Page 1

Altos R700 Series

User’s guide

Page 2

Copyright © 2002 Acer Incorporated

All Rights Reserved.

Altos R700 Server Board

User’s guide

Original issue: December 2002

Changes may be made periodically to the information in this publication without obligation

to notify any person of such revision or changes. Such changes will be incorporated in new

editions of this manual or supplementary documents and publications. This company makes

no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims the implied warranties of merchantability or fitness for a

particular purpose.

Record the model number, serial number, purchase date, and place of purchase information in

the space provided below. The serial number and model number are recorded on the label

affixed to your computer. All correspondense concerning your unit should include the serial

number, model number, and purchase information.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopy, recording, or otherwise,

without the prior written permission of Acer Incorporated.

Model Number : _________________________________

Serial Number: ___________________________________

Purchase Date: ___________________________________

Place of Purchase: ________________________________

Acer and the Acer logo are registered trademarks of Acer Inc. Other company’s product

names or trademarks are used herein for identification purposes only and belong to their

respective companies.

Page 3

iii

Notices

FCC notice

Class A devices do not have an FCC logo or FCC IDE on the label. Class B devices

have an FCC logo or FCC IDE on the label. Once the class of the device is

determined, refer to the following corresponding statement.

Class A equipment

This device has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if not installed

and used in accordance with the instructions, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to

correct the interference at personal expense.

Class B equipment

This device has been tested and found to comply with the limits for a Class B

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This device generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this device does cause harmful interference to radio or television

reception, which can be determined by turning the device off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/television technician for help

Page 4

iv

Notice: Shield cables

All connections to other computing devices must be made using shielded cables

to maintain compliance with FCC regulations.

Notice: Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.) certified to

comply with the Class A or Class B limits may be attached to this equipment.

Operation with noncertified peripherals is likely to result in interference to

radio and TV reception.

Caution! Changes or modifications not expressly approved by

the manufacturer could void the user’s authority, which is granted

by the Federal Communications Commission, to operate this

server.

Use conditions

This part complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Notice: Canadian users

This Class A/Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Page 5

Important safety instructions

Read these instructions carefully. Save these instructions for future reference.

1 Follow all warnings and instructions marked on the product.

2 Unplug this product from the wall outlet before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

3 Do not use this product near water.

4 Do not place this product on an unstable cart, stand, or table. The product

may fall, causing serious damage to the product.

5 Slots and openings on the back or bottom side of the chassis are provided

for ventilation; to ensure reliable operation of the product and to protect

it from overheating, these openings must not be blocked or covered. The

openings should never be blocked by placing the product on a bed, sofa,

rug, or other similar surface. This product should never be placed near or

over a radiator or heat register, or in a built-in installation unless proper

ventilation is provided.

6 This product should be operated from the type of power indicated on the

marking label. If you are not sure of the type of power available, consult

your dealer or local power company.

7 Do not allow anything to rest on the power cord. Do not locate this

product where persons will walk on the cord.

8 If an extension cord is used with this product, make sure that the total

ampere rating of the equipment plugged into the extension cord does not

exceed the extension cord ampere rating. Also, make sure that the total

rating of all products plugged into the wall outlet does not exceed the fuse

rating.

9 Never push objects of any kind into this product through chassis slots as

they may touch dangerous voltage points or short out parts that could

result in a fire or electric shock. Never spill liquid of any kind on the

product.

10 Do not attempt to service this product yourself, as opening or removing

covers may expose you to dangerous voltage points or other risks. Refer all

servicing to qualified service personnel.

11 Unplug this product from the wall outlet and refer servicing to qualified

service personnel under the following conditions:

a When the power cord or plug is damaged or frayed

b If liquid has been spilled into the product

c If the product has been exposed to rain or water

v

Page 6

vi

d If the product does not operate normally when the operating

instructions are followed. Adjust only those controls that are covered

by the operating instructions since improper adjustment of other

controls may result in damage and will often require extensive work

by a qualified technician to restore the product to normal condition.

e If the product has been dropped or the cabinet has been damaged

f If the product exhibits a distinct change in performance, indicating a

need for service.

12 Replace the battery with the same type as the product's battery we

recommend. Use of another battery may present a risk of fire or explosion.

Refer battery replacement to a qualified service technician.

13 Warning! Batteries may explode if not handled properly. Do not

disassemble or dispose of them in fire. Keep them away from children and

dispose of used batteries promptly.

14 Use only the proper type of power supply cord set (provided in your

accessories box) for this unit. It should be a detachable type: UL listed/CSA

certified, type SPT-2, rated 7A 125V minimum, VDE approved or its

equivalent. Maximum length is 15 feet (4.6 meters).

Page 7

Notices iii

FCC notice iii

Important safety instructions v

1 Description 1

Server Board Features 2

Server Board Connector and

Component Locations 3

Back Panel Connectors 5

Processor 7

Memory 8

PCI Riser Slots 9

Video 10

SCSI Controller 11

Network Controller 12

NIC Connector and Status LEDs 12

System Cooling 13

Keyboard and Mouse 14

RJ-45 Serial Port 15

ACPI 17

System Management 18

Baseboard Management Controller 18

Field Replaceable Units and Sensor Data Records 18

System Event Log 19

Platform Event Management 19

Emergency Management Port 20

Acer Advance Server Management (ASMe) 21

Security 22

Intrusion Switch Monitoring 22

Software Locks 22

Using Passwords 22

Secure Mode 23

Summary of Software

Security Features 24

vii

2 Installation Procedures 27

Rearrange the Standoffs 28

Install the Server Board 29

Install the Processor Retention Brackets 30

Installing Processors 31

Memory 34

Connect Cables 35

Installing a Service Partition on the Server (Optional) 36

Page 8

viii

Installing your Operating System 36

Installing Acer Advance Server Management 36

3 Upgrading 39

Tools and Supplies Needed 40

Cautions 41

Replacing the Back up Battery 43

4 Configuration Software and Utilities 45

Service Partition (Optional) 47

Configuration Utilities 48

System Software Update Sequence 48

Hot Keys 50

Power-On Self-Test (POST) 51

BIOS Setup 52

If BIOS Setup Is Inaccessible 52

Temporarily Changing the Boot Device Priority 52

Running the Adaptec SCSISelect Utility 54

When to Run the Adaptec SCSISelect Utility 54

Running the SCSISelect Utility 54

Configuring the Adaptec SCSI Adapter 55

Direct Platform Control (DPC) Console 57

DPC Console Modes of Operation 57

Running the DPC Console 58

Using the System Setup Utility 59

Creating SSU Diskettes 59

Running the SSU 60

Setting Boot Device Priority 62

Setting Passwords and Security Options 62

Viewing the System Event Log 63

Viewing FRU Information 64

Viewing Sensor Data Records 65

Updating System Firmware and BIOS 65

Saving and Restoring the System Configuration 67

Alerting for Platform Events 68

Managing the Server Remotely 71

Software Updates 74

Creating a Bootable Diskette 74

Software Update Package 74

Recovering the BIOS 75

Firmware Update Utility Description 76

Running the Firmware Update Utility 76

FRU/SDR Load Utility Description 76

Page 9

5 Solving Problems 81

Resetting the System 82

Initial System Startup 83

Checklist 83

Running New Application Software 85

Checklist 85

After the System Has Been

Running Correctly 86

Checklist 86

More Problem Solving Procedures 87

Monitoring POST 87

Verifying Proper Operation of Key System Lights 87

Confirming Loading of the Operating System 88

Specific Problems and

Corrective Actions 89

Power Light Does Not Light 89

No Characters Appear on Screen 89

Characters Are Distorted or Incorrect 90

System Cooling Fans Do Not Rotate Properly 90

Diskette Drive Activity Light Does Not Light 91

CD-ROM Drive Activity Light Does Not Light 91

Problems with Application Software 92

Bootable CD-ROM Is Not Detected 92

Problems with Network 93

ix

6 Technical Reference 95

Server Board Jumpers 97

Diagnostic LEDs 99

POST Error Codes and Messages 108

BIOS Recovery Beep Codes 112

Bootblock Error Beep Codes 113

Appendix A: Equipment Log and

Power Consumption Worksheets 115

Equipment Log 116

Current Usage 118

Calculating Power Usage 118

Worksheet, Calculating DC Power Usage 118

Worksheet, Total Combined Power

Used by the System 120

Page 10

x

Page 11

1 Description

Page 12

2

1 Description

Server Board Features

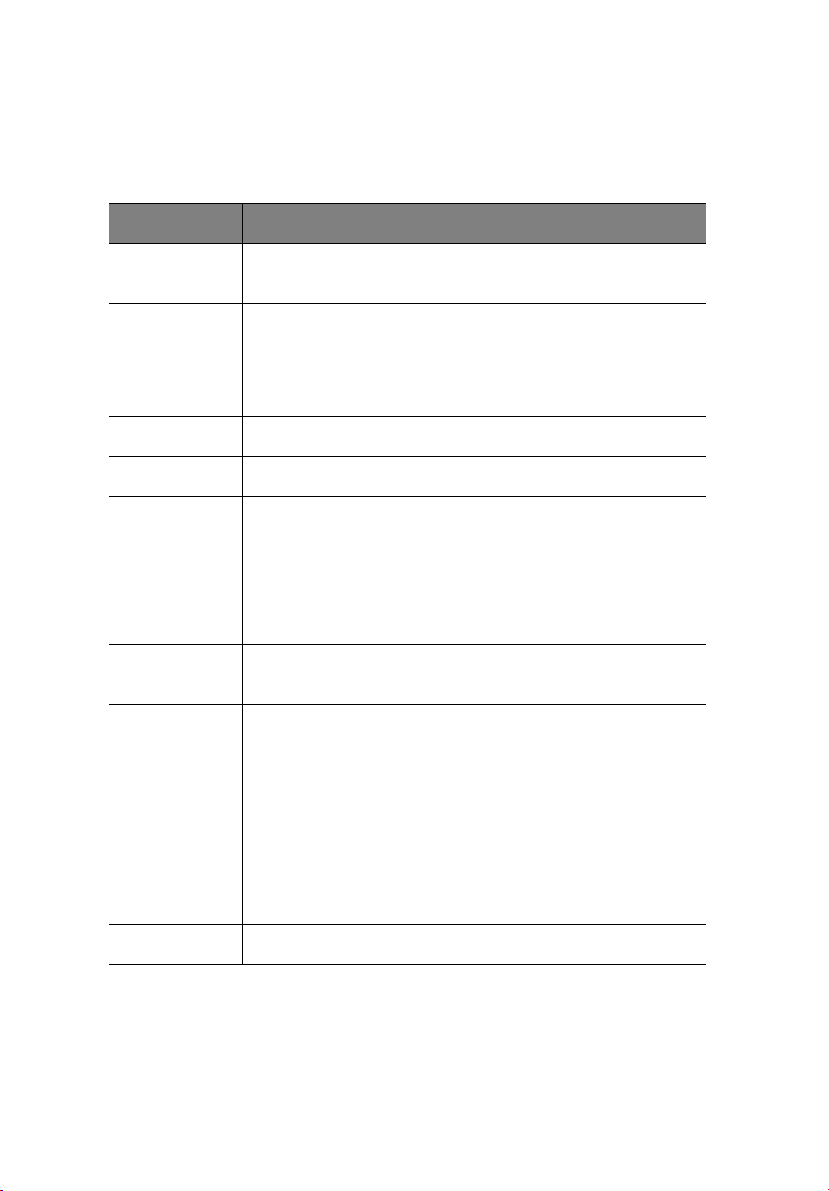

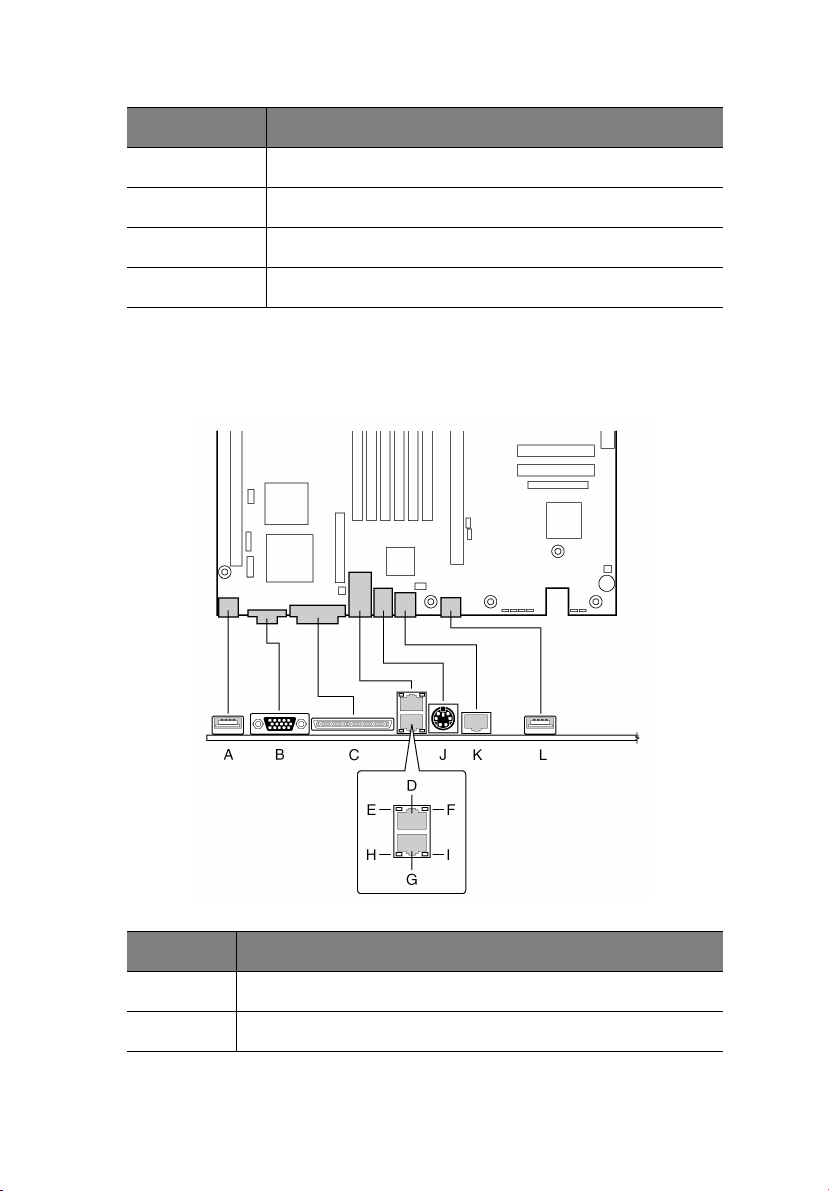

Table 1 Server Board Features

Feature Description

Processors Dual processor slots supporting Intel® Xeon™ processors

in an INT3/FCPGA Socket 604 package.

Memory Six dual inline memory module (DIMM) slots support:

• DDR-200 or DDR-266

168-pin, DIMMs

• From 256MB to 12 GB of memory

Graphics Integrated onboard ATI RAGE† XL PCI SVGA controller.

Video Memory 8 MB SDRAM of video memory.

PCI bus Two PCI riser slots capable of supporting either of the

following configurations:

• 1U configuration-one full-length, full-height 64-bit PCI

riser slot and one Low Profile (LP) 64-bit PCI riser slot.

• 2U configuration-three full-length, full-height 64-bit PCI

riser slots and three LP 64-bit PCI riser slots.

1

compliant, ECC, registered, 72-bit,

Network Dual on-board 10/100/1000 Network Interface Controllers

(NIC).

System I/O

(see Table 1)

Form Factor Server ATX form factor.

N lеду=aaoJOSS=бл=лмййзкнЙЗ=пбнЬ=RPPjeт=cкзен=pбЗЙ=_мл=Ecp_FK

aaoJOMM=зк=aaoJOSS=~кЙ=ДзнЬ=лмййзкнЙЗ=пбнЬ=QMMjeт=cp_K

One PS/2† keyboard/mouse port (6 pin DIN).

One VGA video port (15 pin).

Two external USB ports, internal header providing two

additional USB.

One external serial port (RJ-45), one internal COM 1

header.

One external SCSI port (SCSI server board only), one

internal.

Two NIC ports (RJ-45).

Page 13

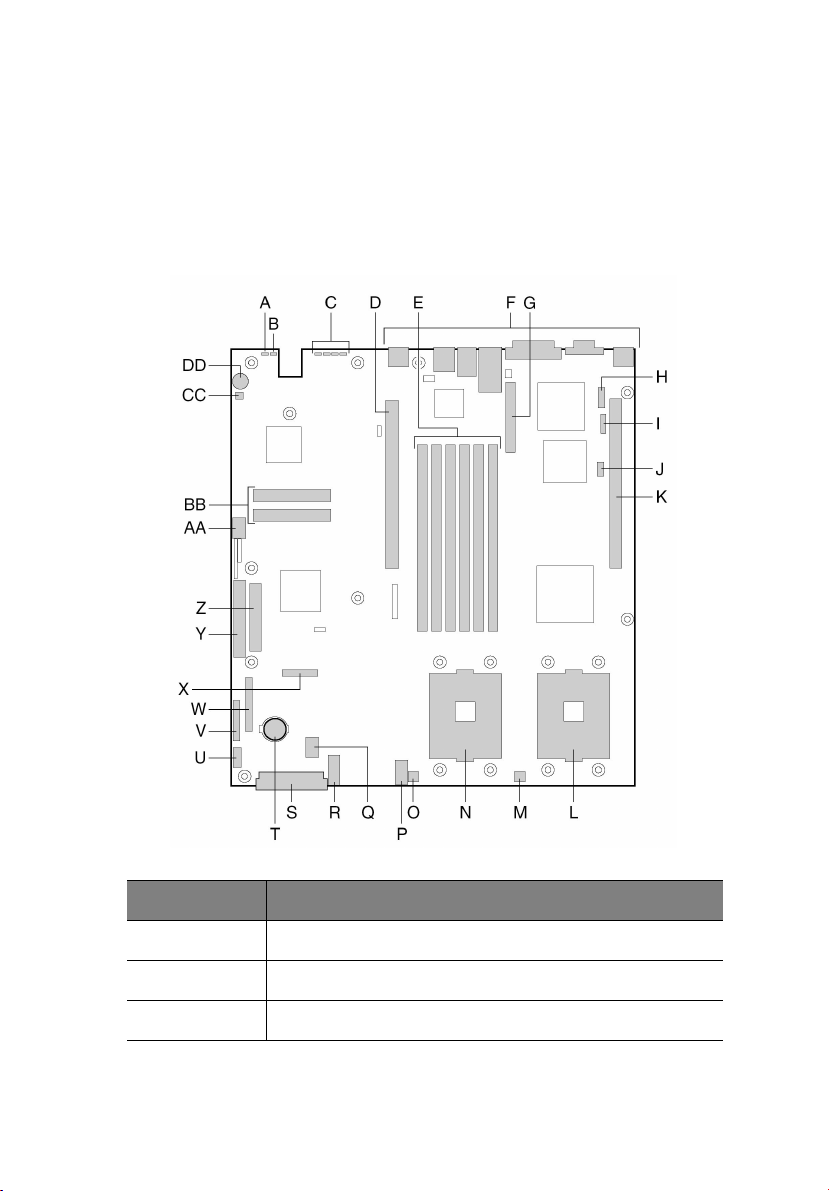

Server Board Connector and Component Locations

The Altos R700 Server Board comes only in SCSI version. Figure 1 is a

view of SCSI versions.

3

Label Description

A System status LED

B ID LED

C Diagnostic LEDs (POST code)

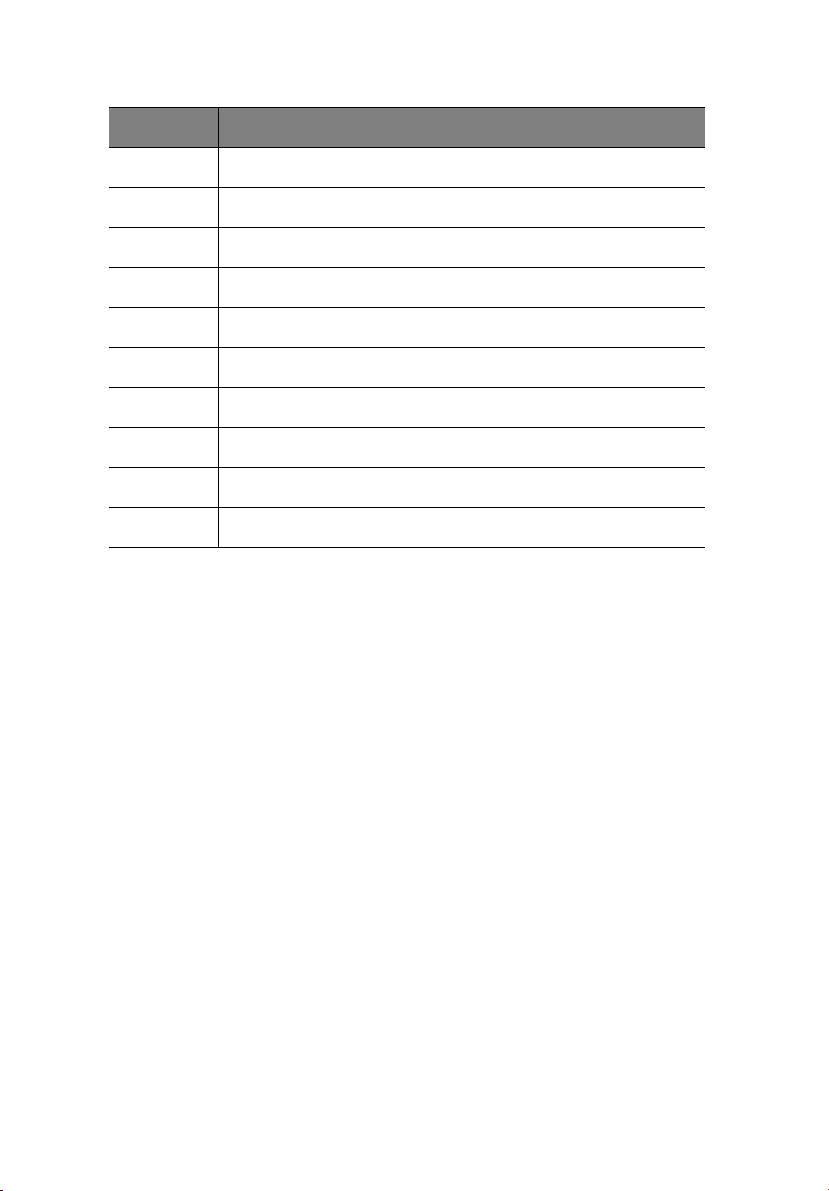

Page 14

4

Label Description

D 64-bit PCI riser slot for PCI-X bus B (full height)

EDIMM slots

F I/O ports

G SCSI channel B connector (SCSI version only)

H COM 1 serial header

I ICMB connector

J IPMB connector

K 64-bit PCI riser slot for PCI-X bus C (low profile)

L Secondary processor socket

M Secondary processor fan connector

N Primary processor socket

O Primary processor fan connector

1 Description

P Auxiliary signal connector

Q Sys fan 1 connector

R Sys fan 2 connector

S Main power connector

T Battery

U Power supply signal connector

V ATX front panel connector

W SSI front panel connector

X Floppy/FP/IDE connector

Y ATA/IDE connector

Z Floppy drive connector

Page 15

Label Description

AA USB 2 & 3 header

BB ATA-100 connectors (ATA version only)

CC Hard Disk Drive LED header

DD Speaker

Back Panel Connectors

5

Label Description

A USB 0 connector

B Video connector

Page 16

6

Label Description

C SCSI channel A connector (SCSI server board only)

D NIC 2 RJ-45 connector

E Status LED

F Speed LED

G NIC 1 RJ-45 connector

H Status LED

I Speed LED

J PS/2 keyboard/mouse connector

K RJ-45 serial port

L USB 1 connector

1 Description

Page 17

Processor

The Altos R700 server board accommodates one or two Intel Xeon

processors with 512k cache in the INT3/FCPGA Socket 604 package. This

processor uses the .13 micron technology.

7

Page 18

8

1 Description

Memory

The system board has six 168-pin DIMM slots each supporting 72-bit

ECC registered DDR DIMMs (DDR-200 or DDR-266 compatible). Memory

is partitioned in three banks. You may install a minimum of 256 MB

(128MB x 2) and as much as 12 GB. Memory must be installed in pairs,

starting with bank 1 (slots 1B and 1A).

The controller automatically detects, sizes, and initializes the memory

array, depending on the type, size, and speed of the installed DIMMs,

and reports memory size and allocation to the server via configuration

registers.

Note: Use DIMMs that have been tested for compatibility with the

server board. Contact your sales representative or dealer for a

current list of approved memory modules.

Page 19

PCI Riser Slots

The server board has two PCI riser slots. Riser slot B provides the

following features:

• 184 pin, 5 volt keyed, 64-bit expansion slot connector

• Support for either a 1-slot or a 3-slot PCI riser card

• Support for both full length and low profile PCI cards

Riser C provides the following features:

• 184 pin, 5 volt keyed, 64-bit expansion slot connector

• Support for either a 1-slot or a 3-slot PCI riser card

• Support for only low profile PCI cards

9

Page 20

10

1 Description

Video

The Altos R700 Server Board uses an ATI RAGE XL PCI graphics

accelerator with 8 MB of video SDRAM.

The embedded SVGA video subsystem supports:

• Resolutions up to 1600 x 1200 under 2D and 1024 x 768 under 3D

• CRT and LCD monitors up to 100 Hz vertical refresh rate

The server board supports disabling of the onboard video through the

BIOS setup menu or when a plug in video card is installed in any of the

PCI slots.

Page 21

11

SCSI Controller

The SCSI version of the server board includes an embedded Adaptec

AIC-7899W / 7902W controller providing dual Ultra160/Ultra 320* Low

Voltage Differential (LVD) SCSI channels.

The SCSI bus is terminated on the server board with active terminators

that cannot be disabled. The onboard device must always be at one

end of the bus. The device at the other end of the cable must also be

terminated. LVD devices generally do not have termination built-in and

need to have a termination source provided. Non-LVDs devices

generally are terminated through a jumper or resistor pack on the

device itself..

Note: Ultra 320 only for AIC-7902W

Page 22

12

1 Description

Network Controller

Note: To ensure EMC product regulation compliance, the system

must be used with a shielded LAN cable.

The server board uses the Intel® 82546EB Fast Ethernet Controller and

supports two 10Base-T/1000Base-TX network subsystems.

The 82546EB controller supports the following features:

• 32-bit PCI master interface

• Integrated IEEE 802.3 10Base-T, 100Base-TX and 1000Base-TX

compatible PHY†

• IEEE 820.3u auto-negotiation support

• Full duplex support at 10 Mbps, 100 Mbps, and 1000 Mbps

operation

• Low power +3.3 V device

On the Altos R700 Server Board, NIC 1 can be used as both a network

interface and server management interface.

NIC Connector and Status LEDs

The 82546 controller drives LEDs on the network interface connector

that indicate link/activity on the LAN and speed of operation. The

green LED indicates network connection when on and TX/RX activity

when blinking. The speed LED indicates 1000 Mbps when amber, 100

Mbps when green, and 10 Mbps when off.

Page 23

13

System Cooling

The chassis includes four 60-mm non-hot-swappable system fans for

cooling the processor(s), hard drives, and add-in cards. The system fans

are mounted in a fan module located in the middle of the chassis to

pull cooling air through the chassis. The power supply contains a single

fan for cooling.

Note: The noise emission is under 70 dB.

Page 24

14

1 Description

Keyboard and Mouse

The keyboard/mouse controller is PS/2-compatible. If specified through

the System Setup Utility (SSU), the server may be locked automatically

if there is no keyboard or mouse activity for a predefined length of

time. Once the inactivity (lockout) timer has expired, the keyboard and

mouse do not respond until the previously stored password is entered.

A Y-cable can be used if both a PS/2 mouse and keyboard are required

at the same time.

Page 25

15

RJ-45 Serial Port

The rear RJ-45 serial port is a fully functional serial port that supports

any standard serial device and provides support for serial

concentrators. For server applications that use a serial concentrator to

access the server management features of the baseboard, a standard 8pin CAT-5 cable from the serial concentrator is plugged directly into

the rear RJ-45 serial port. The 8 pins of the RJ-45 connector can be

configured to match either of two pin-out standards used by serial port

devices. To accommodate either standard, the J5A2 jumper block

located directly behind the rear RJ-45 serial port must be jumpered

appropriately according to the desired standard.

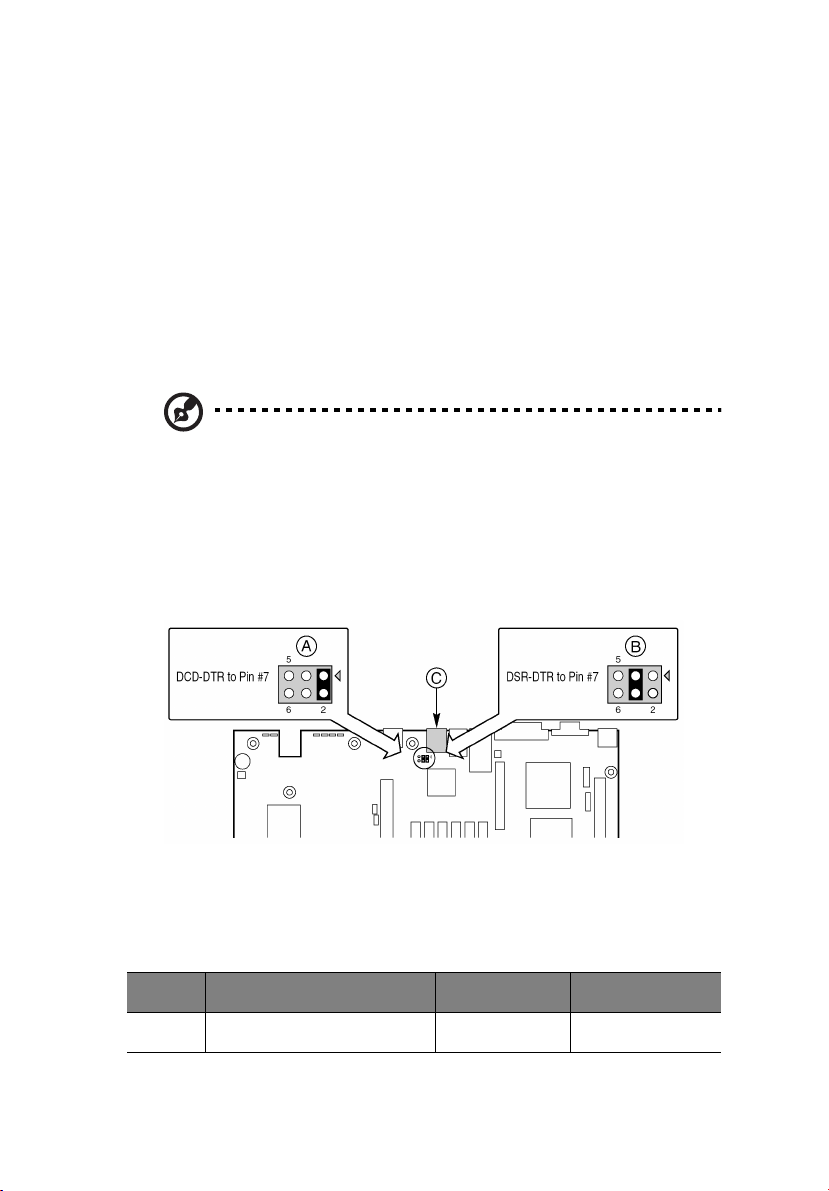

Note: By default, the RJ-45 serial port is configured to support a

DSR signal.

For serial devices that require a DSR signal (default), the J5A2 jumper

must be configured in position 3-4 (See figure below, B).

For serial devices that require a DCD signal, the jumper must be in

position 1-2 (See figure below, A).

For server applications that require a DB9 serial connector, you must

use an 8-pin RJ-45-to-DB9 adapter. The following table defines the pinout required for the adapters to provide RS232 support.

RJ-45 Signal Abbreviation DB9

1 Request to Send RTS 7

Page 26

16

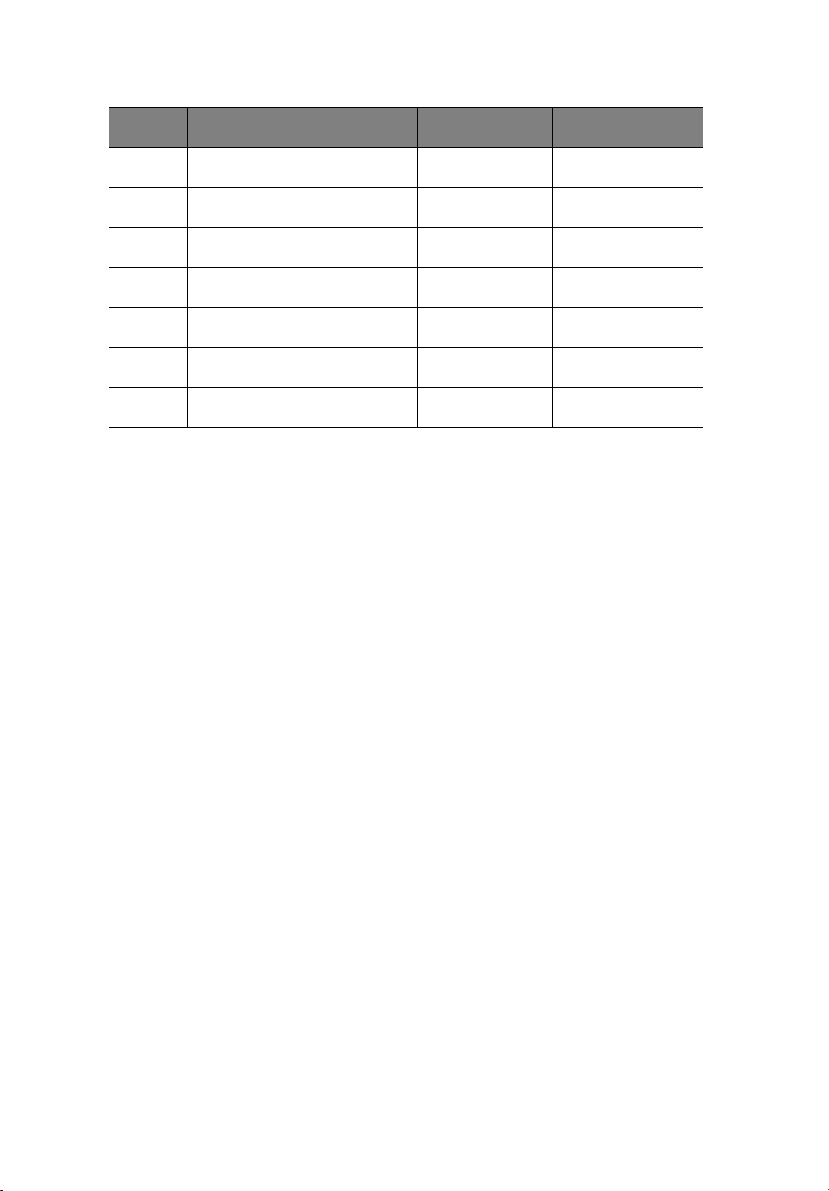

RJ-45 Signal Abbreviation DB9

2 Data Terminal Ready DTR 4

3 Transmitted Data TD 3

4 Signal Ground SGND 5

5 Ring Indicator RI 9

6 Received Data RD 2

7 DCD or DSR DCD/DSR 1 or 6

8 Clear to Send CTS 8

1 Description

Page 27

17

ACPI

The Altos R700 server board supports the Advanced Configuration and

Power Interface (ACPI) as defined by the ACPI 2.0 specification. An

ACPI aware operating system can put the system into a state where the

hard drives spin down, the system fans stop, and all processing is

halted. However, the power supply will still be on and the processors

will still be dissipating some power, so the power supply fans will still

run.

The Altos R700 server board supports sleep states s0, s1, s4, and s5:

• s0: Normal running state.

• s1: Processor sleep state. No context will be lost in this state and

the processor caches will maintain coherency.

• s4: Hibernate or Save to Disk: The memory and machine state are

saved to disk. Pressing the power button or other wakeup event

will restore the system state from the disk and resume normal

operation. This assumes that no hardware changes have been

made to the system while it was off.

• s5: Soft off: Only the RTC section of the CSB and the BMC are

running in this state. No context is saved by the OS or hardware.

Caution: The system is off only when the AC power cord is

disconnected.

Page 28

18

1 Description

System Management

ASMe integrates system management features into the hardware and

provides additional features through ASMe Server Management

software. This section describes the integrated hardware features, Acer

Advance Server Management software, and the System Setup Utility

and FRU/SDR Load Utility used to configure the hardware features.

Baseboard Management Controller

Acer server boards incorporate a baseboard management controller

(BMC), which is a dedicated microcontroller for system management

activities. The BMC performs the following functions:

• Monitors system components and sensors, including processors,

memory, fans, power supplies, temperature sensors, and chassis

intrusion sensors.

• Manages nonvolatile storage for the system event log (SEL), sensor

data records (SDRs), and baseboard field-replaceable unit (FRU)

inventory.

• Interfaces with the emergency management port (EMP) and LAN1

port to send alerts and interact with remote management systems.

• Provides the main front panel control functions (power on/off,

reset, and so on).

Field Replaceable Units and Sensor Data Records

Field replaceable units (FRUs) are major modules in the chassis that

contain active electronic circuitry. FRUs can store information-such as

board serial number, part number, name, and asset tag-that can be

read using the System Setup Utility (see “Viewing FRU Information” on

page 64). The BMC stores FRU information for the baseboard in a

nonvolatile storage component on the board.

The BMC uses Sensor Data Records (SDRs) to identify the sensors in the

system for monitoring. SDRs provide a list of the sensors, their

characteristics, location, type, and type-specific information, such as

default threshold values, factors for converting a sensor reading into

the appropriate units (mV, rpm, degrees Celsius), and information on

the types of events that a sensor can generate. The BMC stores SDR

information in a nonvolatile storage component on the baseboard.

Page 29

19

You can use the FRU/SDR Load Utility (see “FRU/SDR Load Utility

Description” on page 76) to initialize or update the FRU and SDR

information. Acer server boards are shipped from the factory with

some sensors disabled, because the actual configuration of the chassis

is only determined when the user completes the system configuration.

Chassis-specific information in the FRU, such as chassis part number, is

also absent. For these reasons, it is important to run the FRU/SDR Load

Utility as part of the system setup process. You should also run the FRU/

SDR Load Utility whenever you change the number of fans, processors,

or power supplies in the server.

System Event Log

The BMC manages a system event log (SEL), where it records significant

or critical system events. Such events include temperatures and events.

The BIOS, software, and other devices can also log events by sending

messages to the BMC. The SEL is stored in nonvolatile storage.

You can view the current contents of the SEL by using the System Setup

Utility (see “Viewing the System Event Log” on page 63).

Platform Event Management

Events can trigger alerts and other actions by the BMC. The server is

configured with the following set of standard events:

• Temperature sensor out of range

• Voltage sensor out of range

• Fan failure

• Chassis intrusion

• Power supply fault

• BIOS uncorrectable ECC error

• BIOS POST error

• Processor fault resilient booting (FRB) failure

• Fatal nonmaskable interrupt (NMI) from a source other than the

front panel switch

• Watchdog timer reset, power down, or power cycle

• System restart (reboot)

Alerts can take either of these forms:

Page 30

20

1 Description

• Platform event pages -- the BMC dials a paging service and

sends a predefined paging string. To use platform event paging

(PEP), you must attach an external modem to the emergency

management port (Serial 2).

• BMC LAN alerts -- the BMC sends an alert to a predefined

destination on the LAN.

You can configure PEP and BMC LAN alerts by using the System Setup

Utility (see “Alerting for Platform Events” on page 68).

Emergency Management Port

The emergency management port (EMP) refers to the use of the Serial

2 port, with either an external modem or direct serial connection, for

remote management. The BMC controls the port and interfaces with

remote access software, such as the Direct Platform Control application

in Acer Advance Server Management.

You can configure the EMP by using the System Setup Utility (SSU) or

the System Configuration Wizard (SCW).

EMP and Serial Over LAN

The RJ-45 Serial 2 port on the back panel can be configured in several

different ways: as a standard serial port, as an Emergency

Management Port, or for serial output redirection over a LAN. You can

configure these settings using either the SSU or the SCW.

Note:

Important Altos R700 Server Chassis considerations: If you

have configured the Serial 2 port for use as an Emergency

Management Port and “always available”, the Serial 2 port will be

accessible only by remote server management software. The

operating system will never be able to access the port.

If you have configured the Serial 2 port for Serial Over LAN, the

port’s functionality will only be impacted when there is an active

Serial Over LAN session from a remote console. At all other times

either the operating system or EMP will control the port,

depending on your configuration.

Page 31

21

Acer Advance Server Management (ASMe)

Acer Advance Server Management (ASMe) is a system management

package that is included on the ASMe CD. ASMe applications interact

with the integrated hardware system management features of the

server to allow you to monitor and manage a server from a remote

workstation:

• Remote connection from a Windows-based client workstation over

a LAN, or over a modem or direct serial connection to the

emergency management port on the server.

• Real-time monitoring and alerting for server hardware sensors.

• Emergency management when the server is off (but still connected

to AC power) lets you verify the state of the server, diagnose

hardware problems, and power on/off or reset the server.

• Run the System Setup Utility to change the server configuration.

ASMe can use an optional service partition on the server that you are

managing. The service partition is a special disk partition on the system

drive that contains a ROM-DOS operating system and DOS-based

utilities, including the System Setup Utility, FRU/SDR Load Utility, and

Remote Diagnostics. The server can be booted to the service partition,

either locally or remotely, to provide access to the utilities.

For more information on Acer Advance Server Management and the

individual ASMe applications, see the ASMe CD.

Page 32

22

1 Description

Security

Intrusion Switch Monitoring

To help prevent unauthorized entry or use of the server, Acer Advance

Server Management server management software monitors the chassis

intrusion switch if one is installed. Opening an access cover will

transmit an alarm signal to the server board, where BMC firmware and

server management software process the signal. The system can be

configured through ASMe to respond to an intrusion a number of

ways, including powering down or locking the keyboard.

Software Locks

The BIOS Setup and the System Setup Utility (SSU) provide a number of

security features to prevent unauthorized or accidental access to the

system. Once the security measures are enabled, you can access the

system only after you enter the correct password(s). For example:

• Enable the keyboard lockout timer so that the server requires a

password to reactivate the keyboard and mouse after a specified

time out period¾1 to 120 minutes.

• Set and enable a supervisor password.

• Set and enable a user password.

• Set secure mode to prevent keyboard or mouse input and to

prevent use of the front panel reset and power switches.

• Activate a hot key combination to enter secure mode quickly.

• Disable writing to the diskette drive when secure mode is set.

• Disable access to the boot sector of the operating system hard disk

drive.

Using Passwords

You can set either the user password, the supervisor password, or both

passwords. If only the user password is set, you:

• Must enter the user password to enter BIOS Setup or the SSU.

• Must enter the user password to boot the server if Password on

Boot is enabled in either the BIOS Setup or SSU.

Page 33

23

• Must enter the user password to exit secure mode.

If only the supervisor password is set, you:

• Must enter the supervisor password to enter BIOS Setup or the

SSU.

• Must enter the supervisor password to boot the server if Password

on Boot is enabled in either the BIOS Setup or SSU.

• Must enter the supervisor password to exit secure mode.

If both passwords are set, you:

• May enter the user password to enter BIOS Setup or the SSU.

However, you will not be able to change many of the options.

• Must enter the supervisor password if you want to enter BIOS

Setup or the SSU and have access to all of the options.

• May enter either password to boot the server if Password on Boot

is enabled in either the BIOS Setup or SSU.

• May enter either password to exit secure mode.

Secure Mode

Configure and enable the secure boot mode by using the SSU. When

secure mode is in effect:

• You can boot the server and the operating system will run, but you

must enter the user password to use the keyboard or mouse.

• You cannot turn off system power or reset the server from the

front panel switches.

Secure mode has no effect on functions enabled via remote server

management or power control via the watchdog timer.

Taking the server out of secure mode does not change the state of

system power. That is, if you press and release the power switch while

secure mode is in effect, the system will not be powered off when

secure mode is later removed. However, if the front panel power

switch remains depressed when secure mode is removed, the server

will be powered off.

Page 34

24

1 Description

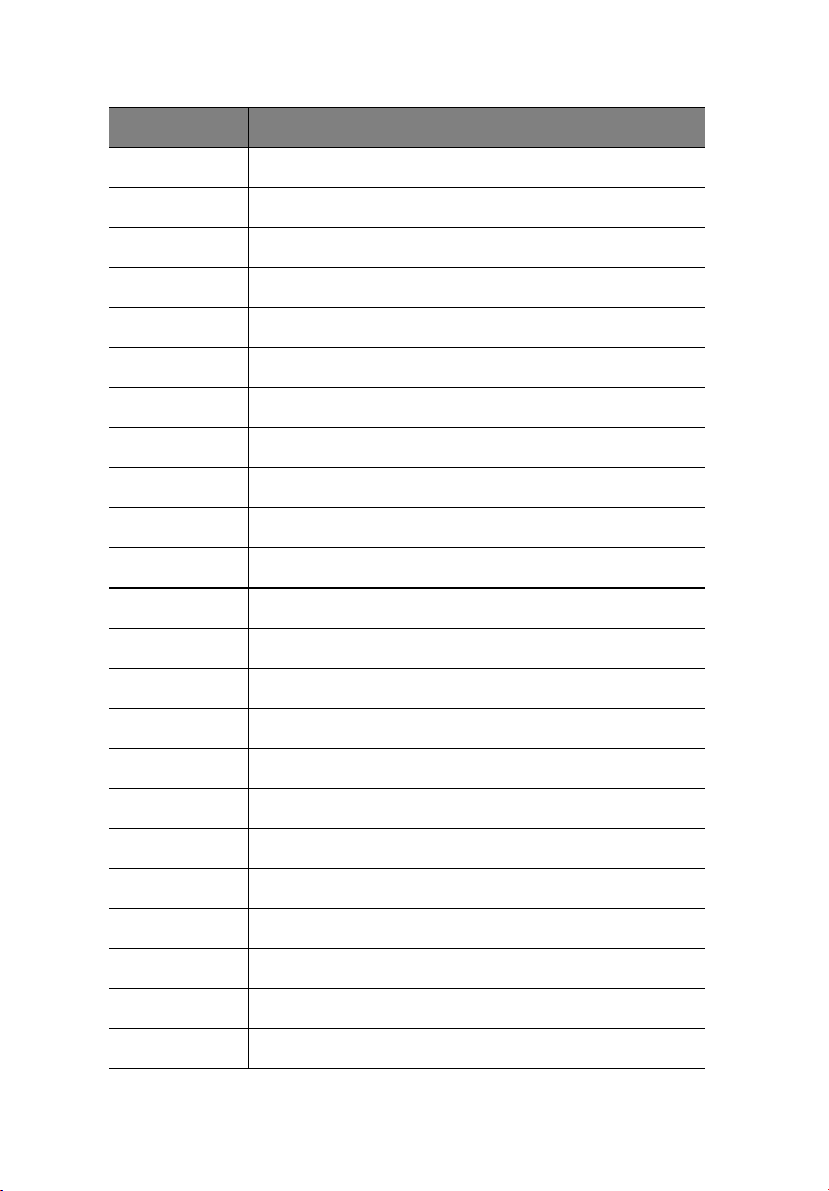

Summary of Software Security Features

The table below lists the software security features and describes what

protection each offers. In general, to enable or set the features listed

here, you must run the SSU and go to the Security Subsystem Group,

menu. The table also refers to other SSU menus and to the Setup

utility.

Feature Description

Secure Mode How to enter secure mode:

• Setting and enabling passwords automatically

places the system in secure mode.

• If you set a hot-key combination (through

Setup), you can secure the system simply by

pressing the key combination. This means you

do not have to wait for the inactivity time-out

period.

When the system is in secure mode:

• The server can boot and run the operating

system, but mouse and keyboard input is not

accepted until the user password is entered.

• At boot time, if a CD is detected in the CDROM drive or a diskette in drive A, the system

prompts for a password. When the password is

entered, the server boots from CD or diskette

and disables the secure mode.

• If there is no CD in the CD-ROM drive or

diskette in drive A, the server boots from drive

C and automatically goes into secure mode. All

enabled secure mode features go into effect at

boot time.

To leave secure mode: Enter the correct

password(s).

Disable writing to

diskette

In secure mode, the server will not boot from or

write to a diskette unless a password is entered.

To write protect access to diskette whether the

server is in secure mode or not, use the Setup

main menu, Floppy Options, and specify Floppy

Access as read only.

Page 35

Feature Description

25

Set a time out period so

that keyboard and

mouse input are not

accepted

Also, screen can be

blanked, and writes to

diskette can be

inhibited

Control access to using

the SSU: set supervisor

password

Control access to the

system other than SSU:

set user password

Specify and enable an inactivity time out period

of from 1 to 120 minutes.

If no keyboard or mouse action occurs for the

specified period, attempted keyboard and mouse

input will not be accepted.

The monitor display will go blank, and the

diskette drive will be write protected (if these

security features are enabled through Setup).

To resume activity: Enter the correct password(s).

To control access to setting or changing the

system configuration, set a supervisor password

and enable it through Setup.

If both the supervisor and user passwords are

enabled, either can be used to boot the server or

enable the keyboard and/or mouse, but only the

supervisor password will allow Setup to be

changed.

To disable a password, change it to a blank entry

or press CTRL-D in the Change Password menu of

the Supervisor Password Option menu found in

the Security Subsystem Group.

To clear the password if you cannot access Setup,

change the Clear Password jumper (see “6

Technical Reference” on page 95).

To control access to using the system, set a user

password and enable it through Setup.

To disable a password, change it to a blank entry

or press CTRL-D in the Change Password menu of

the User Password Option menu found in the

Security Subsystem Group.

To clear the password if you cannot access Setup,

change the Clear Password jumper (see “6

Technical Reference” on page 95).

Boot without keyboard The system can boot with or without a keyboard.

During POST, before the system completes the

boot sequence, the BIOS automatically detects

and tests the keyboard if it is present and displays

a message.

Page 36

26

Feature Description

1 Description

Specify the boot

sequence

The sequence that you specify in setup will

determine the boot order. If secure mode is

enabled (a user password is set), then you will be

prompted for a password before the server fully

boots. If secure mode is enabled and the “Secure

Boot Mode” option is also enabled, the server will

fully boot but will require a password before

accepting any keyboard or mouse input.

Page 37

2 Installation

Procedures

Page 38

28

2 Installation Procedures

Rearrange the Standoffs

If your chassis does not have board mount standoffs placed as shown,

you must rearrange them so they match the holes in the server board.

Failure to properly rearrange the metal standoffs may cause the server

board to malfunction and may permanently damage it. Your chassis

may be different from the illustration.

Page 39

29

Install the Server Board

To ensure proper grounding and support, it is recommended that you

install screws in all the required mounting holes for your chassis. You

may need to move cables out of the way to properly install your server

board.

1 While placing the board on the chassis standoffs, carefully position

the board I/O connectors into the rear chassis I/O openings.

2 Adjust board position to align mounting holes with standoffs.

3 Using the screws that came with your chassis, mount the board to

the chassis.

Note: If you install the server board into an Altos R700 chassis,

you will not use all of the mounting holes. See your chassis

documentation for more details.

Page 40

30

2 Installation Procedures

Install the Processor Retention Brackets

There are four brackets, two for each processor socket. For each

bracket, do the following:

1 Place the bracket (A) on the server board.

2 Insert and tighten two screws (B) to secure the bracket.

Page 41

Installing Processors

1 Raise the locking bar on the socket.

2 Aligning the pins of the processor with the socket, insert the

processor into the socket.

31

Page 42

32

2 Installation Procedures

3 Lower the locking bar completely.

4 Follow the instructions packaged with your boxed processor for

preparing the heat sink and processor for installation.

5 Position the heat sink above the processor.

6 Aligning the raised metal surfaces, place the heat sink on top of

the processor.

7 Place the heat sink clip (1) so the tab on the clip engages the slot

on the heat sink (A).

Page 43

8 Press one end of the clip down (2).

9 Press the other end of the clip down (3).

33

Page 44

34

2 Installation Procedures

Memory

Only DDR-200 or DDR-266 compliant SDRAM is supported by the server

board. Install from 256 MB to 12 GB of registered, ECC memory, using

up to six DIMMs. A 1U chassis requires lowprofile (LP) 1.2-inch DIMMs.

DIMMs must be installed in pairs and in the following order: 1B and

1A, 2B and 2A, 3B and 3A.

Installed DIMMs must be the same speed and must all be registered.

Page 45

Connect Cables

Before connecting cables, consult the documentation supplied with

your chassis.

35

Label Description

A External SCSI channel A connector (SCSI server board only)

B Internal SCSI channel B connector (SCSI server board only)

C Serial 1 header

D Combined Floppy/Front Panel/IDE connector (For use in an Altos

chassis only)

E Fan module connector

F Fan module connector

G Processor fan connectors (For use in a non Altos chassis only)

H Auxiliary power connector

Page 46

36

Label Description

I Main power connector

J Power supply signal connector

K Front panel connector (For use in a non Altos chassis only)

L Floppy connector (For use in a non Altos chassis only)

M IDE connector (For use in a non Altos chassis only)

N USB header

O ATA-100 primary/secondary connectors (ATA server board only)

2 Installation Procedures

Installing a Service Partition on the Server (Optional)

The Service Partition provides advanced remote management and

configuration functionality. Installing it on a server is optional.

1 Power-on the server, insert the Acer Advance Server Management

CD into the CD-ROM drive, and boot to the CD.

2Select Utilities > Run Service Partition Administrator > Create

Service Partition-first time.

3 Select an available hard drive. The server will reboot to the CD.

4Select Format Service Partition and Install Software.

5 Exit the menu. Remove the CD and reboot to install the server

operating system. After installing the operating system, proceed

to Acer Advance Server Management Installation.

Installing your Operating System

Install your operating system now.

Installing Acer Advance Server Management

You can install Acer Advance Server Management on a local server or

on a remote workstation that is used to manage a LAN/WAN.

Page 47

1 Insert the Acer Advance Server Management CD into the system’s

CD-ROM.

2 Click Install Server Management.

3 Select the applicable system option.

4 Review the Acer Software License Agreement and click Accept.

5 If installing to a local server, click Install Now. If this is a multiple

system installation, click Add to compile a list of systems and then

click Install Now.

6Select Reboot Now or Reboot Later.

7 Remove the Acer Advance Server Management CD.

37

Page 48

38

2 Installation Procedures

Page 49

3 Upgrading

Page 50

40

3 Upgrading

Tools and Supplies Needed

• Jumper removal tool or needle nosed pliers

• Phillips† (cross head) screwdriver (#1 bit and #2 bit)

• Pen or pencil

• Antistatic wrist strap and conductive foam pad (recommended)

Page 51

Cautions

These warnings and cautions apply throughout this chapter. Only a

technically qualified person should configure the server board.

Cautions:

System power on/off: The power button DOES NOT completely

turn off the system AC power, 5V standby is still active whenever

the system is plugged in. To remove power from system, you must

unplug the AC power cord from the wall outlet. Make sure the AC

power cord is unplugged before you open the chassis, add, or

remove any components.

Hazardous conditions, devices & cables: Hazardous electrical

conditions may be present on power, telephone, and

communication cables. Turn off the server and disconnect the

power cord, telecommunications systems, networks, and modems

attached to the server before opening it. Otherwise, personal

injury or equipment damage can result.

Electrostatic discharge (ESD) & ESD protection: ESD can

damage disk drives, boards, and other parts. We recommend that

you perform all procedures in this chapter only at an ESD

workstation. If one is not available, provide some ESD protection

by wearing an antistatic wrist strap attached to chassis ground

(any unpainted metal surface) on your server when handling

parts.

41

ESD and handling boards: Always handle boards carefully. They

can be extremely sensitive to ESD. Hold boards only by their

edges. After removing a board from its protective wrapper or

from the server, place the board component side up on a

grounded, static free surface. Use a conductive foam pad if

available but not the board wrapper. Do not slide board over any

surface.

Installing or removing jumpers: A jumper is a small plastic

encased conductor that slips over two jumper pins. Some jumpers

have a small tab on top that you can grip with your fingertips or

with a pair of fine needle nosed pliers. If your jumpers do not

have such a tab, take care when using needle nosed pliers to

Page 52

42

3 Upgrading

remove or install a jumper; grip the narrow sides of the jumper

with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent

problems with the function controlled by that jumper. Take care

to grip with, but not squeeze, the pliers or other tool you use to

remove a jumper, or you may bend or break the stake pins on the

board.

Page 53

43

Replacing the Back up Battery

The lithium battery on the server board powers the real time clock

(RTC) in the absence of AC power. When the battery starts to weaken,

it loses voltage, and the server settings stored in CMOS RAM in the RTC

(for example, the date and time) may be wrong. Contact your customer

service representative or dealer for a list of approved devices.

To replace the battery:

1 Before proceeding, record your custom BIOS settings.

2 Observe the safety and ESD precautions at the beginning of this

chapter.

3 Open the chassis and locate the battery.

4 Push the upper end of the metal retainer away from the battery-

the battery pops up.

5 Remove the battery from its socket.

6 Dispose of the battery according to local ordinance.

7 Remove the new lithium battery from its package.

8 Being careful to observe the correct polarity, lay the battery in the

socket.

9 Push the battery down-the metal retainer locks the battery in the

socket.

10 Close the chassis.

11 Run Setup to restore the configuration settings to the RTC.

12 Restore your custom BIOS settings.

Page 54

44

3 Upgrading

Page 55

4 Configuration

Software

Utilities

and

Page 56

46

4 Configuration Software and Utilities

Page 57

Service Partition (Optional)

When you are setting up your server system, you can install a service

partition onto your hard drive. The service partition includes utilities,

and other software that be run locally or remotely to assist in system

management. The service partition uses approximately 40 MB of hard

disk space.

Note: It is highly recommended that you install the service

partition before installing an operating system. For more

information, see the Service Partition section in the Installation

Guide for Acer Advance Server Management. This document is

included on the ASMe CD shipped with your server board.

47

Page 58

48

4 Configuration Software and Utilities

Configuration Utilities

System Software Update Sequence

When you update the system software, you should do it in the

following order.

1 Update firmware (BMC & HSC)

2Update FRU/SDR

3 Unplug system for 30 seconds

4Update BIOS

5 Clear CMOS

Configuration Utilities Table:

Utility Description and brief procedure Page

Adaptec SCSISelect

Utility

Direct Platform

Control (DPC) Console

System Setup Utility

(SSU) and Client

System Setup Utility

(CSSU)

BIOS Update Utility Use to update the BIOS or recover from a

Use to configure or view the settings of

the SCSI host adapters and onboard SCSI

devices in the system.

Use to access and monitor the server

remotely.

Use for viewing and configuring server

management options, viewing the

system event log (SEL), setting boot

device priority, or setting system security

options.

The SSU can run either from the

configuration software CD or from a set

of bootable diskettes. You can create the

diskettes from the CD.

The CSSU is run from the service

partition via the DPC console. It provides

the same functionality as the SSU, but

from a remote console.

Information entered via the SSU/CSSU

overrides information entered via BIOS

Setup.

corrupted BIOS update.

54

57

59

65, 75

Page 59

Utility Description and brief procedure Page

49

Firmware Update

Utility

FRU/SDR Load Utility Use to update the Field Replaceable Unit

Use to update BMC flash ROM or other

firmware.

(FRU) and Sensor Data Record (SDR) flash

components.

NOTE: You must run the FRU/SDR Load

utility whenever the BMC is updated or if

you change your processors.

76

76

Page 60

50

4 Configuration Software and Utilities

Hot Keys

Use the numeric pad of the keyboard to enter numbers and symbols.

To Do T h i s : Press These Keys

Secure your system immediately. <Ctrl+Alt>+hot key (Set your hot key

combination with the SSU or BIOS

Setup)

Enter the Adaptec SCSI Utility

during POST.

Enter BIOS Setup during POST. <F2>

Abort memory test during POST. <ESC> (Press while BIOS is updating

Display a menu for selecting the

boot device.

To remove the splash screen. <ESC>

<Ctrl+A> (SCSI version only)

memory size on screen)

<ESC> (Press anytime after memory

check)

Page 61

51

Power-On Self-Test (POST)

Each time you turn on the system the BIOS begins execution of the

Power-On Self-Test (POST). POST discovers, configures, and tests the

processors, memory, keyboard, and most installed peripheral devices.

The time needed to test memory depends on the amount of memory

installed. POST is stored in flash memory.

1 Turn on your video monitor and system. After a few seconds, POST

begins to run and displays a splash screen.

2 While the splash screen is displayed:

• Press <F2> to enter the BIOS Setup (see “BIOS Setup”)

OR

• Press <Esc> to view POST diagnostic messages and change the

boot device priority for this boot only (see “Temporarily

Changing the Boot Device Priority” on page 52).

3 After pressing <F2> or <Esc> during POST, you can press <Ctrl+A>

to run the SCSISelect Utility. For more information, see“Running

the Adaptec SCSISelect Utility” on page 54.

4 If you do not press <F2> or <Esc> and do NOT have a device with

an operating system loaded, the boot process continues and the

system beeps once. The following message is displayed:

“Operating System not found”

5 At this time, pressing any key causes the system to attempt a

reboot. The system searches all removable devices in the order

defined by the boot priority.

Page 62

52

4 Configuration Software and Utilities

BIOS Setup

You can run BIOS Setup with or without an operating system being

present. BIOS Setup stores most of the configuration values in batterybacked CMOS; the rest of the values are stored in flash memory. The

values take effect when the system is booted. POST uses these values to

configure the hardware. If the values and the actual hardware do not

agree, POST generates an error message.

Record BIOS Setup Settings

Record your BIOS Setup settings. If default values ever need restoring

(after a CMOS clear, for example), you must run BIOS Setup again. Your

record will make this much easier.

If BIOS Setup Is Inaccessible

If you have a misconfigured diskette drive, and you cannot use BIOS

Setup to correct the problem, you might need to clear CMOS memory.

To clear CMOS, either of two methods can be used.

1 Press the reset button and hold it down for four seconds or more,

and then, while holding the reset button down, press the power

button. Release both buttons at the same time.

2 Move the Clear CMOS jumper found on the configuration jumper

block on the baseboard.

Temporarily Changing the Boot Device Priority

During POST, you can change the boot device priority for the current

boot process. The changes are not saved for the next boot process.

1 Boot the server.

2 At any time during POST, press <Esc>. When POST completes, a

popup Boot menu displays.

3 Use the arrow keys to highlight the device you want the server

system to boot from first. For example, if you want the server

system to boot from the CD-ROM first, you select “ATAPI CD-ROM

Drive.”

Note: One of the selections on the popup Boot menu is “Enter

Setup.” Selecting this option brings you into the BIOS Setup.

Page 63

4Press <Enter>.

5 The boot process continues. When finished, a system prompt

displays.

53

Page 64

54

4 Configuration Software and Utilities

Running the Adaptec SCSISelect Utility

Each host adapter includes an onboard SCSISelect configuration utility

that allows you to configure/view the settings of the host adapter and

devices in the server.

The system finds the Adaptec SCSI host adapter and displays the

message Adaptec SCSI BIOS V x.xxx where x.xxx is the version number

of the SCSISelect utility.

Pressing <Ctrl+A> at this time allows you to configure the Adaptec AIC7XXX SCSI host adapter.

When to Run the Adaptec SCSISelect Utility

Use the SCSISelect utility to:

• Change default values

• Check and/or change SCSI device settings that may conflict with

those of other devices in the server

• Do a low-level format on SCSI devices installed in the server

Running the SCSISelect Utility

1 When this message appears on the video monitor:

<<<Press <Ctrl><A> for SCSISelect(TM) Utility!>>>

2 Press <Ctrl+A> to run the utility. When the main menu for the host

adapter appears, choose the device that you want to configureeach SCSI bus accepts up to 15 devices.

Use the following keys to navigate through the menus and submenus:

Press To

ESC Exit the utility

Enter Select an option

↑ Return to previous option

↓ Move to the next option

Page 65

Press To

F5 Switch between color and

monochrome

F6 Reset to host adapter defaults

Configuring the Adaptec SCSI Adapter

The Adaptec SCSI adapter has two busses. Select the bus from the

following menu:

Menu Item Options

55

You have an adapter in your system.

Move the cursor to the bus:device:channel of

the one for configuration and press Enter.

<F5> - Toggle color/monochrome.

Bus:Device:Channel

01:06:A

01:06:B

After selecting the bus, the following menu displays:

Host Adapter Option Comment

AIC-7XXX at

Bus:Device:Channel

01:06:A (or 01:06:B)

Configure/View

Host Adapter

Settings

SCSI Distk

Utilities

Press Enter to view the

Configuration Menu.

Press Enter to view the SCSI Disk

Utilities Menu. This menu allows

you to format hard disks and/or

verify disk media.

Page 66

56

4 Configuration Software and Utilities

When you are finished, press Esc> and make your selection from the

following menu:

Feature Option Comment

Exit Utility? Yes

No

When you finish configuring your SCSI

devices, press Esc. Then select Yes and press

Enter. When this message appears:

Please press any key to reboot.

Press any key, and the server reboots.

Page 67

57

Direct Platform Control (DPC) Console

Direct Platform Control (DPC) Console is part of Acer Advance Server

Management. Direct Platform Control is a server management

application that supports remote system management via LAN, or an

RS-232 serial connection to the server serial 2 port over a modem or a

direct serial cable. The Direct Platform Control Console provides the

ability for remote management of Acer servers via modem or LAN with

a capability to run DOS-based programs.

DPC console runs on a client workstation. It communicates with a

server by:

• Accessing the server management capabilities of the on-board NIC

• A Windows 2000 compatible modem.

• An RS-232 connection to the server’s serial 2 port.

DPC Console is independent of the server operating system.

Even when the server is off, you can use DPC Console to verify the state

of a server or diagnose a problem with the server hardware. DPC

console features allows you to:

• Establish connection to remote servers

• Server Control: power on, power off, and reset operations

• Retrieve and display entries in the System Event Log (SEL)

• Retrieve and display Sensor Data Records (SDR)

• Retrieve and display Field Replaceable Unit (FRU) information

• Retrieve and display current Remote Sensor Access (RSA)

information

• Access a phone book for remote connection management

• Remote control of the service partition

• File transfer from / to the server

DPC Console Modes of Operation

There are four DPC console modes of operation:

• EMP mode. Access the DPC console features using the DPC console

window menus and/or toolbar. Active when a connection is

established through the EMP port.

Page 68

58

• DPC over LAN mode. Access the DPC console features using the

DPC console window menus and/or toolbar. Active when a

connection is established through the LAN.

• Re-direct mode. Active when the server is running BIOS console

redirection. In this mode, the DPC console launches a separate

window. The window operates as an ANSI terminal and

communicates with the server through the port. Character-based

commands you type in the DPC Console go directly to the server,

and the DPC Console displays the text that you would normally see

on the server console.

To use this mode, you must configure the Console Redirection

option of BIOS Setup for Redirect mode. Enabling Console

Redirection requires that the Boot Time Diagnostics Screen be

Enabled in BIOS Setup. If the redirection window does not display

information, the Console Redirection is either incorrectly

configured or disabled, the EMP is disabled in BIOS Setup, or the

server is in protected mode. For DPC to function, the server must

NOT be in graphics mode.

• If the DPC console fails to connect in EMP within 10 seconds and

the server can operate in Redirect mode, a prompt is displayed

with the option to switch to Re-direct mode.

• Service Partition mode. Entered when the server reboots from the

service partition and the DPC Console has successfully connected to

the server through a modem. This mode allows running of DOSbased programs that are stored on the service partition and

transferring of files.

4 Configuration Software and Utilities

Running the DPC Console

For more information about setting up and running the DPC Console,

see the document named “ASMe_Install_Guide.pdf.” This document is

in the ASMe\DOCS directory on the ASMe CD accompanying the Altos

R700 server board.

Page 69

59

Using the System Setup Utility

The System Setup Utility (SSU) is located on the System Resource CDROM shipped with the server.

Run the System Setup Utility to:

• Set boot device priority

• Set passwords and security options

• View system events

• View FRU information

• View sensor data records

• Update system firmware and BIOS

• Save and restore the system configuration

• Set up the server to send alerts for platform events

• Set up the server for remote management

Using either the System Setup Utility or BIOS Setup, you can specify the

boot device sequence and set up system passwords and security

options. Both utilities access the same stored configuration data for

these items, and the result of making a change to these settings using

either utility is identical.

The SSU consists of a collection of task-oriented modules plugged into

a common framework called the Application Framework (AF). The

Application Framework provides a launching point for individual tasks

and a location for setting customization information.

Creating SSU Diskettes

You can run the SSU directly from the Utilities menu of the System

Resource CD-ROM, from a set of DOS diskettes, or from the service

partition of the hard disk.

If you choose to run the SSU from a set of DOS diskettes, you must

create the SSU diskettes from the Resource CD-ROM as follows:

1 Boot to the System Resource CD-ROM.

2 Choose Create Diskettes > Create Diskettes by Device/Function >

System Setup Utility.

3 Follow the instructions displayed.

Page 70

60

Alternatively, if you have a workstation with the Microsoft Windows

operating system, you can insert the CD into that system and create the

diskettes on that system.

4 Configuration Software and Utilities

Running the SSU

When the SSU starts in the default local execution mode, the SSU

accepts input from the keyboard or mouse. The SSU presents a VGAbased GUI on the primary monitor.

If you run the SSU from read-only media, such as the CD-ROM, you

cannot save user preference settings (such as screen colors).

The SSU supports ROM-DOS version 6.22. The SSU will not operate

from a “DOS box” running under an operating system such as

Windows.

Start the SSU using one of the following methods:

• From diskettes: Insert the first SSU diskette in drive A and boot the

server from the diskette.

You are prompted to insert the second diskette. After loading

completes the SSU starts automatically.

• From the System Resource or ASMe CD-ROM: Boot the server to

the System Resource CD and start the SSU from the Utilities menu.

• From the Service Partition: Boot the server to the Service Partition

and execute the following DOS commands:

C:\> cd ssu

C:\SSU> ssu.bat

The mouse driver loads if it is available; press Enter to continue.

When the SSU title appears on the screen, press Enter to continue.

Working with the SSU Interface

You can access features of the SSU interface using the mouse or

keyboard:

• Mouse-Click once to choose menu items and buttons or to select

items in a list, such as the Available Tasks list. To run a list item,

such as one of from the Available Tasks list, select the item and

click OK or double-click the item.

Page 71

61

• Keyboard-Use the tab and arrow keys to highlight buttons and

press the spacebar or Enter to execute. You can also execute a

menu or button by using the Alt key in combination with the

underlined letter in the name of the menu or button.

You can have more than one task open at the same time, although

some tasks might require complete control to avoid possible conflicts.

The tasks achieve complete control by keeping the task as the center of

operation until you close the task window.

The SSU has a build-in help system, which you access by clicking a Help

button or choosing the Help menu.

Customizing the SSU Interface

The SSU lets you customize your interface using the Preferences section

of the main window. The AF sets these preferences and saves them in

the AF.INI file so that they take effect the next time you start the SSU.

There are four user customizable settings:

• Color-lets you change the default colors associated with different

items on the screen using predefined color combinations. The

color changes take effect immediately.

• Mode-lets you set the desired expertise level: novice, intermediate,

or expert. The expertise level determines which tasks are visible in

the Available Tasks section and which actions each task performs.

For a new mode setting to take effect, you must exit the SSU and

restart it.

• Language-lets you change the text in the SSU to the appropriate

language. For a new language setting to take effect, you must exit

the SSU and restart it.

• Other-lets you show or hide the status bar at the bottom of the

SSU main window. The change takes effect immediately.

Note: If you run the SSU from read-only media (CD-ROM, for

example), these preferences are lost when you exit the SSU.

Exiting the SSU

Exiting the SSU closes all SSU windows.

Page 72

62

4 Configuration Software and Utilities

Setting Boot Device Priority

To change the boot priority of a device:

1 From the SSU Main window, choose Boot Devices.

2 In the Multiboot Options Add-in window, select a device.

3 Click the Move Up button to move it up in the list. Click the Move

Down button to move it down.

Setting Passwords and Security Options

You can set a user password and an administrator password. On some

systems, you must set an administrator password before you can set a

user password. On other systems, the passwords are independent. You

can set the same passwords and security options by using BIOS Setup.

Setting the Administrator Password

The Admin Password button lets you set or change the administrator

password used by both the SSU and the system BIOS. This option is not

available if both an administrator and a user password are set and you

entered only the user password when you started the SSU. All changes

to the administrator password take effect immediately.

To change or clear the administrator password:

1 From the SSU Main window, choose Security.

2 Click the Admin Password button.

3 If you are changing passwords, enter the old password.

4 Enter the new password (or leave blank to clear).

5 Confirm the password by entering it again (or leave blank to

clear).

6 Click OK to save the password and return to the Security window.

Setting the User Password

The User Password button lets you set or change the user password

used by both the SSU and the system BIOS. All changes to the user

password take effect immediately.

To change or clear the user password:

Page 73

1 From the SSU Main window, choose Security.

2 Click the User Password button.

3 If you are changing passwords, enter the old password in the first

box.

4 Enter the new password (or leave blank to clear).

5 Confirm the password by entering it again (or leave blank to

clear).

6 Click OK to save the password and return to the Security window.

Setting Security Options

For a description of security features, see “Security” on page 22.

To set the security options:

1 In the Security window, click the Options button.

2 For each option, select the desired setting from the list. The

options are:

• Security Hot Key: The key combination that can be used to

put the server into secure mode.

• Secure Mode Timer: If no keyboard or mouse activity occurs

during the chosen time interval, the server enters secure

mode.

• Secure Mode Boot: Enable forces the server to boot directly

into secure mode.

• Video Blanking: Enable turns off the video when the server is

in secure mode.

• Floppy Write: Enable prevents writing to the diskette drive

while the server is in secure mode.

• Power Switch Inhibit: Enable prevents the power and reset

buttons from functioning when the server is in secure mode.

Disable allows the power and reset buttons to function

normally when the server is in secure mode.

3 Click Save to save the settings and return to the Security window.

63

Viewing the System Event Log

To view the System Event Log (SEL):

Page 74

64

1 From the SSU Main window, choose SEL Manager.

When you start the SEL Manager, it automatically loads the current

list of events from nonvolatile memory.

2 Use the F4 and F5 keys to scroll the window contents to the left

and right to view all of the columns.

3 Use the File and SEL menu items to work with the SEL information:

• Open: Views data from a previously saved SEL file.

• Save As: Saves the currently loaded SEL data to a file.

• Properties: Displays information about the SEL.

• Clear SEL: Clears the SEL data from the nonvolatile storage

area.

• Reload: Refreshes the display by reading the current SEL

entries from the server.

• Sort By: Sorts the displayed events by event number, time

stamp, sensor type and number, event description, or event

generator ID.

4 Configuration Software and Utilities

Viewing FRU Information

To view the Field Replaceable Unit (FRU) information:

1 From the SSU Main window, choose FRU Manager.

When you start the FRU Manager, it automatically loads the

current list of events from nonvolatile memory.

The FRU Manager window has a navigation pane on the left that

displays, in a tree format, the inventory of components in the

server. The tree has three categories: Chassis, Board, and Product.

Clicking on a category expands or collapses a list of components

for that category. Clicking on an individual component displays the

FRU information for that component in the presentation pane in

the upper right. The description pane in the lower right displays a

description of the currently selected FRU area.

2 Use the F4 and F5 keys to scroll the window contents to the left

and right to view all of the columns.

3 Use the File and FRU menu items to work with the FRU

information:

• Open: Views data from a previously saved FRU file.

Page 75

65

• Save As: Saves the currently loaded FRU data to a file.

• Properties: Displays the number of FRU devices in the system and

the number being displayed. Only FRU devices with valid FRU areas

are displayed.

• Reload: Refreshes the display by reading the current FRU entries

from the server.

Viewing Sensor Data Records

To view the Sensor Data Records (SDR):

1 From the SSU Main window, choose SDR Manager.

When you start the SDR Manager, it automatically loads the SDR

entries from non-volatile memory.

The SDR Manager window has a navigation pane on the left that

displays, in a tree format, the sensor data records. The tree has

categories for each type of record. Clicking on a category expands

or collapses a list of SDRs for that category. Clicking on an

individual SDR displays the information for that SDR in the

presentation pane in the upper right. The description pane in the

lower right displays a description of the currently selected SDR

type.

2 Use the F4 and F5 keys to scroll the window contents to the left

and right to view all of the columns.

3 Use the File and SDR menu items to work with the SDR

information:

• Open: Views data from a previously saved SDR file.

• Save As: Saves the currently loaded SDR data to a file.

• Properties: Displays information about the SDR, including IPMI

version, number of SDR entries, time stamps for changes to the

SDR information, and free space remaining.

• Reload: Refreshes the display by reading the current SDR entries

from the server.

Updating System Firmware and BIOS

Using the SSU, you can update the BIOS, update the firmware, and

verify the firmware. Procedures for each are given below. You can also

update the BIOS and firmware without using the SSU.

Page 76

66

4 Configuration Software and Utilities

Updating the BIOS

To update the BIOS:

1 Download the update from the Acer support website.

2 From the SSU Main window, choose System Update. (System

Update is available only in Expert mode.)

When you start System Update, it automatically displays the

current revision information for the system firmware and BIOS.

3 From the File menu, choose Load and choose a .uif or .bio file to

use for the update.

4 Click the Update button to update the BIOS.

Updating the Firmware

To update the system firmware:

1 Download the update from the Acer support website.

2 From the SSU Main window, choose System Update. (System

Update is available only in Expert mode.)

When you start System Update, it automatically displays the

current revision information for the system firmware and BIOS.

3 From the File menu, choose Load and choose a .uif or .hex file to

use for the update.

4 Click the Update button to perform the update.

Verifying the Firmware

To compare the system firmware in nonvolatile memory with a

firmware file:

1 Download the update from the Acer support website.

2 From the SSU Main window, choose System Update. (System

Update is available only in Expert mode.)

When you start System Update, it automatically displays the

current revision information for the system firmware and BIOS.

3 From the File menu, choose Load and choose a .hex file to use for

the update.

4 Click the Verify button to compare the firmware code in

nonvolatile storage with the selected file.

Page 77

Saving and Restoring the System Configuration

Using the SSU, you can save the following configuration information

to a file:

• Platform type, BIOS revision, and firmware revision

• CMOS settings

• Extended system configuration data (ESCD)

• Settings for the emergency management port (EMP), platform

event paging (PEP), and BMC LAN alerts

Data is saved from all sources. There is no way to choose only certain

pieces of configuration data to save. You can also restore the

information from a saved configuration file.

Note: BIOS passwords are stored in the file. Restoring a

configuration can change passwords on a server. EMP and LAN

passwords are not stored in the file.

Saving a Configuration

To save the system configuration:

1 From the SSU Main window, choose Config Save/Restore.

(Configuration Save/Restore is available only in Expert mode.)

2 Click Save To File and specify a filename and location.

67

Restoring a Configuration

To restore the system configuration from a file: