APPLICATION

The V5055 Gas Valves are used with the V4055, V4062,

and V9055 Fluid Power Actuators to control gas flow to

commercial and industrial burners.

V5055A-F

Industrial Gas Valves

PRODUCT DATA

FEATURES

• Used with natural or liquefied petroleum (LP) gases.

• V5055 normally closed valves are rated for final shutoff

service (safety shutoff).

• V5055A,C,D,E Valves are for On-Off service.

• V5055B Valve has a characterized guide and in

combination with the V4055, V4062, and V9055 Fluid

Power Actuators, provides slow-opening, hi-lo-off,

and modulating functions respectively.

• V5055C,E,F Valves have a double seal and are used

with V4055D,E Actuators to provide proof-of-closure

switch and valve seal overtravel interlock.

• V5055D,E,F Valves are for high pressure applications

(see Table 1).

• Seven valve sizes from 3/4 to 3 inches have NPT

threaded connections. Models are available with

BSP-PL threads. V5055A,B,C Valves are available

in a 4 inch size and have flange connections.

• Most models have 1/4 inch upstream and downstream

tap and plug. BSP-PL thread models have 1/4 inch

upstream tap and plug.

• Valve body rating of 75 psi (517.1 kPa).

• Yellow SHUT indicator attached to the valve stem

provides an indication of the valve closed position.

• Unpainted, die-cast aluminum body.

® U.S. Registered Trademark

© 2004 Honeywell International Inc.

All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ......................................................... 2

Gas Valve Sizing .............................................................. 4

To Size Two Identical Valves Piped In Series ................... 4

Installation ........................................................................ 6

Operation and Checkout .................................................. 7

Service Information .......................................................... 9

Put UPC Code Here

60-2307—15

V5055A-F INDUSTRIAL GAS VALVES

SPECIFICATIONS

Models:

V5055A Industrial Gas Valve for On-Off service.

Pipe Size: 3/4, 1, 1-1/4, 1-1/2, 2, 2-1/2, 3, and 4 in.

(only V5055A,B,C available in 4 in. size).

V5055B Industrial Gas Valve with characterized guide for

slow opening, HI-LO-OFF, or modulating service.

V5055C: Same as V5055A but incorporates a double seal.

Used with the V4055D Actuator to a provide

Pipe Threads: NPT or BSP-PL Threads (equivalent to ISO

R7 and DIN 2999). Available on inlet and outlet of 3/4 to 3 inch

valves. Four inch valves have flange connections.

proof-of-closure switch and a valve seal overtravel

interlock.

Pressure Ratings: See Table 1.

V5055D: Same as V5055A but for high pressure applications.

V5055E: Same as V5055C but for high pressure applications.

Valve Body Rating: 75 psi (517.1 kPa).

V5055F: Same as V5055E but meets the intent of EN161

leakage requirements.

Valve Capacities: At 1 in. (0.25 kPa) pressure drop; based

on gas with specific gravity of 0.64.

Type of Gas: Natural or liquefied petroleum (LP) only.

Table 1. Pressure Ratings of Valve-Actuator Combinations.

Actuator

V5055A,C

Valve

Diff.

V4055A,D

b

a

Closeoff

c

V4055B,E,F

b

Diff.

psi kPa psi kPa psi kPa psi kPa psi kPa psi kPa

5 34.5 15 103.4 15 103.4 15 103.4 5 34.5 15 103.4

a

Closeoff

V4062,V9055

c

Diff.

b

a

Closeoff

3/4 to 3 in.

V5055A,C

3 20.7 15 103.4 5 34.5 15 103.4 3 20.7 15 103.4

4 in.

V5055B

5 34.5 15 103.4 15 103.4 15 103.4 5 34.5 15 103.4

3/4 to 3 in.

V5055B

3 20.7 15 103.4 5 34.5 15 103.4 3 20.7 15 103.4

4 in.

V5055D,E,F

d

5 34.5 75 517.1 25 172.4 75 517.1 5 34.5 75 517.1

3/4, 1, 1-1/4, 1-1/2 in.

V5055D,E

5 34.5 45 310.3 15 103.4 45 310.3 5 34.5 45 310.3

2, 2-1/2. 3 in.

a

Use a V4055D, V4055E, V4062D, or V9055D (with proof-of-closure switch) with a V5055C,E or F (with double seal) for valve

seal overtravel interlock.

b

Maximum operating pressure differential.

c

Maximum close-off pressure without seal leakage. This is the maximum allowable pressure drop to which a valve may be

subjected while fully closed, and is independent of the valve body rating.

d

V5055F available in 1 in., 1-1/4 in., 1-1/2 in. and 2 in. sizes only.

Upstream Tapping and Plug: 1 /4 in. NPT or BSP-PL

is standard.

Downstream Tapping and Plug:

1/4 in. NPT on most domestic models.

1/8 in. NPT on V5055C1182.

c

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2307—15 2

V5055A-F INDUSTRIAL GAS VALVES

Ambient Operating Temperature Rating:

-40°F to 150°F (-40°C to 66°C); -40°F to 125°F

(-40°C to 52°C) when used with V9055.

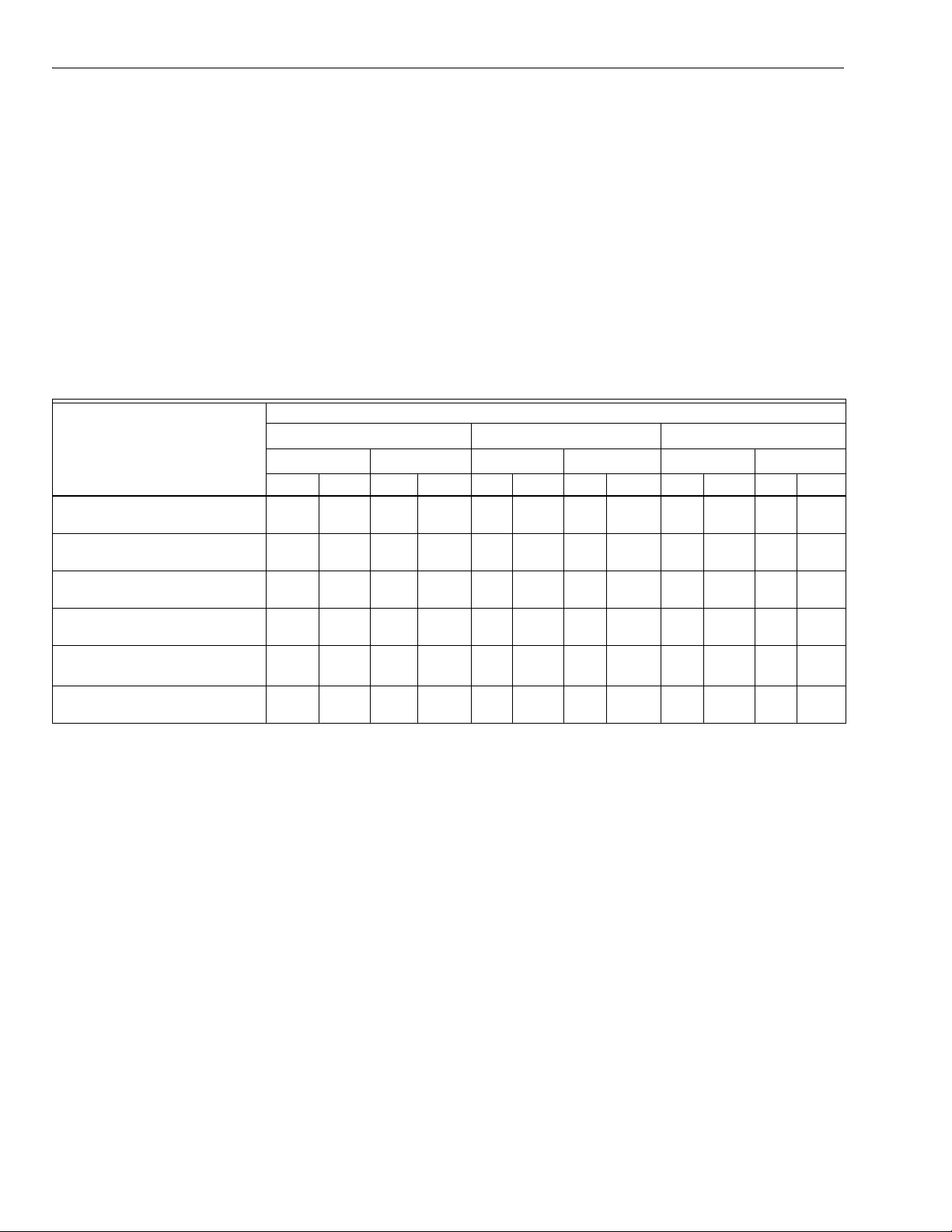

Table 2. Valve Rated Capacity.

CSA Rated Capacity

Valve Size (in.)

3/4 665 18.8

1 960 27.2

1-1/4 1406 39.8

1-1/2 1717 48.6

2 3620 102.5

2-1/2 4250 120.3

3 5230 148.1

4 (V5055A) 10200 288.8

4 (V5055B,C) 9180 259.9

1 2 3 4 5 6 7 8 91 2 3 4 5 6 7 8 91 2 3 4 5 6 7 891

1

100.0

9

(25)

8

7

6

5

4

3

cf/h cu m/hr

Material: Die-cast aluminum.

Mounting: Mounts directly in the gas supply line.

Dimensions: See Fig. 2 and 3.

Weight:

3/4, 1, 1-1/4, 1-1/2, in. valve: 4 lb. (1.8 kg).

2 in. valve: 8 lb. (3.6 kg).

2-1/2, 3 in. valve: 11 lb. (5.0 kg).

4 in. valve: 28 lb. (12.7 kg).

100.0

9

8

7

6

5

4

3

2

10.0

1

(2.5)

9

8

7

6

5

4

3

[1 in. wc = 0.25 kPa]

2

PRESSURE DROP, INCHES WC

11.0

(0.25)

.9

.8

.7

.6

.5

.4

.3

.2

3/4 INCH

1 INCH

1 INCH

1 1/4 INCH

1 1/2 INCH

2 INCH

2 1/2 INCH

3 INCH

4 INCH V5

B, C

055

4 INCH V5

055

2

1.0

9

8

7

6

5

4

3

2

1.0

.9

.8

.7

.6

.5

.4

A

.3

.2

.1

100

(2.8)

CAPACITY, IN CUBIC FEET PER HOUR (cf/h) FOR GAS WITH SPECIFIC GRAVITY OF 0.64 [1 cf/h = 0.0283 cu m/hr]

1000

(28)

10,000

(283)

Fig. 1. Flow curves for V5055 Valves.

3 60-2307—15

100,000

(2830)

M9542

.1

V5055A-F INDUSTRIAL GAS VALVES

Replacement Parts:

Replacement Seal Assembly: Includes valve seal, bonnet

seal, and tube of lubricant.

133393A: for 3/4, 1, 1-1/4, and 1-1/2 in. valves

133392A: for 2, 2-1/2, and 3 in. valves.

137253A: for 4 in. valves.

Replacement Bonnet Assembly: Includes complete bonnet

assembly, plus the required replacement seal assembly.

See Table 3.

Table 3. Replacement Bonnet Assemblies.

Replacement

Valve Model Valve Size (in.)

V5055A

(On-Off)

V5055B

(Characterized

guide)

V5055C

(Valve-closed

indicator)

V5055D

(High pressure

On-Off)

V5055E (Valve

Closed Indicator)

Approvals:

The following combinations of V5055 Valves (3/4 through

4 in.) and V4055, V4062 and V9055 Fluid Power Actuators

are approved by these agencies:

Underwriters Laboratories Inc. Listed: (File No. MH1639,

Guide No. YIOZ):

V4055A,B,D,E/V5055A,B,C,D,E,F

V4062/V5055A,B,C,E,F

V9055/V5055A,B,C,E,F

Industrial Risk Insurers (Formerly F.L.A.) Acceptable:

V4055A,B,D,E/V5055A,B,C,D,E,F

V4062/V5055A,B,C,E,F

V9055/V5055A,B,C,E,F

Factory Mutual Approved (Report No. ID92A.AF).

CSA File No. 158158-1205788:

V4055A/V5055A,B V4055E/V5055E

V4055B/V5055D V4062/V5055B,C

V4055D/V5055C V9055/V5055B,C

NOTE: CSA does not certify models equipped with

BSP threads.

British Gas Corporation and Dutch Gas Institute Approved:

3/4, 1, 1-1/4,

1-1/2

2, 2-1/2, 3 133417AA

4 136911AA

3/4, 1, 1-1/4,

1-1/2

2, 2-1/2, 3 133417BA

4 136911BA

3/4, 1, 1-1/4,

1-1/2

2, 2-1/2, 3 133417CA

4 136911CA

3/4, 1, 1-1/4,

1-1/2

2, 2-1/2, 3 136307AA

3/4, 1, 1-1/4, 1-1/2 136308BA

2, 2-1/2, 3 136307BA

Bonnet Assembly

133398AA

133398BA

137398CA

136308AA

V4055 or V4062 with V5055A1145, A1152, A1160,

A1178, B1168, B1184, B1192, B1200, B1218.

Australian Gas Association Approved:

V5055B1267, B1275, and B1291.

DIN-DVGW Approved (Germany):

V5055A1145, A1152, A1160, A1178, B1168, B1184,

B1192, B1200, and B1218.

GAS VALVE SIZING

1. Check the burner nameplate for (a) the type of gas

used, and (b) the gas flow capacity. The capacity will

be listed in Btu/h (Btus per hour) or in cf/h (cubic foot

per hour).

2. Call the gas utility for information on (a) the specific

gravity (sp gr) and (b) Btu per cubic foot (Btu/cu ft) for

type of gas used.

3. Find the capacity in cf/h. If the capacity is listed in

Btu/h, convert to cfh by the following formula:

Capacity in cf/h = :Btu/h (from burner nameplate)

Btu/cu ft (from gas utility)

4. For gases with specific gravities other than 0.64,

multiply the burner cfh by the proper conversion factor.

See Table 4.

Table 4. Gas Conversion Factors.

Type of Gas sp gr (average) Multiply cf/h by:

Manufactured 0.60 0.968

Mixed 0.70 1.046

Propane 1.53 1.546

Butane 1.98 1.759

5. Use the corrected burner capacity in cf/h when

determining the gas valve size in Fig. 1.

6. Determine the maximum pressure drop across the valve

and draw a horizontal line at this pressure in Fig. 1.

7. Draw a vertical line in Fig. 1 at the capacity (cf/h)

previously determined. Use the corrected capacity for

a gas with a specific gravity other than 0.64.

8. Use the valve size at the intersection of the horizontal

and vertical lines. If the intersection is between valve

sizes, use the next higher size to the right.

TO SIZE TWO IDENTICAL VALVES PIPED IN SERIES

1. Find the cf/h for the type of gas used.

2. Consider both valves as one unit. Determine the total

maximum pressure drop across the unit.

3. Find the pressure drop across the first valve by

assuming it to be 45 percent of the total pressure drop.

4. Find the valve size from Fig. 1.

5. The second valve will be the same size as the first

valve.

60-2307—15 4

V5055A-F INDUSTRIAL GAS VALVES

6-3/4 (172)

3-23/32 (95)

27/32 (21)

1

A

KNOCKOUT

FOR1/2 INCH

CONDUIT (4)

1-9/32

(33)

C

B

5 (127)

1/4 INCH NPT

DOWNSTREAM

TAP AND PLUG

1

ALLOW 2 IN. (51 mm) CLEARANCE FOR ACTUATOR REMOVAL.

VALVE

SIZE

INCH

3/4

1

1-1/4

1-1/2

2

2-1/2

3

11-1/8

11-1/8

11-1/8

11-1/8

11-1/4

11-3/4

11-3/4

IN.

DIM A

MM

282.6

282.6

282.6

282.6

285.8

298.5

298.5

DIM B

IN. MM

2-3/4

2-3/4

2-3/4

2-3/4

2-7/8

3-3/8

3-3/8

69.9

69.9

69.9

69.9

73.0

85.7

85.7

D

8-3/16

8-3/16

8-3/16

8-3/16

8-5/16

8-13/16

8-13/16

DIM C

IN. MM

1/4 INCH NPT UPSTREAM

TAP AND PLUG

DIM D

IN. MM

208.0

5-3/4

208.0

5-3/4

208.0

5-3/4

208.0

5-3/4

211.1

8-3/8

223.8

9-1/4

223.8

9-1/4

146.1

146.1

146.1

146.1

212.7

235.0

235.0

2-1/4

2-1/4

2-1/4

2-1/4

2-3/4

2-3/4

2-3/4

DIM E

IN. MM

57.2

57.2

57.2

57.2

69.9

69.9

69.9

OCTAGON

F

DIM F

IN. MM

4-13/16

4-13/16

4-13/16

4-13/16

7-19/32

7-19/32

7-19/32

122.2

122.2

122.2

122.2

192.9

192.9

192.9

OCTAGON

IN. MM

2-13/16

2-13/16

2-13/16

2-13/16

3-1/2

4-1/2

4-1/2

71.4

71.4

71.4

71.4

88.9

114.3

114.3

M9585

Fig. 2. Approximate dimensions of the 3/4 through 3 in. V5055 Valves, with valve actuator, in in. (mm).

(171.5)

6-3/4

3-23/32

E

14-5/32

(360)

(94.5)

(21.4)

27/32

KNOCKOUT

FOR1/2 INCH

CONDUIT (4)

1-9/32

(33)

1

5 (127)

11-7/32

(285)

3/4 (19)

DIAMETER

(16)

9-5/32

(233)

5-25/32

(147)

45 (16)

12-1/2 (318)

1

ALLOW 2 IN. (51 mm) CLEARANCE ABOVE V4055 SO IT MAY BE REMOVED FROM VALVE.

2

DIMENSIONS ON DIN-APPROVED VALVES: 1/4 - 19 BSP.PL UPSTREAM PLUG (2),

.71 IN (18 mm) DIAMETER BOLT HOLE (16), 7.087 IN (180 mm) DIAMETER BOLT CIRCLE.

1/4 - 18 NPT

UPSTREAM

PLUG (2)

2

4 (102)

DIAMETER

7-1/2 (191)

DIAMETER

M9584

Fig. 3. Approximate dimensions of the 4 in. V5055 Valves, with valve actuator, in in. (mm).

5 60-2307—15

V5055A-F INDUSTRIAL GAS VALVES

INSTALLATION

IMPORTANT:

The V5055 Valve is designed to provide control

of gaseous fuel (natural and LP gas) flow in

applications in which there is minimal exposure to

water. V5055 Valves used in maritime, beverage,

food processing, outdoor and other installations in

which occasional exposure to water is experienced

may be subject to valve stem and spring corrosion.

The presence of corrosion decreases the operating

life of the valve. V5055 Valves used in such

installations should be inspected at least annually

and should have the valve bonnets replaced if

corrosion is noted.

A V4055 Valve Actuator with a NEMA 4 rating is also

recommended for such installations. The water-tight

design of the NEMA 4 rated V4055 Actuator prevents

water from entering the V4055 valve stem and spring

chamber through the actuator. Under certain

conditions, some water may be retained by the

external upper portion of the valve body. The

retained water is effectively excluded from the valve

stem and spring chamber by a functional seal that is

incorporated into the NEMA 4 rated actuator.

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame

safeguard control technician.

4. After installation is complete, check out product

operations as provided in these instructions.

WARNING

Electrical Shock Hazard and Explosion Hazard.

Can cause serious injury, death or property

damage.

1. Turn off gas supply before starting installation.

2. Disconnect power supply for valve actuator before

beginning installation to prevent electrical shock

and equipment damage.

3. Be sure the valve is installed so the arrow on

the valve points in the direction of gas flow.

(Gas pressure helps to close the valve.)

Location

Install the valve in the gas supply line downstream from the

pressure regulator. The valve and actuator may be mounted in

any position that allows sufficient clearance for installation and

for repair or replacement.

1. The valve position indicators should be easily visible

with the valve and actuator in the final position.

2. The final position of the valve and actuator must allow

for damper linkage, if used.

IMPORTANT:

Allow room for turning the valve body (actuator not

attached) onto the gas piping. Swing dimensions,

measured from the center of the pipe are:

3/4 through 1-1/2 in. valves: 4 in. (101.6 mm).

2 through 3 in. valves: 5 in. (127.0 mm).

4 in. valves: 7 in. (177.8 mm).

Mounting (Figs. 4 through 6)

WARNING

Explosion Hazard.

Can cause serious injury, death or property

damage.

If flow is not in the direction of the arrow on the valve

body, the valve may not shut off.

60-2307—15 6

1. Use new, properly reamed, pipe, free from chips.

2. Do not thread pipe too far (Fig. 4). Valve distortion or

malfunction may result from excess pipe in the valve.

V5055A-F INDUSTRIAL GAS VALVES

TWO CLEAN

THREADS,

MODERATE

AMOUNT

OF DOPE

CORRECT:

NORMAL

FULL

THREAD

CORRECT:

NORMAL

FULL

THREAD

11USE PIPE DOPE RESISTANT TO ACTION OF LP GAS.

EXCESS DOPE MAY BLOCK

DISK OFF

VALVE

SEAT

LOOSE

CHIPS

REAM PIPE,

BLOW OUT

CHIPS (TO AVOID

LODGING ON SEAT)

INCORRECT:

TOO LONG,

DISTORTS

VALVE SEAT

INCORRECT:

TOO LONG,

DISTORTS

VALVE SEAT

M9571

Fig. 4. Preparing the pipes.

3. Remove the protective caps from the ends of the valve.

Do not attach the valve actuator until the valve body

installation is complete.

4. Apply good quality pipe dope resistant to action of

LP gas, putting a moderate amount on the male threads

only. Use dope sparingly; if pipe dope lodges on the

valve seat, it will prevent proper closure.

5. Install valve with the gas flow in the direction indicated

by the arrow on the casting.

6. Apply a parallel jaw wrench only to the flat next to the

pipe being inserted (Fig. 5). A wrench applied to the

valve body itself, or to the end farthest from the pipe

being inserted, may distort the casting, causing a

malfunction. Do not use the valve for a lever.

7. Be sure the gas flow is in the same direction as the

arrow on the bottom of the valve body.

8. Use two threaded companion flanges, two gaskets

(included with valve), and 16 bolts (with washers and

nuts) for mounting a 4 in.-V5055 Valve. Mount a

threaded flange and gasket on each end of the valve as

shown in Fig. 6. Then screw the pipes into the threaded

flanges. Apply dope sparingly, and use wrenches and

vises properly as shown in Fig. 4 and 5.

9. Make sure the power supply is disconnected from

the valve actuator. Then mount the actuator on the

valve body and complete the electrical and linkage

connections following the instructions packed with the

actuator.

Checkout

WARNING

Explosion Hazard.

Can cause serious injury, death or property

damage.

Do not allow fuel to accumulate in the combustion

chamber. If fuel is allowed to enter the chamber

for longer than a few seconds without igniting, an

explosive mixture could result.

CORRECT:

VISE GRIPS END

NEXT TO PIPE

BEING INSERTED

CORRECT:

WRENCH CORRECTLY

APPLIED NEXT

TO PIPE BEING

INSERTED

INCORRECT:

Fig. 5. Installing a 3/4 through 3 in. V5055 Valve.

WRENCH HERE

STRAINS

VALVE BODY

M9580

OPERATION AND CHECKOUT

Operation

A V5055 Industrial Gas Valve is operated by a V4055, V4062,

or V9055 Fluid Power Gas Valve Actuator. The valve opens

when the actuator is energized, and closes when power is

removed. When closed, the valve seals off against the

rated close-off pressure with no power applied. For further

information, refer to the Instructions for the actuator.

7 60-2307—15

V5055A-F INDUSTRIAL GAS VALVES

NUT AND WASHER

(NOT INCLUDED)

GASKET

(2 INCLUDED WITH VALVE)

4 IN. VALVE

THREADED COMPANION

FLANGE (2 - NOT INCLUDED)

Fig. 6. Installing a 4 in. V5055 Valve.

CAUTION

Equipment Damage Hazard.

Operation without proper checkout can damage

the equipment.

1. Do not put the system into service until you have

satisfactorily completed the following Valve Leak

Test, all applicable tests described in the Checkout

section of the Instructions for the flame safeguard

control, and any other tests required by the burner

manufacturer.

2. All tests must be performed by a trained,

experienced flame safeguard control technician.

3. Close all manual fuel shutoff valves as soon as

trouble occurs.

After the installation is complete, cycle the valve several times

with the manual fuel shutoff cock closed. Make sure the valve

and actuator function properly. Also perform the Valve Leak

Test that follows before putting the valve into service.

Valve Leak Test (Fig. 7)

This is a test for checking the closure tightness of a gas

safety shutoff valve. It should be performed by qualified

personnel during the initial startup of a burner system, or

whenever the valve or valve bonnet is replaced (see

Service Information section). It is recommended that this

test also be included in the scheduled inspection and

maintenance procedures. For a periodic inspection test,

follow steps 1, 3, 4, 5, 8, 9, 10, 12, 13, 16, and 17.

5/8 X 3 IN. [76] BOLT

(16 - NOT INCLUDED)

GAS

SUPPLY

UPSTREAM

MANUAL

GAS COCK

CAN ALSO BE A PERMANENT PETCOCK.

1

PRV = PRESSURE REGULATING VALVE.

2

3

SSOV = SAFETY SHUTOFF VALVE.

USE ONLY ONE OF THE DOWNSTREAM TAPS ON THE SS0V.

4

4 IN. PIPE

PRV

2 3

1/4 IN. (6 MM)

FLEXIBLE

TUBING

1/4 IN. (6 MM)

ALUMINUM OR

COPPER PILOT

TUBING

1

2

(13 MM)

DABC E

LEAK

4

TEST

TAP

SSOV

M9581

DOWNSTREAM

MANUAL

GAS COCK

BURNER

F

MANUAL

TEST

PETCOCK

JAR OR GLASS

WITH WATER

CUT AT

45 DEGREE

ANGLE

1

M9547F

Fig. 7. Valve leak test.

1. De-energize the control system to assure that there is

no power to the safety shutoff valve (C) shown in Fig. 7.

2. Close the upstream manual gas cock (A).

3. Make sure the manual test petcock (F) is closed in the

leak test tap assembly (D).

60-2307—15 8

V5055A-F INDUSTRIAL GAS VALVES

4. Remove the leak test tap plug and connect the test

apparatus to the Leak Tap (D).

5. Close the downstream manual gas cock (E).

6. Open the upstream manual gas cock (A).

7. Run the safety shutoff valve (C) to its fully open position

(through the safety system); then immediately

de-energize the system to close the valve.

8. Immerse a 1/4 in. tube vertically 1/2 in. (12.7 mm) into

a jar of water.

9. Slowly open the test petcock (F).

10. When the rate of bubbles coming through the water

stabilizes, count the number of bubbles appearing

during a ten-second period. Each bubble appearing

during a ten-second period represents a flow rate of

approximately 0.001 cfh.

To meet U.S. requirements, leakage must not exceed the

values listed in Table 5.

Table 5. Allowable Leakage for V5055 Valves.

Allowable

V5055 Pipe

Size (in.)

3/4, 1, 1-1/4,

1-1/2

2, 2-1/2, 3 940 24 4.1

4125433 3.03

a

Based on natural gas at standard conditions, test pressures

provided by ANSI Z21.21, Section 2.4.2 and a maximum of

235 cc/hr (air) per inch of seal-off diameter. Seal-off diameter

is not to be confused with pipe size.

b

V5055F leakage rate is 1 bubble in 7.6 seconds.

NOTE: For international leak test requirements, contact

the office of the appropriate approval agency.

leakage

a,b

(cc/hr)

573 14 6.7

Maximum

Number of

bubbles per 10

sec.

Minimum

Number of

Seconds for

10 bubbles

After the test:

11. Close the upstream manual gas cock (A).

12. Close the test petcock (F), remove the test apparatus,

and replace the leak test tap plug (D).

13. Open the upstream manual gas cock (A) and energize

the safety shutoff valve (C).

14. Test with soap bubbles to assure that there is no leak

at the test tap (D).

15. De-energize the safety shutoff valve (C).

16. Open the downstream manual gas cock (E).

17. Restore the system to normal operation. If two safety

shutoff valves are utilized, each V5055 valve is to be

checked for tightness of closure.

SERVICE INFORMATION

WARNING

Explosion and Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

1. Before servicing, turn off the gas supply and

disconnect all electrical power to the valve actuator.

2. Only qualified service technicians should attempt

to service or repair flame safeguard controls and

burner systems.

3. Do not disassemble the valve bonnet assembly;

the valve seat is not replaceable.

4. Failure to properly position and seat the seals in the

valve body may result in a hazardous gas leak.

Scheduled Inspection and Maintenance

Setup and follow a schedule for periodic inspection and

maintenance, including the burner, all other controls, and

the valve(s). It is recommended that the Valve Leak Test in

the Checkout section be included in this schedule. Refer to

the Instructions for the primary safety control for more

information.

Valve Bonnet Replacement

The entire valve bonnet may be replaced without removing

the valve body from the gas line. Do not disassemble the

valve bonnet assembly; the valve seat is not replaceable.

For part numbers, refer to Replacement Parts in the

Specifications section. Complete instructions for replacing

the bonnet assembly are included with the replacement part.

Replacement of Seals (Fig. 8 or 9)

When removing the bonnet to inspect and clean the valve,

install new seals (see Replacement Parts in Specifications

section). Coat the new seals with the grease provided, and

position them in the valve body as shown in Fig. 8 or 9.

Failure to properly position and seat the seals in the valve

body may result in a hazardous gas leak.

After the new bonnet assembly is installed, or the bonnet is

removed for any reason, check for gas leakage around the

bonnet seal. Turn on the gas at the manual valve. Paint the

seal area with a rich soap and water solution. Bubbles

indicate a gas leak. If a leak is detected, check to see that

the bonnet screws are tight. If necessary, turn off the gas

again and remove the bonnet to be sure the seals are

properly seated.

9 60-2307—15

V5055A-F INDUSTRIAL GAS VALVES

BONNET SEAL

LARGE SEAL

VALVE SEAL

Fig. 8. Proper positions of valve and bonnet

seals in 3/4 through 3 in. valves.

M9578

SMALL SEAL

Fig. 9. Proper positions of valve and

bonnet seals in 4 in. valve.s

M9579

60-2307—15 10

11 60-2307—15

V5055A-F INDUSTRIAL GAS VALVES

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

M1V 4Z9

60-2307—15 G.R. Rev. 11-04 www.honeywell.com

Loading...

Loading...