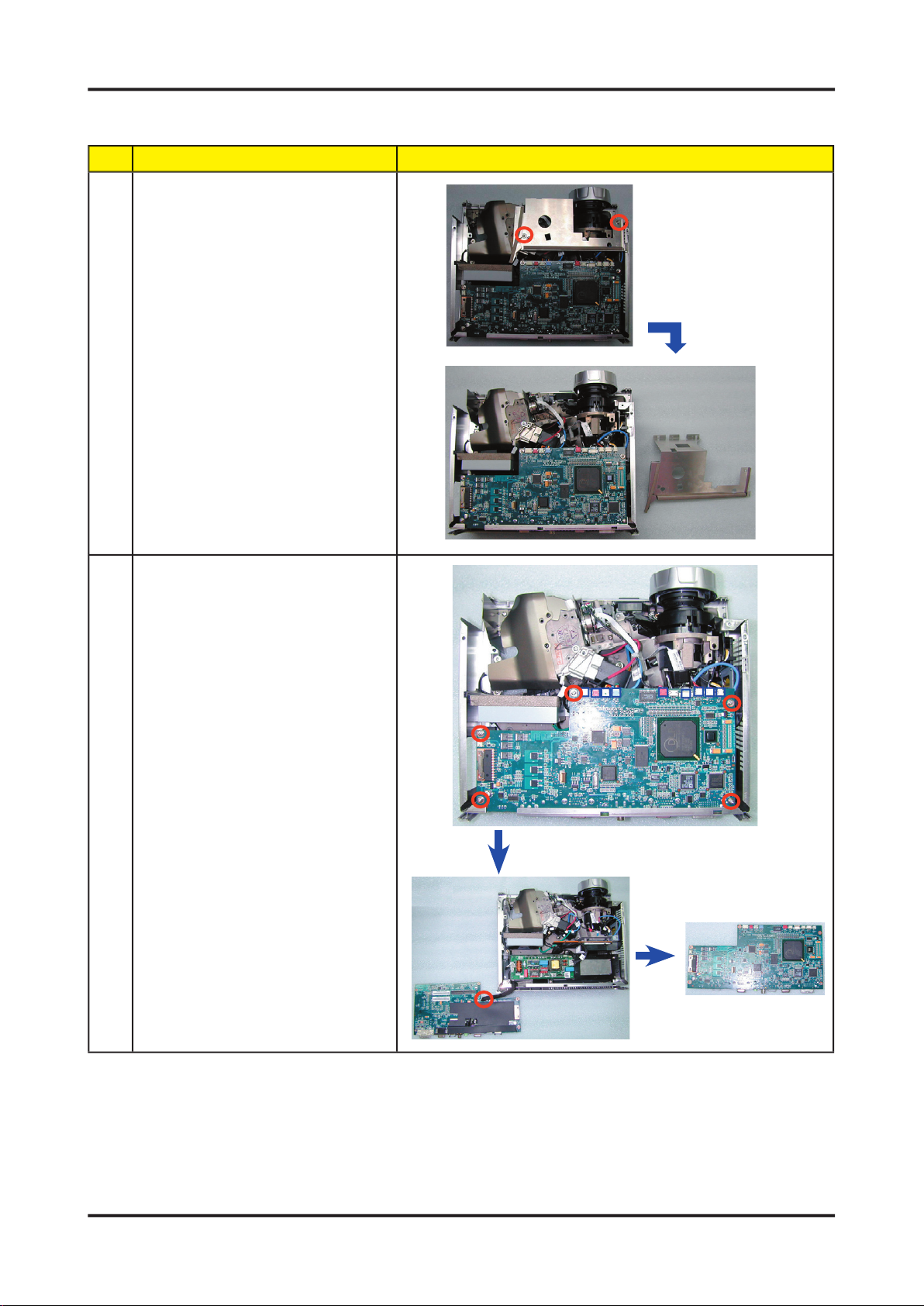

No Procedure Photo

1 Unscrew 6 hex screws to

remove the Back Cover.

2 Remove Side Covers directly.

(Right Cover & Left Cover)

4. Remove Back Cover and Side Covers

25 Chapter 3

5. Remove Main Board

No Procedure Photo

1 Unscrew 2 screws to remove

the shielding.

2 Unplug 9 connects, unscrew 5

screws in the Top and then un

plug 1 connector in the Bottom

to remove the Main Board.

Loading...

Loading...