Page 1

APPLICATION

The V4046C and V8046C Magnetic Valves provide on-off

control of gas flow in supply line.

V4046C, V8046C

Magnetic Valves

PRODUCT DATA

FEATURES

• Normally closed valves which open immediately when

energized.

• V4046C is for line voltage applications; V8046C is for

24 Vac applications.

• Provides on-off control of manufactured, Liquefied

Petroleum (LP), and natural gases with high sulfur

content.

• Used with pilot burners in industrial applications.

• All models close in one second (maximum) on power

failure.

• Heavily loaded spring plunger maintains valve seating

when the coil is de-energized, permitting the valve to

be mounted in any position.

• Valve may be pipe-mounted or mounted on bracket

support furnished by installer.

• Powerhead assembly can be rotated 360 angular

degrees.

• Solenoid coil is field-replaceable without removing the

valve body from the piping connection.

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Wiring ............................................................................... 5

Checkout and Service ...................................................... 5

66-2008-3

Page 2

V4046C, V8046C MAGNETIC VALVES

SPECIFICATIONS

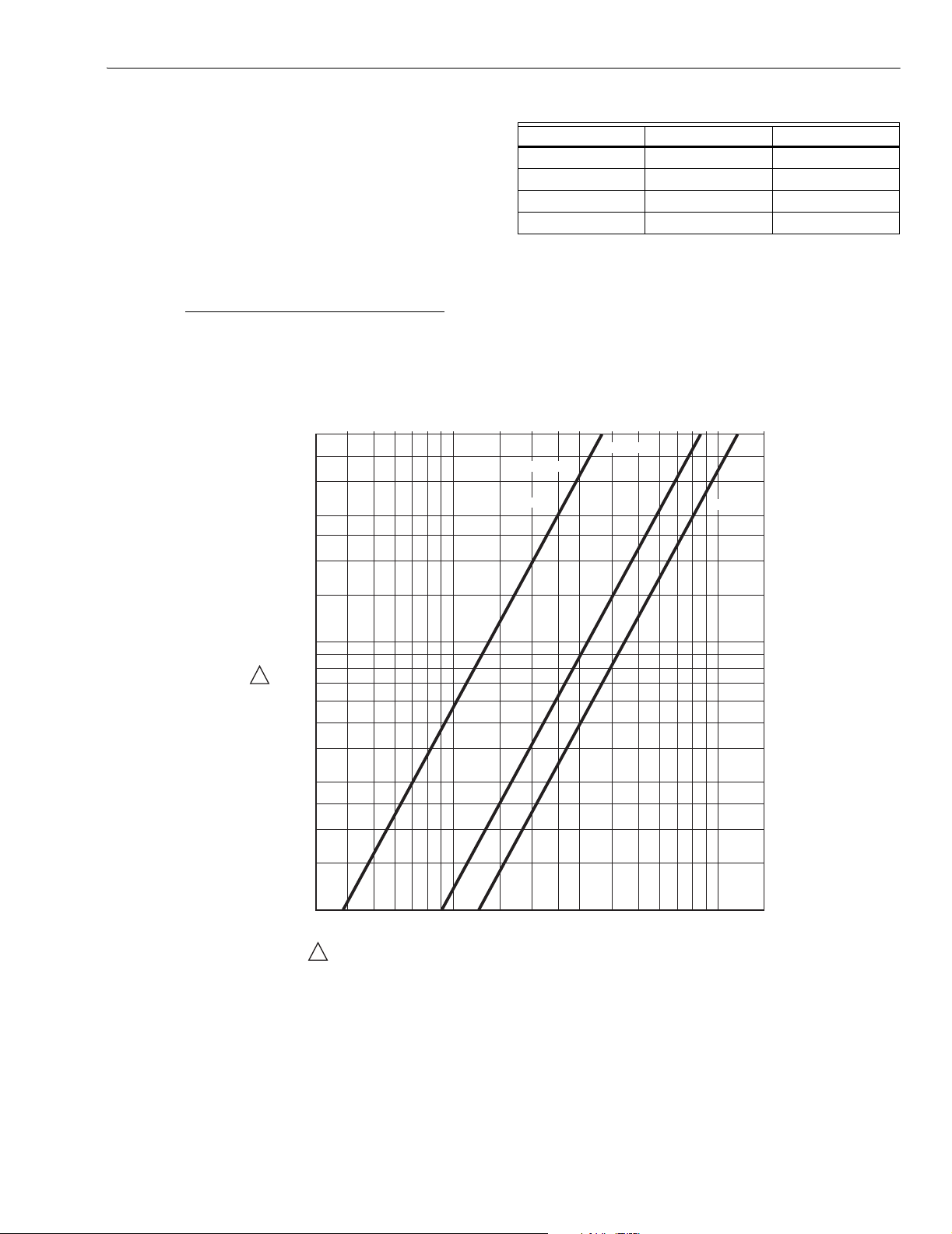

Models: See Table 1.

Table 1. Model Specifications.

Pressure Rating

Model

V4046C 10 69 20

V8046C 20

a

1/2 psi in AGA rating.

b

See body sizes, Fig. 2. 55 cfh (1.56 cmh) is for large body valve with 1/4-18 NPT threads; 67 cfh (1.90 cmh) is for large body

valve with 3/8-18 NPT threads.

c

Natural gas, 1000 btu/cu ft measured at one inch pressure drop, 0.64 specific gravity. See Gas Capacity Conversion Factors.

a

55

67

55

67

Gas Flow

b

m/hr btuh

0.57

1.56

1.90

0.57

1.56

1.90

Gas Heat

Capacitya

20,000

55,000

67,700

20,000

55,000

67,700

c

Operation

Energized

Opens

Immediately

Vol tag e s

(60 Hz)psi kPa cfh

120

208

24

Table 2. Coil VA Ratings.

24 Vac,

Model

V4046C — 13.8 13.7

V8046C 14.1 — —

Types of Gas: Suitable for all domestic gases including high

sulfur content LP gas.

Valve Material: Aluminum.

Valve Pattern: Straight-through.

Pipe Size: See Fig. 1.

Valve Action on Power Failure: All models close in one sec-

ond maximum.

Mounting:

Can be mounted in any position. Mounts directly in pipe line or

on a support bracket. See Fig. 2 for tapped holes provided

in bottom of valve body. Conduit outlet on powerhead can

be rotated through 360 degrees with respect to valve body.

60 Hz

120 Vac, 60 Hz208 Vac, 60

Hz

Wiring Connection: Two 36-in. (915 mm) leadwires; 1/2 in.

conduit bushing.

Ambient Temperature Range: -40°F to +125°F (-40°C to

+54°C).

Approvals:

Underwriters Laboratories, Inc. Listed: File NO. MH1639, V3,

S3; Guide No. YIOZ; V4046C, V8046C for gas.

Factory Mutual Listed: V4046C, V8046C for gas.

CSA 158158-250000605.8, Guide Numbers C3371-03, 83.

(60 Hz models only).

Replacement Parts: Coil assemblies include coil, leadwire,

insulator and bobbin. See Table 3.

Table 3. Coil Assemblies for V4046C, V8046C Valves.

Part Number Used On

116671A V4046C; 120 Vac, 60 Hz

116782A V4046C; 208 Vac, 60 Hz

11668A V8046C; 24 Vac, 60 Hz

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

66-2008—3 2

Page 3

V4046C, V8046C MAGNETIC VALVES

6.0

0

B

1.

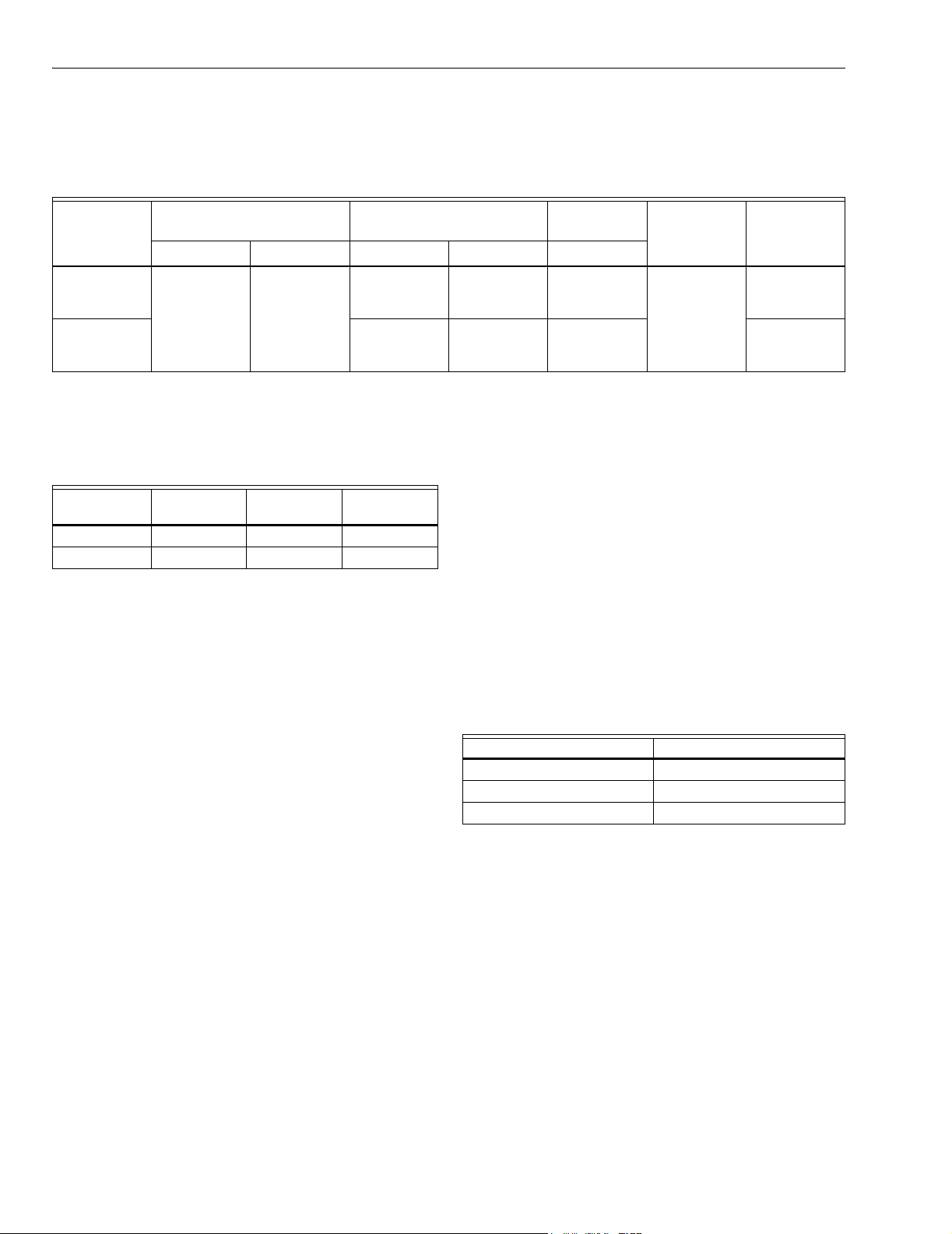

Gas Valve Sizing

1. Check the burner nameplate for:

a. the type of gas used, and

b. the gas flow capacity. The capacity will be listed in

British thermal units per hour(Btuh) or in cubic feet

per hour (cfh).

2. Contact the local gas utility for information regarding:

a. the specific gravity (sp gr) and

b. the Btu per cubic foot (Btucf) for the type of gas

used.

3. Find the capacity in cfh. If the capacity is listed in Btu,

convert to cfh using the following formula:

Capacity in cfh = Btuh (burner nameplate)

Btu/cu ft (gas utility)

4. For gases with specific gravity other than 0.64, multiply

the burner cfh using the proper conversion factor in

Table 4.

5.0

4.0

3.0

2.5

2.0

Table 4. Gas Conversion Factors.

Type of Gas sp gr (average) Multiply cfh by

Manufactured 0.60 0.968

Mixed 0.70 1.046

LP-Propane 1.53 1.546

LP-Butane 1.98 1.759

5. Use the corrected burner capacity in cfh when

determining the gas valve size in Fig. 1.

6. Determine the maximum pressure drop to be taken

across the valve. If pressure drop is not in pounds per

square inch (psi), multiply the value in known pressure

units by the conversion factor.

7. Plot the capacity (cfh) vs. pressure drop (psi) in Fig. 1 to

find the proper valve size.

NOTE: Use the corrected cfh for gas other than 0.64 sp gr.

1/4 INCH LARGE

1/8 INCH

1/4 INCH SMALL

3/8 INCH

1.5

PRESSURE

DROP (P SI)

1.0

.9

1

.8

.7

.6

.5

.4

.3

.25

.2

.15

.1

30 40 50 60 70 80 90 100 150 200 250 300 400 500 600 700 800 900 1000 150

1

TO CONVERT PRESSURE DROP IN INCHES WC TO PSI UNITS, MULTIPLY UNITS IN INCHES WC By .036

TO CONVERT PRESSURE DROP FROM PSI TO INCHES WC, MULTIPLY UNITS IN PSI BY 27.7.

FLO W (CFH ) OF NAT UR AL GA S SP . GR. .64

M20743

Fig. 1. Pressure drop (psi) vs.flow capacity (cfh) on V4046C, V8046C gas valves only.

Dimensions. See Fig. 2.

3 66-2008—3

Page 4

V4046C, V8046C MAGNETIC VALVES

DIM. B

1-3/4 (45)

Fig. 2. V4046C, V8046C approximate dimensions in in. (mm).

1/2-14 NPSM

36 IN. (915)

LEADS (2)

MODEL

V4046C,

V8046C

SEE TAB

BODY

SIZE

SMALL

SMALL

LARGE

LARGE

1-5/8

(41)

1-3/8

(35)

THREAD

SIZE

1/8-27 NPT

1/4-18 NPT

1/4-18 NPT

3/8-18 NPT

1-3/16

(30)

DIM. A

DIM. A DIM. B

IN MM IN MM

5/16

3/8

1/2

1/2

1-1/4 (32)

BASIC

CENTER

8

2-3/4

10

3

13

3-1/4

13

3-1/4

1-3/4 (45)

70

76

83

83

M16595

2-5/8 (67)

45°

BASIC

CENTER

8-32 x 1/4 IN.(6)

DEEP (2)

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. The installer must be a trained, experienced flame

safeguard technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

Explosion and Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

1. Turn off gas supply before beginning installation.

2. Disconnect electrical power before beginning

installation or servicing procedure. More than one

disconnect can be involved.

3. To avoid damage or distortion of the valve when

installing rigid or flexible conduit, the conduit fittings

should not be subjected to more than 5 ft-lbs torque

when screwing the fitting into the valve coil case

(powerhead). An approximation of 5 ft-lbs torque is

hand-tightened plus 1/8 turn. When securing the

rigid or flexible conduit in the conduit fitting using

the setscrew, use only enough force to secure the

conduit to avoid damage/distortion of the valve.

4. Always loosen the coil nut before attempting to

rotate the powerhead.

5. Do not tighten the valve on the gas pipe using the

coil housing (powerhead) as a handle.

Gas and Air Installations

Mount the gas valves in the pilot gas supply line upstream

from the burner. Ambient temperatures at the valve location

must be within -40°F to +125°F (-40°C to +54°C).

Mounting

The V4046C and V8046C Valves will operate in any mounting

position required by the installation, as long as gas flow is in

the direction indicated by the arrow.

Use iron pipe for at lease one of the valve connections to

insure adequate support and to confirm with

recommendations of Underwriters Laboratories, Inc.

If the installation does not support the valve adequately, a

mounting bracket should be devised and installed.

Preparing Piping and Installing Valve

1. Use new, properly reamed pipe, free from chips.

2. Do not thread pipe too far. Valve distortion or valve

malfunction may result from excess pipe in valve.

3. Apply a moderate amount of good quality pipe dope to

the pipe only (see Fig. 3). If pipe dope lodges on the

valve seat, it will prevent proper closure. If using LP

gas, use pipe dope resistant to action of LP gas.

4. Install the valve with gas flow in the direction indicated

by the arrow on the valve body. Gas must be in the

same direction as indicated by the arrow.

5. Move the powerhead to the desired position and then

tighten the hexagonal nut located on the top of the

valve.

66-2008—3 4

Page 5

V4046C, V8046C MAGNETIC VALVES

T:

EXCESS DOPE MAY BLOCK

,

T

M20744

D

M20746

P

A

TWO CLEAN

THREADS,

MODERATE

AMOUNT

OF DOPE

CORRECT:

NORMAL

FULL

THREAD

11USE PIPE DOPE RESISTANT TO ACTION OF LP GAS.

DISK OFF

VALVE

SEAT

LOOSE

CHIPS

INCORREC

TOO LONG

DISTORTS

VALVE SEA

Fig. 3. Preparing the pipe threads.

Gas and Air Applications

Test for leaks by painting pipe joints with a soapy solution.

Excessive bubbles indicate a leak.

WIRING

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before wiring to prevent

electrical shock or equipment damage. More than one

disconnect can be involved.

All wiring must conform to local codes and ordinances.

Leadwires on these devices are long enough to reach the

junction box on most burner installation. The powerhead on all

models rotates 360 degrees, permitting the electrical service

to be brought to it from any convenient direction.

See Fig. 4 and 5 for typical wiring hookups for V4046C and

V8046C, respectively.

V4046C

PILOT VALVE

NEUTRAL SIDE OF

POWER SUPPLY

1 PROVIDE DISCONNECT MEANS AND OVERLOA

PROTECTION AS REQUIRED.

Fig. 4. Typical hookup of V4046C. See Flame Safeguard

wiring diagram to determine correct terminal for pilot

valve connection.

FLAME

SAFEGUARD

CONTROL

1

M20745

V4046C

PILOT VALVE

AT20 (OEM MODEL)

OR AT30

24V 60 HZ TRANSFORMER

L1

L2

(HOT)

OWER SUPPLY. PROVIDE DISCONNECT MEANS

ND OVERLOAD PROTECTION AS REQUIRED.

CONTROLLER

Fig. 5. Typical hookup of V8046C.

CHECKOUT AND SERVICE

Checkout

Put the system in operation and observe through at least one

cycle to be sure valve functions as described.

NOTE: Valve clicks audibly when it opens and when it

closes. Listen for clicks to make sure valve is

opening and closing properly.

Service

IMPORTANT

If the valve will not open when the thermostat and

limit control are calling for heat:

If the valve will not close with one or more of the

control contacts open:

Do not assume that the valve needs replacement

until all other sources of trouble have been

eliminated.

1. Make sure that the pilot is burning properly, the

Pilotstat® Control (if used) is holding in, and the limit

control contacts are closed.

2. Make sure that normal gas pressure is available at the

valve.

3. Make sure that the bleed line is unobstructed.

4. Check the power supply at the valve. If no voltage is

indicated, check the power source (transformer or line

source) and circuit controls. If proper voltage is present

at the valve, but the valve does not pull in, replace the

valve coil.

1. Make sure that the gas flow is in the direction of the

arrow on the valve body.

2. Check for a short in the wiring circuit.

5 66-2008—3

Page 6

V4046C, V8046C MAGNETIC VALVES

Maintenance

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect the power supply before replacing the

solenoid coil. More than one disconnect can be

involved.

The V4046C and V8046C Magnetic Valves are built to give

long and reliable service without attention. If necessary, the

solenoid coil is replaced as follows (see Fig. 6):

1. Disconnect the power supply before replacing the

solenoid coil.

2. Remove the nut on top of the valve by turning it

counterclockwise .

3. Lift the powerhead assembly off the spindle.

4. Disconnect and remove the solenoid coil.

5. Connect the replacement coil and reassemble.

NOTE: The valve need not be removed from the pipe

installation to change the solenoid coil.

CASE

VALVE BODY

Fig. 6. Removing the solenoid coil.

NUT

INSULATING

PAPER

COIL

COVER

M20747

66-2008—3 6

Page 7

7 66-2008—3

Page 8

Automation and Control Solutions

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

66-2008—3 G.R. Rev. 08-02 www.honeywell.com

M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...