AbsolutAire LMB24-3-T Installation Manual

198

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

LMB24-3

LMCB24-3

LMX24-3

LMB24-3-T

LMCB24-3-T

LMX24-3-T

LMB24-3-P5-T

LMB24-3-P10-T

LMB24-3-S

LMX120-3

LMB24-SR

LMCB24-SR

LMX24-SR

LMB24-SR-T

LMCB24-SR-T

LMX24-SR-T

LMX120-SR

LMX24-PC

LMB(X)24-MFT

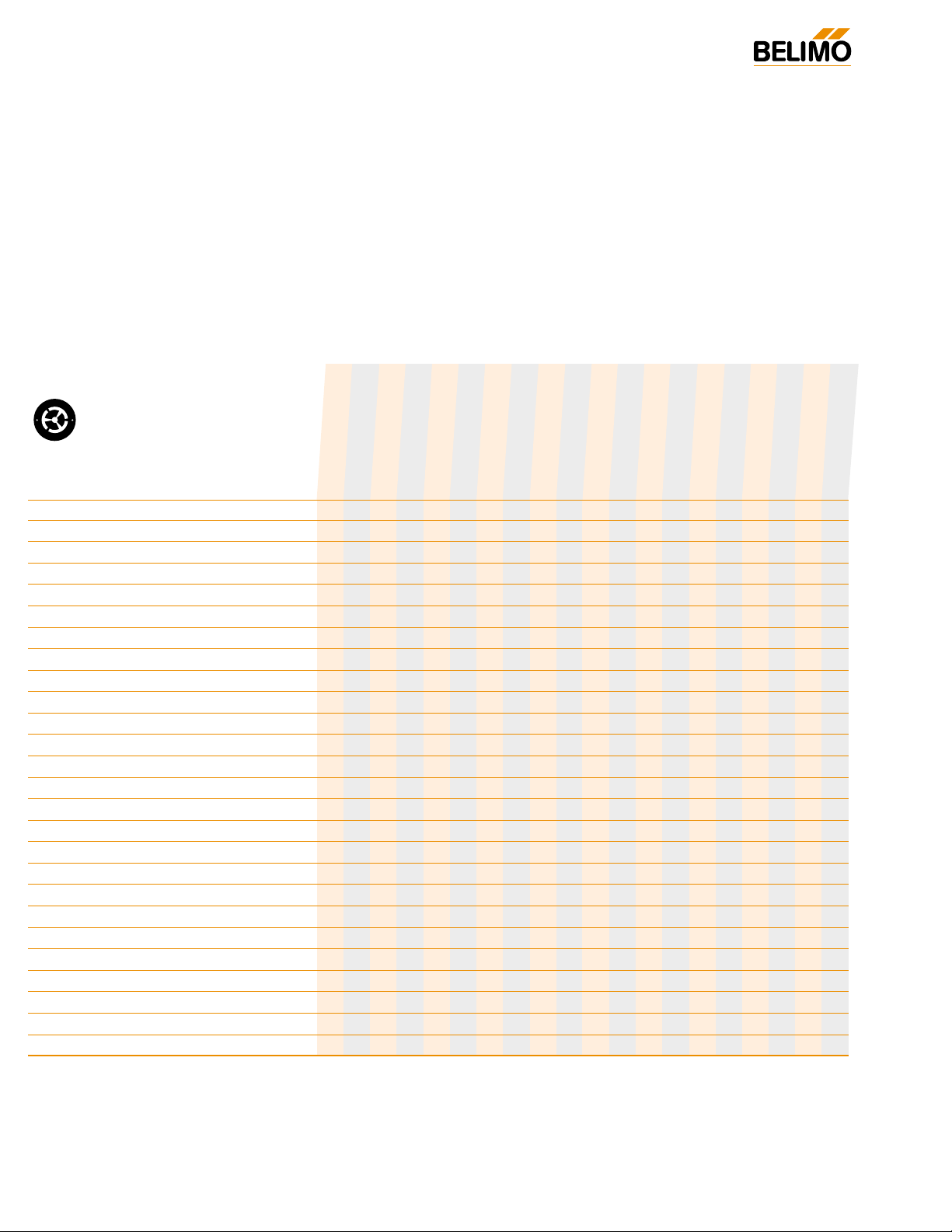

LM Series - At A Glance

Pages 200 202 204 200202204200 200 200 206 208 210 212 208 210 212 214 216 218 220

Basic Product ●● ●● ●●● ●● ●● ●

Flexible Product ●● ●●●●●●●

Torque 45 in-lb [5 Nm] ●●●●●●●●●●●●●●●●●●●●

Angle of Rotation 95 degrees ●●●●●●●●●●●●●●●●●●●●

Power Supply 24 VAC/DC ●●●●●●●●● ●●●●●● ●●●

100 to 240 VAC ●●

Control Input On/Off, Floating Point ●●●●●●●●●●

2 to 10 VDC (4 to 20mA) ●●●●●●●

Multi-Function Technology ●

0 to 135Ω ●

0 to 20V Phasecut ●

Feedback None ●●●●●● ●●● ●●●

5 kΩ Potentiometer ●

10 kΩ Potentiometer ●

2 to 10 VDC ●● ● ●

Variable (0 to 10 VDC) ●●

Running Time 95 seconds ●●●●●●● ●

35 seconds ●● ●●

Adj. 35 to 150 seconds ●● ●●●●●●

Wiring Plenum Rated Cable ●●● ●●● ●●●

Appliance Rated Cable ●● ●

Terminal Strip ●●●●● ●●●

Conduit Fitting ●●● ●●●●● ●●●●

Auxiliary Switch Built-In ●

Add-On ●●●●●●●●●●●●●●●●●●●●

Installation and Operation… (page 265).

*Based on 4 in-lb/ft2damper torque loading. Parallel blade. No edge seals.

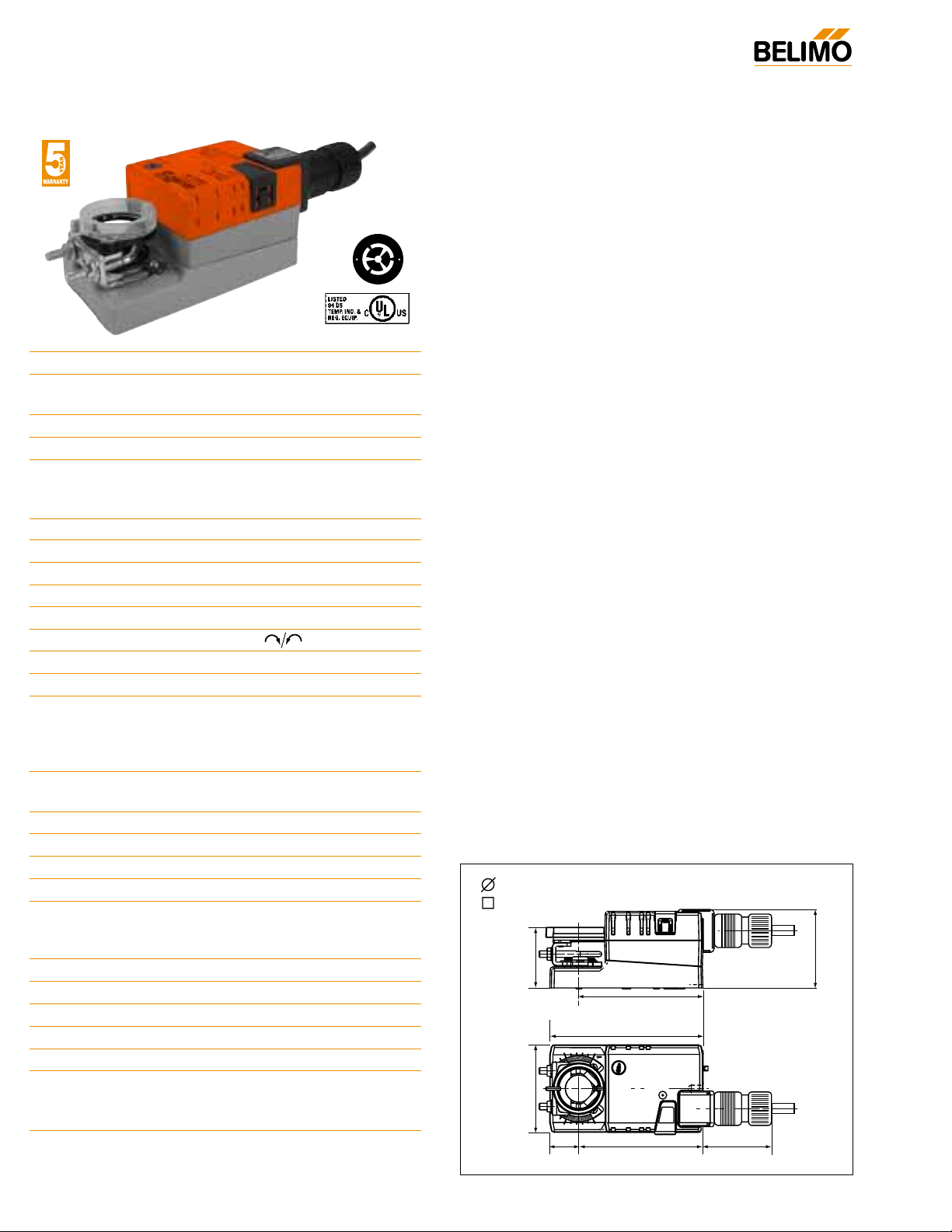

LM Series Direct Coupled Actuator

Versatile and Powerful

● Minimum 45 in-lb torque in a compact package.

For damper areas up to 11 sq-ft*

All Actuators

have BDCM

LMX24-MFT95

®

O

M

L

©

O

A

H

B

r

r

o

u

t

s

o

h

M

l

e

s

C

s

D

199

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

LM

LM Series Direct Coupled Actuator

● Brushless DC Motor for Added Accuracy and

Controllability.

● Cut Labor Costs with Simple Direct Coupling.

● Self-Centers on 5/8" Jackshafts with Standard Clamp or

3/4" with Flexible Line Selection or Accessory Clamp.

● Check Damper Position with Clear Position Indicator.

● Don’t Worry about Actuator Burn-Out; Belimo is

Overload Proof throughout Rotation.

● Enjoy Added Flexibility with Easy Mechanical Stops

to Adjust Angle of Rotation.

● Need to Change Control Direction? Do it easily with

a Simple Switch.

● Easily Accessible Manual Override Button

helps you Pre-Tension Damper Blades.

● Fully Adjustable Built-In Auxiliary Switch (LMB24-3-S).

● Auxiliary Switch and Feedback Potentiometer Add-Ons

Mount Directly on Clamp, Includes Conduit Connector.

● Standard 3ft Plenum Rated Cable and Conduit

Connector Provided on Basic Models.

● Added Flexibility to Select Clamp, Electrical

Connection, and Running Time to fit your Specific

Application with Belimo’s New Flexible Line of

Actuators.

The Belimo Difference

● Customer Commitment.

Extensive product range. Application assistance.

Same-day shipments. Free technical support. Five year warranty.

●

Low Installation and Life-Cycle Cost.

Easy installation. Accuracy and repeatability.

Low power consumption. No maintenance.

●

Long Service Life.

Components tested before assembly. Every product tested before shipment.

30+ years direct coupled actuator design.

©

H

A

L

O

M

O

B

r

u

s

h

l

e

s

s

D

C

M

o

t

o

r

A CLOSER LOOK…

Bulk Packaging Offers Big

Value for Large jobs,

Stocking Orders.

®

200

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

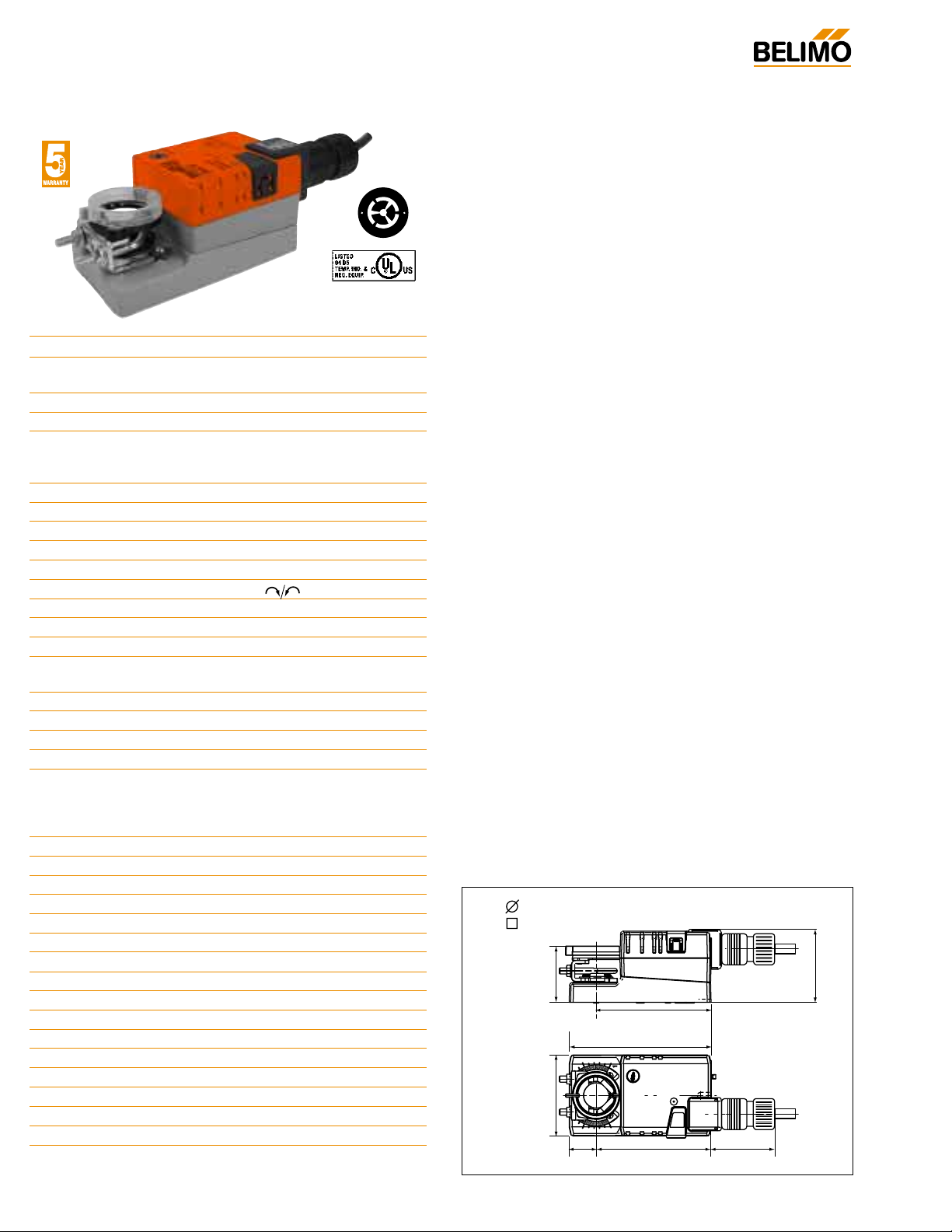

Technical Data LMB24-3… on/off-floating

Power Supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power Consumption 1.5 W (0.2 W)

Transformer Sizing 3 VA (Class 2 power source)

Electrical Connection 3 ft, 18 GA plenum rated cable

3 ft, 18 GA appliance rated cable (-S)

1/2” conduit connector

Overload Protection electronic throughout 0 to 95° rotation

Control on/off, floating point

Input Impedance 600Ω

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 45 in-lb [5 Nm]

Direction of Rotation reversible with switch

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 95 seconds, constant independent of load

Humidity 5 to 95% RH non condensing

(EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2/IP54

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2

No. 24-93, CE acc. to 89/336/EEC

(and 2006/95/EC for -S versions)

Noise Level <35dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 1.1lbs [0.5 Kg],

LMB24-3-S

Auxiliary switch Adj. 0°to 100°, SPDT 3 A (0.5A) @ 250 VAC

Weight 1.4lbs [0.6 Kg]

LMB24-3-P10-T

Electrical connection Screw terminal (for 26 to 14 GA wire)

Feedback 10 kΩ, 1W potentiometer

LMB24-3-P5-T bulk pack only)

Feedback 5 kΩ, 1W potentiometer

Housing NEMA 1/IP20

LMB24-3-T

Electrical connection Screw terminal (for 26 to 14 GA wire)

Housing NEMA 1/IP20

†Rated Impulse Voltage 800V, Type of action 1,

(1.B for -S version), Control Pollution Degree 3.

1.85” [47]

2.34” [59.4]

2.6” [66]

4.57” [116]

3.47” [88]

3.7” [94]

0.86” [22]

2” [50.8]

1/4” to 3/4” [6 to 20]

5/16” to 3/4” [8 to 26]

LMB24-3 (-S)(-T)

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 V

Torque min. 45 in-lb for control of damper

surfaces up to 11 sq ft.

LMB24-3 LMB24-3.1 (bulk) LMB24-3-P10-T

LMB24-3-T LMB24-3-T.1 (bulk) LMB24-3-S

LMB24-3-P5-T LMB24-3-P5-T.1 (bulk)

Application

For on-off and floating point control of dampers in HVAC systems. Actuator sizing should be done in accordance with the

damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 1/4”

up to 5/8” in diameter by means of its standard universal

clamp. Shafts up to 3/4” diameter can be accommodated by

an accessory clamp.

Operation

The actuator is not provided with and does not require any

limit switches, but is electronically protected against overload.

The anti-rotation strap supplied with the actuator will prevent

lateral movement.

The LMB series provides 95° of rotation and a visual indicator

which indicates position of the actuator. When reaching the

damper or actuator end position, the actuator automatically

stops. The gears can be disengaged with manual release on

the actuator cover.

The LMB24-3… actuators use a sensorless Brushless DC motor,

which is controlled by an Application Specific Integrated Circuit

(ASIC). The ASIC monitors and controls the actuator’s rotation

and provides a digital rotation sensing (DRS) function to prevent

damage to the actuator in a stall condition. Power consumption

is reduced in holding mode.

The LMB24-3-S version is provided with 1 built-in auxiliary

switch. This SPDT switch is provided for safety interfacing or

signaling, for example, for fan start-up. The switching function

is adjustable 0 to 95°. The auxiliary switch is double insulated

so an electrical ground connection is not necessary.

Add on auxiliary switches or feedback potentiometers are easily

fastened directly onto the actuator body for signaling and

switching functions.

Dimensions

(All numbers in brackets are in millimeters.)

D120

®

O

L

A

H

B

r

u

s

h

l

e

s

s

D

M

©

O

r

o

t

o

M

C

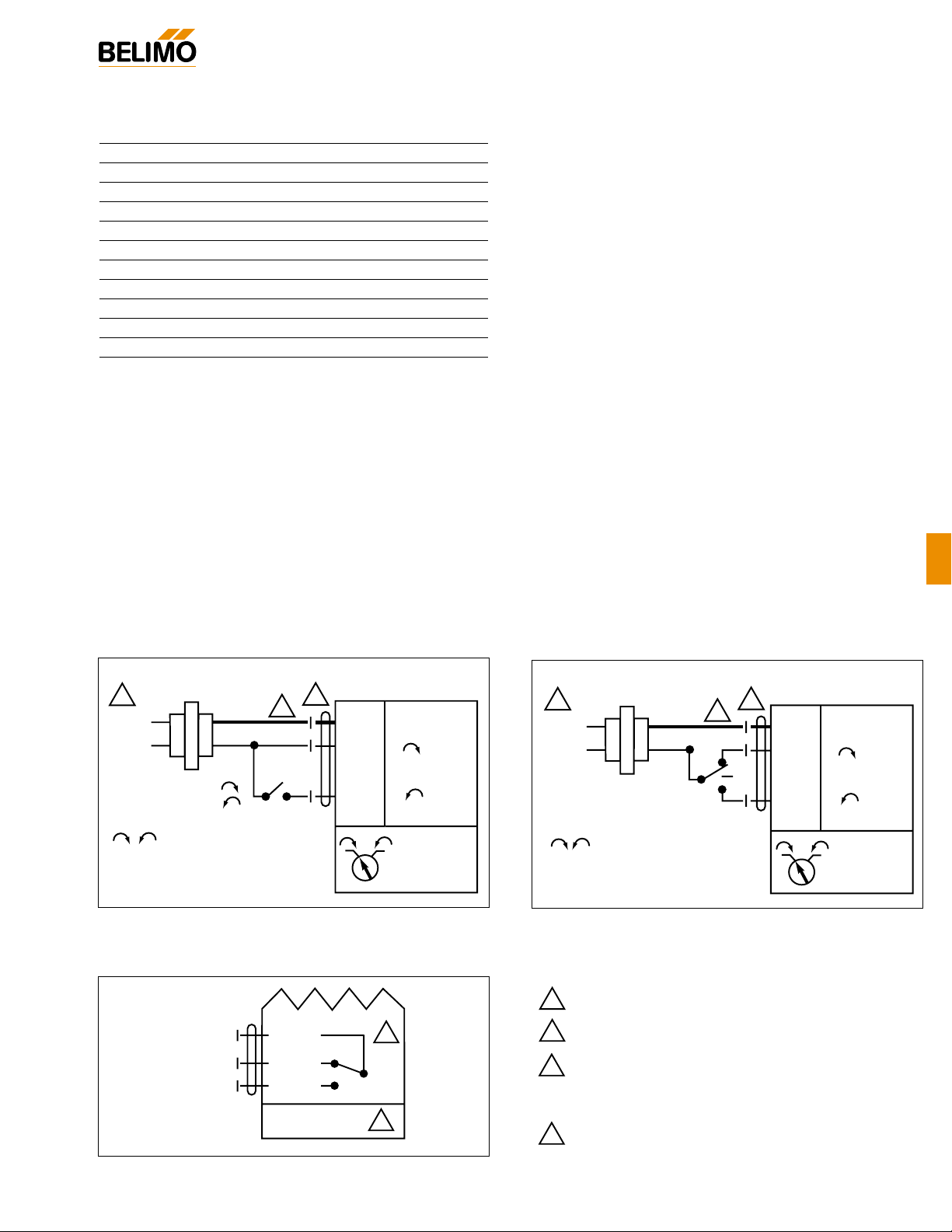

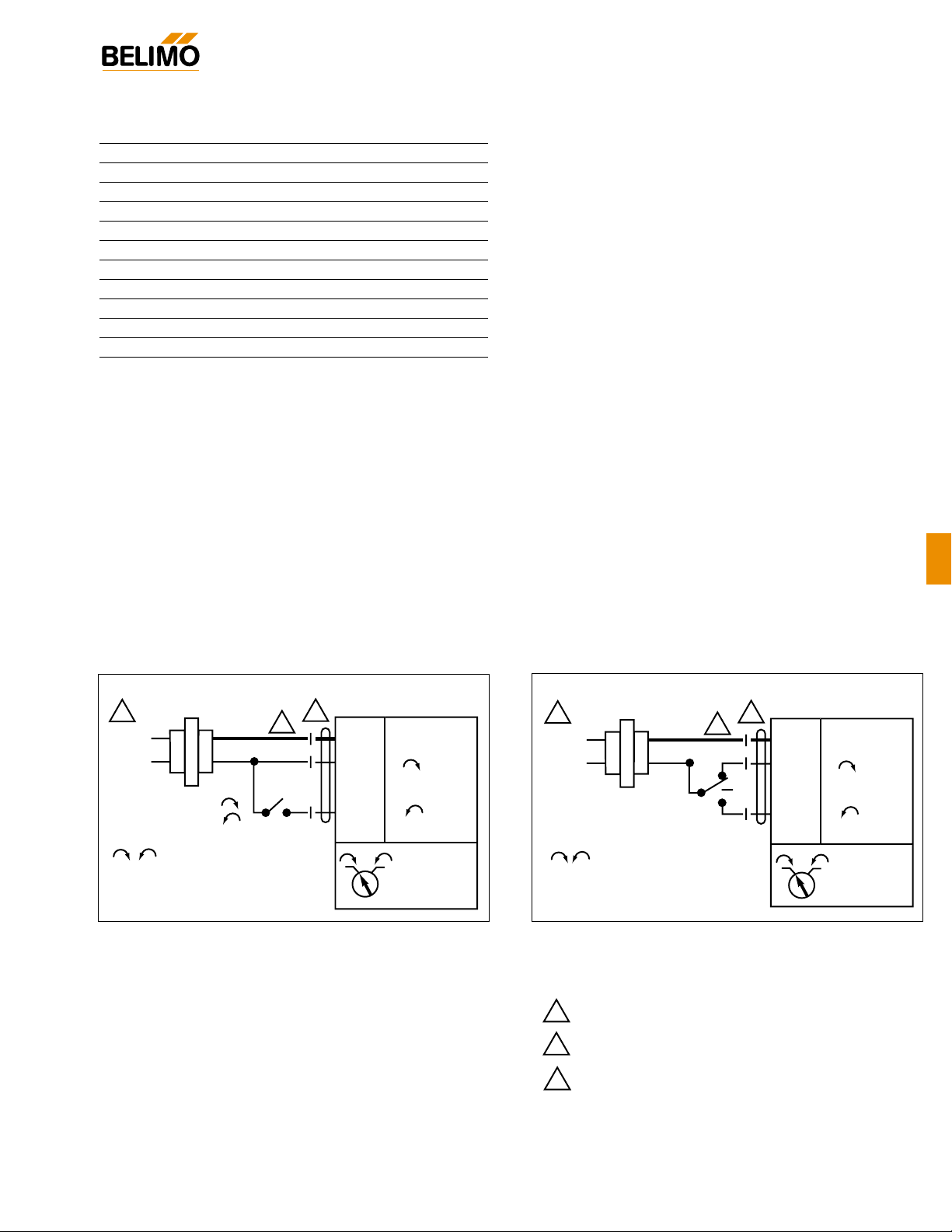

Wiring Diagrams

LMB24-3 (-S)(-T)

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 V

201

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

LM

®

LMB24-3 - Typical Specification:

Floating point, on/off control damper actuators shall be electronic direct-coupled type, which require no crankarm and linkage and be capable of direct mounting to a shaft from 1/4” to

5/8”. Shafts up to 3/4” diameter can be accommodate with an

accessory clamp. Actuators shall have Brushless DC motor

technology and be protected from overload at all angles of rotation. Actuators shall have reversing switch and manual override

on the cover. If required, actuator will be provided with screw

terminal strip for electrical connections (LMB24-3-T). If

required, actuators shall be provided with one adjustable SPDT

auxiliary switch. Actuators with auxiliary switches must be constructed to meet the requirements for double insulation so an

electrical ground is not required to meet agency listings. Run

time shall be constant and independent of torque. Actuators

shall be cULus listed, have a 5-year warranty, and be manufactured under ISO 9001 International Quality Control

Standards. Actuators shall be as manufactured by Belimo.

Accessories

K-LM20 3/4” [20 mm] Shaft Clamp

AV6-20 Shaft Extension

ZG-LMSA Shaft Adaptor for 1/2” Diameter Shafts

ZG-LMSA-1 Shaft Adaptor for 3/8” Diameter Shafts

ZS-T Terminal Cover for NEMA 2

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

Tool-06 8 mm & 10 mm Wrench

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

Note: When using LMB24-3… actuators, only use acces-

sories listed on this page.

W266

W267

On/Off

Auxiliary Switch of LMB24-3-S

W268

Floating Point or On/Off control

24 V AC Transformer

1

Line

Volts

a open

a closed

4

2

a

Blk (1) Common

Red (2) +

Wht (3) +

The indication of direction

is valid for switch position 1.

Vlt (S1)

Red (S2)

Wht (S3)

NC

NO

10

3

0° to 95°

4

–

24 V AC Transformer

1

2

Line

Volts

The indication of direction

4

Blk (1) Common

Red (2) +

Wht (3) +

10

–

is valid for switch position 1.

Notes:

1

Provide overload protection and disconnect as required.

Actuators may also be powered by 24 VDC.

2

For end position indication, interlock control, fan startup,

3

etc., xMB24-3-S incorporates one built-in auxiliary

switches: 1 x SPDT, 3A (0.5A) @250 VAC, UL listed,

adjustable 0° to 95°.

Meets cULus requirements without the need of an

4

electrical ground connection.

202

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

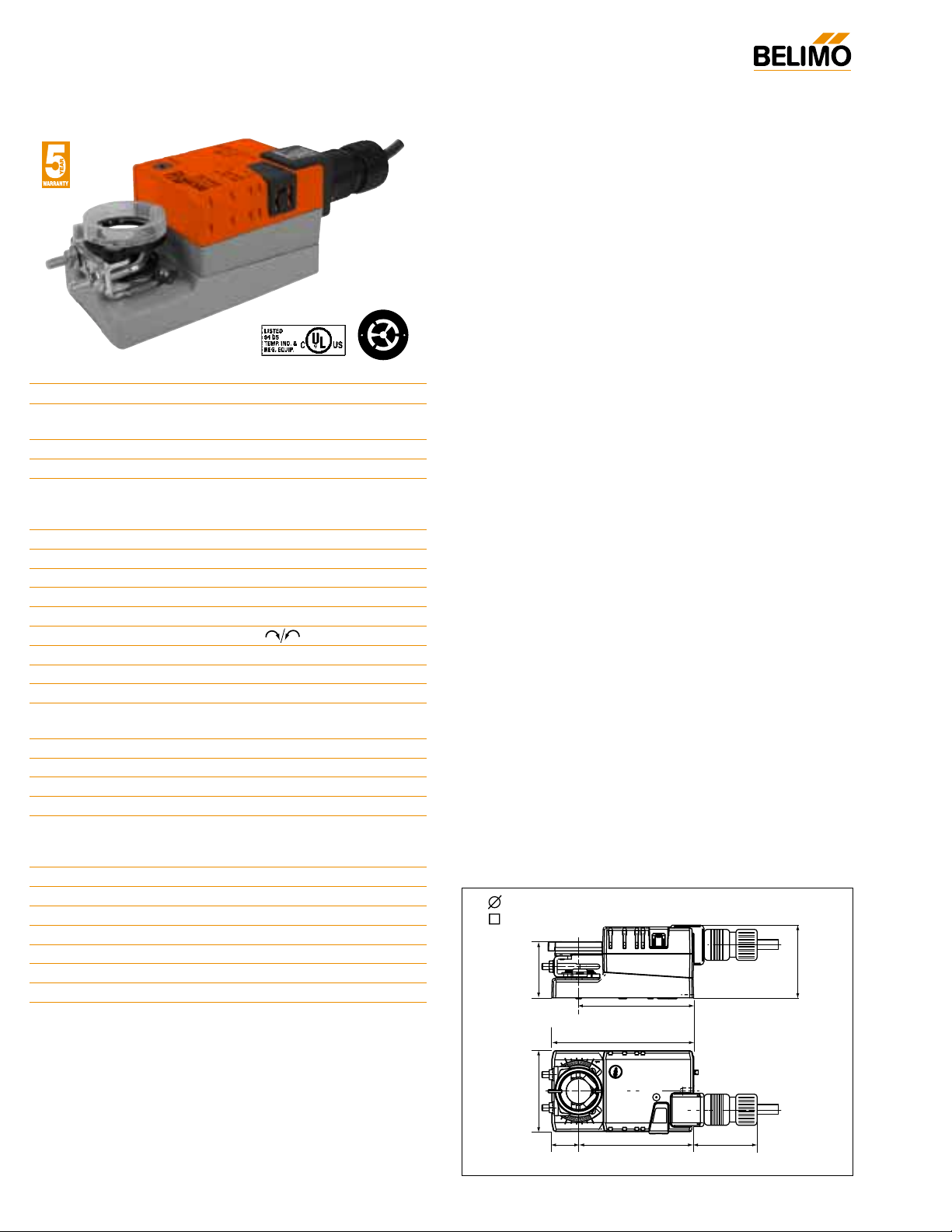

Technical Data LMCB24-3… on/off-floating

Power Supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power Consumption 1.5 W (0.2 W)

Transformer Sizing 3 VA (Class 2 power source)

Electrical Connection 3 ft, 18 GA plenum rated cable

3 ft, 18 GA appliance rated cable (-S)

1/2” conduit connector

Overload Protection electronic throughout 0 to 95° rotation

Control on/off, floating point

Input Impedance 600Ω

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 45 in-lb [5 Nm]

Direction of Rotation reversible with switch

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 35 seconds, constant independent of load

Humidity 5 to 95% RH non condensing

(EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2/IP54

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2

No. 24-93, CE acc. to 89/336/EEC

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 1.1lbs [0.5 Kg],

LMCB24-3-T

Electrical connection Screw terminal (for 26 to 14 GA wire)

Housing NEMA 1/IP20

†Rated Impulse Voltage 800V, Type of action 1,

Control Pollution Degree 3.

1.85” [47]

2.34” [59.4]

2.6” [66]

4.57” [116]

3.47” [88]

3.7” [94]

0.86” [22]

2” [50.8]

1/4” to 3/4” [6 to 20]

5/16” to 3/4” [8 to 26]

LMCB24-3 (-T)

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 V

Torque min. 45 in-lb for control of damper

surfaces up to 11 sq ft.

LMCB24-3

LMCB24-3-T

Application

For on-off and floating point control of dampers in HVAC systems. Actuator sizing should be done in accordance with the

damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 1/4”

up to 5/8” in diameter by means of its standard universal

clamp. Shafts up to 3/4” diameter can be accommodated by

an accessory clamp.

Operation

The actuator is not provided with and does not require any

limit switches, but is electronically protected against overload.

The anti-rotation strap supplied with the actuator will prevent

lateral movement.

The LMB series provides 95° of rotation and a visual indicator

which indicates position of the actuator. When reaching the

damper or actuator end position, the actuator automatically

stops. The gears can be disengaged with manual release on

the actuator cover.

The LMCB24-3… actuators use a sensorless Brushless DC

motor, which is controlled by an Application Specific Integrated

Circuit (ASIC). The ASIC monitors and controls the actuator’s

rotation and provides a digital rotation sensing (DRS) function to

prevent damage to the actuator in a stall condition. Power consumption is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily

fastened directly onto the actuator body for signaling and

switching functions.

Dimensions

(All numbers in brackets are in millimeters.)

D120

O

M

L

©

O

A

H

B

r

r

o

u

t

s

o

h

M

l

e

s

C

s

D

®

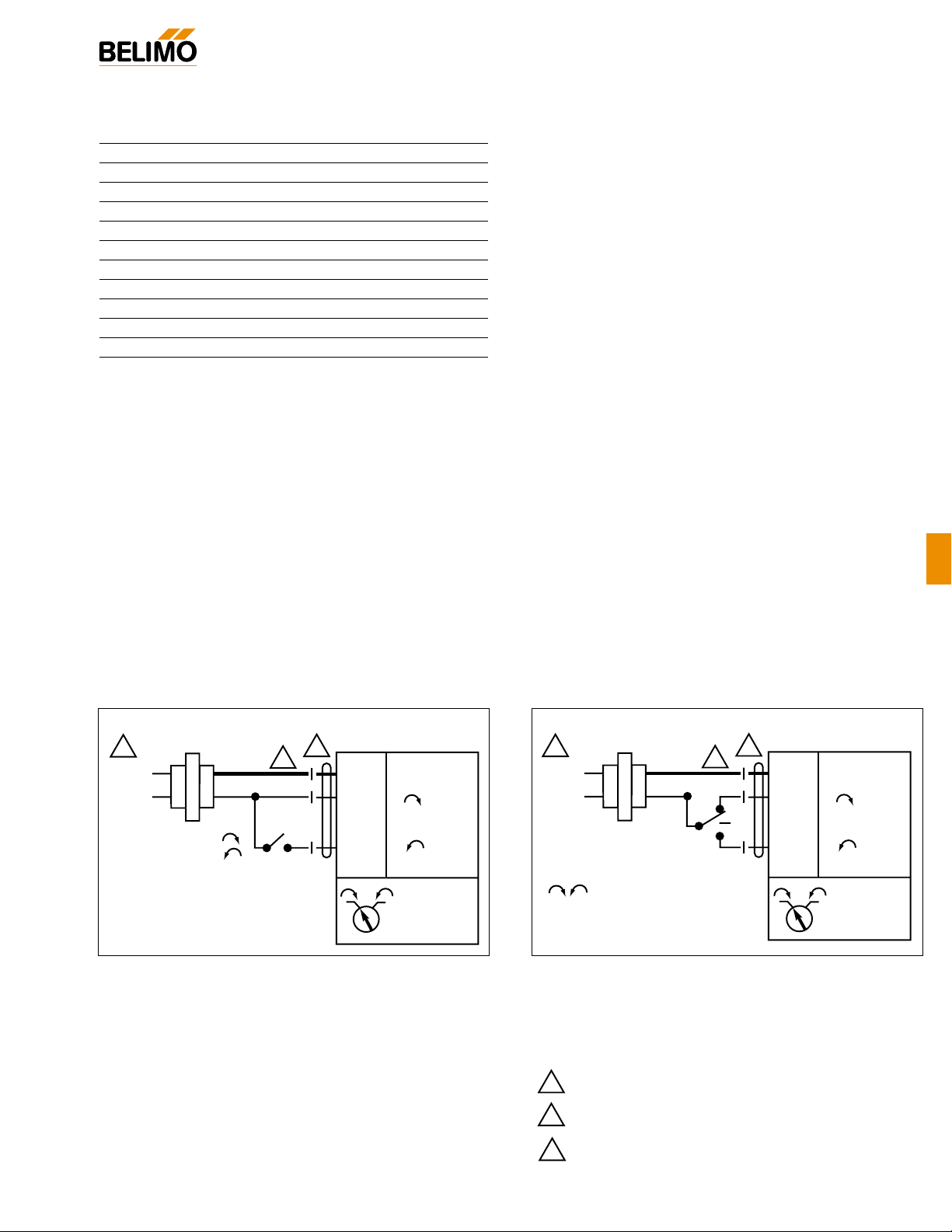

Wiring Diagrams

203

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

LM

LMCB24-3 (-T)

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 V

LMCB24-3 - Typical Specification:

Floating point, on/off control damper actuators shall be electronic direct-coupled type, which require no crankarm and linkage and be capable of direct mounting to a shaft from 1/4” to

5/8”. Shafts up to 3/4” diameter can be accommodate with an

accessory clamp. Actuators shall have Brushless DC motor

technology and be protected from overload at all angles of rotation. Actuators shall have reversing switch and manual override

on the cover. If required, actuator will be provided with screw

terminal strip for electrical connections (LMCB24-3-T). If

required, actuators shall be provided with one adjustable SPDT

auxiliary switch. Actuators with auxiliary switches must be constructed to meet the requirements for double insulation so an

electrical ground is not required to meet agency listings. Run

time shall be constant and independent of torque. Actuators

shall be cULus listed, have a 5-year warranty, and be manufactured under ISO 9001 International Quality Control

Standards. Actuators shall be as manufactured by Belimo.

Accessories

K-LM20 3/4” [20 mm] Shaft Clamp

AV6-20 Shaft Extension

ZG-LMSA Shaft Adaptor for 1/2” Diameter Shafts

ZG-LMSA-1 Shaft Adaptor for 3/8” Diameter Shafts

ZS-T Terminal Cover for NEMA 2

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

Tool-06 8 mm & 10 mm Wrench

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

Note: When using LMCB24-3… actuators, only use acces-

sories listed on this page.

W266

W267

On/Off

Floating Point or On/Off control

®

24 V AC Transformer

1

Line

Volts

a open

a closed

4

2

a

Blk (1) Common

Red (2) +

Wht (3) +

The indication of direction

is valid for switch position 1.

10

–

24 V AC Transformer

1

2

Line

Volts

The indication of direction

4

Blk (1) Common

Red (2) +

Wht (3) +

10

–

is valid for switch position 1.

Notes:

Provide overload protection and disconnect as required.

1

Actuators may also be powered by 24 VDC.

2

Meets cULus requirements without the need of an

4

electrical ground connection.

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

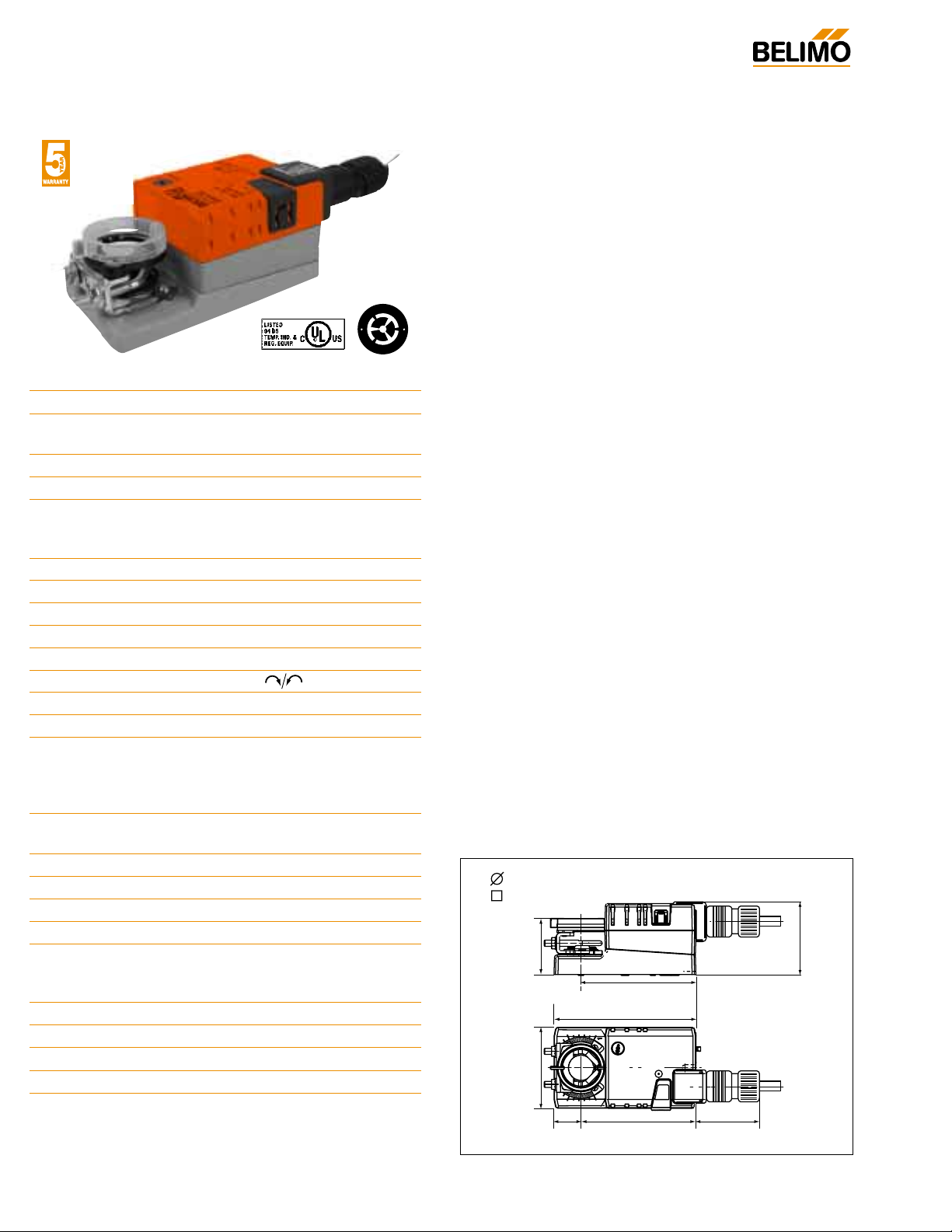

Technical Data LMX24-3… on/off-floating

Power Supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power Consumption 1.5 W (0.2 W)

Transformer Sizing 2 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

1/2” conduit connector

❑ 3 ft [1m] ❑ 10 ft [3m] ❑ 16 ft [5m]

Overload Protection electronic throughout 0 to 95° rotation

Control on/off, floating point

Input Impedance 600Ω

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 45 in-lb [5 Nm]

Direction of Rotation reversible with switch

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time ❑ 150 seconds ❑ 45 seconds

❑ 95 seconds ❑ 35 seconds

❑ 60 seconds

constant independent of load

Humidity 5 to 95% RH non condensing

(EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2/IP54

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2

No. 24-93, CE acc. to 89/336/EEC

Noise Level <35dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 1.1lbs [0.5 Kg],

LMX24-3-T

Electrical connection screw terminal (for 26 to 14 GA wire)

❑ unprotected (NEMA 1)

❑ protected (NEMA 2)

†Rated Impulse Voltage 800V, Type of action 1,

Control Pollution Degree 3.

1.85” [47]

2.34” [59.4]

2.6” [66]

4.57” [116]

3.47” [88]

3.7” [94]

0.86” [22]

2” [50.8]

1/4” to 3/4” [6 to 20]

5/16” to 3/4” [8 to 26]

LMX24-3 (-T)

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 V

Torque min. 45 in-lb for control of damper

surfaces up to 11 sq ft.

LMX24-3

LMX24-3-T

Application

For on-off and floating point control of dampers in HVAC systems. Actuator sizing should be done in accordance with the

damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 1/4”

up to 5/8” in diameter by means of its standard universal

clamp. Shafts up to 3/4” diameter can be accommodated by

an accessory clamp.

Operation

The actuator is not provided with and does not require any

limit switches, but is electronically protected against overload.

The anti-rotation strap supplied with the actuator will prevent

lateral movement.

The LMX series provides 95° of rotation and a visual indicator

which indicates position of the actuator. When reaching the

damper or actuator end position, the actuator automatically

stops. The gears can be disengaged with manual release on

the actuator cover.

The LMX24-3… actuators use a sensorless Brushless DC motor,

which is controlled by an Application Specific Integrated Circuit

(ASIC). The ASIC monitors and controls the actuator’s rotation

and provides a digital rotation sensing (DRS) function to prevent

damage to the actuator in a stall condition. Power consumption

is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily

fastened directly onto the actuator body for signaling and

switching functions.

Dimensions

(All numbers in brackets are in millimeters.)

D120

204

®

L

A

H

B

r

u

s

h

l

e

s

s

O

M

©

O

r

o

t

o

M

C

D

LM

Wiring Diagrams

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

W343

W344

On/Off

Floating Point or On/Off control

LMX24-3 (-T)

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 24 V

LMX24-3 - Typical Specification:

Floating point, on/off control damper actuators shall be electronic direct-coupled type, which require no crankarm and linkage and be capable of direct mounting to a shaft from 1/4” to

5/8”. Shafts up to 3/4” diameter can be accommodate with an

accessory clamp. Actuators shall have Brushless DC motor

technology and be protected from overload at all angles of rotation. Actuators shall have reversing switch and manual override

on the cover. If required, actuator will be provided with screw

terminal strip for electrical connections (LMX24-3-T). Run time

shall be constant and independent of torque. Actuators shall be

cULus listed, have a 5-year warranty, and be manufactured

under ISO 9001 International Quality Control Standards.

Actuators shall be as manufactured by Belimo.

Accessories

K-LM20 3/4” [20 mm] Clamp

AV6-20 Shaft Extension

ZG-LMSA Shaft Adaptor for 1/2” Diameter Shafts

ZG-LMSA-1 Shaft Adaptor for 3/8” Diameter Shafts

ZS-T Terminal Cover for NEMA 2

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

Tool-06 8 mm & 10 mm Wrench

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

Note: When using LMX24-3… actuators, only use acces-

sories listed on this page.

®

205

24 V AC Transformer

1

Line

Volts

a open

a closed

3

2

a

Blk (1) Common

Red (2) +

Wht (3) +

The indication of direction

is valid for switch position 1.

10

–

LMX24-3

24 V AC Transformer

1

Line

Volts

The indication of direction

3

2

Blk (1) Common

Red (2) +

Wht (3) +

10

is valid for switch position 1.

Notes:

Provide overload protection and disconnect as required.

1

Actuators may also be powered by 24 VDC.

2

–

LMX24-3

Meets cULus requirements without the need of an

3

electrical ground connection.

206

J20741 - Subject to change. © Belimo Aircontrols (USA), Inc.

Technical Data LMX120-3 on/off-floating

Power Supply 100 to 240 VAC, 50/60 Hz (nominal)

85 to 265 VAC, 50/60 Hz (tolerance)

Power Consumption 2 W (0.5 W)

Transformer Sizing 4 VA (Class 2 power source)

Electrical Connection 18 GA appliance rated cable

1/2” conduit connector

❑ 3 ft [1m] ❑ 10 ft [3m] ❑ 16 ft [5m]

Overload Protection electronic throughout 0 to 95° rotation

Control on/off, floating point

Input Impedance 600Ω

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 45 in-lb [5 Nm]

Direction of Rotation reversible with switch

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time ❑ 150 seconds ❑ 45 seconds

❑ 95 seconds ❑ 35 seconds

❑ 60 seconds

constant independent of load

Humidity 5 to 95% RH non condensing

(EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2/IP54

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL60730-1A/-2-14,

CAN/CSA E60730-1, CSA C22.2

No. 24-93, CE acc. to 89/336/EEC

Noise Level <35dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 1.1lbs [0.5 Kg]

†Rated Impulse Voltage 4kV, Type of action 1,

Control Pollution Degree 3.

1.85” [47]

2.34” [59.4]

2.6” [66]

4.57” [116]

3.47” [88]

3.7” [94]

0.86” [22]

2” [50.8]

1/4” to 3/4” [6 to 20]

5/16” to 3/4” [8 to 26]

LMX120-3

On/Off-Floating Point Control, Non-Spring Return, Direct Coupled, 100 to 240 VAC

Torque min. 45 in-lb for control of damper

surfaces up to 11 sq ft.

Application

For on-off and floating point control of dampers in HVAC systems. Actuator sizing should be done in accordance with the

damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft from 1/4”

up to 5/8” in diameter by means of its standard universal

clamp. Shafts up to 3/4” diameter can be accommodated by

an accessory clamp.

Operation

The actuator is not provided with and does not require any

limit switches, but is electronically protected against overload.

The anti-rotation strap supplied with the actuator will prevent

lateral movement.

The LMX series provides 95° of rotation and a visual indicator

which indicates position of the actuator. When reaching the

damper or actuator end position, the actuator automatically

stops. The gears can be disengaged with manual release on

the actuator cover.

The LMX120-3 actuators use a sensorless Brushless DC motor,

which is controlled by an Application Specific Integrated Circuit

(ASIC). The ASIC monitors and controls the actuator’s rotation

and provides a digital rotation sensing (DRS) function to prevent

damage to the actuator in a stall condition. Power consumption

is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily

fastened directly onto the actuator body for signaling and

switching functions.

Dimensions

(All numbers in brackets are in millimeters.)

D120

A

H

B

r

u

s

h

l

O

M

L

©

O

r

o

t

o

M

e

s

C

s

D

®

Loading...

Loading...