ABB MS 325 Instruction Manual

E

Operating instructions Low-voltage switchgear

According to IEC/EN 60 ... 947-1/-4-1/-2-1 for low-voltage

switchgear,

Directive 94/9/EG for explosion-protected areas,

EN 60079-14 for electrical equipment for gas explosion

endangered areas

EN 50281-1 for electrical equipment for dust explosion

endangered area

Power manual motor starter

MS 325

II (2) GD

Table of contents

Safety instructions .............................................. 7

Technical data .................................................... 8

General description ............................................ 9

Transport, storage .............................................. 9

Installation .......................................................... 9

Operation ........................................................... 9

Commissioning................................................... 9

Example of the suitability of an overload relay . 10

Dimensions ...................................................... 10

Approvals and authorizations ........................... 10

Tripping characteristics .................................... 31

Safety instructions

¦ Type MS 325 ABB manual motor starters

are suitable for the protection of motors of

the protective system EEx e. It has been

checked and certified by the Physikalisch

Technische Bundesanstalt (PTB) in Braunschweig.

¦ Mounting and installation may only be done

by trained technical personnel, who observe

the relevant regulations!

¦ Insufficiently tightened locking screws lead

to an inadmissible rise in temperature!

¦ A triggered device may only be restarted

after elimination of the cause of failure by

trained technical personnel.

¦ The device may only be opened by technical

personnel authorized by the manufacturer.

Non-observance results in the expiry of all

warranty claims!

7

Power manual motor starter MS 325

E

Technical Data

Rated operating voltage Ue [V] 690

Rated insulation voltage Ui [V~] 690

Rated current Ie [A] 0.1 ... 25 / 14 ranges

Tripping class 10A

Rated frequency [Hz] 50/60, other frequencies (16 2/3 … 400) on request

Electromagnetic tripping

Response values 0.1 ... 0.63 A: 7.5 - 12 times (x Ie)

Disconnected characteristics according to IEC/EN 60947-1

Service life mechanical/electrically 100.000 connections

Permissible ambient temperature

- Storage [°C] -50 to +80

- Operation [°C] -20 to +50

Temperature compensation [°C] -20 to +50

Phase-failure protection asymmetrical load activates premature release

Protection system IP20

Connection cross sections Clamp screw size: Pozidrive size 2

Torque of the cage clamps max. 1.4 Nm

Wire [mm²] 1 x 10 / 2 x 4

Rope, 7-stranded [mm²] 1 x 10 / 2 x 4

Wire strand [mm²] 1 x 6

Mounting position any

Mounting can be snapped on 35 mm

Approvals and authorizations see page 10

According to IEC/EN 60 ... 947-1/-4-1/-5-1 for low-voltage switchgear,

Directive 94/9/EG for explosion-protected areas,

EN 60079-14 for electrical equipment for gas explosion endangered areas

EN 50281-1 for electrical equipment for dust explosion endangered area

0.63 … 2.50 A: 9 - 14 times

2.5 ... 6.30 A: 10 - 15 times

6.3 … 25 A: 12.5 - 17.5 times

8

2CDC 131 005 M5703

ABB STOTZ-KONTAKT

Power manual motor starter MS 325

E

General description

The MS 325 is offered in 14 different current ranges: 0.16 - 25 A.

The tripping function prevents a short-circuit on the basis of a current-dependent delayed bimetal overload release and an

instantaneous electromagnetic overload release.

The overload release is adjustable to the consumer current by a setting knob. The overload release is firmly adjusted by the

factory depending upon current range.

Transport, storage

• ABB manual motor starters are accordingly packed ex factory for the in each case agreed upon transport mode.

• Avoid blows and impacts.

• Pay attention to possible damage of the packing or of the device.

• Store the device dry and weather-protected.

• Protect the device against dirt.

Installation

Mounting, electrical connection and start-up are only to be done by trained technical personnel. Adhere to the unit-referred

conditions and specifications of the manufacturer. In the case of violation the protection of the explosion proof motor/consumer

is no longer upright.

• Ensure that motor and wiring correspond to the release class

• Mounting on mounting rail: Hang device in from above and engage

• Removing from mounting rail: Actuate latching clip on the device underside with screwdriver

• Connect the electrical conductors according to the valid guidelines/conductor cross sections: Observe the max. screw

tightening torque of 1.4 Nm.

According to IEC/EN 60 ... 947-1/-4-1/-5-1 for low-voltage switchgear,

Directive 94/9/EG for explosion-protected areas,

EN 60079-14 for electrical equipment for gas explosion endangered areas

EN 50281-1 for electrical equipment for dust explosion endangered area

Operation

• Setting of the motor rated current on the front adjustment knob. Adjust the desired rated current value on the head of

the arrow.

• Short-circuit protection: The devices are stable up to a certain limit depending upon mode of operation (values on

rating plate, in the catalogue or on request). When exceeding this limit suitable fuses must be installed in series

(approximate values on request).

• The tripping period at the coordinate points I

of the motor. Whether this requirement is fulfilled, must be examined using the tripping characteristic.

(motor starting current ratio) must be smaller than heating up period t

A/IN

The appropriate tripping characteristics are contained in this documentation. They can also be requested from the

manufacturer.

• Motors for heavy starting (ramp-up time > 1.7 x t

Design Test Certificate for EEx e - motors by start up monitoring.

–time) are to be protected according to the specifications of the EEC

E

• All 3 main current paths must be flowed through by current, in order to achieve the indicated equipment

characteristics.

• Operate only in closed areas without less favourable operating conditions (e. g. dust, corrosive steams, damaging gases).

• Suitable encapsulations are to be foreseen in dusty and damp rooms.

• In the case of Ex applications proof of the effectiveness of the installed protection devices is required before start-up!

Commissioning

• Test the release mechanics by means of pointed item at the test window.

• Check if all connections have been duly executed.

• Check rated current setting. The actual currents apply.

E

ABB STOTZ-KONTAKT

9

2CDC 131 005 M5703

E

Power manual motor starter MS 325

According to IEC/EN 60 ... 947-1/-4-1/-5-1 for low-voltage switchgear,

Directive 94/9/EG for explosion-protected areas,

EN 60079-14 for electrical equipment for gas explosion endangered areas

EN 50281-1 for electrical equipment for dust explosion endangered area

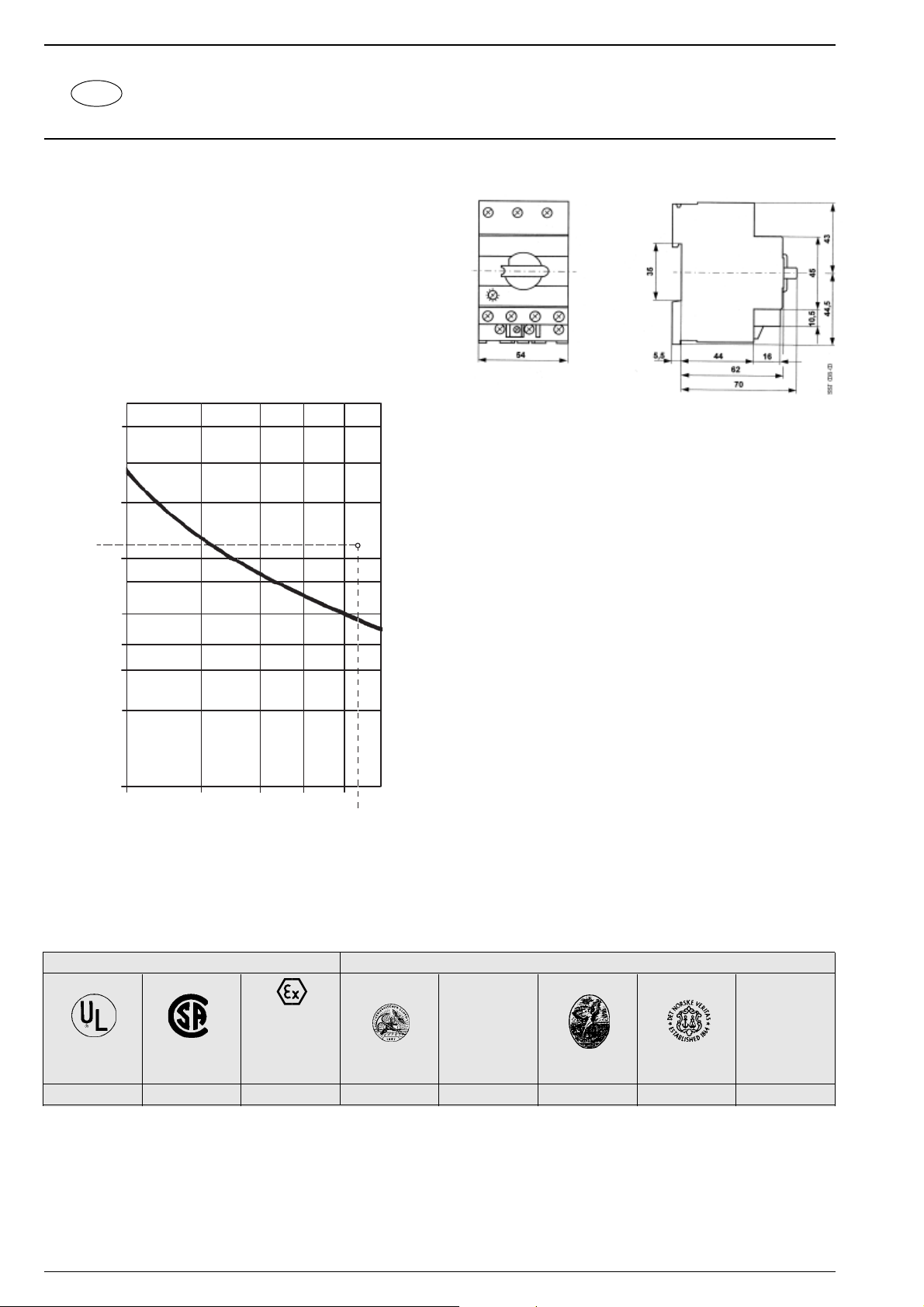

Example of the suitability of a selected manual

motor starter:

The motor with increased security has the following data

(normal starting up):

Output = 7.5 kW

= 7.4

I

A/IN

tE-Time = 11 seconds

Tripping curve downwards, the tripping time is lower

than the t

[s]

-time of the motor.

E

40

20

11

10

6

JJ

JJ

J

4

3

Dimensions

2

Tripping time

1

3

4

5

Multiple of setting current

7 8

6

7.4

Approvals and authorizations

Approvals Ship classification companies

Phys.-Techn.

Bundesanstalt

UL CSA EEx ''e'' GL LRS BV DNV

USA Canada Germany Germany Great Britain France Norway

■■■■■■■

■ Approval available; rating plates carry the test symbol, if sign obligation exists.

PTB

10

2CDC 131 005 M5703

ABB STOTZ-KONTAKT

Loading...

Loading...