Page 1

SERVICE MANUAL

Model Name : PD100/PD100D/PD120/

PD120D/XD1170D/XD1270D

Prepared by SI :

________________________________________

Prepared by TSE :

________________________________________

Check by :

________________________________________

Approved by :

________________________________________

Date Revise Version Description

2005/8 V1.0 Initial Issue(PD100/PD100D/PD120/PD120D)

2006/7 V2.0 add XD1170D&1270D models, add pages 2/5/7/15/49/80-111

Copyright July, 2006 . All Rights Reserved

P/N#36.82V01G001 . Document#82V-G04-02A

Page 2

Preface

This manual is applied to Acer PD100 0.55 inch 120 DDR DMD SVGA Micro Portable

Projector / PD100D 0.55 inch 120 DDR DMD SVGA Micro Portable Projector / PD120 0.55

inch 120 DDR DMD SVGA Micro Portable Projector / PD120D 0.55 inch 120 DDR DMD SVGA

Micro Portable Projector / XD1170D 0.55 inch 120 DDR DMD SVGA Micro Portable Projector

/ XD1270D 0.55 inch 120 DDR DMD XGA Micro Portable Projector. The manual gives you a

brief description of basic technical information to help in service and maintaining the product.

Your customers will appreciate the quick response time when you immediately identify

problems that occur with our products. We expect your customers will appreciate the service

that you offer them.

This manual is for technicians and people who have an electronic background. Please

send the product back to the distributor for repairing and do not attempt to do anything that is

complex or is not mentioned in the troubleshooting.

NOTICE :

The information found in this manual is subject to change without prior notice. Any

subsequent cha nges made to the data herein will be incorporated in further edition.

PD100/PD100D/PD120/PD120D/XD1170D/XD1270D Service Manual

Copyright July, 2006

All Rights Reserved

Manual Version 2.0

Page 3

PD100 PD100D PD120 PD120D XD1170D XD1270D

Service Guide

Service guide files and updates are available

on the AIPG/CSD web; for more information,

please refer to http://csd.acer.com.tw

PRINTED IN TAIWAN

Page 4

Revision History

Please refer to the table below for the updates made on PD100, PD100D, PD120, PD120D, XD1170D, XD1270D service guide.

Date Chapter Updates

II

Page 5

Copyright

Copyright © 2006 by Acer Incorporated. All rights reserved. No part of this publication may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language or computer language, in

any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without

the prior written permission of Acer Incorporated.

Disclaimer

The information in this guide is subject to change without notice.

Acer Incorporated makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranties of merchantability or fitness for any particular

purpose. Any Acer Incorporated software described in this manual is sold or licensed "as is". Should the

programs prove defective following their purchase, the buyer (and not Acer Incorporated, its distributor, or its

dealer) assumes the entire cost of all necessary servicing, repair, and any incidental or consequential

damages resulting from any defect in the software.

Acer is a registered trademark of Acer Corporation.

Intel is a registered trademark of Intel Corporation.

Pentium 4 and Celeron are trademarks of Intel Corporation.

Other brand and product names are trademarks and/or registered trademarks of their respective holders.

III

Page 6

Conventions

The following conventions are used in this manual:

Screen messages

NOTE Gives bits and pieces of additional

WARNING Alerts you to any damage that might

CAUTION Gives precautionary measures to

IMPORTANT Reminds you to do specific actions

Denotes actual messages that appear

on screen.

information related to the current

topic.

result from doing or not doing specific

actions.

avoid possible hardware or software

problems.

relevant to the accomplishment of

procedures.

IV

Page 7

Preface

Before using this information and the product it supports, please read the following general information.

1. This Service Guide provides you with all technical information relating to the BASIC CONFIGURATION

decided for Acer's "global" product offering. To better fit local market requirements and enhance product

competitiveness, your regional office MAY have decided to extend the functionality of a machine (e.g.

add-on card, modem, or extra memory capability). These LOCALIZED FEATURES will NOT be covered

in this generic service guide. In such cases, please contact your regional offices or the responsible

personnel/channel to provide you with further technical details.

2. Please note WHEN ORDERING FRU PARTS, that you should check the most up-to-date information

available on your regional web or channel. If, for whatever reason, a part number change is made, it will

not be noted in the printed Service Guide. For ACER-AUTHORIZED SERVICE PROVIDERS, your Acer

office may have a DIFFERENT part number code to those given in the FRU list of this printed Service

Guide. You MUST use the list provided by your regional Acer office to order FRU parts for repair and

service of customer machines.

V

Page 8

Table of Contents

Chapter 1 System Introduction 1

Technical Specification 1

Product Overview 2

Chapter 2 Firware Upgrade 7

Equipment Needed 7

Installation Procedure 8

USB Driver Upgrade Procedure 10

Firmware Upgrade Procedure 12

EDID Upgrade 1 5

Equipment Needed 15

Setup Procedure 16

EDID Key-in Procedure 16

Chapter 3 Mechanical Disassembly and Reassembly 1 9

Equipment Needed 19

General Information 19

Mechanical Disassembly Procedure 20

Mechanical Reassembly Procedure 33

Chapter 4 Troubleshooting 46

Equipment Needed 46

LED Lighting Message 46

Main Procedure 47

Function Test and Alignment Procedure 4 9

Product / Test Equipment / Test Condition 49

Inspection Procecdure 50

Guide to Entering Service Mode and Factory Reset (PD100) 53

Chapter 5 Exploded Overview 54

Exploded Overview 54

Appendix Serial Number Definition System 112

I. Serial Number System Definition 112

II. PCBA Code Definition 113

III. The Different Parts (PD100 / PD100D / PD120 / PD120D / XD1170D /

XD1270D ) 114

IV. Identification Method for “D” Model 118

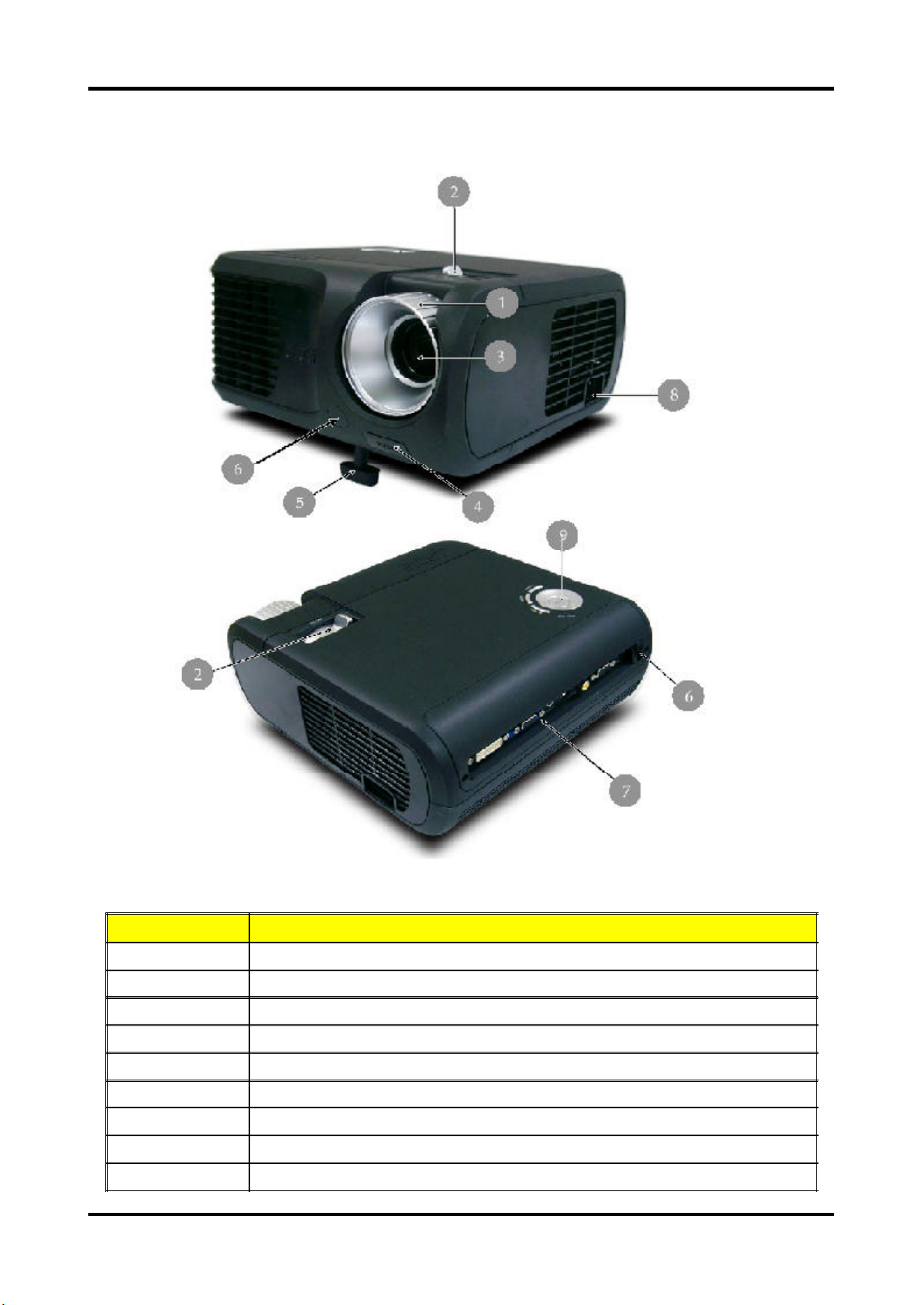

Page 9

System Introduction

Tec hnical Specification

Item Description

Dimensions (WxHxD) 230 x 122.8 x 238 mm

Tilt Angle 7 degree with elevator mechanism

Keystone correction +/-16 degree (32 degree) (Horizontal)

Lamp Door Projection Lamp power supply shut off automatically when door open

Universal AC 100-240V ~ 50-60Hz with PFC input

Power Supply

200W for Philips UHP Lamp @ normal operation

Variance FAN speed control

(Depends on temperature variant)

Chapter 1

Throw Distance

Contrast

Uniformity

Temperature

Maximum Humidity

Lamp Life

Altitude

MTBF Operating more than 12,000 hours (90% Confidence Level)

1.5m - 10m (Optical Performance)

1.5m - 12m (Mechanical Travel)

1000 : 1 Full White and Black (Minimum; Full Power Mode)

1800 : 1 Full White and Black (Typical; Full Power Mode)

75% Japan standard (Minimum; Full Power Mode)

85% Japan standard (Typical; Full Power Mode)

Opterating : 5~35oC

Storage : -20~60oC

Operating : 5~35oC, 80%RH (Max.), non-condensing

Storage : -20~60oC, 80%RH (Max.), non-condensing

1500 hours min, 50% survival rate (Full Power Mode)

2000 hours min, 50% survival rate (Eco Mode)

Operating : 0~2,500 ft for 5 oC~35oC

2,500~5,000 ft for 5 oC~30oC

5,000~10,000 ft for 5 oC~25oC

Storage : 40,000 ft (Max.)

1 Cha pter 1

Page 10

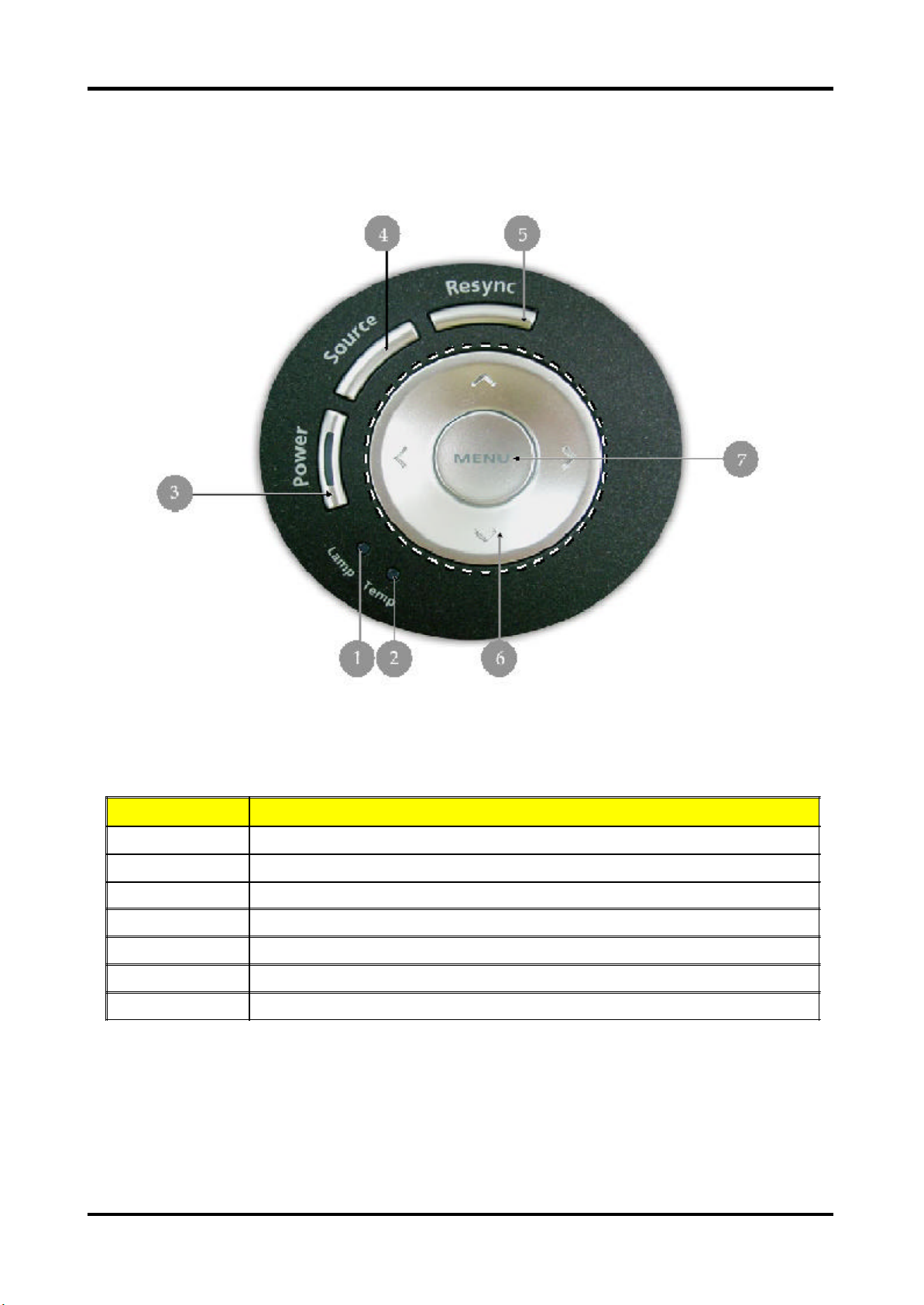

Tec hnical Specifica tion(PD1 00/PD100D/PD120/PD120D)

Item Description

Weight Approx. 4.85 lbs (2.2 Kg)

Projection Lens F#2.7~3.0, f=21.83mm~23.81mm, 1.10X Mechanical Zoom Lens

Brightness

Acoustic noise level

1700 ANSI Lumens (Typical; Full Power Mode)

1170 ANSI Lumens (Typical; Eco Mode)

38 dB(A) (Typical, Under 23 +/- 20C; Full Power Mode without

DVD/wireless)

30 dB(A) (Typical, Under 23 +/- 20C; Eco Mode without DVD/wireless)

Tec hnical Spe cification(XD1 170D)

Item Description

Weight Approx. 5.3 lbs (2.4 Kg)

Projection Lens F#2.35~2.47, f=21.83mm~23.81mm, 1.10X Mechanical Zoom Lens

Brightness

Acoustic noise level

1850 ANSI Lumens (Typical; Full Power Mode)

1450 ANSI Lumens (Typical; Eco Mode)

35 dB(A) (Typical, Under 23 +/- 20C; Full Power Mode without

DVD/wireless)

30 dB(A) (Typical, Under 23 +/- 20C; Eco Mode without DVD/wireless)

Tec hnical Spe cification(XD127 0D)

Item Description

Weight Approx. 4.85 lbs (2.2 Kg)

Projection Lens F#2.35~2.47, f=21.83mm~23.81mm, 1.10X Mechanical Zoom Lens

Brightness

Acoustic noise level

Cha pter 1 2

1850 ANSI Lumens (Typical; Full Power Mode)

1450 ANSI Lumens (Typical; Eco Mode)

35 dB(A) (Typical, Under 23 +/- 20C; Full Power Mode without

DVD/wireless)

30 dB(A) (Typical, Under 23 +/- 20C; Eco Mode without DVD/wireless)

Page 11

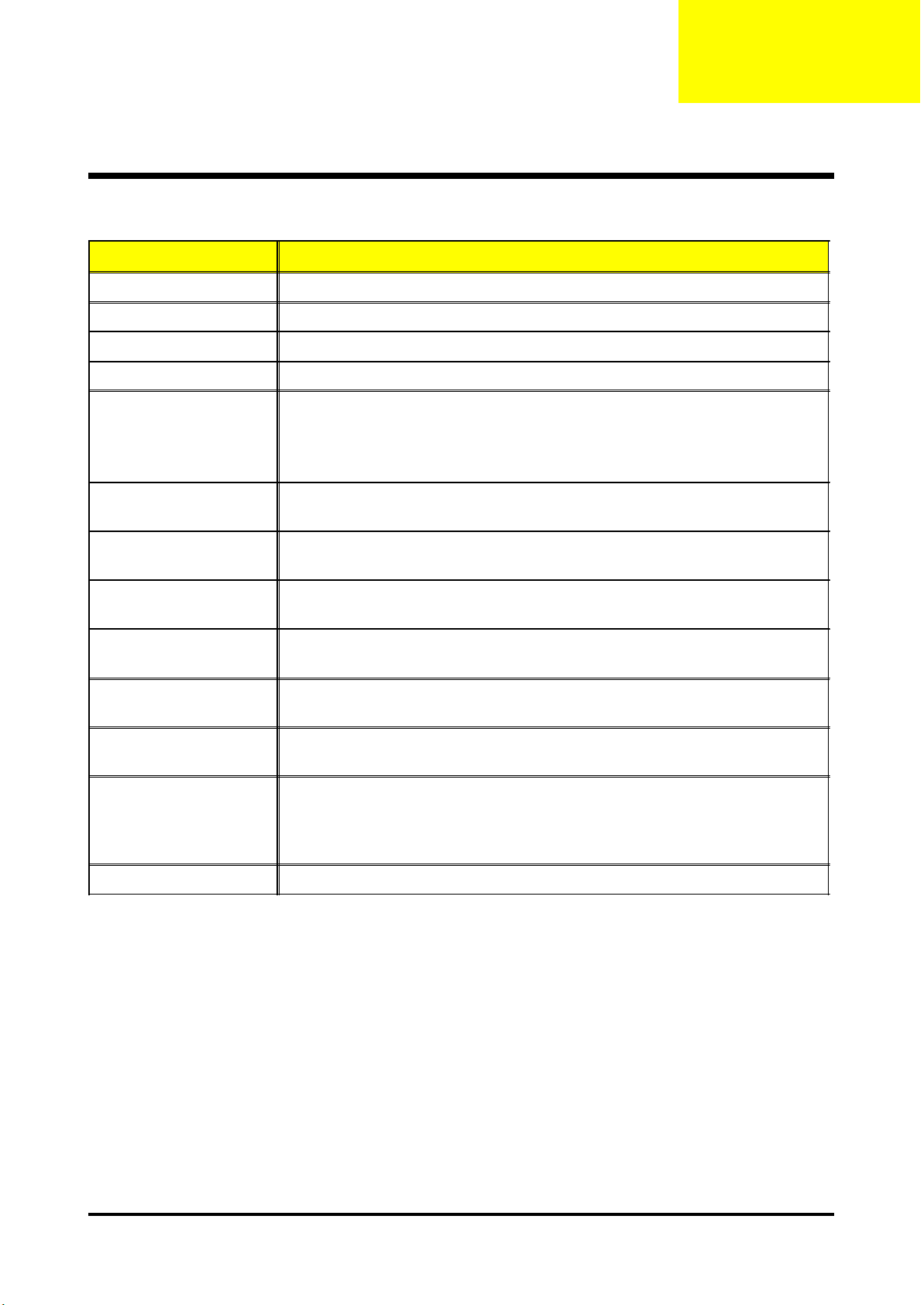

Pr oduct Overview

M ain Unit

Item Description

1 Focus Ring

2 Zoom Ring

3 Zoom Lens

4 Elevator Button

5 Elevator Foot

6 Remote Control Receiver

7 Connection Ports

8 Power Socket

9 Control Panel

3 Cha pter 1

Page 12

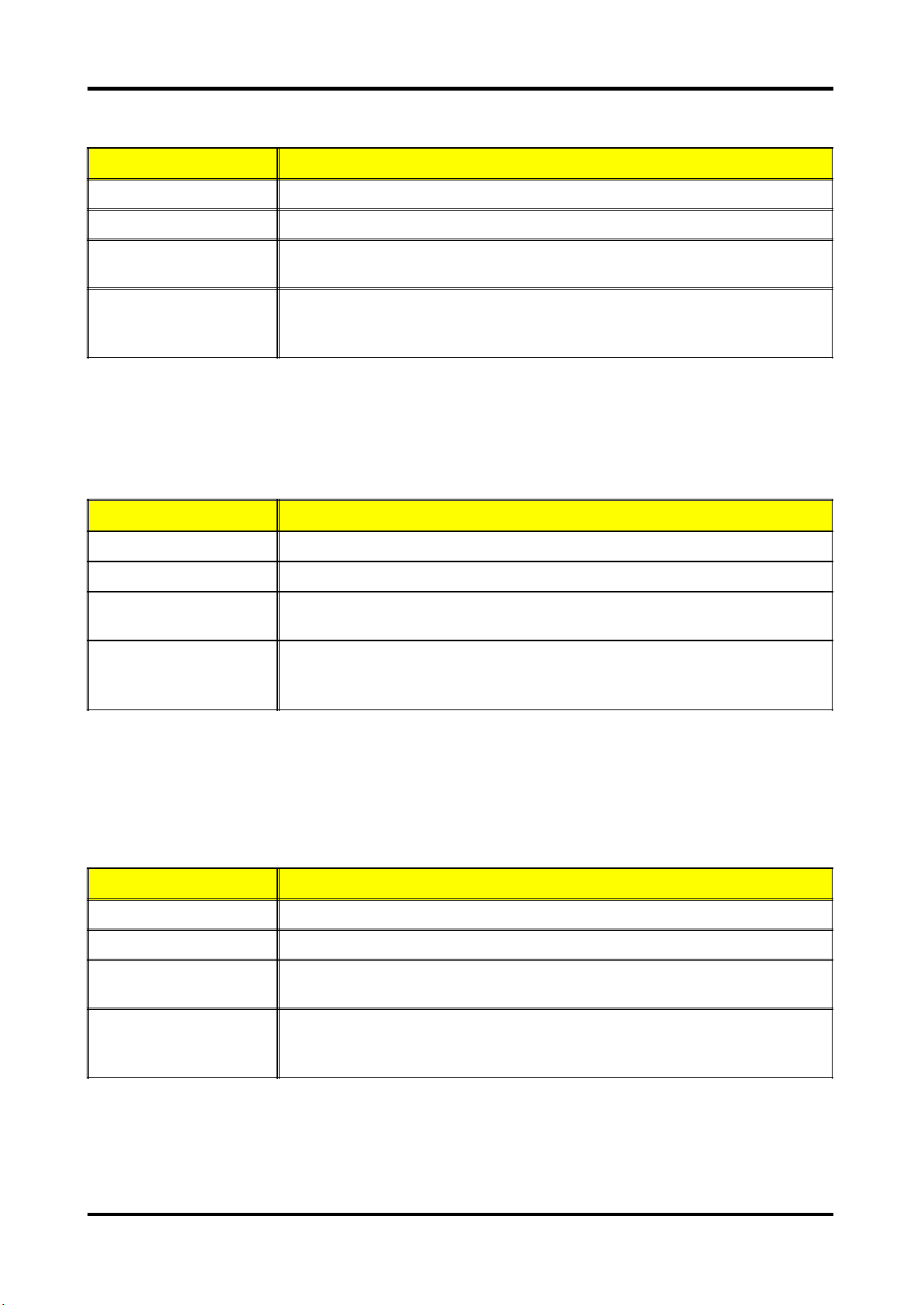

Control Panel

Item Description

1 Lamp Indicator LED

2 Temp Indicator LED

3 Power / Standby and Indicator LED (Power LED)

4 Source

5 Resync

6 Four Directional Select Keys

7 Menu

Cha pter 1 4

Page 13

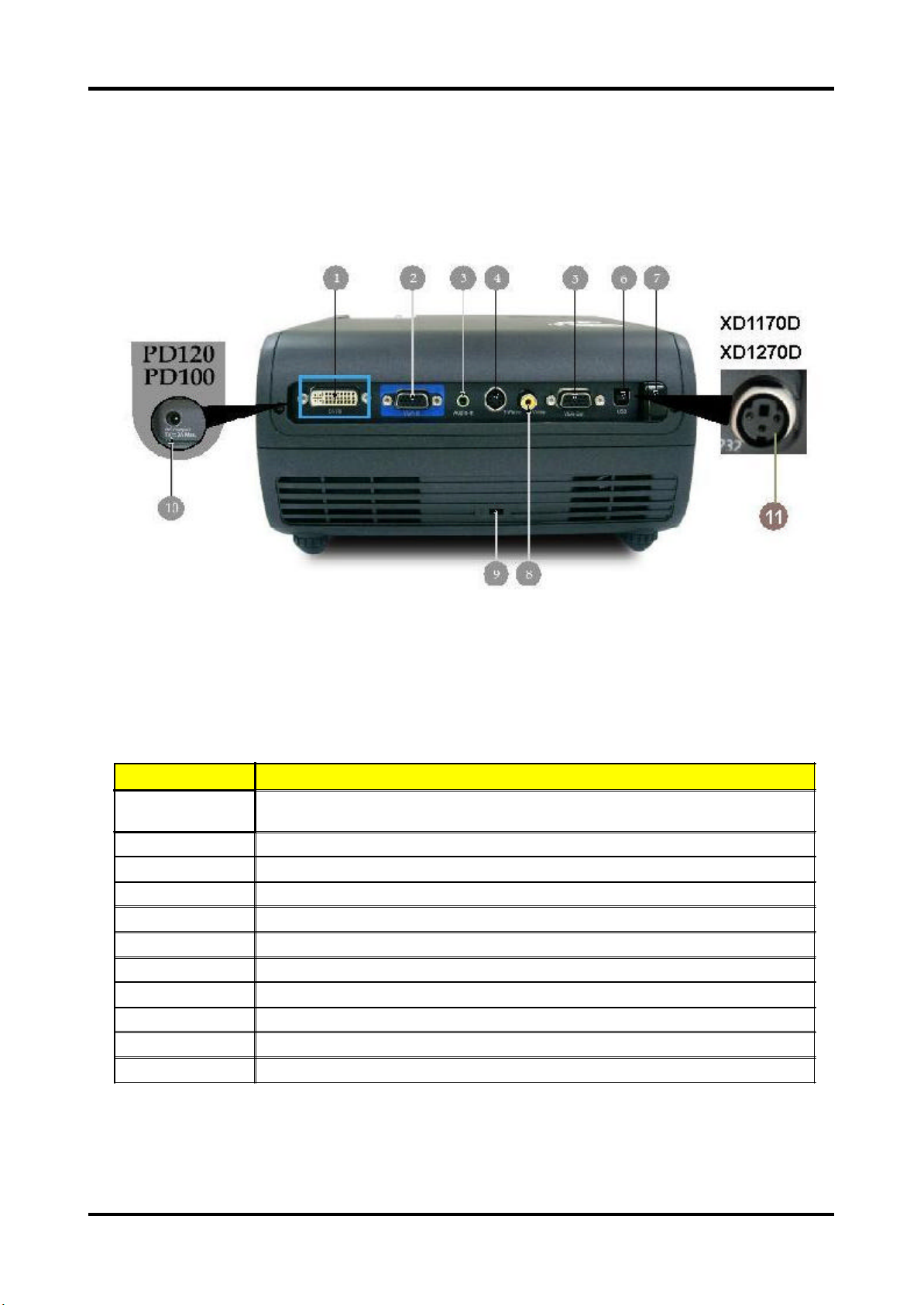

Connecti on Ports

Item Description

1

2 PC Analog Signal / HDTV / Component Video Input Connector

3 Audio Input Connector

4 S-Video Input Connector

5 Monitor Loop-through Output Connector

6 USB Connector

7 Remote Control IR Receiver (for PD100/PD100D/PD120/PD120D only)

8 Composite Video Input Connector

9 KensingtonTM Lock Port

10 5V DC Output Jack (dfor attached dongle device) (for PD100 only) (for PD120 only)

11 RS232 Connector (for XD1170D only) (for XD1270D only)

DVI Input Connector (for Digital signal with HDCP function)

(Optional)

5 Cha pter 1

Page 14

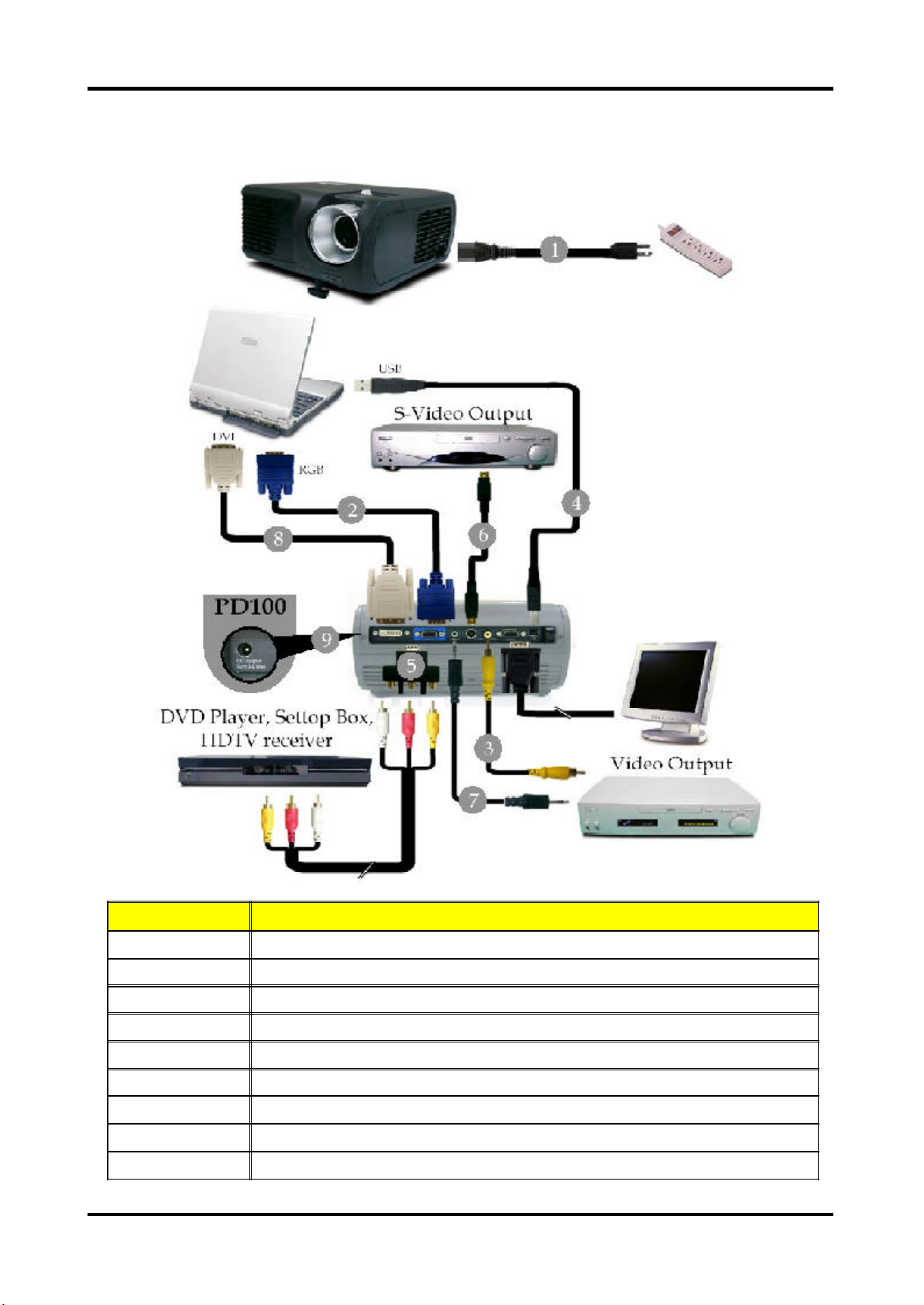

Connecting t he Projector

Item Description

1 Power Cord

2 VGA Cable

3 Composite Video Cable

4 USB Cable

5 VGA to Component / HDTV Adapter

6 S-Video Cable

7 Audio Cable Jack / Jack

8 DVI Cable (Optional Accessory)

9 5V DC Output Jack for attached Dongle Device (for PD100 only) (for PD120 only)

Cha pter 1 6

Page 15

Chapter 2

Firmware Upgrade

Equipment Needed

Software : (DDP 2000- USB)

- DLP Composer

- Firmware (PD100 /PD100D / PD120 / PD120D/XD1170D/XD1270D)

Hardware :

Item Photo Item Photo

Projector

(PD100 /

PD100D)

Power Cord

USB Cable PC or Laptop

Projector

(PD120 /

PD100D)

Projector

(XD1170D/XD1270D)

7 Cha pter 2

Page 16

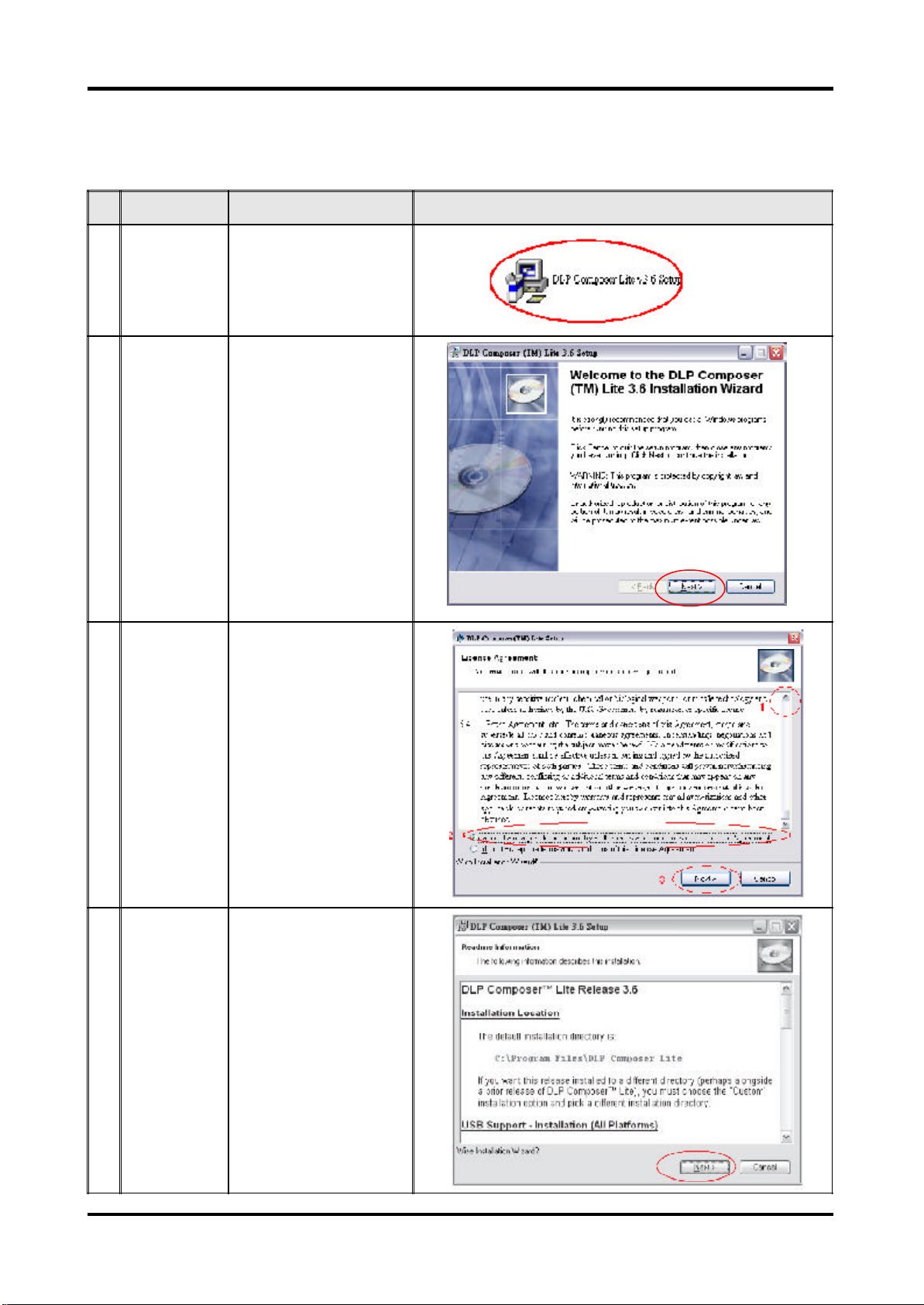

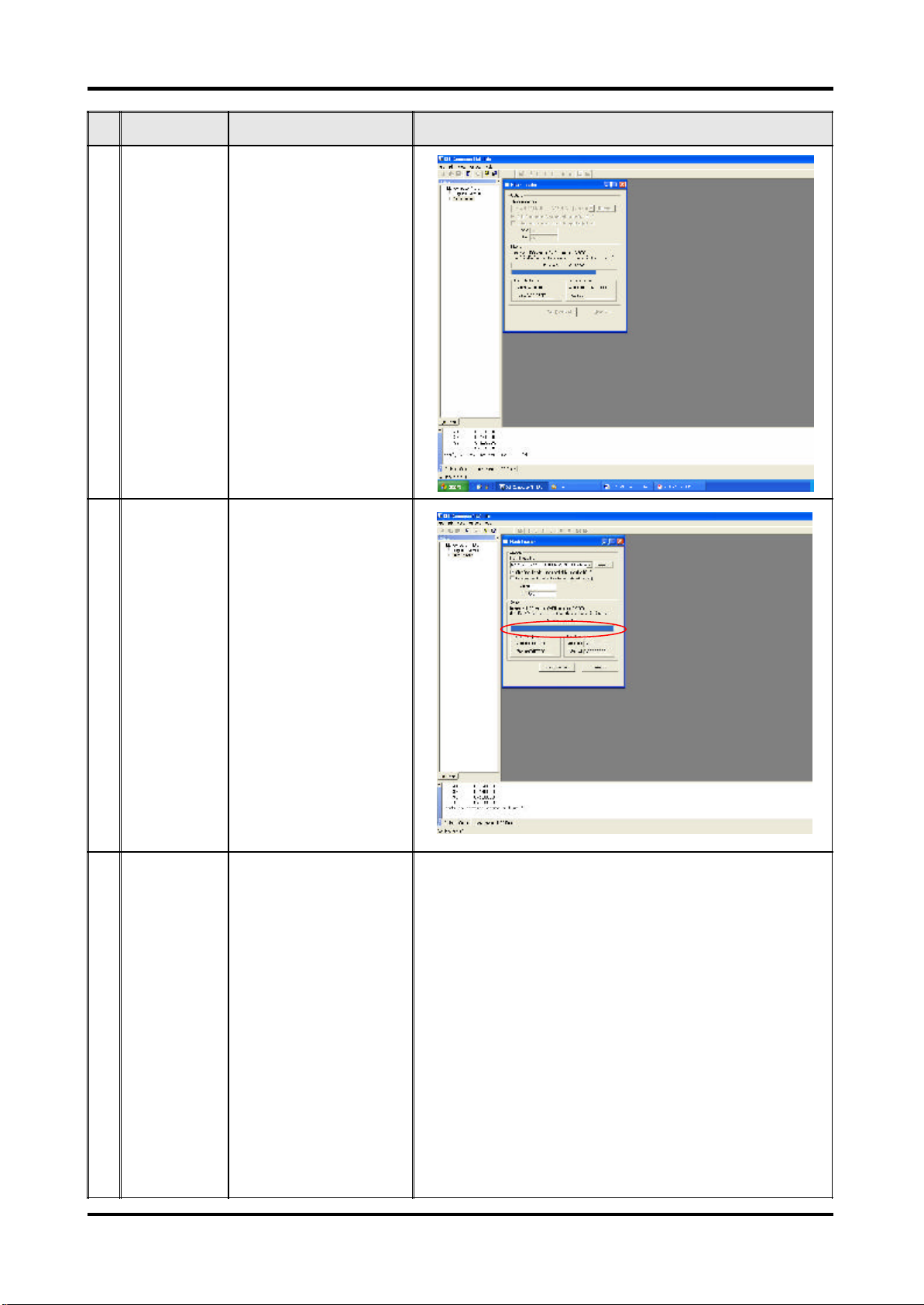

Ins tallation Procedure

DLP Composer Lite Setup Procedure

No Step Procedure Photo

1 Execute FW

program

2 Next Click "Next" button.

3 Next 1. Reading the "License

Choose "DLP Composer

Lite v3.6 Setup" program.

Agreement" rules.

2. Choose "I accept and

agree to be bound by all

the terms and conditions

of this License

Agreement" icon,

3. Click "Next" button.

4 Next Click ""Next"" button.

Cha pter2 8

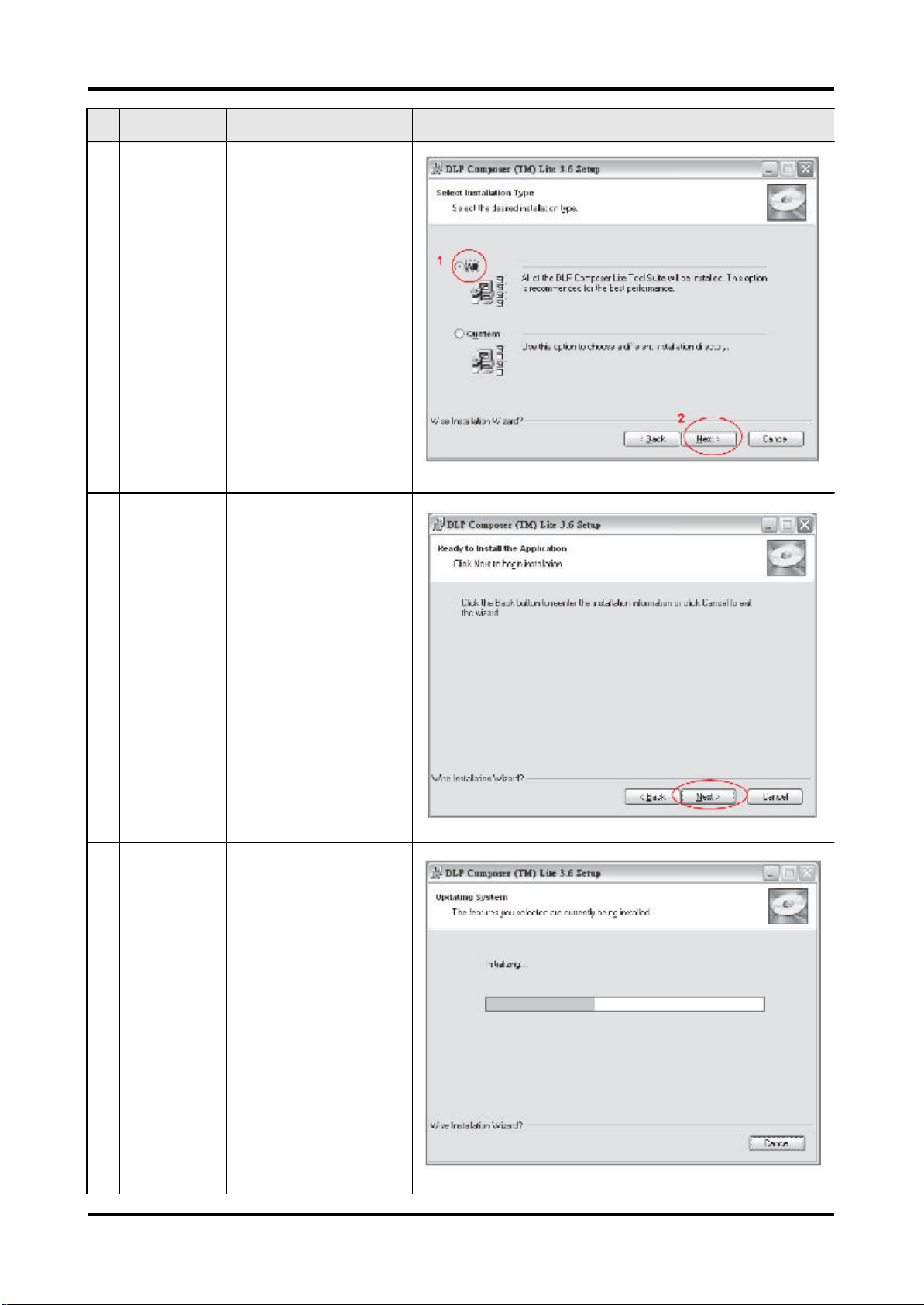

Page 17

No Step Procedure Photo

5 Next 1. Choose "All" icon

2. Click "Next" button.

6 Next Click "Next" button.

7 Processing The program is executing

"Initializing" status.

9 Cha pter 2

Page 18

USB Driver Upgrade Procedure

No Step Procedure Photo

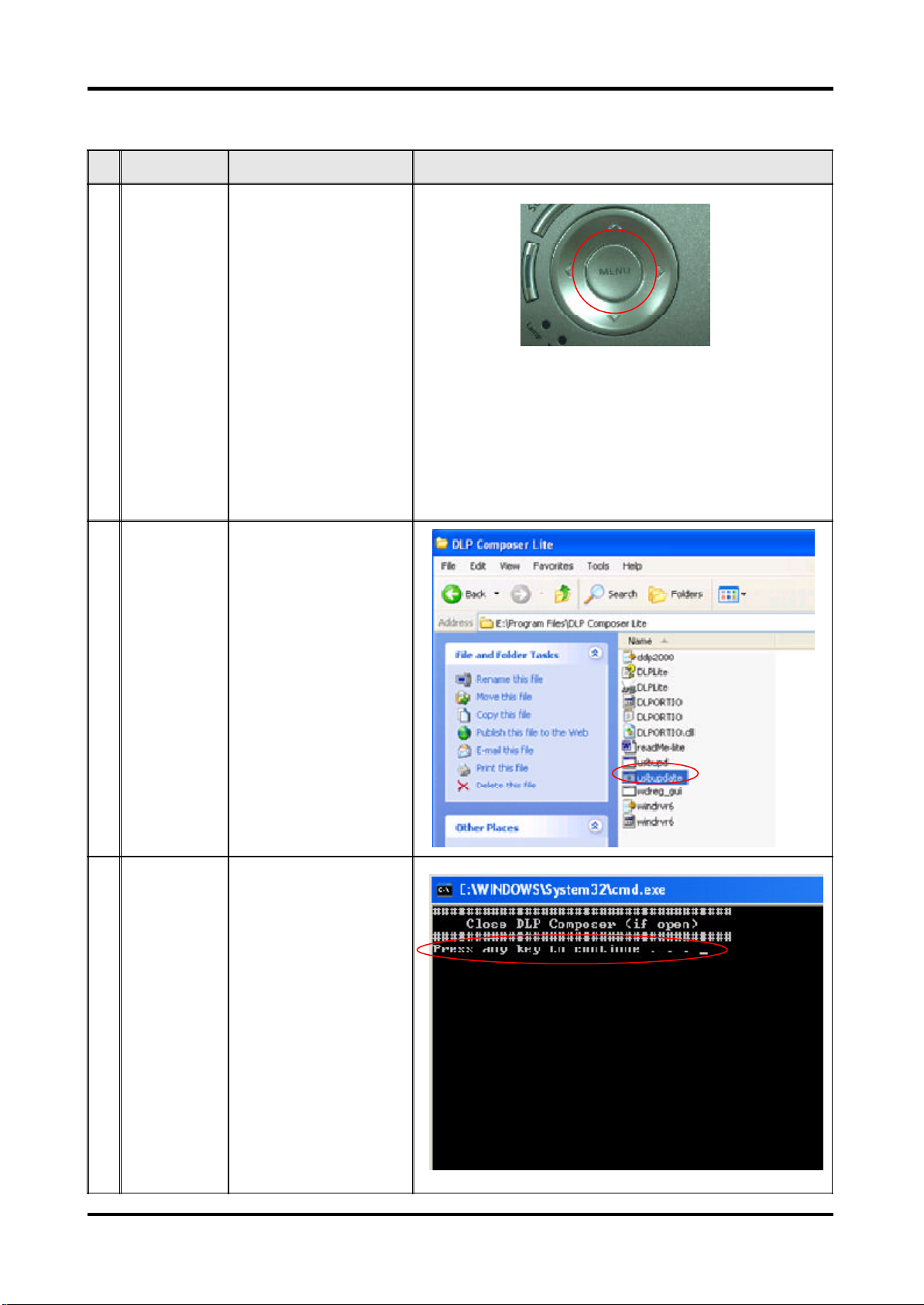

1 Set-up 1. Plug in USB Cable into

the Projector.

2. Hold on "Menu" button

and then plug in Power

Cord.

3. Wait for about 5

seconds.

(Note: The system fan will

not function. The light will

not function as well.)

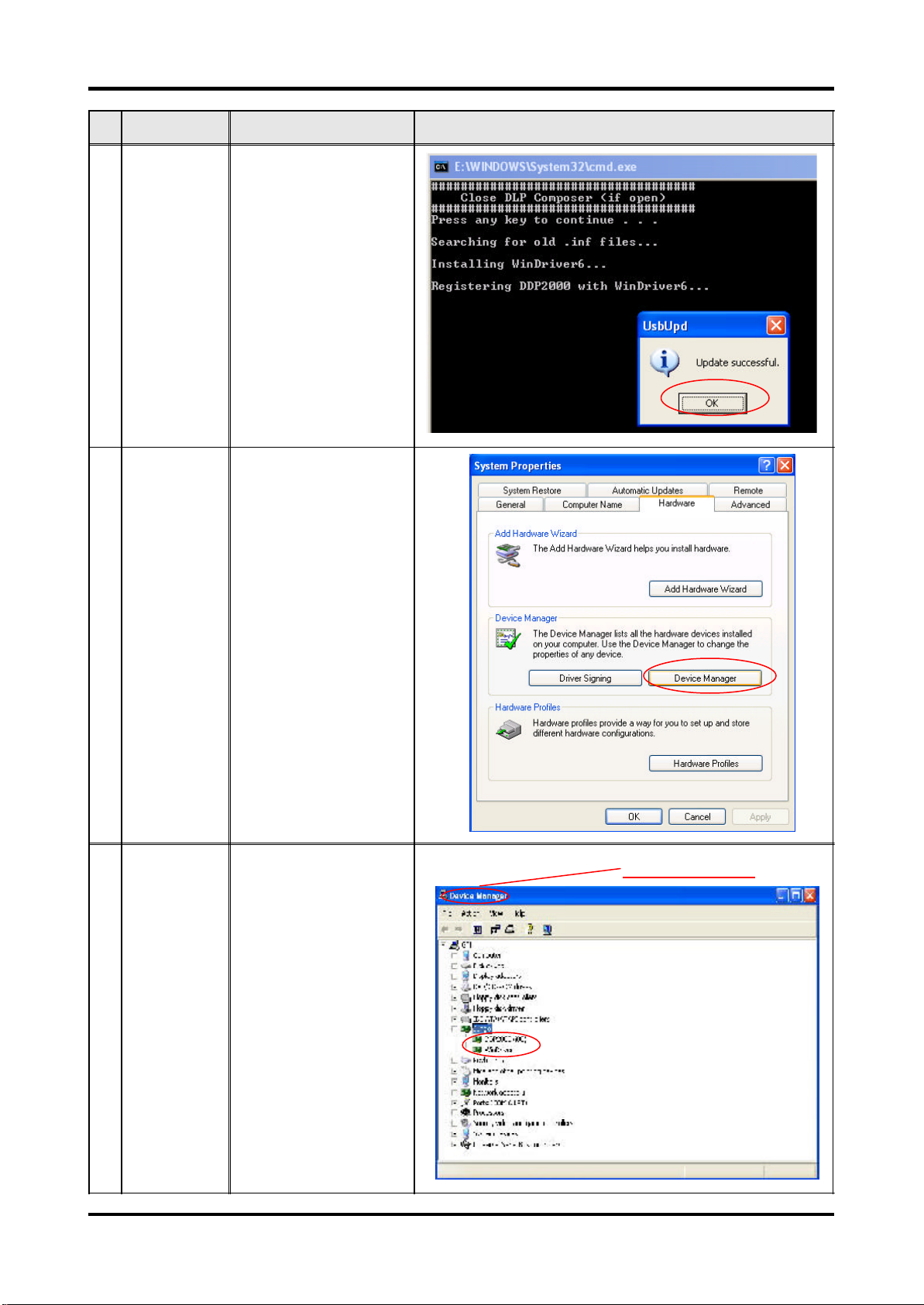

2 Execute

Program

3 Type any key to

continue

Execute the C:\Program

files\DLP

Composer\usbupdata.cmd.

(Note: The "DLP

Composer" program

must be closed first.)

Press any key to continue.

Then, wait for about 1

minute.

Cha pter2 10

Page 19

No Step Procedure Photo

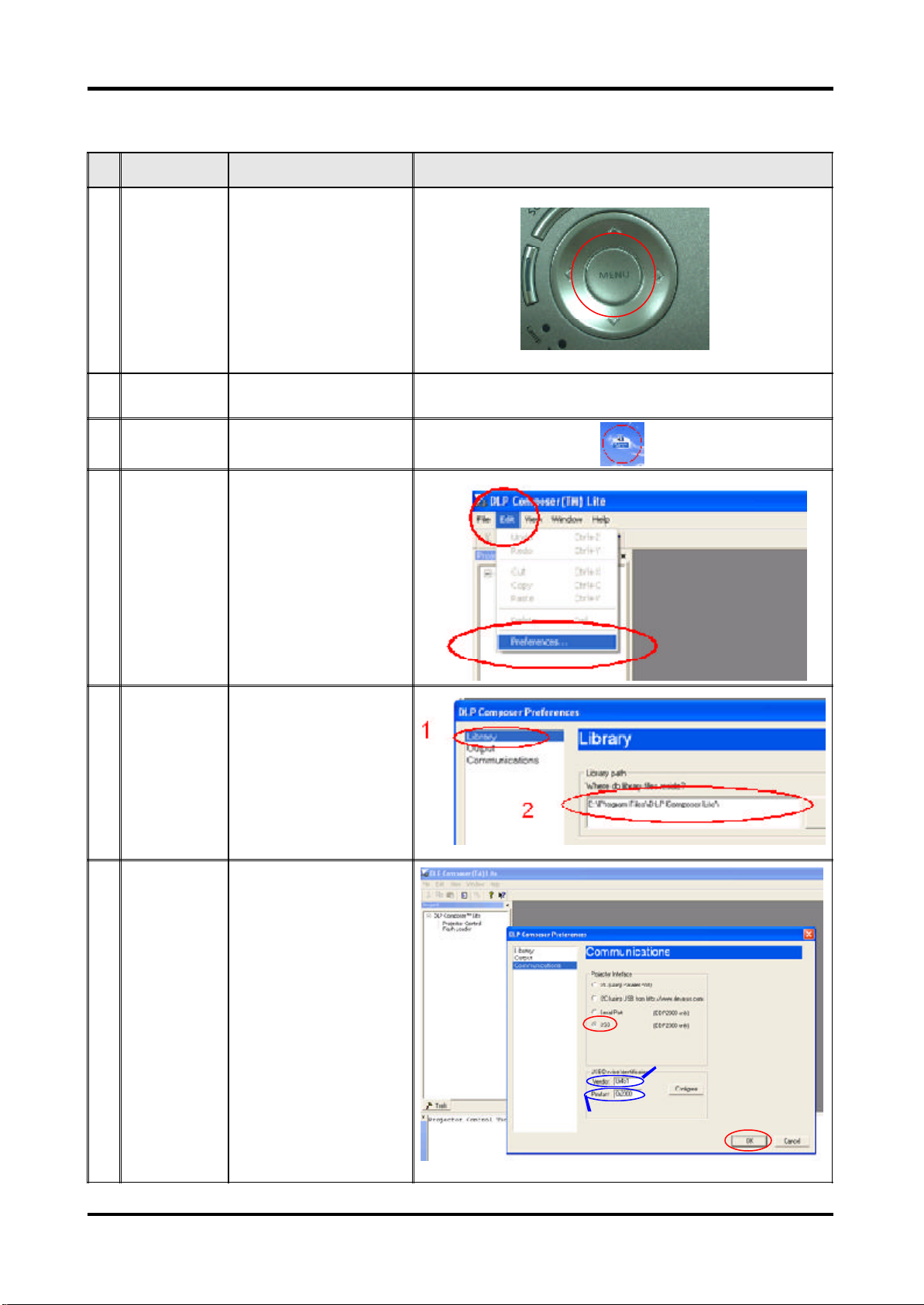

4 Update

Successfully

5 Device

Manager

Click "OK". The USB driver

is updated successfully.

1. Right click "My computer"

on the desktop.

2. Select "Properties" on

the popup menu to launch

the "System Properties"

window.

3. Choose "Hardware" and

then click "Device

Manager".

6 Ensure

"DDP2000" &

"WinDriver" are

properly

installed

Click "Jungo" to ensure

"DDP2000" and

"Windriver" are properly

installed. If not, repeart

Step 1~5.

Device Manager

11 Cha pter 2

Page 20

Fir mware Upgrade Pr ocedure

No Step Procedure Photo

1 Set-up 1. Plug in USB Cable into

the Projector.

2. Hold on "Menu" button

and then plug in Power

Cord.

3. Wait for about 5

seconds.

(Note: The system fan will

not function. The light will

not function as well.)

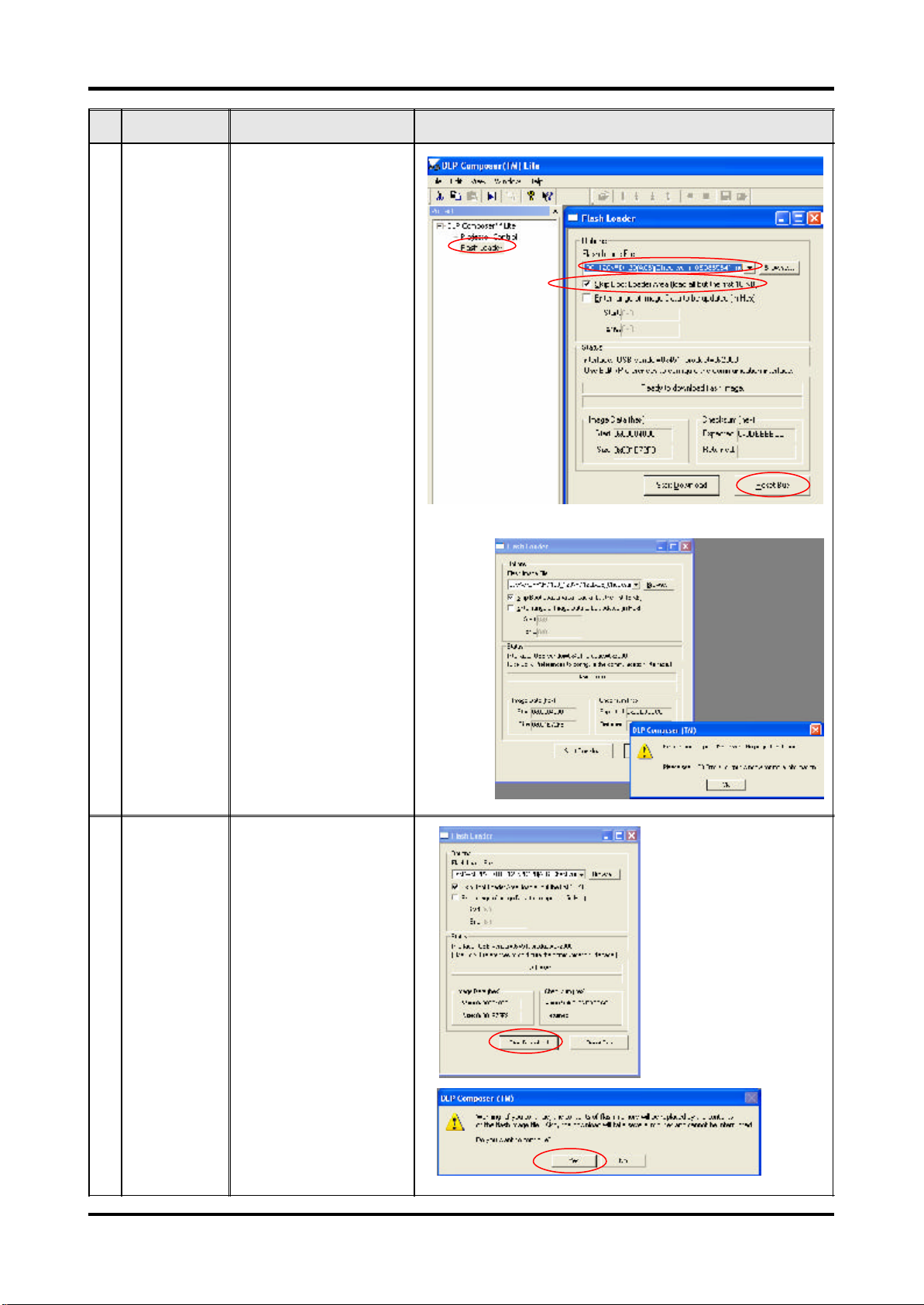

2 Set-up Link PC COM1 and

projector

3 Execute the "DLP

Compose

4 Click "Edit" and

"Preferences".

5 1. Click "Library".

2. The library path located

in the default installation

directory is:

C:\Program Files\DLP

Composer.

If not, press "Browse" to

select the right path.

6 1. Select

"Edit\Preferences\

Communications" and

choose "USB".

2. Click "OK".

TM"

file.

.

1

2

1

USB

Vendor: 0x451

Product: 0x2000

2

OK

Cha pter2 12

Page 21

No Step Procedure Photo

7 1. Choose "Flash Loader"

2. Click "Browse" to search

the firmware file. (PD100

/ PD120)

3. Select the item "Skip

Boot Loader Area (load

all but the first 16KB)."

4. Click "Reset Bus" to

erase the flash memory.

(Note: If the error message

"cannot open USB driver No projectors found"

appears, please unplug the

USB Cable and replug,

then re-do 4. Click "Reset

Bus" to erase the flash

memory.)

1

2

3

Note:

4

8 1. If the firmware is ready,

click "Start Download" to

process the firmware

upgrade.

2. Click "Yes" to erase the

flash memory.

1

2

13 Cha pter 2

Page 22

No Step Procedure Photo

9 Proceeding Proceeding Picture

10 1. When Firmware Upgrade

Process is finished, the

LED power

2. Unplug USB Cable and

Power Cord. Re-plug in

Power Cable after 3 mins.

11 Check

Firmware

Restart the unit and enter

the Service Mode to check

the Firmware Version.

(For entering Service

Mode, please refer to

Chapter 4 Function Test

and Alignment Procedure.)

Cha pter2 14

Page 23

EDI D Upgrade

Equipment Needed

Software:

- EDI D Key-in Program

- EDI D Program (Generic V0.51)

- EDI D Table (*.ini)

Hardware:

- V3 Fixture for EDI D Key-in

(Fixture: JP3 must be closed)

Item Photo Item Photo

RS-232 Cable

(F - M)

DVI Cable

(for "D" Model)

VGA Cable Power Cord

PC

Projector

(PD100 /

PD100D)

Power Adapter

for Fixture

Generic Fixture

One additional

monitor (for

checking the

program

execution)

Projector

(PD120 /

PD120D)

Projector

(XD1170D/

XD1270D)

15 Cha pter 2

Page 24

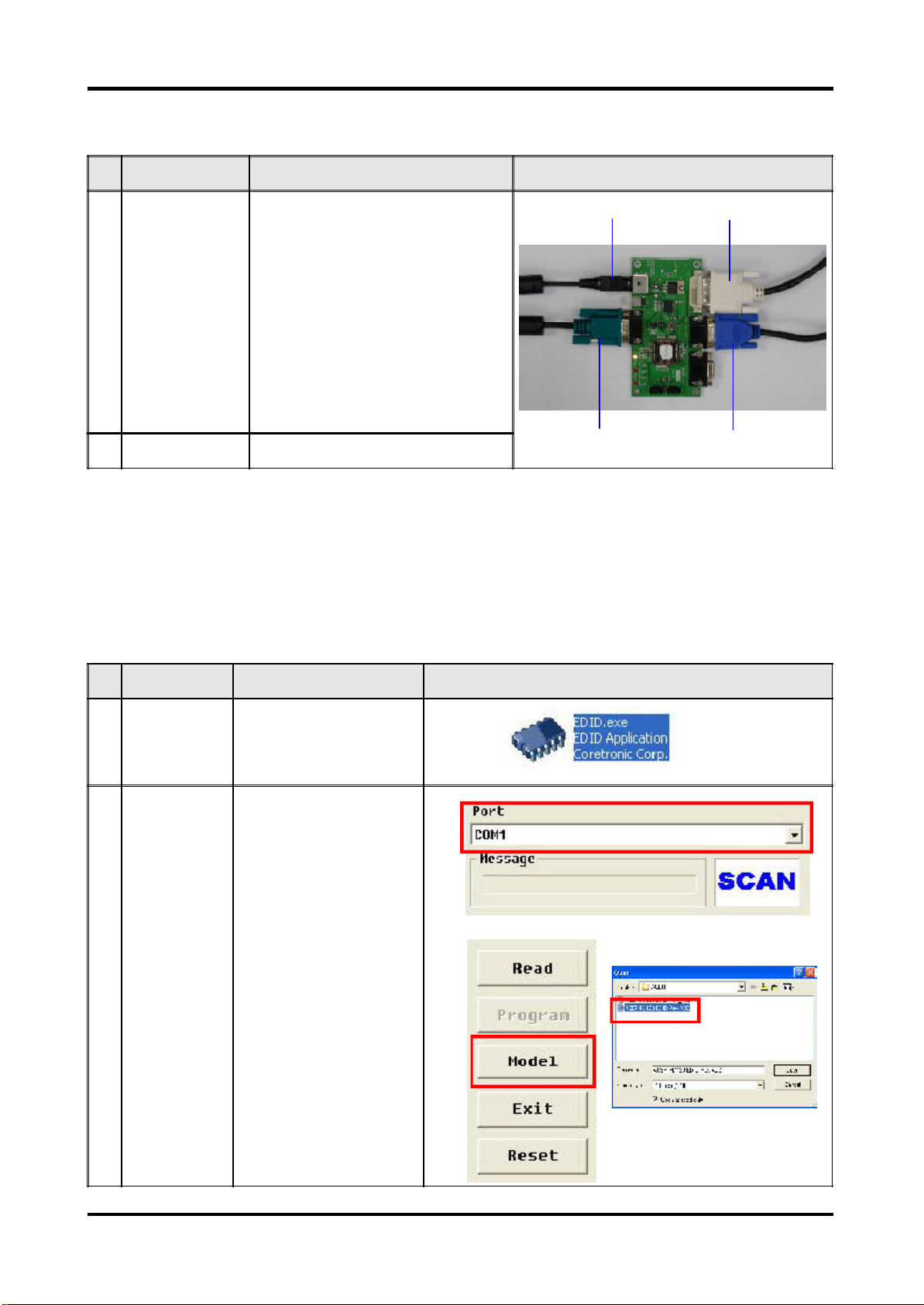

Setup Procedure

No Step Procedure Photo

1 Connect All Ports 1. Power Adapter to Fixture JP1

2. Fixture P1 to PC COM1 Port

3. Fixture P2 to Projector Analog Port

4. Fixture P3 to Projector Digital Port

2. Power On Fixture Power on Fixture

ED ID Key-In Procedure

Adapter

JP1

P1

RS-232 Cable

To Digital Port

P3

P2

To Analog Port

No Step Procedure Photo

1 Execute EDID

Program.

2 Choose Model 1. In the Port Selection Bar,

Click on "EDID" to execute

EDID Program.

please choose the Port

that you use.

Ex: If you use "COM 1",

choose COM 1 in the

Port selection.

2. Click on "Model".

3. Choose the EDID that

responses to the model

that you choose.

1

32

Cha pter2 16

Page 25

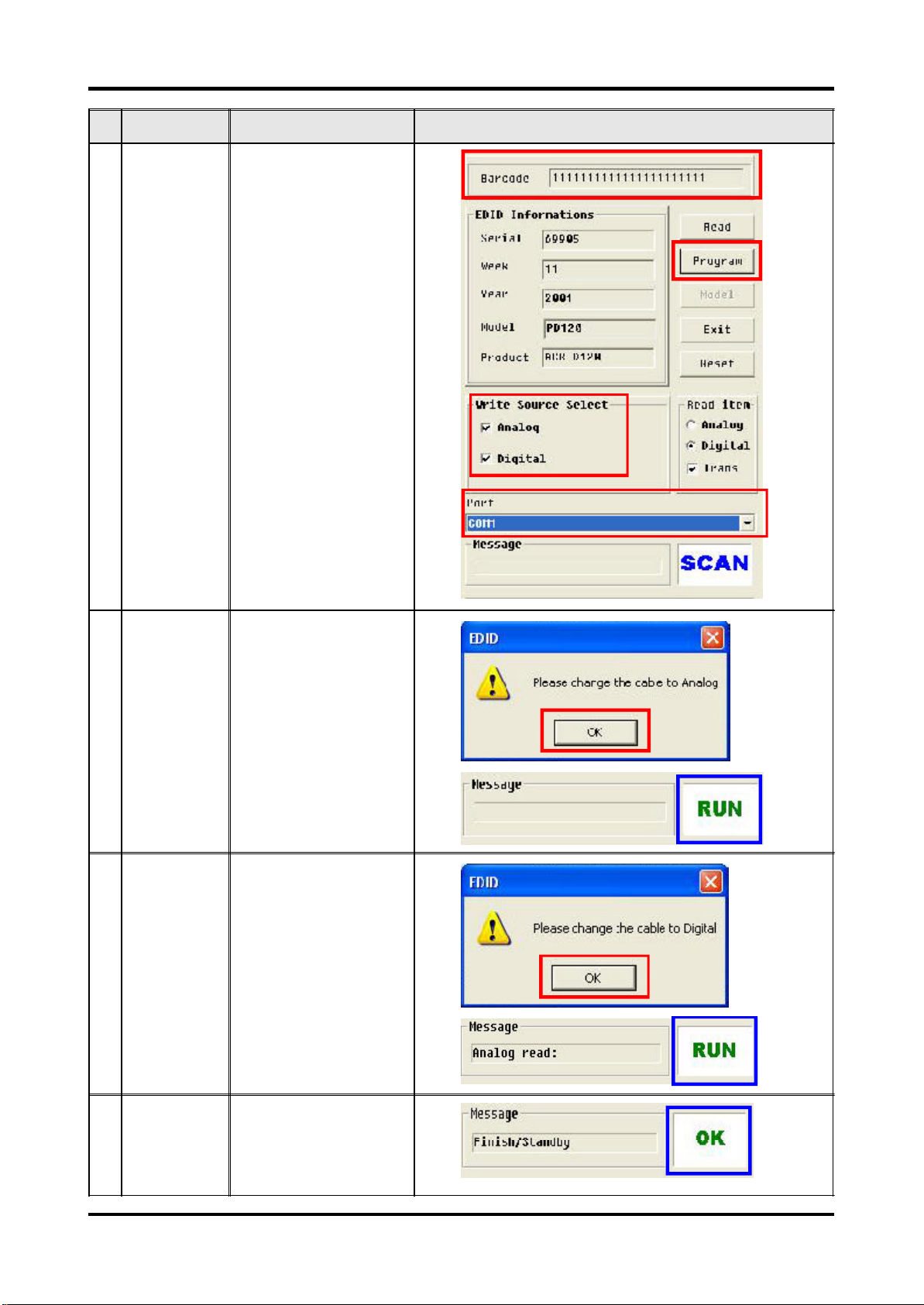

No Step Procedure Photo

3 Key in Serial

Number

1. Key in the Serial Number

into the Barcode blank

space.

2. In "White Source Select",

make a check in "VGA"

and "DVI".

(Only for "D" Model.)

3. Check the COM Port is

"COM 1".

4. Click "Program".

1

4

2

3

4 Change Cable

to Analog

5 Change Cable

to Digital

"Please change the Cable

to Analog" message is

shown on the screen, then

click "OK".

Note: "RUN" message will

appear on the screen.

"Please change the Cable

to Digital" message is

shown on the screen, then

click "OK".

Note: "RUN" message will

appear on the screen.

6 Finished When the EDID program is

completed, the message,

"OK", will appear on the

screen.

17 Cha pter 2

Page 26

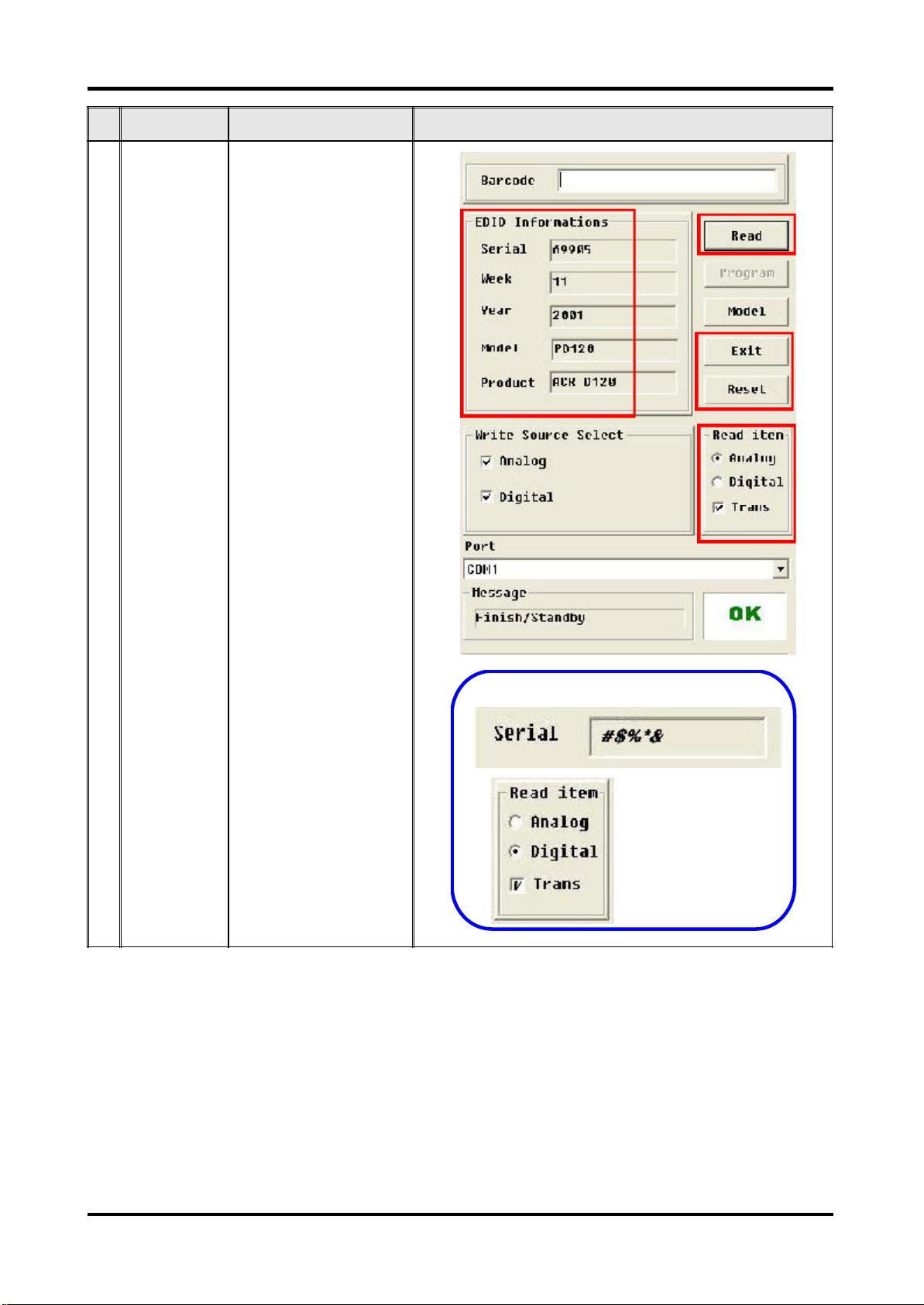

No Step Procedure Photo

7 Check the

whole process

1. In the "Read Item"

Selections, choose the

Port that you use.

Ex: If you use the Analog

Port, choose "Analog" in

the "Read Item".

Note: If the code in the

Serial Blank is scrambled,

please make a check in

"Trans".

2. Click on "Read" to read

EDID information.

3. The "EDID Informations"

will show the result.

4. Click "Reset" to do the

next unit or "Exit" to close

the EDID program.

3

2

4

1

Note

Cha pter2 18

Page 27

Chapter 3

Mechanical Disassembly & Reassembly

This section provides disassembly & Reassembly procedures for PD100 Micro Portable SVGA

DMD Projector. Before you begin any of these procedures, be sure to turn off the power,

computer system, and other attached devices; then disconnect the power cable from the

electrical outlet. Moreover, when you disassemble the projector, be sure to put the screws

in a safe place and separate them according to their category.

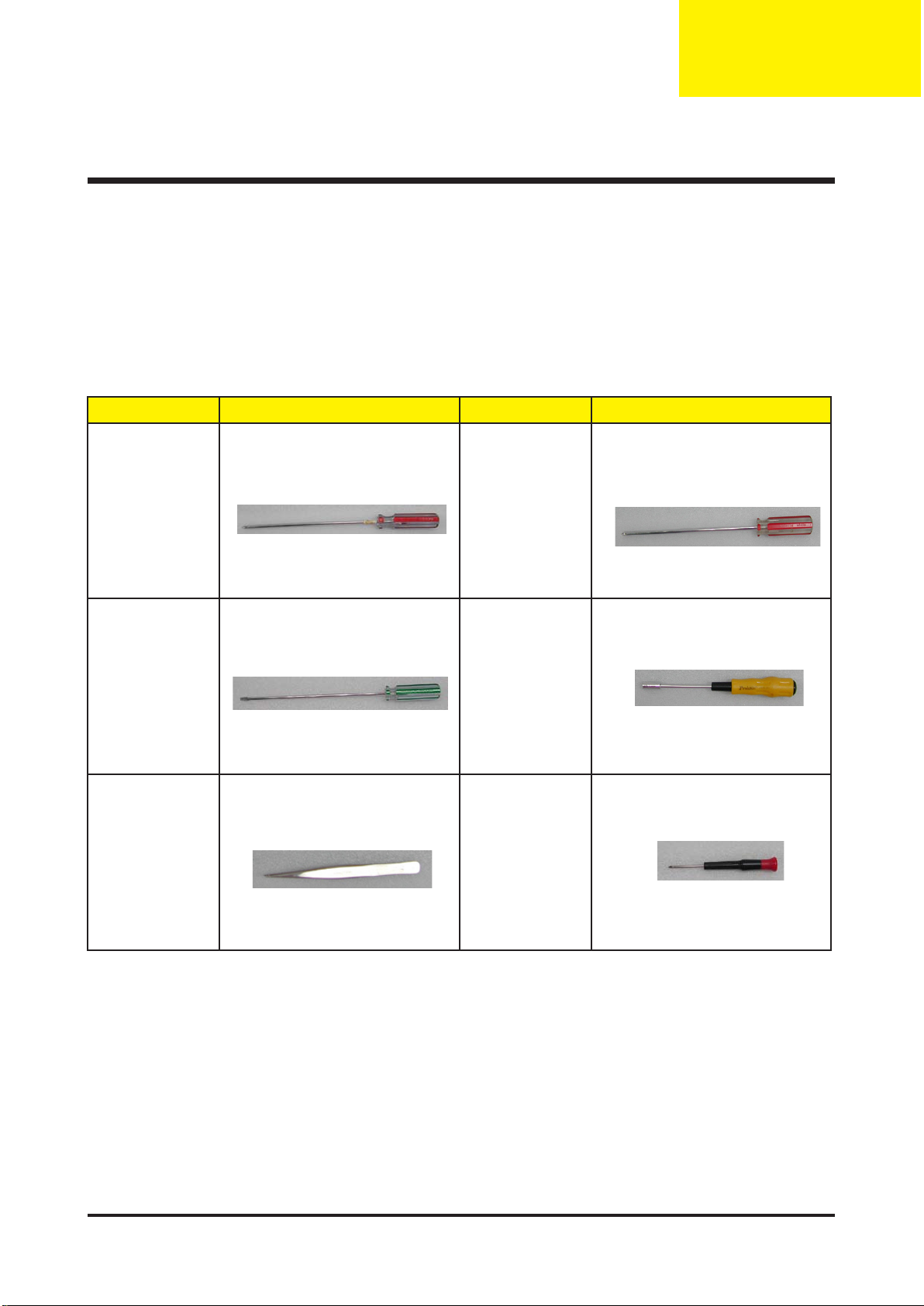

Equipment Needed

Item Photo Item Photo

Philips (+) : 107 Philips (+) : 102

Screw Bit

Tweezers Screw Bit

Hex Screw :

5mm

General Information

Before You Begin

Before proceeding with the disassembly procedure, make sure that you do the following

procedures:

1. Turn off the power of the system and all the peripherals.

2. Unplug the AC adapter and all power and signal cables from the system.

3. Anti-static wrist strap.

19 Chapter 3

Page 28

Chapter 3 20

Mechanical Disassembly Procedure

1. Remove Lamp Module

No Procedure Photo

1 Unscrew 2 screws to remove

the Lamp Cover.

2 Unscrew 2 screws to remove

the Lamp Module.

Page 29

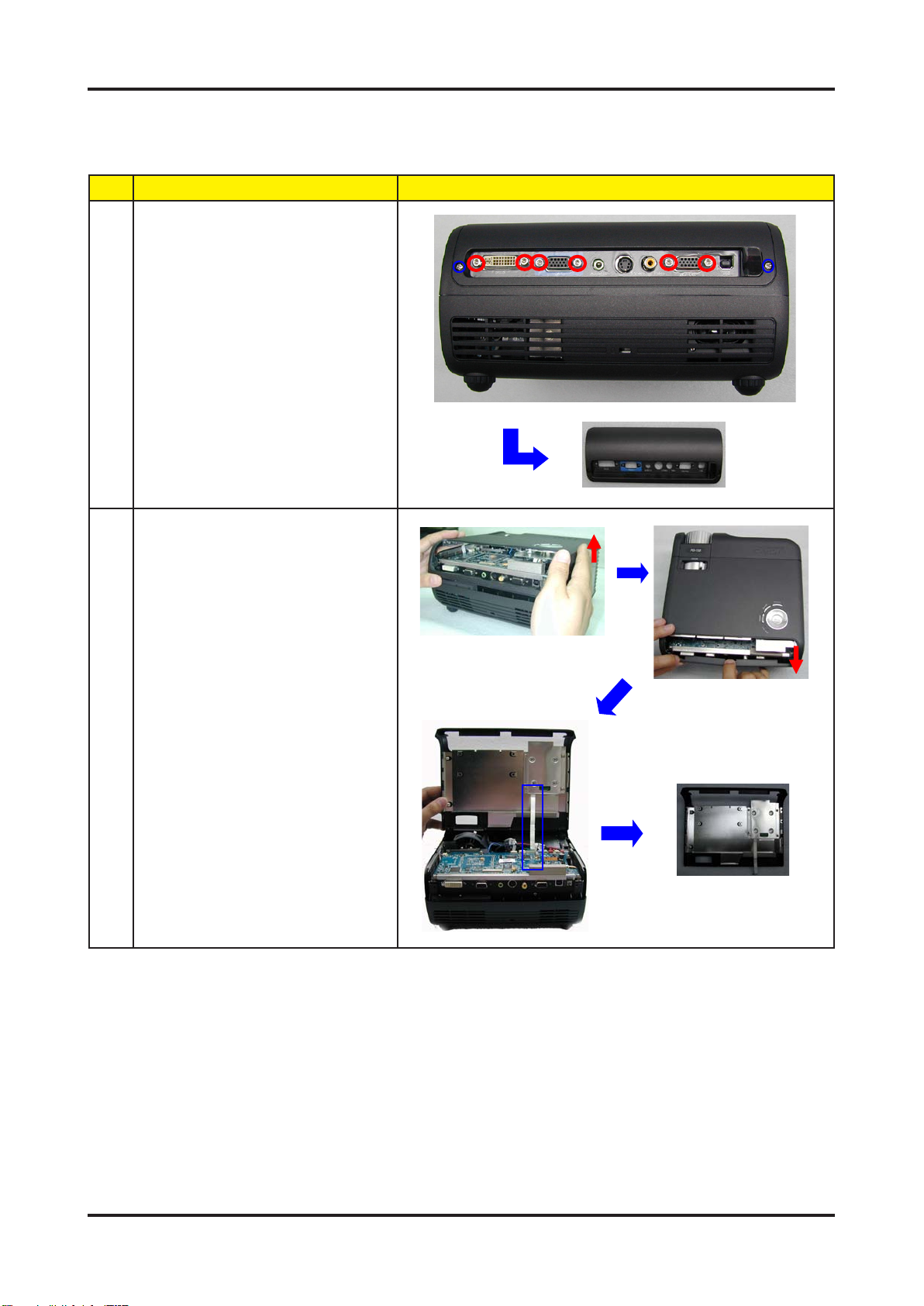

2. Remove IO Cover / Top Cover

No Procedure Photo

1 Unscrew 2 screws & 6 hex

screws to remove the IO

Cover.

2 1. Lift up the Top Cover rst

and then pull the Bottom

Cover for easily separting the

Top Cover.

2. Remove 1 FPC Cable to

remove the Top Cover.

21 Chapter 3

Page 30

Chapter 3 22

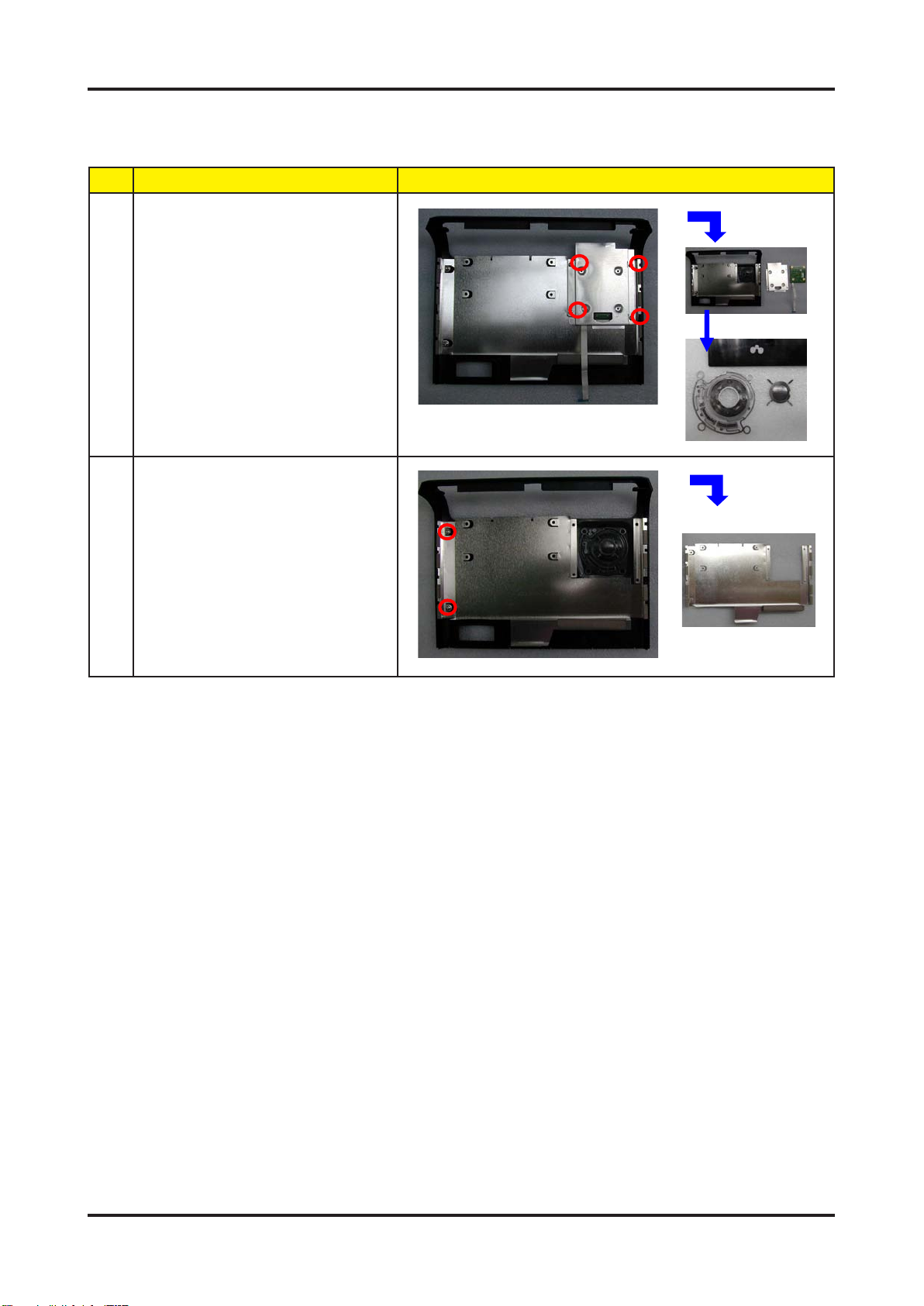

3. Remove Keypad Board

No Procedure Photo

1 1. Unscrew 4 screws to

remove the Keypad Board.

2. Separate the Keypad

Module.

2 Unscrew 2 screws to remove

the Top Cover Shielding.

Page 31

4. Remove Front Cover / IR Sensor Board / Elevator

Push Button

No Procedure Photo

1 1. Unscrew 1 screw to remove

the IR Receiver.

2. Unscrew 2 screws to

remove the Front Cover.

2 Unplug 1 connector (red color)

to remove the Front Cover

Module.

3 Remove the Front IR Cover

directly, and loosen 2 tenons

to remove the IR Receiver

Board.

4 Loosen 2 tenons to remove

the Elevator Push Button

directly.

23 Chapter 3

Page 32

Chapter 3 24

5. Remove Bottom Cover Module

No Procedure Photo

1 Remove Bottom Cover

Sponge.

2 Remove Side Covers. (Right

Cover & Left Cover)

Note 1:

When disassembing the Side

Cover, push the side cover

outside forwards and then pull

it up directly.

Note 2:

When reassembing the Side

Cover, please locate & align

the tenons as the picture

shows.

3 Unplug 2 tenons in the

shieldings to separate the

Bottom Cover Module with the

unit.

Page 33

6. Remove Main Board

No Procedure Photo

1 Unplug 8 connectors rst and

then unscrew 4 screws.

Note:

When Reassembling the

Main Board with the Top

Cover, please be aware of the

wire arrangement. The wire

arrangement should go as the

picture shows (not exceeding

1/2 of the red blank space) to

best allocate the Top Cover

Sponge.

2 1. Lift up the front part of Main

Board rst; then, take off the

Main Board.

2. Unplug 1 connector to

remove the Main Board.

25 Chapter 3

Page 34

Chapter 3 26

7. Remove EMI Shielding / Speaker

No Procedure Photo

1 Unscrew 4 screws to remove

the EMI Shielding Cover of

units.

2 Unscrew 2 screws to remove

the Speaker.

Note:

The Speaker isn’t designed

with error-proof. Please be

aware of wire-arrangement as

the picture shows.

Page 35

8. Remove Axial Fan Module

No Procedure Photo

1 Unscrew 3 screws to remove

Axial Fan Module.

2 Unscrew 4 screws to remove

the System Fan.

Note:

The System Fan isn’t

designed with error-proof.

Please be aware of the wirearrangement.

27 Chapter 3

Page 36

Chapter 3 28

9. Remove Lamp Driver

No Procedure Photo

1 Unscrew 4 screws.

2 Unplug 2 connectors to

remove the Lamp Driver

Module.

Note:

When assembling the LVPS,

please be aware of the

LVPS connector connection.

(the shorter wire should be

connected to the LVPS,

and the longer wire should

be connected to the Lamp

Driver.)

3 Unscrew 4 screws to separate

the Lamp Driver Housing.

Page 37

10. Remove LVPS / Interlock Swtich / Thermal Switch

No Procedure Photo

1 1. Unscrew 4 screws

2. Unscrew 1 screw in the

grounding wire.

3. Unplug 1 connector in the

Interlock Swtich to remove the

LVPS.

2 1. Unscrew 2 screws to

remove the Interlock Switch.

2. Unscrew 1 screw to remove

the Assy Thermal Switch

Board.

2

1

3

2

1

29 Chapter 3

Page 38

Chapter 3 30

11. Remove Engine Module

No Procedure Photo

1 Unscrew 3 screws to remove

the Engine Module.

2 1. Unscrew 1 screw to remove

the Light Cut.

2. Unscrew 1 screw to remove

the Thermal Sensor.

1

2

3 Unscrew 1 screw to remove

Photo Sensor Board.

4 1. Unscrew 4 screws and tear

off 1 EMI tape to remove the

Heatsink.

2. Unscrew 4 big hex screws

to remove the DMD Board.

3. Separate the DMD Board.

Page 39

No Procedure Photo

When reassembling the DMD

Module, please be aware of

the following Notes.

Note1:

The DMD Heasink Spring

Plate should be placed as the

picture shows.

Note 2:

The DMD Insulator Mylar &

DMD Heatsink Backer Plate

should be placed as the

picture shows.

Note 3:

The DMD Chip should be

reassembled as the picture

shows.

5 Unscrew 1 screw to remove

the Color Wheel.

6 1. Unscrew 2 screws to

remove the Zoom Ring &

Stopper.

2. Unscrew 3 screws to

remove the Focus Ring.

Zoom Ring

Zoom Ring Stopper

31 Chapter 3

Page 40

Chapter 3 32

12. Remove Elevator / Blower Fan

No Procedure Photo

1 Unscrew 4 screws to remove

the Elevator.

2 Unscrew 3 screws to remove

the Blower Fan.

Page 41

Mechanical Reassembly Procedure

1. Assemble Elevator / Blower Fan

No Procedure Photo

1 Screw 4 screws to assemble

the Elevator.

2 Screw 3 screws to assemble

the Blower Fan.

33 Chapter 3

Page 42

Chapter 3 34

2. Assemble Engine Module

No Procedure Photo

1 1. Screw 2 screws to

assemble the Zoom Ring &

Stopper.

2. Screw 3 screws to

assemble the Focus Ring.

2 Screw 1 screw to assemble

the Color Wheel.

Zoom Ring

Zoom Ring Stopper

3 When reassembling the DMD

Module, please be aware of

the following Notes.

Note1:

The DMD Heasink Spring

Plate should be placed as the

picture shows.

Note 2:

The DMD Insulator Mylar &

DMD Heatsink Backer Plate

should be placed as the

picture shows.

Note 3:

The DMD Chip should be

reassembled as the picture

shows.

Page 43

No Procedure Photo

1. Assemble the DMD Board

Components.

2. Screw 4 big hex screws to

assemble the DMD Board.

3. Screw 4 screws and put on

1 EMI tape to assemble the

Heatsink.

4 Screw 1 screw to assemble

the Photo Sensor Board.

5 1. Screw 1 screw to assemble

the Light Cut.

2. Screw 1 screw to assemble

the Thermal Sensor.

6 Assemble 3 screws to

assemble the Engine Module.

1

2

35 Chapter 3

Page 44

Chapter 3 36

3. Assemble Interlock Swtich / Thermal Switch / LVPS

No Procedure Photo

1 1. Screw 2 screws to

assemble the Interlock Switch.

2. Screw 1 screw to assemble

the Assy Thermal Switch

Board.

2

1

2 1. Screw 4 screws

2. Screw 1 screw in the

grounding wire.

3. Plug 1 connector in the

Interlock Swtich to assemble

the LVPS.

2

1

3

Page 45

4. Assemble Lamp Driver

No Procedure Photo

1 Screw 4 screws to assemble

the Lamp Driver Housing.

2 Plug in 2 connectors.

Note:

Please be aware of the wire

arrangement of the LVPS with

the Lamp Driver. (The shorter

wire should be connected to

the LVPS; while the longer

wire should be connected to

the Lamp Driver.)

3 Screw 4 screws to assemble

the Lamp Driver Module.

37 Chapter 3

Page 46

Chapter 3 38

5. Assemble Axial Fan Module

No Procedure Photo

1 Screw 4 screws to assemble

the System Fan.

2 Screw 3 screws to assemble

Axial Fan Module.

Note:

Please be aware of the wire

arrangement of the system

fan. (the wire should be in the

upper left side.)

Page 47

6. Assemble Speaker / EMI Shielding

No Procedure Photo

1 Screw 2 screws to assemble

the Speaker.

Note:

Please be aware of the wire

arrangement of the speaker.

2 Screw 4 screws to assemble

the EMI Shielding Cover of

Units.

39 Chapter 3

Page 48

Chapter 3 40

7. Assemble Main Board

No Procedure Photo

1 1. Plug 1 connector.

2. Locate the front part of

Main Board.

2 Screw 4 screws and plug in 8

connectors to assemble the

Main Board.

Note:

When Reassembling the

Main Board with the Top

Cover, please be aware of the

wire arrangement. The wire

arrangement should go as the

picture shows (not exceeding

1/2 of the red blank space) to

best allocate the Top Cover

Sponge.

Page 49

8. Assemble Bottom Cover Module

No Procedure Photo

1 Assemble the shieldings with

the Main Unit based on the 2

tenons.

2 Assemble Side Covers.

(Right Cover & Left Cover)

Note:

When reassembing the Side

Cover, please locate & align

the tenons as the picture

shows.

3 Assemble the Bottom Cover

Sponge.

41 Chapter 3

Page 50

Chapter 3 42

9. Assemble Front Cover / IR Sensor Board / Elevator

Push Button

No Procedure Photo

1 Assemble the Elevator Push

Button directly.

2 Assemble the IR Receiver

Board and put on the Front IR

Cover directly.

3 Plug in 1 connector (red color)

to assemble the Front Cover

Module.

4 1. Screw 1 screw to assemble

the IR Receiver.

2. Screw 2 screws to

assemble the Front Cover.

Page 51

10. Assemble Keypad Board

No Procedure Photo

1 Screw 2 screws to assemble

the Top Cover Shielding.

2 1. Assemble the Keypad

Module.

2. Screw 4 screws to

assemble the Keypad Board.

43 Chapter 3

Page 52

Chapter 3 44

11. Assemble Top Cover / IO Cover

No Procedure Photo

1 1. Put on 1 FPC Cable to

assemble the Top Cover.

2. Push the Bottom Cover

rst; then, push down the Top

Cover to assemble the Top

Cover.

2 Screw 2 screws & 6 hex

screws to assemble the IO

Cover.

Page 53

12. Assemble Lamp Module

No Procedure Photo

1 Screw 2 screws to assemble

the Lamp Module.

2 Screw 2 screws to assemble

the Lamp Cover.

45 Chapter 3

Page 54

Troubleshooting

Equipment Needed

- PC or Pattern Generator

- DVD Player (Video, S-Video, Audio)

- Quantum Data 802B or CHROMA 2327

LED Lighting Message

Power LED

Message

Red Blue

Chapter 4

Temp LED Lamp LED

Standby State

(Input power cord)

Lamp lighting O

Power on O * O O

Power off (Cooling) Quick Flashing

Error (Lamp fail)

Error (Thermal fail) O O

Error (Fan lock fail) O O Flashing O

Error (Over Temp.)

Error

(Lamp Breakdown)

Slow Flashing O O O

*

O O

O O O

O O O

*

O O

*

O O O *

=> Light On => Light Off

*

O

O

Cha pter 4 46

Page 55

Main Procedure

No Symptom Procedure

1 No Power - Ensure the Power Cord and AC Power Outlet are securely connected

- Check Lamp Cover and Interrupt Switch

- Ensure all connectors are securely connected and aren't broken

- Check DC-DC

- Check Ballast

- Check Main Board

2 Auto Shut Down - Check LED Status

a. Lamp LED Light

- Check Lamp

- Check Lamp Driver

- Check Main Board

b. Temp LED Light

- Check Thermal Sensor

- Check Thermal Switch

- Check Fan

c. Color Wheel

- Check Color Wheel

- Check Photo Sensor

d. No Power

- Refer to "No Power" troubleshooting

3 No Image - Ensure the Signal Cable and Source work as well

(If you connect multiple sources at the same time, use the "Source"

button on the control panel to swtich)

- Ensure all connectors are securely connected and aren't broken

- Check Main Board

- Check DMD Board

- Check Color Wheel

- Check DMD Chip

- Check Engine Module

4 No Light On - Ensure all connectors are securely connected and aren't broken

- Check Lamp Module

- Check DC-DC

- Check Ballast

- Check Main Board

5 Mechanical Noise - Check Color Wheel

- Check Fan Module

6 Line Bar / Line Defect - Sometimes it's because of the DMD Chip and the DMD Board did

not assemble properly

- Check DMD Board

- Check DMD Chip

- Check Main Board

7 Image Flicker - Do "Reset" of the OSD Menu

- Ensure the Signal Cable and Source work as well

- Check Lamp Module

- Check Color Wheel

- Check DMD Board

- Check Main Board

8 Color Abnormal - Do "Reset" of the OSD Menu

- Adjust Color Wheel Index

- Check Main Board

- Check DMD Board

- Check Color Wheel

47 Cha pter 4

Page 56

No Symptom Procedure

9 Poor Uniformity / Shadow - Ensure the Projection Screen without dirt

- Ensure the Projection Lens is clean

- Ensure the Brightness is within spec.

(Replace the Lamp if the Brightness is less than spec.)

- Check Engine Module

10 Dead Pixel / Dust

(Out of spec.)

11 Garbage Image - Ensure the Signal Cable and Source work as well

12 Remote Controll or Control

Panel Failed

13 Function Abnormal - Do "Reset" of the OSD Menu

- Ensure the Projection Screen without dirt

- Ensure the Projection Lens is clean

- Clean DMD Chip and Engine Module

- Check DMD Chip

- Check Engine Module

- Check Main Board

- Check DMD Board

- Remote Control

a. Check Battery

b. Check Remote Control

c. IR Receiver

- Control Panel

a. Check FPC

b. Check Keypad

c. Check Main Board

- Check Main Board

- Check DMD Board

Cha pter 4 48

Page 57

Function Test & Alignment Procedure

Product

- PD100 / PD100D/ PD120D / PD120 / XD1170D / XD1270D

Te st Equipment

- I BM PC with XGA resolution (Color Video Signal & Pattern Generator)

- DVD player with Multi-system (NTSC/PAL/SECAM), equipped “Component” “S-Video” and

“Composite”

- HDTV Tuner or Source (480P, 1080i)

- Minolta CL-100

- Quantum Data 802B or CHROMA2316

- After changing parts, check the information below.

Charge

Parts/Update

M/B v v v v v v

FW v v v v v

Color Wheel v

Lamp Module v

Version

Update

Color Wheel

Index

ADC

Calibration

Video

Calibration

Reset Lamp

Use Time

Factory

Reset

Te st Condition

- Circumstance Brightness : Dark room less than 2.5 lux.

- I nspection Distance : 1.5m~3m for functional inspection

- Screen Size : 60 inches diagonal (wide)

- After repairing each PD100, the unit should be burn-in (Refer to the table below).

Symptom Burn-in Time

Normal Repair 2 Hours

NFF 4 Hours

EDID

Auto Shutdown 6 Hours

49 Cha pter 4

Page 58

Inspection Procedure

No Step Specification Procedure

1 Frequency

and Tracking

2 Boundary Horz. And Vert.

3 Focus The text in the

4 HDTV No discolor - Test Signal : 480P, 1080i (PD100)

5 Color

Performance

Eliminate visual

wavy noise by

Rsync,

Frequency or

Tracking

selection.

position of video

should be

adjustable to be

the screen

frame.

corner should be

clear after adjust

the focus ring.

1. No image

(discolor)

2. No light

leakage

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : General 1

- check and see if image sharpness and

focus are well-performed.

- No video noise is allowed.

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : General 1

- Adjust Resync or Frequency / Tracking /

H. Position / V. Position to the inner of the

screen.

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : Full Screen

- Adjust the center clearly; meanwhile, one

slightly vague corner in the image is allowed.

- Test Pattern : Master

- Equipment: Quantum Data 802B or

CHROMA2327

*Please refer to page 4~7 to enter Service Mode.

Use 480P signal, smtpe bar pattern to do video

calibration; then, 4:3 screen and 1080i signal. If the

test result was in discoloration or flickering, please

return the unit back to the repair center. (by Model)

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : 64 RGBW Scale Pattern & 32 Grays

Pattern

- Please check and ensure if each color is

normal and distinguishable.

- If not, please adjust color index of the

Engineering Mode.

6 Screen

Uniformity

Should be

compliant with

60%.(Minimum)

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : Full White Pattern & Full Black

Pattern

- Please check and ensure the unit is under the

spec.

- Please check and see if it's in normal conidtion.

- If not, please return the unit to repair area.

*Please check and see if there are dead

pixels on DMD Chip.

- The total number and distance of dead pixels

should be compliant with the spec.

Note:

(1) Bright Pixel:

Test Pattern: Full Black Pattern

- Please check and ensure that the unit cannot

accept any bright pixel.

- If not, please return the unit to repair area.

(2) Dark Pixel:

Test Pattern: Full White Pattern

- Please check and ensure that the pixel number

should be smaller or amount to 5 pixels.

- If not, please return the unit to repair area.

Cha pter 4 50

Page 59

No Step Specification Procedure

7 Light Leak The unit can't

8 Calibration Calibration

9 Contrast /

Brightness

accept the

leakage is

brighter than

Gray 10 pattern

Pattern should

be in full screen

mode

Gray level should

be

distinguishable

and without color

abnormal

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : 32 Grays, Gray 10_HP, Gray 30_HP

(From Top to Bottom)

- Please check and see if the light leaks.

- Follow up TI DMD Chip Spec.

- Once Main Board is changed, firmware upgrade,

Video Calibration & ADC Calibration should be

done as well.

- Video Calibration

- Test Signal : 720x480@75Hz (PD100)

- Test Pattern : Master

- PC Calibration

- Test Signal : 800x600@75Hz (PD100)

- Test Pattern : White (Top) Black (Bottom)

Note:

1. Calibration Pattern should be in Full Screen

Mode.

2. Please refer to 4-6. Guide to Entering Service

Mode and Facotry Reset for entering Service

Mode.

3. Choose and access Video Calibration & PC

Calibration for correction in Service Mode.

Choose "Exit" to leave the Service Mode after all.

- Test Pattern: 64 RGBW scale

10 R, G, B and

White Color

Performance

Each R, G, B

color should be

normal without

color abnormal

issue

- Test Pattern: R, G, B and White Color

51 Cha pter 4

Page 60

No Step Specification Procedure Photo

11 Dead Pixel

(Bright pixel)

Dead Pixel

(Dark pixel)

12 Blemish

(Bright)

Cannot accept

any bright pixel

The numbers of

dead pixel

should be

smaller or

amount to 6

pixel.

The bright

blemish cannot

be accepted if

the problem

appear with Gary

30 pattern

- Test Pattern : Full Black

- Test Pattern : Full White

- Test Pattern : Full Black / Gray 30

13 Blemish

(Dark)

The dark blemish

cannot be

accepted if the

problem appear

with Blue 60

pattern.

- Test Pattern : Full white / Blue 60

Cha pter 4 52

Page 61

Guide to Entering Servic e Mode and Factory Res et (PD100)

No Item Steps

1 Service Mode Please do the following steps to enter Service Mode:

1. Turn on the projector.

2. Press "Power", "Left" button, "Left" button and "Menu" by order to enter the

Service Mode. (As the following pictures show)

1

Power

2 Factory Reset After final QC step, we have to erase all saved change again and restore the

factory defaults. Execute the Factory Reset to restore the deault setting.

2

“Left” button

3

“Left” button

4

Menu

53 Cha pter 4

Page 62

Expl oded Overview

PD100 Exploded Overview

Chapter 5

Exploded Parts List

Item Part Number Description

1 70.82V22G001 ASSY FRONT COVER MODULE PD100

2 70.82V24G001 ASSY TOP COVER MODULE PD100

3 70.82V15G001 ASSY BOTTOM HOUSING MODULE PD100

4 70.82G09G001 ASSY LAMP MODULE EP7190

5 70.82V23G001 ASSY BACK COVER DC MODULE PD100

6 70.82V33G001 ASSY LAMP COVER MODULE PD100

7 85.1A323.100 SCREW PAN MECH M3*10 BLACK

8 85.005AGG040 SCREW I/O STEEL #4-40UNC*H4*L5.5 NYLOK

9 85.5A323.060 SCREW BIN MECH M3*6 Black

10 61.00079G001 GROUNDING CABLE CLAMP FN-008 "PINGOOD

11 61.00018G002 LOCK SCREW PAN MECH M3*8.5-3.5 BLACK

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 54

Page 63

PD120 Exploded Overview

Exploded Parts List

Item Part Number Description

1 70.82V03G001 ASSY FRONT COVER MODULE PD120

2 70.82V07G001 ASSY TOP COVER MODULE PD120

3 70.82V01G001 ASSY BOTTOM HOUSING MODULE PD120

4 70.82G09G001 ASSY LAMP MODULE EP7190

5 70.82V14G001 ASSY BACK COVER DC MODULE PD120

6 70.82V32G001 ASSY LAMP COVER MODULE PD120

7 85.1A323.100 SCREW PAN MECH M3*10 BLACK

8 85.005AGG040 SCREW I/O STEEL #4-40UNC*H4*L5.5 NYLOK

9 85.5A323.060 SCREW BIN MECH M3*6 Black

10 61.00079G001 GROUNDING CABLE CLAMP FN-008 "PINGOOD

11 61.00018G002 LOCK SCREW PAN MECH M3*8.5-3.5 BLACK

Note: Please refer to RSPL for updated Part Number.

55 Cha pter 5

Page 64

PD100 Assy Bottom Housing Module

Exploded Parts List

Item Part Number Description

1 70.82V09G001 ASSY BOTTOM BASE MODULE PD120

2 70.82V17G001 ASSY ENGINE MODULE PD100

3 61.82G12G001 LAMP LIGHTCUT TOP FOR E19 AL 0.6t EP7190

4 70.82V10G001 ASSY AXIAL FAN MODULE PD120

5 70.82V04G001 ASSY BOTTOM EMI SHIELDING MODULE PD120

6 80.82V51G001 PCBA MAIN BD PD100

7 51.82V19G001 ZOOM RING MYLAR PD120

8 70.82V25G001 ASSY BOTTOM COVER MODULE PD100

9 52.82V04G001 BOTTOM COVER SPONGE PD120

10 51.82G16G001 ELEVATOR FOOT PC+ABS C6200 EP7190 "GREEN'

11 42.87120G001 W.A. GROUND #20 UL1007 BLACK 80mm p3.0/p3.0 LT20

12 85.1A123.050 SCREW PAN MECH M3*5 Ni

13 85.1A626G050 SCREW PAN MECH M2.6*5 BLACK NYLOK

14 70.82G19G001 ASSY LAMP DRIVER MDULE EP7190

15 41.82G03G001 EMI GASKET USB CONNECTOR EP719

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 56

Page 65

PD120 Assy Bottom Housing Module

Exploded Parts List

Item Part Number Description

1 70.82V09G001 ASSY BOTTOM BASE MODULE PD120

2 70.82V11G001 ASSY ENGINE MODULE PD120

3 61.82G12G001 LAMP LIGHTCUT TOP FOR E19 AL 0.6t EP7190

4 70.82V10G001 ASSY AXIAL FAN MODULE PD120

5 70.82V04G001 ASSY BOTTOM EMI SHIELDING MODULE PD120

6 80.82V01G001 PCBA MAIN BD PD120

7 51.82V19G001 ZOOM RING MYLAR PD120

8 70.82V02G001 ASSY BOTTOM COVER MODULE PD120

9 52.82V04G001 BOTTOM COVER SPONGE PD120

10 51.82G16G001 ELEVATOR FOOT PC+ABS C6200 EP7190 "GREEN'

11 42.87120G001 W.A. GROUND #20 UL1007 BLACK 80mm p3.0/p3.0 LT20

12 85.1A123.050 SCREW PAN MECH M3*5 Ni

13 85.1A626G050 SCREW PAN MECH M2.6*5 BLACK NYLOK

14 70.82G19G001 ASSY LAMP DRIVER MDULE EP7190

15 41.82G03G001 EMI GASKET USB CONNECTOR EP719

Note: Please refer to RSPL for updated Part Number.

57 Cha pter 5

Page 66

PD100 Assy Bottom Cover Module

Exploded Parts List

Item Part Number Description

1 51.82V02G002 BOTTOM COVER PC+ABS PD100

2 51.82V17G001 LEFT COVER PC+ABS PD120

3 51.82V18G001 RIGHT COVER PC+ABS PD120

4 52.89601.001 ADJUST FOOT RUBBER EP759

5 86.03123.035 HEX CAP HEAD NUT M3*0.5P L3.5 NI

6 52.82V10G001 BOTTOM COVER SPONGE-2 PD120

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 58

Page 67

PD120 Assy Bottom Cover Module

Exploded Parts List

Item Part Number Description

1 51.82V02G001 BOTTOM COVER PC+ABS PD120

2 51.82V17G001 LEFT COVER PC+ABS PD120

3 51.82V18G001 RIGHT COVER PC+ABS PD120

4 52.89601.001 ADJUST FOOT RUBBER EP759

5 86.03123.035 HEX CAP HEAD NUT M3*0.5P L3.5 NI

6 52.82V10G001 BOTTOM COVER SPONGE-2 PD120

Note: Please refer to RSPL for updated Part Number.

59 Cha pter 5

Page 68

PD120 Assy Bot tom Base Module

Exploded Parts List

Item Part Number Description

1 49.88604.002 SPEAKER 8ohm 2W X16 EP759

2 85.1A123.050 SCREW PAN MECH M3*5 Ni

3 52.82G11G001 SPEAKER SPONGE EP7190

4 61.82V01G001 EMI SHIELDING AL PD120

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 60

Page 69

PD100 Assy Top Cover M odule

Exploded Parts List

Item Part Number Description

1 51.82V03G001 TOP COVER PC+ABS PD120

2 61.82V04G001 TOP COVER SHIELDING SPTE PD120

3 51.82Q03G001 KEYPAD MAIN BUTTON PC+ABS PD322

4 51.82Q05G001 LED HOUSING PC PD322

5 51.82Q06G001 POWER LED HOUSING PC PD322

6 80.82Q03G001 PCBA KEYPAD BOARD PD322 ''GREEN''

7 61.82V03G001 KEYPAD SHIELDING AL PD120

8 85.WA123.040 SCREW PAN TAP M3*4 Ni

9 42.82V02G001 CABLE FFC 14P P=0.5 120mm PD120

10 51.82Q04G011 KEYPAD MENU BUTTON PC+ABS PD120

11 41.82V05G001 EMI GASKET W4*H3*L15mm PD120

12 41.82V04G001 EMI GASKET W10*H6.5*L70mm PD120

13 41.81M02G001 EMI GASKET W17*H23*L30mm

Note: Please refer to RSPL for updated Part Number.

61 Cha pter 5

Page 70

PD120 Assy Top Cover M odule

Exploded Parts List

Item Part Number Description

1 51.82V03G001 TOP COVER PC+ABS PD120

2 61.82V04G001 TOP COVER SHIELDING SPTE PD120

3 51.82Q03G001-B KEYPAD MAIN BUTTON PC+ABS PD322

4 51.82Q05G001 LED HOUSING PC PD322

5 51.82Q06G001-B POWER LED HOUSING PC PD322

6 80.82Q03G001 PCBA KEYPAD BOARD PD322 ''GREEN''

7 61.82V03G001 KEYPAD SHIELDING AL PD120

8 85.WA123.040 SCREW PAN TAP M3*4 Ni

9 42.82V02G001 CABLE FFC 14P P=0.5 120mm PD120

10 51.82Q04G011 KEYPAD MENU BUTTON PC+ABS PD120

11 41.82V05G001 EMI GASKET W4*H3*L15mm PD120

12 41.82V04G001 EMI GASKET W10*H6.5*L70mm PD120

13 41.81M02G001 EMI GASKET W17*H23*L30mm

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 62

Page 71

PD120 Assy Bot tom Base Module

Exploded Parts List

Item Part Number Description

1 61.82G01G001 BASE PLATE Mg ALLOY AZ91D EP7190

2 51.85816.001 LIMIT SWITCH HOLDER PPS XB31

3 51.85824.001 LIMIT SWITCH BOTTOM HOLDER PPS XB31

4 75.88514.002 ASSY LIMIT SWITCH CHERRY DB3C A1LB-5A

5 85.1A62G.050 SCREW PAN MECH M2.6*5 BLACK NYLOK

6 70.82V34G001 ASSY ELEVATOR MODULE PD120

7 61.00029.001 SCREW PAN MECH M3*5*D8 Ni

8 61.87340G001 STAND OFF M3*4L D8.0 2100MP

9 85.3A122.040 SCREW CAP MECH M2*4 Ni

10 41.82V01G001 EMI GASKET W17*H27*L35mm PD120

11 76.82G01G001 BUY ASSY W.A. 2P 150mm LVPS/LAMP EP719

12 61.85913.001 ELEVATOR SPRING SUS304 SB21

13 80.82V04G001 PCBA THERMAL SENSOR BOARD PD120

14 51.82G24G001 BASE PLATE INSULATION MYLAR FOR LVPS EP7190

15 70.82V26G001 ASSY BLOWER FAN MODULE PD120

16 85.1C224G050 SCREW PAN MECH M4*5 COLOR W/TOOTH WASHER

17 85.1A123.050 SCREW PAN MECH M3*5 Ni

18 70.82V31G001 ASSY LVPS MODULE PD120

19 52.88504G001 LVPS BOTTOM THERMAL PAD 26*21*3mm Fujipoly GR-b

Note: Please refer to RSPL for updated Part Number.

63 Cha pter 5

Page 72

PD120 Assy Axial Fan Module

Exploded Parts List

Item Part Number Description

1 49.80N01G001

2 61.82V02G001 FAN-LAMP BRACKET AL PD120

3 85.1F123.260 SCREW PAN MECH E/SF M3*26 Ni

4 52.82V07G001 LAMP BRACKET SPONGE PD120

5 51.00075.001 WIRE MOUNTS PG-FW-4D XB31

Note: Please refer to RSPL for updated Part Number.

SUNON 70*20 R-TYPE AXIAL FAN, GM1207PKVX-A 70*70*20mm, JST

CONNECTOR,GREEN SUMITUDE

Cha pter 5 64

Page 73

PD100 Assy Engine M odule

Exploded Parts List

Item Part Number Description

1 70.82V27G001 ASSY ENGINE BOTTOM COVER MODULE PD120

2 70.82V18G001 ASSY ENGINE TOP MODULE PD100

3 85.1A123.050 SCREW PAN MECH M3*5 Ni

4 41.82V02G001 EMI TAPE W30*L30mm PD120

Note: Please refer to RSPL for updated Part Number.

65 Cha pter 5

Page 74

PD120 Assy Engine M odule

Exploded Parts List

Item Part Number Description

1 70.82V27G001 ASSY ENGINE BOTTOM COVER MODULE PD120

2 70.82V12G001 ASSY ENGINE TOP MODULE PD120

3 85.1A123.050 SCREW PAN MECH M3*5 Ni

4 41.82V02G001 EMI TAPE W30*L30mm PD120

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 66

Page 75

PD100 Assy Engine Top Cover Module

Exploded Parts List

Item Part Number Description

1 11.009F0G005-C CNNT F 166P FOR 0.55" SVGA LGA DMD SOCKET;FOXCONN

2 23.82G01G002 PROJECTION LENS BARREL CHA

3 48.859DMGD13

4 51.80B31G002 DMD INSULATOR MYLAR 0.435t T90

5 51.82V09G001 FOCUS RING PC+ABS PD120

6 51.82V10G001 ZOOM RING PC+ABS PD120

7 51.82G08G001 ZOOM RING ORBIT PC+ABS C6200 EP7190

8 51.82G22G001 ZOOM ANTI-ABRASION TEFLON EP7190

9 52.82G03G002 RELAY SEALED RUBBER-2 EP719

10 52.82G10G001 RELAY CUSHION RUBBER EP7190

11 52.87130G001 RUBBER BLOWER 595925

12 52.87319G001 DMD THERMAL PAD 18*13*0.5t

13 52.89627G002 DMD SEAL RUBBER BF1000 3.2t EP719

14 61.80J48G002 DMD HEATSINK BACKER PLATE A6061 739

15 61.82G02G001 ENGINE TOP COVER Mg ALLOY AZ91D EP7190

16 61.83A03G001 DMD HEATSINK AL 1070 DP718

17 61.88608G001 DMD HEATSINK SPRING PLATE SUS301 0.4t Ivy10X

18 61.88611G001 DMD SCREW Ivy10X

19 61.89643G001 DMD MASK PLATE SUS301 0.15t EP759

20 00.82V02G001 BARE PCB L:6 DMD BD FOR PD120

21 85.1A123.050 SCREW PAN MECH M3*5 Ni

22 85.1A123.060 SCREW PAN MECH M3*6 Ni

23 85.YA321G051 SCREW FLAT HEAD TAP M1.7x5 D3 BALCK

Note: Please refer to RSPL for updated Part Number.

67 Cha pter 5

Page 76

PD120 Assy Engine Top Cover Module

Exploded Parts List

Item Part Number Description

1 11.009F0G005 CNNT F 166P FOR 0.55" SVGA LGA DMD SOCKET;FOXCONN

2 23.82G01G002 PROJECTION LENS BARREL CHA

3 48.82GDMGD01 DMD 1024*768 PIXEL DDR FTP 0.55" XGA

4 51.80B31G002 DMD INSULATOR MYLAR 0.435t T90

5 51.82V09G001 FOCUS RING PC+ABS PD120

6 51.82V10G001 ZOOM RING PC+ABS PD120

7 51.82G08G001 ZOOM RING ORBIT PC+ABS C6200 EP7190

8 51.82G22G001 ZOOM ANTI-ABRASION TEFLON EP7190

9 52.82G03G002 RELAY SEALED RUBBER-2 EP719

10 52.82G10G001 RELAY CUSHION RUBBER EP7190

11 52.87130G001 RUBBER BLOWER 595925

12 52.87319G001 DMD THERMAL PAD 18*13*0.5t

13 52.89627G002 DMD SEAL RUBBER BF1000 3.2t EP719

14 61.80J48G002 DMD HEATSINK BACKER PLATE A6061 739

15 61.82G02G001 ENGINE TOP COVER Mg ALLOY AZ91D EP7190

16 61.83A03G001 DMD HEATSINK AL 1070 DP718

17 61.88608G001 DMD HEATSINK SPRING PLATE SUS301 0.4t Ivy10X

18 61.88611G001 DMD SCREW Ivy10X

19 61.89643G001 DMD MASK PLATE SUS301 0.15t EP759

20 00.82V02G001-B BARE PCB L:6 DMD BD FOR PD120

21 85.1A123.050 SCREW PAN MECH M3*5 Ni

22 85.1A123.060 SCREW PAN MECH M3*6 Ni

23 85.YA321G051 SCREW FLAT HEAD TAP M1.7x5 D3 BALCK

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 68

Page 77

PD120 Assy Back Cover DC Module

Exploded Parts List

Item Part Number Description

1 51.82V12G001 BACK IR LENS PC PD120

2 51.82V21G001 BACK IO OVERLAY-DC PC PD120

3 41.82V12G001 EMI TAPE W41*L129mm PD120

4 51.82V04G011 BACK COVER-DC PC+ABS PD120

Note: Please refer to RSPL for updated Part Number.

69 Cha pter 5

Page 78

PD100 Assy Back Cover DC Module

Exploded Parts List

Item Part Number Description

1 51.82V12G001 BACK IR LENS PC PD120

2 51.82V21G001 BACK IO OVERLAY-DC PC PD120

3 41.82V12G001 EMI TAPE W41*L129mm PD120

4 51.82V04G012 BACK COVER-DC PC+ABS PD100

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 70

Page 79

PD100 Assy Front Cover

Exploded Parts List

Item Part Number Description

1 51.82V01G002 FRONT COVER NORYL 9406P PD100

2 51.82V08G002 FRONT PUSH BUTTON PC+ABS PD100

3 51.82V11G001 FRONT IR LENS PC PD120

4 52.82V02G001 FRONT IR COVER RUBBER PD120

5 80.82V05G001 PCBA IR SENSOR BD FOR PD120

6 35.82V01G002 MODEL NAME LABEL PC PD100

7 35.82V03G001 ACER LOGO LABEL PD120

8 52.82V11G001 FRONT COVER SPONGE PD120

9 51.82V22G001 MYLAR LIGHT CUT PD120

Note: Please refer to RSPL for updated Part Number.

71 Cha pter 5

Page 80

PD120 Assy Blower Fan Module

Exploded Parts List

Item Part Number Description

1 49.83A01G001 DELTA 4520 BLOW

2 52.82G08G001 BLOWER 4520 RUBBER EP7190

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 72

Page 81

PD120 Assy Engine Bottom Cover Module

73 Cha pter 5

Page 82

Exploded Parts List

Item Part Number Description

1 23.82G02G001 MIRROR WITH ONE COATING SURFACE

2 23.82G06G001 ASPHERICAL ZEONEX RELAY LENS

3 23.82G10G001 SQUARE UV-IR 17*17mm^2 T=2.75mm

4 23.82G20G001 BK7 CONDENSER LENS p13.00mm

5 23.82G20G011 BK7 CONDENSER LENS p15.00mm

6 43.80N01G001 THERMAL SWITCH 120J TI , YS11A120B-026, WHITE JST CONNECTOR,

7 51.82G13G001 CONDENSER HOLDER PC+20%GF EP7190 "GREEN'

8 52.82G04G002 RELAY SIDE SEALED RUBBER-2 EP719

9 52.82G09G001 CONDENSER CUSHION RUBBER EP7190

10 52.82G12G001 FAN HOLDER SEALED-1 HT800 EP719

11 52.82G13G001 FAN HOLDER SEALED-2 HT800 EP719

12 52.82G14G001 FAN HOLDER SEALED-3 HT800 EP719

13 61.82G03G001 ENGINE BOTTOM COVER Mg ALLOY AZ91D EP7190

14 61.82G11G001 MIRROR HOLDER PLATE SUS301 0.25t EP7190

15 51.82G25G001 RELAY LENS MYLAR EP719

16 61.82G19G001 ROD HIDE RAY PLATE AL 0.4t EP7190

17 61.82G21G001 ROD FIX PLATE SUS301 0.25t EP7190

18 61.82G22G001 UV-IR GLASS HOLDER SUS301 0.2t EP7190

19 70.82G15G001 ASSY COLOR WHEEL MODULE EP7190

20 70.83S05G001 ASSY ROD MODULE PJ406D

21 75.82G08G001 BUY ASSY 50*25 BLOWER FAN DUCT AL EP719

22 85.0A122G030 SCREW DOUBLE FLAT MECH M2*3Ni

23 85.1A123.050 SCREW PAN MECH M3*5 Ni

24 85.1A523G080 SCREW PAN MECH M3*8 Ni NYLOK

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 74

Page 83

PD120 Assy Le ns Cap Module

Exploded Parts List

Item Part Number Description

1 52.82V01G001 LENS COVER RUBBER PD120

2 61.82V08G001 LENS COVER PLATE PD120

3 51.83150G001 CAP STRAP TDP-T90

Note: Please refer to RSPL for updated Part Number.

75 Cha pter 5

Page 84

PD120 Assy LVPS Module

Exploded Parts List

Item Part Number Description

1 42.80S07G001 W.A. 14P 190mm LVPS TO M/B TDP-T90 ''

2 42.81G01.001 W.A. 2P #20 160mm LAPS/BALLAST H31

3 75.80W19G001 ASSY LVPS LITEON 200W 2300MP

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 76

Page 85

PD100 Assy Lamp Cover Module

Exploded Parts List

Item Part Number Description

1 51.82V13G002 LAMP COVER NORYL 9406P PD100

2 61.82V09G001 LAMP COVER PLATE SPTE PD120

3 52.82V08G001 LAMP COVER SPONGE PD120

Note: Please refer to RSPL for updated Part Number.

77 Cha pter 5

Page 86

PD120 Assy Lamp Cover Module

Exploded Parts List

Item Part Number Description

1 51.82V13G001 LAMP COVER NORYL 9406P PD120

2 61.82V09G001 LAMP COVER PLATE SPTE PD120

3 52.82V08G001 LAMP COVER SPONGE PD120

Note: Please refer to RSPL for updated Part Number.

Cha pter 5 78

Page 87

PD120 Assy El evator Module

Exploded Parts List

Item Part Number Description

1 51.82V06G001 ELEVATOR HOLDER PC+ABS PD120

2 51.82V07G001 ELEVATOR PUSH PC+ABS PD120

3 51.86809.001 ELEVATOR BODY NYLON+GF DP725

4 61.86814.001 ELEVATOR EXTEND SPRING DP725

5 61.85913.001 ELEVATOR SPRING SUS304 SB21

Note: Please refer to RSPL for updated Part Number.

79 Cha pter 5

Page 88

Appendix A

Ex ploded Overv iew

D.C. XD1170D

Cha pter 5

80

Page 89

Item P/N Description

1 70.82V47G001 ASSY FRONT COVER MODULE XD1170D

2 70.82V63G001 ASSY TOP COVER MODULE-1 XD1270D

3 70.82V46G001 ASSY BOTTOM HOUSING MODULE XD1170D

4 70.82V61G001 ASSY LAMP MODULE XD1270D

5 70.82V48G001 ASSY BACK COVER MODULE XD1270D

6 75.82V09G011 BUY ASSY LAMP COVER MODULE XD1270D

7 85.1A323G100 SCREW PAN MECH M3*10 BLACK

8 85.005AGG040 SCREW I/O STEEL #4-4UNC*H4*L5

9 85.5A323G060 SCREW BIN MECH M3*6 BLACK

10 61.00079G001 GROUNDING CABLE CLAMP FN-008"GREEN"

11 61.00018G002 LOCK SCREW PAN MECH M3*8.5-3.5

12 51.00001G001 CABLE TIE PG-YJ-80

Cha pter 5

81

Page 90

ASSY FRONT COVER MODULE XD1170D

Item P/N Description

1 51.82V01G011 FRONT COVER NORYL 9406P XD1270D

2 51.82V08G011 FRONT PUSH BUTTON PC+ABS XD1270D

3 51.82V11G001 FRONT IR LENS PC PD120

4 52.82V02G001 FRONT IR COVER RUBBER PD120

5 80.82V05G001 PCBA IR SENSOR BD FOR PD120

6 35.82V01G032 MODEL NAME LABEL PC XD1170D

7 52.82V11G001 FRONT COVER SPONGE PD120

8 51.82V22G001 MYLAR LIGHT CUT PD120

9 41.82V18G001 EMI FRONT COVER TAPE PD120

10 52.82V09G001 LENS SUPPORT RUBBER PD120

Cha pter 5

82

Page 91

ASSY ENGINE MODULE XD1170D

Item P/N Description

1 70.82V52G001 ASSY ENGINE BOTTOM COVER MODULE XD1270D

2 70.82V54G001 ASSY ENGINE TOP COVER MODULE XD1170D

3 85.1A123G050 SCREW PAN MECH M3*5 Ni

4 41.82K09G001 EMI TAPE 30*50mm

Cha pter 5

83

Page 92

ASSY BOTTOM HOUSING MODULE XD1170D

Cha pter 5

84

Page 93

PART NUMBER LIST

Item P/N Description

1 70.82V42G001 ASSY BOTTOM BASE MODULE XD1270D

2 70.82V53G001 ASSY ENGINE MODULE XD1170D

3 61.82G12G001 LAMP LIGHTCUT TOP FOR E19 AL

4 70.82V10G001 ASSY AXIAL FAN MODULE PD120

5 70.82V59G001 ASSY BOTTOM EMI SHIELDING MODULE XD1270D

6 80.82V71G002 PCBA MAIN BOARD FOR XD1170D

7 51.82V19G011 ZOOM RING MYLAR XD1270D

8 70.82V60G001 ASSY BOTTOM COVER MODULE XD1270D

9 52.82V04G002 BOTTOM COVER SPONGE-2 PD120

10 51.82G16G001 ELEVATOR FOOT PC+ABS EP719

11 42.87120G001

W.A. GROUND #20 UL1007 BLACK 80mm%%c3.0/%%c3.0

LT20

12 85.1A123.050 SCREW PAN MECH M3*5

13 85.1A626G050 SCREW PAN MECH M2.6*5 BLACK NYLOK

14 70.82V44G001 ASSY LAMP DRIVER MODULE XD1270D

15 43.80N01G001

THERMAL SWITCH 120C TI, YS11A120B-026, WHITE JST

CONNECTOR.

16 51.82V09G011 FOCUS RING PC+ABS XD1270D

17 85.YA321G052 SCREW FLAT HEAD TAP M1.7*5 D2.5 BLACK

18 51.82V10G011 ZOOM RING PC+ABS XD1270D

19 51.82G08G002 ZOOM RING ORBIT PC MN3600H EP719

Cha pter 5

85

Page 94

ASSY ENGINE TOP COVER MODULE XD1170D

Cha pter 5

86

Page 95

PART NUMBER LIST

Item P/N Description

1 11.009F0G005

2 23.85R01G001 PROJECTION LENS YM09H

3 48.859DMGD13 DMD 800*600 PIXEL DDR FTP 0.55" SVGA

4 51.80B31G002 DMD INSULATOR MYLAR 0.435t T90

5 51.82G22G001 ZOOM ANTI-ABRASION TEFLON EP7190 "GREEN"

6 52.82G03G002 RELAY SEALED RUBBER-2 EP719

7 52.82G10G001 RELAY CUSHION RUBBER EP7190 "GREEN"

8 52.87130G001 RUBBER BLOWER 595925 "GREEN"

9 52.87319G001 DMD THERMAL PAD 18*13*0.5t "GREEN"

10 52.89627G002 DMD SEAL RUBBER BF1000 3.2t EP719

11 61.80J48G002 DMD HEATSINK BACKER PLATE 739 AL6061 "GREEN"

12 61.82G02G001 ENGINE TOP COVER Mg Alloy-AZ91D EP7190

13 61.83A03G001 DMD HEATSINK AL 1070 DP718

14 61.88608G001 DMD HEATSINK SPRING PLATE SUS301 0.4t Ivy10X

CNNT F 166P FOR 0.55" SVGA LGA DMD

SOCKET;FOXCONN

15 61.88611G001 DMD SCREW Ivy10X "GREEN"

16 61.89643G001 DMD MASK PLATE SUS301 0.15t EP759

17 80.82V02G001 PCBA DMD BD FOR PD120

18 85.1A123G050 SCREW PAN MECH M3*5 NI

19 85.1A123G060 SCREW PAN MECH M3*6 Ni

Cha pter 5

87

Page 96

XD1170D PROJECTION DISPLAY PROJECTOR

ASSY SYSTEM FAN 80x25 MODULE

Cha pter 5

88

Page 97

PART NUMBER LIST

Item P/N Description

1 DC.82V70G001 D.C. XD1170D

2 36.86B01G001 USER'S GUIDE MULTILINGUAL (CD) ACER PD127

3 42.87305G001 CABLE VGA 15P 1.8M BLK 2100MP

4 42.86502G002 ADAPTER D-SUB TRANSFORM RCA JACK PD120

5 45.82V01G101 INFRARED REMOTE CONTROLLER PD100 ACER

6 36.86B02G001 QUICK START CARD MULTILINGUAL ACER PD127

7 36.00006G031 WARRANTY CARD ,EUROPE FOR ACER

8 42.87205G001 CABLE COMPOSITE VIDEO 1.8M 3200MP

9 46.82U01G002 BATTERY #4 1.5V LR03 TDP-P8 (ACER)

10 42.87217G001 CABLE S-VHS 2M 3200MP

11 42.87215G001 CABLE MINI JACK TO MINI JACK 2M 3200MP

12 42.87304G001 CABLE USB(A) TO USB(B) 1.8M BLK 2100MP ; MOLEX

13 51.86213G001 PE BAG ZIPPER #9 W/RECYCLING MARK EzPro 736

14 53.82V02G001 SOFT CARRY BAG-2 PD120

15 70.82V29G001 ASSY LENS CAP MODULE PD120

16 35.86301G001 SPEC LABEL BLANK PD120

17 35.82V05G001 WARNING LABEL 30mm*40mm XD1270D

18 35.52302G091 LABEL CARTON 108*92 BLANK

19 51.80T48G001 PE BAG 450*350*0.07 (Recycle Mark)

20 57.00001G001 PACK SIO2 DRIER 20g

21 55.82V01G001 PAPER SUPPORT PD120

22 56.82V01G001 CUSHION-R EPE EP120

23 56.82V02G001 CUSHION-L EPE EP120

24 55.80N01G006 CARTON CARRY BOX PD120

25 55.80T01G011 CARTON ONTSIDR BOX PD523

26 35.82V02G001 LABEL CARTON(SEAL) 110*50mm PD120

27 42.50112G003

CABLE POWER CORD 1830mm SP-023+1S14 EUR

"ACER"

28 42.53506G002 CABLE POWER-CORD AC SP60+AS14 1.8M BLACK

29 42.83620G002 CABLE POWER CODE AC 6ft BLACK(SWITZERLAND)

Cha pter 5

88

Page 98

Appendix A

Ex ploded Overv iew

D.C. XD1270D

Chapter 5

89

Page 99

Item P/N Description

1 70.82V45G001 ASSY FRONT COVER MODULE XD1270D

2 70.82V63G001 ASSY TOP COVER MODULE-1 XD1270D

3 70.82V41G001 ASSY BOTTOM HOUSING MODULE XD1270D

4 70.82V61G001 ASSY LAMP MODULE XD1270D

5 70.82V48G001 ASSY BACK COVER MODULE XD1270D

6 75.82V09G011 BUY ASSY LAMP COVER MODULE XD1270D

7 85.1A323G100 SCREW PAN MECH M3*10 BLACK

8 85.005AGG040 SCREW I/O STEEL #4-4UNC*H4*L5

9 85.5A323G060 SCREW BIN MECH M3*6 BLACK

10 61.00079G001 GROUNDING CABLE CLAMP FN-008"GREEN"

11 61.00018G002 LOCK SCREW PAN MECH M3*8.5-3.5

12 51.00001G001 CABLE TIE PG-YJ-80

Chapter 5

90

Page 100

ASSY LVPS MODULE XD1270D

Item P/N Description

1 42.82V04G001 W.A. 14P/16P 190mm LVPS TO M/B XD1270D

2 42.81G01G001 W.A. 2P #20 160mm LAPS/BALLAST PD120

3 75.80W18G002 ASSY LVPS MATRITEK 200W EP719(CT2300-B)

Chapter 5

91

Loading...

Loading...