AbsolutAire HMA Service Manual

INSTALLATION, SERVICE

AND ENGINEERING GUIDE

MAKE-UP AIR

BURNER

HMA Series with

Adapto Pilot

Patent No. 3,186,697

The MAKE-UP AIR GAS BURNER is well suited for allevi-

ating heating problems caused by excessive ventilation.

Where it is necessary or desirable to replace large

amounts of air, heaters of this type are used to temper the

incoming air and thus relieve the building heating plant of

an extra load. No build-up of contaminants is possible because the make-up air is never recirculated; once heated it

enters and blends with the air in the building and is discharged by the exhaust system.

INSTALLER: Inform and demonstrate to

the user the correct operation and

maintenance of this appliance. Inform the

user of the hazards of storing flammable

liquids and vapors in the vicinity of this

appliance and remove such hazards.

USER: Retain this manual for future

reference. If other than routine service

or maintenance as described in this

manual is required, contact a qualified

service agency. DO NOT ATTEMPT

REPAIRS. An inadvertent service error

could result in a dangerous condition.

CODE COMPLIANCE IS THE SOLE

RESPONSIBILITY OF THE INSTALLER.

WARNING: If the information in

these instructions is not followed

exactly, a fire or explosion may

result causing property damage,

personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch;

do not use any phone in your

building.

Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

If you cannot reach your gas

supplier, call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

MIDCO International Inc.

4140 WEST VICTORIA STREET, CHICAGO, ILLINOIS 60646 / (312) 604-8700 FAX: (312) 604-4070

PRINTED IN U.S.A.

192

8470-40

I OPERATING PRINCIPLES

The MIDCO Make-up Air Burner is designed to operate

in a duct of flowing fresh air. Fuel gas is fed directly to

the burners; kinetic energy of the air stream furnishes

combustion air. It will function properly at the velocity

and pressures associated with the usual ventilating systems.

■ The burner must be installed to fire with, and parallel

to, the air flow. By virtue of velocity impact and suction

generated by the diverging shape of the combustion baffles, air is induced through the air ports into the combustion zone. The air supply is constant, though only that

which mixes with the gas flowing from the burner ports

takes part in combustion.

■ When a very small quantity of gas is admitted to the

burner, sufficient mixing takes place in the low fire slot

within the burner casting and combustion takes place in

this zone. Since the low fire zone is contained within the

burner casting it is effectively shielded from fire disrupting uncontrolled air entry.

■ As the gas supply is increased the flame progresses

into the intermediate fire zone where an additional supply of air is available. At higher or full capacity, mixing

occurs at the larger air ports of the high fire zone augmented by air spilling over the end of the baffles.

■ On a reduction of gas supply the reverse sequence

takes place, the flame receding to a location of lesser air

supply until the low fire zone is reached.

■ The system above is suitable for a turndown ratio of

approximately 30 to 1.

tor, usually 15% to 20%. The static pressure rating of

the blower should also be selected on the basis of the

o

standard 70

rating temperature. The entire system will,

of course, operate at approximately this temperature in

warm weather and the design pressure drop will apply

as calculated. In cold weather the portion of the heater

downstream of the burner will remain at 70

o

, though the

inlet side will run at outdoor temperatures, which will result in slightly reduced pressure losses.

■ The total pressure rating of the blower must include

allowance for the resistance of the heater and pressure

drop at the burner, together with pressure losses at the

inlet screen, inlet louvres filters, outlet louvres if used,

plus the external pressure rating of the heater, if any.

■ The MIDCO Make-Up Air Burner will also operate

satisfactorily when located downstream of the blower,

which is known as a push-thru system, though a mixing

plenum may be required at the heater discharge opening. Blower and motor selections must be made on the

basis of corrections for the coldest anticipated inlet temperature. In this system the heater outlet CFM will vary

due to the expansion of air on heating.

■ Refer to MIDCO for further information regarding spe-

cial applications or push-thru system.

II AIR SUPPLY

The heater will generally contain the blower equipment

within the same casing in which the burner is located.

Any of the standard type blowers can be used whether

of the centrifugal or axial flow (van-axial, tube-axial or

propeller). In either case the air flow must be substantially straight and velocity must be within the proper

range to develop the desired turndown and capacity

within the space allowed.

■ The MIDCO Make-Up Air Burner is designed to oper-

ate in a make-up air heater and an air stream taken directly from outdoors. Recirculation is not permitted because of the possibility of build-up of contaminants, and

is prohibited by local health codes for this reason. However, it can be used with recirculation in certain process

heating applications, such as ovens.

■ To avoid stratification of the heated air, the burners

are usually located on the suction side of the blower to

take advantage of the mixing effect of the blower. This

is known as a pull-thru system. In selecting a blower for

this case, catalog CFM ratings can be used without correction since the heater outlet temperature of approximately 70

temperature. Motor horsepower rating will also apply directly for operating conditions, though an increase of up

to 20% will occur when the inlet air is unheated and enters the heater at below zero temperatures. This will

load the motor a corresponding 20% but ordinarily this

condition will exist only for a short period during start up

and is compensated for by the service factor of the mo-

o

will correspond to the standard blower rating

FIGURE 1 Combustion Pattern

-2-

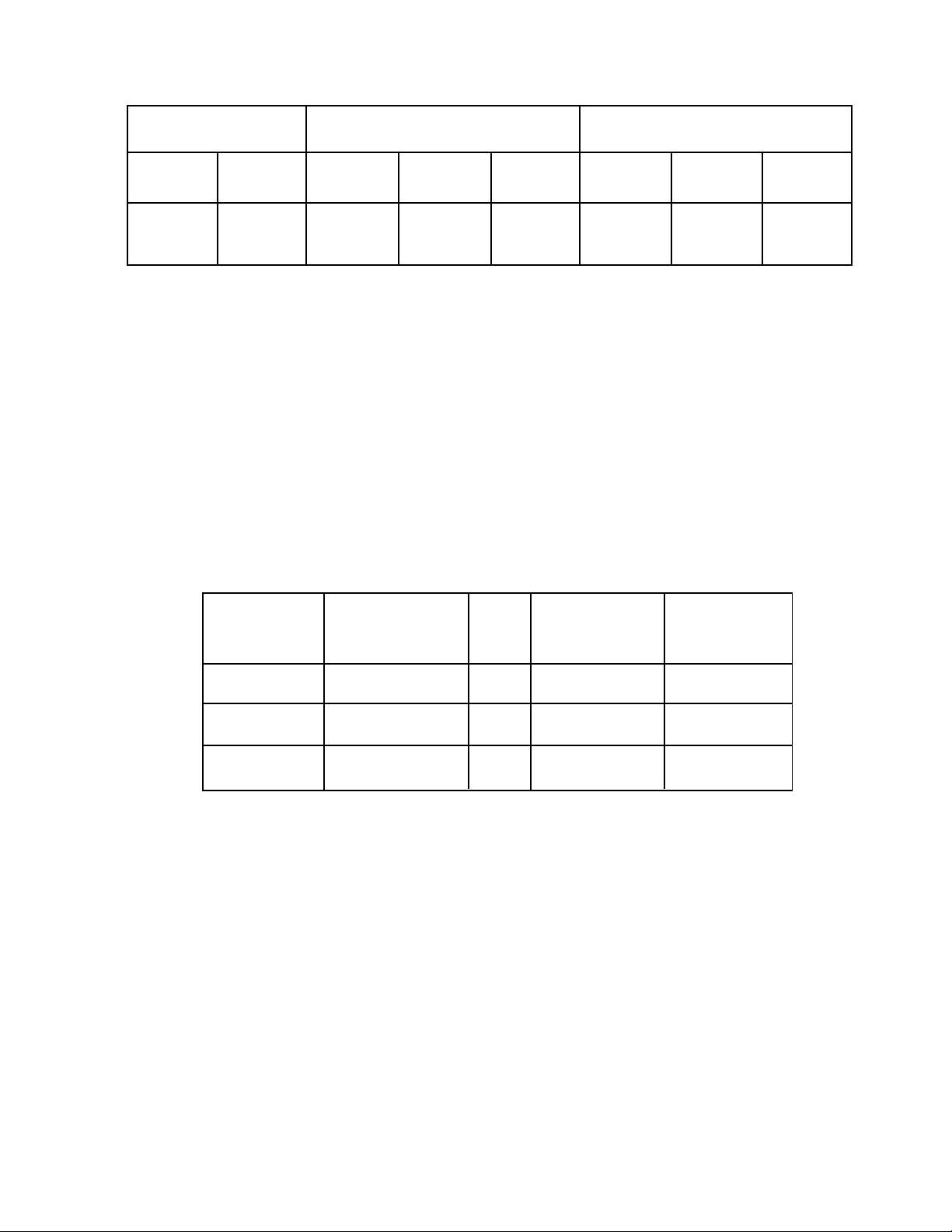

III BURNER CAPACITY.

AIR FLOW AT BURNER

BASED ON 70o (STD)

BLOWER RATING

DESIGN

VELOCITY

FPM

3200

2850 (ideal)

2500

DESIGN

PRESSURE

DROP W.C.

.70"

.55"

.45"

Reduce capacity 4% for each 1,000 feet altitude over 2,000 feet.

* Flame lengths are given to the end of the main mass of flame, excluding any isolated

wisps or flashes, and for normal operation -- that is, with cold inlet air (design minimum).

BURNER CAPACITY (PER FOOT)

MAXIMUM

CAPACITY

BTU/Hr.

550,000

550,000

550,000

NAT & LP GAS

MINIMUM

CAPACITY*

BTU/Hr.

19,000

18,000

17,000

TURN

DOWN

29:1

30:1

32:1

APPROXIMATE LENGTH OF FLAME

PROJECTING BEYOND END OF

BURNER AND PROFILE PLATE*

450,000

BTU/Ft.

7 - 8"

9 - 10"

11 - 12"

500,000

BTU/Ft.

10 - 11"

12 - 13"

14 - 15"

550,000

BTU/Ft.

13 - 14"

15 - 16"

17 - 18"

TABLE 1 Design Data (Pull-Thru System)

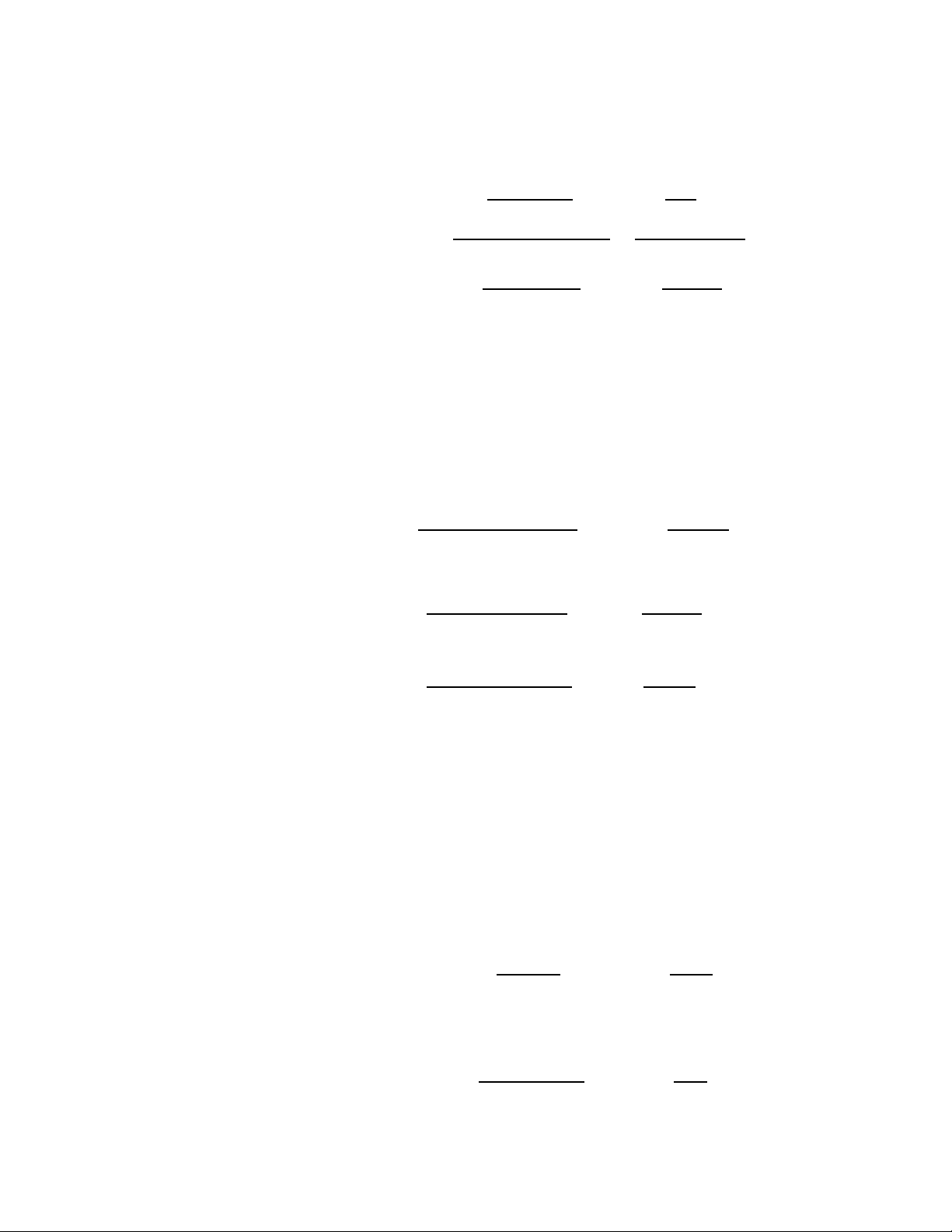

AI R F LOW VARIATIONS DUE TO HEA TIN G IN A PULL-THRU SY STE M

■ Velocity and pressure drop figures shown in Table 1 apply to standard design conditions. However, these condi-

tions apply only when air enters the heater at 70

o

and requires little or no heat. In practice with the burner operating,

these figures will vary, especially with inlet air at the minimum design temperature. This is because the blower handles

a constant volume of air regardless of its temperature. When the air is heated expansion takes place ahead of the

blower and just downstream of the burner. It follows therefore that when the air is being heated a lesser volume enters

the heater, causing a reduction, both in velocity and pressure drop at the burner. Table 2 shows the variation for minimum temperature air entry and with full input to the burner. Flame lengths given in Table 1 apply to conditions shown

in Table 2.

■ Request MIDCO Bulletin 8470-51 for procedure for testing a heater with warm inlet temperatures.

DESIGN

VELOCITY AT

BURNER

(from Table 1)

3200 fpm

2850 fpm

2500 fpm

EXAMPLE: A heater rated for 100o rise, 70o outlet temperature at a design velocity of 2850

fpm and a design pressure drop of .55" W.C., will in actual operation pass 2300 fpm over the

burner with a .36" W.C. drop when air enters at -30

DESIGN

PRESSURE DROP

AT BURNER

(from Table 1)

.70" W.C.

.55" W.C.

.45" W.C.

TEMP

TABLE 2 Air Flow Variations

IV HEAT REQUIREMENTS, BURNER

LENGTH AND PROFILE AREA

The fuel consumption is determined only by air delivery of

the heater and the desired temperature rise. The air delivery of the heater or group of heaters is usually equal to, or

slightly in excess of, the total exhaust potential of the

building ventilating system. The temperature rise is the

difference between the coldest anticipated outdoor temperature and desired outlet temperature, usually a few degrees above indoor temperature.

■ The burner capacity must be accurately correlated to

the heat demand for best results. If it were undersized, it

is obvious that in severe weather the outlet temperature

AIR

RISE

75

100

75

100

75

100

ACTUAL COLD

AIR VELOCITY

AT BURNER

o

o

o

o

o

o

o

.

2750 fpm

2600 fpm

2450 fpm

2300 fpm

2150 fpm

2000 fpm

ACTUAL COLD

AIR PRESSURE

DROP AT

BURNER

.52" W.C.

.46" W.C.

.41" W.C.

.36" W.C.

.33" W.C.

.29" W.C.

would be too low. On the other hand, oversizing will displace the burner turndown range, wasting some of the

maximum capacity potential and causing too great a temperature rise at low fire. However, the wide turndown

range allows some latitude in sizing since in actual practice the extreme range will rarely be required.

■ THE CALCULATIONS AND THE EXAMPLE FOLLOW-

ING APPLY TO A PULL-THRU SYSTEM. Calculations

are simple because, as noted above, the usual outlet temperature will approximately match standard conditions

o

(70

). Push-thru systems require corrections for varying

air temperature at the blower, as do high outlet temperature systems, which are not covered by these instructions.

-3-

HEA T REQUIREMENTS

INSTRUCTION

1. Calculate temperature rise. (Outlet

temperature usually designed for 75

o

85

.)

2. Determine permissible rise in mild

weather (usually 4

o

to 6o).

3. Calculate turn down ratio

4. *Calculate maximum hourly BTU

5. Calculate minimum hourly BTU

* Formula above includes 1:1 constant for heat content of air and .92 factor, which is an average ratio of net and gross

heating value of common fuel gases.

** Assume a heater with an air delivery of 27,500 cfm. Minimum outdoor temperature -20

o

85

.

o

to

FORMULA

Outlet temperature

less inlet temperature

Maximum rise

Minimum rise

Cfm x maximum rise x 1.1

.92

Maximum input

Turn down ratio

EXAMPLE**

o

105

o

5

105

5

27,500 x 105 x 1.1

.92

3,300,000

21

o

. Desired outlet temperature

o

= 21 to 1

o

= 157,000

= 3,300,000

BUR NER LENG TH

The ideal burner length is such as to sufficiently spread the heat in front of the blower to yield uniform outlet temperatures. Other factors to consider are: air pressure drop at the burner, flame length, turn-down ratio, burner to hater casing clearance, and the maximum per foot capacity rating of the burner.

INSTRUCTION

1. Divide maximum hourly BTU by 550,000

to determine minimum feet of burner

2. Check your heater cross section for

physical fit of burner

3. Recalculate per foot capacity for actual

burner length

4. Determine air velocity at burner

See Section IV and Figure 6

FORMULA

Total maximum capacity

Per foot maximum capacity

Total maximum capacity

Actual burner length

See Section II and Table 1

EXAMPLE

3,300,000

550,000

Assume 6

1/2 ft. straight burner desirable

3,300,000

6

Assume 2850 fpm (.55" pressure drop)

= 6 ft.

= 510,000 per ft.

1/2

5. Calculate minimum BTU requirements

per foot

6. Determine burner minimum capacity

Total minimum capacity

Burner length

See Table 1

157,000

6

Minimum = 18,000 BTU/ft. therefore 24,000 acceptable

= 24,000 BTU per ft.

1/2

rating

7. Check operating characteristics

See Tables 1 and 2

Flame length = approx. 13"

Actual velocity at -20

o

Actual pressure drop at -20

= 2,300 ft.

o

= .36" W.lC.

PROFILE ARE A

In calculating velocity consider only the open area (profile area), less the area occupied by the burner. The burner

width at the flame baffle is 7

for areas of other sections.

1. Calculate total burner area

2. Calculate net profile area

3. Calculate gross profile area

4. Calculate length of profile opening

5. Calculate height of profile opening

7/8"; thus a one-foot section will cover 941/2 square inches or .65 square feet. See page 10

INSTRUCTION

Feet of Burner x area per foot

Burner & net area combined

Burner length plus 4" each end

FORMULA

Total cfm

o

70

velocity

Gross profile area

Length

EXAMPLE

61/2 x .65 = 4.2 sq. ft.

27,500

= 9.6 sq. ft.

2850

4.2 + 9.6 = 13.8 sq. ft.

78" + 4 + 4 = 86" (7.15 ft.)

13.8

= 1.93 ft. = 23"

7.15

-4-

Loading...

Loading...