Page 1

ACER Group

Springwood Industrial, Inc. Klim Industrial, Inc.

1062 N. Kraemer Place 244 N. Randolphville Road

Anaheim, CA 92806 Piscataway, NJ 08854

Tel: 714-632-9701 Fax: 714-632-9730 Tel: 732-752-9100 Fax: 732-752-9101

http://www.acergroup.com

http://www.acergroup.com

info@acergroup.com

acer_klim@yahoo.com

PROCEDURE TO SETUP AGS-1020AHD SURFACE GRINDER

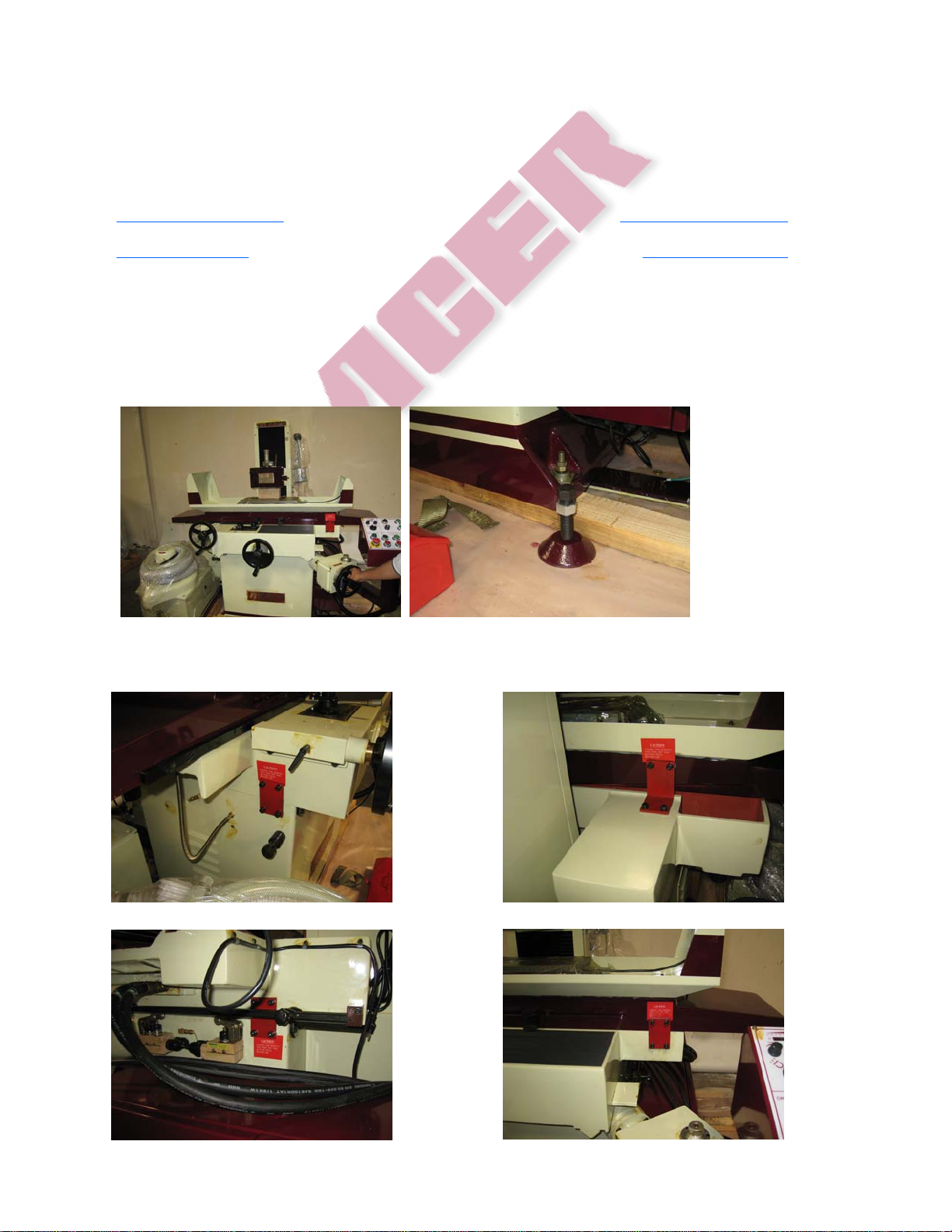

1. Unwrap the machine and check out machine for any physical damage. If so, report to your dealer as soon as

possible. Touch-up paint is inside the toolbox. Use it as needed.

2. Turn vertical handwheel clockwise (spindle up) to take out spindle support block (See figure on left). Move machine to appropriate location. Put 3 leveling screw, nut and pad on machine (See figure on righ t).

Remove the four brackets.

Page 2

3. Check input power that will be used for the machine. Power required for our machines are: 230V three phase (3Φ) or 460V three

phase (3Φ). Power must be first specified upon ordering. Please connect the power to R.S.T.G Ground terminal as follows with minimum

current of 12 amps (230V).

4. Hook up two electronic conduct connectors and wire, from hydrau-

Solenoid

lic system, one from dust suction and coolant system.

Power

Hydraulic Mo-

Coolant

System

5. Connect two corresponding hydraulic hoses: A-A, B-B, P-P, T-T as

labeled.

6. Fill up hydraulic oil Mobile DTE25 (minimum 30 gallons) and

lubricating oil (See figure on left). Make sure filling gauge is at F.

Fill up lube oil Vetra #2 way oil (see figure on right).

Page 3

7. Turn on control. Make sure all the motors are running clockwise (spindle motor, hydraulic motor, cross-feed

motor, vertical rapid motor, and coolant pump motor). 1) Turn on Main Power switch (See Fig. 1) Release emergency button. Then press the circuit power on. (See Fig. 2) 2) Turn on chuck control. Press spindle (See Fig. 3 &

4), hydraulic (See Fig. 4 & 5) and dust suction and coolant system buttons (See Fig. 6 & 7). to check rotation. 3)

Check cross-feed motor by toggling in and out switch while function switch is in manual mode & surface grinding

mode (See Fig. 8). 4) Check rapid vertical motor by pressin g up and d ow n push butt o ns whi l e fu nct ion switch is in

rapid mode (See Fig. 9).

Chuck Control

Switch

Circuit Power

Crossfeed Function

Switch

Hydraulic On/Off

Button

Crossfeed Forward/

Reverse Button

Function Switch

Emergency Button

Fig. 1

Main

Spindle On/Off

Button

Fig. 2

Rapid Up/Down

Push Button

Coolant On/Off

Push Button

Page 4

Fig. 3 Tap wheel with object to make sure wheel is Fig. 4 Push On and Off immediately. Make sure spindle

not cracked. The sound should be clear and consistent. rotation is clockwise.

Fig. 5 Make sure hydraulic motor rotation is clockwise.

Fig. 6 Make sure the dust collector motor is runningclockwise.

Fig. 7 Make sure the coolant pump is running

clockwise. Fig. 8 Make sure table crossfeed moving direction is correct.

Function Switch on Surface Grinding Mode, Cross Feed fuc

tion on Manual mode.

Fig. 9 Make sure Rapid Up/Down direction is correct. Make sure Function Switch on Rapid Mode.

Page 5

If opposite direction, please turn off main power by pushing emergency button and main power switch. Switch any two power lines

that go into the machine.

8. Leveling the machine

Precisely level the machine on a solid foundation. Precise leveling of the grinder is important to the finish of the

product and the tolerance of the machine.

9. For auto lube pump, we recommend you use way oil #2 or for hydraulic oil, use Mob il DTE 25 or fo llow the

manual suggestion.

10. Read through the operation manual and choose the correct wheel for application.

11. Ready to run your grinder: please read through the AGS-1020AHD manual to familiarize yourself with all

functions, features and controls.

Should you have any questions or comments, please contact your local dealer first. They will th en refer you to

Acer 714-632-9701 (West Coast) or 732-752-9100 (East Coast) for further assistance.

Loading...

Loading...