Page 1

—

ABB DRIVES FOR HVAC

ACH480 drives

Hardware manual

Page 2

—

ACH480 manuals

List of related manuals

Drive manuals and guides Code (English)

ACH480 drives hardware manual 3AXD50000245949

ACH480 quick installation guide 3AXD50000247141

ACH480 drives firmware manual 3AXD50000247134

Option manuals and guides

ACX-AP-x assistant control panel user’s manual 3AUA0000085685

DPMP-01 mounting platform for control panels 3AUA0000100140

DPMP-02/03 mounting platform for control panels 3AUA0000136205

FBIP-21 BACnet/IP adapter module user's manual 3AXD50000028468

FBIP-21 BACnet/IP adapter module quick guide 3AXD50000158171

FCAN-01 CANopen adapter module user's manual 3AFE68615500

FCNA-01 ControlNet adapter module user's manual 3AUA0000141650

FDNA-01 DeviceNet adapter module quick guide 3AFE68573360

FECA-01 EtherCAT adapter module user's manual 3AUA0000068940

FENA-01/-11/-21 Ethernet adapter module user's manual 3AUA0000093568

FEPL-02 Ethernet POWERLINK adapter module user's manual 3AUA0000123527

FMBT-21 Modbus/TCP adapter module quick guide 3AXD50000158560

FPBA-01 PROFIBUS DP adapter module user's manual 3AFE68573271

FPNO-21 PROFINET adapter module user's manual 3AXD50000158614

FSCA-01 RS-485 adapter module user's manual 3AUA0000109533

UL Type 1 kit QIG for ACS380 and ACS480 - frames R0 to R2 3AXD50000235254

UL Type 1 kit QIG for ACS380 and ACS480 - frames R3 to R4 3AXD50000242375

Tool and maintenance manuals

Drive composer PC tool user's manual 3AUA0000094606

Converter module capacitor reforming instructions

NETA-21 remote monitoring tool user’s manual 3AUA00000969391

NETA-21 remote monitoring tool installation and start-up guide 3AUA0000096881

3BFE64059629

You can find manuals and other product documents in PDF format on the

Internet. See section Document library on the Internet on the inside of the

back cover. For manuals not available in the Document library, contact your

local ABB representative.

Page 3

Hardware manual

ACH480 drives

Table of contents

1. Safety instructions

4. Mechanical installation

6. Electrical installation

2018 ABB Oy. All Rights Reserved.

3AXD50000245949 Rev A

EN

EFFECTIVE: 2018-11-22

3

Page 4

4

Page 5

Table of contents 5

Table of contents

1. Safety instructions

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Use of warnings and notes in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Precautions before electrical work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Additional instructions and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Additional instructions for permanent magnet motor drives . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General safety in operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Introduction to the manual

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Purpose of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Contents of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Categorization by frame (size) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

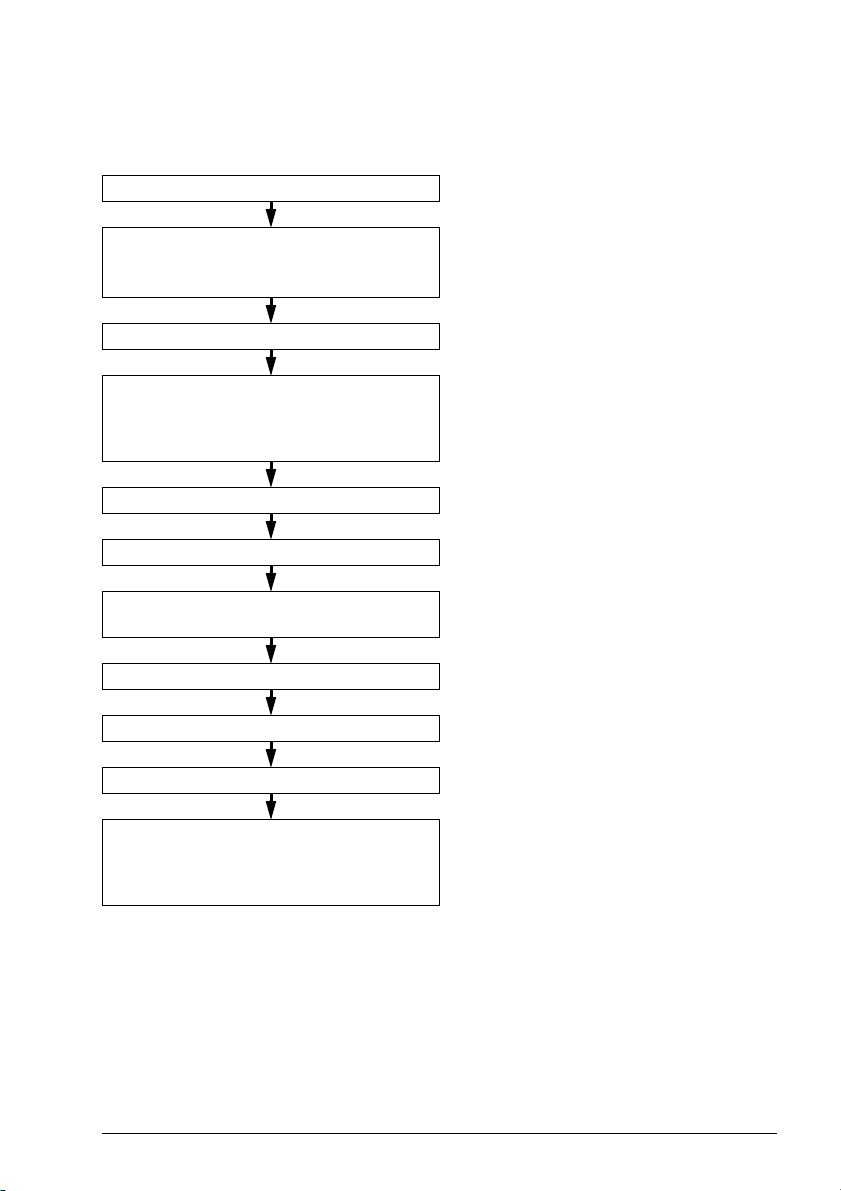

Quick installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3. Hardware description

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Product variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

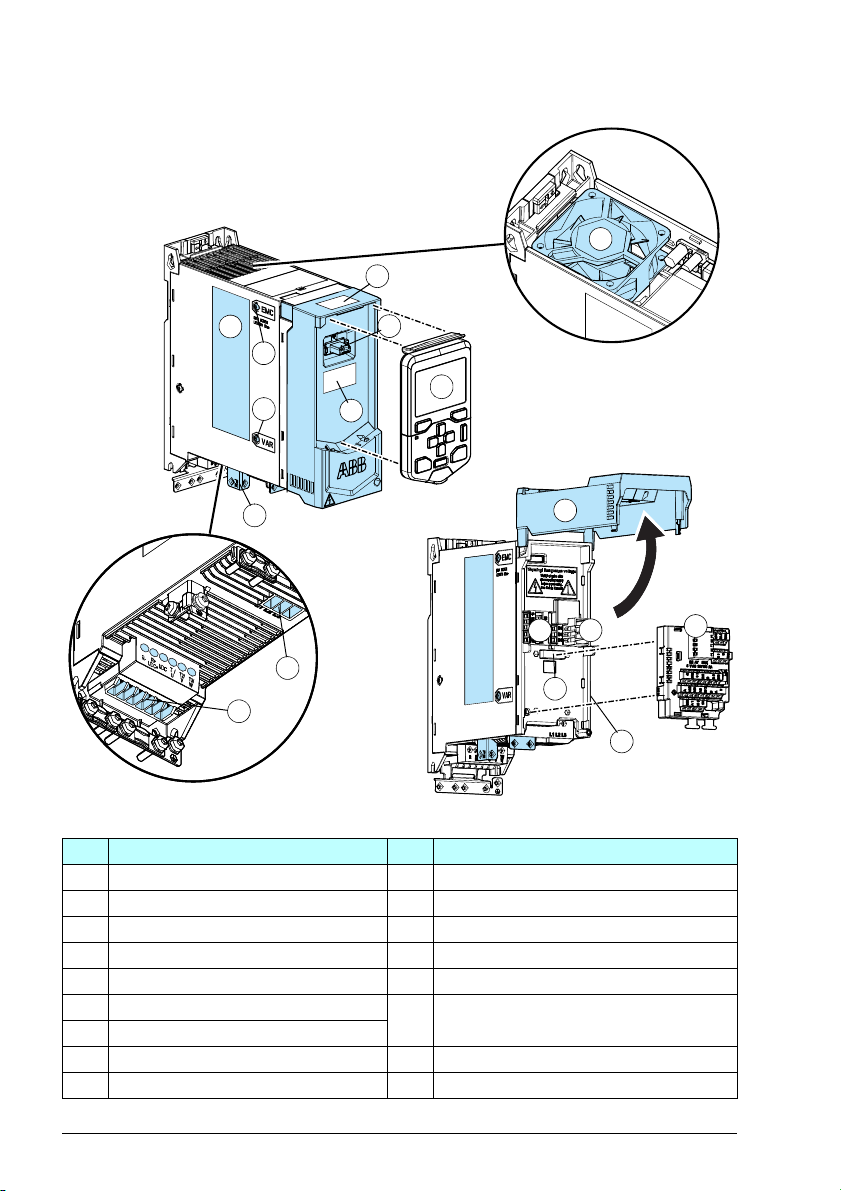

Hardware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Standard unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Base unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mounted options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Drive labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Model information label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Software information label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Type designation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Type designation key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4. Mechanical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 6

6 Table of contents

Examining the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Unpacking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installing the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

To install the drive with screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

To install the drive to a DIN installation rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5. Planning the electrical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Selecting the supply disconnecting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Other regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Checking the compatibility of the motor and drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Typical power cable sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Recommended power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power cable types for limited use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Not allowed power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Motor cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Additional US requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Signals in separate cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Signals that can be run in the same cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Control panel to PC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Control panel to drive connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Modbus RTU cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Separate control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Continuous motor cable shield or conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Implementing short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Protecting the drive and input power cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . . 50

Protecting the motor and motor cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Implementing thermal overload protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Protecting the drive, and the input power and motor cables against thermal overload . . 51

Protecting the motor against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Protecting the drive against ground faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Residual current device compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Implementing the emergency stop function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Implementing the Safe torque off function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Using a safety switch between the drive and motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Using a contactor between the drive and motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Protecting the contacts of relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6. Electrical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Page 7

Table of contents 7

Measuring insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Input power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Brake resistor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Compatibility with IT (ungrounded) and corner-grounded TN systems . . . . . . . . . . . . . . . . . . 57

EMC filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

EMC filter disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Ground-to-phase varistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

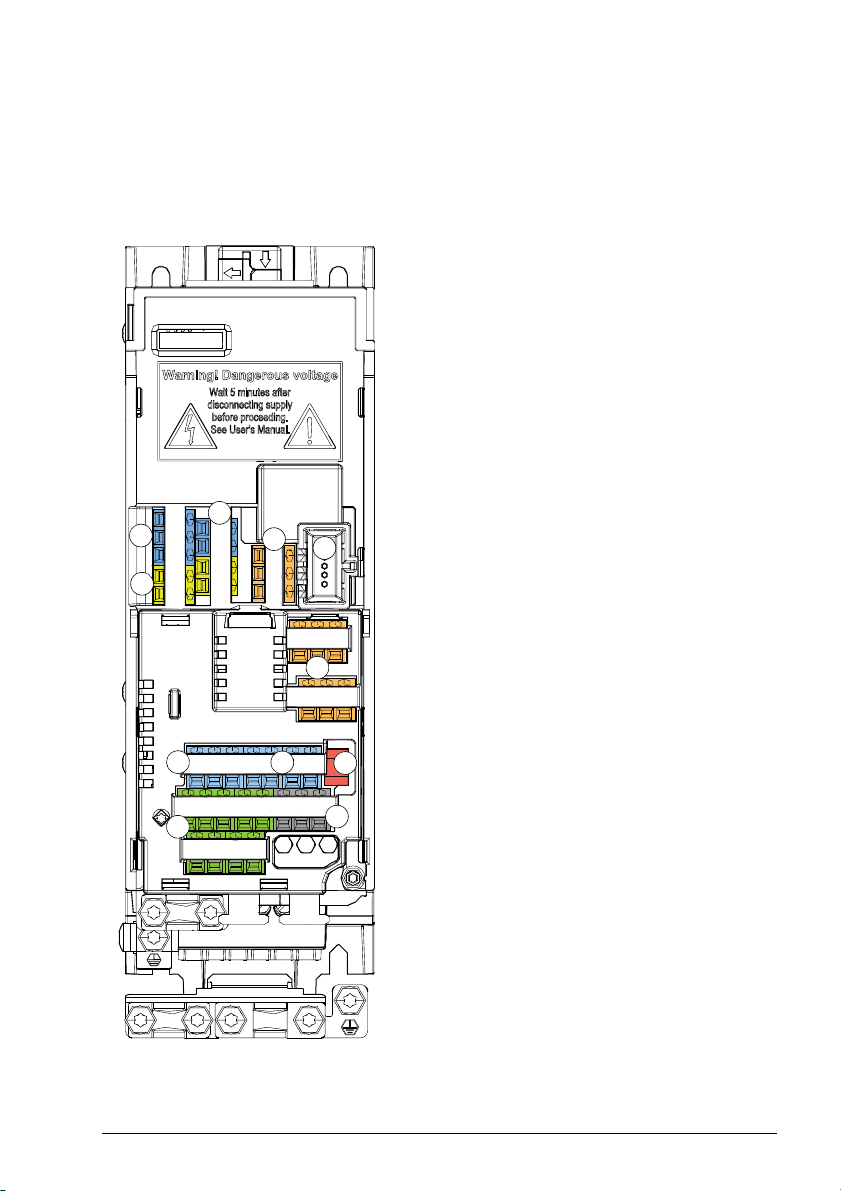

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

I/O connections (HVAC default) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting EIA-485 embedded fieldbus terminal to the drive . . . . . . . . . . . . . . . . . . . . . 65

Control cable connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Auxiliary voltage connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

To install a front option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

To remove a front option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

To install a side option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

To remove a side option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7. Installation checklist

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8. Maintenance

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Cleaning the heat sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Replacing the cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

To replace the cooling fan for frame sizes R1, R2 and R3 . . . . . . . . . . . . . . . . . . . . . . . . 78

To replace the cooling fan for frame R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Servicing the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Capacitor reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9. Technical data

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

IEC ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

NEMA ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Surrounding air temperature derating, IP20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Switching frequency derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Page 8

8 Table of contents

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fuses (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

gG fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

gR fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

UL fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Alternate short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Miniature circuit breakers (IEC environment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Self-protected combination manual controller – Type E

USA (UL) environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Losses, cooling data and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Terminal data for the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Terminal data for the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

External EMC filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Electric power network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Motor cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Motor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Control connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Brake resistor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Compliance with the European Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . 104

Compliance with the European EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Compliance with the European RoHS Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Compliance with the European WEEE Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Compliance with the European Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Compliance with EN 61800-3:2004 + A1:2012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Category C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Category C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Category C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

UL checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

CSA marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

RCM marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

EAC marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

WEEE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

China RoHS marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

TÜV marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Generic disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Cyber security disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10. Dimension drawings

Frame R1 (400 V) (front & side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Page 9

Table of contents 9

Frame R1 (400 V) (bottom & rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Frame R2 (400 V) (front & side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Frame R2 (400 V) (bottom & rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Frame R3 (front & side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Frame R3 (bottom & rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Frame R4 (front & side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Frame R4 (bottom & rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11. Resistor braking

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Operation principle and hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Selecting the brake resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Reference brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Selecting and routing the brake resistor cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Minimizing electromagnetic interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Maximum cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

EMC compliance of the complete installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Brake resistor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Protecting the system in brake circuit fault situations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Protecting the system in cable and brake resistor short-circuit situations . . . . . . . . . . . . 125

Protecting the system against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Measuring the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

12. Safe torque off function

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Compliance with the European Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Connection principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Connection with internal +24 V DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Connection with external +24 V DC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Wiring examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Activation switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Cable types and lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Grounding of protective shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Start-up including acceptance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Acceptance test reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Acceptance test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Fault tracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Safety data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Page 10

10 Table of contents

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

TÜV certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13. BAPO-01 power extension module

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Voltage and current rating for the auxiliary power supply . . . . . . . . . . . . . . . . . . . . . . . 146

Power loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

14. BIO-01 I/O extension module

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Control connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Further information

Page 11

Safety instructions 11

1

Safety instructions

Contents of this chapter

This chapter contains the safety instructions which you must obey when you install

and operate the drive and do maintenance on the drive. Obey the safety instructions

to prevent injury or death, or damage to the equipment.

Use of warnings and notes in this manual

Warnings tell you about conditions which can cause injury or death, or damage to the

equipment. They also tell you how to prevent the danger. Notes draw attention to a

particular condition or fact, or give information on a subject.

The manual uses these warning symbols:

Electricity warning tells you about hazards from electricity which can

cause injury or death, or damage to the equipment.

General warning tells you about conditions, other than those caused by

electricity, which can cause injury or death, or damage to the equipment.

Electrostatic sensitive devices warning tells you about the risk of

electrostatic discharge which can cause damage to the equipment.

Page 12

12 Safety instructions

General safety in installation, start-up and maintenance

These instructions are for all personnel that install the drive and do maintenance work

on it.

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• Handle the drive carefully.

• Use safety shoes with a metal toe cap.

• Keep the drive in its package or protect it otherwise from dust and burr from

drilling and grinding until you install it.

• Vacuum clean the area below the drive before the start-up to prevent the drive

cooling fan from drawing the dust inside the drive.

• Protect also the installed drive against dust and burr. Electrically conductive

debris inside the drive may cause damage or malfunction.

• Do not cover the air inlet and outlet when the drive runs.

• Make sure that there is sufficient cooling.

• Before you connect voltage to the drive, make sure that the drive covers are on.

Keep the covers on during operation.

• Before you adjust the drive operation limits, make sure that the motor and all

driven equipment can operate throughout the set operation limits.

• Before you activate the automatic fault reset or automatic restart functions of the

drive control program, make sure that no dangerous situations can occur. These

functions reset the drive automatically and continue operation after a fault or

supply break. If these functions are activated, the installation must be clearly

marked as defined in IEC/EN 61800-5-1, subclause 6.5.3, for example, “THIS

MACHINE STARTS AUTOMATICALLY”.

• The maximum number of drive power-ups is two per minute. Too frequent powerups can damage the charging circuit of the DC capacitors. The maximum total

number of chargings is 15000.

• If you have connected safety circuits to the drive (for example, emergency stop

and Safe torque off), validate them at the start up.

Note:

• If you select an external source for the start command and it is on, the drive starts

immediately after a fault reset, unless you configure the drive for pulse start.

• When the control location is not set to local, the stop key on the control panel

does not stop the drive.

• Drives can be repaired only by an authorized person.

Page 13

Safety instructions 13

Electrical safety in installation, start-up and maintenance

Precautions before electrical work

These warnings are for all personnel who do work on the drive, motor cable or motor.

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur. If you are not a qualified electrician, do

not do electrical installation or maintenance work. Do these steps before you begin

any installation or maintenance work.

1. Clearly identify the work location.

2. Disconnect all possible voltage sources.

• Open the main disconnector at the power supply of the drive.

• Make sure that reconnection is not possible. Lock the disconnector to open

position and attach a warning notice to it.

• Disconnect any external power sources from the control circuits before you do

work on the control cables.

• After you disconnect the drive, always wait for 5 minutes to let the

intermediate circuit capacitors discharge before you continue.

3. Protect any other energized parts in the work location against contact.

4. Take special precautions when close to bare conductors.

5. Measure that the installation is de-energized.

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive input power terminals (L1, L2,

L3) and the grounding terminal (PE) is close to 0 V.

• Make sure that the voltage between the drive DC terminals (UDC+ and UDC-)

and the grounding terminal (PE) is close to 0 V.

6. Install temporary grounding as required by the local regulations.

7. Ask for a permit to work from the person in control of the electrical installation

work.

Page 14

14 Safety instructions

Additional instructions and notes

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• If you install the drive on an IT system (an ungrounded power system or a highresistance-grounded [over 30 ohms] power system), disconnect the internal EMC

filter; otherwise the system will be connected to ground potential through the EMC

filter capacitors. This can cause danger or damage the drive.

Note: Disconnecting the internal EMC filter increases the conducted emission

and reduces the drive EMC compatibility considerably.

• If you connect the drive to an IT system (an ungrounded power system or a highresistance-grounded [over 30 ohms] power system), disconnect the varistor from

ground. Failure to do so can cause damage to the varistor circuit.

• If you install the drive on a corner-grounded TN system, disconnect the internal

EMC filter; otherwise the system will be connected to ground potential through the

EMC filter capacitors. This will damage the drive.

Note: Disconnecting the internal EMC filter increases the conducted emission

and reduces the drive EMC compatibility considerably.

• Use all ELV (extra low voltage) circuits connected to the drive only within a zone

of equipotential bonding, that is, within a zone where all simultaneously

accessible conductive parts are electrically connected to prevent hazardous

voltages appearing between them. You can accomplish this by a proper factory

grounding, that is, make sure that all simultaneously accessible conductive parts

are grounded to the protective earth (PE) bus of the building.

• Do not do insulation or voltage withstand tests on the drive.

Note:

• The motor cable terminals of the drive are at a dangerous voltage when the input

power is on, regardless of whether the motor is running or not.

• The DC and brake resistor terminals (UDC+, UDC-, R+ and R-) are at a

dangerous voltage.

• External wiring can supply dangerous voltages to the terminals of relay outputs.

• The Safe torque off function does not remove the voltage from the main and

auxiliary circuits. The function is not effective against deliberate sabotage or

misuse.

WARNING! Use a grounding wrist band when you handle the printed circuit

boards. Do not touch the boards unnecessarily. The components on the boards

are sensitive to electrostatic discharge.

Page 15

Safety instructions 15

Grounding

These instructions are for all personnel who are responsible for the electrical

installation, including the grounding of the drive.

WARNING! Obey these instructions. If you ignore them, injury or death, or

equipment malfunction can occur, and electromagnetic interference can

increase.

• If you are not a qualified electrician, do not do grounding work.

• Always ground the drive, the motor and adjoining equipment to the protective

earth (PE) bus of the power supply. This is necessary for the personnel safety.

Proper grounding also reduces electromagnetic emission and interference.

• In a multiple-drive installation, connect each drive separately to the protective

earth (PE) bus of the power supply.

• Make sure that the conductivity of the protective earth (PE) conductors is

sufficient. Refer to Selecting the power cables on page 42. Obey the local

regulations.

• Connect the power cable shields to the protective earth (PE) terminals of the

drive.

• Make a 360° grounding of the power and control cable shields at the cable entries

to suppress electromagnetic disturbances.

Note:

• You can use power cable shields as grounding conductors only when their

conductivity is sufficient.

• Standard IEC/EN 61800-5-1 (section 4.3.5.5.2.) requires that as the normal touch

current of the drive is higher than 3.5 mA AC or 10 mA DC, you must use a fixed

protective earth (PE) connection. In addition,

• install a second protective earth conductor of the same cross-sectional area

as the original protective earthing conductor,

or

• install a protective earth conductor with a cross-section of at least 10 mm

or 16 mm2Al,

or

• install a device which automatically disconnects the supply if the protective

earth conductor breaks.

2

Cu

Page 16

16 Safety instructions

Additional instructions for permanent magnet motor drives

Safety in installation, start-up and maintenance

These are additional warnings that apply to permanent magnet motor drives. The

other safety instructions in this chapter are also valid.

WARNING! Obey these instructions. If you ignore them, injury or death and

damage to the equipment can occur.

• Do not work on a drive when a rotating permanent magnet motor is connected

to it. A rotating permanent magnet motor energizes the drive including its input

power terminals.

Before installation, start-up and maintenance work on the drive:

• Stop the motor.

• Disconnect the motor from the drive with a safety switch or by other means.

• If you cannot disconnect the motor, make sure that the motor cannot rotate during

work. Make sure that no other system, like hydraulic crawling drives, can rotate

the motor directly or through any mechanical connection like felt, nip, rope, etc.

• Measure that the installation is de-energized.

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive output terminals (T1/U, T2/V,

T3/W) and the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive input power terminals (L1, L2,

L3) and the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive DC terminals (UDC+, UDC-) and

the grounding (PE) terminal is close to 0 V.

• Install temporary grounding to the drive output terminals (T1/U, T2/V, T3/W).

Connect the output terminals together as well as to the PE.

Start-up and operation:

• Make sure that the operator cannot run the motor over the rated speed. Motor

overspeed causes overvoltage that can damage or explode the capacitors in the

intermediate circuit of the drive.

Page 17

Safety instructions 17

General safety in operation

These instructions are for all personnel that operate the drive.

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• Do not control the motor with the disconnector at the drive power supply. Use the

control panel start and stop keys or the start/stop commands from an external

control device connected through the I/O or fieldbus interface.

• Give a stop command to the drive before you reset a fault. If you have an external

source for the start command and the start is on, the drive will start immediately

after the fault reset, unless you configure the drive for pulse start. See the

firmware manual.

• Before you activate automatic fault reset functions of the drive control program,

make sure that no dangerous situations can occur. These functions reset the

drive automatically and continue operation after a fault.

Note: When the control location is not set to Local, the stop key on the control panel

will not stop the drive.

Page 18

18 Safety instructions

Page 19

Introduction to the manual 19

2

Introduction to the manual

Contents of this chapter

The chapter describes the applicability, target audience and purpose of this manual. It

describes the contents of this manual. The chapter also has a flowchart for the

delivery, installation and commissioning of the drive.

Applicability

The manual applies to ACH480 drives.

Target audience

The reader must know the fundamentals of electricity, wiring, electrical components

and electrical schematic symbols.

Purpose of the manual

This manual has the information needed to plan the installation, and install,

commission and service the drive.

Page 20

20 Introduction to the manual

Contents of this manual

• Safety instructions (on page 11) gives the safety instructions that you must obey

when you install, commission, operate and service the drive.

• Introduction to the manual (on page 19) describes the applicability, target

audience, purpose and contents of this manual.

• Hardware description (on page 25) describes the operation principle, layout,

power connections and control interfaces, type designation information.

• Mechanical installation (on page 35) describes how to examine the installation

site, unpack, examine the delivery and install the drive mechanically.

• Planning the electrical installation (on page 41) describes how to plan the

electrical installation of the drive.

• Electrical installation (on page 55) describes how to measure the insulation of the

assembly and the compatibility with IT (ungrounded) and corner-grounded TN

systems. It shows how to connect the power and control cables, install optional

modules and connect a PC.

• Installation checklist (on page 73) contains a checklist for the mechanical and

electrical installation of the drive before start-up.

• Maintenance (on page 75) contains the preventive maintenance instructions and

LED indicator descriptions.

• Technical data (on page 83) contains the technical specifications of the drive.

• Dimension drawings (on page 111) shows the dimension drawings of the drive.

• Resistor braking (on page 121) tells you how to select the brake resistor.

• Safe torque off function (on page 129) describes the STO features, installation

and technical data.

• BAPO-01 power extension module (on page 143) describes the optional BAPO01 module.

• BIO-01 I/O extension module (on page 147) decribes the optional I/O extension

module.

Related documents

Refer to List of related manuals on page 2 (the inner front cover).

Categorization by frame (size)

The drive is manufactured in frame sizes, for example, R0, R1, R2 and so on.

Information that is applicable only to certain frames shows the frame size. Some

instructions only apply to specific frame sizes. You can read the frame size from the

type designation label on the drive, refer to Drive labels on page 30.

Page 21

Introduction to the manual 21

Quick installation and commissioning flowchart

Task Refer to

Identify the frame size: R0, R1, R2, etc. Type designation key on page 32.

Plan the installation.

Check the ambient conditions, ratings and

required cooling air flow.

Unpack and check the drive. Unpacking the delivery on page 37.

If the drive is connected to an IT (ungrounded)

system or corner-grounded TN system, make

sure that the internal EMC filter is not

connected.

Install the drive. Installing the drive on page 38.

Route the cables. Routing the cables on page 49.

Measure the insulation of the input cable,

motor and motor cable.

Connect the power cables. Connecting the power cables on page 59.

Connect the control cables. Connecting the control cables on page 62.

Examine the installation. Installation checklist on page 73.

Planning the electrical installation on page 41.

Technical data on page 83.

Type designation key on page 32.

Compatibility with IT (ungrounded) and

corner-grounded TN systems on page 57.

Measuring insulation on page 56.

Commission the drive. Refer to the ACH480 drives quick installation

guide (3AXD50000247141 [English]) and the

ACH480 drives firmware manual

(3AXD50000247134 [English]).

Page 22

22 Introduction to the manual

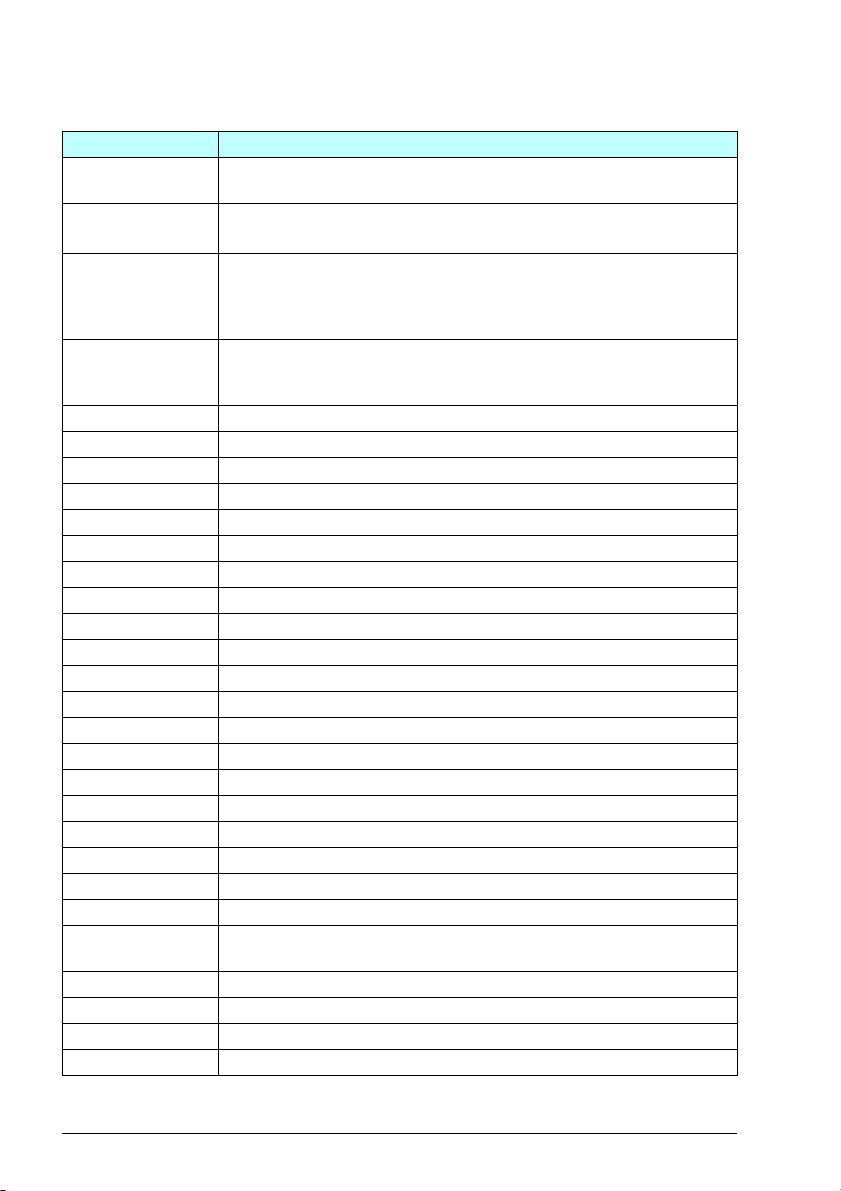

Terms and abbreviations

Term/abbreviation Explanation

ACX-AP-X Assistant control panel. An advanced operator keypad for

BACnet™ BACnet™ is a registered trademark of American Society of Heating,

Brake chopper Conducts the surplus energy from the intermediate circuit of the drive to

Brake resistor Dissipates the drive surplus braking energy conducted by the brake

Capacitor bank Refer to DC link capacitors.

CDPI-02 Communication adapter module

Control board Circuit board in which the control program runs.

BAPO-01 Optional side-mounted auxiliary power extension module

BCBL-01 Optional USB to RJ45 cable

BIO-01 Optional I/O extension module underneath the fieldbus option

CCA-01 Optional cold configuration adapter

DC link DC circuit between rectifier and inverter

DC link capacitors Energy storage which stabilizes the intermediate circuit DC voltage

DPMP-01 Mounting platform for ACX-AP control panel (flange mounting)

DPMP-02 Mounting platform for ACX-AP control panel (surface mounting)

Drive Frequency converter for controlling AC motors

EFB Embedded fieldbus

EMC Electromagnetic compatibility

FBA Fieldbus adapter

FBIP-21 Optional BACnet/IP adapter module

FCAN-01 Optional CANopen adapter module

FCNA-01 Optional ControlNet adapter module

FDNA-01 Optional DeviceNet adapter module

FECA-01 Optional EtherCAT adapter module

FENA-21 Optional Ethernet adapter module for EtherNet/IP, Modbus TCP and

FEPL-02 Optional Ethernet POWERLINK adapter module

FLON-01 Optional LONWORKS adapter module

FPBA-01 Optional PROFIBUS DP adapter module

FSCA-01 Optional RS-485 adapter module

communication with the drive.

Refrigerating and Air-Conditioning Engineers (ASHRAE).

the brake resistor when necessary. The chopper operates when the DC

link voltage exceeds a certain maximum limit. The voltage rise is

typically caused by deceleration (braking) of a high inertia motor.

chopper to heat. Essential part of the brake circuit. Refer to Brake

chopper.

PROFINET IO protocols

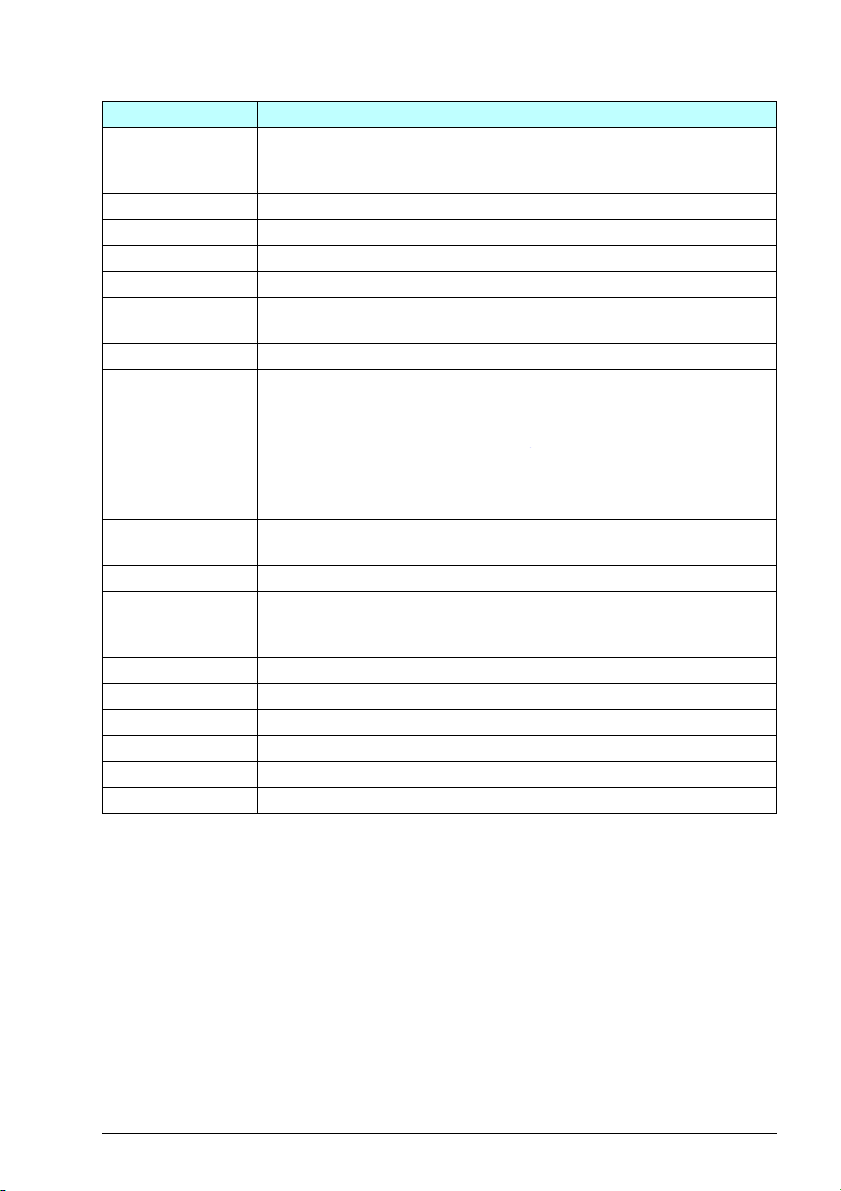

Page 23

Introduction to the manual 23

Term/abbreviation Explanation

Frame (size) Refers to drive physical size, for example, R0 and R1. The type

I/O Input/Output

IGBT Insulated gate bipolar transistor

Intermediate circuit Refer to DC link.

Inverter Converts direct current and voltage to alternating current and voltage.

Macro Pre-defined default set of parameters in a drive control program. Each

NETA-21 Optional remote monitoring tool

Network control With fieldbus protocols based on the Common Industrial Protocol

Parameter User-adjustable operation instruction to the drive, or signal measured or

PLC Programmable logic controller

PROFIBUS,

PROFIBUS DP,

PROFINET IO

R0, R1, R2, R3… Frame (size)

RCD Residual current device

Rectifier Converts alternating current and voltage to direct current and voltage.

RFI Radio-frequency interference

SIL Safety integrity level. Refer to Safe torque off function on page 129.

STO Safe torque off. Refer to Safe torque off function on page 129.

designation label attached to the drive shows the frame of the drive,

refer to Type designation key on page 32.

macro is intended for a specific application.

TM

), such as DeviceNet and Ethernet/IP, denotes the control of the

(CIP

drive using the Net Ctrl and Net Ref objects of the ODVA AC/DC Drive

Profile. For more information, refer to

www.odva.org, and to FDNA-01

DeviceNet adapter module user’s manual (3AFE68573360 [English])

and FENA-01/-11/-21 Ethernet adapter module user’s manual

(3AUA0000093568 [English]).

calculated by the drive

Registered trademarks of PI - PROFIBUS & PROFINET International

Page 24

24 Introduction to the manual

Page 25

Hardware description 25

3

Hardware description

Contents of this chapter

This chapter describes the operation principle, layout, type designation label and type

designation information. It shows a general diagram of the power connections and

control interfaces.

General description

The ACH480 is a drive for controlling asynchronous AC induction motors, permanent

magnet synchronous motors and ABB synchronous reluctance motors (SynRM

motors). It is optimized for cabinet mounting.

Product variants

The drive has two primary products:

• Standard unit (for example, ACH480-04-02A7) with the Assistant control panel

ACH-AP-H and an I/O module with integrated EIA-485 RIIO-01.

• Base unit (for example, ACH480-04-02A7+0J400+0L540) without a control panel

and without an I/O module RIIO-01 with EIA-485.

Refer to Type designation key on page 32.

Page 26

26 Hardware description

1

2

4

5

6

7

9

12

14

16

10

8

15

11

13

3

17

Hardware overview

No. Description No. Description

1 Type designation label 10 Motor and braking resistor terminals

2 Model information label 11 Cooling fan (not on R0)

3 Software information label 12 Front cover

4 Control panel connection 13 Fixed control terminals

5 Control panel 14 Cold configuration connection (CCA-01)

6 EMC filter grounding screw 15 Slot for front option modules

7 Varistor grounding screw

8 PE connection (motor) 16 I/O or fieldbus module

9 Input power terminal 17 Side option slot for side-mounted options

(I/O module or fieldbus module)

Page 27

Hardware description 27

RELAYS MAX

250V AC 30 DC 2A

24V

DGND

DCOM

D 3

D 4

D 5

D 6

AI2

AGND

A01

A02

AGND

B +

A -

DGND

SCR

AI1

AGND

+10V

RO2C

R02A

RO2B

RO3C

R 3A

RO3B

D 1

DI2

IN1

IN2

ON

RO C

RO1A

RO1B

+24V

DGND

DCOM

SGND

OUT1

1

1

2

3

4

5

8

10

7

9

6

11

Control connections

There are fixed control connections on the base unit and optional control connections

based on the installed option module.

Standard unit

Connections of the base unit:

1. Auxiliary voltage outputs

2. Digital inputs

3. Safe torque-off connections

4. Relay output connection

5. Cold configuration connection for CCA-01

Connections of the standard I/O module

RIIO-01:

6. Digital inputs

7. Analog inputs and outputs

8. Relay output connections

9. Embedded fieldbus EIA-485 (BACnet

MS/TP, Modbus RTU, N2)

10. Auxiliary voltage output

11.Termination switch and bias resistor switch

Page 28

28 Hardware description

D 1

DI2

IN1

IN2

+24V

DGND

DCOM

SGND

OUT1

RO C

RO1A

RO1B

1

2

3

4

5

6

Base unit

Connections of the base unit:

1. Auxiliary voltage outputs

2. Digital inputs

3. Safe torque-off connections

4. Relay output connection

5. Cold configuration connection for CCA-01

6. Front option module slot 1

Page 29

Hardware description 29

Mounted options

For information on mounted optional modules, refer to:

• BAPO-01 power extension module on page 143.

• BIO-01 I/O extension module on page 147.

Control panel

The drive supports these assistant control panels:

• ACH-AP-H (included in the standard delivery)

•ACH-AP-W

• CDPI-02 communication adapter module

For information on the assistant control panels, refer to the ACX-AP-x Assistant

control panels user’s manual (3AUA0000085685 [EN]).

For information on how to start up the drive, and modify the settings and parameters,

refer to the ACH480 drives firmware manual (3AXD50000247134 [English]).

PC connection

To connect a PC to the drive, there are two alternatives:

1. Use an ACH-AP-H/ACH-AP-W assistant control panel as a converter with a USB

Mini-B type cable.

2. Use a USB to RJ45 converter BCBL-01 (3AXD50000032449) with CDPI-02

(3AXD50000009929).

For information on the Drive composer PC tool, refer to Drive composer PC tool

user's manual (3AUA0000094606 [English]).

Page 30

30 Hardware description

AC,480-04-04A1-4

S/N: 1170301940

1

2

3

AC,480-04-04A1-4

3~400V/480 V (frame R1)

Pld: 1.5 kW (2 hp)

Phd: 1.1 kW (1.5 hp)

SW v2.02.0.8

1

2

3

5

4

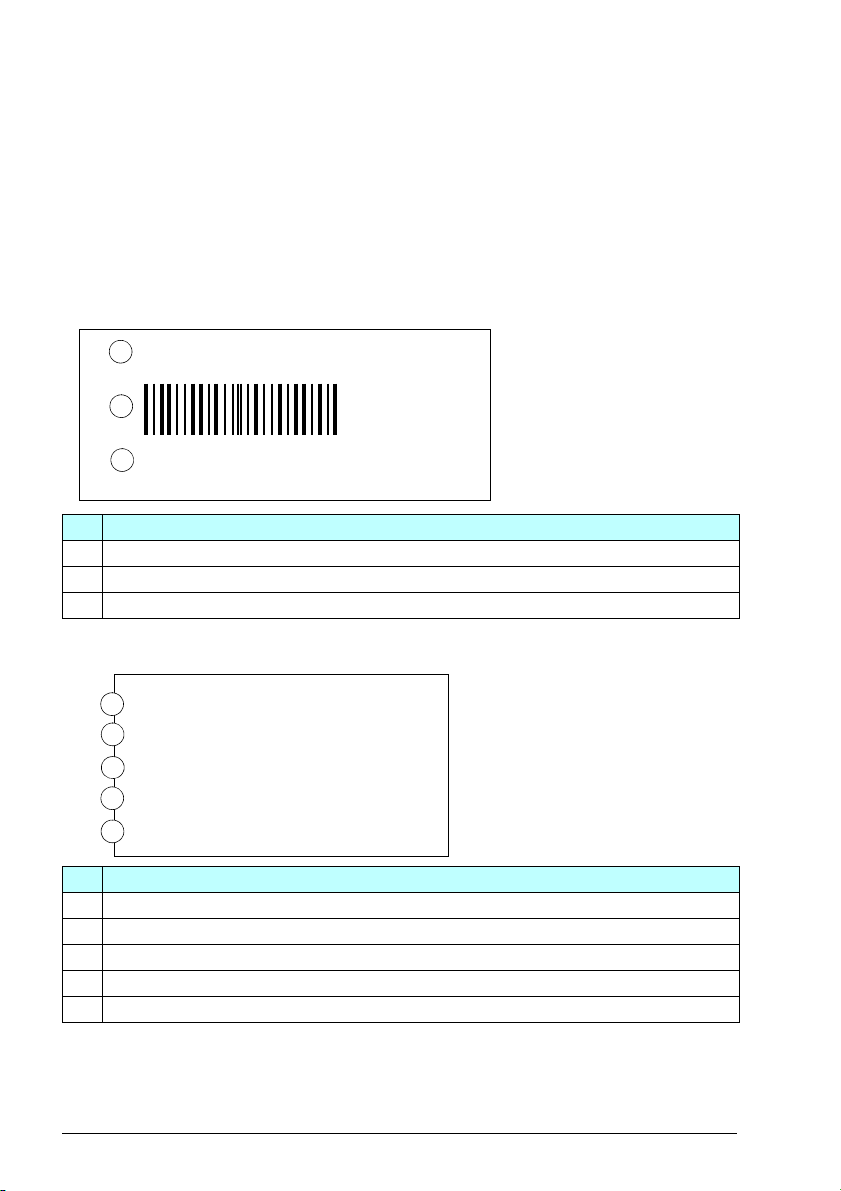

Drive labels

The drive has these labels:

• Model information label on the top of the drive

• Software information label on the front cover

• Type designation label on the left side of the drive

For label positions, refer to Hardware overview on page 26.

Model information label

No. Description

1 Drive type

2 Bar code

3 Serial number

Software information label

No. Description

1 Drive type

2 Input voltage rating and frame size

3 Typical motor power in light-duty use (10% overload)

4 Typical motor power in heavy-duty use (50% overload)

5 Drive software version

Page 31

Type designation label

ABB Oy

,ŝŽŵŽƟĞϭϯ

ϬϬϯϴϬ,ĞůƐŝŶŬŝ

&ŝŶůĂŶĚ

,ϰϴϬͲϬϰͲϬϰϭͲϰ

ŝƌĐŽŽůŝŶŐ

/ĐĐϭϬϬŬIP20

h>ŽƉĞŶƚLJƉĞ

FRAME

Zϭ

/ŶƉƵƚ

KƵƚƉƵƚ

^EϭϭϳϬϯϬϭϵϰϬ

hϭ

Ĩϭ

U2

/ůĚ

/ŚĚ

f2

ϯΕϰϬϬϰϴϬs

50/60 Hz

ϯΕϬhϭ

ϯϴϯϰ

ϯϯϯ

Ϭϱϵϵ,nj

IND.CONT.EQ.

1PDS

/ŶƉƵƚĐƵƌƌĞŶƚŝƐƐĐĂůĞĚďLJ

ŵŽƚŽƌŽƵƚƉƵƚĐƵƌƌĞŶƚ

KƵƚƉƵƚ

4

ϯϴϯϰ

ϯϯϯ

/ŶƉƵƚ

ϲϰϱϰ

ϲϭϱϰ

ϱϯϰϴ

/ŶƉƵƚ;ǁŝƚŚ

ϱйĐŚŽŬĞͿ

ϰϯϰ

ϯϴϯϰ

ϯϯϯ

e

1

2

3

4

5

6

This is a sample type designation label.

No. Description

1 Type designation, refer to Type designation key on page 32.

2Frame (size)

3 Degree of protection

4 Nominal ratings, refer to Ratings on page 84.

5 Valid markings

6 S/N: Serial number of format MYYWWXXXX, where

M:

YY:

WW:

XXXX:

Manufacturer

Year of manufacture: 15, 16, 17, … for 2015, 2016, 2017, …

Week of manufacture: 01, 02, 03, … for week 1, week 2, week 3, …

Running item number that starts each week from 0001.

Hardware description 31

Page 32

32 Hardware description

Type designation key

The type designation tells you the specifications and configuration of the drive. For

more information on the ratings, refer to Technical data on page 83.

Sample type code: ACH480-04-12A7-4+XXXX

Segment A B C D

ACH480 - 04 - 02A7 - 4 + Option codes

Code Description

Basic codes

A Construction 04 = Module, IP20

04 When there aro no options: cabinet optimized module, IP20, assistant

control panel with USB, I/O module with embedded Modbus RTU, EMC

C2 filter (internal EMC filter), safe torque off, braking chopper, coated

boards, quick installation and start-up guide.

B Drive size

e.g. 12A7 Nominal output current rating of the inverter.

C Voltage rating

4 3-phase 380...480 V AC

D Option codes (plus codes)

Control panel and panel options

J400 ACH-AP-H Assistant control panel

J429 ACH-AP-W Assistant control panel with Bluetooth interface

0J400 Without control panel

I/O

L515 BIO-01 I/O extension module (front option, can be used with a fieldbus

module)

L534 BAPO-01 External 24 V DC (side option)

L540 Standard I/O module RIIO-01 with embedded EIA-485 (front option,

cannot be used with a fieldbus module)

0L540 Without standard I/O module RIIO-01 with embedded EIA-485

Fieldbus adapters

K451 FDNA-01 DeviceNet

K454 FPBA-01 PROFIBUS DP adapter module

K457 FCAN-01 CANopen adapter module

K458 FSCA-01 RS-485 adapter module

K462 FCNA-01 ControlNet

K465 FBIP-21 BACnet/IP adapter module

K469 FECA-01 EtherCAT adapter module

K470 FEPL-02 Ethernet POWERLINK adapter module

TM

adapter module

TM

adapter module

Page 33

Code Description

K475 FENA-21 Ethernet adapter module

K491 FMBT-21 Modbus/TCP adapter module

K492 FPNO-21 Profinet adapter module

Documentation

+R700 English

+R701 German

+R702 Italian

+R703 Dutch

+R704 Danish

+R705 Swedish

+R706 Finnish

+R707 French

+R708 Spanish

+R709 Portuguese

(in Portugal)

+R711 Russian

+R714 Turkish

Hardware description 33

Full set of printed manuals in

the selected language. An

English manual is included, if a

translation is not available.

The product package includes

the Quick installation and start-

up guide.

Page 34

34 Hardware description

R-

L1

L2

L3

T1/U

T2/V

T3/W

R+

1

2

3

4

Operation principle

The figure shows the simplified main circuit diagram of the drive.

No. Description

1 Rectifier. Converts alternating current and voltage to direct current and voltage.

2 DC link. DC circuit between rectifier and inverter.

3 Inverter. Converts direct current and voltage to alternating current and voltage.

4 Brake chopper. Conducts the surplus energy from the intermediate DC circuit of the

drive to the brake resistor when it is necessary and if an external brake resistor is

connected to the drive. The chopper operates when the DC link voltage exceeds a

certain maximum limit. The voltage rise is typically caused by deceleration (braking) of

a motor. The user obtains and installs the brake resistor when needed.

Page 35

Mechanical installation 35

4

Mechanical installation

Contents of this chapter

The chapter tells you how to examine the installation site, unpack, check the delivery

and install the drive mechanically.

Installation alternatives

You can install the drive:

• With screws on to a wall

• With screws on to an assembly plate

• On to a DIN installation rail (with the integrated lock)

Installation requirements:

• Make sure that there is a minimum of 75 mm of free space at the top and bottom

of the drive (at the cooling air inlet and outlet).

• You can install several drives side by side. Note that side-mounted options require

20 mm of space on the right side of the drive.

• Install R0 drives upright. R0 drives do not have a cooling fan.

• You can install R1, R2, R3 and R4 drives tilted by up to 90 degrees from vertical to

fully horizontal orientation.

• Make sure that the cooling air exhaust at the top of the drive is not below the

cooling air inlet at the bottom of the drive.

Page 36

36 Mechanical installation

• Make sure that the hot exhaust air from a drive does not flow into the cooling inlet

of other drives or equipment.

• The drive has an IP20 ingress protection classification for cabinet installation.

Examining the installation site

Make sure that:

• There is sufficient cooling. Refer to Losses, cooling data and noise on page 93.

• The operating conditions are within the specifications in Ambient conditions on

page 101.

• The installation surface is as close to vertical as possible, of non-flammable

material and strong enough to support the drive. Refer to Dimensions and weights

on page 92.

• The material above and below the drive is non-flammable.

• There is sufficient free space above and below the drive for service and

maintenance.

Required tools

To install the drive mechanically, you need the following tools:

• A drill and suitable drill bits

• A screwdriver or wrench with a set of suitable bits (PH0–3, PZ0–3, T15–40, S4–7)

(For motor cable terminals, the recommended shaft length is 150 mm)

• A tape measure and spirit level

• Personal protective equipment

Page 37

Mechanical installation 37

Unpacking the delivery

Make sure that all of the items are present and that there are no signs of damage.

Standard drive package contents:

•Drive

• Assistant control panel (not installed)

• I/O module RIIO-01 with EIA-485 (BACnet MS/TP, Modbus RTU, N2) (not

installed)

• Mounting template (for R3 and larger drives)

• Installation accessories (cable clamps, cable ties, hardware, etc.)

• Options, if ordered with a plus code. Note that if a fieldbus adapter is ordered, it

replaces the I/O module RIIO-01 with EIA-485 of the standard delivery.

• Multilingual warning sticker sheet (residual voltage warning)

• Safety instructions

• Quick installation and start-up guide

• Hardware and Firmware manuals, if ordered with a plus code

Page 38

38 Mechanical installation

W

H

1

2

3

4

5

Installing the drive

You can install the drive:

• With screws to a suitable surface

• To a DIN installation rail with the integrated lock

To install the drive with screws

1. Mark the surface for the mounting holes.

Refer to Dimensions and weights on

page 92. Use the supplied mounting

template for the R3 and R4 frames.

2. Drill the holes for the mounting screws.

3. Start to tighten the screws into the

mounting holes.

4. Install the drive onto the mounting

screws.

5. Tighten the mounting screws.

Page 39

To install the drive to a DIN installation rail

1

2

3

1

2

3

1. Move the locking part to the left.

2. Push and hold the locking button down.

3. Put the top tabs of the drive onto the top

edge of the DIN installation rail.

4. Put the drive against the bottom edge of

the DIN installation rail.

5. Release the locking button.

6. Move the locking part to the right.

7. Make sure that the drive is correctly

installed.

To remove the drive, use a flat-head

screwdriver to open the locking part.

Mechanical installation 39

Page 40

40 Mechanical installation

Page 41

Planning the electrical installation 41

5

Planning the electrical installation

Contents of this chapter

This chapter contains the instructions to plan the electrical installation of the drive, for

example, to check the compatibility of the motor and drive, and select the cables,

protections as well as cable routing.

Make sure that the installation is designed and done according to the applicable local

laws and regulations. ABB does not assume any liability whatsoever for any

installation which breaches the local laws and/or other regulations. If the

recommendations given by ABB are not followed, the drive may experience problems

that the warranty does not cover.

Selecting the supply disconnecting device

Install a hand-operated input disconnecting device between the AC power source

and the drive. You must be able to lock the disconnecting device to the open position

for installation and maintenance work.

European Union

To meet the European Union Directives, according to standard EN 60204-1, Safety of

Machinery, the disconnecting device must be one of the following types:

• Switch-disconnector of utilization category AC-23B (EN 60947-3).

• Disconnector that has an auxiliary contact that in all cases causes switching

devices to break the load circuit before the opening of the main contacts of the

disconnector (EN 60947-3).

• Circuit breaker suitable for isolation in accordance with EN 60947-2.

Page 42

42 Planning the electrical installation

Other regions

The disconnecting device must conform to the applicable local safety regulations.

Checking the compatibility of the motor and drive

Use an asynchronous AC induction motor, permanent magnet motor or synchronous

reluctance motor (SynRM) with the drive. Several induction motors can be connected

to the drive at a time.

Make sure that the motor and the drive are compatible according to the rating table in

Ratings on page 84. The table lists the typical motor power for each drive type.

Selecting the power cables

• Select the input power and motor cables according to the local regulations

• Make sure that the input power and the motor cables can carry the corresponding

load currents. Refer to Ratings on page 84.

• Make sure that the cable is rated for at least 70

temperature of the conductor in continuous use. For the US, refer to Additional

US requirements on page 46.

• The conductivity of the PE conductor must be sufficient, see below.

• A 600 V AC cable is accepted for up to 500 V AC.

• To comply with the EMC requirements of the CE mark, use an approved cable

type. Refer to Recommended power cable types on page 45.

Use a symmetrical shielded cable to decrease:

• The electromagnetic emissions of the drive system.

• The stress on the motor insulation.

• The bearing currents.

°C maximum permissible

Make sure that the protective conductor has adequate conductivity.

Unless local wiring regulations state otherwise, the cross-sectional area of the

protective conductor must agree with the conditions that require automatic

disconnection of the supply required in 411.3.2. of IEC 60364-4-41:2005, and be

capable of withstanding the prospective fault current during the disconnection time of

the protective device.

You can select the cross-sectional area of the protective conductor from the table

below or calculate it according to 543.1 of IEC 60364-5-54.

This table shows the minimum cross-sectional area related to the phase conductor

size according to IEC 61800-5-1 when the phase conductor and the protective

conductor are made of the same metal. If this is not so, select the cross-sectional

area of the protective earthing conductor in a manner that produces a conductance

equivalent to that which results from the application of this table:

Page 43

Planning the electrical installation 43

Cross-sectional area of the phase

conductors S (mm

16 S

S <

16 < S <

35 < S S/2

2

)

35 16

Minimum cross-sectional area of the

protective conductor S

(mm2)

p

Refer to the IEC/EN 61800-5-1 requirement on grounding on page 15.

Typical power cable sizes

These are the typical cross-sectional area of the power cables at the nominal drive

current.

Typ e

ACH480-04-…

1-phase U

02A4-1 R0 3×1.5 + 1.5 16

03A7-1 R0 3×1.5 + 1.5 16

04A8-1 R1 3×1.5 + 1.5 16

06A9-1 R1 3×1.5 + 1.5 16

07A8-1 R1 3×1.5 + 1.5 16

09A8-1 R2

12A2-1 R2

3-phase U

02A4-2 R1 3×1.5 + 1.5

03A7-2 R1 3×1.5 + 1.5 16

04A8-2 R1

06A9-2 R1

07A8-2 R1

09A8-2 R1 3×2.5 + 2.5

12A2-2 R2 3×2.5 + 2.5

17A5-2 R3 3×6 + 6

25A0-2 R3

032A-2 R4

048A-2 R4

055A-2 R4

3-phase UN= 380…480 V

02A7-4 R1 3×1.5 + 1.5 16

03A4-4 R1 3×1.5 + 1.5 16

= 200…240 V

N

= 200…240 V

N

Frame mm2 (Cu)

3×2.5 + 2.5 14

3×2.5 + 2.5 14

3×1.5 + 1.5

3×1.5 + 1.5

3×1.5 + 1.5

3×10 + 10

3×25 + 16

3×25 + 16

(1

3×6 + 6 10

AWG

16

16

16

16

14

14

14

8

4

4

Page 44

44 Planning the electrical installation

Typ e

Frame mm2 (Cu)

(1

AWG

ACH480-04-…

04A1-4 R1 3×1.5 + 1.5 16

05A7-4 R1 3×1.5 + 1.5 16

07A3-4 R1 3×1.5 + 1.5 16

09A5-4 R1 3×2.5 + 2.5 14

12A7-4 R2 3×2.5 + 2.5 14

018A-4 R3 3×6 + 6 10

026A-4 R3 3×6 + 6 10

033A-4 R4 3×10 + 10 8

039A-4 R4 3×16 + 16 6

046A-4 R4 3×25 + 16 4

050A-4 R4 3×25 + 16 4

1) This is the size of a typical power cable (symmetrical, shielded, three-phase copper cable). Note that for the

input power connection, you typically must have two separate PE conductors, that is, the shield alone is not

sufficient. Refer to Grounding on page 15.

Refer also to Terminal data for the power cables on page 94.

Page 45

Recommended power cable types

PE

PE

PE

PE

PVC

EMT

PE

Symmetrical shielded cable with three phase conductors and a

concentric PE conductor as the shield. The shield must meet the

requirements of IEC 61800-5-1 (refer to page 42). Make sure that

local/state/country electrical codes permit this cable type.

Symmetrical shielded cable with three phase conductors and a

concentric PE conductor as the shield. A separate PE conductor is

required if the shield does not meet the requirements of IEC 61800-5-1

(refer to page 42).

Symmetrical shielded cable with three phase conductors and