Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

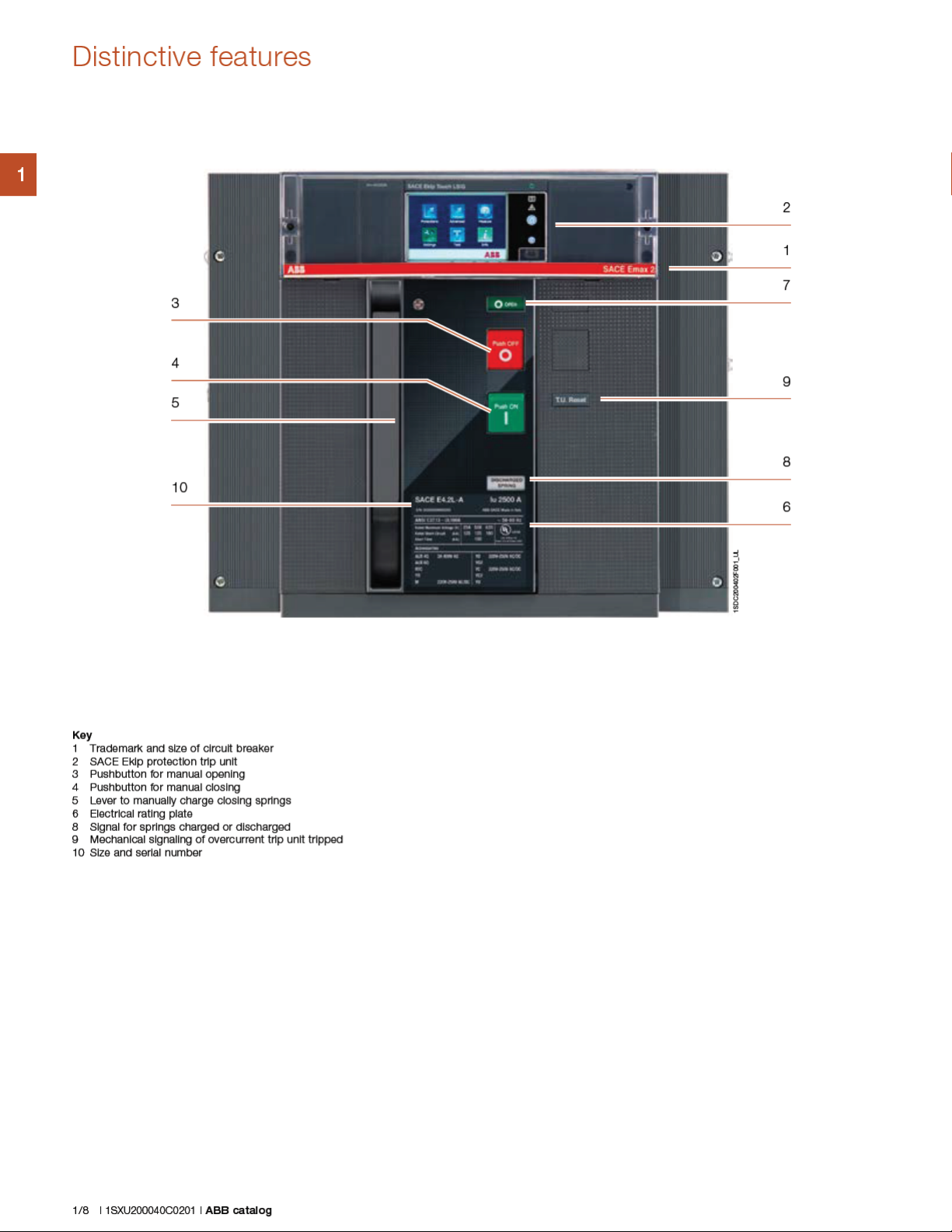

Distinctive features

1

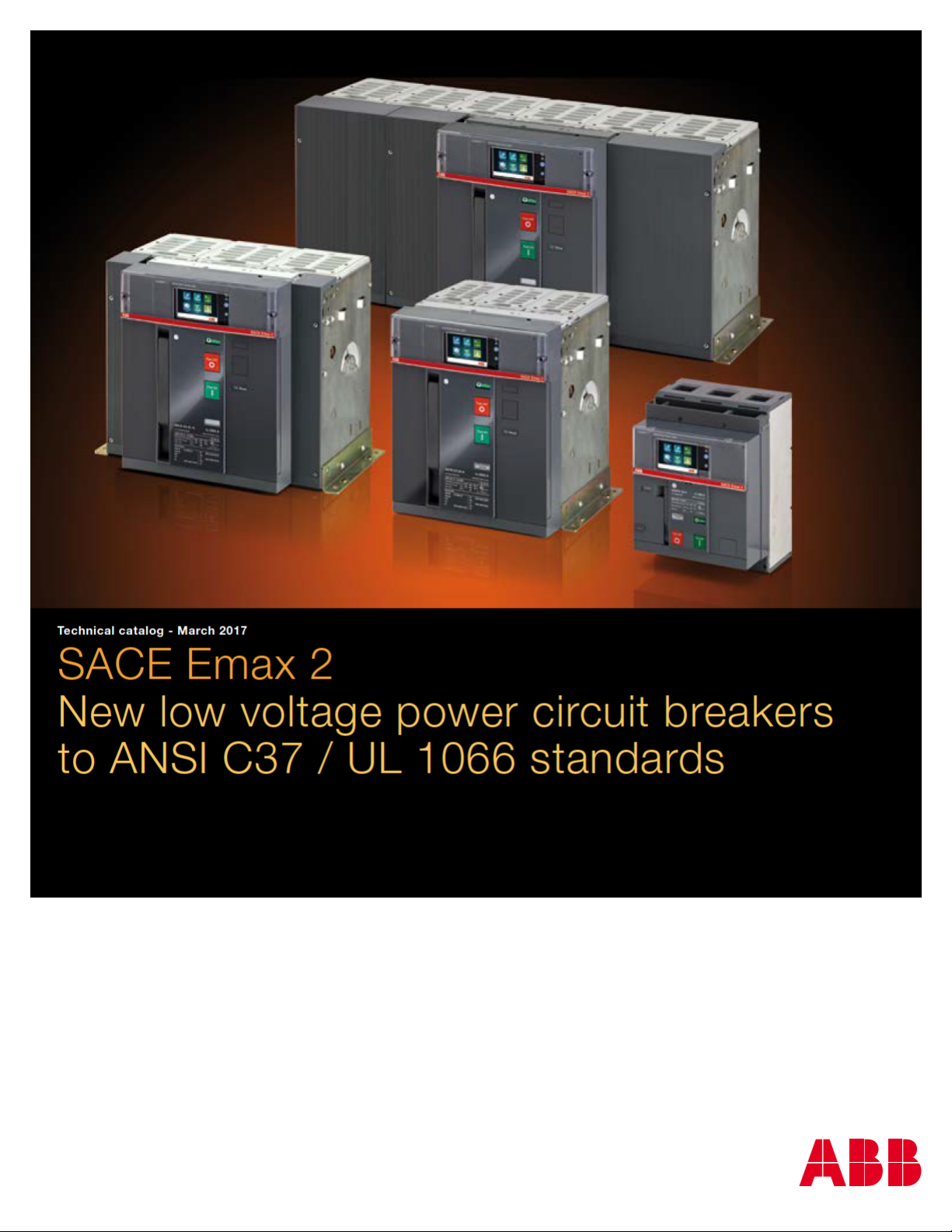

Performance

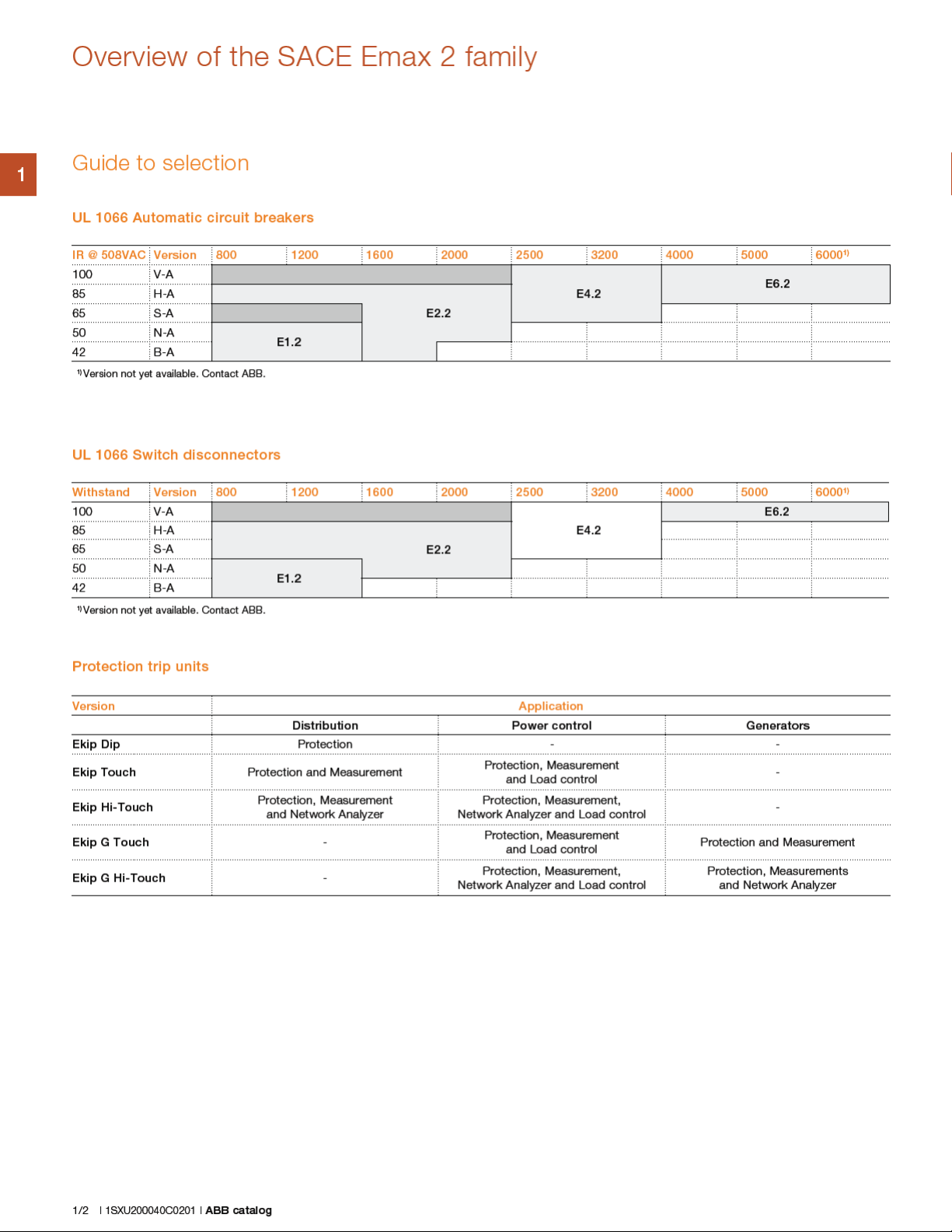

The SACE Emax 2 for UL 1066 range is made up of 4 sizes: E1.2, E2.2, E4.2 and E6.2 up to 6000A1), which enable switchgear of

compact dimensions and high ratings to be built with busbars of reduced length and cross-section.

The protection trip units, auxiliary connections and main accessories are the same throughout the range to simplify design and

installation. Furthermore, the sizes from E2.2 to E6.2 have the same height and depth.

The rating levels are updated and uniform throughout the sizes to meet the demands and needs of today’s installations, from

42kA to 150kA at 508V and to standardize switchgear projects.

High short-time withstand currents, together with the efficiency of the protection functions, guarantee complete selectivity in all

situations. Accurate design and choice of materials enable optimization of the overall dimensions of the circuit breaker. In this way

switchgear of compact dimensions can be built and outstanding savings at the same performance can be obtained.

In particular:

– E1.2 offers 1200A with an interrupting rating of up to 65kA and a short-time withstand current of 50kA in an extremely

compact structure. In the three and four pole version, it offers the sturdiness of SACE Emax with reduced dimensions and

enables switchgear of 65kA to be built in units of 16 inches, which is indispensable in places where reduced dimensions are

essential, such as naval and offshore installations.

– E2.2 enables ratings of up to 2000A to be achieved in switchgear with a width of 16 inches when the three pole version is

used. In addition, it provides an interrupting rating of up to 100kA and withstand current of up to 85kA.

– E4.2 is the new standard for circuit breakers up to 3200A. It is designed for interrupting ratings up to 100kA at 508V and

short-time withstand currents of up to 100kA without the need for particular precautions.

– E6.2 is the top of the range, with an interrupting rating of 100kA, a withstand rating of up to 100kA and a structure that

allows 6000A

1)

to be reached, even in complex installation conditions.

1)

Version not yet available. Contact ABB.

1/6 | 1SXU200040C0201 | ABB catalog

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

The Ranges

SACE Emax 2 power circuit breakers UL 1066 2/2

SACE Emax 2 switch disconnectors UL 1066 2/4

SACE Emax 2 power circuit breakers IEC 60947 2/6

SACE Emax 2 switch disconnectors IEC 60947 2/8

SACE Emax 2 power circuit breakers and switch disconnectors

for applications up to 1150V AC IEC 60947 2/10

SACE Emax 2 other versions 2/12

2

ABB catalog | 1SXU200040C0201 | 2/1

Page 18

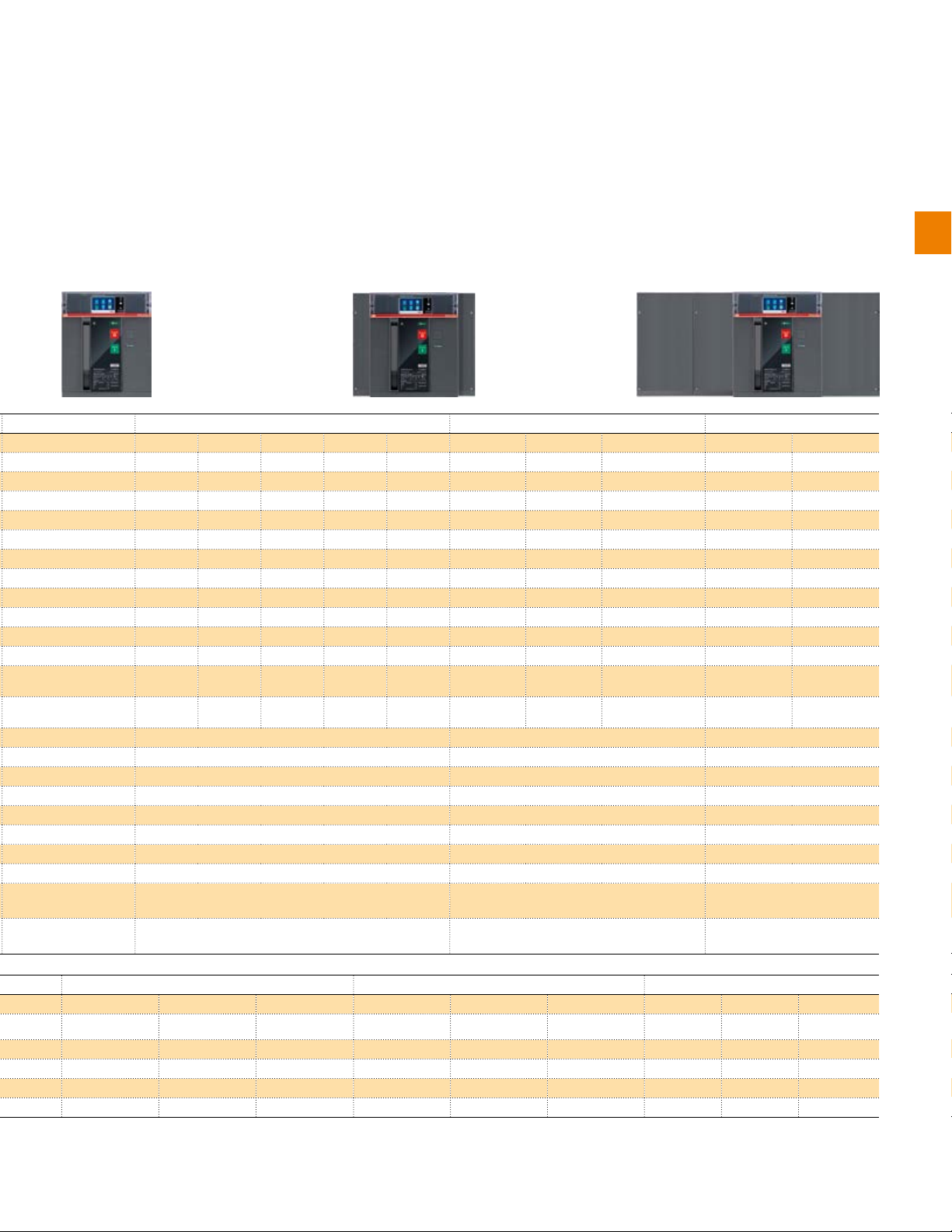

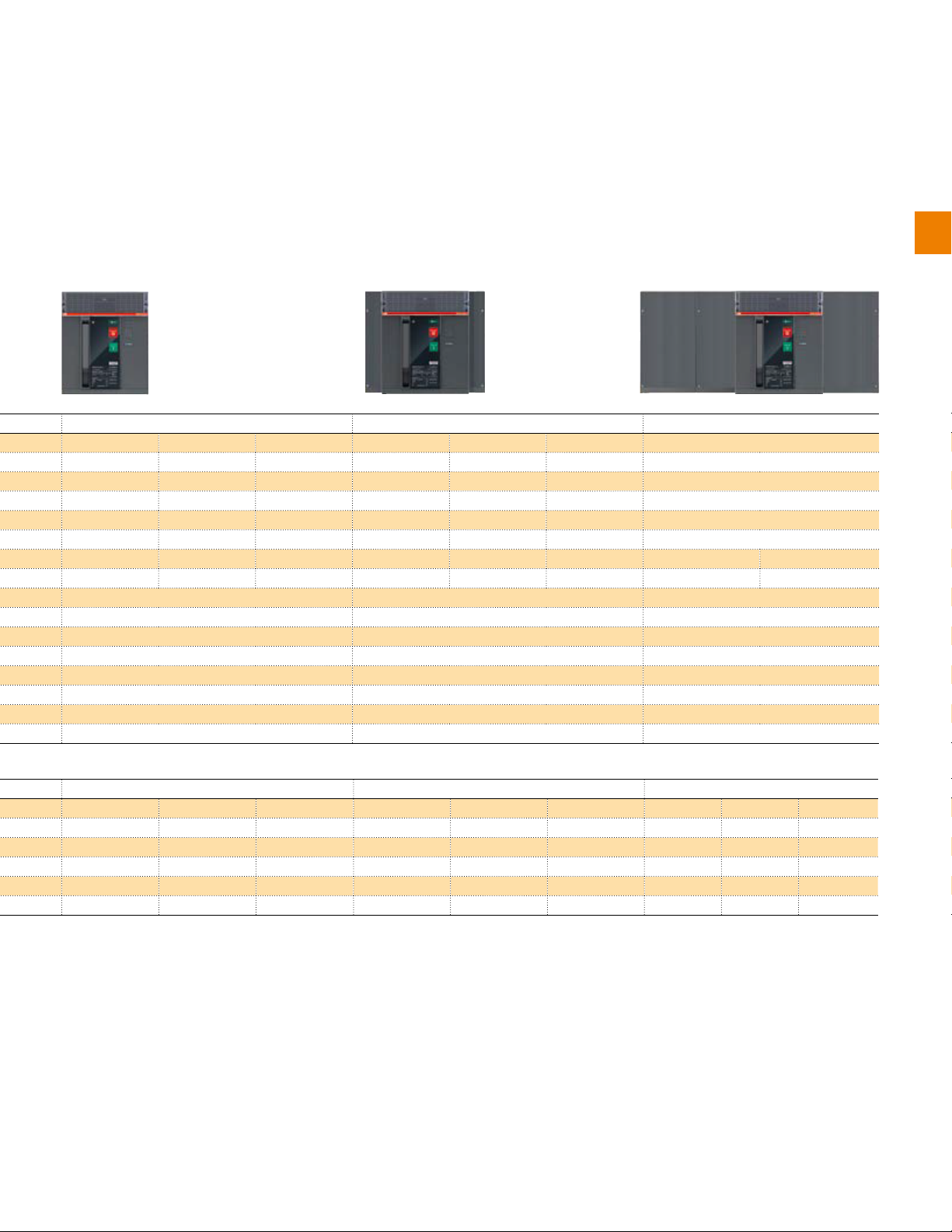

SACE Emax 2 power circuit breakers UL 1066

Common data

Rated maximum voltage [V] 635

Rated voltage [V] 600

2

Test voltage (1min. 50/60 Hz) [kV] 2.2

Frequency [Hz] 50 - 60

Number of poles 3 - 4

Version Fixed (F) - Drawout (W)

1SDC200424F001_UL

SACE Emax 2 for UL1066

Performance levels

Current

Neutral pole current-carrying capacity for 4 pole CBs

Interrupting rating at

rated maximum voltage

Rated short time current

Trip times Break time with fault current < rated short

Overall dimensions

Weights

254 V [kA] 42 50 65

508 V [kA] 42 50 65

635 V [kA] 42 42 42

time current

Break time with fault current > rated short

time current

H - Fixed [in/mm] 11.65 / 296

D - Fixed [in/mm] 7.20 / 183

W - Fixed 3p [in/mm] 8.27 / 210

W - Fixed 4p/4p full size [in/mm] 11.02 / 280

H - Draw out [in/mm] 14.33 / 363.5

D - Draw out [in/mm] 11.06 / 281

W - Draw out 3p [in/mm] 10.94 / 278

W - Draw out 4p/4p full size [in/mm] 13.70 / 348

Fixed 3p / 4p / 4p full size [lbs/Kg] 30.9/35.3 lbs - 14/16 kg

E1.2

B-A N-A S-A

[A] 800 800 250

[A] 1200 1200 400

[A] 800

[A] 1200

[A]

[A]

[%Iu] 100 100 100

[kA] 42 50 50

[ms] 40 40 40

[ms] 25 25 25

SACE Emax 2 for UL1066

Mechanical life with regular ordinary

maintenance prescribed by the

manufacturer

Electrical life with regular ordinary

maintenance prescribed by the

manufacturer

1)

Version not yet available. Contact ABB.

2/2 | 1SXU200040C0201 | ABB catalog

Draw out 3p / 4p / 4p full size [lbs/Kg] 90.4/102.5 lbs - 41/46.5 kg

E1.2

[A] < 800 800 1200

[No. cycles x 1000] 20 20 20

Frequency [Cycles/Hour] 60 60 60

508 V [No. cycles x 1000] 8 8 7

635 V [No. cycles x 1000] 8 8 6.5

Frequency

[Cycles/Hour] 30 30 30

Page 19

2

1SDC200425F001_UL

1SDC200426F001_UL

E2.2 E4.2 E6.2

B-A N-A S-A H-A V-A S-A H-A V-A H-A V-A

1600 1600 800 800 250 2500 2500 800 4000 4000

1)

6000

100 100 100 100 100 100 100 100 50-100 50-100

42 50 65 85 100 65 85 100 85 100

42 50 65 85 85 65 85 100 85 100

40 40 40 40 40 40 40 40 40 40

25 25 25 25 25 25 25 25 25 25

14.61/371 14.61/371 14.61/371

15.47/393 15.47/393 15.47/393

1SDC200427F001_UL

1)

115/148 lbs - 52/67 Kg

up to 1600A: 128/150 lbs - 58/68 Kg

2000A: 135/239lbs - 61/108kg

Up to 2500A: 161/203 lbs - 73/92 kg

3200A: 201/256 lbs - 91/116 kg

Up to 2500A: 261/325 lbs - 118/147 kg

3200A: 300/377 lbs - 136/171 kg

314/360/406 lbs

142/163/184 kg

486/554/620 lbs

220/251/281 kg

E2.2 E4.2 E6.2

< 1600 1600 2000 < 2500 2500 3200 4000 5000 6000

60 60 60 60 60 60 60 60 60

15 12 10 10 8 7 4 3 2

30 30 30 20 20 20 10 10 10

ABB catalog | 1SXU200040C0201 | 2/3

1)

Page 20

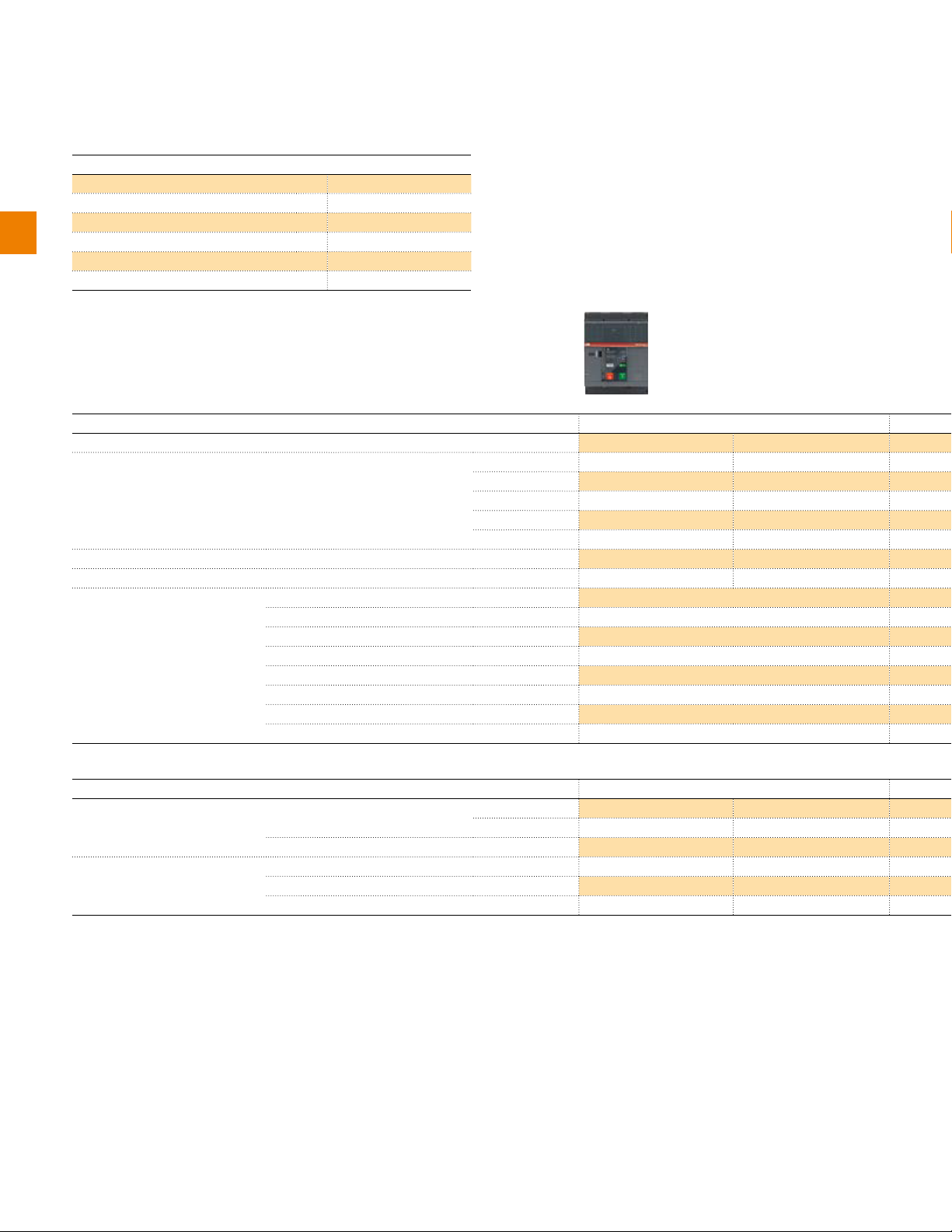

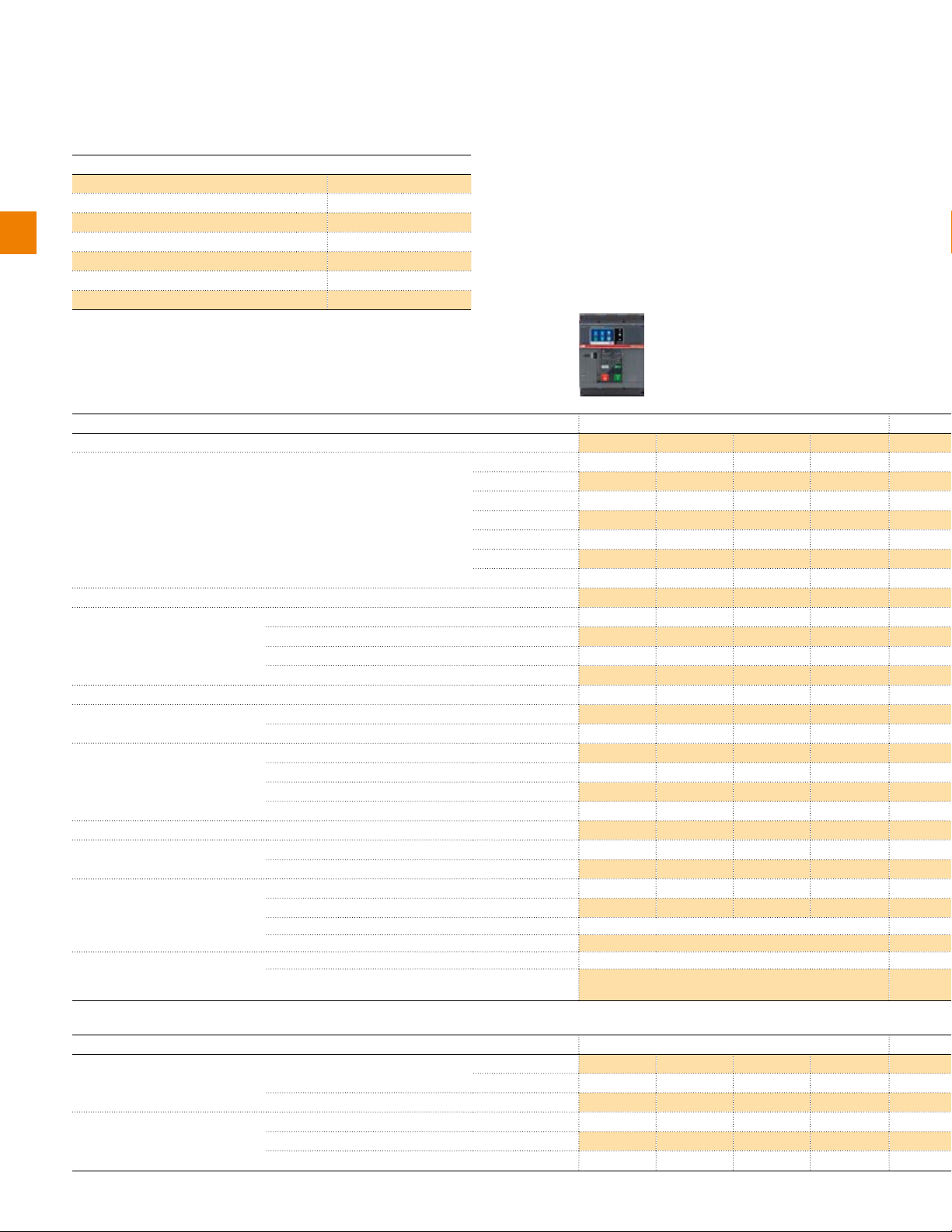

SACE Emax 2 switch disconnectors UL 1066

Common data

Rated maximum voltage [V] 635

Rated voltage [V] 600

2

Test voltage (1min. 50/60 Hz) [kV] 2.2

Frequency [Hz] 50 - 60

Number of poles 3 - 4

Version Fixed (F) - Drawout (W)

1SDC200428F001_UL

SACE Emax 2 for UL1066

Performance levels

Current

Neutral pole current-carrying capacity for 4 pole CBs

Rated short time current

Overall dimensions

1) Rated short-time current is equal to 42kA at 635V.

SACE Emax 2 for UL1066

Mechanical life with regular ordinary

maintenance prescribed by the

manufacturer

Electrical life with regular ordinary

maintenance prescribed by the

manufacturer

1) Version not yet available. Contact ABB.

H - Fixed [in/mm] 11.65 / 296

D - Fixed [in/mm] 7.20 / 183

W - Fixed 3p [in/mm] 8.27 / 210

W - Fixed 4p/4p full size [in/mm] 11.02 / 280

H - Draw out [in/mm] 14.33 / 363.5

D - Draw out [in/mm] 11.06 / 281

W - Draw out 3p [in/mm] 10.94 / 278

W - Draw out 4p/4p full size

Frequency [Cycles/Hour] 60 60

508 V [No. cycles x 1000] 8 7

635 V [No. cycles x 1000] 8 6.5

Frequency

E1.2

B-A N-A

[A] 800 800

[A] 1200 1200

[A]

[A]

[A]

[%Iu] 100 100

[kA] 42 50

[in/mm] 13.70 / 348

E1.2

[A] 800 1200

[No. cycles x 1000] 20 20

[Cycles/Hour] 30 30

1)

2/4 | 1SXU200040C0201 | ABB catalog

Page 21

2

1SDC200429F001_UL

1SDC200430F001_UL

E2.2 E4.2 E6.2

N-A S-A V-A S-A H-A V-A L-A

1600 800 800 2500 2500 800 4000

1)

100 100 100 100 100 100 50-100 50-100

50 65 85 65 85 100 100 100

14.61/371 14.61/371 14.61/371

15.47/393 15.47/393 15.47/393

407/16.02 21.69/551 36.57/929 - 42.09/1069

E2.2 E4.2 E6.2

< 1600 1600 2000 < 2500 2500 3200 4000 5000 6000

1SDC200431F001_UL

60 60 60 60 60 60 60 60 60

15 12 10 10 8 7 4 3 2

30 30 30 20 20 20 10 10 10

ABB catalog | 1SXU200040C0201 | 2/5

Page 22

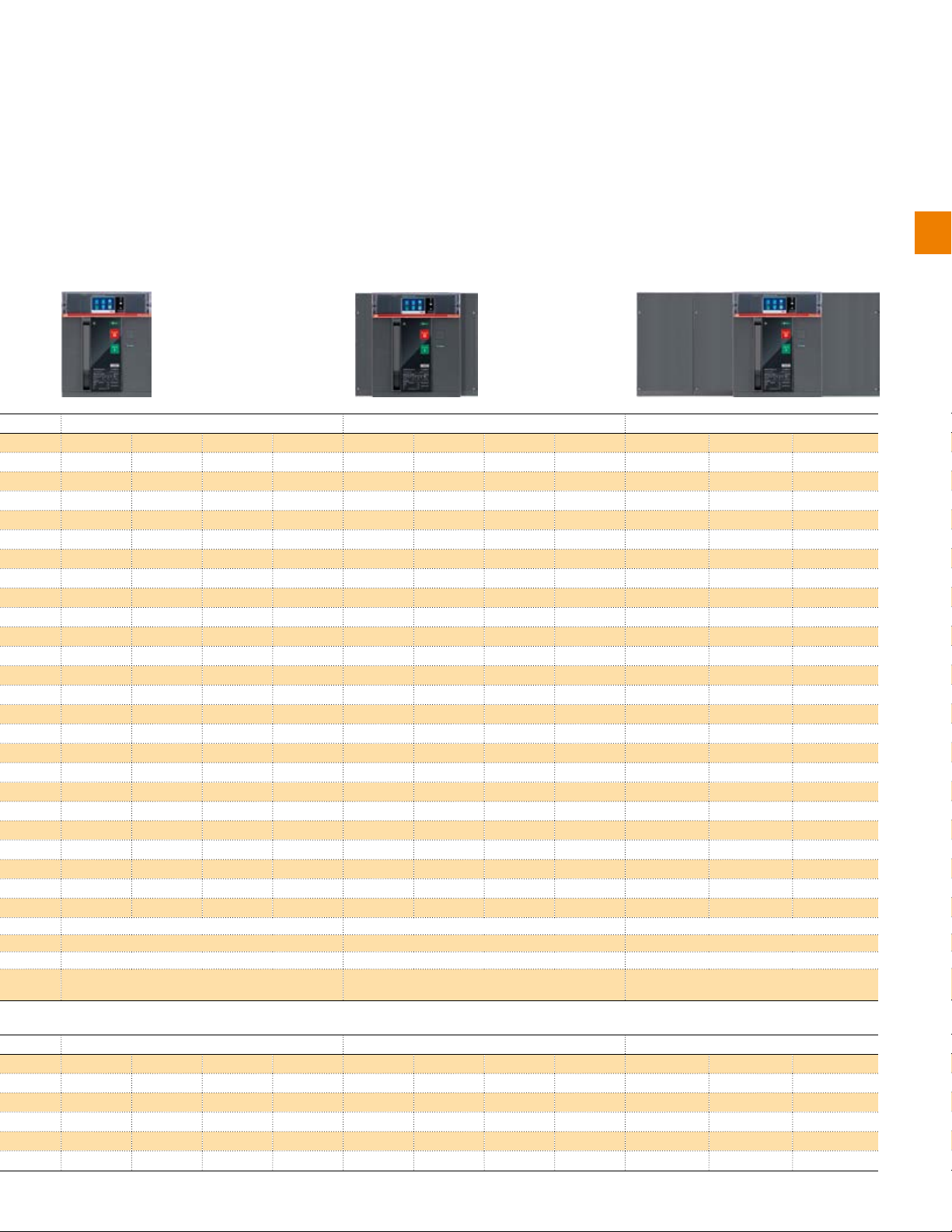

SACE Emax 2 power circuit breakers IEC 60947

Common data

Rated service voltage Ue [V] 690

Rated insulation voltage Ui [V] 1000

2

Rated impulse withstand voltage Uimp [kV] 12

Frequency [Hz] 50 - 60

Number of poles 3- 4

Version Fixed (F) - Drawout (W)

Isolation behaviour IEC 60947-2

1SDC200424F001_UL

SACE Emax 2 for IEC 60947

Performance levels

Rated uninterrupted current Iu @ 40°C

Neutral pole current-carrying capacity for 4-pole CBs

Rated ultimate short-circuit

breaking capacity Icu

Rated service short-circuit breaking capacity Ics

Rated short-time withstand

current Icw

Rated short-circuit making

capacity (peak value) Icm

Utilization category (according to IEC 60947-2)

Breaking time

Dimensions

Weights (CB with trip unit and

current sensor)

1) Ics: 50kA for 400V…440V voltage; 2) Ics: 125kA for 400V...440V voltage; 3) E4.2H 3200A: 66kA Icw (3s)

400-415 V [kA] 42 50 66 150

440 V [kA] 42 50 66 130

500-525 V [kA] 42 42 50 100

690 V [kA] 42 42 50 45

(1s) [kA] 42 42 50 15

(3s) [kA] 24 24 36 -

400-415 V [kA] 88 105 145 330

440 V [kA] 88 105 145 286

500-525 V [kA] 88 88 105 220

690 V [kA] 88 88 105 132

I<Icw [ms] 40 40 40 40

I>Icw [ms] 25 25 25 10

H - Fixed/Withdrawable [mm] 296/363.5 296/363.5 296/363.5 296/363.5

D - Fixed/Withdrawable [mm] 183/271 183/271 183/271 183/271

W - Fixed 3p/4p/4p full size [mm] 210/280

W - Withdrawable 3p/4p/4p full size [mm] 278/348

Fixed 3p/4p kg 14/16

Withdrawable 3p/4p/4p full size

including fixed part

[A] 630 630 250 630

[A] 800 800 630 800

[A] 1000 1000 800 1000

[A] 1250 1250 1000 1250

[A] 1600 1600 1250

[A] 1600

[A]

[%Iu] 100 100 100 100

[%Icu] 100 100 100

kg 38/43

E1.2

B C N L

1)

B B B A

100

SACE Emax 2 for IEC 60947

Mechanical life with regular ordinary

maintenance prescribed by the

manufacturer

Electrical life with regular ordinary

maintenance prescribed by the

manufacturer

2/6 | 1SXU200040C0201 | ABB catalog

E1.2

[Iu] ≤ 1000 1250 1600 1250 L

[No. cycles x 1000] 20 20 20 20

Frequency [Oper./Hour] 60 60 60 60

440 V [No. cycles x 1000] 8 8 8 3

690 V [No. cycles x 1000] 8 6.5 6.5 1

Frequency

[Oper./Hour] 30 30 30 30

Page 23

2

1SDC200425F001_UL

1SDC200426F001_UL

E2.2 E4.2 E6.2

B N S H N S H V H V X

1600 800 250 800 3200 3200 3200 2000 4000 4000 4000

100 100 100 100 100 100 100 100 50-100 50-100 50-100

42 66 85 100 66 85 100 150 100 150 200

100 100 100 100 100 100 100 100

2)

100 100 100

42 66 66 85 66 66 85 100 100 100 120

42 50 50 66 50 66 75

3)

75 100 100 100

88 145 187 220 145 187 220 330 220 330 440

B B B B B B B B B B B

40 40 40 40 40 40 40 40 40 40 40

25 25 25 25 25 25 25 25 25 25 25

371/425 371/425 371/425 371/425 371/425 371/425 371/425 371/425 371/425 371/425 371/425

1SDC200427F001_UL

317/407 425/551 803/929/1069

41/53 56/70 109/125/140

54/99 110/136 207/234/260

E2.2 E4.2 E6.2

< 1600 1600 2000 2500 < 2500 2500 3200 4000 4000 5000 6300

60 60 60 60 60 60 60 60 60 60 60

15 12 10 8 10 8 7 5 4 3 2

30 30 30 30 20 20 20 20 10 10 10

ABB catalog | 1SXU200040C0201 | 2/7

Page 24

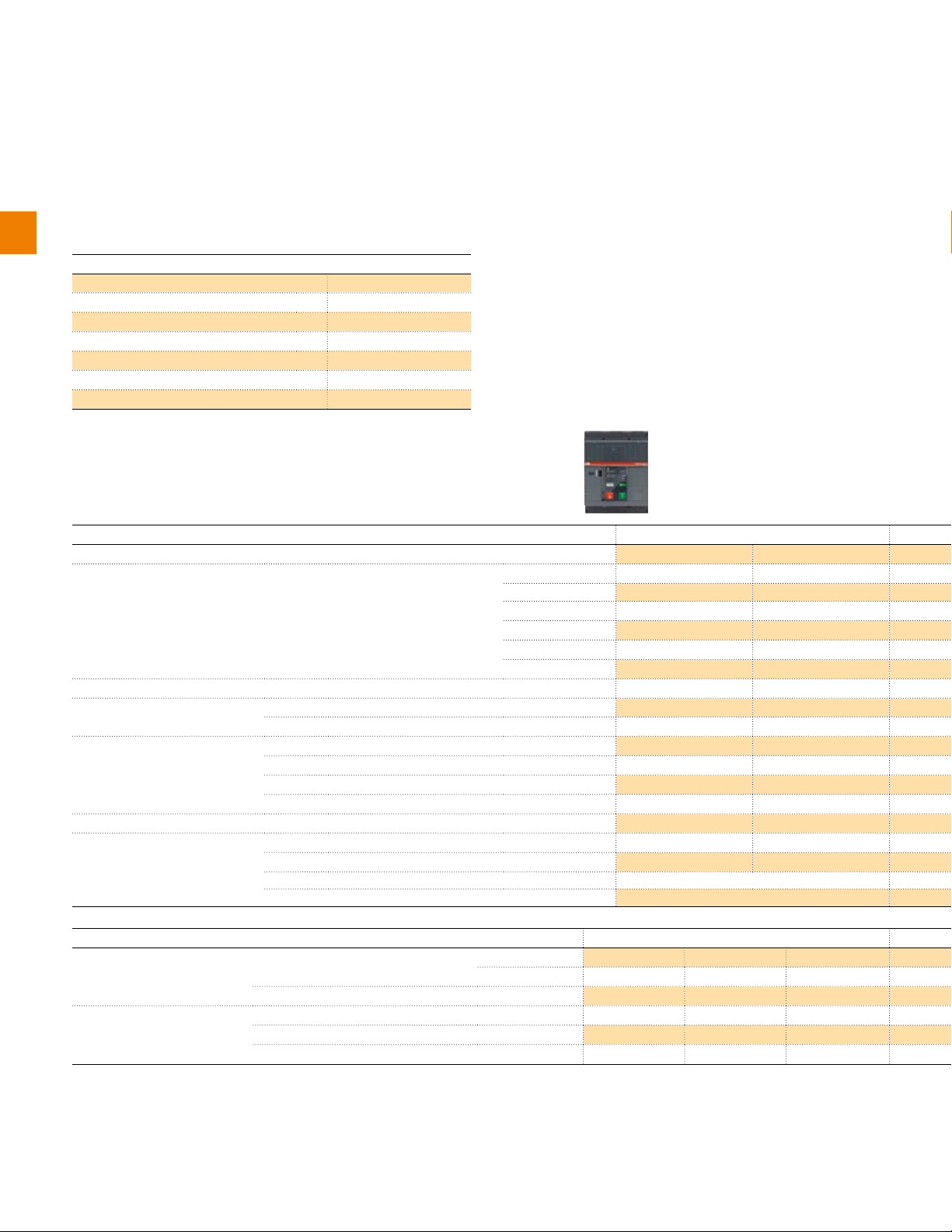

SACE Emax 2 switch disconnectors IEC 60947

Switch disconnectors, identified with the abbreviation “/MS”, are devices that satisfy the isolating specifications provided by

the IEC 60947-3 Standard. The switch disconnectors are derived from the corresponding automatic circuit breakers, and they

have the same dimensions and accessory options. This version differs from the automatic circuit breakers only because of the

absence of protection trip units.

2

Common data

Rated service voltage Ue [V] 690

Rated insulation voltage Ui [V] 1000

Rated impulse withstand voltage Uimp [kV] 12

Frequency [Hz] 50 - 60

Number of poles 3- 4

Version Fixed (F) - Drawout (W)

Isolation behaviour IEC 60947-3

1SDC200428F001_UL

SACE Emax 2 for IEC 60947 E1.2

Performance levels

Rated uninterrupted current Iu @ 40°C

Neutral pole current-carrying capacity for 4-pole CBs

Rated short-time withstand current

Icw

Rated short-circuit making capacity

(peak value) Icm

Utilization category (according to IEC 60947-3)

Dimensions H - Fixed / Withdrawable

(1s)

(3s)

400-415 V

440 V

500-525 V

690 V

D - Fixed / Withdrawable

W - Fixed 3p/4p/4p full size [mm] 210 / 280

W - Withdrawable 3p/4p/4p full size

[A] 630 250

[A] 800 630

[A] 1000 800

[A] 1250 1000

[A] 1600 1250

[A] 1600

[%Iu] 10 0 100

[kA] 42 50

[kA] 24 36

[kA] 88 105

[kA] 88 105

[kA] 88 105

[kA] 88 105

[mm] 296 / 363.5 296 / 363.5

[mm] 183 / 271 183 / 271

[mm] 278 / 348

B/MS N/MS

AC-23A AC-23A

SACE Emax 2 for IEC 60947

Mechanical life with regular

ordinary maintenance prescribed

by the manufacturer

Electrical life with regular

ordinary maintenance prescribed

by the manufacturer

2/8 | 1SXU200040C0201 | ABB catalog

Frequency [Oper./Hour] 60 60 60

440 V [No. cycles x 1000] 8 8 8

690 V [No. cycles x 1000] 8 6.5 6.5

Frequency [Oper./Hour] 30 30 30

E1.2

[Iu] < 1000 1000 1600

[No. cycles x 1000] 20 20 20

Page 25

The device, when in the open position, guarantees an isolating distance between the main contacts of the circuit breaker that is

sufficient to ensure that the installation downstream is not live.

Furthermore the switch disconnectors, if used with an external protection relay with maximum delay of 500ms, enable a

breaking capacity at a maximum rated operating voltage (Ue) equal to the value of rated short-time withstand current (Icw) for

one second.

2

1SDC200429F001_UL

E2.2 E4.2 E6.2

B/MS N/MS H/MS N/MS H/MS V/MS H/MS

160 0 800 800 3200 3200 2000 4000

100 100 100 100 100 100 50-100

42 66 85 66 85 100 100

42 50 66 36 66 75 100

88 145 187 145 187 220 220

88 145 187 145 187 220 220

88 145 187 145 187 220 220

88 145 187 145 187 220 220

AC-23A AC-23A AC-23A AC-23A AC-23A AC-23A AC-23A

371 / 425 371 / 425 371 / 425 371 / 425 371 / 425 371 / 425 371 / 425

270 / 383 270 / 383 270 / 383 270 / 383 270 / 383 270 / 383 270 / 383

317 / 407 425 / 551 803 / 929 / 1069

E2.2 E4.2 E6.2

< 1600 1600 2000 2500 < 2500 2500 3200 4000 4000 5000 6300

1SDC200430F001_UL

1SDC200431F001_UL

60 60 60 60 60 60 60 60 60 60 60

15 12 10 8 10 8 7 5 4 3 2

30 30 30 30 20 20 20 20 10 10 10

ABB catalog | 1SXU200040C0201 | 2/9

Page 26

2

2/10 | 1SXU200040C0201 | ABB catalog

Page 27

Protection trip units

Introduction 3/2

Architecture 3/4

Protection trip units for power distribution

Ekip Dip 3/6

Ekip Touch 3/10

Ekip Hi-Touch 3/20

Protection trip units for generators

Ekip G Touch 3/24

Ekip G Hi-Touch 3/29

Protection trip units for power control

Ekip Power Controller 3/32

Technical characteristics for protection trip units

Protection functions 3/38

Measurement functions 3/48

3

ABB catalog | 1SXU200040C0201 | 3/1

Page 28

Page 29

Page 30

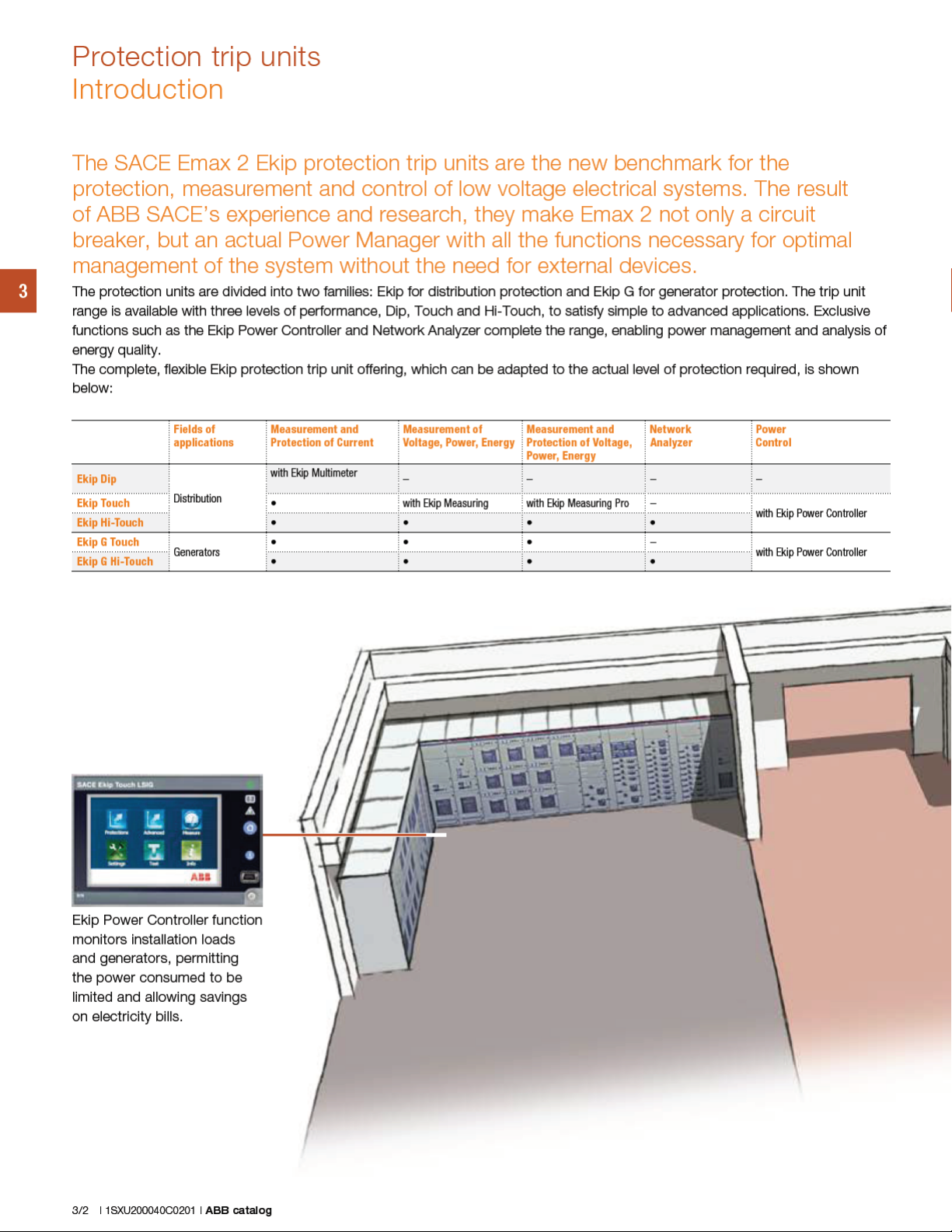

Protection trip units

Architecture

All SACE Emax 2 circuit breakers are equipped with protection trip units that are

interchangeable from the front with just a few, simple operations by the customer.

There is no need to dismantle the circuit breaker or access any internal or sensitive

parts.

3

This enables personalization of the functions available, even during commissioning or when the circuit breaker has already been

installed. In particular, SACE Ekip consists of:

– Protection trip unit, available with different interfaces and versions that range from basic to more complete; it contains a

latest generation microprocessor that performs all the functions of protection and control.

– Ekip Measuring Module, connected internally to Emax 2, performs voltage, power and energy measurements with high

accuracy without requiring any external connection or voltage transformer. The Ekip Measuring Pro version also performs

all protection functions based on voltage and power without the need for external units, thereby simplifying design and

construction of the system.

– Interchangeable rating plug enables all protection thresholds to be adjusted according to the rated current, increasing

flexibility for the customer. It is useful in installations that are prepared for future development or in cases in which the power

supplied may be limited temporarily.

– Main board is the mechanical housing of the trip unit, which includes a micro-controller for measuring currents and the

self-protection functions. The separation of main board and protection trip unit ensures excellent reliability and immunity to

conducted and radiated emissions. Integrated new generation Rogowski sensors, which are sensitive to the true r.m.s. value

of the current, guarantee high accuracy of both measurements and protection.

3/4 | 1SXU200040C0201 | ABB catalog

1SDC200444F001

Page 31

All protection trip units of the SACE Emax 2 family are self-powered by current

that flows through the circuit breaker. They guarantee excellent reliability due to a

system of self-controlled internal connections. The setting, testing and downloading

of reports can be carried out directly from a Smartphone, Tablet or PC.

Easily installed cartridge type modules enable the units to be integrated into the most complex systems. Additional functions

can be created, such as:

– Synchrocheck, checks the synchronization between two busbar systems before enabling circuit breaker closing;

– Communication with all supervision systems is available in the Modbus, Profibus and DeviceNet protocols as well as the

modern Modbus TCP, Profinet and EtherNet/IP protocols;

– Integration into Smart Grids according to the IEC61850 standard (used to communicate with high and medium voltage

substation automation systems), without the need for an external converter;

– Multi-voltage supply module, which enables the protection trip unit and modules present to be supplied with any auxiliary

voltage available in direct or alternating current;

– Programmable logic management with Ekip Signaling modules that make a high number of electrical input and output

contacts available;

– Logical interlocks between circuit breakers, which can be made with the Ekip Link proprietary communication protocol,

avoiding complex wiring because of the transmission of all signals via bus.

3

ABB catalog | 1SXU200040C0201 | 3/5

1SDC200445F001

Page 32

Protection trip units for power distribution

Ekip Dip

Characteristics

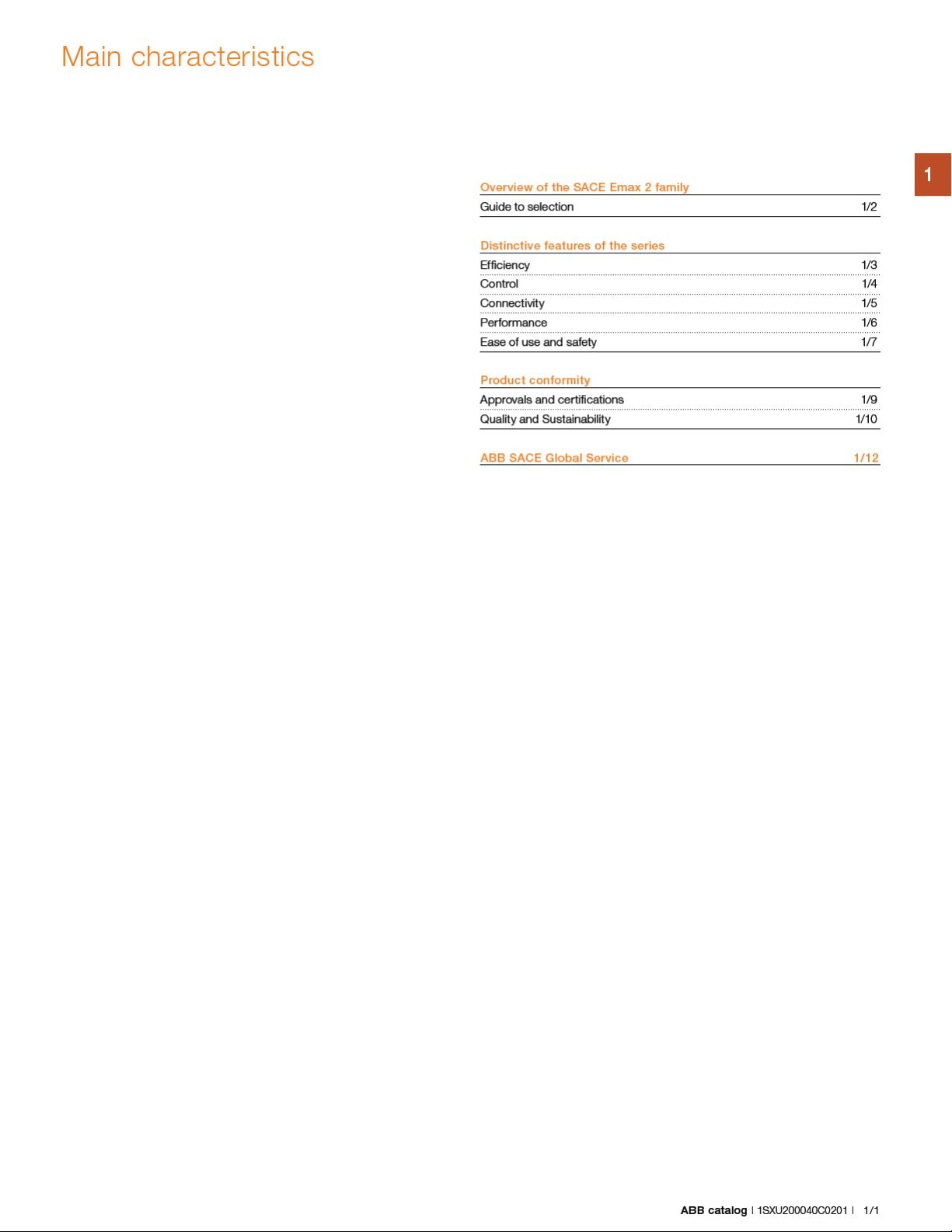

Ekip Dip is the new protection trip unit of the SACE Emax 2 family for all

applications in which high accuracy and reliable protection against overcurrent are

required. Ekip Dip offers a complete set of standard protection functions. Dedicated

LEDs allow the fault that caused tripping to be determined.

3

The unit is available in the following versions:

– Ekip Dip LI

– Ekip Dip LSI

– Ekip Dip LSIG

1

2

3

Key:

1. Power-on LED for Signaling correct operation

(watchdog)

2. LEDs for alarm Signaling of L, S, I and G

protection functions and diagnostics

3. Dip switches for setting the protection functions

4

5

6

1SDC200446F001

4. Dip switches for setting the network frequency

and neutral protection device

5. Pushbutton for test and for indicating the cause

of tripping

6. Test and programming connector

3/6 | 1SXU200040C0201 | ABB catalog

Page 33

Page 34

Protection trip units for power distribution

Ekip Dip

Measurements

The Ekip Dip unit measures phase and neutral current with great accuracy: 1% including the current transformers in the 0.2 ...

1.2 In range (class 1 in accordance with IEC 61557-12). Using the current sensors in the circuit breaker and without the need to

install an external measuring system, it is possible to view the measurements from the display on the front of the Ekip Multimeter

and Ekip Control Panel.

Ekip Dip also records the characteristics of the circuit breaker, to enable a rapid analysis during troubleshooting or maintenance:

– Maximum and average current values per phase;

3

– Date, time, fault current per phase and type of protection tripped over the last 30 trips;

– Date, time and type of operation of the last 200 events (for example: opening/closing of the circuit breaker, pre-alarms, editing

settings);

– Number of mechanical and electric operations of the circuit breaker;

– Total operating time;

– Contact wear (endurance);

– Date and time of the last maintenance carried out, in addition to the estimate of the next maintenance required;

– Circuit-breaker identifying data: type, serial number, firmware version, name of the device as assigned by the user.

The values can be displayed on the front of the Ekip Multimeter or Ekip Control Panel or by Ekip Connect software on a

Smartphone, Tablet or PC by using the communication units Ekip T&P or Ekip Bluetooth.

Watchdog

All the protection trip units of the SACE Emax 2 family ensure high reliability owing to an electronic circuit that periodically controls

the continuity of the internal connections, such as trip coil, rating plug and each current sensor (Ansi 74). In the event of a

malfunction, the LEDs indicate the corresponding alarm to enable the fault to be identified rapidly. Furthermore, Ekip Dip detects

and indicates that the circuit breaker has been opened because one of the protection functions has been tripped (Ansi BF code).

In order to preserve the correct operation of the unit, Ekip Dip is also provided with self-protection against abnormal temperature

(OT) inside the protection trip unit. The user can set it to open the circuit breaker or to merely indicate an alarm.

User interface

Ekip offers a great variety of thresholds and trip times, the protections can be set by dip-switches. Up to 5 LEDs are also

available (depending on the version) to indicate correct operation or alarms. The interface always enables the status of the

installation to be identified clearly and quickly:

– correct operation (green LED)

– overcurrent pre-alarms or alarms

– presence of self-control functions alarms

– maintenance interval expired

– indication of tripped protection after a fault

The protection tripped indication is activated by pressing the iTest key, and operates without the need of an external power

supply because a battery is installed inside the unit.

Communication

The Ekip Bluetooth wireless communication unit enables the operator to interact with the protection trip unit by computer,

Smartphone or Tablet. In fact, the free Ekip Connect software for Smartphones, Tablets and PC, enables measurements and

fault data to be read along with alarm status and information from the circuit breaker to be displayed. It is also possible to set

parameters such as date, time and thermal memory and for records to be reset.

3/8 | 1SXU200040C0201 | ABB catalog

Page 35

Test function

The test port on the front of the protection trip unit can be used to run circuit breaker tests by connecting one of the following

devices:

– Ekip TT to run the trip test, the LEDs test and check absence of alarms detected by the watchdog function;

– Ekip T&P to permit not only the trip test and LEDs test but also to run the test of the individual protection functions and save

the relative report;

– ITest key that is pressed to run the battery test when the circuit breaker is disconnected.

Supply

The Ekip Dip protection trip unit does not require an external supply for the protection functions or for the alarm indication

functions because it is self-supplied by the current sensors installed on the circuit breaker. A three-phase 100A current suffices

to activate the LED indications.

The Ekip Supply module enables an auxiliary supply to be easily connected and is able to receive both a direct current supply

(24-48VDC or 110-240VDC) and an alternating current (110-240VAC) to activate additional functions such as:

– G protection at values below 100A or below 0.2 In;

– connecting to external devices such as Ekip Multimeter and Ekip Control Panel;

– recording the number of operations.

The Ekip Dip protection trip unit also has a battery that enables the indication of the cause of the fault to be viewed for an unlimited

time after tripping. In addition to that, the battery enables date and time to be maintained and updated, thus ensuring the chronology

of the events. On the other hand, when the unit is switched off, the battery test can be run by simply pressing the iTest key.

Supply Ekip Supply

Nominal voltage 24-48V DC 110-240V AC/DC

Voltage range 21.5 - 53V DC 105-265V AC/DC

Rated power (including modules) 10W max. 10W max.

Inrush current ~10 A for 5 ms ~10 A for 5 ms

3

Whenever cartridge modules are not used in the terminal box area, the trip unit can be supplied by means of a galvanically

isolated 24V DC auxiliary voltage.

ABB catalog | 1SXU200040C0201 | 3/9

Page 36

Protection trip units for power distribution

Ekip Touch

Characteristics

Ekip Touch is the new protection trip unit for SACE Emax 2 that provides a

complete series of protections and high accuracy measurements of all electric

parameters and can be integrated perfectly with the most common automation and

supervision systems.

3

The simple and intuitive touch screen interface enables the operator to access

all the information and settings rapidly and easily by minimizing installation and

commissioning time.

The unit is available in the versions:

– Ekip Touch LI

– Ekip Touch LSI

– Ekip Touch LSIG

1

Key:

1. Wide high-resolution color touch screen display

2. Power-on LED to indicate correct operation

(watchdog)

3. Pre-alarm LED

2

3

4

5

6

7

1SDC200466F001

4. Alarm LED

5. Home pushbutton to return to home page

6. Pushbutton for test and indicating cause of trip

7. Test and programming connector

3/10 | 1SXU200040C0201 | ABB catalog

Page 37

Page 38

Page 39

Page 40

Page 41

Measurements

Measurements and meters

All versions of the Ekip Touch unit measure the RMS value of the currents of

the three phases (L1, L2, L3) and of neutral (Ne) with 1% accuracy in the 0.2 to

1.2 In range (class 1 in accordance with IEC 61557-12). The complete range of

measurement is from 0.03 to 16x In, where In is the value of the rating plug.

The display shows the current of the most loaded phase both in numeric and

analogue format on an ammeter with a 0-125% In scale for rapid identification of

the load of the circuit breaker.

1SDC200468F001

Alternatively, bar graphs that show the currents of the three phases and of neutral

on a 0-125% In scale in addition to the numeric value of the most loaded phase

can be selected as the default page. The bar graphs are yellow in the event of a

pre-alarm and red in the event of an overload to enable an irregular condition to be

identified immediately.

Where applicable, the measurement of the ground fault current is shown on a

dedicated page. The ammeter can operate both in self-supplied mode and with

auxiliary voltage. In the latter case, the display always has back lighting and the

ammeter is also active at currents below 100A.

1SDC200469F001

3

1SDC200470F001

Adding the Ekip Measuring or Ekip Measuring Pro module to Ekip Touch enables

Ekip Touch to be used as a multimeter to measure the values of:

– Voltage: phase-phase, phase-neutral (accuracy 0.5%);

– Power: active, reactive, apparent (accuracy 2%);

– Energy: active, reactive, apparent (accuracy 2%);

– Frequency (accuracy 0.2%);

– Power factor by phase and total;

– Peak factor.

Maximum values and values register

The Ekip Touch unit is able to supply the measurement trend of certain parameters

over a settable period of time such as: average power, maximum power,

maximum and minimum current, maximum and minimum voltage. The values of

the last 24 time intervals are recorded in the unit with a relative timestamp and

can be consulted directly from the display or remotely using one of the available

communication protocols. The communication can also be used to synchronize the

recording time interval.

Data logger

Ekip Touch is always supplied with the exclusive Data Logger (register) function

that stores with high sampling frequency the instantaneous values of all the

measurements in two memory buffer registers. The data can be easily downloaded

by the Ekip Connect unit and transferred to any personal computer. This enables the

current and voltage waveforms to be analyzed for rapid fault analysis. The function

continuously stores and stops recording, with a selectable delay, whenever the event

set by the user occurs (e.g. trip or alarm). In this manner, it is possible to analyze the

complete evolution of the fault: from the start to its complete elimination.

ABB catalog | 1SXU200040C0201 | 3/15

Page 42

Protection trip units for power distribution

Ekip Touch

Information on trip and opening data

If a trip occurs, Ekip Touch stores all the information that is required for rapid

identification and elimination of the causes:

– Protection tripped

– Opening data (current, voltage or frequency)

– Time-stamping (data, time and consecutive opening number)

3

If the iTest key is pressed, the trip unit displays all these data directly on the display.

No auxiliary supply is required. The information is also available to the user with the

circuit breaker open or without current flow, due to the battery installed inside the unit.

Maintenance indicators

A complete set of information about the circuit breaker and its operation is available

for effective fault analysis and preventive scheduling of maintenance. All the

information can be seen from the display or from a PC using a communication unit.

In particular:

– Date, time, fault current by phase and type of protection tripped over the last 30

trips;

– Date, time and type of operation of the last 200 events (example: opening/closing

of the circuit breaker, pre-alarms, editing of settings, ect.);

1SDC200471F001

– Number of operations of the circuit breaker: divided into mechanical operations

(no current), electrical operations (with current) and protection function (trip);

– Contact wear (enduarnce) estimated in function of the number and type of

openings;

– Total operating time of the circuit breaker with circulating current;

– Date and time of the last maintenance session, scheduling of the next

maintenance session;

– Circuit-breaker identifying data: type, serial number, firmware version, device

name assigned by the user.

3/16 | 1SXU200040C0201 | ABB catalog

All the information can be viewed directly from the display and from a Smartphone,

Tablet (with Ekip Bluetooth) or PC using the front port of the trip unit or the system

communication.

Page 43

Watchdog

All of the trip units in the SACE Emax 2 family ensure high reliability because of an electronic circuit that periodically controls

continuity of the internal connections, such as trip coil, rating plug and each current sensor (Ansi 74). In the event of an alarm,

a message is shown on the display, and if it is set during the installation phase, the trip unit can command the opening of

the circuit breaker. If a protection function intervenes, Ekip Touch always checks that the circuit breaker has been opened by

auxiliary contacts that indicate the position of the main contacts. Otherwise, Ekip Touch indicates an alarm (ANSI BF code Breaker Failure) to be used to command the opening of the circuit breaker located upstream.

Ekip also contains self-protection that preserves the correct operation of the unit against abnormal temperatures (OT) inside

the protection trip unit. The user disposes of the following indications or controls:

– “Warning” LED for temperature below -4°F/-20°C or above 158°F/70°C, at which the trip unit operates correctly with the

display switched off

– “Alarm” LED for temperature outside the operating range, at which the trip unit commands the opening of the circuit breaker

(if set during the configuration phase).

User interface

All Ekip Touch operations are simple and intuitive due to the wide graphic color

touchscreen display. For example, all the main information is listed on one page

(settable by default), thus enabling the state of the installation to be identified rapidly:

maximum current, maximum voltage, active, reactive, apparent power and energy.

In addition, the use of Ekip Touch is further simplified by the possibility of scrolling

through the menu and reading the alarms in one of the languages that can be set

directly from the display: Italian, English, German, French, Spanish, Portuguese,

Chinese, Russian, Turkish and Thai.

The home pushbutton enables you to return, at any moment, to the main page and

1SDC200472F0011SDC200473F001

the iTest key enables the information to be viewed after a circuit breaker trip or test.

3

As in the previous generation of trip units, a password system is used to manage

“Read” or “Edit” modes. The default password, 00001, can be edited by the user.

The protection parameters (curve and trip thresholds) are settable in “Edit” mode

whereas it is always possible to consult the information in “Read” mode.

On the front of the trip unit there are also two LEDs: a pre-alarm LED (square yellow

LED) and an alarm LED (red triangular LED); a message on the display always

accompanies the flashing of the LEDs for clear identification of the type of event.

The list of all the alarms active at that moment can be viewed by simply touching

the display on the white strip in the bottom left of the alarms zone.

Ekip Touch is also supplied with a front port that permits a temporary connection to

devices for test, supply or communication (for example Ekip T&P).

ABB catalog | 1SXU200040C0201 | 3/17

Page 44

Protection trip units for power distribution

Ekip Touch

Communication

Communication modules that can be installed inside the circuit breaker enable Ekip Touch to be integrated into the most

modern supervision systems with protocols:

– IEC 61850

– Modbus TCP

– Modbus RS-485

– Profibus

3

– Profinet

– DeviceNet

– EtherNet/IP

The integration into communication systems enables measurements, statuses and alarms to be programmed and viewed by

remote functions. If the circuit breaker has to be opened and closed remotely, the Ekip Com Actuator module can be installed

in the circuit breaker front, in the right-hand accessories chamber.

For each circuit breaker, several communication modules with different protocols can be used simultaneously; for example, this

enables the circuit breaker to be connected to the Ekip link system to obtain local supervision from the front of the switchgear

and to simultaneously integrate it into a communication network. In addition, for applications requiring very high reliability, up

to two modules of the same protocol can be inserted by use of the redundant version that enables two different addresses to

communicate on the same bus.

Test function

For testing the circuit breaker, it is possible to use the test port and the iTest key positioned on the front of the protection trip

unit. The available functions are:

– trip test, test of the display and of the LEDs and check of absence of alarms detected by the watchdog function using Ekip

TT (always supplied with Ekip Touch);

– test of the single protection functions and saving of the report, in addition to the trip test and test of the display, using Ekip

T&P;

– test of the battery with the circuit breaker switched off by pressing the iTest key.

3/18 | 1SXU200040C0201 | ABB catalog

Page 45

Supply

The Ekip Touch protection trip unit is self-supplied by the current sensors and does not require an external supply for the

basic protection functions or for the alarm indication functions. All protection settings are stored in a non-volatile memory that

maintains the information, even without a power supply. To activate the indication functions the ammeter and the display, a

100A three-phase current suffices.

An auxiliary supply can easily be connected. The Ekip Supply module can be connected to supplies of both direct current and

alternating current to activate additional functions such as:

– using the unit with circuit breaker open;

– using additional modules such as Ekip Signaling and Ekip Com;

– connection to external devices such as Ekip Multimeter and Ekip Control Panel;

– recording the number of operations;

– G protection with values below 100A or below 0.2 In;

– zone selectivity;

– Gext and MCR protection functions.

Supply Ekip Supply

Nominal voltage 24-48V DC 110-240V AC/DC

Voltage range 21.5-53V DC 105-265V AC/DC

Rated power (including modules) 10W max. 10W max.

Inrush current ~10 A for 5 ms ~10 A for 5 ms

The Ekip Supply module allows the cartridge modules to be used in the terminal box area. Otherwise, the trip unit can be

supplied by means of a galvanically isolated 24 VDC auxiliary voltage.

3

The Ekip Measuring Pro module can supply the Ekip Touch trip unit with line voltage above 85V. In addition, if the module is

installed with voltage pick-ups on the supply side, the trip unit can be used even if the circuit breaker is open.

The Ekip Touch protection trip unit is also supplied with a battery that enables the cause of the fault to be indicated after a trip,

without a time limit. In addition, the battery enables date and time to be updated, thus ensuring the chronology of the events.

When Ekip Touch is operating, it uses an internal control circuit to indicate automatically that the battery is flat. On the other

hand, when the unit is switched off the battery test can be run by simply pressing the iTest key.

ABB catalog | 1SXU200040C0201 | 3/19

Page 46

Page 47

Page 48

Protection trip units for power distribution

Ekip Hi-Touch

Directional overcurrent (D – ANSI 67): the protection is able to recognize the direction of the current

during the fault period and thus detect if the fault is upstream or downstream of the circuit breaker. The

protection, with fixed time trip curve (t=k), intervenes with two different time delays (t7bw and t7fw),

according to the current direction. In ring distribution systems, this enables the distribution portion to be

identified in which the fault occurred and to disconnect it while maintaining the operation of the rest of the

installation.

3

Generator

Zone selectivity for protection D (ANSI 68): enables the possibility to connect circuit breakers among

them, that in case of fault rapidly isolate the fault area, disconnecting the installation only at the level

LOAD B LOAD C

nearest to the fault, maintaining the operation of the rest of the installation. The function is particularly

useful in ring and grid installations where, in addition to the zone, it is also essential to define the

flow direction of the power that supplies the fault. It is possible to enable directional zone selectivity

Forward

power flow

LOAD A

FAULT

Backward

power flow

alternatively to the zone selectivity of the protections S and G, and in the presence of an auxiliary supply.

Start-up function for protection D: enables higher trip thresholds to be set at the outgoing point, as

available for protections S, I and G.

t

U9

Second protection against undervoltage and overvoltage (UV2 and OV2 – ANSI 27 and 59): enables

two minimum and maximum voltage thresholds to be set with different delays in order to be able to

discriminate, for example, between voltage dip transients due to the start-up of a motor and an actual fault.

t9

U16

t16

V

t

f17

Second protection against underfrequency and overfrequency (UF2 and OF2 – ANSI 81L and 87H):

enables two minimum and maximum frequency thresholds to be set simultaneously. For example, only an

alarm can be set to be tripped when the first threshold is reached, and the circuit breaker can be set to

f12

t17

be opened when the second threshold is reached.

t12

Dual setting of protections: Ekip Hi-Touch can store a set of alternative parameters for all protections.

f

This second series (set B) can replace, if necessary, the default series (set A) by an external control.

The control can be given when the network configuration is edited, for example when an emergency

source is activated in the system, changing the load capacity and the short-circuit levels. Another typical

application is protecting the operator opposite the switchgear against the electric arc. In this case,

protection delays are minimized to safeguard the operator (Set A), whereas in the absence of an operator

the protections are set to ensure selectivity with the circuit breakers downstream (Set B). It is possible to

activate series B by:

– Digital input available with an Ekip Signaling module;

– Communication network, by means of one of the Ekip Com communication modules;

– Directly from the Ekip Hi-Touch display;

– By a settable internal time, after the circuit breaker has closed.

3/22 | 1SXU200040C0201 | ABB catalog

Page 49

Measurements

The Ekip Hi-Touch trip unit offers a complete series of measurements, common to Ekip Touch:

– Measurements and counters: currents, voltage, power, energy;

– Maximum values and value log;

– Data logger;

– Information on the trip and opening data;

– Maintenance indicators.

Ekip Hi-Touch integrates the exclusive Network Analyzer function, which analyzes the quality of energy consumed by the

installation, in accordance with the provisions of international standards EN50160, IEC 61000-4-30, IEEE 1159 and IEEE 1250,

in terms of harmonic content, average value and long or short term changes in voltage. Changes in the quality of energy can

cause malfunctions in the switchgear and a reduction in their lifespan, as well as increasing losses and reducing the energy

efficiency of the installation.

It is therefore increasingly important to assess the quality of the energy and the economic impact it has on the productive

process, so that the appropriate preventive and corrective actions can be taken. With Ekip Hi-Touch, the causes of an increase

in power lost in transformers or motors, or a reduction in the lifespan of cables and capacitors, can be identified without the

need to install any external instrumentation.

The Network Analyzer function performs continuous monitoring of the quality of energy, and shows all results through a display

or communication module. In particular:

– Hourly average voltage value: in accordance with international standards, this must remain within 10% of the rated value,

but different limits can be defined according to the needs of the installation. The positive sequence voltage is obtained from

the three line voltages and compared with the limits. If the limits are exceeded, Ekip Hi-Touch generates a Signaling event. The

quantity of these events is stored in a counter. The counter values are available for each of last 7 days, as well as the total. The

measures availabe are the positive and negative sequence voltages and positive and negative sequence currents of the last

interval monitored. The interval calculation time of the average values can be set between 5 minutes and 2 hours.

– Interruptions / short dips in voltage (voltage interruptions / voltage dip): if the voltage remains below the threshold for more

than 40ms, Ekip Hi-Touch generates an event that is counted in a dedicated log. The voltage is monitored on all lines.

– Short voltage spikes (voltage transients, spikes): if the voltage exceeds the threshold for 40ms, set for a pre-determined

time, Ekip Hi-Touch generates an event that is counted.

– Slow voltage sags and swells (voltage sag / voltage swell): when the voltage goes outside the range of acceptable limit values

for a time greater than the one set, Ekip Hi-Touch generates an event that is counted. Three values can be configured for

voltage sags and two for voltage swells, each of which associated to a time limit: this enables us to verify whether the voltage

remains within a curve of values that are acceptable by equipment such as computers. The voltage is monitored on all lines.

– Voltage imbalances: if the voltages are not equal or the phase displacements between them are not exactly 120°, an

imbalance occurs, which is manifested with a negative sequence voltage value. If this limit exceeds the threshold value set,

an event is stored which is counted.

– Harmonic analysis: the harmonic content of voltages and currents, measured to the 50th harmonic, as well as the value of

total harmonic distortion (THD), is available in real time on the display or through the communication modules. Ekip Hi-Touch

also generates an alarm if the THD value or the magnitude of at least one of the harmonics exceeds the values set.

The voltage is monitored on all lines and currents on all phases.

3

All information can be displayed directly on the screen or on a smartphone, tablet or PC using the front port of the trip unit

(with Ekip Bluetooth) or installation communication.

Other functions

Ekip Hi-Touch integrates all the features in terms of user interface, communication, test and supply described for Ekip Touch

equipped with Ekip Measuring Pro.

ABB catalog | 1SXU200040C0201 | 3/23

Page 50

Page 51

Protection functions

The Ekip G Touch trip unit provides all the protection functions of Ekip Touch and, in addition, provides a series of dedicated

generator protections. If Ekip G is tripped, it opens the circuit breaker and prevents it from closing again until it has been reset

manually or electrically by the operator (lockout relay – code ANSI 86).

The trip unit is provided with the following protection functions:

– Overload (L – ANSI 49);

– Time-delayed overcurrent (S – ANSI 51 & 50TD);

– Thermal memory;

– Instantaneous overcurrent (I – ANSI 50);

– Closing on short circuit (MCR);

– Ground fault (G – ANSI 51N & 50NTD);

– Instantaneous ground fault (G - ANSI 50N);

– Ground fault on toroid (CT) (G ext – ANSI 51G & 50GTD);

– Neutral protection;

– Start-up function;

– Zone selectivity for functions S and G (ANSI 68);

– Current imbalance (IU – ANSI 46);

– Undervoltage (UV – ANSI 27);

– Overvoltage (OV – ANSI 59);

– Underfrequency (UF – ANSI 81L);

– Overfrequency (OF – ANSI 81H);

– Voltage imbalance (VU – ANSI 47);

– Differential ground fault (Rc – ANSI 87N);

– Reverse active power (RP – ANSI 32R);

– Synchrocheck (SC – ANSI 25, optional);

– Cyclical direction of phases (ANSI 47);

– Power factor (ANSI 78);

– Current thresholds;

– Power Controller function (optional);

– Second protection against instantaneous overcurrent (2I).

3

L1 L2 L3

The following protection is also available:

Differential ground fault (Rc - ANSI 87N): protects against internal ground fault on generator winding. It is

required that the toroid (CT) hugs the active conductors and the ground conductor. Rc protection is integrated

by a dedicated residual current rating plug and the external toroid (CT).

ABB catalog | 1SXU200040C0201 | 3/25

Page 52

Protection trip units for generators

Ekip G Touch

The specific functions for generator protections are described below, for each of which it is possible to choose the operating

mode: active, only alarm or deactivated. All the voltage and frequency protections also operate when the circuit breaker is

open, enabling the fault to be identified before the closing of the circuit breaker.

t

3

t20

K

1

Ks

K

1

Ks

1

Ks

I20KsxI20

U

UhUI

Voltage controlled overcurrent protection (S(V) - ANSI 51V): protection from maximum current with

constant trip time (t = k) that is sensitive to the voltage value. The set current threshold, following a

voltage drop, decreases by steps or linearly.

I

In step mode (controlled mode) the protection is tripped at the set threshold (I20) if the voltage is above

U, whereas it is tripped at the lower threshold of the factor Ks (I20 * Ks) if the voltage is below U.

V

On the other hand, in linear mode (restrained mode) two voltage limits are selected within which the

protection is tripped at the set threshold (I20) reduced by the factor K corresponding to the measured

voltage. The variation of the factor K is proportional to the voltage, and for voltages greater than the upper

threshold (Uh) the threshold I20 works, whereas for voltages below the lower threshold (UI) the minimum

threshold (I20 * Ks) applies.

V

2

V12V23

α

α

3

V31

Residual overvoltage (RV – ANSI 59N): with constant trip time (t = k), protects against insulation loss in

systems with insulated neutral or with neutral ground with impedance.

1

3/26 | 1SXU200040C0201 | ABB catalog

Page 53

Page 54

Protection trip units for generators

Ekip G Touch

Measurements

The Ekip G Touch trip unit provides a complete series of measurements, which are common to Ekip Touch:

– Measurements and meters: currents, voltage, power, energy, frequency;

– Maximum values and values register;

– Data logger;

– Information on trip and opening data;

– Maintenance indicators.

3

All the information can be viewed directly from the display of the trip-unit, by means of the external Ekip Multimeter display or

by Smartphone, Tablet or PC using the front port of the trip unit (with Ekip Bluetooth) or the system communications.

Other functions

Ekip G Touch provides the same characteristics in terms of user interface, communication, test and power supply described for

Ekip Touch equipped with Ekip Measuring Pro.

3/28 | 1SXU200040C0201 | ABB catalog

Page 55

Page 56

Protection trip units for generators

Ekip G Hi-Touch

Protection functions

The Ekip G Hi-Touch trip unit is provided with the following protection functions, common to Ekip Hi-Touch:

– Overload (L – ANSI 49);

– Time-delayed overcurrent (S – ANSI 51 & 50TD);

– Time-delayed overcurrent, second threshold (S2 – ANSI 50TD);

– Thermal memory;

– Instantaneous overcurrent (I – ANSI 50);

3

– Directional overcurrent (D – ANSI 67);

– Voltage controlled overcurrent protection (S(V) – ANSI 51V);

– Closing on short circuit (MCR);

– Ground fault (G – ANSI 51N & 50NTD);

– Instantaneous ground fault (G - ANSI 50N);

– Second protection against ground fault (ANSI 50GTD/51G & 64REF);

– Ground fault on toroid (CT) (Gext – ANSI 51G & 50GTD);

– Neutral protection;

– Start-up function;

– Zone selectivity for functions S and G (ANSI 68);

– Zone selectivity for directional protection D (ANSI 68)

– Start-up function for protection D;

– Current imbalance (IU – ANSI 46);

– Undervoltage (UV – ANSI 27);

– Undervoltage, second threshold (UV2 – ANSI 27);

– Overvoltage (OV – ANSI 59);

– Overvoltage, second threshold (OV2 – ANSI 59);

– Underfrequency (UF – ANSI 81L);

– Underfrequency, second threshold (UF2 – ANSI 81L);

– Overfrequency (OF – ANSI 81H);

– Overfrequency, second threshold (OF2 – ANSI 81H);

– Voltage imbalance (VU – ANSI 47);

– Residual overvoltage (RV – ANSI 59N);

– Differential ground fault (Rc – ANSI 87N);

– Loss of field or reverse reactive power (RQ – ANSI 40 or 32R);

– Reverse active power (RP – ANSI 32R);

– Reactive overpower (OQ – ANSI 32OF);

– Active overpower (OP – ANSI 32OF);

– Active underpower (UP - ANSI 32LF);

– Synchrocheck (SC – ANSI 25, optional);

– Cyclical direction of phases (ANSI 47);

– Power factor (ANSI 78);

– Current thresholds;

– Dual setting of protections;

– Power Controller function (optional);

– Second protection against instantaneous overcurrent (2I).

3/30 | 1SXU200040C0201 | ABB catalog

Page 57

In addition, the following protections are also available:

f(Hz)

t

t21

t20

Q

Q25

Q24

failure

50/60Hz

Ks

KsxI21

1

Ks

frequency

after failure

frequency

after failure

Time

I21I20KsxI20

kq kq2

Rate of change of frequency (ROCOF – ANSI 81R): enables both positive and negative frequency

variations to be detected rapidly. The protection is constant and is tripped when the frequency variation

in Hz/s is greater than the set threshold.

Second protection against voltage controlled overcurrent protection (S2(V) - ANSI 51V): available in

addition to the protection S(V), enables total selectivity to be achieved in all installations.

I

Second protection against loss of field or reverse reactive power (RQ – ANSI 40 or 32R): enables

the generator’s de-energization curve to be followed very accurately, thereby avoiding any unnecessary

disconnection.

P

3

Measurements

The Ekip G Hi-Touch trip unit provides all the measurements available with Ekip Hi-Touch:

– Network Analyzer, in conformity to EN50160 and IEC 61000-4-30;

– Measurements and meters: currents, voltage, power, energy, frequency;

– Maximum values and values register;

– Data logger;

– Information on trip and opening data;

– Maintenance indicators.

Other functions

Ekip G Hi-Touch has all the features of Ekip Touch equipped with Ekip Measuring Pro in terms of user interface, communication,

test and power supply.

ABB catalog | 1SXU200040C0201 | 3/31

Page 58

Page 59

Page 60

Page 61

Management of loads

According to the consumption estimate at the end of the period, Ekip Power Controller will take different actions:

– if the value estimated is greater than the power set as a target, Ekip Power Controller makes the decision to disconnect one

of the loads controlled from the power supply, or to connect a generator;

– if the value estimated is equal or slightly less than the average power set as a target, Ekip Power Controller makes the

decision to leave the conditions of the controlled loads and generators unchanged;

– if the value estimated is significantly lower than the average power set as a target, Ekip Power Controller makes the decision

to reconnect one of the loads controlled to the power supply, or switch off a generator if one or more of these have been

switched on previously.

This operation is carried out cyclically each time by calculating a new estimate: therefore, if the estimate of power consumed

continues to be too high despite the fact that a load has been disconnected, Ekip Power Controller will proceed to

disconnect another and so on, until the power limit is respected. In this way, the number of connected or disconnected loads

varies dynamically, and always with the guarantee that only the minimum number needed to maintain the power limit are

disconnected.

Priority of loads

If the decision made is to disconnect or re-connect one of the loads controlled, Ekip Power Controller proceeds according

to an established order: the load indicated as the first will be that of least importance, or that for which a temporary period

of deactivation is acceptable; the load indicated as the second will be the next one in order of importance, and so on. The

loads that have been disconnected in that order will be re-connected in the reverse order, beginning with the load that is most

important for the installation. In this way, the impact on the production process can be minimized, limiting the disconnection

time for loads of the highest priority. Furthermore, by gradually connecting and disconnecting the loads in order of priority,

voltage imbalances and consumption peaks that can affect the network are avoided.

3

Protection of the installation

Ekip Power Controller can be integrated perfectly into the installation’s protection devices. In fact, if one of the controlled circuit

breakers opens due to an overcurrent or by manual operation, Ekip Power Controller considers the load unavailable until the

operator resets it, making it available again. In this way, safe operation of the installation is always guaranteed.

ABB catalog | 1SXU200040C0201 | 3/35

Page 62

Page 63

Installation

Ekip Power Controller is not only simple to implement and use, it is also very flexible because of parameters which have been

specially developed to satisfy the needs of all applications.

Installation parameters:

– Power limit: this is the average power that Ekip Power Controller respects, which can be selected in kW directly from the

display.

– Evaluation window: this is the period in which the distributor of electrical energy evaluates the maximum power, which can be

selected within a wide range to respect the local needs of each country.

– Synchronization input: this is used to synchronize the clock inside Ekip with that of the meter. It can also be used to signal a

change in band.

Parameters of the user:

– Type of user: can be selected from among load and generator.

– Minimum disconnection time (T off min): this is the minimum time for which a load or generator is not supplied with power

following disconnection. This is useful when you wish to avoid frequent operations on users that are at the top of the priority

list. Ekip Power Controller reconnects the load or generator only after the time set has passed.

– Maximum disconnection time (T off max): this is the maximum time for which no power is permitted. It is required, for

example, in the case of an oven to keep the temperature within the established limits. When the time has passed, Ekip Power

Controller reactivates it automatically, disconnecting, if necessary, a load of a higher priority.

– Minimum connection time (T on min): minimum time for which a load or generator is kept powered following reconnection. It

is useful in the event the generator has a minimum time for which it must remain connected. Until the time set has passed,

Ekip Power Controller will not disconnect the load, connecting, if necessary, loads of a higher priority.

– Time window: this is the hours in the day when a load or generator can be operated. It is useful, for example, in the case of a

cafeteria that cannot be disconnected during meal times, or a diesel generator that can not be operated at night due to noise

pollution.

– Temporary unavailability: a user can be temporarily deactivated, for example, because it is undergoing maintenance, through

the circuit breaker display or digital input connected to a manual/automatic selector. The digital input can also be used, for

example, in the case of a fridge, to manage its interruptability: with active input the fridge cannot be disconnected as it is

above the minimum temperature, with inactive input, on the other hand, it can be disconnected.

3

Power limit can be set directly in kW

Time bands up to 4

Synchronization with contactor •

Evaluation time 5…120 min

Number of loads/generators up to 15

Priority from 1 to 15

t on min 1…360 min

t off min 1…360 min

t off max 1…360 min

Temporary disabling input 1 for each device

Controllable devices load/generator

Type of control - molded case or power circuit breaker

- modular circuit breakers

- contactors

- control circuit of load/generator

Type of connections - wired

- with Ekip Link communication for ACB

ABB catalog | 1SXU200040C0201 | 3/37

Page 64

Technical characteristics for protection trip units

Protection functions

ABB Code ANSI/IEEE C37.2

Code

L 49 Overload protection I1 = 0.4 - 0.42 - 0.45 - 0.47 - 0.5 - 0.52 - 0.55 - 0.57 - 0.6 - 0.62 - 0.65 - 0.67 - 0.7 -

3

S 50TD Time-delayed overcurrent protection I2 = 0.6 - 0.8 - 1 - 1.5 - 2 - 2.5 - 3 - 3.5 - 4 - 5 - 6 - 7 - 8 - 9 - 10 x In

51 Time-delayed overcurrent protection I2 = 0.6 - 0.8 - 1 - 1.5 - 2 - 2.5 - 3 - 3.5 - 4 - 5 - 6 - 7 - 8 - 9 - 10 x In

I 50 Istantaneous overcurrent protection I3= 1.5 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9 - 10 -11 - 12 - 13 - 14 - 15 x In

G 50N TD Ground fault protection I4

51N Ground fault protection I4

(1) With Vaux all thresholds are available. Without Vaux minimum threshold is limitated to: 0.3 In (with In = 100 A), 0.25 In (with In = 400 A) or 0.2 In (for all others ratings).

(2) Maximum acceptable setting = 1200A; if user sets higher values, Ekip Dip limits the active threshold at 0.4s and shows the incongruency by led flashing.

(3) Maximum acceptable setting = 0.4s; if user sets higher values, Ekip Dip limits the active tripping time time at 0.4s and shows the incongruency by led flashing.

The tollerances above apply to trip units already powered by the main circuit with current flowing in at least two-phases or an auxiliary power supply. In all other cases the following tollerance values apply

Function Threshold

0.72 - 0.75 - 0.77 - 0.8 - 0.82 - 0.85 - 0.87 - 0.9 - 0.92 - 0.95 - 0.97 - 1 x In

Thermal memory

Tolerance tripping between 1.05 and 1.2 x I1

Tolerance ± 7% If ≤ 6 x In

Thermal memory

Tolerance ± 7% If ≤ 6 x In

Tolerance ± 10%

Tolerance ± 7%

Tolerance ± 7%

± 10% If > 6 x In

± 10% If > 6 x In

(1)(2)

= 0.1 - 0.2 - 0.3 - 0.4 - 0.6 - 0.8 - 1 x In

(1)(2)

= 0.1 - 0.2 - 0.3 - 0.4 - 0.6 - 0.8 - 1 x In

ABB Code Trip threshold Trip time

L

S ± 10% ± 20%

I ± 15% ≤ 60ms

G

Trip between 1.05 and 1.2 x I1 ± 20%

± 15% ± 20%

3/38 | 1SXU200040C0201 | ABB catalog

Page 65

with If = 3 I1

t1 = 3 - 12 - 24 - 36 - 48 - 72 - 108 - 144 s

± 20% If > 6 x In

t2 = 0,1 - 0,2 - 0,3 - 0,4s

(3)

The better of the two data:

± 10% o ± 40 ms"

t2 = 0,1 - 0,2 - 0,3 - 0,4s

(3)

± 15% If ≤ 6 x In

± 20% If > 6 x In

yes, with rating

plug L=off

50 ... 90 I1

Step 1%

t = k / I

Yes t = k

Yes t = k / I

2

3

2

t4 = 0,1 - 0,2 - 0,4s

t4 = 0,1 - 0,2 - 0,4s

(3)

(3)

Yes 50…..90% I4

step 1%

Yes 50…..90% I4

step 1%

t = k

t = k / I

2

ABB catalog | 1SXU200040C0201 | 3/39

Page 66

Technical characteristics for protection trip units

Protection functions

ABB Code ANSI Code Function Thereshold Threshold step Tripping time Time Step

L 49 Overload Protection I1 = 0,4…1 x In 0,001 x In with I = 3 I1

3

S 50TD Time-delayed overcurrent protection I2 = 0,6...10 x In 0,1 x In with I > I2

68 Zone selectivity t2sel = 0,04…0,2s 0,01s

51 Time-delayed overcurrent protection I2 = 0,6...10 x In 0,1 x In with I = 10 In

I 50 Istantaneous overcurrent protection I3= 1,5...15 x In 0,1 x In with I> I3 Instantaneous

G 50N TD Ground fault protection I4

68 Zone selectivity t4sel = 0,04…0,2s 0,01s

51N Ground fault protection I4

IU 46 Current unbalance protection I6= 2…90% In

2I 50 Programmable istantaneous overcurrent

MRC Closing on short-circuit protection I3= 1,5...15 x In 0,1 x In with I> I3 Instantaneous

Gext 50G TD Ground fault protection I41

68 Zone selectivity t41sel = 0,04…0,2s 0,01s

51G Ground fault protection I41

Rc 64 50N TD

87N

Thermal Memory

Tolerance Sgancio tra 1,05 e 1,2 x I1 ± 10% I ≤ 6 x In

Start up Activation: 0,6…10 x In 0,1 x In Range: 0,1…30s 0,01s

Tolerance ± 7% I ≤ 6 x In

Thermal Memory

Tolerance ± 7% I ≤ 6 x In

Start up Activation: 1,5…15 x In 0,1 x In Range: 0,1…30s 0,01s

Tolerance ± 10% ≤ 30 ms

Start up Activation: 0,2…1 x In 0,02 x In Range: 0,1…30s 0,01s

Tolerance ± 7% The better of the two data:

Tolerance ± 7% ± 15%

Tolerance ± 10% The better of the two data:

protection

Tolerance ± 10% ≤ 30 ms

Tolerance ± 10% ≤ 30 ms

Start up Activation: 0,1…1 x In 0,02 x In Range: 0,1…30s 0,01s

Tolerance ± 7% The better of the two data:

Tolerance ± 7% ± 15%

Residual current protection

Differential ground fault protection

Tolerance - 20% ÷ 0% 140ms@0.06s (maximum trip time)

± 10% I > 6 x In

± 10% I > 6 x In

(1)(2)

= 0,1...1 x In 0,001 x In with I > I4

(1)(2)

= 0,1...1 x In 0,001 x In with I = 4 In

unbalance

I31= 1,5…….15 xIn 0,1 x In with I> I31

(1)(2)

= 0,1...1 x In Toroid (CT) 0,001 x In Toroid

(1)(2)

= 0,1...1 x In 0,001 x In with I = 4 In

I∆n= 3 - 5 - 7 - 10 - 20 - 30A with I > I∆n

1%In with unbalance > I6

(CT)

t1 = 3...144 s

± 20% I > 6 x In

t2 = 0,05...0,4s

The better of the two data:

± 10% o ± 40 ms

t2 = 0,05...0,4s

± 15% I ≤ 6 x In

± 20% I > 6 x In

t4 = Istantaneous (with vaux)

+ 0,1…0,4s

± 10% o ± 40 ms

or 50 ms with t4=Istantaneous

t4 = 0,1…0,4s

t6 = 0,5…60s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

Instantaneous

Monitor time Range: 40…500ms

with I > I41

t41 = 0,1…0,4s

± 10% o ± 40 ms

t41 = 0,1…0,4s

t∆n = 0,06 - 0,1 - 0,2 - 0,3 - 0,4 - 0,5 - 0,8s

950ms@0.80s (maximum trip time)

1s

0,01s

0,01s

0,05s

0,05s

0,5s

0,01s

0,05s

0,05s

3/40 | 1SXU200040C0201 | ABB catalog

Page 67

yes, with rating plug

L=off

no no 50...90% I1

step 1%

t = k / I

2

● ● ● ●

● ● ● ●

3

yes yes yes no t = k

yes yes yes no t = k / I

yes no yes no t = k

yes yes yes 50…..90% I4

t = k

step 1%"

yes yes 50…..90% I4

t = k / I

step 1%

yes yes no no t = k

● ● ● ●

● ● ● ●

● ● ● ●

2

● ● ● ●

● ● ● ●

● ● ● ●

● ● ● ●

● ● ● ●

● ● ● ●

● ● ● ●

2

● ● ● ●

● ● ● ●

yes no no t = k

yes no yes no t = k

yes yes yes 50…..90% I41

t = k

step 1%

yes

yes yes yes 50…..90% I41

t = k / I

step 1%

Attivabile with

no no t = k

rating plug Rc

● ● ● ●

● ● ● ●

● ● ● ●

● ● ● ●

2

● ● ● ●

● ● ● ●

ABB catalog | 1SXU200040C0201 | 3/41

Table continued on next page

Page 68

Technical characteristics for protection trip units

Protection functions

ABB Code ANSI Code Function Thereshold Threshold step Tripping time Time Step

LC1/2

Iw1/2

3

UV 27 Undervoltage Protection U8= 0,5….0,98 x Un 0,001 x Un with U < U8

OV 59 Overvoltage protection U9= 1,02….1,5 x Un 0,001 x Un with U > U9

VU 47 Voltage unbalance protection U14= 2…90% Un unbalance 1% Un with unbalance > U14

UF 81L Underfrequency protection f12= 0,9….0,999 x fn 0,001 x fn with f < f12

OF 81H Overfrequency protection f13= 1,001….1,1 x fn 0,001 x fn with f > f13

RP 32R Reverse active power protection P11= -1…-0,05 Sn 0,001 Sn P > P11

Cyclical

direction

Power factor 78 3phase Power factor PF3 = 0,5…0,95 0,01

S2 50TD Time-delayed overcurrent protection I5 = 0,6...10 x In 0,1 x In with I > I5

D 67 Directional overcurrent protection

47 Cyclical direction of the phases 1-2-3 or 3-2-1

68 Zone selectivity t5sel = 0,04…0,2s 0,01s

68 Zone selectivity t7sel = 0,1…0,8s 0,01s

Current threshold LC LC1=50%...100% I1

LC2=50%...100% I1

Current threshold Iw Iw1= 0,1…10 In

Activation Iw1: Up/Down

Iw2= 0,1…10 In

Activation Iw2: Up/Down

Tolerance ± 10%

Tolerance ± 2% The better of the two data:

Tolerance ± 2% The better of the two data:

Tolerance ± 5% The better of the two data:

Tolerance ± 1% (with fn ± 2%) The better of the two data:

Tolerance ± 1% (with fn ± 2%) The better of the two data:

Tolerance ± 10% The better of the two data:

Start up Activation: 0,6…10 x In 0,1 x In Range: 0,1…30s 0,01s

Tolerance "± 7% I ≤ 6 x In

± 10% I > 6 x In"

I7 = 0,6...10 x In 0,1 x In with I > I7

(forward & backward)

Start up (forward & backward) Activation: 0,6…10 x In 0,1 x In Range: 0,1…30s 0,01s

Trip direction Forward & backward

Minimun angle direction 3.6, 7.2, 10.8, 14.5, 18.2, 22,

25.9, 30, 34.2, 38.7, 43.4,

48.6, 54.3, 61, 69.6 (°)

Tolerance ± 7% I ≤ 6 x In

± 10% I > 6 x In

1%

1%

0,01 x In

0,01 x In

0,01s

t8 = 0,05…120s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

0,01s

t9 = 0,05…120s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

0,5s

t14 = 0,5…60s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

0,01s

t12 = 0,15…300s

± 10 % (min=30ms) o ± 40 ms

(for t < 5 s) / ± 100 ms (for t ≥ 5 s)

0,01s

t18 = 0.15…300s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

0,1s

t11 = 0,5…100s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

0,01s

t5 = 0,05...0,8s

The better of the two data:

± 10% o ± 40 ms

0,01s

t7 = 0,1...0,8s

The better of the two data:

± 10% o ± 40 ms

3/42 | 1SXU200040C0201 | ABB catalog

Page 69

● ● ● ●

yes only Signaling no no -

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

● ● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

3

yes only Signaling no no -

yes yes yes no t = k

yes yes no no t = k

● ● ●

● ● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

● ●

Table continued on next page

ABB catalog | 1SXU200040C0201 | 3/43

Page 70

Technical characteristics for protection trip units

Protection functions

ABB Code ANSI Code Function Threshold Threshold step Tripping time Time Step

UV2 27 Undervoltage Protection U15= 0,5….0,98 x Un 0,001 x Un with U < U15

3

OV2 59 Overvoltage protection U16= 1,02….1,5 x Un 0,001 x Un with U > U16

UF2 81L Underfrequency protection f17= 0,9….0,999 x fn 0,001 x fn with f < f17

OF2 81H Overfrequency protection f18= 1,001….1,1 x fn 0,001 x fn with f > f18

S(V) 51V Voltage controlled overcurrent protection I20 = 0,6...10 x In 0,1 x In with I > I20

RV 59N Residual overvoltage protection U22= 0,05….0,5 x Un 0,001 x Un with U > U22

OP 32OF Active overpower protection P26= 0,4…2 Sn 0,001 Sn P > P26

OQ 32OF Reactive overpower protection Q27= 0,4…2 Sn 0,001 Sn Q > Q27

UP 32LF Active underpower protection P23 = 0,1...1 x Sn 0,001 x Sn with P < P23

Tolerance ± 2% The better of the two data:

Tolerance ± 2% The better of the two data:

Tolerance ± 1% (with fn ± 2%) The better of the two data:

Tolerance ± 1% (with fn ± 2%) The better of the two data:

Step Mode Ul= 0,2…1 x Un 0,01 x Un

Ks= 0,1…1 0,01

Linear Mode Ul= 0,2…1 x Un 0,01 x Un

Uh= 0,2…1 x Un 0,01 x Un

Ks= 0,1…1 0,01

Tolerance ± 10% The better of the two data:

Tolerance ± 5% The better of the two data:

Tolerance ± 10% The better of the two data:

Tolerance ± 10% The better of the two data:

Start up Range: 0,1…30s 0,01s

Tolerance ± 10% The better of the two data:

t15 = 0,05…120s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t16 = 0,05…120s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t17 = 0,15…300s

± 10 % (min=30ms) o ± 40 ms

(for t < 5 s) / ± 100 ms (for t ≥ 5 s)

t18 = 0.15…300s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t20 = 0,05…30s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t22 = 0,05…120s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t26 = 0,5…100s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t27 = 0,5…100s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

t23 = 0,5…100s

± 10 % o ± 40 ms (for t < 5 s) /

± 100 ms (for t ≥ 5 s)

0,01s

0,01s

0,01s

0,01s

0,01s

0,01s

0,5s

0,5s

0,5s

3/44 | 1SXU200040C0201 | ABB catalog

Page 71

yes yes yes no t = k

● ●

3

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

yes yes yes no t = k

● ●

● ●

● ●

● ●

● ●

● ●

● ●

yes yes yes no t = k

yes yes yes no t = k

yes yes no t = k

● ●

● ●

● ●

Table continued on next page

ABB catalog | 1SXU200040C0201 | 3/45

Page 72

Technical characteristics for protection trip units

Protection functions

ABB Code ANSI Code Function Threshold Threshold step Tripping time Time Step

RQ 40/32R Loss of field or reverse reactive

power protection

3

Loss of field or reverse reactive

power protection

Voltage minimum threshold Vmin= 0.5….1,2 0,01

Tolerance ± 10% The better of the two data:

S2(V) 51V Voltage controlled overcurrent protection I21 = 0,6...10 x In 0,1 x In with I > I21

Step Mode Ul2= 0,2…1 x Un 0,01 x Un

Linear Mode Ul2= 0,2…1 x Un 0,01 x Un

Tolerance ± 10% The better of the two data:

ROCOF 81R Rate of change of frequency protection f28= 0,4….10 Hz/s 0,2 Hz/s with f > f28

Trip direction Up & down

Tolerance ± 5% The better of the two data:

Synchrocheck SC25 Synchrocheck (Live busbars) Ulive=0,5…1,1 Un

Tolerance ± 10%

Synchrocheck (Live,Dead busbars) Ulive=0,5…1,1 Un

Frequency check off

Fase check off

Dead bar configuration Reversed/standard

Primary voltage 100……..1150 100, 115, 120,

Secondary voltage 100………120 100, 110, 115,

Tolerance ± 10%

Q24= -1…-0,1 Sn 0,001 Sn Q > Q24

Kq= -2…2 0,01

Q25= -1…-0,1 Sn 0,001 Sn Q > Q25 0,5s

Kq2= -2…2 0,01

Ks2= 0,1…1 0,01

Uh2= 0,2…1 x Un 0,01 x Un

Ks2= 0,1…1 0,01

∆U=0,02…0,12 Un

∆f= 0,1…1Hz

∆φ= 5…50° elt

Udead=0,02…0,2 Un

0,001 Un

0,001 Un

0,1Hz

5° elt

0,001 Un

0,001 Un

190, 208, 220,

230, 240, 277,

347, 380, 400,

415,440, 480,

500, 550, 600,

660, 690, 910,

950, 1000, 1150

120

t24 = 0,5…100s