Page 1

A1500

Universal

ABUS TECHNOLOGIES INC.

Process Indicator

User Manual

Page 2

WARNING

This manual should be passed on to the end user.

The contents of this manual are subject to change without prior notice.

All rights reserved.

ABUS gives no warranty of any kind with regard to this manual, including, but not limited to, fitness

for a particular purpose.

If any question arises or errors are found, or if any information is missing from this manual, please

A1500

inform your supplier or inform at info@abustek.com

The specifications mentioned in this manual are limited to those for the standard type under the

specified model number break-down and do not necessarily apply for customized instruments.

Please note that changes in the specifications, construction, or component parts of the instrument

may not immediately be reflected in this manual at the time of change.

If the customer or any third party is harmed by the use of this product, ABUS assumes no

responsibility for any such harm owing to any defects in the product which were not predictable, or

for any indirect damages.

The integral modules specifically HART module are not manufactured by ABUS.

Although Warning hazards are related to personal injury, and Caution hazards are associated

with equipment or property damage, it must be understood that operation of damaged equipment could,

under certain operational conditions, result in degraded process system performance leading to

personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of

our equipment. Use of this manual for any other purpose is specifically prohibited and its contents are

not to be reproduced in full or part without prior approval of Technical Communications Department,

ABUS Technologies

.

HEALTH AND SAFETY

To ensure that our products are safe and without risk to health, the following points must be

noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained

personnel and in accordance with the information given. Any deviation from these instructions will

transfer the complete liability to the user.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when

operating in conditions of high pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept

dry. Normal safe handling procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data

sheets (where applicable) may be obtained from the Company address on the back cover, together with

servicing and spares information.

ABUS TECHNOLOGIES INC.

2

Page 3

4

6

16

.

A1500

CATALOGUE

Contents Page No.

1. Introduction 4

2. Presentation

Technical Parameters

3. Dimensions 5

4. Ordering Details 5

5. Connections 5

6. Installation

1. Recommendation

2. Panel

3. Alarm

7. Configuration

1. Programming the Indicator

2. Serial Communication

4

7

7

8

9

9

12

8. Operation

Configuration Protection

1.

Special Functions

2.

9. Maintenance

1. Troubleshooting

2. Special Recommendation

3. Input Calibration

10. Safety Precautions 17

11. Warranty 17

14

14

15

16

16

16

ABUS TECHNOLOGIES INC.

3

Page 4

1. INTRODUCTION

A1500 is a universal process indicator which accepts a large variety of input

signals and sensors. A six-digit LED display shows measured value and all

programming parameters. Instrument configuration is achieved from the keyboard,

without any hardware change. Thus, the selection of input type and type of alarms

action, besides other special functions, are accessed and defined from the frontal

keyboard. The user should read this manual thoroughly before using the instrument. It

must be handled with care and should be used accordingly for best results.

2. PRESENTATION

Technical Parameters

Power: 85 to 265Vac/dc, 50/60 Hz (basic model);

A1500

24 Vdc/ac, optional;

Maximum consumption: VA

Relays: ALM1 and ALM2: SPDT - 3A / 250Vac (3A / 30Vdc);

ALM3 and ALM4: SPST – NA 3A / 250Vac (3A / 30Vdc) (optional);

All input signals are factory calibrated. Thermocouples are calibrated according to NBS standards

(NBR12771), RTD’s NBR 13773/97 (IEC-751), (

Internal resolution: 128000 levels,

Display resolution: 62000 levels (-31000 to 31000)

Sampling rate: 5 measurements per second for TC and RTD

measurements for 0-50mA, 4-20mA, 0-5V, 0-10V

Accuracy: Thermocouples J, K, T, N: ± 0.25% of full scale +1°C.

Thermocouples E, R, S, B: ± 0.25% of full scale +3°C.

Pt100: 0.2% of full scale

Current or voltage: 0.15% of full scale

Cold junction compensation error: ± 1 °C

Warm up time: 15 minutes

Input impedance: 0-50mV, Pt100 and T/C: >10M

0-5V, 0-10V > 1M

4-20mA: 15

Pt100 measure: 3-wire circuit, 750A excitation current.

=0.00385).

PV retransmission resolution: 4000 levels, 550max.

Working conditions: 0 to 55°C, 35 to 85% relative humidity.

Front panel: IP65, Polycarbonate UL94 V-2;

Back panel: IP30, ABS+PC UL94 V-0;

Weight: 240g basic version; 265g with options

Dimension: 48×96×92 mm

Panel cut out: 45×93mm

ABUS TECHNOLOGIES INC.

4

Page 5

HOLE

3. DIMENSIONS

A1500

PANEL

DIMENSION

CODE

A1500 96 48 90 44 100 92 45

PANEL

DIMENSION

W H W H D W H

CASE DIMENSION

CUTOUT

DIMENSION

4. ORDERING DETAILS

The standard unit includes 2 SPDT relays, 1 digital input and 24 Vdc (A1500) or 10

Vdc (A1500LC) supply output.

Option 1 : 2 SPST alarm relays (ALM3 and ALM4).

Option 2 : 4-20 mA / 0-20 mA analog output.

Option 3 : RS485 Modbus communication interface.

Option 4 : 24 Vac/Vdc power supply input.

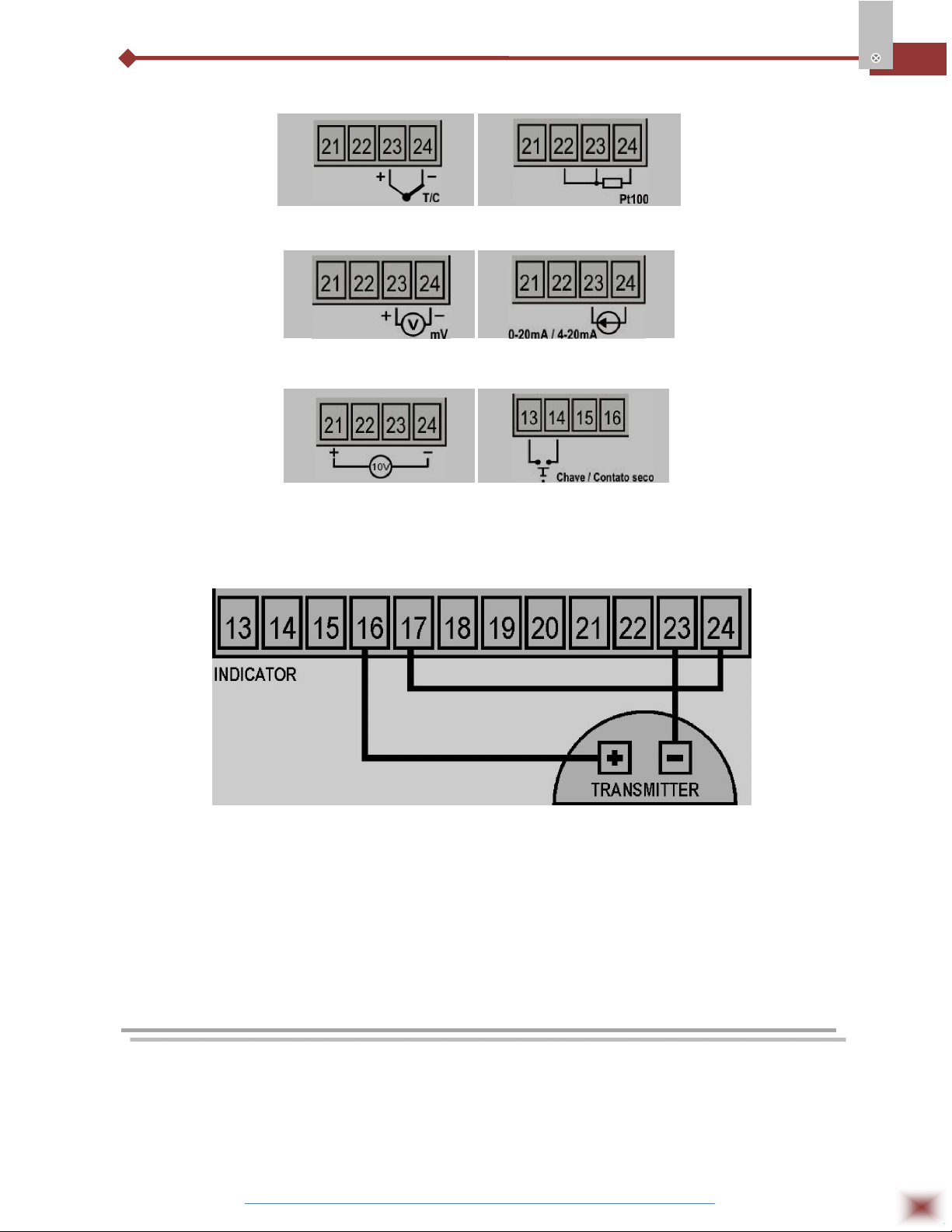

5. CONNECTIONS

The internal electronics can be removed from the front panel without any cable

disassembly. The input signals and power connections are shown in Figure 2.

Figure 2 – Back Panel Terminals

Sensor or input signal connection

These connections should be well done and terminals must be well tightened.

Thermocouples must be installed with proper extension or compensation cables.

Pt100 RTDs must be 3-wire connected and the wires connected to terminals 17

and 18 should have the same electrical resistance (same wire gauge) for proper

cable distance compensation.

Four-wire RTDs can be connected by disconnecting the fourth wire. Two-wire

RTDs can be connected by shortening terminals 22 and 23 and connecting the

Pt100 to terminals 16 and 17.

ABUS TECHNOLOGIES INC.

5

Page 6

Figures below show how connections are made for each type of input.

Figure 3 – Thermocouple

Connection

Figure 5 – Voltage Connection Figure 6 – Current Connection

Figure 7 – Connection for 0-

10V

Figure 4 – 3 wire Pt100

Connection

Figure 8 – Digital Input

A1500

Figure 9 shows connections made to measure signals from a 4-20mA

transmitter supplied by the 24 V power supply, the indicator provides.

Figure 9 – Two-wire transmitter with internal power supply

5.1 Digital Input (Dig In)

The digital input can be used by connecting a switch (or equivalent) to its terminals, as shown in

Figure 8 above.

5.2 Analog output

The analog output of A1500 can be 0-20 mA or 4-20mA, which can be selected during

programming. This output is available at terminals 29 and 30.

6. INSTALLATION

The indicator must be attached to a panel. Remove the two plastic fixing clamps

from the instrument. Insert the unit into the panel cut-out and put back the fixing

clamps from the rear.

ABUS TECHNOLOGIES INC.

6

Page 7

6.1 Recommendation

1. Input signal wires should be laid out away from power lines and preferably inside grounded

conduits.

2. Instrument mains (line) supply should be suitable for this purpose and should not be shared.

3. In controlling and monitoring applications, possible consequences of any system failure must be

considered in advance. The internal alarm relay dos not warrant total protection.

4. RC filters (47 and 100nF, serial) are highly recommended for valve and contactor coils, etc.

6.2 Panel

A1500

Panel Attribute

S.No. Parameters Description

1

2

3

4

5

6

7

8

9

10

11

12

A1

A2

A3

A4

Rx

Tx

P

◄

▲

▼

F

Display Shows the process variable (PV) and the programming prompts.

Show active alarms.

Show active alarms.

Show active alarms.

Show active alarms.

Indicate RS485 communication line is active.

Indicate RS485 communication line is active.

Program Key: This key is used to access different displays with the

programmable parameters of the device.

Back Key: This key is used to go back to the previous parameter

displayed in the menu cycle.

UP / MAX Key: This key is used to increase parameter value, as well

as to display maximum values stored in memory.

DOWN / MIN Key: This key is used to decrease parameter value, as

well as to display minimum values stored in memory.

This special function key is used for pre-programmed functions as

explained in the SPECIAL FUNCTION KEY section of this manual.

ABUS TECHNOLOGIES INC.

7

Page 8

6.3 Alarm

6.3.1 Alarm Functions

The alarms can be set to operate in seven different functions. These functions are shown in

table 2 and described below. The alarm can also be set as disabled.

A1500

Lo

Ierr

Dif.lo

ALrEF – SP.AL)

(

ALrEF + SP.AL)

(

(ALrEF – SP.AL) and (ALrEF + SP.AL)

Sensor break –

The alarm is triggered whenever the sensor breaks or is badly connected.

Low alarm –

The alarm relay is triggered whenever the measured value is below the alarm set point.

High alarm - Ki

The alarm relay is triggered whenever the measured value is above the alarm set point.

Differential low –

Deviation alarm: Alarm relay is triggered whenever the difference (deviation) between the value

measured and the reference value (AlrEF) is beyond values defined in SP.AL. For this function, the

triggering point is defined as:

Differential high – Dif.ki

Deviation alarm: Alarm relay is triggered when the difference (deviation) between the

value measured and the reference value (AlrEF) is beyond values defined in SPAL. For this

function, the triggering point is defined as:

Differential (or Band) out of range – Dif.ov

Deviation alarm: Alarm relay is triggered when the difference (deviation) between the

measured value and the reference value (AlrEF) is higher than the value defined in SPAL. For

this function, the triggering points are defined as:

Differential (or Band) within range –

Deviation alarm: Alarm relay is triggered when the difference (deviation) between the

measured value and the reference value (AlrEF) is lower than the value defined in SPAL. For

this function, the triggering points are defined as:

ALrEF – SP.AL) and (ALrEF + SP.AL)

(

6.3.2 Alarm Timer

The alarms can be configured in the alarm timer. The user can set delays in the alarm action,

define just one pulse for an alarm event, or make the alarm work in the form of sequential pulses.

Table 3 shows these advanced functions. Times T1 and T2 can be programmed from 0 to 6500

seconds (refer to item 8.2). Set 0 (zero) at the T1 and T2 to prompt for a normal non-timer alarm

operation. The LED lights will flash whenever there is an alarm condition regardless of the current alarm

status which may be temporarily off because of the timer action.

6.3.3 Alarm Initial Blocking

The initial blocking option inhibits the alarm from being recognized if an alarm condition is

present when the controller is first energized. The alarm will be triggered only after the occurrence of a

ABUS TECHNOLOGIES INC.

Dif.In

8

Page 9

Likewise, with Peak Hold function programmed the high limit is displayed with the

non alarm condition followed by a new occurrence for the alarm. The initial blocking is disabled for the

sensor break alarm function.

ADVANCED

FUNCTION

T1 T2

ACTION

A1500

Normal

Operation

Delayed 0 1s to 6500s

Pulse 1s to 6500s 0

Oscillator 1s to 6500s 1s to 6500s

0 0

7. COFIGURATION

7.1 Programming the Indicator

7.1.1 Work Cycle

This is the first cycle. At power up the indicator will display the Process Variable (PV). The

alarm triggering points are also displayed at this cycle (alarm Set-points). To run through this cycle just

press the P key.

PARAMETERS

PROMPT PARAMETER DESCRIPTION

Measure. Shows the measured variable. For Pt100 or thermocouples the display will

show the absolute temperature value.

For 4-20mA, 0-50mV, 0-5V and 0-10mV inputs the display shows the values defined

in the”in.LoL” and “in.kiL” prompts.

8.8.8.8.8.

Al.ref

Sp.al1

Sp.al2

Sp.al3

Sp.al4

With the hold function programmed the display shows the frozen variable and

alternates with the message “koLd”.

“P.koLd” prompt alternately.

Should any fault situation occur the indicator will display an error message which

can be identified at item 11 of this manual?

Differential Alarm Reference Value - This prompt is shown only when there is an

alarm programmed with differential function. Value used as a reference for

differential alarms triggering.

Set Points of Alarms 1, 2, 3 and 4 - Defines the operation point of each alarm

programmed with “Lo” or “ki” functions.

When the alarms are programmed with differential function, the alarm set point

value represents the deviation value of these alarms.

ABUS TECHNOLOGIES INC.

9

Page 10

F KEY FUNCTION

–

Defines functions for F Key. Options are

Digital Input Function

–

Defines the function for the digital input. Options are:

7.1.2 Alarm Cycle

PARAMETERS

fV.al1

fV.al2

fV.al3

fV.al4

A1500

PROMPT PARAMETER DESCRIPTION

Alarm Function - Defines the alarms 1, 2, 3 and 4 function, as defined in item 4.1

oFF : Alarm off

iErr : Broken or Shorted Sensor

Lo : Low value

ki : High value

DiF.Lo : Differential low

DiF.Hi : Differential high

DiF.ov : Differential out of range

DiF.in : Differential within range

Ky.al1

Ky.al2

Ky.al3

Alarm Hysteresis

This is the difference from the measured value to the point where the alarm is

turned ON and OFF.

ky.al4

Bl.al1

Bl.al2

Bl.al3

Alarm Blocking

Should any alarm condition occur, each alarm can be disabled when energizing

the indicator? Refer to item 4.3.

bl.al4

Al1t1

Al1t2

Al2t1

Al2t2

Al3t1

Al3t2

Alarm Timer

The user can set delayed, momentarily or sequential alarms as shown in table 3 by

defining times T1 and T2.

To disable this function just set zero for T1 and T2.

Al4t1

Al4t2

7.1.3 Function Cycle

PARAMETERS

PROMPT PARAMETER DESCRIPTION

oFF - Key not used.

f.fvnc

Dig.in

filtr

ofset

bavd

Adres

Hold - Hold PV

RSt - Resets Peak and Valley

P.koL - Peak Hold

These functions are described in item 5.2.

oFF - kold - rESEt - PkoLd

Refer to item 5.2.

Input Digital Filter - Adjustable from 0 to 20, this is used to reduce instability of the

measured value. 0 means the filter is off and 20 means maximum filtering. The

higher the filter value the lower is the measured value response.

Display Offset - This a value which is added to the PV to offset any measurement

deviation or sensor error. The offset is shown directly in the programmed

engineering unit. For °F measurements the null reference is at 32°F.

Baud Rate - Serial digital communication speed in bps.

Programmable: 1200, 2400, 4800, 9600, 19200, 38400 and 57600 bps.

Communication Address - A number that identifies the instrument in a multidrop

network.

ABUS TECHNOLOGIES INC.

10

Page 11

Defines the extreme points (lower and upper) of the customized linearization. Values

7.1.4 Configuration Cycle

A1500

PARAMETERS

In.typ

Dp.pos

Vnit

s.root

In.lol

PROMPT PARAMETER DESCRIPTION

Input Type - Selects the input signal or sensor type to be connected to the PV

terminals. Refer to table 1 for options.

Changing this parameter will change all other parameters related to PV and

alarms, therefore it should be the first parameter to be set.

Decimal Point Position - Defines the decimal point position in the displayed value. It

is displayed when linear input types 0-50mV, 4-20mA, 0-5V or 0-10V are selected at

the “in.tYP” prompt.

Temperature Unit - Selects °C or °F indication. This prompt is not shown for input

types 0-50mV, 4-20mA, 0-5V or 0-10V is selected at the “in.tYP” prompt.

Square Root - This prompt is only shown for input type 0-50mV; 4-20mA and 0-5V

are selected at the “in.tYP” prompt.

Set “YES” and the square root will be applied to the measured value within the limits

programmed in “in.LoL” and “in.kiL”.

The display will show the low limit value should the input signal be below 1% of the

range.

Input Low Limit - Sets the low limit for input type 0-50mV, 4-20mA, 0-5V or 0-10V.

When the PV Retransmission is used this limit defines the corresponding 4mA (or

0mA) in relation to the input value.

Input High Limit - Sets the high limit for input type 0-50mV, 4-20mA, 0-5V or 0-10V.

In.kil

Ovt.ty

Ovt.er

7.1.5 Customized Linearization Cycle

PARAMETERS

Inp.01

Inp.20

When the PV Retransmission is used this limit defines the corresponding 20mA in

relation to the input value.

Analog Output Type - Selects the analog output type to either 0- 20mA or 4-20mA.

4-20 mA Output behavior in case of failures – Defines the output as 4-20 mA when

there is an error in the indication.

Do – Applies a value < 4 mA;

UP – Applies a value > 20 mA

must be in the input signal unit:

0-50 mV, 4-20mA or 0-5V. For 0-10V select 0-5V.

PROMPT PARAMETER DESCRIPTION

Ovt.01

ovt.20

Defines the proportional indications in respect to each segment of the customized

linearization. Values are in desired indication unit (within the Indication Lower and

Upper Limits).

ABUS TECHNOLOGIES INC.

11

Page 12

7.1.6 Calibration Cycle

All input types are factory calibrated. Should it be required, calibration should only be done by

experienced personnel. If this cycle is accidentally accessed do not touch the or keys. Just go through

all cycles until the display shows the main or operation menu.

PARAMETERS

PROMPT PARAMETER DESCRIPTION

A1500

In.lo(

In.ki(

Ov.lo(

Ov.Ki(

(J lo

k.type

The table below shows the sequence of cycles and parameters presented in the indicator display. There

are parameters that must be defined for each alarm available:

Input Low Calibration - Sets the Process Variable low calibration (offset). Several key

strokes at or might be necessary to increment one digit.

Input High Calibration - Sets the Process Variable span calibration (gain).

Analog Output Low Calibration - Sets the analog current output low calibration

(offset).

Analog Output Span Calibration - Sets the analog current output high calibration

(span) of the analog output (20mA).

Cold Junction Calibration - Allows the user to adjust this calibration directly in

degrees, of temperature in the indicator terminals.

Hardware Type - These parameters adapt the software to the hardware available

and should not be changed by the user.

2 Alarms 3

2 Alarms and 4-20 mA 19

2 Alarms and RS485 35

2 Alarms, 4-20 mA and RS485 51

4 Alarms 15

4 Alarms and 4-20 mA 31

4 Alarms and RS485 47

4 Alarms, 4-20 mA and RS485 63

Work

Cycle

8.8.8.8.8. Fv.al1 f.fvn( In.typ Inp.01 -inp.30 In.lo(

Al.ref Df.al1 Dig.in Dp.pos OVt.01 - ovt.30 In.ki(

Sp.al1 Ky.al1 Filtr Vnit Ov.lo(

Bl.al1 Ofset Sroot Ov.ki(

Al.1t1 Bavd In.lol (j lo

Al.1t2 adres In.kil k.type

OVT.TY

OVT.er

Alarm

Cycle

Function

Cycle

Configuration

Cycle

Customized

Linearization Cycle

Calibration

Cycle

7.2 Serial Communication

The indicator can be supplied with an asynchronous RS-485 digital communication interface for

master-slave connection to a host computer (master). The indicator works as a slave only and all

commands are started by the computer which sends a request to the slave address. The addressed unit

sends back the requested reply. Broadcast commands (addressed to all indicator units in a multi-drop

network) are accepted but no reply is sent back in this case.

ABUS TECHNOLOGIES INC.

12

Page 13

7.2.1 Characteristics

RS-485 compatibility with two-wire connection, from the host is up to 31 slaves in a multi-drop

network topology. And Up to 247 units can be addressed by the MODBUS RTU protocol. Maximum

network distance: 4,000 feet. Time of indicator disconnection: Maximum of 2ms after the last byte. Te

communication signals are electrically isolated from the rest of the instrument, and can be 1200, 2400,

4800, 9600, 19200, 38400, and 57600 bps.

Number of data bits: 8, without parity or pair parity

Number of stop bits: 1

Time to start response transmission: Up to 100ms after acknowledging the command.

Protocol: MODBUS (RTU)

7.2.2 Rs485 Interface: Electrical Connection

RS-485 signals are:

A1500

D1= D: Bidirectional data line

D:

D0= Inverted bidirectional data line

C = GND: Ground Optional connection to improve communication performance

Figure 11 shows an example of an RS-485 network. If the computer does not have an RS-485 port

available an external RS232RS485 converter should be used.

Figure 11 - RS-485 network connection

ABUS TECHNOLOGIES INC.

13

Page 14

8. OPERATION

For best results, this indicator requires correct setting of parameters as input

type (T/C, Pt100, 4-20mA, etc), alarms triggering point, alarm function, etc. These

parameters are divided in five levels or groups of parameters which we will refer to as

Cycles.

A1500

S.NO.

1 Work Free Access

2 Alarms

3 Functions

4 Configuration Reserved Access

5

6 Calibration

CYCLE ACCESS

Customized

Linearization

Table-4: Parameter Cycles

The work cycle has free access. All other cycles require a certain combination

of key strokes to be accessed. The combination is and keys, when pressed

simultaneously within the cycle chosen, just press to go to the subsequent

parameters of this cycle. At the end of each cycle the display will go back to the work

cycle.

After reaching the intended prompt just press or key to change this

parameter accordingly. All changes are recorded in non-volatile memory as we move

to next prompt. After 25 seconds with no key pressed the indicator will return to the

measuring cycle (work cycle).

8.1 Configuration Protection

As safety measure, changes can be prevented by a combination of keys for each cycle. The

protected parameters could be still viewed but not changed.

To protect a cycle, just press and keys simultaneously for 3 seconds, at the

beginning of the referred cycle.

To unlock this cycle just press the same keys again for 3 seconds. The display will briefly flash

confirming that the cycle was locked or unlocked.

For further protection, the unlock operation through the keypad may be disabled by changing

the position of an internal strap inside the indicator:

When PROT is OFF, the user is allowed to lock and unlock the cycles using the keypad as

explained above.

If PROT is ON, the cycles lock/unlock operation is disable.

ABUS TECHNOLOGIES INC.

14

Page 15

8.2 SPECIAL FUNCTIONS

8.2.1 Maximum and Minimum

The indicator memorizes the measured maximum and minimum values (peak and valley).

These two values are shown by pressing either the MAX or MIN keys. Pressing both keys

simultaneously will clear the memory for a new peak and valley detection.

8.2.2 Special Function Key and Digital Input

The F key (special function key) in the frontal panel and the optional digital input can execute

special functions according to the user selection. Figure 8 shows how to activate the digital input. The

special functions for the F key and for the digital input are explained as it follows.

KOLD - FREEZE MEASURED VALUE

The hold function freezes the measured value showed in the display. Each time the F key or

the digital inputs are selected, alternates from hold to normal mode. Whenever the indicator is in the

A1500

hold mode a

“koLd” message is briefly displayed to show the operator that the displayed value is the

frozen value and not the present reading.

PKOLD - MAXIMUM VALUE

The Peak Hold function shows the maximum value measured since the last time the F key was

pressed or the digital input activated. Each activation of the F key or digital input triggers a new Peak

Hold cycle and the display resets with a new peak value.

RESET - CLEARS MAXIMUM AND MINIMUM

This function works the same way as the MAX and MIN keys pressed simultaneously, as

explained in the 5.1 section. If this “

reset” function is programmed, every touch of the F key or activation

of the digital input will clear the memory and a new cycle of maximum and minimum values memorization

will start.

8.2.3 Process Variable Retransmission

As an option, the indicator can be supplied with an isolated 0-20mA or 4-20mA analog output

for Process Variable (PV) retransmission. The PV values that define the range of the 0mA/4mA to 20mA

retransmission can be programmed by the user in the high and low indication limits, at configuration

level. When this option is available, retransmission will be always active, so that the user will not be

required to turn it on or off. For a voltage output signal an external shunt (calibrated resistor) should be

installed at the analog output terminals.

8.2.4 Extra 24 Vdc Power Supply – Extra P.S

The indicator provides a voltage power supply of 24 Vdc to excite the field transmitters with 25

mA current capacity. It is available at the 16 and 17 terminals at the back panel.

8.2.5 Customized Linearization

Three types of signals can be user-customized to fit special linearization profiles. This means

that the operator can configure the instrument to read non-standard crescent non-linear signals with

high accuracy.

ABUS TECHNOLOGIES INC.

15

Page 16

9. MAINTENANCE

9.1 Troubleshooting

Connection errors or improper configuration will result in malfunctioning of the indicator.

Carefully revise all cable connections and programming parameters before operating the unit. Some

error messages will help the user identify possible problems.

MESSAGE POSSIBLE PROBLEM

Measured value is above the programmed sensor or input signal limit.

Measured value is below the programmed sensor or input signal limit.

Open input. No sensor is connected or the sensor is broken.

A1500

Pt100 cable resistance is too high or the sensor is badly connected.

Different messages other than the ones above should be reported to the manufacturer. Please

inform the serial number if this should occur. The serial number can be viewed at the display by

pressing the

time the unit is powered. The instrument might display false error messages especially concerning the

type of input selected.

key for about 3 seconds. The software version of the instrument can be viewed at the

9.2 Special Recommendations

Should the indicator be repaired, some special handling care should be taken. The device must

be withdrawn from the case and immediately placed in an anti-static wrap; protected from heat and

humidity.

9.3 Input Calibration

Should calibration of some scale be necessary, proceed as it follows:

1. Program the indicator with the type of input requiring calibration;

2. Program the high and low limits of the measure (in.lol and in.kil) for the extreme of the type of

input programmed;

3. Assign the input a corresponding signal and a know indication/measure and slightly over the low

limit of the indication/measure;

“parameter. Use the MIN and MAX keys to select the expected values;

4. Access the “

5. Assign the input a corresponding signal and a known indication and slightly below the higher limit of

the indication/measure;

6. Access the “

7. Repeat steps c to f until no new adjustment is necessary.

inLo

inki

“parameter. Use the MIN and MAX keys to select the expected values;

Note: When verifications are preceded, note if the Pt100 excitation/activation current the calibrator

requires is compliant to the Pt100 excitation current used in this instrument: 750µA.

ABUS TECHNOLOGIES INC.

16

Page 17

10. SAFETY PRECAUTIONS

1. The unit should be powered for 15 minutes before use.

2. Use in ambient temperature of 0-60˚C.

3. Avoid vibrations, shock, excessive dust, corrosive chemical materials or gaseous

environment.

4. Input wire should not be too long. If measured signal have to be far away from the

unit, please use 2-core shielded cable.

5. Use this instrument in the scope of its specifications, otherwise fire or malfunctions

may result.

6. Contact of the instrument, with organic solvents or oils should be avoided.

7. Do not turn on the power supply until all of the wiring is completed. Otherwise

A1500

electrical shock, fire or malfunction may result.

8. Do not disassemble, repair or modify the instrument.

9. All connections should be tightened properly.

10. Power supply should be constant, should not be fluctuating.

11. WARRANTY

ABUS provides the original purchaser of this instrument a one (1) year warranty

against defects in material and workmanship under the following terms:

The one year warranty begins on the day of shipment as stated on the sales bill.

During the warranty period all costs of material and labor will be free of charge

provided that the instrument does not show any evidence of misuse.

For maintenance, return the instrument with a copy of the sales bill to our factory.

All transportation and insurance costs should be covered by the owner of the

equipment.

Should any sign of electrical or mechanical shock, abuse, bad handling or misuse

be evident the warranty voids and maintenance costs will be charged.

ABUS TECHNOLOGIES INC.

www.abustek.com, E-M ail: info@abustek.com

ABUS TECHNOLOGIES INC.

17

Loading...

Loading...