Page 1

ABUS TECHNOLOGIES INC.

A4000

User Manual

Page 2

WARNING

This manual should be passed on to the end user.

The contents of this manual are subject to change without prior notice.

All rights reserved.

ABUS gives no warranty of any kind with regard to this manual, including, but not limited to, fitness

for a particular purpose.

If any question arises or errors are found, or if any information is missing from this manual, please

A4000

inform your supplier or inform at info@abustek.com

.

The specifications mentioned in this manual are limited to those for the standard type under the

specified model number break-down and do not necessarily apply for customized instruments.

Please note that changes in the specifications, construction, or component parts of the instrument

may not immediately be reflected in this manual at the time of change.

If the customer or any third party is harmed by the use of this product, ABUS assumes no

responsibility for any such harm owing to any defects in the product which were not predictable, or

for any indirect damages.

The integral modules specifically HART module are not manufactured by ABUS.

Although Warning hazards are related to personal injury, and Caution hazards are associated

with equipment or property damage, it must be understood that operation of damaged equipment could,

under certain operational conditions, result in degraded process system performance leading to

personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of

our equipment. Use of this manual for any other purpose is specifically prohibited and its contents are

not to be reproduced in full or part without prior approval of Technical Communications Department,

ABUS Technologies

HEALTH AND SAFETY

To ensure that our products are safe and without risk to health, the following points must be

noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained

personnel and in accordance with the information given. Any deviation from these instructions will

transfer the complete liability to the user.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when

operating in conditions of high pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept

dry. Normal safe handling procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data

sheets (where applicable) may be obtained from the Company address on the back cover, together with

servicing and spares information.

ABUS TECHNOLOGIES INC.

2

Page 3

.

A4000

CATALOGUE

Contents Page No.

1. Introduction 4

2. Presentation

Technical Parameters

4

4

3. Dimensions 5

4. Ordering Details 5

5. Connections 6

6. Installation

1. Input Signal

2. Function key and lamps

7. Configuration

1. Configuration Process

Key Operation Instructions

2.

Programmable Curve Controller

3.

Additional Notes

4.

8. Operation

Example for Usage

9.

Maintenance

Troubleshooting

7

7

7

8

8

10

10

12

14

14

15

10. Safety Precautions 16

11. Warranty 16

ABUS TECHNOLOGIES INC.

3

Page 4

1. INTRODUCTION

A4000 series is a Microprocessor based Digital Process Controller, which can

be applied to high-precision measurement and control of temperature, pressure,

discharge, liquid level and humidity etc... A four-digit LCD dual display indicates

measured value and set-value for all programming parameters. Instrument

configuration is achieved from the front panel keyboard, without any hardware change.

The user should read this manual thoroughly before using the instrument. It must be

handled with care and should be used accordingly for best results.

2. PRESENTATION

Technical Parameters

A4000

Display: Range: -1999 ~ 9999

Setting Mode: A: Panel Setting

B: External Setting

C: Programmable Curve Setting (Ramp & Soak)

Isolation Output:

One loop analogue or control output, resolution more than 12 digits.

Current 0-20mA is adjustable, output impedance 600 Ohm. The unit only supplies 4-

20mA and 0-20mA analogue output. If the user requires Voltage, he/she can

connect impedance of 250 Ohm to get voltage 1-5V. (Accuracy depends on the

impedance connected).

Relay contact switch output: 250V/3A or 30VDC/3A. The main control output can be

selected freely by the user.

SSR pulse voltage output: 24VDC/30mA.

SCR contact output: Can contact 5-500A SSR.

Sampling Rate: <0.5S

Control mode: PID control; Preset curve control; Pulse width control;

Direct electronic machine control etc...

The products can supply two wires isolate power 24V/30mA.

Communication: RS485 (optional)

Can calibrate Zero & Span and make it more reliable and accurate.

Power: 85-265V AC/DC, consumption: <5VA

Ambient Temperature: 0-50°C

ABUS TECHNOLOGIES INC.

4

Page 5

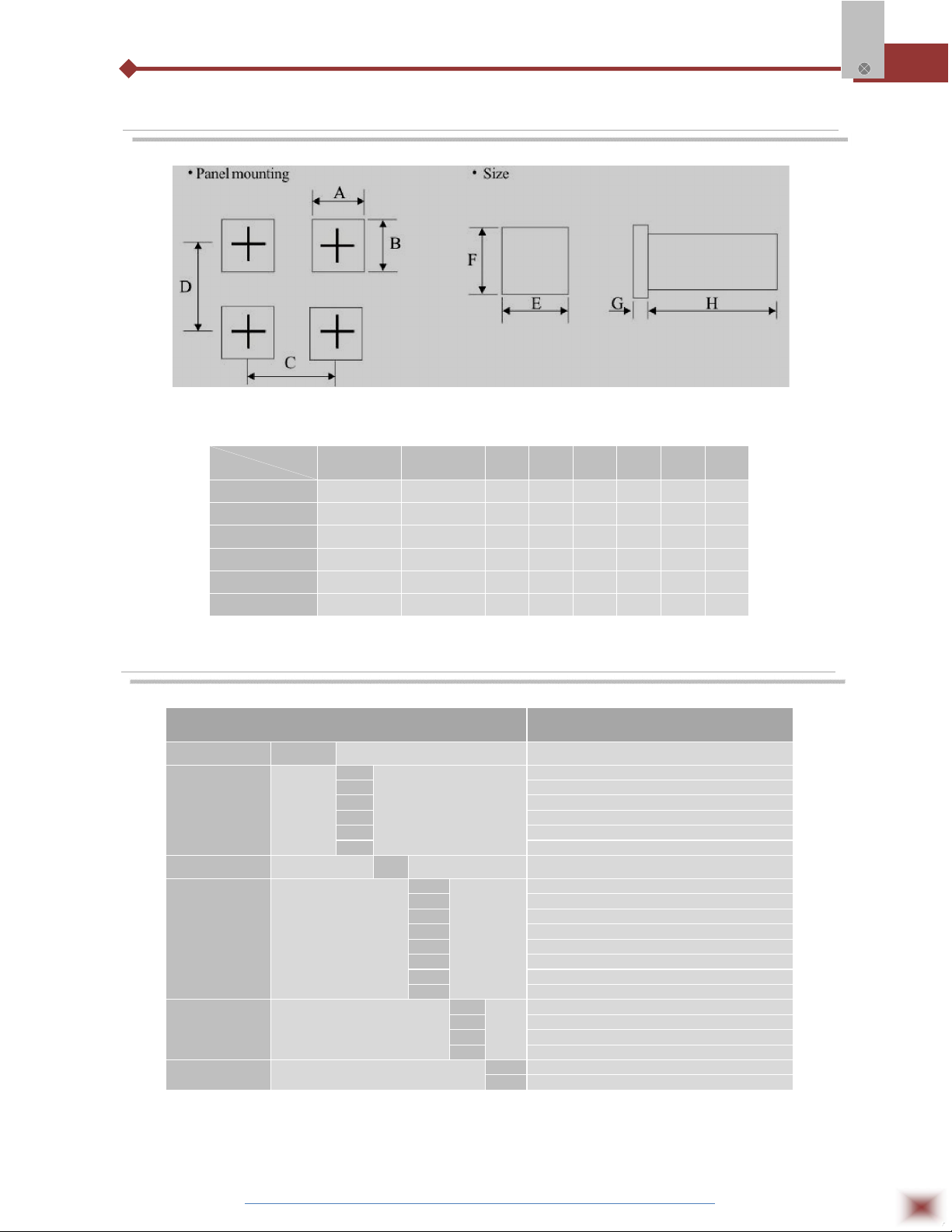

3. DIMENSIONS

Weight Outline Dimension

A4000

CODE

SIZE

A4000 – 4

A4000 – 6

A4000 – 7

A4000 – 8

A4000 – 9

A4000 – 16

A B C D E F G H

44+0.5 44+0.5 30 25 48 48 5 100

44+0.5 91+0.5 25 30 48 96 12 100

67.5+0.8 67.5+0.8 30 14 72 72 12 100

91+0.5 44+0.5 30 25 96 48 12 100

91+0.5 91+0.5 25 25 96 96 18 100

153.5+0.5 76+0.5 25 25 160 80 13.5 70

4. ORDERING DETAILS

TYPE DESCRIPTION

Product A4000 A4000 Series

4

Size

Power Supply

Main Control

Output

Alarm Output

6 48W x 48H x 100L

7 72W x 72H x 100L

8 96W x 48H x 100L

9 96W x 96H x 100L

16 160W x 80H x 70L

C

48W x 48H x 100L

D 85 ~ 265 Vac/dc

E 3-phase shift control

F 3-phase SCR contact control

H Ingle phase SCR contact control

N Open loop direct

P PWM time curve control

L Remote preset control

D

Y Single phase shift control

R Relay output

S SSR output

K SCR output

0 None

Close loop direct

Current output

2 2-Alarm.

ABUS TECHNOLOGIES INC.

5

Page 6

5. CONNECTIONS

Connection (The final connection is according to the label on the product incase

of any modification.) Every mode has one control output, 3 phase SCR control, 3phase shift control, direct electronic machine control, program control.

A4000

ABUS TECHNOLOGIES INC.

6

Page 7

6. INSTALLATION

6.1 Input Signal

SIGNAL

SELECTING

SIGNAL TYPE RANGE RESOLUTION ACCURACY

A4000

INPUT

IMPEDANCE

FACTORY

SETTING

B

5

R

T

E

J

Pt

Cu50/Cu100 Cu50/Cu100 -50.0 ~ 150°C 0.1°C 0.5% Back

Ln

or

T/C b 600 ~ 1700°C 1°C 0.5% >100K

T/C S 0 ~ 1700°C 1°C 0.5% >100K

T/C R 500 ~ 1600°C 1°C 0.5% >100K

T/C T 0.0 ~ 400.0°C 0.1°C 0.5% >100K

T/C E 0 ~ 1000°C 1°C 0.5% >100K

T/C J 0 ~ 1000°C 1°C 0.5% >100K

T/C K 0 ~ 1200°C 1°C 0.5% >100K

T/C -200 ~ 600°C 0.1°C 0.5%

0 ~ 400 Ω

0-1V 0.5% >20K

0-5V 0.5% >100K

0-10V 0.5% >200K

0-10mA

4-20mA

-1999 ~ 9999

12bit A/D

0.5% 0.2mA

0.5% <102Ω 4-20mA 0-20mA

0.2mA

Yes

0-50mV -20 ~ 100mV 0.5% >100K

0-10V

Note:

1. The resolution of R/S/B is 1°C; Resolution of the other signals is 0.1 in case the display is value less than 400. In case the

display value more than 400, the resolution is 1°C, over range display or negative display can also be specified at the time of

order..

2. Pulse: Square wave, triangle wave, sine wave (need to mention when order), rating more than 4V or less than IV. Frequency

Range: 0-60KHz.

6.2 Function Keys and Lamps

6.2.1 KEYS

A: SET: Set Key

B: ▲/▼: Increase/Decrease Key

C: SET+▲: Hold the set key, press ▲ will shift digit.

D: LED flashes, press SET key to confirm Parameter.

E: The digit shifts to another one to be modified.

6.2.2 LAMPS

SV red lamp On: Indicate the set value; Flash: Indicate the external setting input value (the second input value of loop 2).

MV red lamp On: Indicate control output value. In case it is manual manipulation, it indicate the manipulate.

MAN green lamp On: Manual manipulate; Flash: In the case of auto-tune; Off: automatism.

ABUS TECHNOLOGIES INC.

7

Page 8

Self-Check when Power is On

PID Parameter setting mode

7. CONFIGURATION

7.1 Configuration Process

A4000

ABUS TECHNOLOGIES INC.

8

Page 9

Calibrate Menu Setting Mode

A4000

ABUS TECHNOLOGIES INC.

9

Page 10

7.2 Key Operation Instruction

7.2.1 KEY OPERATION PROCEDURE

1. When the unit is in the state of measuring, please SET key for 3 seconds to enter parameters

P, I, D…

2. Press SET key to select the parameter that to be modified. Hold SET key and press increase

key, LED flashes, as the same operations, it shift to another digit, press increase/decrease to

modify the value. Press SET key to confirm.

3. In the menu of parameter adjustment, select parameter LCK, when LCK=000 or LCK=010, in

the state of manipulation (MAN lamp on), press SET key for 3 seconds to enter calibrate

parameter menu. Modification of the parameters, same as in above, i.e. Step 2.

4. The unit will go back to the measuring estate without any operation for 5 seconds.

5. In PID adjust and calibrate menu, if LCK=010, all parameters for read only, but not for

modification. Anyway, the value of LCK can be modified by the user.

A4000

7.2.2 FUNCTION OPERATIONS

1. To convert the displaying windows: Press SET key, SV lamp on indicates the setting value; MV

lamp on indicates control output values; SV lamp flash indicates the measuring value of loop

input.

2. When SV lamp is On, the procedure of modification is same as Key Operations.

3. MV value modification: MV lamp On, and if it is manual manipulation (MAN lamp On), please

modify, referring the procedure of Key Operations.

4. Auto/Manual manipulate convert is

On: Manual Tune;

Off: Auto –tune, Press A/M key to convert.

5. Auto adjust operation: Press SET key for 3 seconds, enter parameter P, I, D… Set P 6 0, then

press SET key to select parameter AT and set AT=1, MAN lamp flashes, it means that the unit

is in auto-tune state. Press SET key to quit. At this moment, please don’t perform any key

operation and wait for auto-adjust to complete. When auto-adjust is finished, MAN lamp is Off,

the unit refreshes the PID value by itself.

6. Auto when power On: When the system is running, if user wants to switch auto-tune

immediately, please do as following: Enter P, I, D…Press Set key to select parameter MAN

and set MAN=1. On the other hand, if you want manual manipulate, set MAN=0.

7.3 Programmable Curve Controller

Key Operations:

1. SET key: Parameter Select/Confirm key.

2. Press SET key and increase key at the same time, LED flashes, the value can be modified.

Hold SET key and then press increase key to shift to the digit you want to modify.

ABUS TECHNOLOGIES INC.

10

Page 11

3. Increase/Decrease key to modify the value.

4. A/M key: Auto manipulate convert key, when the program is running, it will pause (MAN lamp

On). Press A/M key, it will continue running (MAN lamp off).

5. Press SET key and A/M key at the same time to turn On/Off the program. The key operation is

not available when its non-program running.

6. Curve setting method: In the ofline state, press ▲/▼ key at the same time, the SV window

displays in and enter the parameter setting area, press SET key to select the parameter SV00

and begin to set the parameter of curve.

7. In the course of setting, SET is a curve parameter selection key.

8. When the setting is finished, press ▲/▼ key at the same time. To quit.

12 Segments of program curve, running parameter are as under:

A4000

In the table, the curve is “free” set by the user. SV00 is the beginning of the curve

running. TM00 is the time SV00 to SV01. TM01 is the time from SV01 to SV02...

SVXX: Stands for the value of each turning point. It should belong to the range of measuring

(FL1 to FH1).

TMXX: Stands for the running time of each stage. The range of timing is 0.0-540 minutes or

more.

The program will come to end in case the next turning point is set to 0. For example, there are

only 4 stages. You should set TM04=0, meanwhile SV04 ≠ 0, then the program comes to end.

To set TMXX=0: Shift the flashing digit to the left, press decrease key till it displays 0.

Before grogram starts: Normal operation, is set ehemeter in auto-tune state, running the system

with the controller in a set point to acquire the value of P, I, D.

Output when program starts: Before start, the user can set the output value as he wants.

Manipulate steps: set MV value as to pre-heat, if the user wants always heating before program

starting, he can set MV=100.

Program pauses: During the course of program running, press A/M key can pause running and

MAN lamp is On. At this moment, the user can modify the control output value by manipulate;

the unit will wait for other action such as heating, running stage and Preset stops when program

pauses.

Program continues: When the program pauses, press A/M key can make it continue to run the

program. MAN lamp is Off.

Program ends: When the program reaches the end of the last stage, or reaches the next stage

that is set value 0, the program will come to end. At this moment the unit will display “END”.

Meanwhile output stops, and alarm 2 takes action.

Displaying convert: Press SET key to select the parameters. SV lamp On indicates preset value

of the parameter, SV lamp flashes indicates parameter of running stage. MV lamp On indicates

the control output value.

AL1 and AL2: In non-programmable curve control, AL1 and AL2 are used for the 4 Alarm

modes. In programmable curve control, AL1 is used for normal style of alarm; AL2 is used for

alarming program ends.

ABUS TECHNOLOGIES INC.

11

Page 12

7.4 Additional Notes

7.4.1 Additional A4000/A4000 16-bit input signal selection

A4000

7.4.2 Additional notes of manipulate operator/ electronic-machine driver.

1. When the adjustor is a non-electronic machine control output, all key operations are the

same as stated before.

2. When the adjustor is non-electronic machine (required the electronic machine driver must

have Low-High location equipment.) control output, some parameters should be modified as

follows:

HY: Blind spot of motor control setting. Range: 1.0-5.0%

Ct: The running time of full open to full close to full open. Range: 20-250 seconds.

AL1: Normal alarm mode.

OUTL: Value output law value. Range: 0.0 ~ 50.0%.

AL2: Change to motor positive-tune control.

OUTH: Value output high value. Range: 30.0 ~ 100.0%

OUT: Motor reverse-turn control.

3. Displaying operations:

PV displays the measuring value.

SV lamp on displaying preset value, SV lamp flashes displaying value feedback value,

MV lamp on displaying control output value.

ABUS TECHNOLOGIES INC.

12

Page 13

Manual Manipulation: MAN lamp On means manual manipulation. Press SET key select

MV lamp is On, at this moment the window can be set to show the present between the

total power on running time and the whole running time of the motor or value. The

percent shows the location value of the value. When changing the manual manipulate

value, the unit will stop after running the set timing. When it is auto-tune, it displays the

running location value of value.

Auto-tune: the unit runs as PID mode

Auto/manual manipulate converts: Press A/M key to convert.

4. Value feedback signal calibrations

Feedback signal voltage/current: When it is input by voltage 0-5V, 1-5V, 0-10V or

current 0-10mA, 4-20mA, the unit should be calibrated by the factory. Otherwise the

user should calibrate on the spot.

Feedback impedance of value is less than 1K, the user should calibrate on the spot.

Steps are as follows:

Connect all wires, according to the instructions in manual. And then switch

on the power.

Press A/M key to make Man lamp On. Press SET key for more than 3

seconds entering parameter P,I,D...Select LCK and set LCK=000, and then

press SET key for more than 3 seconds again to enter the parameter

calibrate area.

Press SET key to select IN1, set IN1=rt, it means impedance input.

Press SET key, select and select nL1. At this moment, value motor will

close. Waiting for full range running time, till low location switch takes action.

Then press SET key to confirm. The unit will display 0.0 (low values

calibrate) at this moment.

Press SET key, select nH1. At this moment, value motor will open. Waiting

for full range running time, till high location switch takes action. Then press

SET and increase key at the same time, LED flashes, press SET key to

confirm. The unit will display 100.0 (high value calibrate) at this moment.

Feedback impedance of value is more than 1K

External impedance should be used to share partly of the full voltage to make it

about 60mV. Select the input signal IN1=Ln, and then calibrate as mentioned above.

A4000

ABUS TECHNOLOGIES INC.

13

Page 14

Control wire connections (control mode convert BSET1.6=1 means open control,

BSET1.6=0 means close control)

A4000

7.4.3 Remote control operations:

1. Remote control setting: Set parameter BSET1.7=1 and it means the unit for remote control.

The factory has set this parameter before sales.

2. Remote control connection wires: In normally, the remote control input is connected to the

terminal +5V, GND and mA according to the voltage/current input.

3. Remote input displaying: SV and MV windows display remote input value, press SET key to

select, when SV flashes, the SV window displays remote control value. This is set by input

value of parameters IN2, FL2, FH2 and nH2.

4. Error elimination of faulty wire connection: In this case the input signal exceeds the range of

measuring, the unit will cancel external setting function. It changes to internal panel setting.

It will not display external value at this moment. SV lamp On means, that it can change the

setting value.

8. OPERATION

Example for Usage

Relay Control

ABUS TECHNOLOGIES INC.

14

Page 15

The connection of SCR

The

connection of SCR

A4000

9. MAINTENANCE

Troubleshooting

Heating Control

INFORMATION

SPECIFICATIONS

Sensor not connected or input

signal is too low.

Sensor not connected or input

signal is too high.

ABUS TECHNOLOGIES INC.

ELIMINATE

Check and connect the

sensor properly, or reset the

low alarm value.

Check and connect the

sensor properly, or reset

the high alarm value.

15

Page 16

10. SAFETY PRECAUTIONS

1. The unit should be powered for 15 minutes before use.

2. Use in ambient temperature of 0-60˚C.

3. Avoid vibrations, shock, excessive dust, corrosive chemical materials or gaseous

environment.

4. Input wire should not be too long. If measured signal have to be far away from the

unit, please use 2-core shielded cable.

5. Use this instrument in the scope of its specifications, otherwise fire or malfunctions

may result.

6. Contact of the instrument, with organic solvents or oils should be avoided.

7. Do not turn on the power supply until all of the wiring is completed. Otherwise

A4000

electrical shock, fire or malfunction may result.

8. Do not disassemble, repair or modify the instrument.

9. All connections should be tightened properly.

10. Power supply should be constant, should not be fluctuating.

11. WARRANTY

ABUS provides the original purchaser of this instrument a one (1) year warranty

against defects in material and workmanship under the following terms:

The one year warranty begins on the day of shipment as stated on the sales bill.

During the warranty period all costs of material and labor will be free of charge

provided that the instrument does not show any evidence of misuse.

For maintenance, return the instrument with a copy of the sales bill to our factory.

All transportation and insurance costs should be covered by the owner of the

equipment.

Should any sign of electrical or mechanical shock, abuse, bad handling or misuse

be evident the warranty voids and maintenance costs will be charged.

ABUS TECHNOLOGIES INC.

www.abustek.com, E-M ail: info@abustek.com

ABUS TECHNOLOGIES INC.

16

Loading...

Loading...