Page 1

AF09 ... AF80 4-pole contactors

Technical data

Main pole - Utilization characteristics according to IEC

Contactor types

Standards IEC 60947-1 / 60947-4-1 and EN 60947-1 / 60947-4-1

Rated operational voltage Ue max. 690 V

Rated frequency (without derating) 50 / 60 Hz

Conventional free-air thermal current Ith

acc. to IEC 60947-4-1, open contactors, θ ≤ 40 °C

With conductor cross-sectional area 6 mm² 6 mm² 16 mm² 16 mm² 35 mm² 35 mm² 50 mm²

AC-1 Utilization category

For air temperature close to contactor

Ie / Rated operational current AC-1

Ue max. ≤ 690 V, 50/60 Hz

With conductor cross-sectional area 4 mm² 6 mm² 10 mm² 16 mm² 35 mm² 35 mm² 50 mm²

AC-3 Utilization category

For air temperature close to contactor θ ≤ 60°C

Ie / Max. rated operational current AC-3 (1)

5

M

3-phase motors

3

Rated operational power AC-3 (1)

M

3

Rated making capacity AC-3 10 x Ie AC-3 acc. to IEC 60947-4-1

Rated breaking capacity AC-3 8 x Ie AC-3 acc. to IEC 60947-4-1

Short-circuit protection device for contactors

Without thermal overload relay - Motor protection excluded

Ue ≤ 500 V AC - gG type fuse 25 A 32 A 50 A 63 A 80 A 110 A 160 A

Rated short-time withstand current Icw

At 40 °C ambient temperature,

in free air from a cold state

Maximum breaking capacity

cos φ = 0.45

Power dissipation per pole

Max. electrical switching frequency

(1) For the corresponding kW/A values of 1500 r.p.m, 50 Hz or 1800 r.p.m, 60 Hz, 3-phase motors, see "Motor Rated Operational Powers and Currents"

(2) For the protection of motor starters against short circuits, see "Coordination with Short-circuit Protection Devices".

(3) 400 V 3-phase motors only.

1500 r.p.m. 50Hz

1800 r.p.m. 60Hz

3-phase motors

N.O. main pole

N.C. Main pole

AC / DC operated

θ ≤ 40 °C

θ ≤ 60 °C

θ ≤ 70 °C

220-230-240V

380-400V

415V

440V

500V

690V

220-230-240V

380-400V

415V

440V

500V

690V

1 s

10 s

30 s

1 min

15 min

at 440 V

at 690 V

at 440 V

at 690 V

Ie / AC-1

Ie / AC-3

AC-1

AF09 AF16 AF26 AF38 AF40 AF52 AF80

35 A 35 A 55 A 55 A 105 A 105 A 125 A

25 A 30 A 45 A 55 A 70 A 100 A 125 A

25 A 30 A 40 A 45 A 60 A 80 A 105 A

22 A 26 A 32 A 37 A 50 A 70 A 90 A

9 A 18 A 23.2 A 23.2 A 40 A 53 A 80 A

9 A 18 A 22 A 22 A 40 A 53 A 80 A

9 A 18 A 21.2 A 21.2 A 40 A 53 A 80 A

9 A 18 A 20 A 20 A 40 A 53 A 80 A

9.5 A 15 A 17.6 A 17.6 A 35 A 45 A 65 A

7 A 10.5 A 10.5 A 10.5 A 25 A 35 A 49 A

2.2 kW 4 kW 5.5 kW 5.5 kW 11 kW 15 kW 22 kW

4 kW 7.5 kW 11 kW (3) 11 kW (3) 18.5 kW 22 kW 37 kW

4 kW 9 kW 11 kW 11 kW 22 kW 30 kW 45 kW

4 kW 9 kW 11 kW 11 kW 22 kW 30 kW 45 kW

5.5 kW 9 kW 11 kW 11 kW 22 kW 30 kW 45 kW

5.5 kW 9 kW 9 kW 9 kW 22 kW 30 kW 45 kW

300 A 300 A 450 A 450 A 1000 A 1000 A 1200 A

150 A 150 A 300 A 300 A 600 A 600 A 780 A

80 A 80 A 225 A 225 A 350 A 350 A 450 A

60 A 60 A 150 A 150 A 250 A 250 A 300 A

35 A 35 A 55 A 55 A 110 A 110 A 140 A

250 A 250 A - - 950 A 950 A 1100 A

106 A 106 A - - 600 A 600 A 750 A

----600 A - 900 A

----300 A - 750 A

0.8 W 1.2 W 1.6 W 2.3 W 3 W 6.3 W 8 W

0.1 W 0.35 W 0.42 W 0.42 W 1 W 1.7 W 3.2 W

600 cycles/h

5/220 | ABB

1SBC101989S0201 - Rev. B

Page 2

AF09 ... AF80 4-pole contactors

Technical data

Main pole - Utilization characteristics according to UL/NEMA/CSA

Contactor types

Standards UL 508, CSA C22.2 N°14 UL 60947-4-1, CSA-C22.2 No. 60947-4-1

Max. operational voltage 600 V

UL / CSA general use rating

With conductor cross-sectional area

1 pole

2 poles in serie

3 poles in serie

4 poles in serie

With conductor cross-sectional area AWG 10 AWG 10 AWG 8 AWG 8 AWG 6 AWG 4 AWG 2

Max. electrical switching frequency

For general use 600 cycles/h

Note: 4-pole contactors fitted with 2 N.O. + 2 N.C. main poles, see "General technical data".

(1) 20 A for AF09..-22-00 and AF16..-22-00.

5

AC / DC operated

600 V AC

80 V DC

160 V DC

240 V DC

320 V DC

AF09 AF16 AF26 AF38 AF40 AF52 AF80

25 A 30 A 45 A 55 A 60 A 80 A 105 A

AWG 10 AWG 10 AWG 8 AWG 6 AWG 6 AWG 4 AWG 2

25 A (1) 30 A (1) 45 A 55 A 60 A 80 A 105 A

25 A (1) 30 A (1) 45 A 55 A 60 A 80 A 105 A

25 A 30 A 45 A 55 A 60 A 80 A 105 A

25 A 30 A 45 A 55 A 60 A 80 A 105 A

Main pole utilization characteristics - 4 N.O. non-reversing contactors

Contactor types

Lighting application - UL / CSA - breaking all lines

Electrical discharge lamps (ballast)

1-phase per pole

3-phase break all lines

Elevator control, load switching, 500 000 electrical operating cycles

acc. to CSA B44.1 / ASME 17.5 paragraph 19.2.1

1-phase

Horse power rating

3-phase

Horse power rating

Note: 4-pole contactors fitted with 2 N.O. + 2 N.C. main poles, see "General technical data".

AC / DC operated

347 V AC

600 V AC

110-120 V AC

220-240 V AC

200-208 V AC

220-240 V AC

440-480 V AC

550-600 V AC

AF09 AF16 AF26 AF38 AF40 AF52 AF80

20 A 30 A 45 A 50 A - - 20 A 30 A 45 A 50 A - - -

- 1/2 hp - - - - -

- 1-1/2 hp - - - - -

-3 hp-----

-3 hp-----

- 7-1/2 hp - - - - -

- 10 hp - - - - -

5/222 | ABB

1SBC100066S0201

Page 3

AF09 ... AF80 4-pole contactors

Technical data

General technical data

Contactor types

Rated insulation voltage Ui

acc. to IEC 60947-4-1 690 V 1000 V

acc. to UL / CSA 600 V

Rated impulse withstand voltage Uimp. 6 kV 8 kV

Electromagnetic compatibility Devices complying with IEC 60947-1 / EN 60947-1 - Environment A and B (1)

Ambient air temperature close to contactor

Operation -40...+70 °C

Storage -60...+80 °C

Climatic withstand Category B according to IEC 60947-1 Annex Q

Maximum operating altitude (without derating) 3000 m

Mechanical durability

Number of operating cycles 10 millions operating cycles

Max. switching frequency 3600 cycles/h

Shock withstand

acc. to IEC 60068-2-27 and EN 60068-2-27

5

Mounting position 1

4 N.O.

Main poles

C1

A

B1

A

B2

2 N.O. + 2 N.C.

Main poles

C2

Vibration withstand

acc. to IEC 60068-2-6

(1) Environment B: all AF09 … AF38 contactors produced since week 08-2013. AF09 … AF38-..-..-12 (48...130 V 50/60 Hz-DC) compliant to environment A only.

For environment B: select AF09 … AF38-..-..-22.

AC / DC operated

Shock direction

A

B1

B2

C1

C2

A

B1

B2

C1

C2

AF09 AF16 AF26 AF38 AF40 AF52 AF80

1/2 sinusoidal shock for 11 ms: no change in contact position, closed or open position

30 g 20 g

25 g closed position / 5 g open position 20 g closed position / 5 g open position

15 g 10 g

25 g 20 g

25 g 20 g

30 g closed position / 25 g open position 20 g

25 g closed position / 5 g open position 20 g closed position / 4 g open position

15 g closed position / 10 g open position 10 g

25 g closed position / 20 g open position 20 g

25 g closed position / 20 g open position 20 g

5...300 Hz

4 g closed position / 2 g open position

Remark for 4-pole contactors fitted with 2 N.O. + 2 N.C. main poles

7

R5

R3

1

These contactors are suitable for controlling 2 separate circuits, i.e. 2 loads with 2 separate supplies, or 1 circuit comprising

2 separate loads with a single supply (see diagrams below). When the contactor operates there is no mechanical overlapping

between the N.O. poles and the N.C. poles: BREAK before MAKE.

8

R6

R4

!

These contactors are not suitable for a reversing starter or for controlling a single load from 2 separate supplies.

Block diagrams

– Single supply and 2 separate loads – 2 separate supplies and 2 separate loads

Supply

5/224 | ABB

A1

R3

1

R4

2

A2

Load

Load

7

R5

8

R6

A1

A2

Main

supply

Back-up

supply

7

R5

R3

1

8

R6

R4

2

Load

Load

1SBC 101990S 0201

Page 4

AF09 ... AF80 4-pole contactors

Technical data

Magnet system characteristics

Contactor types

Coil operating limits

acc. to IEC 60947-4-1

AC control voltage 50/60 Hz

Rated control circuit voltage Uc 24...500 V AC

Coil consumption

DC control voltage

Rated control circuit voltage Uc 12...500 V DC 20...500 V DC

Coil consumption

PLC-output control (AF..Z) ≥ 500 mA 24 V DC -

5

Drop-out voltage ≤ 60 % of Uc min. ≤ 60 % of Uc min.

Voltage sag immunity

acc. to SEMI F47-0706 (AF..Z) conditions of use on request conditions of use on request

Dips withstand

-20 °C ≤ θ ≤ +60°C

Operating time

Between coil energization and:

Between coil de-energization and:

AC / DC operated

AC supply

DC supply

Average pull-in value

Average holding value

Average pull-in value

Average holding value

N.O. contact closing

N.C. contact opening

N.O. contact opening

N.C. contact closing

AF09 AF16 AF26 AF38 AF40 AF52 AF80

At θ ≤ 60 °C 0.85 x Uc min...1.1 x Uc max.

At θ ≤ 70 °C 0.85 x Uc min...Uc max.

At θ ≤ 60 °C 0.85 x Uc min...1.1 x Uc max.

At θ ≤ 70 °C (AF) 0.85 x Uc min...Uc max. - (AF..Z) 0.85 x

Uc min...1.1 x Uc max.

(AF) 50 VA - (AF..Z) 16 VA 40 VA

(AF) 2.2 VA / 2 W - (AF..Z) 1.7 VA / 1.5 W 4 VA / 2 W

(AF) 50 W - (AF..Z) 12...16 W 40 W

(AF) 2 W - (AF..Z) 1.7 W 2 W

(AF..Z) 22 ms average for Uc ≥ 24 V 50/60 Hz or

Uc ≥ 20 V DC

40...95 ms 48...120 ms

38...90 ms 44...115 ms

11...95 ms 16...110 ms

13...98 ms 18...113 ms

at θ ≤ 70 °C 0.85 x Uc min ... 1.1 x Uc max

at θ ≤ 70 °C 0.85 x Uc min ... 1.1 x Uc max

24 ms average

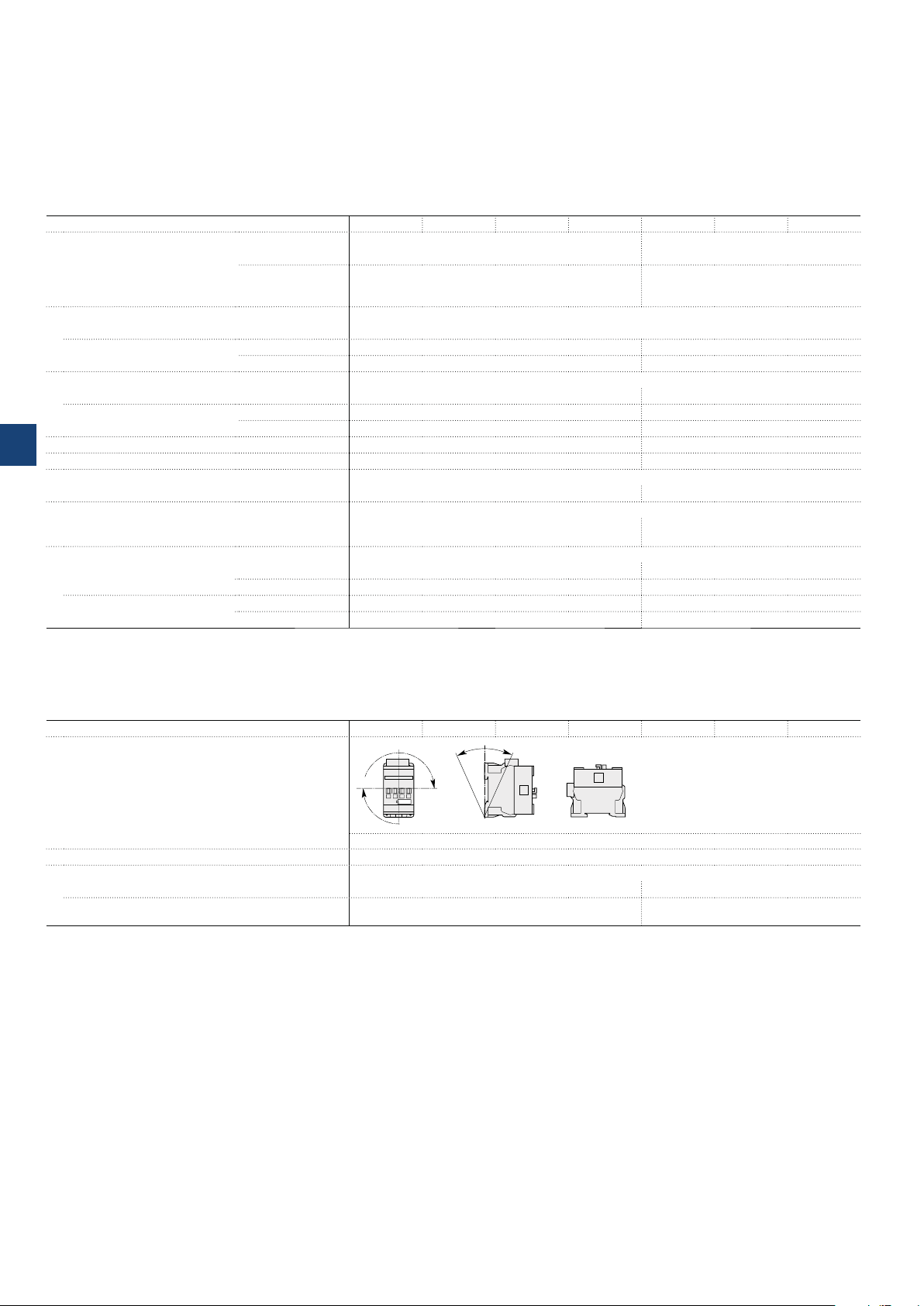

Mounting characteristics and conditions for use

Contactor types

Mounting positions

Mounting distances The contactors can be assembled side by side

Fixing

On rail according to IEC 60715, EN 60715 35 x 7.5 mm or 35 x 15 mm 35 x 15 mm

By screws (not supplied) 2 x M4 screws placed diagonally 2 x M4 or 2 x M6 screws

AF09 AF16 AF26 AF38 AF40 AF52 AF80

. 2

Pos

Pos. 4

Pos. 1 Pos. 1 ± 30°

Max. add-on N.C. auxiliary contacts: see accessory fitting details for a 4-pole contactor AF09 ... AF80

+30° -30°

Pos. 3

Pos. 5

placed diagonally

5/226 | ABB

1SBC 101991S02 01

Page 5

AF09 ... AF80 4-pole contactors

Technical data

Connecting characteristics

Contactor types

Main terminals

AF09 AF16 AF26 AF38 AF40 AF52 AF80

Screw terminals with

cable clamp

Connection capacity (min. ... max.)

Main conductors (poles)

Rigid Solid (≤ 4 mm²)

Stranded (≥ 6 mm²)

Flexible with non insulated ferrule

Flexible with insulated ferrule

Bars or lugs

L

6

Connection capacity acc. to UL/CSA

Stripping length 10 mm 12 mm 16 mm 17 mm

Tightening torque 1.5 Nm / 13 lb.in 2.5 Nm / 22 lb.in 4 Nm / 35 lb.in 6 Nm / 53 lb.in

Auxiliary conductors

(coil terminals)

Rigid solid

Flexible with non insulated ferrule

Flexible with insulated ferrule

Lugs

L

6

Connection capacity acc. to UL/CSA

Stripping length 10 mm

Tightening torque 1.2 Nm / 11 lb.in

Degree of protection

acc. to IEC 60947-1 / EN 60947-1 and IEC 60529 / EN 60529

Main terminals IP20 IP10

Coil terminals IP20

Screw terminals Delivered in open position, screws of unused terminals must be tightened

Main terminals M3.5 M4.5 M6 M8

Coil terminals M3.5

Screwdriver type

Screwdriver type

1 x

1...6 mm² 1.5...16 mm² 6...35 mm² 6...70 mm²

2 x

1...6 mm² 1.5...16 mm² 6...35 mm² 6...50 mm²

1 x

0.75...6 mm² 1.5...16 mm² 4...35 mm² 6...50 mm²

2 x

0.75...6 mm² 1.5...16 mm² 4...35 mm² 6...50 mm²

1 x

0.75...4 mm² 1.5...16 mm² 4...35 mm² 6...50 mm²

2 x

0.75...2.5 mm² 1.5...16 mm² 4...35 mm² 6...50 mm²

L <

9.6 mm - 9.2 mm 12.2 mm

1 or 2 x

AWG 16...10 AWG 16...6 AWG 10...2 AWG 6...1

1 x

1...2.5 mm²

2 x

1...2.5 mm²

1 x

0.75...2.5 mm²

2 x

0.75...2.5 mm²

1 x

0.75...2.5 mm²

2 x

0.75...1.5 mm²

L <

8 mm

1 or 2 x

AWG 18...14

Flat Ø 5.5 / Pozidriv 2 Flat Ø 6.5 / Pozidriv 2 hexagon socket (s = 4 mm)

Flat Ø 5.5 / Pozidriv 2

Screw terminals with

double connector

2 x (5.5 width x 6.8

depth)

Screw terminals with

double connector

2 x (9.3 width x 7.9/10.3

depth)

Screw terminals with

double connector

2 x (12.4 width x 9.3/11.1

depth)

5

ABB | 5/229

1SBC101988S0201 - Rev. A

Loading...

Loading...