motor protectors

Manual motor protectors

MS116 MS325 MS45X MS49X

Description

Type MS116

• Suitable for use with 3-phase motors up to

10 HP @ 480V

• UL Listed and CSA certied for Group

Motor Installations

• 12 Setting ranges from 0.1 to 16 amps.

• Up to 30kA or 50kA with no back up fuse

required

• 35

mm DIN rail snap-on mounting

• Wide range of accessories

Type MS325

• Suitable for use with 3-phase motors up to

15 HP @ 480V

• UL Listed and CSA certied for Group

Motor Installations

• 12 Setting ranges from 0.1 to 25 amps.

• Up to 50kA or 100kA with no back up fuse

required

• 35

mm DIN rail snap-on mounting

• Wide range of accessories

Type MS45x

• Suitable for use with 3-phase motors up to

40 HP @ 480V

• UL Listed and CSA certied for Group

Motor Installations

• 14 Setting ranges from 11 to 50 amps

• Up to 100kA with no back up fuse required

• 35

mm DIN rail snap-on mounting

• Wide range of accessories

Type MS49x

• Suitable for use with 3-phase motors up to

75 HP @ 480V

• UL Listed and CSA certied for Group

Motor Installations

• 22 Setting ranges from 11 to 100 amps

• Up to 100kA with no back up fuse required

• 35mm DIN rail snap-on mounting

• Wide range of accessories

Manual motor

Low Voltage Products & Systems 5.1

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage 1SXU000023C0202

Protectors

Single motor applications

Single motor applications employing a manual

motor protector (MMP) result in a simple,

compact and economical alternative to

conventional magnetic motor controllers for

manual operation of a single motor. Upstream

short circuit and overcurrent protection in the

form of fuses or a circuit breaker is required

but the MMP can replace the overload relay,

contactor and associated electrical components

and wiring for controlling the contactor.

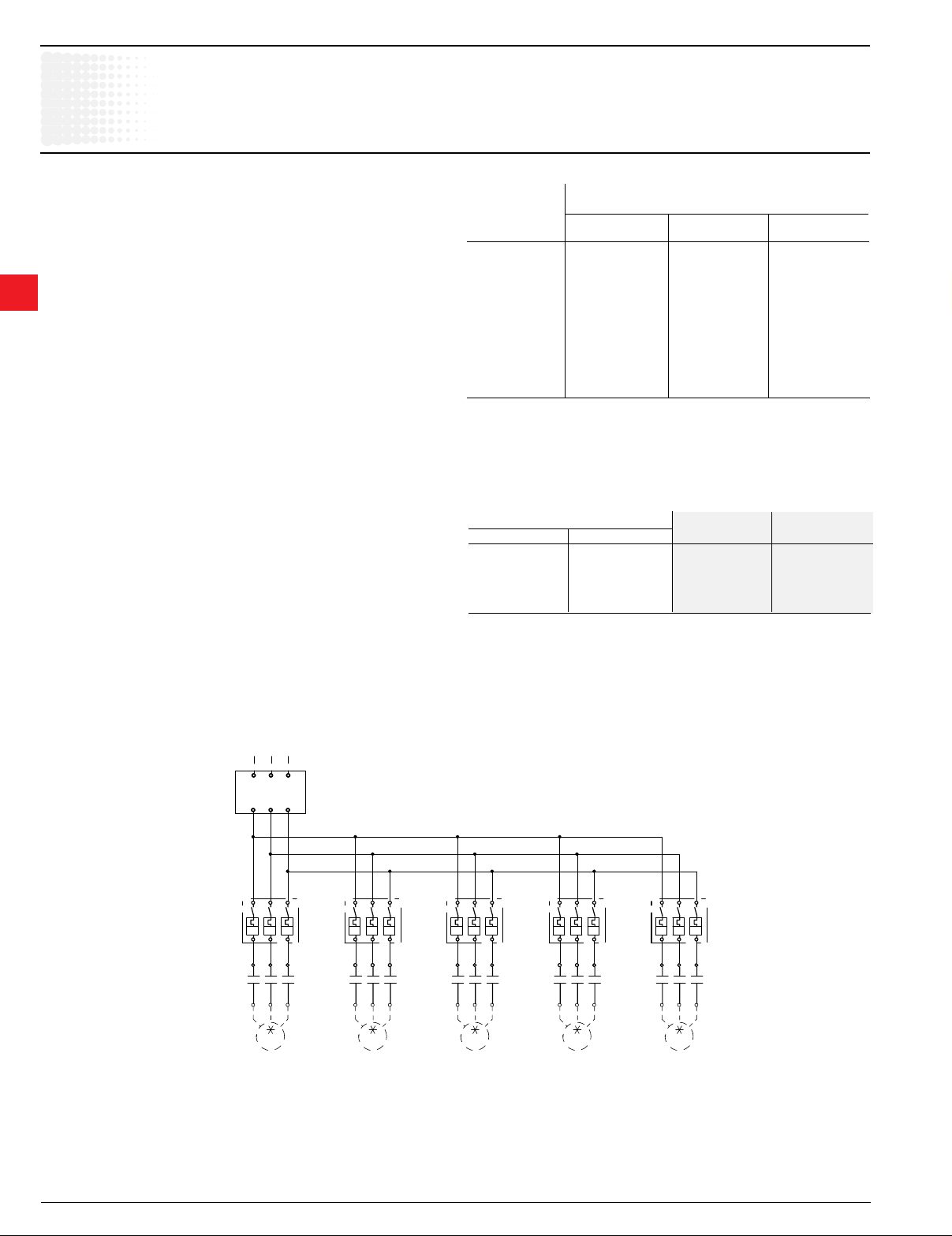

Group motor applications

Group motor installations offer several

advantages when controlling two or more

motors or other loads over conventional single

motor starters. Several MMPs can be grouped

together and fed from a single set of fuses or a

circuit breaker. These devices can be installed

together on a single DIN rail and fed power

through three phase insulated busbars and

a power feed terminal. Protecting this group

of MMPs is a single circuit breaker or fusible

switch, sized specically for the load. Excellent

coordination and short circuit protection can

be achieved, as high as 50kAIC, when using

the MS325 product in this manner. Close

coupling adapters are offered to connect

contactors to the load side of each MMP for

automatic operation of each motor. If a single

motor experiences an overload, the associated

MMP trips and allows the other motors to

continue running. Numerous accessories are

available for signaling in the event of a trip,

to indicate status, to provide shunt trip and

for undervoltage release. The main benets

of group installation are quick, fool proof

assembly, minimal wiring and a reduction of the

necessary enclosure size. The only constraint

is that the upstream circuit protective device

must be sized specically for the load – a

highly desirable feature in order to provide the

closest coordination and the greatest level

of circuit protection. Article 430.53(C) of the

®

NEC

species the requirements for group

motor installations; all ABB MMPs meet these

requirements.

Manual

5

Manual motor

1M

2 4 6

1 3 5

I> I>I>

L1 L2 L3

1C

T1 T2 T3

INCOMING LINES

ISOMAX MCCB

or

Fusible Switch

(If specified)

A

B C

2M

L1 L2 L3

2C

T1 T2 T3

3M

2 4 6

1 3 5

I> I>I>

L1 L2 L3

3C

T1 T2 T3

4M

2 4 6

1 3 5

I> I>I>

L1 L2 L3

4C

T1 T2 T3

5M

2 4 6

1 3 5

I> I>I>

L1 L2 L3

5C

T1 T2 T3

MOTOR MOTOR MOTOR MOTOR MOTOR

2 4 6

1 3 5

I> I>I>

protectors

General information

Selection

Group installation is an approach to building multi-motor control systems in

accordance with Section 430-53 of the National Electrical Code. The selection

of components used in group installations is a simple process which consists of

several steps.

• First is the selection of the appropriate fuse as Branch Circuit Protective

Device (BCPD).

• Second is the selection of the appropriate motor starter and protector.

• Third, the selected MMP must be checked for UL listing with the selected

BCPD and the available short circuit current at the application location.

5

1. Fused disconnect

Calculate maximum fuse size according to NEC 430-53 (c). I

175% x FLC (full load current for largest motor) + the sum of FLC (full load

(fuse size) =

max

current for largest motor) + the sum of FLC values for other motors on that

branch using NEC Table 430-150 on the right. Select fuse from NEC Table 240-6

below. Where I

going to the next high ampere rating.

falls between two fuse ampere ratings NEC 430-53 (c) permits

max

2. Motor protector selection

Select the proper MMP catalog number for each motor load from the following

pages based on the actual motor full load current (FLA) using the “Thermal

setting range” column for reference.

3. MMP Interruption ratings

Using the interruption ratings table on the next page, identify the system

application voltage and interrupting capacity for the type of fuse selected in step

1 above.

NEC 240-6 Standard fuse amperes

15, 20, 25, 30, 40, 45, 50, 60, 70, 80, 90, 110, 125, 150, 175, 200, 225, 250, 300,

350, 400, 450, 500, 600, 700, 800, 1000, 1200, 1600

Examples: Select components for protecting the following 3-phase, 460VAC,

squirrel cage induction motors. The nameplate data are:

1/2 HP, 1.0 FLA; 3 HP, 4.8 FLA; 5 HP, 7.6 FLA; 7.5 HP, 11 FLA;

10 HP, 14 FLA.

Example: using fused disconnect

= 175% x 14 + (11 + 7.6 + 4.8 + 1) = 48.9A

• I

max

• Fuse rating using Table NEC 240-6 = 50A

• Minimum disconnect size = 115% x Total FLA

• NEC 430-150 table = 115% x (14+ 11 + 7.6 + 4.8 + 1) = 44.16

Disconnect for 50A fuses is ok.

Note: Refer to NEC 310-1 and NEC 430-53(d) for cable sizing.

NEC Table 430-150 full load current, 3ph AC motor

Induction type

Horsepower

230V 460V 575V

amps amps amps

squirrel cage & wound rotor

1/2 2 1 .8

3/4 2.8 1.4 1.1

1 3.6 1.8 1.4

1.5 5.2 2.6 2.1

2 6.8 3.4 2.7

3 9.6 4.8 3.9

5 15.2 7.6 6.1

7.5 22 11 9

10 28 14 11

15 42 21 17

20 54 27 22

25 68 34 27

For full load currents of 208 and 200 volt motors, increase the

corresponding 230 volt motor full-load current by 10% and 15%,

respectively.

1

MS325 data

Motor rating at 460V

Horsepower FLA, AC3

1/2 1.0 MS325-1.0 A9C

3 4.8 MS325-6.3 A9C

5 7.6 MS325-9.0 A9C

7.5 11 MS325-12.5 A12C

10 14 MS325-16 A16C

MS325 Contactor

1 These values of full-load current are for motors running at speeds usual for belted motors and motors with normal torque characteristics. Motors built for especially low speeds or high torques

may require more running current, and multispeed motors will have full-load current varying with speed, in which case the nameplate current rating shall be used.

The voltage listed are rated motor voltages. The currents listed shall be permitted for system voltage ranges of 110 to 120, 220 to 240, 440 to 480, and 550 to 600 volts.

5.2 Low Voltage Products & Systems

1SXU000023C0202 ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage