Page 1

User Guide

IM/C505_6

Control

1

/2 DIN Advanced Process Controller

C505

IT

Page 2

ABB

The Company

We are an established world force in the design and manufacture of

instrumentation for industrial process control, flow measurement, gas and

liquid analysis and environmental applications.

As a part of ABB, a world leader in process automation technology, we

offer customers application expertise, service and support worldwide.

We are committed to teamwork, high quality manufacturing, advanced

technology and unrivalled service and support.

The quality, accuracy and performance of the Company’s products result

from over 100 years experience, combined with a continuous program of

innovative design and development to incorporate the latest technology.

The UKAS Calibration Laboratory No. 0255 is just one of the ten flow

calibration plants operated by the Company, and is indicative of our

dedication to quality and accuracy.

BS EN ISO 9001:2000

R

E

G

R

I

S

E

T

Cert. No. Q5907

EN 29001 (ISO 9001)

Lenno, Italy – Cert. No. 9/90A

Use of Instructions

✶

Warning.

An instruction that draws attention to the risk of

injury or death.

Caution.

An instruction that draws attention to the risk of

damage to the product, process or surroundings.

Although

Warning hazards are related to personal injury, and Caution hazards are associated with equipment or

property damage, it must be understood that operation of damaged equipment could, under certain operational

conditions, result in degraded process system performance leading to personal injury or death. Therefore, comply

fully with all

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use

of this manual for any other purpose is specifically prohibited and its contents are not to be reproduced in full or part

without prior approval of the Technical Communications Department.

Warning and Caution notices.

Note.

Clarification of an instruction or additional

information.

Information.

Further reference for more detailed information

or technical details.

D

E

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel

and in accordance with the information given.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating

in conditions of high pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry.

Normal safe handling procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data

sheets (where applicable) may be obtained from the Company address on the back cover, together with

servicing and spares information.

Page 3

GETTING STARTED

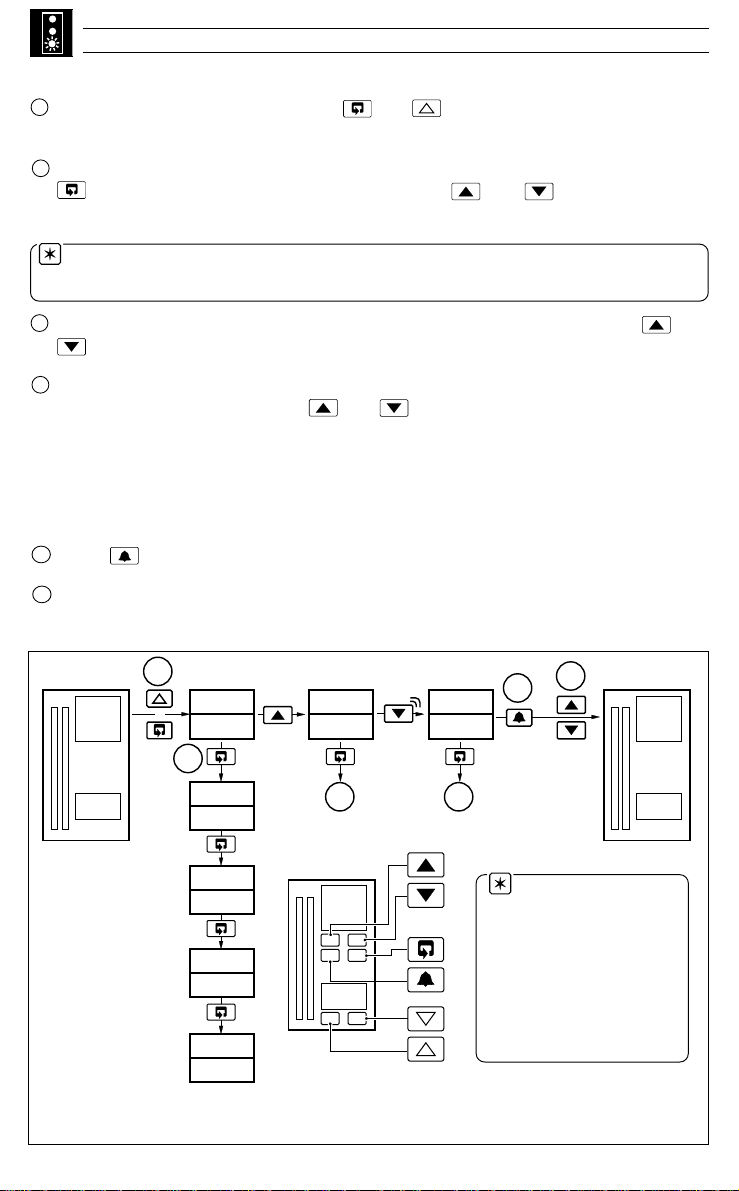

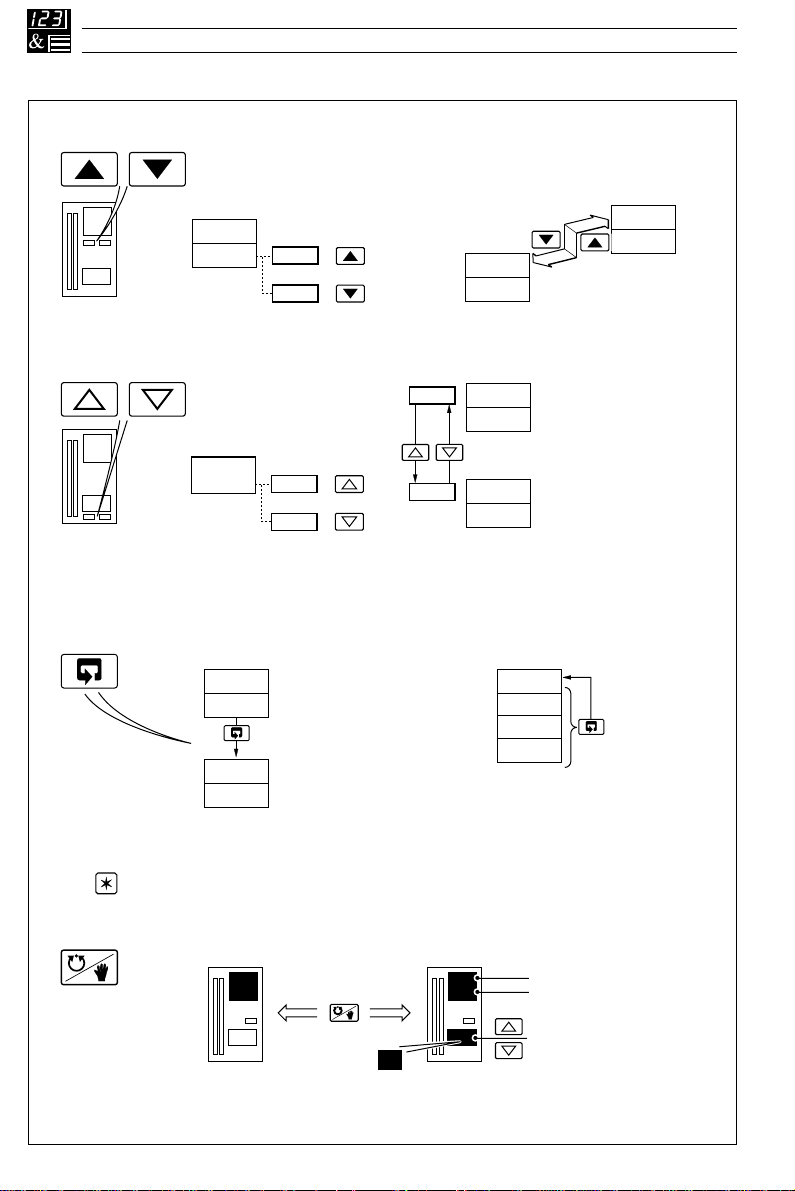

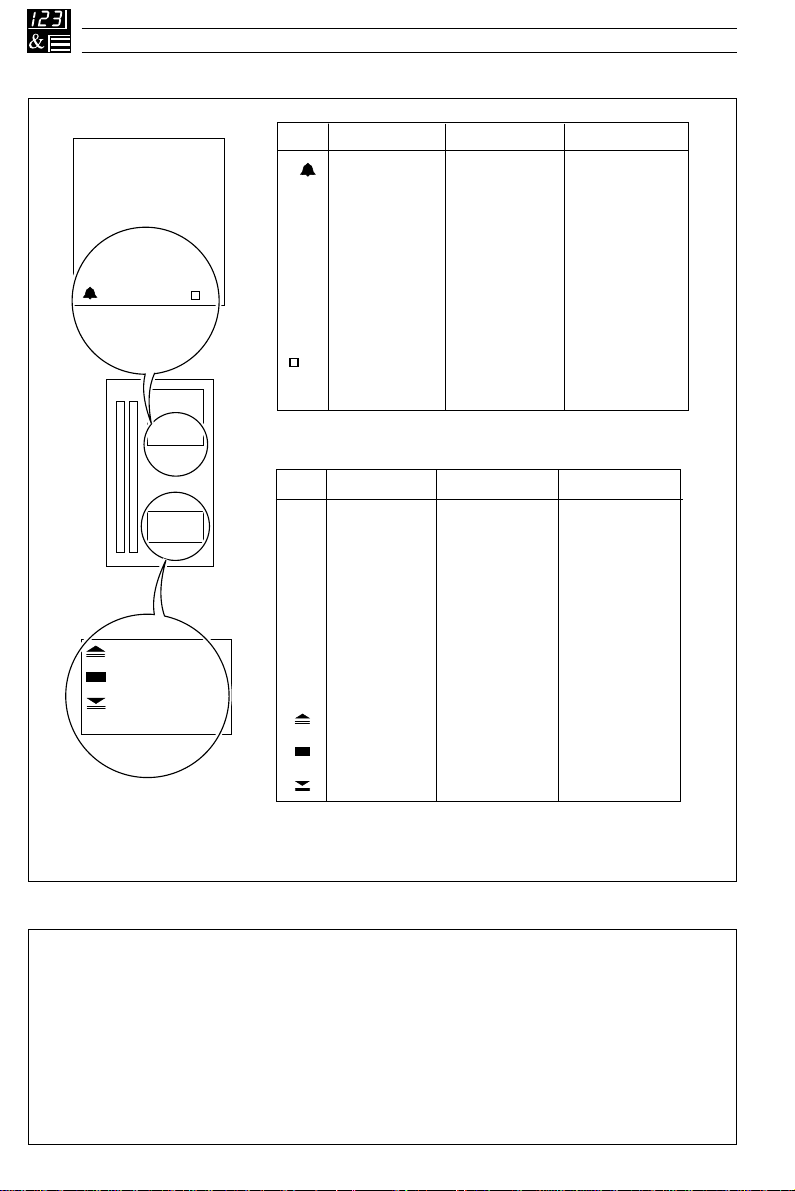

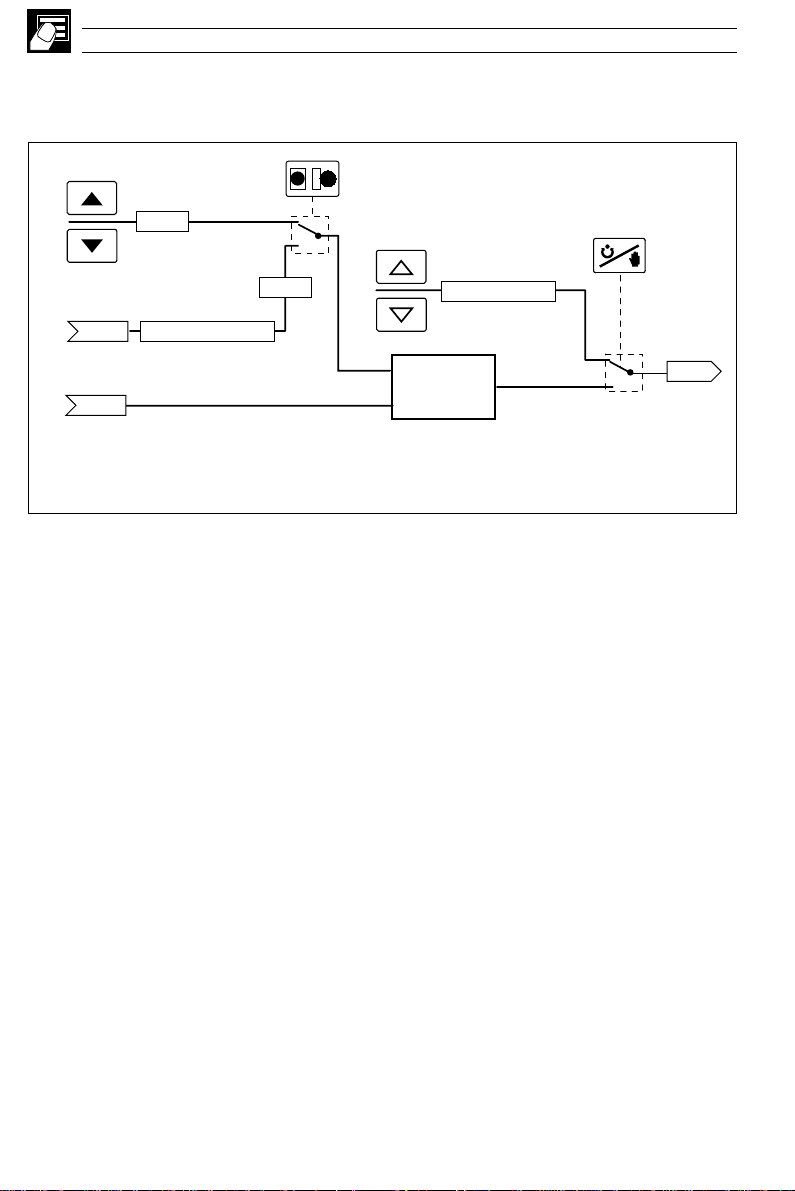

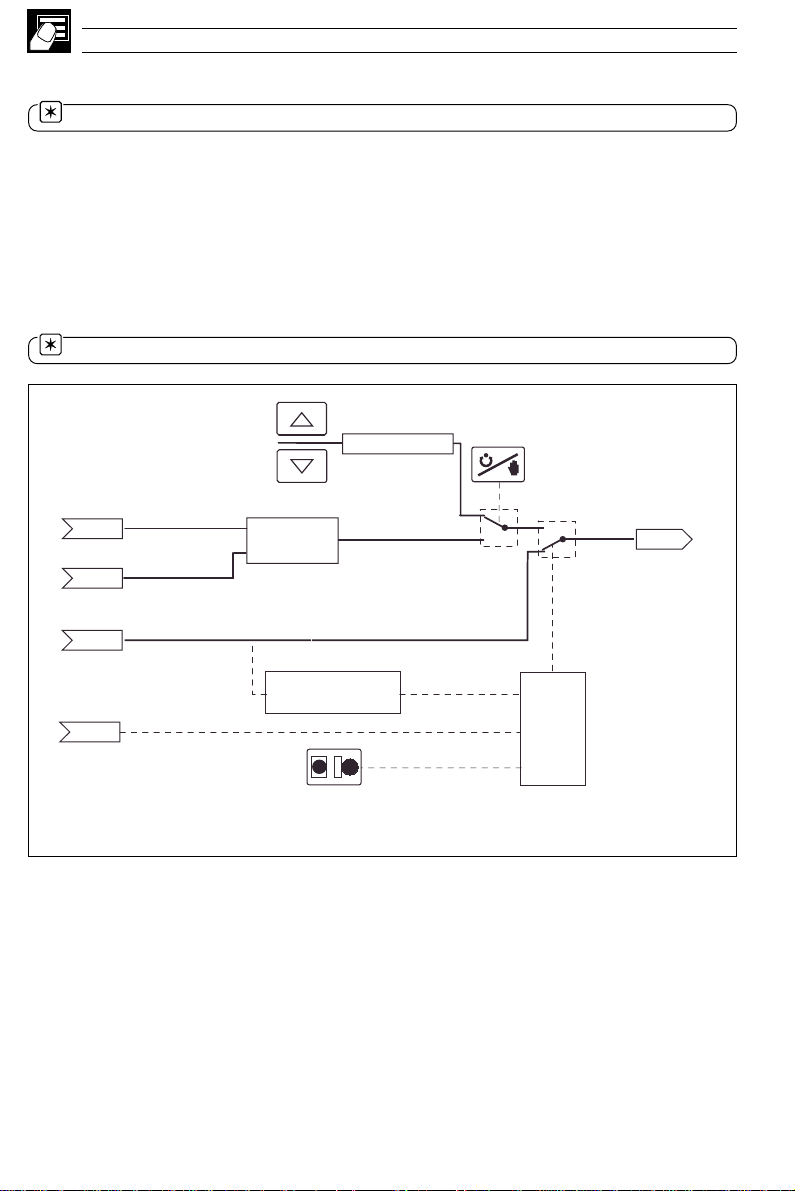

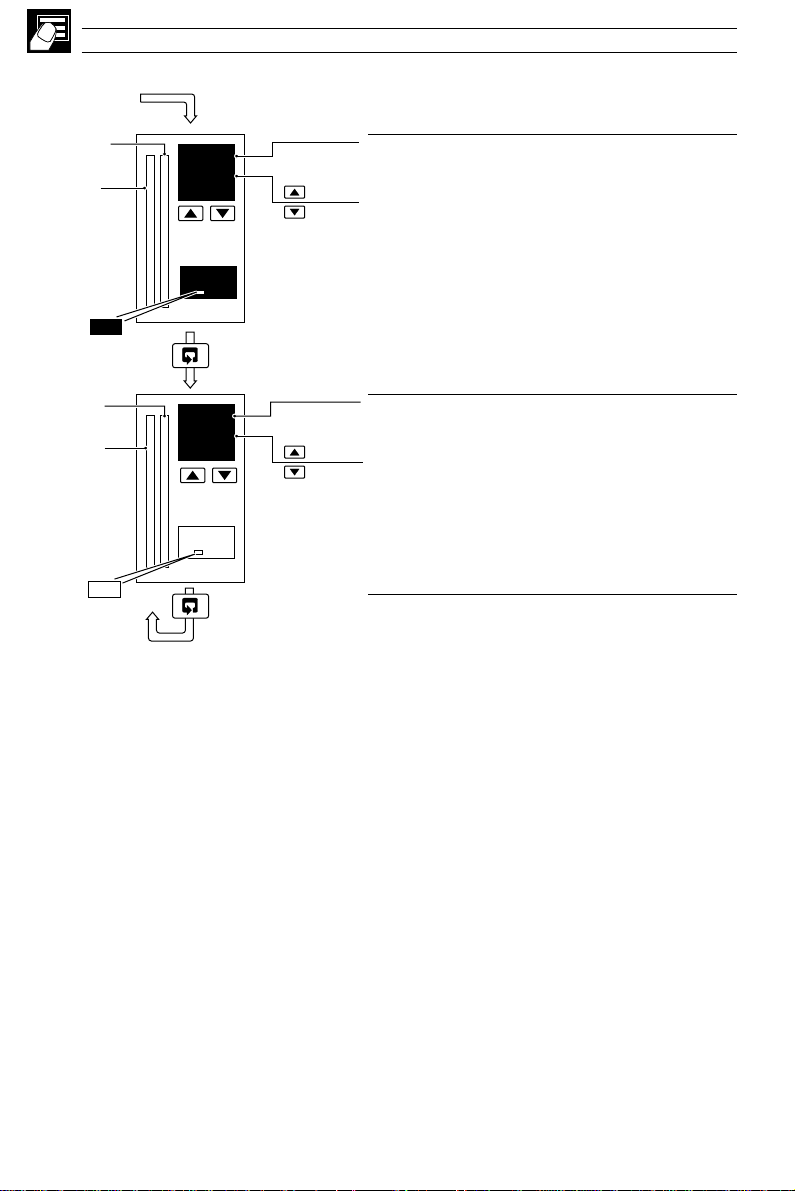

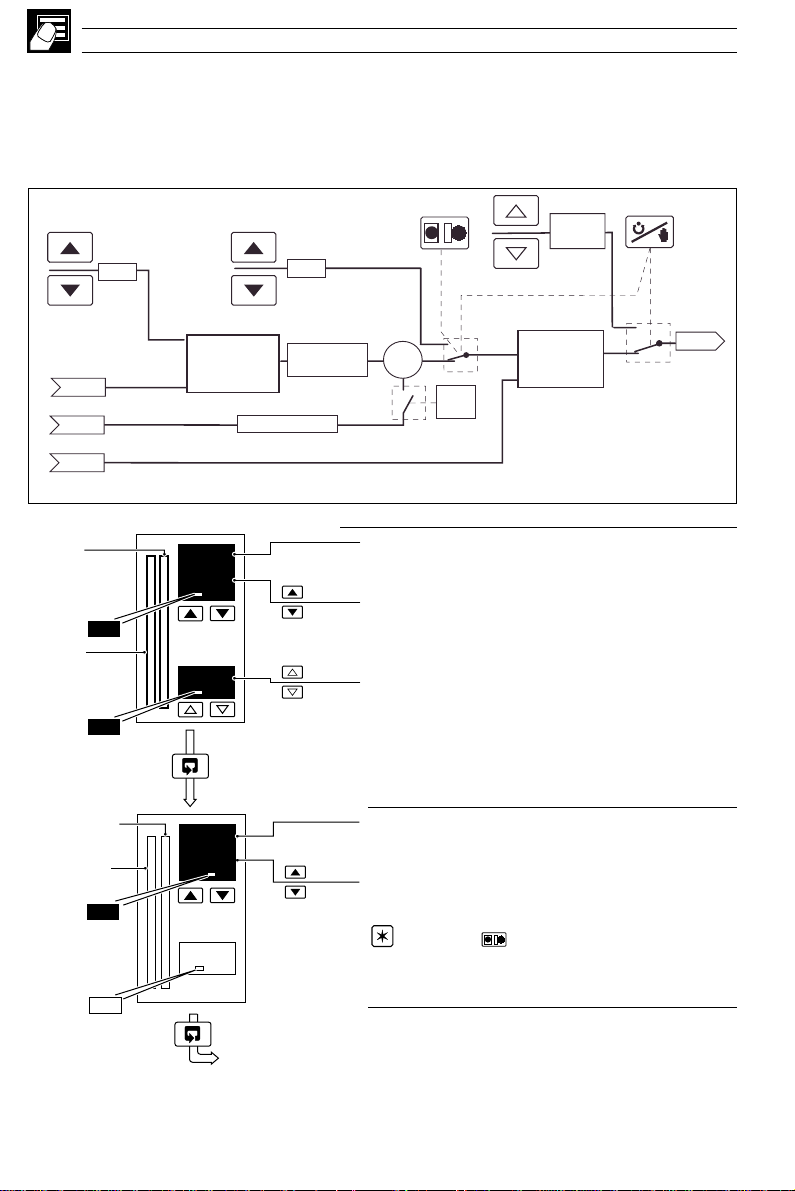

Step 3 – Setting the Parameters (Fig. GS.1)

A

Pow er-up the instrument. Press the and keys simultaneously and hold f or

3 seconds to advance directly to Level 6 – Basic Configuration.

B

Set the appropriate application template, output type and control action. Use the

key to advance between frames and upper and keys to adjust the

default values – see Section 4.2 for further information.

Note. When the output type has been selected, the availab le inputs and outputs

default to the settings shown in Table B on the rear fold-out.

C

If you are not using 4 to 20mA inputs, then select Level 7 using the upper and

keys and set up Analog Inputs I/P1 to I/P3 to suit your process – see Section 4.3.

D

Controller templates only:

Select Level 2 using the upper and keys and set the tune parameters:

• Analog or Motorized Valve Control – set the Proportional, Integral and

Derivative terms.

• Time Proportioning Control – set the Cycle Time, Hysteresis and P, I & D Terms

• Heat/Cool Outputs – set the points at which the Output 1 and Output 2

become active.

E

Press to return to the Operating displays.

F

Adjust the set point to the required value.

Your COMMANDER 500 is now in operation

50.1

50.5

50

A

+

LEV.6

APPL

LEV.7

INPt

LEV2

tUNE

F

E

50.1

50.5

B

t.APP

C D

50

01.SL

O.tYP

ANLG

C.ACt

rEV

FrEJ

50.1

50.5

50

Note. With the

above configuration,

no alarms or limits

have been set and

advanced functionality

(gain scheduling, set

point sources etc.) has

not been enabled.

50

Fig. GS.1 Setting the Parameters

Page 4

GETTING STARTED

The COMMANDER 500 can be configured and made ready for operation in three easy

steps. This 'Getting Started' guide provides an overview of these steps and, where

necessary, refers to the relevant section of the manual.

Step 1 – Decide on the Application Template and the

Output Configuration required

Step 2 – Connect the process inputs and outputs

Step 3 – Power up the instrument, set the template number and the output

configuration details

Your COMMANDER 500 is now ready for operation

Step 1 – Application Template and Output Configuration

• Choose the Template which best suits your application from the list in Table A,

located on the rear fold-out.

• Choose the Control Output Type required from the list of options in Table B on the

rear foldout.

Step 2 – Electrical Connections

Using the labels on the back of the instrument as a guide, connect the process inputs,

outputs and power supplies. Refer to Section 5.2 of this man ual (Electrical Installation)

for more information.

Continued…

Page 5

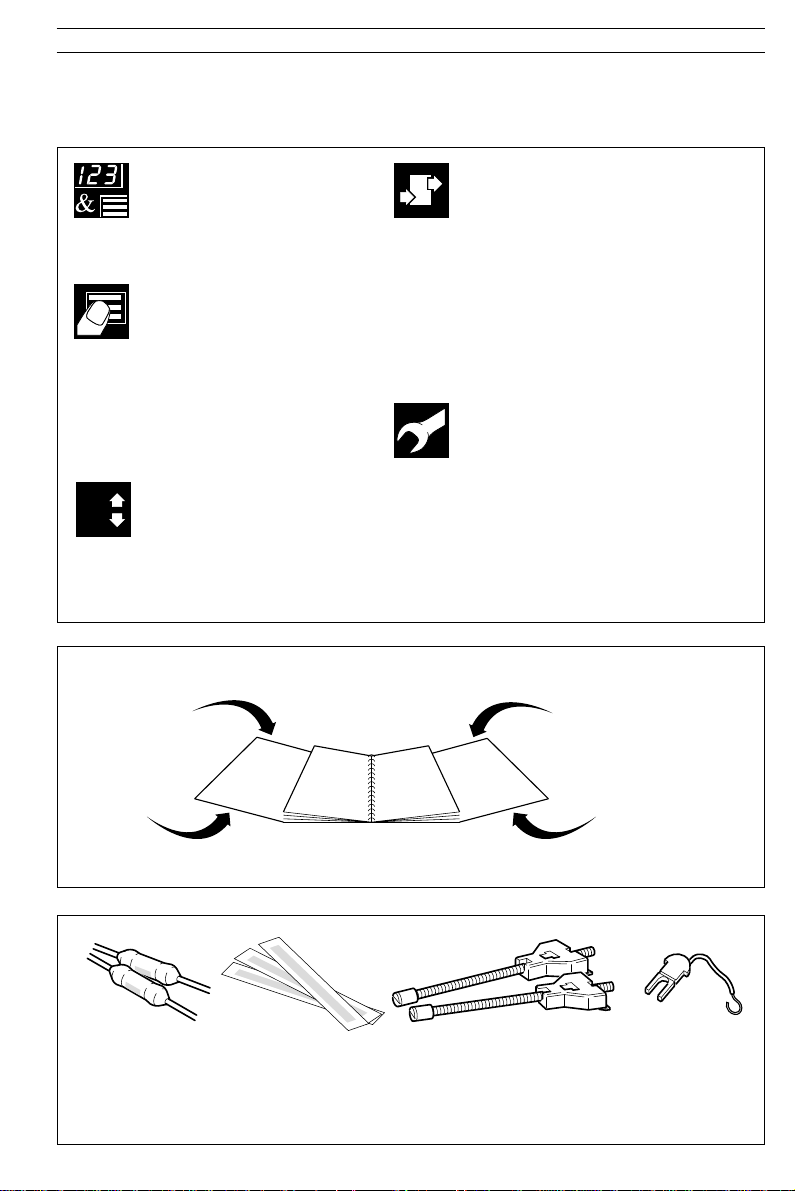

OVERVIEW

This manual is divided into 5 sections which contain all the information needed to install, configure,

commission and operate the COMMANDER 505 Advanced Process Controller. Each section is

identified clearly by a symbol as shown in Fig. 1.

8

Displays and Controls

• Displays and Function Keys

• LED Indication

• Error Messages

Operator Mode (Level 1)

• Single Loop Controller

• Motorized Valve Controller

• Auto/Manual &

Backup Stations

• Feedforward Controllers

• Cascade Controllers

• Ratio Station/Controller

Set Up Mode (Levels 2 to 5)

• Level 2 – Tuning

• Level 3 – Set Points

• Level 4 – Alarm Trip Points

• Level 5 – Valve Setup

Fig. 1 Overview of Contents

Getting

Started

Configuration Mode (Levels 6 to E)

• Level 6 – Basic Configuration

• Level 7 – Input Configuration

• Level 8 – Alarm Configuration

• Level 9 – Set Point Configuration

• Level A – Control Configuration

• Level B – Operator Configuration

• Level C – Output Configuration

• Level D – Serial Communications

• Level E – System Calibration

Installation

• Siting

• Mounting

• Electrical Connections

Table A – Template Applications

B – Output Sources

Getting

Started

Shunt Resistors

2 x 100Ω

(+1 optional)

Process Labels

x3

Fig. 3 Accessories

Fig. 2 Foldouts

Panel Clamps

x2

Table C – Digital Sources

D – Analog Sources

CJ Sensor

x1

(+1 optional)

1

Page 6

CONTENTS

Section Page

OVERVIEW....................................................1

1 DISPLAYS AND FUNCTION KEYS ........3

1.1 Introduction .......................................3

1.2 Use of Function Keys .......................4

1.3 Secret-til-Lit Indicators......................8

1.4 Character Set ....................................8

1.5 Error Messages ................................9

1.6 Processor Watchdog ......................10

1.7 Loop Break Monitor ........................10

1.8 Glossary of Abbreviations...............10

2 OPERATOR LEVEL............................... 11

2.1 Introduction ..................................... 11

2.2 Single Loop Controller

(Templates 1 and 2)........................1 2

2.3 Auto/Manual Station

(Templates 3 and 4)........................1 4

2.4 Analog Backup

(Templates 5 and 6)........................1 6

2.5 Indicator/Manual Loader Station

(Templates 7 and 8)........................1 8

2.6 Single Loop with Feedforward

(Templates 9 and 10)......................19

2.7 Cascade Control

(Templates 11 and 12) .................... 21

2.8 Cascade with Feedforward

(Template 13) ..................................24

2.9 Ratio Controller

(Templates 14 and 15)....................26

2.10Ratio Station

(Templates 16 and 17)....................27

2.11 Heat/Cool Output Types .................28

2.12Motorized Valve Output Types .......29

2.13Auto-tune ........................................30

2.14Control Efficiency Monitor ..............33

3 SET UP MODE .......................................36

3.1 Introduction .....................................36

3.2 Level 2 – Tune ................................ 37

3.3 Level 3 – Set Points........................41

3.4 Level 4 – Alarm Trip Points.............43

3.5 Level 5 – Valve Setup.....................44

4 CONFIGURATION MODE ..................... 47

4.1 Introduction...................................... 47

4.2 Level 6 – Basic Configuration ........48

4.3 Level 7 – Analog Inputs ..................52

4.4 Level 8 – Alarms .............................56

4.5 Level 9 – Set Point Configuration...60

4.6 Level A – Control Configuration......63

4.7 Level B – Operator Configuration...68

4.8 Level C – Output Assignment.........70

4.9 Level D – Serial Communications ..76

4.10Level E – Calibration ......................77

2

Section Page

5 I NSTALLATION......................................80

5.1 Mechanical Installation ...................80

5.2 Electrical Installation .......................85

5.3 Relays ............................................. 87

5.4 Digital Output ..................................87

5.5 Control or Retransmission

Analog Output .................................87

5.6 Motorized Valve Connections .........88

5.7 Input Connections ...........................89

5.8 Output Connections ........................89

5.9 Power Supply Connections.............89

SPECIFICATION .........................................90

APPENDIX A – CONTROL TEMPLATES ..94

A1 Single Loop Controller

(Templates 1 and 2) ........................94

A2 Auto/Manual Station and

Analog backup Station.................... 95

A3 Indicator/Manual Loader Station

(Templates 7 and 8) ........................98

A4 Single Loop Controller with

Feedforward (Templates 9 and 10). 99

A5 Cascade Controllers

(Templates 11 and 12)..................100

A6 Cascade Controller with

Feedforward (Template 13)...........101

A7 Ratio Controller

(Templates 14 and 15)..................102

A8 Ratio Station

(Templates 16 and 17)..................103

APPENDIX B – COMMANDER

CONFIGURATION EDITOR......................104

B1 Introduction ...................................104

B2 Analog Input Customization ......... 104

B3 Programmable Maths Blocks........104

B4 Logic Equations ............................104

B5 Process Alarm Customization ......104

B6 Real Time Alarms .........................104

B7 Delay Timers .................................105

B8 Custom Linearizers.......................105

B9 Template Customization ...............105

B10 Connecting the COMMANDER

PC Configurator ............................105

FRAMES INDEX .......................................106

INDEX ......................................................109

Page 7

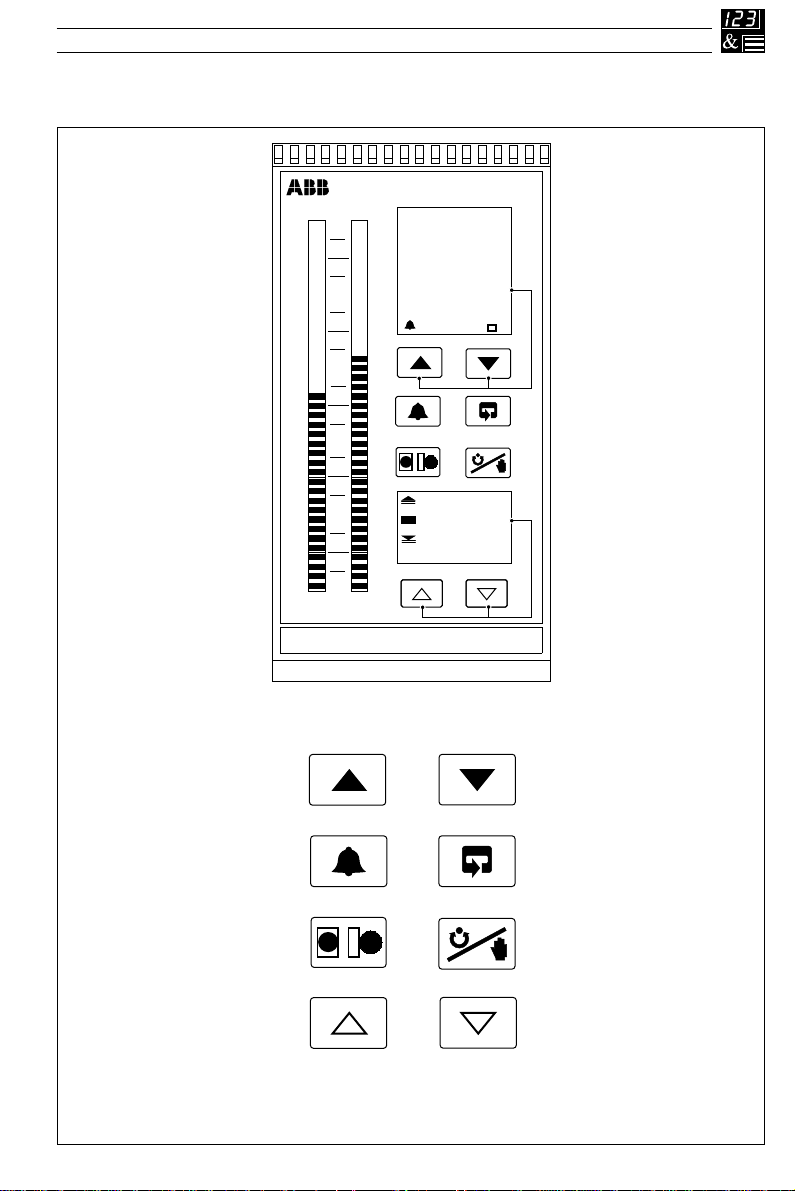

1 DISPLAYS AND FUNCTION KEYS

1.1 Introduction

The COMMANDER 500 front panel displays, function keys and LED indicators are shown in Fig. 1.1.

COMMANDER 500

100

58.8

Raise

Alarm

Acknowledge

80

60

40

L

20

M OP1 OP2 FF

0

Function Keys

62.4

MST SLV

R

L

15.0

R

Lower

Parameter Advance

Local/Remote

Fig. 1.1 Front Panel Displays and Function Keys

L

R

L

Up Down

Auto/manual

3

Page 8

…1 DISPLAYS AND FUNCTION KEYS

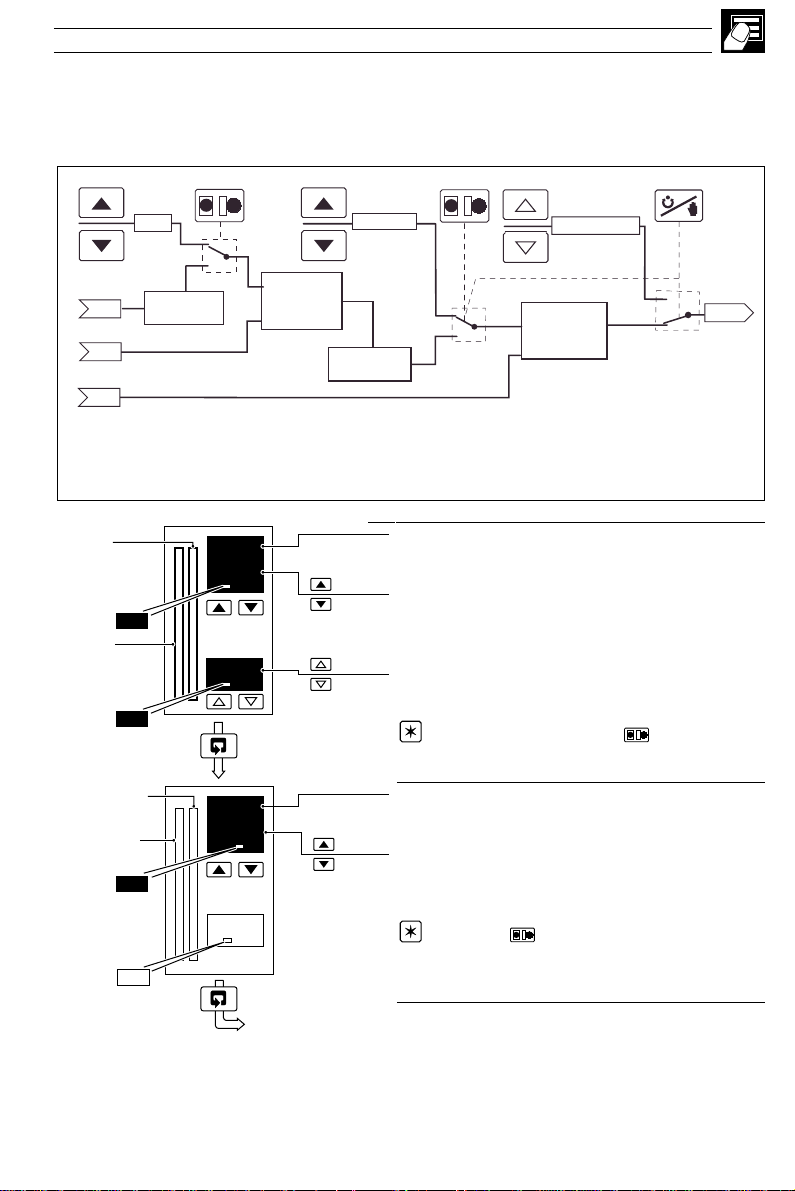

1.2 Use of Function Keys

A – Raise and Lower Keys

bIAS

+

50.0

Use to change/set a parameter value… …move between levelsand…

B – Up and Down Keys

700

Use to adjust the output value…

C – Parameter Advance Key

LEV2

tUnE

CYCl

51.0

49.0

–

+

710

690

–

and…

Frame 1

(top of level)

Frame 2

…move between frames within a Setup

or Configuration level. Any changes made

on the current frame are stored when the

next frame is selected.

5.0

2.00

2.01

LEV1

OPEr

LEV2

tUnE

CYCl

5.0

LEVx

1001

1002

1003

Frame 1

(top of level)

Frame 2

Press and hold

LEV2

tUnE

Note. This key also stores any changes made in the previous frame

D – Auto/Manual Key

4

Use to advance to the next

frame within a level…

Auto Manual

450.2

500.0

70

Use to select Auto or Manual control mode

Fig. 1.2a Use of Function Keys

or…

M

…select the top (LEV.x)

frame from within a level

450.2

500.0

70

Process Variable

Control Set Point

Control Output (%)

Page 9

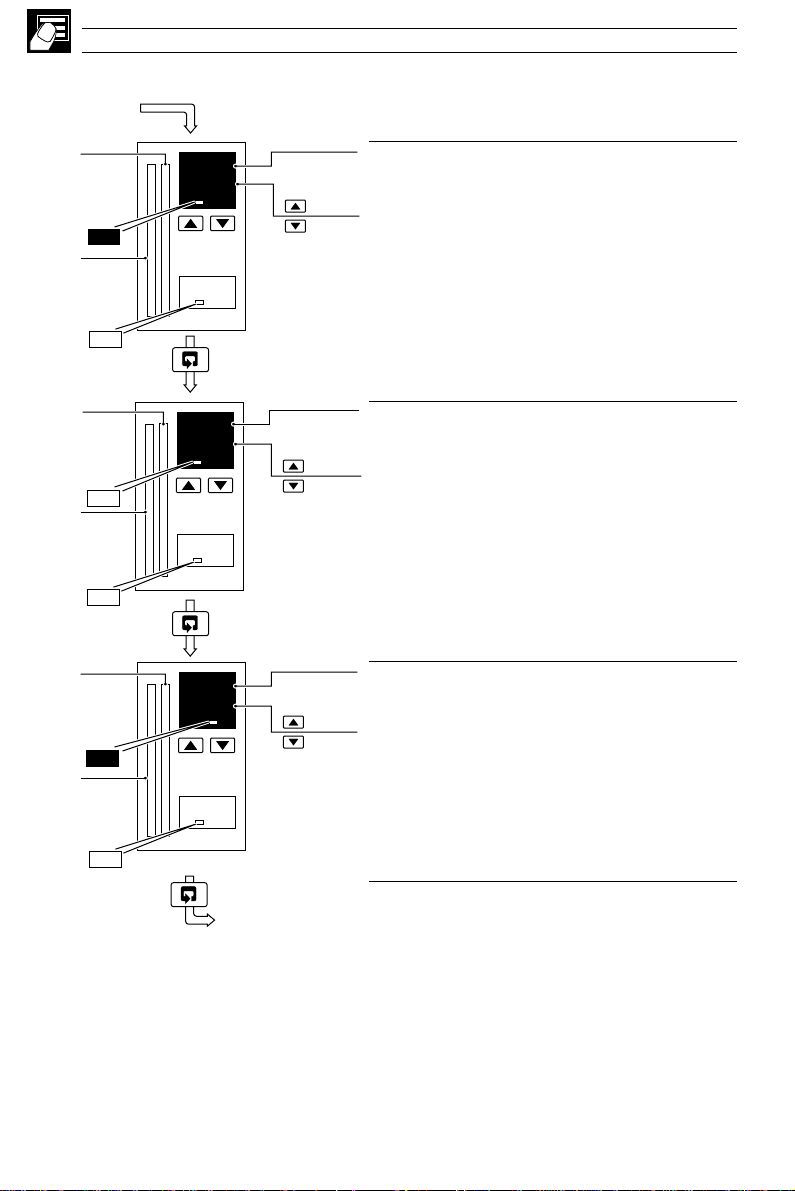

…1.2 Use of Function Keys

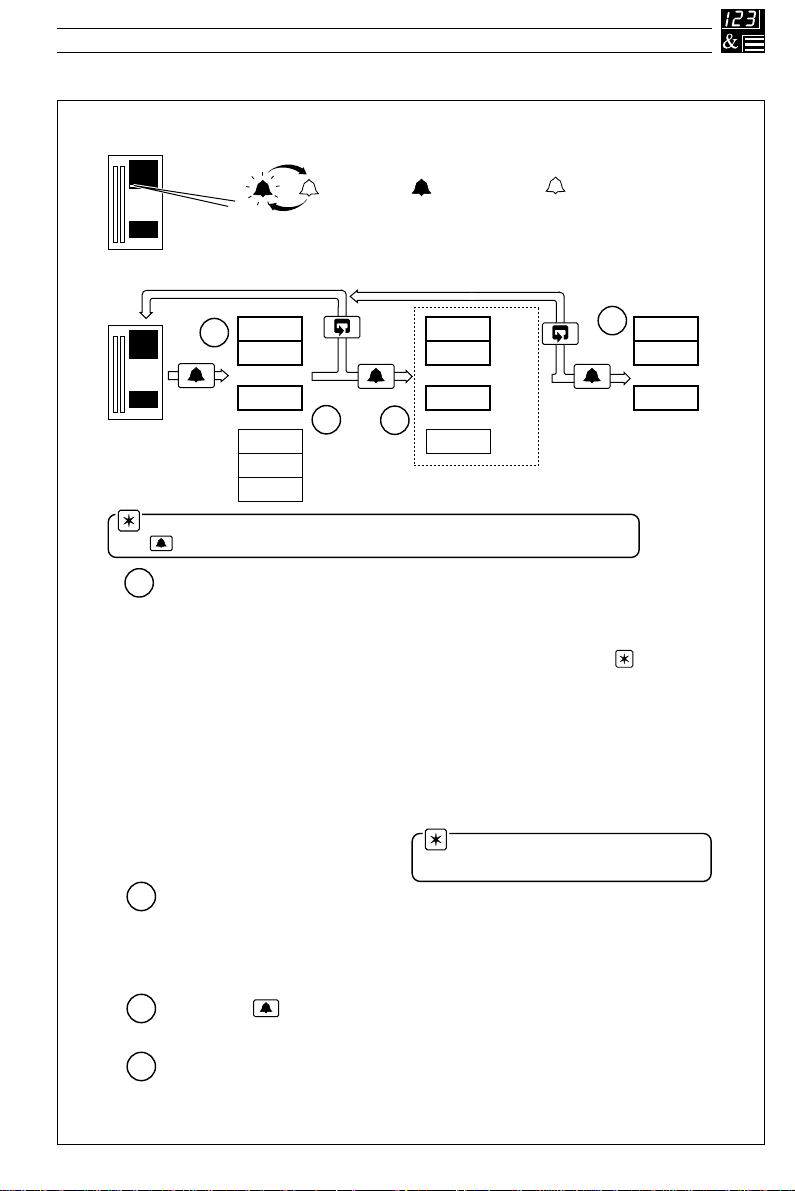

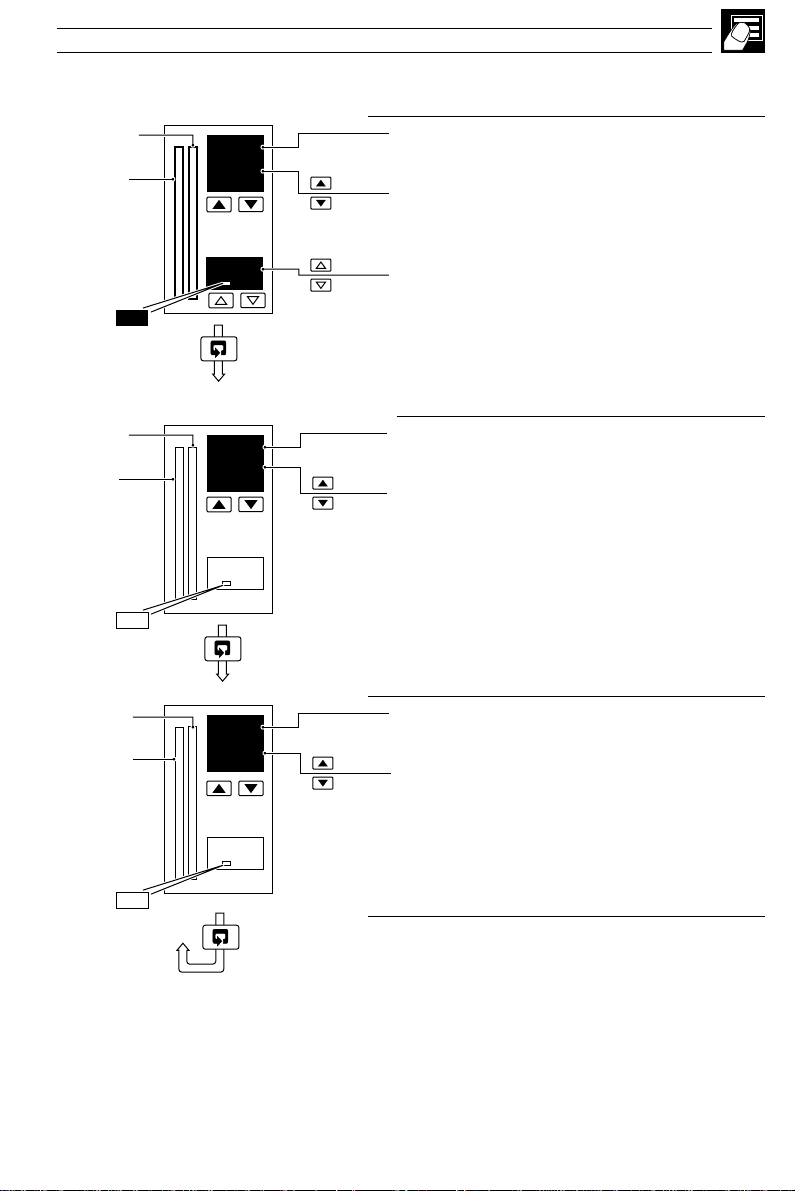

E – Alarm Acknowledgement

Any active,

unacknowledged

alarms

All active

alarms

acknowledged

(Flashing)

450.2

500.0

70

200.3

1.HP1

2003

1HP1

ACt

ACK

LAt

or

CLr

ACK

LAt

or

200.3

2.xxx

ACt

1

2

3

4

Unacknowledged

alarms only

450.2

500.0

70

(On continuously) (Off)

No active

alarms present

Pressing again acknowledges the displayed alarm.

Lower display changes to reflect new status.

3

Next active and unacknowledged alarm is displayed. If no alarms

are active, the next enabled alarm is displayed.

4

The first active and unacknowledged alarm is displayed

(or if no alarms are active, the first enabled alarm is displayed)

1

The lower display shows alarm status:

ACt

Alarm active and unacknowledged

ACK

Alarm active and acknowledged

CLr

Cleared or Inactive alarm

LAt

Unacknowledged latched alarm

2

Note. The time of the power failure

PF.t, is shown in the set point display.

High Process, PV High Output

Low Process, PV Low Output

High Latch, PV Power Failure Time

Low Latch, PV Maths Block 1 High

High Deviation Maths Block 1 Low

Low Deviation Maths Block 2 High

High Process I/P1 Maths Block 2 Low

Low Process I/P1 Maths Block 3 High

High Process I/P2 Maths Block 3 Low

Low Process I/P2 Maths Block 4 High

High Process I/P3 Maths Block 4 Low

Low Process I/P3

HPV HO

LPV LO

HLP PF.t

LLP Hb1

Hd Lb1

Ld Hb2

HP1 Lb2

LP1 Hb3

HP2 Lb3

LP2 Hb4

HP3 Lb4

LP3

Note. If no alarms have been enabled in the Set Up level, pressing

the key has no effect.

1 DISPLAYS AND FUNCTION KEYS…

Fig. 1.2b Use of Function Keys

5

Page 10

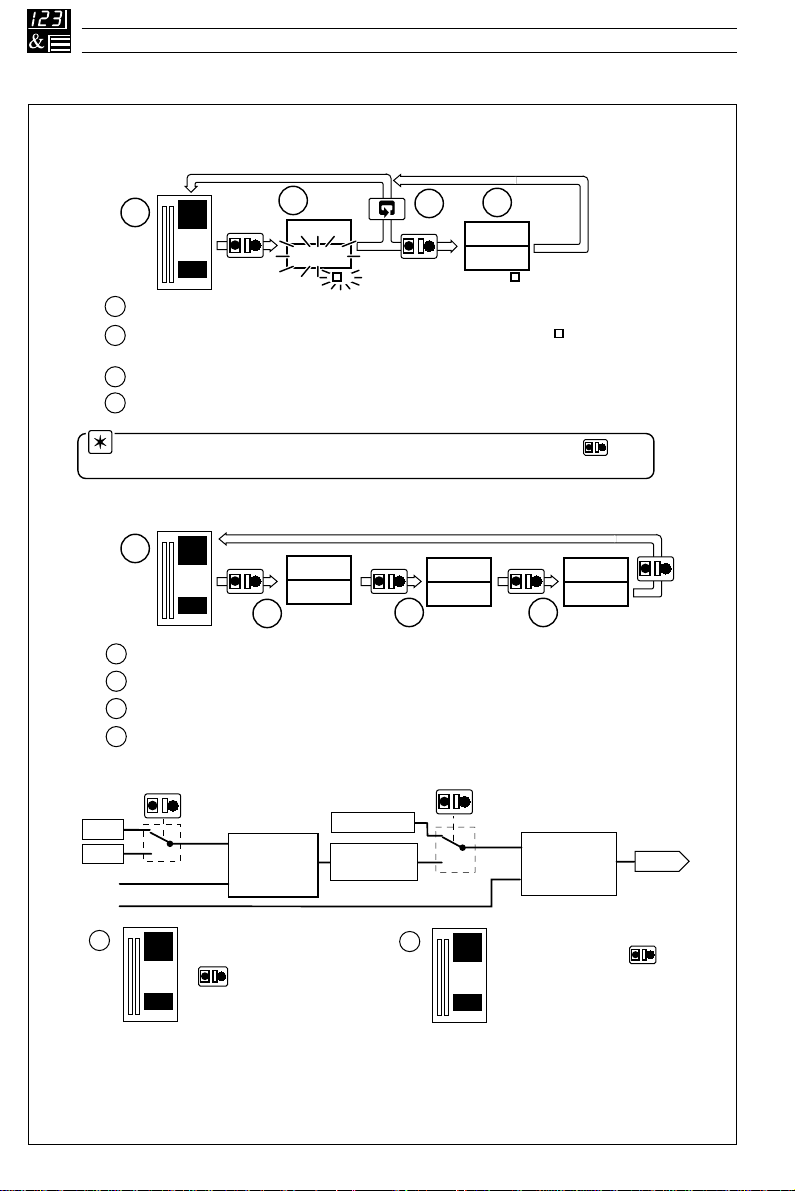

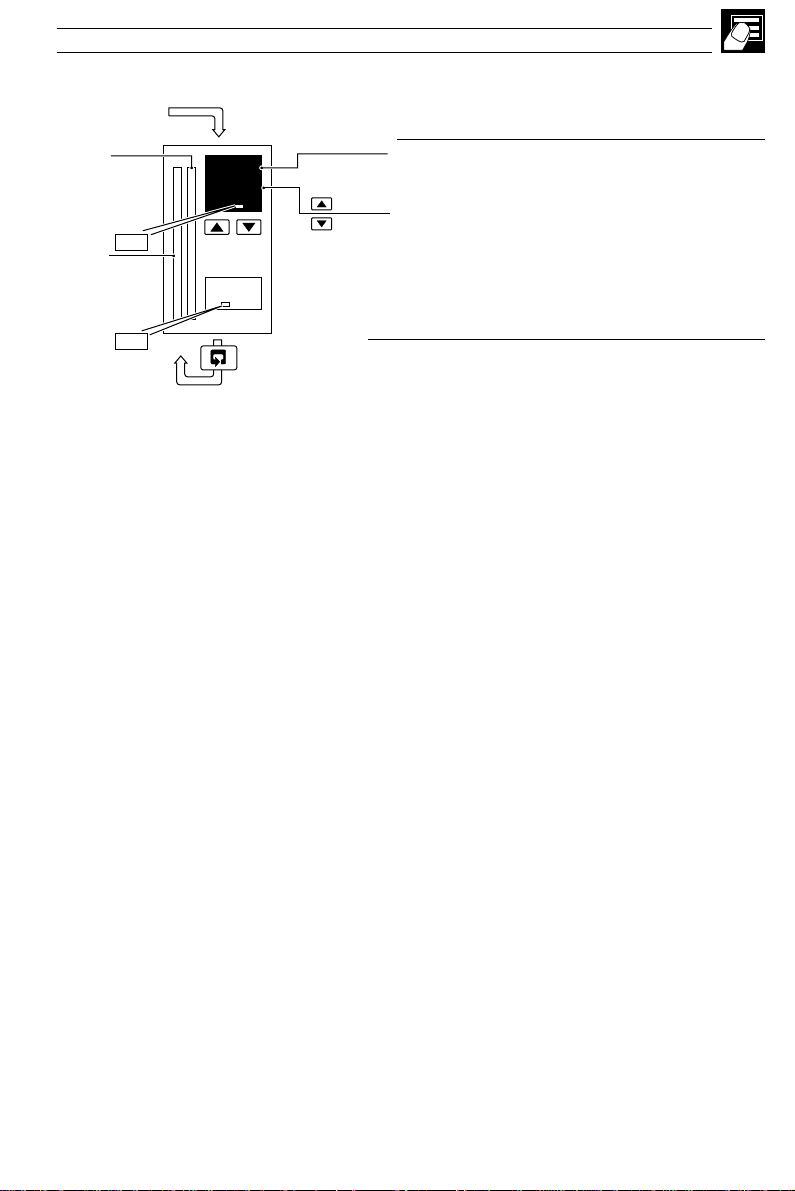

…1 DISPLAYS AND FUNCTION KEYS

…1.2 Use of Function Keys

F – Local / Remote Key

Changing between Local and Remote Set Points

450.2

1

500.0

70

1

Process variable and local set point (ratio) displayed on red and green displays.

Remote set point (ratio) value is displayed. The value and symbol flash to

2

2

450.2

L

R

L

400.0

R

4

L

R

L

3

450.2

400.0

R

R

indicate local set point (ratio) still selected.

3

Remote set point (ratio) selected.

4

Remote selection aborted.

Note. When an Analog Backup Station template is selected, the key

L

is used to switch between local and remote mode – see Sections 2.4 and 4.2.

Selecting Local Set Points 1 to 4

450.2

1

350.0

70

Process variable and local set point 1 displayed.

1

Process variable and local set point 2 displayed

2

Process variable and local set point 3 displayed

3

4

Process variable and local set point 4 displayed

450.2

L

R

L

400.0

2

450.2

L

R

L

475.0

450.2

L

R

L

475.0

43

Selecting Master and Slave Set Points – Cascade Mode

Abbreviations are

detailed in Section 1.8.

Slave PID

Control Loop

When the SLV indicator (see

Fig 1.3) is lit, the key

can be used to switch

between the local slave

set point and the cascade

LSPt

RSPt

M.PV

S.PV

1

L

R

L

M.SPt

Master

Control Loop

450.2

When the MST indicator

350.0

(see Fig 1.3) is lit, the

L

R

L

key can be used to

switch between the Master

70

local and remote set points

PID

Local S.SPt

M.OP x

CrtO + CbIA

L

R

L

S.SPt

450.2

2

350.0

70

slave set point generated

from the master output.

R

L

L

R

L

OP1

L

R

L

Fig. 1.2c Use of Function Keys

6

Page 11

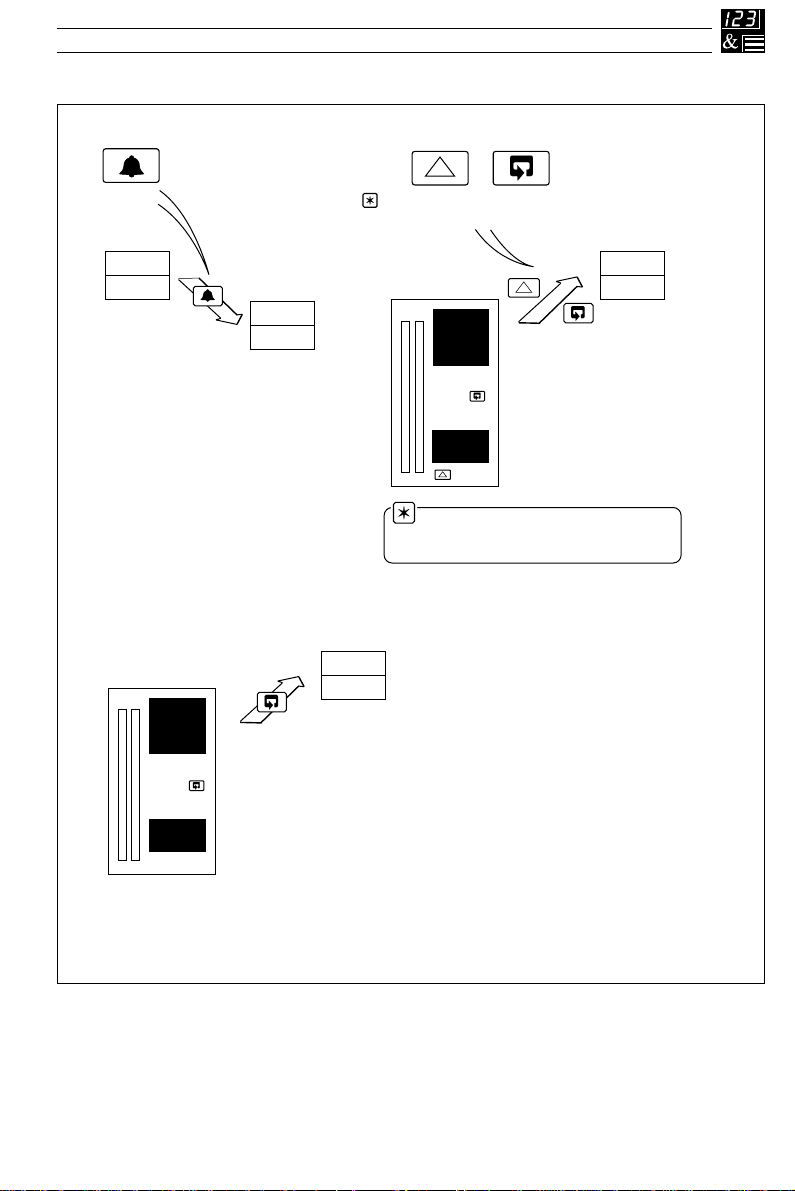

…1.2 Use of Function Keys

G – Short-cut Keys

1 DISPLAYS AND FUNCTION KEYS…

+

Press simultaneously and

hold for 3 seconds

LEVA

CntL

LEV1

OPEr

Press to move from anywhere in

the Configuration level to the first

frame in the Operator level

450.2

350.0

Press and hold to move from the Operator

Level to the Security Code Frame and then

to other levels:

70

Tune Level – See Section 2.13.3

Set Up Level – See Fig. 3.1

Configuration Level – See Fig. 4.1

COdE

0

LEV6

APPL

450.2

350.0

Press to move from

anywhere in the Operator

or Setup levels to the first

page of the Configuration

70

Note. This Short-cut key operates

only when the configuration password is

set to ‘0’

level

Fig. 1.2d Use of Function Keys

7

Page 12

…1 DISPLAYS AND FUNCTION KEYS

1.3 Secret-til-Lit Indicators

450.2

350.0

MST SLV

R

450.2

350.0

150

150

M OP1 OP2 FF

MST

SLV

R

M

OP1

OP2

FF

Flashing

One or more

alarms active and

unacknowledged

A – Upper Display

Flashing

Autotune in

progress

ON

All active alarms

acknowledged

Master controller

parameters

displayed

Slave controller

parameters

displayed

Remote or

Cascade set

point in use

ON

Manual control

selected

Output 1 (heat)

value displayed

Output 2 (cool)

value displayed

Feedforward

disturbance

variable displayed

Valve opening

Valve stopped

Valve closing

B – Lower Display

OFF

No alarms active

Local set point

in use

OFF

Auto control

selected

1.4 Character Set – Fig. 1.4

A

B

C

D

E

F

G

H

8

Fig. 1.3 Secret-til-lit Indicators

I

A

b

C

d

E

F

G

H

Fig. 1.4 Character Set

I

J

J

K

K

L

L

M

M

N

N

or

n

O

O

P

P

R

r

S

S

T

t

U

U

V

V

Y

Y

Page 13

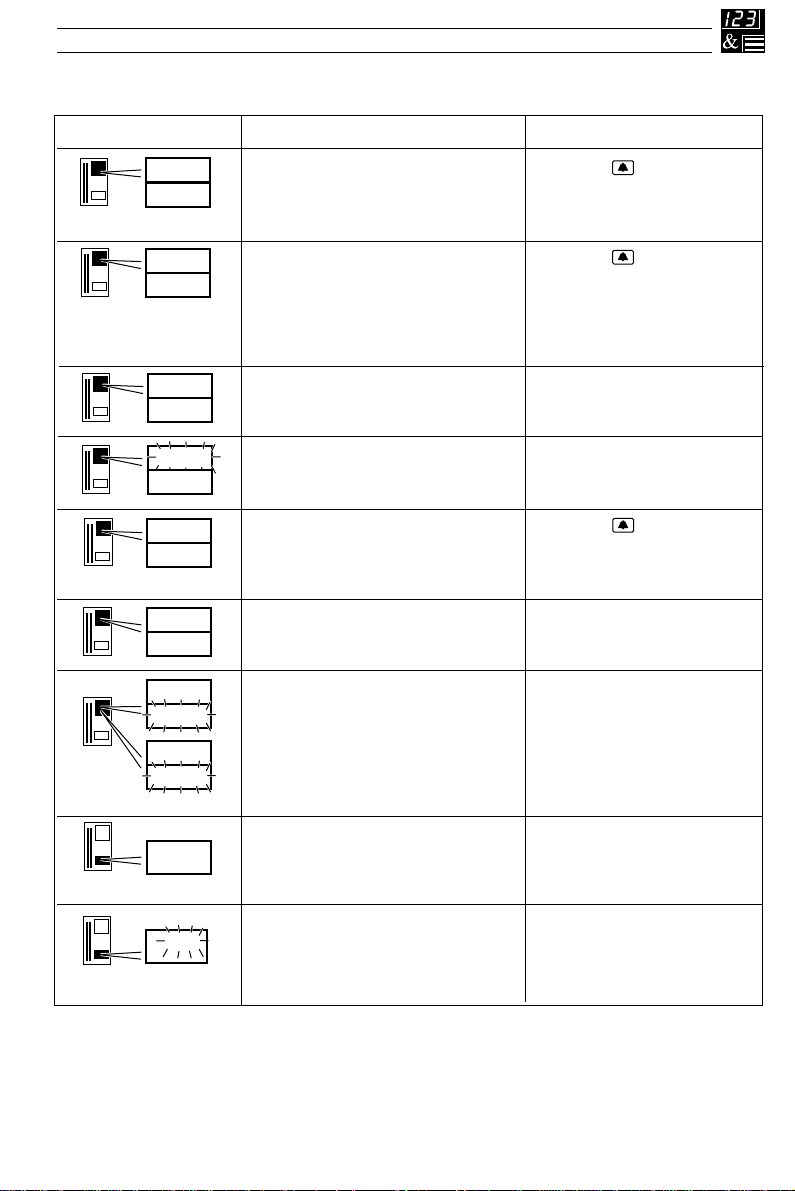

1.5 Error Messages

1 DISPLAYS AND FUNCTION KEYS…

Display

70

70

70

70

70

70

70

or

CAL

Err

Err

NVx

A-d

Err

9999

t.Err

1

CJ.F

1

rSP.F

9999

rAt.F

9999

Error/Action

Calibration Error

Turn mains power off and on again

(if the error persists contact the

Customer Support Organization).

Non-volatile Memory Error

x = 1, 2: Motherboard Memory

x = 3: Option Board Memory

Turn mains power off and on again

(if the error persists, check

configuration/setup settings).

A to D Converter Fault

The analog to digital converter is not

communicating correctly.

Input Value Over/Under Range

Auto-tune Error

The number displayed indicates the

type of error present – see Table 2.1

on page 30.

Cold Junction Failed

Cold junction sensor is faulty or has

not been fitted correctly.

Remote Set Point or External

Ratio Failed. Remote set point input

value is over or under-range. Only

appears if the remote set point (or

external ratio) is displayed or in use.

To clear the display:

Press the key

Press the key

Contact the Customer

Support Organization

Restore valid input

Press the key

Check connections or replace

if faulty.

Restore valid input

StK

999

Valve Sticking

Motorized valve not moving at the

speed expected. Valve may be

sticking.

Position Feedback Fail

Input value is over- or under-range.

Only appears if output type set to

'PFb' – motorized valve with feebac k.

Check that the correct

Regulator Travel Time has

been set – see Section 3.5.

Check the valve.

Restore valid input

9

Page 14

…1 DISPLAYS AND FUNCTION KEYS

1.6 Processor Watchdog

The instrument's processor activity is monitored by an independent watchdog device. When the

output of the watchdog is assigned to a relay or digital output, the relay/digital output de-energizes

if the instrument fails to function correctly.

1.7 Loop Break Monitor

Both analog outputs are monitored continuously to detect a loop break. A warning signal or other

action can be initiated by assigning the loop break signals to relays or digital outputs.

1.8 Glossary of Abbreviations

noitaiverbbAnoitpircseDnoitaiverbbAnoitpircseD

VPelbairaVssecorP1id1tupnIlatigiD

tPSLeulaVtnioPteSlacoL2id2tupnIlatigiD

1PSLeulaV1tnioPteSlacoL3id3tupnIlatigiD

2PSLeulaV2tnioPteSlacoL4id4tupnIlatigiD

3PSLeulaV3tnioPteSlacoL1oa1tuptuOgolanA

4PSLeulaV4tnioPteSlacoL2oa2tuptuOgolanA

tPSCeulaVtnioPteSlortnoC1od1tuptuOlatigiD

tPSReulaVtnioPteSetomeR2od2tuptuOlatigiD

P/ODIPmhtiroglADIPehtfotuptuOVP.MelbairaVssecorPretsaM

1PO)taeh(1tuptuOrellortnoCtPS.MtnioPteSlortnoCretsaM

2PO)looc(2tuptuOrellortnoCPO.MtuptuODIPretsaM

1P/I1tupnIgolanAtPS.StnioPteSevalS

2P/I2tupnIgolanAVP.SelbairaVssecorPevalS

3P/I3tupnIgolanAVWelbairaVdliW

VDelbairaVecnabrutsiD

10

Table 1.1 Glossary of Abbreviations

Page 15

2 OPERATOR LEVEL

2.1 Introduction

The Operator level (Level 1) is the normal day-to-day mode of the COMMANDER 500. This section

describes the operator facilities available on each frame depending on the control template and

output type selected.

The template types detailed in this section are:

• Single loop controller

• Auto/Manual station

• Analog backup station

• Indicator/manual loader station

• Single loop with feedforward control

• Cascade control

• Cascade with feedforward

• Ratio controller

• Ratio station

Note. Only the frames relevant to the selected template are displayed – see Section 4.

In addition, frames used to view the Control Efficiency Monitor and operate motorized valve and heat/

cool output types are also described.

C501

01.SL

2001

01

Fig. 2.1 Power-up Displays

Model – C501

Template (see rear fold-out)

Software series

Software version

11

Page 16

…2 OPERATOR LEVEL

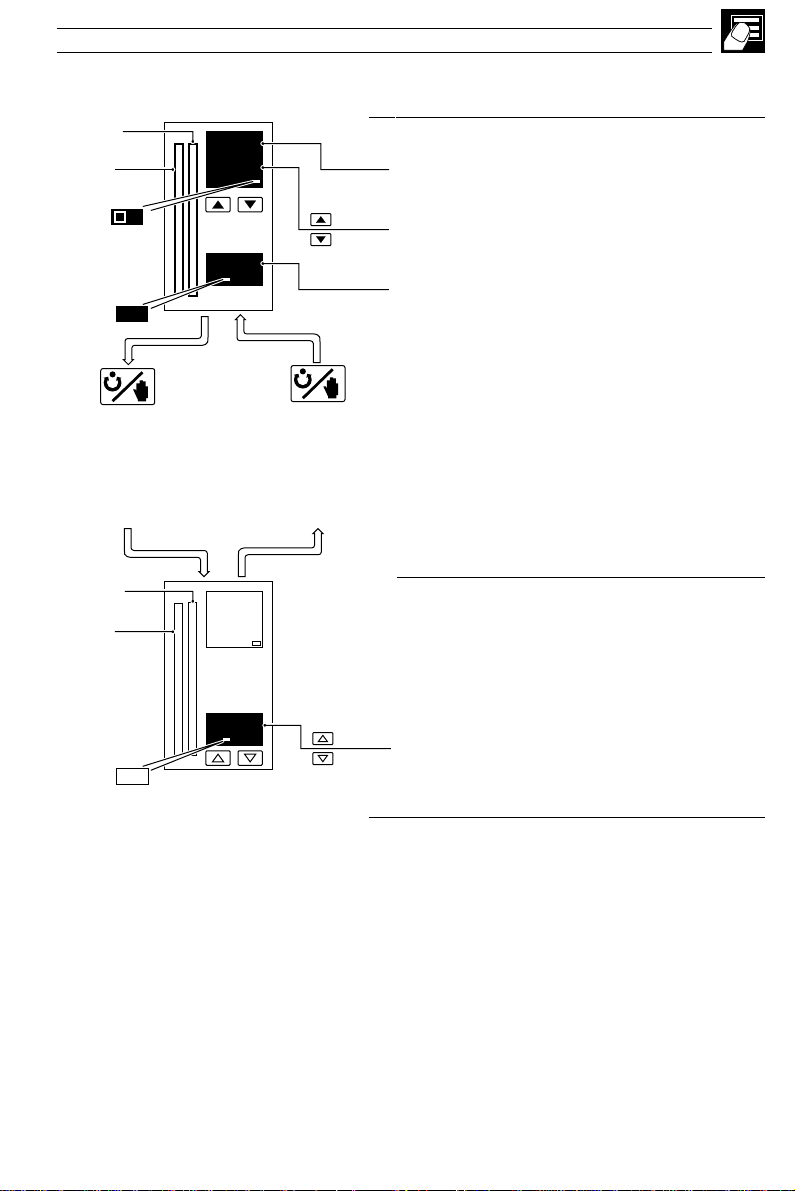

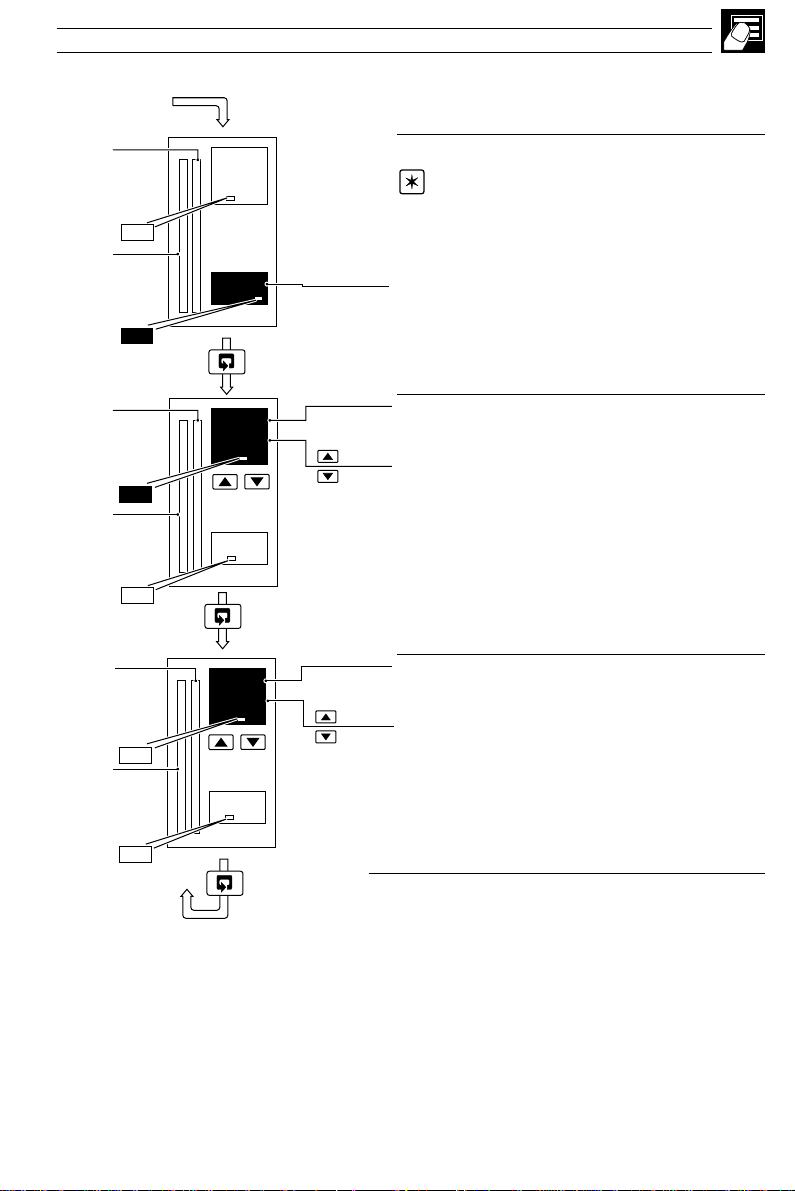

2.2 Single Loop Controller (Templates 1 and 2)

The single loop controller is a basic feedback control system using three-term PID or on/off control

with either a local set point (template 1) or remote set point (template 2).

L

Local Set Point

LSPt

LR

Remote Set Point Input

•1

I/P2

Process Variable Input

I/P1

•1 Template 2 Only

I/P2 x rAtO + bIAS

RSPt

CSPt

PV

Manual Output

PID

Control Loop

Fig. 2.2 Single Loop Controller

PID O/P

Control

Output

OP1

12

Page 17

…2.2 Single Loop Controller (Templates 1 and 2)

2 OPERATOR LEVEL…

Set Point

Process

Variable

Set Point

Process

Variable

OP1

OP1

•1

Process Variable

450.2

500.0

70

rAtO

•1

•2

Control Set Point

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in Local Control Only

Control Output

[0 to 100% (digital/relay outputs),

–10 to 110% (analog outputs)]

Adjustable in manual mode only. With on/off control

selected, 0% = control output off, 100% = control

output on. In manual mode, intermediate values can

be selected. These use 'time proportioning' with a

60s cycle time, e.g. 25% = 15s on, 45s off.

Remote Set Point Ratio

1.000

[0.001 to 9.999]

Remote set point value =

(ratio x remote set point input) + bias

70

Set Point

Process

Variable

bIAS

1.000

•3

Remote Set Point Bias

[In engineering units]

70

OP1

Return to top of page

•1 With the Ramping Set Point function enabled (see Section 3.3, Set Points/ Ramp Rate), the

bargraph shows the actual (ramping) set point value and the digital display shows the target set point

value.

•2 Only displayed if template 2 selected and Ratio Display is enabled – see Section 4.2, Basic

Configuration and Section 4.7, Operator Configuration.

•3 Only displayed if template 2 selected and Bias Display is enabled – see Section 4.2, Basic

Configuration and Section 4.7, Operator Configuration.

13

Page 18

…2 OPERATOR LEVEL

2.3 Auto/Manual Station (Templates 3 and 4)

Note. Refer also to Appendix A2.1 – Series and Parallel Operation.

The auto/manual station provides a backup for a master controller. In normal operation the

COMMANDER 500’s analog output follows the master controller’s output value. A fault in the master

system can be identified either by detecting a low signal on the master output (template 3) or via a

digital signal (template 4). When a fault is detected the COMMANDER 500 goes into manual mode

with its output either set to the last valid master output value or to a configured output value – see

Section 4.6, Control Configuration/ Configured Output 1. When the master output is restored or the

digital input returns to its inactive state, the COMMANDER 500 switches back to auto mode.

Note. The Alarm A1 Trip value must be set when using template 3.

Manual Output

Master Output

I/P2

Digital Select

di1

•1 Template 3 Only

•2 Template 4 Only

Low Signal Select

(Alarm A1)

•1

•2

Fig. 2.3 Auto/Manual Station

Analog Output

ao1

Auto / Manual

Select

14

Page 19

…2.3 Auto/Manual Station (Templates 3 and 4)

2 OPERATOR LEVEL…

Master

output

Process

Variable

•1

•2

Low Master

Output Value

•3

Digital Input

Active

Master

output

Process

Variable

or

or

55.0

50.0

70

55.5

50.0

•1

or

•2

Restored

Master Output

or

•3

Digital Input

Inactive

Auto Mode

Process Variable

Master Output (I/P2)

Control Output = Master Output

[Master Output, 0 to 100%]

Manual Mode

50

M

•1 In template 4 the Auto/Manual switch is overridden by the digital input signal.

•2 Template 3 only – see Section 4.2, Basic Configuration/ Template Application.

•3 Template 4 only – see Section 4.2, Basic Configuration/ Template Application.

Control Output (under COMMANDER 500 control)

[0 to 100%]

15

Page 20

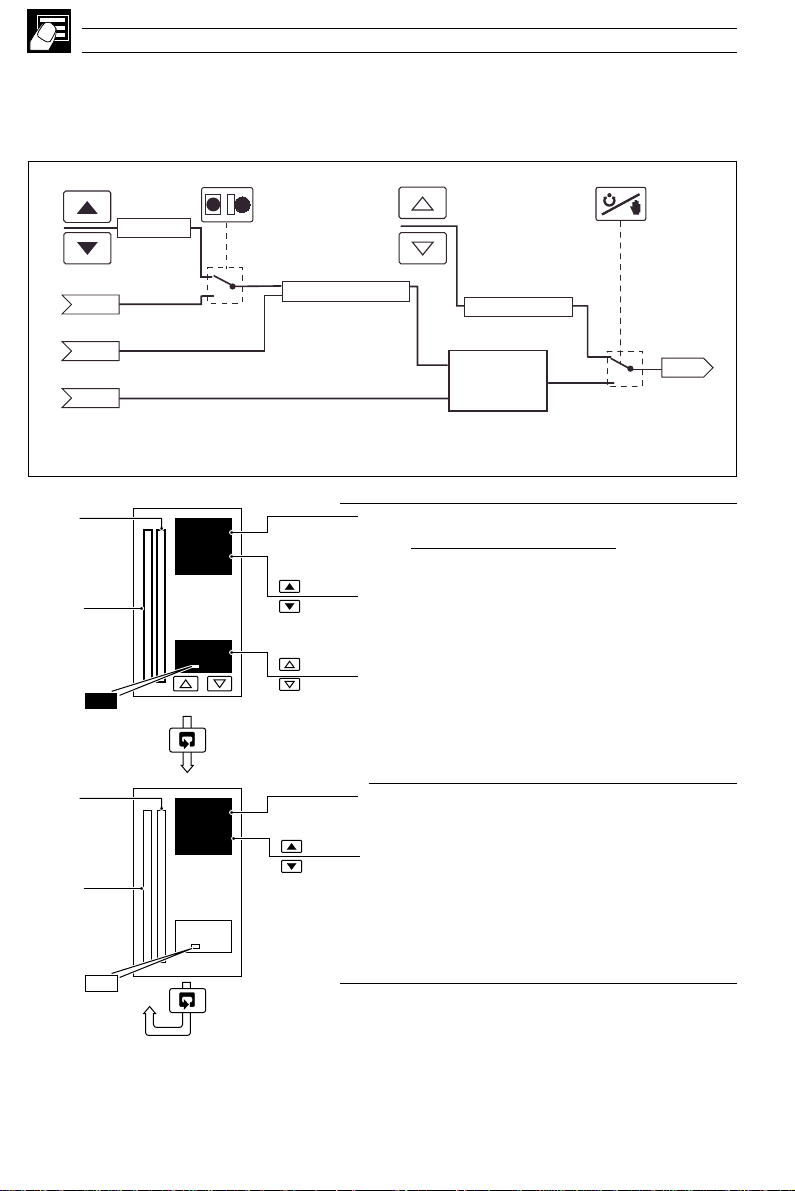

…2 OPERATOR LEVEL

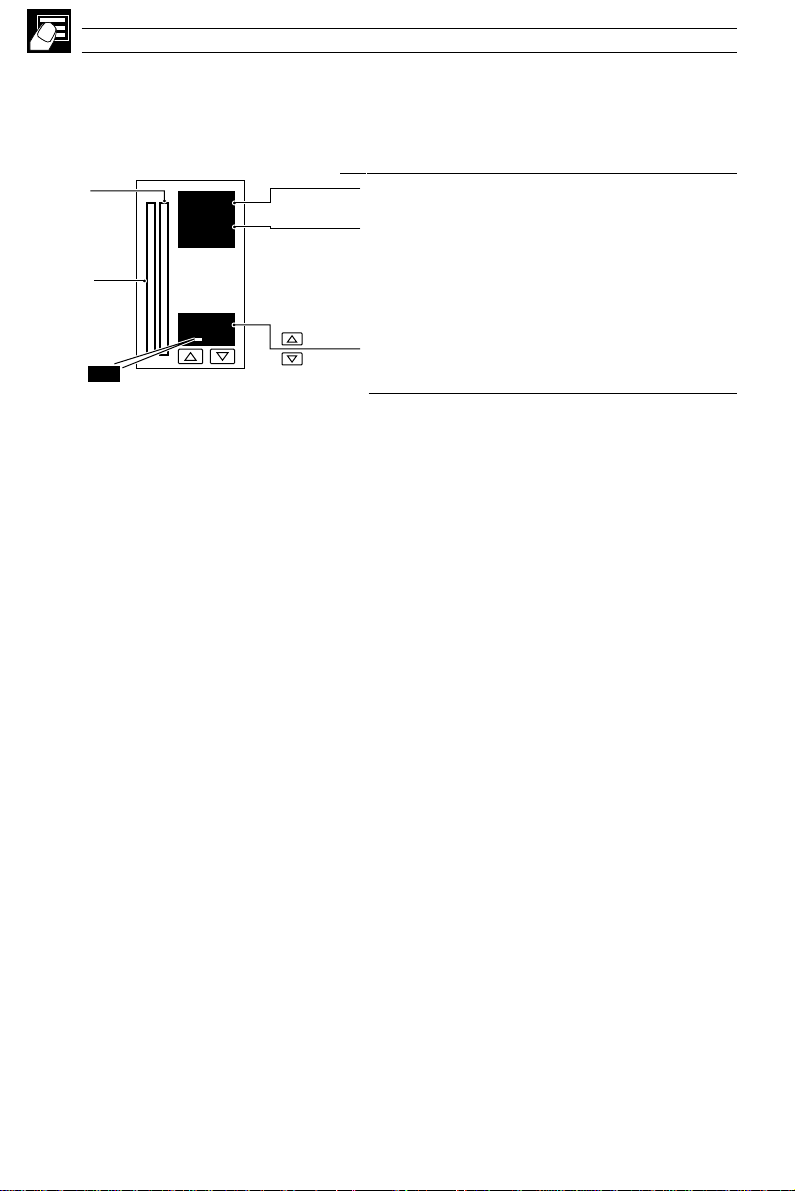

2.4 Analog Backup (Templates 5 and 6)

Note. Refer also to Appendix A2.1 – Series and Parallel Operation.

The analog backup station provides a backup for a master controller. In normal operation (remote

control mode selected) the COMMANDER 500’s current output follows the master controller’s output

value. A fault in the master system can be identified either by detecting a low signal on the master

output (template 5) or via a digital signal (template 6). When a fault is detected the COMMANDER

500 switches into local control mode and the process is controlled by the PID output of the

COMMANDER 500. The COMMANDER 500 PID algorithm tracks the master output value

continuously in order to ensure bumpless transfer from remote to local mode operation. When the

master output is restored or the digital input returns to its inactive state, the COMMANDER 500

switches back to remote control mode.

Note. The Alarm A1 Trip value must be set when using template 5.

Manual Output

Local Set Point

LSPt

Process Variable

I/P1

Master Output

I/P2

Digital Select

di1

•1 Template 5 Only

•2 Template 6 Only

PID

Control Loop

PV

Low Signal Select

(Alarm 1)

L

LR

Fig. 2.4 Analog Backup Station

•1

•2

Local/

Remote

Select

Analog Output

ao1

16

Page 21

…2.4 Analog Backup (Templates 5 and 6)

2 OPERATOR LEVEL…

Set Point

Process

Variable

•1

•2

Set Point

Process

Variable

R

OP1

or

Low Master

Output Value

or

Digital Input

Active

55.0

50.0

70

55.5

50.0

or

•1

Restored

Master Output

or

•2

Digital Input

Inactive

Remote Mode

Process Variable

Set Point

['SPLO' to 'SPHI' – see Section 4.5]

Control Output = Master Output

[Master Output, 0 to 100%]

Local Mode

50

OP1

•1 Template 5 only – see Section 4.2, Basic Configuration/ Template Application.

•2 Template 6 only – see Section 4.2, Basic Configuration/ Template Application.

Control Output (under COMMANDER 500 control)

[0 to 100%]

Adjustable in Manual Mode only.

17

Page 22

…2 OPERATOR LEVEL

2.5 Indicator/Manual Loader Station (Templates 7 and 8)

One or two process variables can be displayed on the digital and bargraph displays. If the control

output is assigned to an analog output, the lower display indicates its value which can be adjusted by

the user.

Process

Variable

(PV2)

Process

Variable

(PV1)

OP1

•1

55.0

50.0

•1

50

•2

Process Variable PV1

Process Variable PV2

Output Value

[–10 to 110%]

•1 Only displayed if template 8 selected – see Section 4.2, Basic Configuration/

Template Application.

•2 Only displayed if control output type is 'analog' (output is assigned to Analog Output 1).

18

Page 23

2 OPERATOR LEVEL…

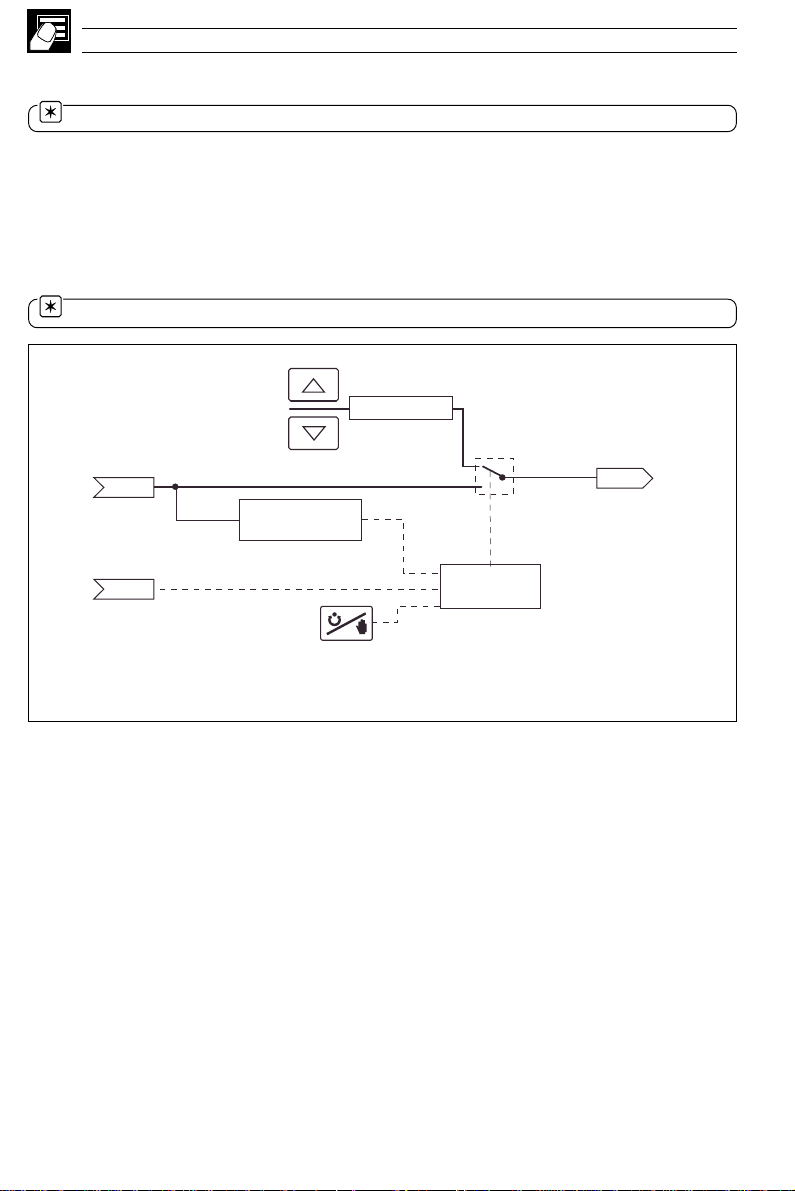

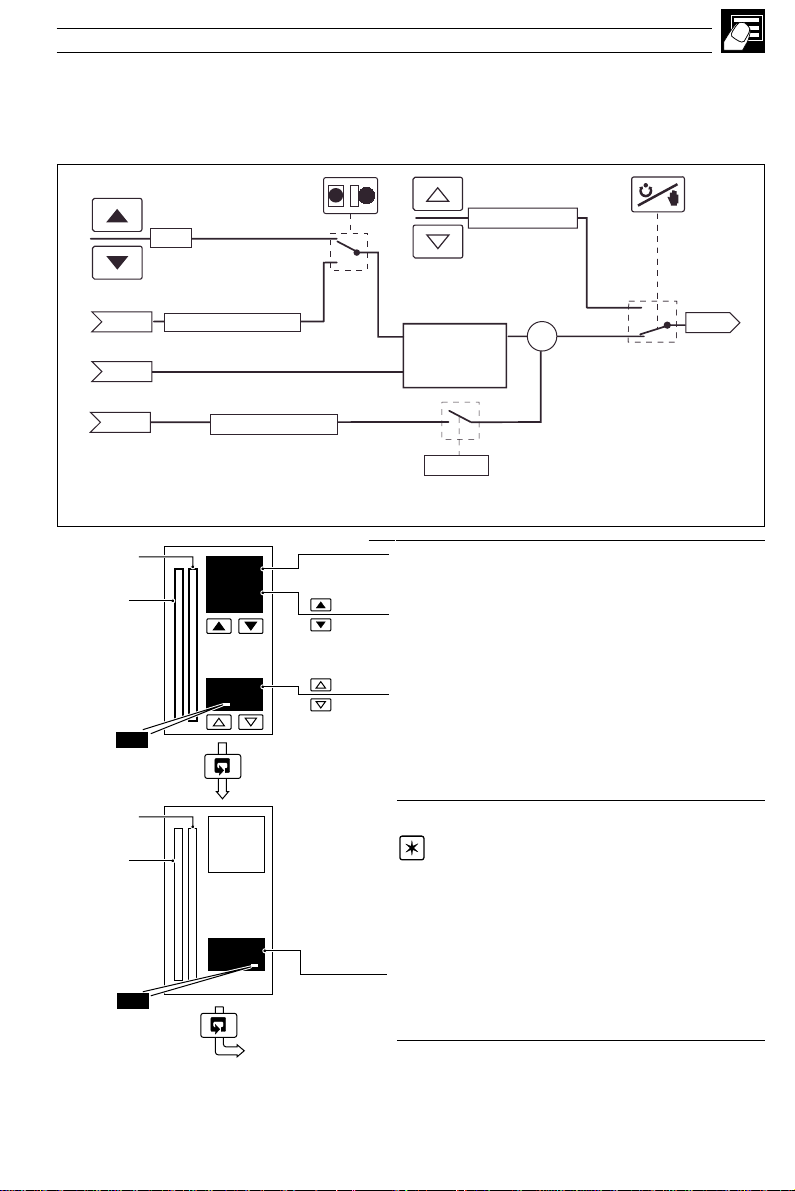

2.6 Single Loop with Feedforward (Templates 9 and 10)

These templates provide three-term PID control with feedforward. The disturbance variable is

weighted by the feedforward gain (FFGn) and the feedforward bias (FFbS) values and added to the

controller output value.

L

Local Set Point

LSPt

LR

Manual Output

Remote Set Point input

•1

PV input

Feedforward Disturbance Variable

I/P2

•1 Template 10 Only

I/P3

I/P1

RSPt x rAtO + bIAS

Control

Set Point

Process

•1

450.2

500.0

Variable

OP1

Control

Set Point

Process

450.2

500.0

Variable

CSPt

∑

PID O/P +

(DV x FFGn + FFbS)

DV x FFGn + FFbS

MPV

PID

Control Loop

FFGN = 0

Fig. 2.5 Single Loop Controller with Feedforward

Process Variable

Control Set Point

•1

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in Local control only.

Control Output

70

[0 to 100%]

Adjustable in Manual control only.

Feedforward

Note. To disable feedforward action (e.g.

during system tuning), set the Feedforward Gain

parameter to 0FF – see Section 3.2, Tune/Level 2 –

Tune.

OP1

50

[0 to 100%]

FF

•1 With the Ramping Set Point function enabled (see Section 3.3, Set Points/ Ramp Rate), the

bargraph shows the actual (ramping) set point value and the digital display shows the target set point

value.

Feedforward disturbance variable signal.

Continued…

19

Page 24

…2 OPERATOR LEVEL

…2.6 Single Loop with Feedforward (Templates 9 and 10)

Set Point

Process

Variable

Set Point

Process

Variable

OP1

OP1

rAtO

1.000

70

bIAS

0. 0

70

•1

•1

Remote Set Point Ratio

[0.001 to 9.999]

Remote set point value =

(ratio x remote set point input) + bias

Remote Set Point Bias

[In engineering units]

Return to Process Variable display

•1 Only displayed if template 10 selected – see Section 4.2, Basic Configuration/Template

Application and Section 4.7, Operator Configuration/Operator Ratio Display and Operator Bias

Display.

20

Page 25

2 OPERATOR LEVEL…

2.7 Cascade Control (Templates 11 and 12)

For cascade control, two internally-linked PID controllers are used, with the first (master) PID

controller providing the set point for the second (slave) controller. The master output is weighted

using the cascade ratio (C.rtO) and bias (C.bIA) values to create the slave set point value.

Local

Set Point

LSPt

Remote Set Point

input

•1

I/P3

Master PV Input

I/P1

Slave PV Input

I/P2

•1 Template 12 Only

Master

Set Point

(MSPt)

MST

Master

Process

Variable

(MPV)

OP1

RSPt x

RSPt

rAtO + bIAS

•1

L

LR

MPV

SPV

450.2

500.0

70

Slave Set

Point

SSPt

Master

Control Loop

PID

M.OP

M.OP x

CrtO + CbIA

Fig. 2.6 Cascade Controller

Master Process Variable (MPV)

•1

Master Control Set Point (MSPt)

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in local control only.

Slave Control Output

[0 to 100%] (–10 to 110% for analog outputs)

Adjustable in manual mode only.

to change between local/remote set point values.

L

LR

SSPt

Manual Output

Slave PID

Control Loop

Note. With template 12 the

L

R

L

key can be used

OP1

Slave

Set Point

(SSPt)

450.2

500.0

Slave Process Variable (SPV)

Slave Set Point (SSPt)

['SPLO' to 'SPHI' – see Section 4.5]

Slave

Process

Variable

(SPV)

SLV

70

OP1

Adjustable in manual or local slave set point modes

only.

L

R

Note. The

L

key can be used in this frame to

change between cascade and local slave set points.

Continued…

•1 With the Ramping Set Point function enabled (see Section 3.3, Set Points/ Ramp Rate), the

bargraph shows the actual (ramping) set point value and the digital display shows the target set

point value.

21

Page 26

…2 OPERATOR LEVEL

…2.7 Cascade Control (Templates 11 and 12)

Master

Set Point

(MSPt)

Master

Process

Variable

(MPV)

Master

Set Point

(MSPt)

Master

Process

Variable

(MPV)

Slave

Set Point

(SSPt)

Slave

Process

Variable

(SPV)

MST

OP1

MST

OP1

SLV

OP1

rAtO

1.000

70

bIAS

0. 0

70

C.rtO

1.000

70

•1

•1

•2

Remote Set Point Ratio

[0.001 to 9.999]

Master remote set point value =

(ratio x remote set point input) + bias

Remote Set Point Bias

[in engineering units]

Cascade Slave Set Point Ratio

[0.001 to 9.999]

Slave set point (SSPt) value =

(ratio x master ouput) + bias [in engineering units]

Continued…

•1 Only displayed if template 12 selected and ratio/bias display enabled – see Section 4.2, Basic

Configuration and Section 4.7, Operator Configuration.

•2 Only displayed if ratio/bias display enabled – see Section 4.7, Operator Configuration.

22

Page 27

…2.7 Cascade Control (Templates 11 and 12)

2 OPERATOR LEVEL

Slave

Set Point

(SSPt)

Slave

Process

Variable

(SPV)

SLV

OP1

C.bIA

0. 0

70

•1

Cascade Slave Set Point Bias

[In engineering units]

Return to Master Process Variable (MPV) display

•1 Only displayed if ratio/bias display enabled – see Section 4.7, Operator Configuration.

23

Page 28

…2 OPERATOR LEVEL

2.8 Cascade with Feedforward (Template 13)

For cascade control, two internally-linked PID controllers are used, with the first (master) PID

controller providing the set point for the second (slave) controller. The feedforward disturbance

variable signal is added to the master output (slave set point). The disturbance signal is weighted by

the feedforward gain (FFGn) and the feedforward bias (FFbs) values.

Local Set Point

LSPt

MSPt

Master PV Input

I/P1

Feedforward Disturbance Variable

I/P3

Slave PV Input

I/P2

Master

Set Point

(MSPt)

MST

MPV

SPV

•1

450.2

500.0

Master

Process

Variable

(MPV)

OP1

L

R

L

FFGn

= 0

SSPt

∑

Master

PID

Control Loop

DV x FFGn + FFbS

Local Slave

Set Point

SSPt

M.OP x

CrtO + CbiA

Fig. 2.7 Cascade Controller with Feedforward

Master Process Variable (MPV)

•1

Master Control Set Point (MSPt)

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in Local control only

Slave Control Output

70

[0 to 100% (–10 to 110% for analog outputs)]

Adjustable in Manual mode only.

Manual

Output

Slave

PID

Control Loop

OP1

Slave

Set Point

(SSPt)

1997

2000

Slave Process Variable (SPV)

Slave Set Point (SSPt)

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in Manual mode only

L

R

Note. The

L

key can be used in this frame to

change between cascade and local slave set points.

Slave

Process

Variable

SLV

70

(SPV)

OP1

Continued…

•1 With the Ramping Set Point function enabled (see Section 3.3, Set Points/ Ramp Rate), the

bargraph shows the actual (ramping) set point value and the digital display shows the target set point

value.

24

Page 29

…2.8 Cascade with Feedforward (Template 13)

2 OPERATOR LEVEL…

Master

Set Point

(MSPt)

Master

Process

Variable

(MPV)

Slave

Set Point

(SSPt)

Slave

Process

Variable

(SPV)

Slave

Set Point

(SSPt)

Slave

Process

Variable

(SPV)

MST

FF

SLV

OP1

SLV

OP1

450.2

500.0

50

C.rtO

1.000

70

C.bIA

0. 0

70

Feedforward Disturbance Variable

Note. To disable feedforward action (e.g.

during system tuning), set the Feedforward Gain

parameter to 0FF – see Section 3.2, Tune.

[0 to 100%]

Feedforward disturbance variable input.

•1

•1

Cascade Slave Set Point Ratio

[0.001 to 9.999]

Slave set point (CSP2) value =

(ratio x master ouput) + bias [in engineering units]

Cascade Slave Set Point Bias

[In engineering units]

Return to Master Process Variable (MPV) display.

•1 Only displayed if enabled in Level B, Operator Configuration – see Section 4.7.

25

Page 30

…2 OPERATOR LEVEL

2.9 Ratio Controller (Templates 14 and 15)

Ratio control enables a controlled process variable to be maintained automatically in definite

proportion to another variable known as the wild variable. The wild variable, weighted by ratio (rAtO)

and bias (bIAS), values forms the control set point for the process variable.

L

LR

Local Ratio

•1

Remote Ratio

I/P3

Wild Variable

I/P2

Process Variable input

I/P1

•1 Template 15 only

Control

Set Point

Process

Variable

(PV)

OP1

Control

Set Point

Process

Variable

(PV)

55.0

50.0

70

bIAS

0. 0

70

rAtO

WV

WV

rAtO +bIAS

x

Fig. 2.8 Ratio Controller

•1

Manual Output

Control

CSPt

PV

PID

Control Loop

PID O/P

Output

OP1

Actual Ratio

Process Variable (PV) – Bias

=

Wild Variable (WV)

Desired Ratio

Adjustable in Local control only.

Control Set Point = (WV x Ratio) + Bias

Control Output

[0 to 100% (–10 to 110% for analog outputs)]

Adjustable in manual mode only.

Bias

[in engineering units]

OP1

Return to Actual Ratio display.

•1 Only displayed if enabled in Level B, Operator Configuration – see Section 4.7.

26

Page 31

2 OPERATOR LEVEL…

2.10 Ratio Station (Templates 16 and 17)

The ratio station provides a set point for a subsequent slave controller. The wild variable (WV) is

weighted by ratio (rAtO) and bias (bIAS) values and is then retransmitted as an analog output value.

L

LR

Local Ratio

•1

Remote Ratio

I/P3

Wild Variable

I/P2

•1 Template 17 only

rAtO

WV

Fig. 2.9 Ratio Station

Manual Output

rAtO +bIAS

WV x

Analog

Output

OP1

Wild

Variable (WV)

Process

Variable

(PV)

OP1

Variable (WV)

Process

Variable

(PV)

OP1

55.0

50.0

70

bIAS

0.0

70

Actual Ratio

Process Variable (PV) – Bias

=

Wild Variable (WV)

Desired Ratio

Adjustable in local control only.

Ratio Setpoint Output

= (WV x Ratio) + Bias

[–10 to 110%]

Adjustable in manual control only.

•1Wild

Bias

[In engineering units]

Return to Actual Ratio display.

•1 Only displayed if enabled in Level B, Operator Configuration – see Section 4.7.

27

Page 32

…2 OPERATOR LEVEL

2.11 Heat/Cool Output Types

2.11.1 Reverse (Heat)/Direct (Cool) or Direct (Heat)/Reverse (Cool)

The active output, either OP1 (Heat) or OP2 (Cool) is displayed and may be adjusted in manual

mode. The OP1 and OP2 l.e.d.s indicate which output is changing.

–100%

OP2 (cool)

0%

Y2.St Y1.St

Fig. 2.10 Typical Response – Reverse/Direct or Direct/Reverse Control Action

450.2

500.0

50

OP1

OP1 (heat)

Output Positive (Heat Output Active)

Heat output

[0 to 100% (0 to 110% in manual mode with analog

outputs)]

Adjustable in manual mode only.

Output Negative (Cool Output Active)

+100%

PID O/P

100%

28

OP2

–50

Cool output

[–100 to 0% (–110 to 0% in manual mode with

analog outputs)]

Adjustable in manual mode only.

Page 33

2 OPERATOR LEVEL…

2.11.2 Reverse (Heat)/Reverse (Cool) or Direct (Heat)/Direct (Cool)

It is not possible to view or adjust the heat/cool outputs directly. The PID output (0 to 100%), used to

calculate the heat (OP1) and cool (OP2) outputs, is displayed and may be adjusted in manual mode.

The OP1 and OP2 l.e.d.s indicate which output is changing.

100%

OP2

(cool)

0%

OP2 l.e.d. lit OP1 l.e.d. lit

Fig. 2.11 Typical Response – Reverse/Reverse or Direct/Direct Control Action

Y2.St

Y1.St

OP1

(heat)

PID O/P

2.12 Motorized Valve Output Types

2.12.1 Motorized Valve with Feedback

450.2

Valve Position Display

500.0

[0 to 100% of travel]

75

Valve opening

Valve stopped

Valve closing

Note. In manual mode, the and keys

can be used to drive the valve open and valve close

relays directly.

100%

0%

2.12.2 Motorized Valve without Feedback (Boundless)

Valve State Display

OPN Valve opening

StP Valve stopped

StP

Valve opening

Valve stopped

Valve closing

CLS Valve closing

Note. In manual mode, the and keys

can be used to drive the valve open and valve close

relays directly.

29

Page 34

…2 OPERATOR LEVEL

2.13 Auto-tune

Note. Auto-tune is not available for Auto/Manual Station, Indicator or Ratio Station

templates, or when boundless or heat/cool control types are selected.

Information.

• Auto-tune optimizes process control by manipulating the COMMANDER 500 output and then

monitoring the process response.

• At the end of an auto-tune, the control parameters are updated automatically.

• Before starting auto-tune, the process variable must be stable.

• The COMMANDER 500 monitors the noise level of the process variable for 30 seconds and if

it is greater than 2% of the engineering range the auto-tune is aborted.

• The COMMANDER 500 selects either 'start-up' or 'at set point' tuning automatically, depending

upon the level of the process variable relative to the control set point.

2.13.1 Start-up Auto-tune

If the process variable is more than ±10% from the set point, 'start-up' tuning is carried out.

• 'Start-up' tuning – steps the output to drive the process towards the set point. The process

response to this step change is monitored and PID parameters are calculated.

• The output step applied = % deviation from the set point x 1.5.

• If no errors exist, the COMMANDER 500 enters auto mode and begins to control the process

using the new PID parameters.

• If an error occurs during the auto-tune, the COMMANDER 500 reverts to manual mode with the

control output set to the default output value. An error message is displayed in the operator

level – see Table 2.1.

1

PV

>10% span

+2%

– 2%

A – Stable process before auto-tune

SPT

PV

t

B – Process response during auto-tune

/4 wave

damping

Controlling to Set Point

Auto-tune complete

Fig 2.12a Typical 'Start-up' Auto-tune Cycles

rorrEnoitpircseDrorrEnoitpircseD

1enut-otuagniruddeliafVP7

2

pets

3enut-otuaotysionootssecorP9edomnoitarugifnocotnituprellortnoC

4enut-otuaottsafootssecorP01resuybdetanimretenut-otuA

5

6

.)selcyc-flahneewteb

enut-otuanagnirudtuodemitsahenut-otuA

8)enut-otua'putratS'(dedeecxetimilVP

sruoh21xam(enut-otuaotwolsootssecorP

11

.gne%52>ybtnioptesmorfdetaivedVP

tsetesnopserycneuqerfgnirudnaps

egnarfo

tsetpets

Table 2.1 Auto-tune Error Codes

30

SPT

t

tuodetaluclacsaweulavDroI,PtnatluserA

gnirudnoitceridgnorwehtnignignahcsiVP

Page 35

2 OPERATOR LEVEL…

2.13.2 'At Set Point' Auto-tune

If the process variable is within 10% of the set point, 'at set point' tuning is carried out.

• 'At set point' tuning – manipulates the control output to produce a controlled oscillation of the

process.

• A step change of ±10% of the starting output value is applied initially. This is adjusted to give an

amplitude of oscillation 3 times the noise level.

• Once the amplitude and period of oscillation are consistent (minimum 2 cycles, maximum 4

cycles) PID parameters are calculated.

• If no errors exist the controller enters auto mode and begins to control the process using the new

PID parameters.

• If an error occurs during the auto-tune, the controller reverts to manual mode with the control

output set to the default output value. An error message is displayed in the operator level –

see Table 2.1.

PV

+2%

– 2%

< ±10 span

A – Stable process before auto-tune

SPT

PV

t

B – Process response during auto-tune

12 hours max.

SPT

Controlling to

Set Point

Auto-tune

complete

t

Fig 2.12b Typical 'At Set Point' Auto-tune Cycles

Note. The time taken to complete auto-tune depends upon the system response time.

Notes For Special Cases.

Cascade Control – the slave loop must be tuned before the master loop. The slave must be

placed into local set point mode (cascade disabled) and the slave set point adjusted to the

required value prior to tuning.

Feedforward Control – during an auto-tune with a controller with feedforward the feedforward

signal is not applied. The feedforward gain and bias values are not changed by the auto-tune and

must be adjusted separately.

Time Proportioning – the cycle time must be set prior to running an auto-tune. The cycle time is

not changed by the auto-tune.

31

Page 36

…2 OPERATOR LEVEL

2.13.3 Auto-tune

1..xx

1.xx

1.xx

xxxx

xxxx

COdE

AtNE

OFF

Accessing the Auto-tune Facility

From any operating frame, press and hold the key

until the 'COdE' frame is displayed.

1

Set the correct auto-tune password.

Auto-tune Enable

Select the type of auto-tune required.

Single Loop Templates Cascade Templates

OFF – Off SLV.A – Slave type A

A – Type A SLV.b – Slave type B

b – Type B MSt.A – Master type A

MSt.b – Master type B

Auto-tune is started automatically when the key is

pressed.

Auto-tune can be stopped at any time by pressing the

key.

Note. Slave control loops only – place the slave

into local set point mode and adjust the set point to the

required value prior to autotuning.

32

PV

xxxx

xxxx

x

1

Type A –

x

2

1

wave damping

/

4

Note. P + I control only – set the derivative term

to 'OFF' in the Tuning Level – see Section 3.2.

Return to the Operating Level.

PV

Set point

x

1

2

=

4

x

1

Fig. 2.13 Autotune Types

Set Point

Type B – Minimum Overshoot

Page 37

2 OPERATOR LEVEL…

2.14 Control Efficiency Monitor

Note. With cascade control, the Control Efficiency Monitor is applicable only to the master

controller.

The Control Efficiency Monitor can be used either to compare the relative performance with different

tuning parameters, or when fine tuning the PID settings, to give optimum control.

When the set point is changed, auto mode is selected or following a power failure, input failure or a

large load disturbance, the control monitor performs a series of measurements to indicate the

effectiveness of the current control parameters.

General guidelines are shown in Table 2.2.

Parameter

Rate of

Approach

Overshoot

Decay Ratio

Settling Time

Error Integral

Ideal

Setting

Fast

Small

Small

Short

Small

Actual

Setting

Too slow

Too large

Too large

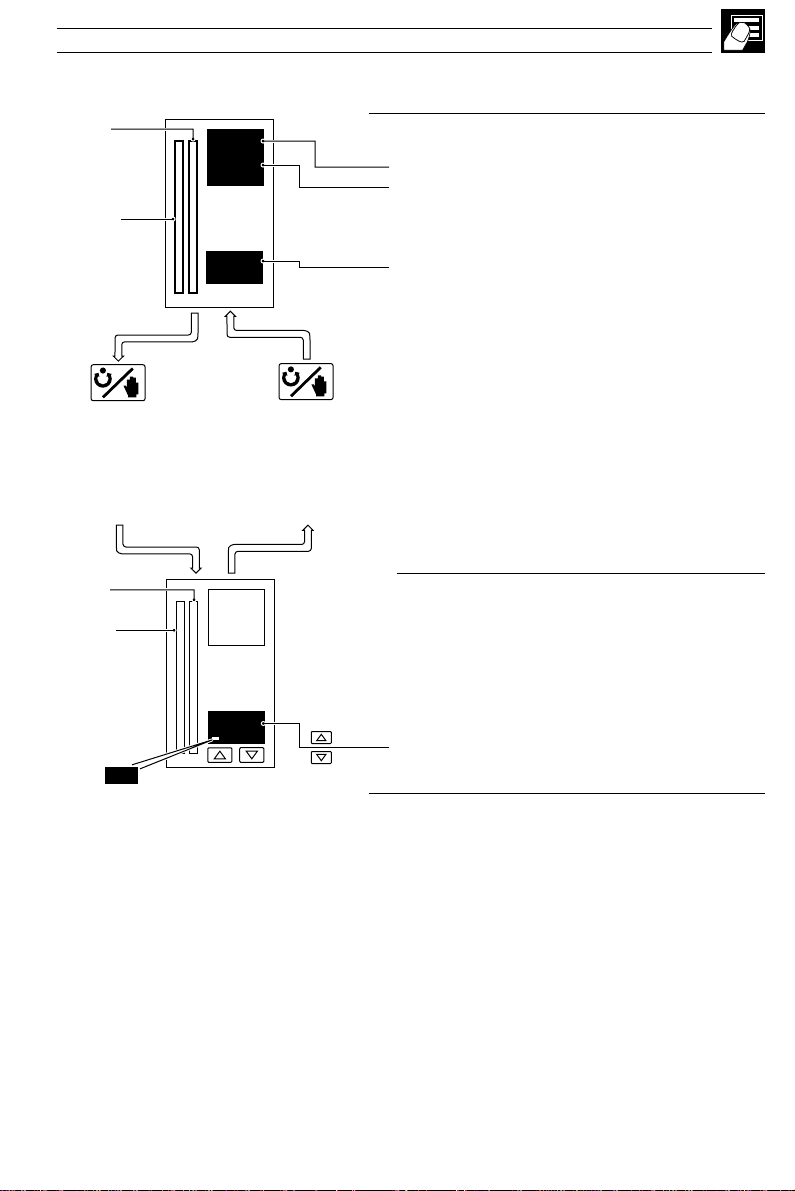

(Oscill-

atory)

Too long

Too large

Effect on Response

Action

• Decrease proportional band

• Decrease integral time

• Increase derivative time

• Increase proportional band

• Increase derivative time

• Increase proportional band

• Increase integral time

• Increase proportional band

• Decrease integral time

If large overshoot and

oscillatory then:

• Increase proportional band

• Increase integral time

• Increase derivative time

If slow approach and

overdamped then:

• Decrease proportional band

• Decrease integral time

Table 2.2 Control Efficiency Monitor Settings

33

Page 38

…2 OPERATOR LEVEL

…2.14 Control Efficiency Monitor

t

x

period

PV

y

2

1

95%

y

1

x

2

+2%

Set Point

–2%

t

Start of

Calculation

approach

t

settle

5%

t

Fig. 2.14 Control Efficiency Monitor Parameters

2.14.1 Manual Tuning

The Control Efficiency Monitor may be used for manually tuning the PID parameters. The following

method describes how to tune the controller for 1/4 wave damping:

a) Set the integral and derivative action times to OFF.

b) Set the proportional band (PB) to a low setting.

c) Apply a small set point change.

d) Use the Control Efficiency Monitor to note the decay ratio.

e) If the decay ratio > 0.25, increase the Proportional Band until decay ratio = 0.25

If the decay ratio < 0.25, decrease the Proportional Band until decay ratio = 0.25

f) Leave the proportional band at the setting which gives 0.25 decay ratio and, using the Control

Efficiency Monitor, note the period between peaks.

g) Calculate and set the following parameters:

Integral action time = Period/1.5

Derivative action time = Period/6

Note. The manual tuning facility must not be used with boundless motorized valve control, as

an Integral Action Time is required for these applications.

34

Page 39

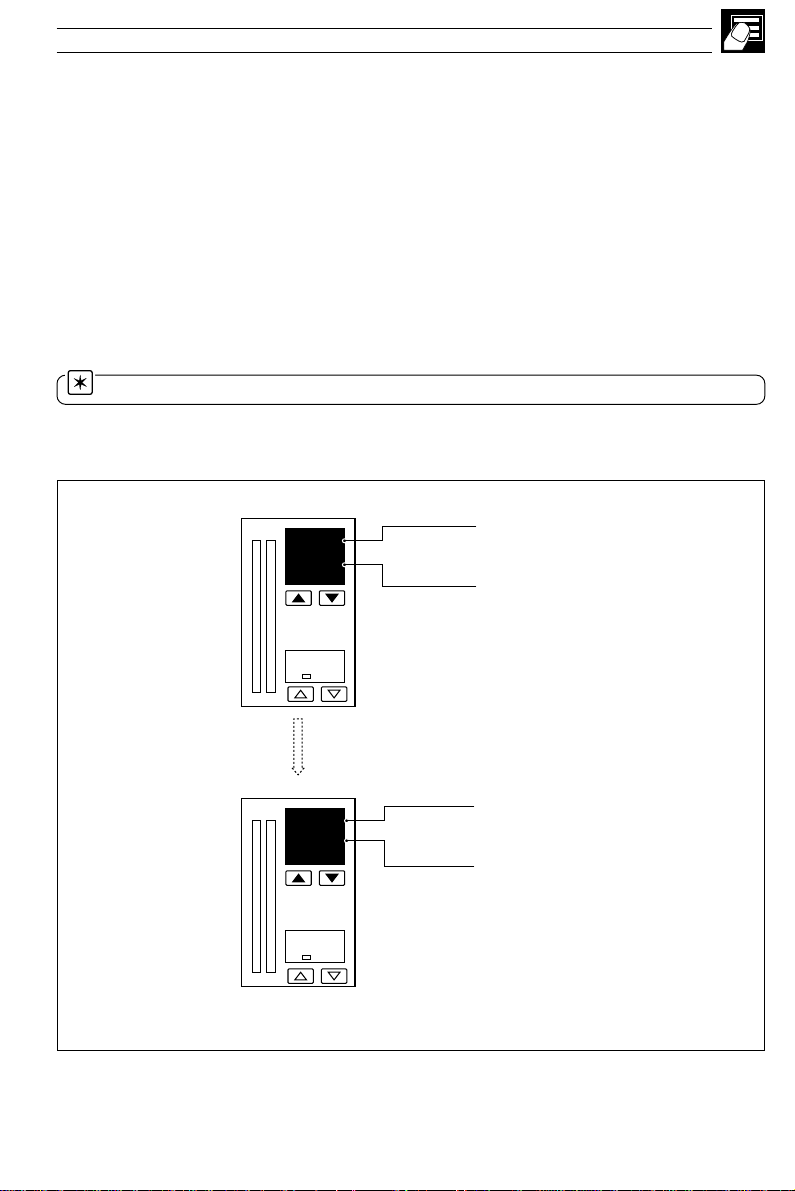

2.14.2 Using the Control Efficiency Monitor

450.2

500.0

Press and hold the lower and keys for 2 seconds.

2 OPERATOR LEVEL…

70

+

rAtE

10.1

OVEr

10

rAtO

0.25

Prd

35

SEtL

0.3

Note.

If the front panel keys are not operated for 60 seconds whilst any

Control Efficiency Monitor frame is being displayed, the instrument

reverts to the first operating frame.

Rate of Approach to Set Point

The rate of change of the process variable between 5 and 95% of the

step change (Y2), measured in engineering units per minute.

Rate of approach =

Overshoot

The maximum error, expressed as a percentage of the set point.

Overshoot =

Decay Ratio

The ratio of the amplitude of the first and second overshoots.

Ratio =

Period

The time (in seconds) between the first two peaks (t

Settling Time

The time taken (in minutes) for the process variable to settle within

±2% of the set point value (t

Set Point

X2

X1

Y1

t

approach

X

1

x100

).

period

).

settle

450.2

500.0

IAE

2.1

Error Integral

The integral of the error value until the process variable settles to

within ±2% of the set point value in 'engineering-unit hours'.

t

Error integral =

Return to the first operating frame.

settle

|PV – SP|dt

0

35

Page 40

8

3 SET UP MODE

3.1 Introduction

To access the Set Up mode (Levels 2 to 5) the correct password must be entered in the security code frame.

Press

450.2

500.0

and hold

COdE

50

AtNE

OFF

LEV1

OPEr

LEV2

LEV3

70

450.2

500.0

70

LEV1

OPEr

Tuning

Cycle time, output 1 & 2

On/off hysteresis values

Proportional bands 1 to 4

Integral action times 1 to 4

Derivative action times 1 & 2

Manual reset value

Feedforward gain and bias

Control deadband

Heat Cool Output 1 & 2 Start

Set Points

Local set point values 1 to 4

Slave set point value

Remote set point ratio/bias

Cascade set point ratio/bias

Ramp rate

Fig. 3.1 Set Up Mode – Overview

Invalid

password

Valid Set Up or

Configuration

password

LEV2

tUNE

LEV4

LEV5

LEV5

VLVE

Alarm Trip Points

Alarm 1 to 8 trip points

Motorized Valve Set Up

With feedback:

Feedback ratio/bias

Deadband

Regulator travel time

Boundless:

Deadband

Regulator travel time

36

Frame number

2.xx

– Level 2

3.xx

– Level 3 etc.

450.2

500.0

2.00

2.00

2.01

Parameter

Fig. 3.2 – Scroll Display Overview

LEV.2

tUNE

CYC.1

1.0

Default

value

Parameter

adjustment

450.2

500.0

2.00

450.2

500.0

2.00

Page 41

3 SET UP MODE…

8

3.2 Level 2 – Tune

Note. Level 2 is not applicable if an Auto/Manual Station, Indicator or Ratio Station template is selected.

2.00

2.01

2.02

2.03

LEV.2

tUNE

CYC.1

1.0

CYC.2

1.0

HYS1

0

•1

•1

•2

•3

Level 2 – Tune

Note. To select this frame from anywhere in this page, press and

hold the

Cycle Time Output 1

[1.0 to 300.0 seconds for time proportioning or 'OnOF' for on/off control]

control or with cascade templates.

Cycle Time Output 2 (Cool)

[1.0 to 300.0 seconds for time proportioning or 'OnOF' for on/off control]

templates.

Output 1 On/Off Hysteresis Value

[In engineering units]

PV

ON

OFF

key for a few seconds.

Note. On/off Control is not available on output 1 with heat/cool

Note. On/off Control is not available on output 2 with cascade

Set Point

Hysteresis

Value

Reverse Acting

Control Output

PV

ON

OFF

2.00...2.04

Hysteresis

Value

Set Point

Direct Acting

Control Output

2.04

HYS2

•4

0

•1 Only displayed if Relay or Digital output type is selected – see Section 4.2, Basic Configuration/ Output Type.

•2 Only displayed if Heat/Cool output type is selected.

•3 Only if On/Off control is selected – see parameters 2.01 and 2.02 above.

•4 Only displayed if Heat/Cool output type is select and the 'CYC.2' parameter is set to 'OnOF'.

Output 2 On/Off Hysteresis Value

[0% to (Y1.St – Y2.St)%] – see parameters 2.22 and 2.23

100%

Output 2

Hys 2

Y2.St

Continued on next page

Y1.St

Output 1

PID Output

37

Page 42

8

…3 SET UP MODE

…3.2 Level 2 – Tune

2.05

Pb-1

•1

100.0

2.06

2.08

Pb-2

100.0

Pb-4

•1

•2

•3

100.0

2.09

IAt.1

OFF

2.10

IAt..2

•2

OFF

2.05...2.13

Proportional Band 1

Enter the value for Proportional Band 1.

[0.1% to 999.9%]

'Pb-1' is the default proportional band and is the proportional band for the

master controller if a cascade template is selected – see Section 4.2 Basic

Configuration/ Template Application.

Proportional Band 2, 3 and 4

Enter the value for Proportional Band 2, 3 and/or 4.

[0.1% to 999.9%]

'Pb-2' is the proportional band for the slave controller if a cascade

template is selected – see Section 4.2, Basic Configuration/ Template

Application.

Integral Action Time 1

[1 to 7200 seconds or 'OFF']

'IAt.1' is the default integral action time and is the integral action time for

the master controller if a cascade template is selected – see Section 4.2,

Basic Configuration/ Template Application.

Integral Action Time 2, 3 and 4

[1 to 7200 seconds or 'OFF']

2..12

IAt.4

•3

OFF

2.13

drV1

OFF

•1 Heat/cool outputs use a common proportional band. The default is 'Pb-1'.

•2 Only displayed if a cascade template or a tune parameter source is selected – see Section 4.2, Basic

Configuration/ Template Application and Section 4.6, Control Configuration/ Tune Parameter Source.

•3 Only displayed if a tune parameter source is selected – see section 4.6, Control Configuration/ Tune

Parameter Source.

38

'IAt.2' is the integral action time for the slave controller if a cascade

template is selected – see Section 4.2, Basic Configuration/ Template

Application.

Derivative Action Time 1

[0.1 to 999.9 seconds or 'OFF']

'drV.1' is the derivative action time for the master controller if a cascade

template is selected – see Section 4.2, Basic Configuration/ Template

Application.

Continued on next page.

Page 43

3 SET UP MODE…

8

…3.2 Level 2 – Tune

2.14

drV2

•1

OFF

2.15

Ab.1

•2

1.0

2.16

Ab.2

•1

1.0

2.17

rSt.1

•3

50.0

2.18

rSt.2

•1

50.0

2.14...2.19

Derivative Action Time 2

[0.1 to 999.9 seconds or 'OFF']

The derivative action time for the slave controller if a cascade template is

selected – see Section 4.2, Control Configuration/ Template Application.

Approach Band 1

[0.1 to 3.0 proportional bands]

This parameter limits when derivative action time 1 is applied. When the

process variable is outside the approach band, derivative action is not applied.

•2

•3

Approach Band 2

[0.1 to 3.0 proportional bands]

This parameter limits when derivative action time 2 is applied to the slave

control loop when a cascade template is selected.

Manual Reset Value 1

The value applied to bring the master control output to the zero error point

under normal load conditions (integral action disabled) or the offset

applied to the control output (integral action enabled).

[0.0 to 100%]

Note. Manual reset is applied whether or not an integral action time

is set.

Manual Reset Value 2

As

Manual Reset Value 1, but applied to the slave output.

[0.0 to 100%]

Note. Manual reset is applied whether or not an integral action time

is set.

2.19

FFGn

•4

1.0

•1 Only displayed if a cascade template is selected – see Section 4.2, Basic Configuration/ Template Application.

•2 Not displayed if the associated derivative action time is set to OFF.

•3 If manual control is selected and no integral action time is set, the manual reset value is calculated

automatically to give bumpless transfer into auto control.

•4 Only displayed if a feedforward template is selected – see Section 4.2, Basic Configuration/ Template Application.

Feedforward Gain

The feedforward value applied to the control output is: (disturbance

variable x feedforward gain) + bias. When set to OFF, feedforward action

is disabled.

[0.1 to 999.9 or OFF]

Note. The feedforward value is normally added to the PID output. Using

the PC Configurator, the value can also be multiplied by the PID output.

Continued on next page.

39

Page 44

8

…3 SET UP MODE

…3.2 Level 2 – Tune

2.20

FFbS

•1

0.0

2..21

Cbnd

OFF

2...22

Y1.St

•2

50.0

2.20...2.23

Feedforward Bias

[–100.0% to 100.0%]

Control Deadband

When the process variable is in the deadband, changes to the control

output due to proportional and integral action are suppressed. When a

cascade template is selected, the control deadband is applied to the

master output only.

[In engineering units or 'OFF']

Set Point

Process Variable

Heat/Cool Output 1 Start

This parameter defines the PID output value above which Output 1 (heat)

becomes active.

[0.0 to 100.0%]

Deadband

Control Output

2...23

Y2.St

50.0

Reverse-direct

Output 2

0%

or direct-reverse

Y2.St Y1.St

PID Output

Output 1

100%

100%

0%

100%

0%

•2

Heat/Cool Output 2 Start

This parameter defines the PID output value below which Output 2 (cool)

becomes active.

[0.0 to ≤ Y1st %] – see Heat/Cool Output 1

Output 2

0%

Reverse-reverse

or direct-direct

Y2.St Y1.St

PID Output

Output 1

100%

LEV2

tUNE

Return to top of page

•1 Only displayed if a feedforward template is selected – see Section 4.2, Basic Configuration/ Template Application.

Not applied to Control Output when Feedforward Gain (frame 2.19) is set to 'OFF'.

•2 Only displayed if a Heat/Cool output type is selected – see Section 4.2, Basic Configuration/ Output Type.

40

Page 45

3 SET UP MODE…

8

3.3 Level 3 – Set Points

Note. Level 3 is not applicable if Auto/Manual Station or Indicator templates are selected.

3.00

3.01

3.02

3.04

3.05

LEV.3

SEtP

LSP1

500

LSP2

200

LSP4

400

S.SPt

300

•1

•1

•2

•1

•2

•3

Level 3 – Set Points

Note. To select this frame from anywhere in this page, press and

hold the

Local Set Point Value 1

Set the default local set point value.

[Within set point high and low limits, in engineering units – see Level 9]

Local Set Point Values 2 to 4

[Within set point high and low limits, in engineering units – see Level 9]

Cascade Slave Set Point Value

Set the slave set point value.

[Within slave set point high and low limits, in engineering units]

Only adjustable in Manual mode.

key for a few seconds.

3.00...3.07

3.06

rAtO

•4

1.000

3.07

BIAS

•4

0

•1 Not displayed for ratio controller or ratio station templates.

•2 Displayed only if a local set point source is selected – see Section 4.5/ Set Point Configuration/ Local/Remote

Set Point Source.

•3 Only displayed if a cascade template is selected.

•4 Displayed only for templates with a remote set point.

Remote Set Point Ratio

The remote set point value is

(ratio x remote set point input) + bias.

[0.001 to 9.999]

Remote Set Point Bias

[In engineering units]

Continued…

41

Page 46

8

…3 SET UP MODE

…3.3 Level 3 – Set Points

3.08

C.rtO

•1

1.000

3.09

C.bIA

•1

0

3.10

r.rtE

OFF

LEV3

SEt.P

3.08...3.10

Cascade Set Point Ratio

In automatic mode, the slave set point value is:

(ratio x master output) + bias.

[0.001 to 9.999]

Cascade Set Point Bias

[In engineering units]

Ramp Rate

[1 to 9999 engineering units per hour, or OFF]

The Ramping Set Point facility can be used to prevent a large disturbance

to the control output when the set point value is changed. The rate set

applies to both the local and the remote set points.

PV

300

200

100

0

* e.g. Ramp Rate = 200 Increments/Hour

Displayed Local Set Point Value

Actual (Ramping) Set Point Value

used by PID Algorithm*

1 Hour

Time

Return to top of page.

•1 Displayed only if a Cascade template is selected – see Section 4.2, Basic Configuration/ Template Application.

42

Page 47

3 SET UP MODE…

8

3.4 Level 4 – Alarm Trip Points

Note. Level 4 is not applicable if all alarm types are set to 'None' – see Section 4.4, Alarms/ Alarm Type.

4.00

4.01

LEV.4

triP

1.xxx

•1

0

Level 4 – Alarm Trip Points

Note. To select this frame from anywhere in this page, press and

hold the

Alarm 1 Trip

Alarm Number and Type

Trip Value

[In engineering units]

template is selected, Alarm 1 is set automatically as a low process alarm

on Analog Input 2.

key for a few seconds.

yalpsiDnoitpircseDyalpsiDnoitpircseD

enoN

ENON

VPH

VPL

PLH

PLL

dH

dL

1PH

1PL

2PH

2PL

3PH

Note. When an auto/manual station template or analog backup

VP,ssecorPhgiH

VP,ssecorPwoL

VP,hctaLhgiH

VP,hctaLwoL

noitaiveDhgiH

noitaiveDwoL

1P/IssecorPhgiH

1P/IssecorPwoL

2P/IssecorPhgiH

2P/IssecorPwoL

3P/IssecorPhgiH

3PL

OH

OL

1bH

1bL

2bH

2bL

3bH

3bL

4bH

4bL

4.00...4.08

3P/IssecorPwoL

tuptuOhgiH2•

tuptuOwoL2•

hgiH1kcolBshtaM

woL1kcolBshtaM

hgiH2kcolBshtaM

woL2kcolBshtaM

hgiH3kcolBshtaM

woL3kcolBshtaM

hgiH4kcolBshtaM

woL4kcolBshtaM

4.02

2.xxx

•1

0

4.08

8.xxx

•1

0

LEV.4

trIP

•1 Not displayed if alarm type set to 'None' – see Section 4.4, Alarms/ Alarm Type.

•2 Applies to PID output with single or heat/cool outputs.

Alarm 2 to Alarm 8 Trip

Alarm Number and Type

See Alarm 1.

Trip Value

[In engineering units]

Return to top of page.

43

Page 48

8

…3 SET UP MODE

3.5 Level 5 – Valve Setup

Note. Level 5 is applicable only for a motorized valve output type – see Section 4.2, Basic Configuration/

Output Type.

PV

PID

Control

Terms

SPt

3.5.1 Valve Setup (Feedback Types)

5.00

LEV.5

U.LU.E

5..01

5.02

VrAt

VbIA

PID

Output

Fig. 3.3 Motorized Valve Output with Feedback – Schematic

(PID O/P x

0

0

V.rAt

V.bIA

+

Level 5 – Valve Setup

Note. To select this frame from anywhere in this page, press and

hold the

Motorized Valve Ratio and Bias

Desired valve position = (Ratio x PID output) + Bias

Motorized Valve Ratio

[0.01 to 10.00]

Motorized Valve Bias

[–100.0 to 100.0%]

Valve

)

Controller

Position Feedback

key for a few seconds.

Open relay

Close relay

5.00...5.04

Process

5.03

5.04

44

LEV.5

VLVE

d.bnd

1..0

r.trU.

30

Motorized Valve Deadband

[0.0 to 100% of the position feedback span]

Position %

Required valve position

Example. If the valve is set to be driven to the 50% open position and the

deadband is set to 4%, the motor stops driving when the position feedback

is 48%. The deadband is between 48% and 52%.

Regulator Travel Time

The time entered is compared with the actual travel time. If the valve is

sticking an error message is generated.

[0 to 5000 seconds, 0 = no check]

Return to top of page.

Deadband

(centered around

required position)

Page 49

3 SET UP MODE…

8

3.5.2 Valve Setup (Boundless Types) – Fig. 3.4

A ‘boundless’ process controller provides an output that is effectively the time derivative of the required regulator

position, i.e. the COMMANDER 500 signals the regulator, not where to go to (position derivative), but in which

direction to travel and how far to move, by a series of integral action pulses. Thus, the COMMANDER 500 does

not need to know the absolute regulator position and is unaffected when regulator reaches the upper or lower limit,

as determined by the regulator’s limit switches (giving rise to the term ‘boundless’).

When a deviation from set point is introduced the regulator is driven, for a length of time equivalent to the

proportional step. The regulator is then driven by integral action pulses until the deviation is within the deadband

setting.

Control

Deviation

Raise

Lower

+

–

Integral

Action Pulses

Proportional

Step

Fig. 3.4 Boundless Control Action

Proportional

Step

Proportional

Integral

Action Pulses

Time

Step

Time

Calculation for Control Pulses (Boundless Control)

The following calculations are shown for guidance when setting deadband, proportional and integral values. They

can be used to check the suitability of boundless control for a particular actuator/application.

Minimum 'ON' time of integral action pulses (for a fixed control deviation).

Travel Time x Deadband %

=

% Proportional Band

Minimum (approximate) time between integral action pulses (for a fixed control deviation)

Integral Action Time x Deadband %

=

Duration of the proportional step

= 2 x

2 x % Control Deviation

% Control Deviation

% Proportional Band

(in seconds)

(in seconds)

x Travel Time in Seconds

% Control Deviation

Set Point – Process Variable

=

% Deadband

=

Eng Hi – Eng Lo

Deadband (eng units)

Eng Hi – Eng Lo

x 100%

x 100%

45

Page 50

8

…3 SET UP MODE

…3.5.2 Valve Setup – Boundless

5.00

LEV.5

U.LU.E

5.03

d.bnd

0

5..04

r.trU.

0

LEV.5

VLVE

5.00...5.04

Level 5 – Valve Setup

Note. To select this frame from anywhere in this page, press and

hold the

Boundless Deadband

[In engineering units]

Regulator Travel Time

The time taken for the regulator to travel from the fully open to the fully

closed position