Page 1

—

ABB Ability™ Quality

Management Solutions

for pulp and paper

Outstanding process visibility and advanced control

Page 2

—

—

At ABB, we’re dedicated to results.

Our focus is to help our customers

strengthen competitiveness and

profitability through continuous

improvement.

From the pulping process

through converting operations,

our solutions provide superior

Table of contents

04 Customer challenges

05 – 07 ABB Ability™ Quality

Management Solutions

08 – 11 Network Platform scanners

12 – 17 Measurements

18 – 19 CD actuator systems

20 – 23 Quality and production process

control

value in maximizing quality,

increasing performance and

reducing operational costs.

25 – 27 User interface

28 – 29 System integration

30 – 31 ABB Ability™ System 800xA:

Commitment to a common

architecture

32 Performance Services

33 Lifecycle management

34 How we meet customers' quality

management needs

Page 3

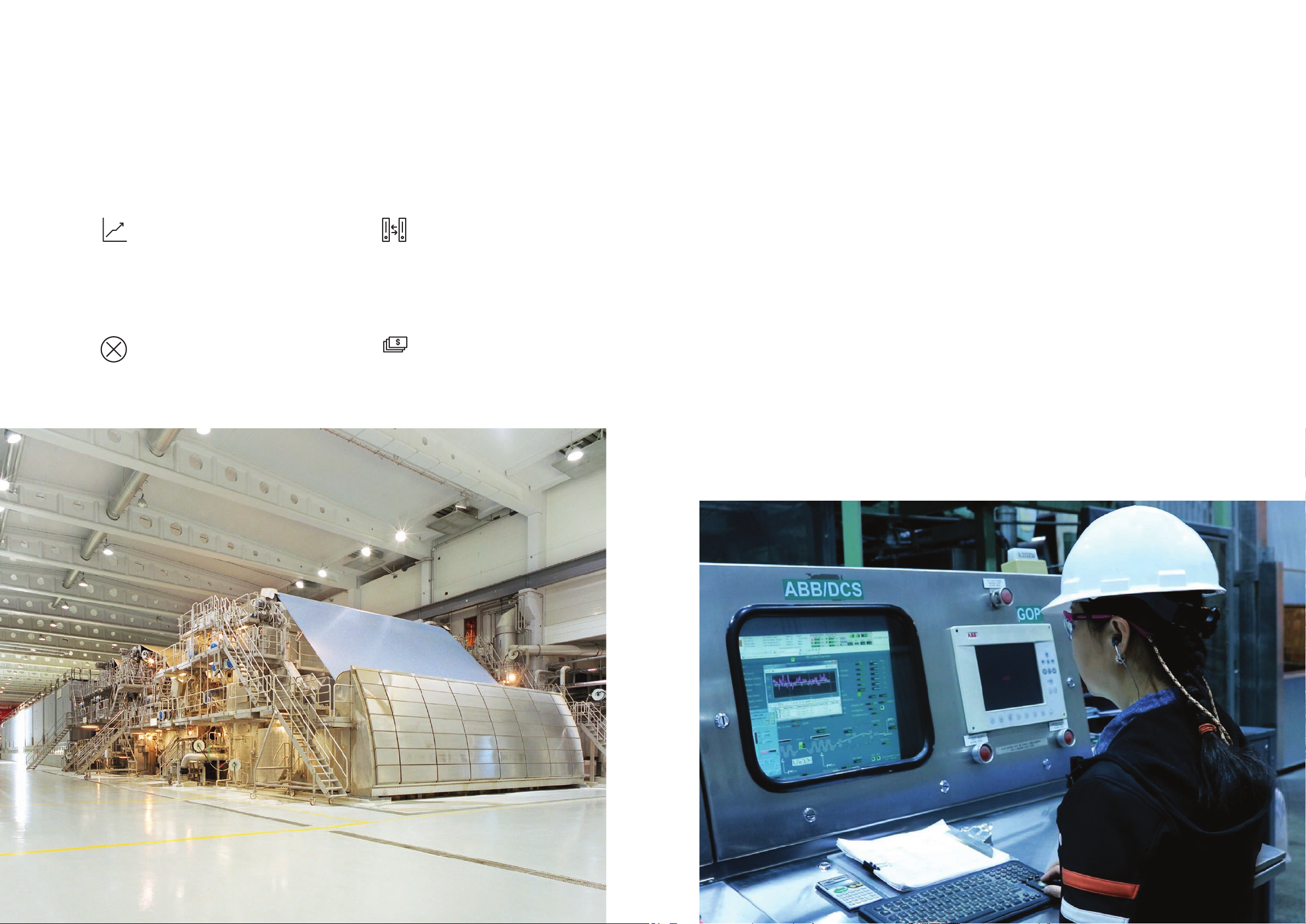

4

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 5

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS

—

Customer challenges

Increased customer demands

Mills in mature, high-cost markets face

tighter specifications and customer

requirements, creating the need for

higher levels of accuracy in quality

testing.

High cost of rejects

Off-spec paper can lead to runnability

issues, rejects and customer

complaints, costing mills profit.

Difficult conditions

Harsh, hot environments at midmachine and press locations make

measurements difficult.

High input costs

Fiber, energy and labor costs can

affect profitability and contribute to

missed opportunities.

—

ABB Ability™ Quality Management Solutions

Leading-edge online measurement and control

performance from the category creator

From our origin as the first on-machine paper property measurement system

provider to the latest advanced control and analytics solutions of today, ABB

solutions have earned a reputation for superior design and performance.

ABB is well-known throughout the industry as the

supplier of choice for comprehensive, integrated

quality measurement and control solutions for

tissue, pulp, paper, packaging and specialty

applications. From a singly applied Cross

Direction (CD) actuator, to standalone

measurement through completely integrated,

large scale paper mill solutions, our customers

count on us as a reliable, performance-driven

technology partner.

From inception, our company has valued and

nurtured the contributions of a strong team of

professionals to design, produce, apply and

support our efforts in the pulp and paper

industr y. In fact, ABB has been providing paper

makers with the most advanced measurements

and controls available for over 70 years. With a

growing team of almost 2,000 dedicated paper

making experts, ABB has the resources to meet

your challenges now and in the future.

Page 4

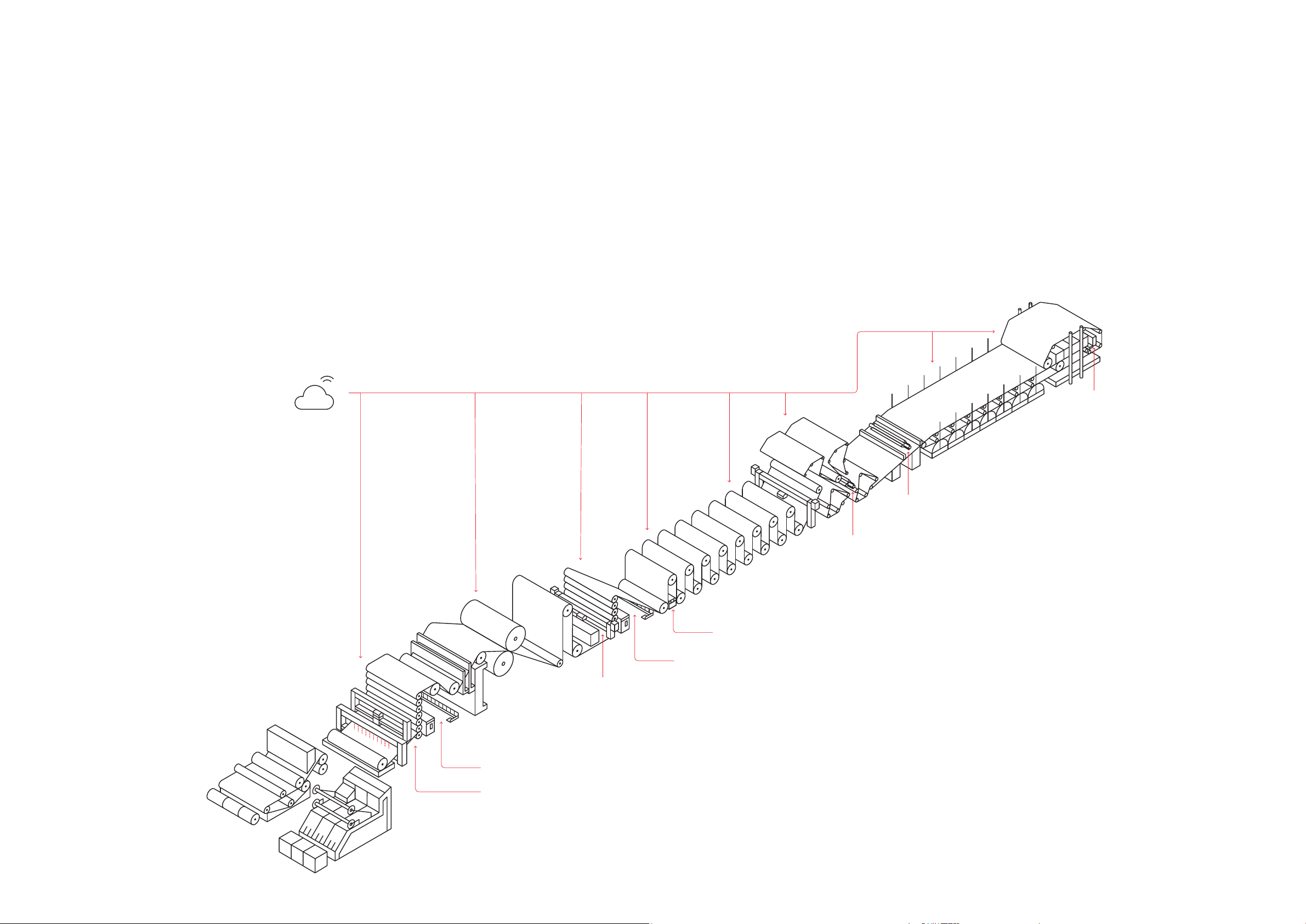

6

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 7

—

ABB Ability™ Quality

Management Solutions

An integrated system with a robust and reliable

design, advanced analytics and an excellent

user experience

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS

ABB Ability™ solutions

Dilution xP profiler

SteamPlus xP profiler

SteamPlus xP profiler

Air-Water xP profiler

Induction xP profiler

Coatweight xP profiler

Induction xP profiler

Network Platform scanner

Evaluate quality throughout the entire

manufacturing process to ensure on-spec paper

at the lowest cost.

• Gain full visibility over process and system

performance with integrated online

measurement, process and quality controls

• Speed up root cause identification of quality

issues and provide faster corrective action

thanks to seamless system integration

• Increase efficiency and product output by

reducing sheet breaks and optimizing

runnability

Page 5

8

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 9

—

Network Platform scanners

Necessary process information

to optimize product quality

NETWORK PLATFORM SCANNERS

ABB provides scanning solutions on more paper

machines than any other company. We have

earned this trust by providing the most advanced

Quality Control System (QCS) measurements,

data acquisition and communication technology

in the industry. This allows excellent insight into

both the measurement system and paper

machine health.

The industry-leading Network Platform family of

scanners enables papermakers to apply the

highest quality measurement technology on all

applications. With a robust, sturdy design,

advanced signal processing and sensor support

features, mills gain precise measurements and

maximum operational performance – even in the

harshest of environments.

—

01 The in dustry-lead ing

Network Platform family

of scanners enables paperma kers to apply th e

highest quality measurement technolo gy on all

applications.

Superior design and performance

ABB Network Platforms are the industry’s strongest and most advanced scanners, providing the

process information necessary to optimize product quality. All platforms are built to specified CD

width for lowest installation cost and greatest flexibility.

The reinforced carbon steel “A”-beam construction with strong end columns provides superior vertical,

horizontal and torsional rigidity. This stable structure is critical for precise alignment of sensor source

and detector heads in harsh environments without the need for compensations.

Expect the same superior design and performance across all Network Platform scanners:

Design

• Smooth exterior with no external openings or

exposed hardware or cables minimizes

contamination

• Fully integrated system electronics are

completely accessible from the end column

• Structural thermal stability means no liquid

cooling and reduced utility costs

• “Seam-side down” upper and lower beams

prevent materials falling in the structure

• Advanced external coatings resist chemical

agents for long corrosion-free life

• Thermal coefficients between structure and the

carriage rails allow for equal expansion and

contraction

• Optical encoder ensures precise sensor

positioning

Performance

• Accurate edge-to-edge measurement of all

critical sheet characteristics

• Reduced risk of sheet breaks with wide sensor

carriage that delivers a long-lasting, smooth

ride across the moving web

• Most detailed product picture with full-sheet,

1,200-datapoint profiles

• Same-point and tight measurement of sheet

edges with streak-optimized sensors

• Smallest variations revealed with edge-to-edge

total sheet measurement and advanced edge

modeling logic

• No realignment necessary throughout life of

scanner with factory laser-aligned rails and

stress-relieved platform structures

—

01

Page 6

10

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 11

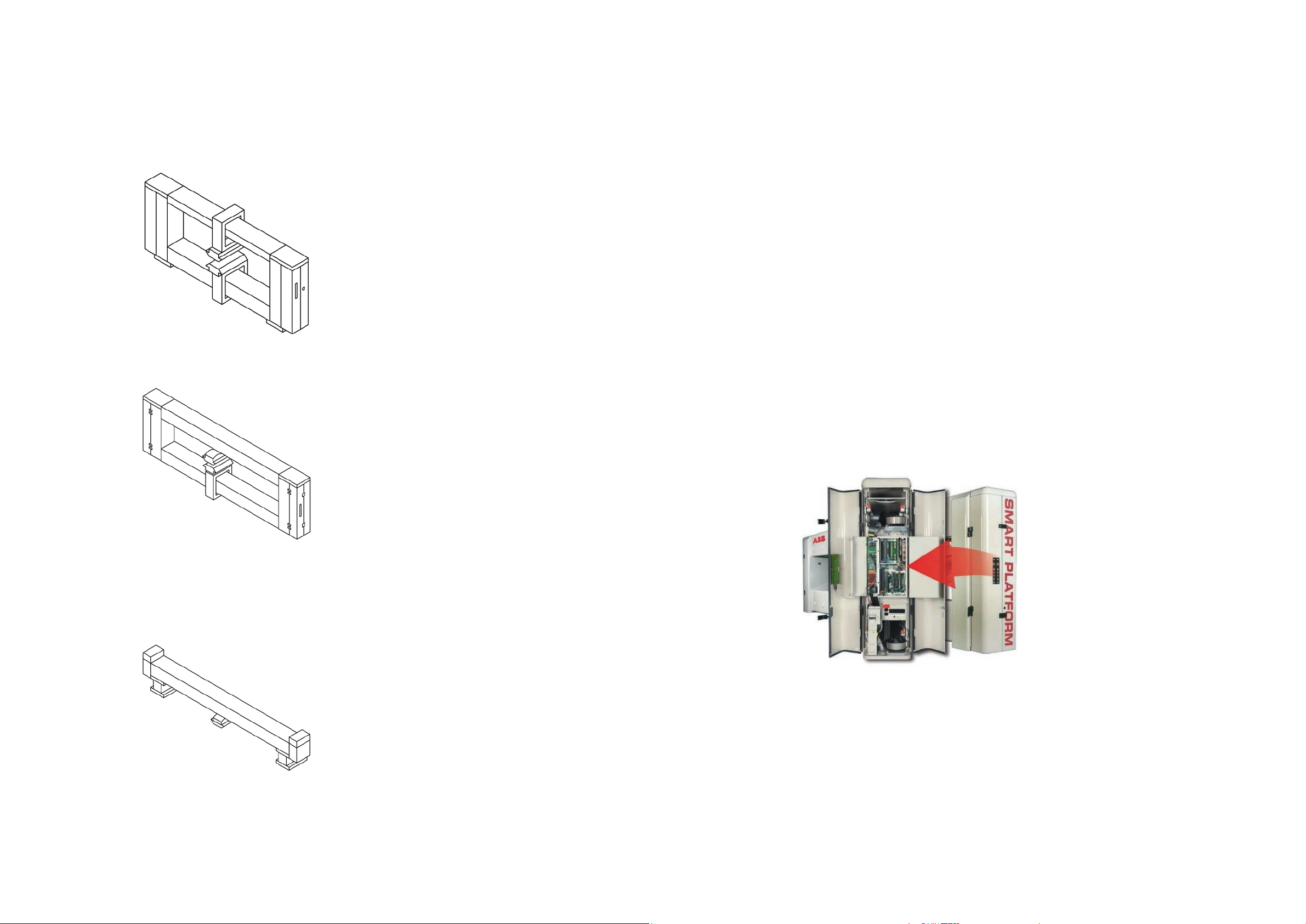

NETWORK PLATFORM SCANNERS

Network Platform scanner family

All Network Platforms include advanced capabilities such as extensive and remote diagnostics, stepby-step expansion and complete end column access for all maintenance tasks. These capabilities

expedite installation while also minimizing downtime and startup requirements and lifecycle costs.

NP800

The Network Platform 800 (NP800) is a high-performance

platform right-sized for scanning of small-to-mid size

tissue and paper machines. The RedDot award-winning

design provides customers with maximum uptime for

continuous precision measurements that detect the

slightest imperfections in the web. The advanced carbon

steel “A” frame provides excellent strength-to-size ratio

enabling cost-effective installation in the tightest locations

and low operational costs.

• Maximum 6.23 M (245 in) sheet trim

• Up to 4 sensors at 25 degree passangle

• Construction: Monocoque 6 mm thick A-Beam with welded

box end column

NP1200

The NP1200 provides scanning sensor support on processes

of all sizes. Its solid 10 mm steel A-frame design is

unparalleled in its ability to provide a rigid foundation for

measurement success. This inherent stability for online

sensors is true even when carrying multi-sensor packages at

extreme pass lines across the widest sheets. To ensure

reliable performance in even the harshest mill environments,

the system is pressurized by air and has a welded and wellsealed exterior with no service covers along the beams.

• Maximum 10.23 M (403 in) sheet trim

• Up to 7 sensors at 25 degree passangle

• Extended widths and pass angles up to 45 degrees are

available upon request

• Construction: Monocoque 10 mm thick A-Beam with

welded box end columns

—

02 Upgrade to the latest

measurement

technology without

the nee d to replace

an existing scanner.

Diagnostics

Included with all scanners are Network Platform

Engineering Tools that allow users to commission,

monitor, maintain and troubleshoot. These userfriendly applications – accessible via the mill

network or through remote connection – include

advanced health reporting, trending and sequence

of event monitoring for the scanner, sensors and

electronics.

Lifecycle path for scanners

Cost-effective lifecycle support and evolution is

extremely important given the mission criticality

of Quality Control Systems. Network Platforms

can be easily updated with the latest processing

and sensor technologies as they are developed to

protect investments over the long term and

ensure a solid foundation for ongoing operation

and future QCS developments.

For previous generations, ABB follows a step-wise

approach to scanner and sensor upgrades to

minimize downtime, lifecycle cost

and budget impact.

Smart Platform to Network Platform Upgrade

The Network Platform structure, mechanical drive

system and cabling is functionally identical to

Smart Platform designs.

As such, our cost-effective upgrade path

leverages the existing scanning platform and

adds new Network Platform software, signal

processing and sensor support features, saving

mills time and money.

With an upgraded frame, mills can also take

advantage of new sensors specifically designed

for the advanced computational and signal

processing capabilities of upgraded architecture,

such as moving from the old Hemi+ moisture

sensor to the High-Performance Infrared

Transmission (HPIR-T) moisture sensor, or

upgrading from Smart Color to the new High

Performance Color Measurement.

Benefits of an upgrade:

• Supports new online Spectral Analysis Package

for sensor signals

• Enables upgrades to latest sensors most of

which have higher sampling rates – some

sensors up to 5,000 samples/sec

• Improved sensor/scanner diagnostics package

and configuration tools

• Enhanced alarm and event handling for

diagnostics

• Significantly improved software update,

backup and restore functionality

RNP1200

The RNP1200 supports ABB single-sided (reflective)

measurements for process locations such as wet presses,

coaters and size presses. Design is the same as the NP1200,

but with a single beam so it is able to fit in tight machine

locations where good reflective moisture or coat weight

measurements are critical.

• Maximum 10.23 M (403 in) sheet trim

• Up to 2 sensors at 25 degree passangle

• Extended widths and pass angles up to 90 degrees

are available upon request.

• Construction: Monocoque 10 mm thick A-Beam

• Mounting and head package customization is also

available

—

02

Page 7

12

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 13

—

Measurements

Improve paper quality with precise and

MEASUREMENTS

continuous online measurement

With over 70 years of experience specifically in online paper property measurement,

ABB is an industry leader in providing unique, leading-edge measurements to

optimize machine stability and improve process efficiency.

ABB’s robust and reliable sensors provide high

resolution, precise and accurate measurements

that take advantage of a unique compact design

for continuous online measurement even in the

harshest environments. Advanced diagnostics

and reporting facilitate faster troubleshooting

and reduced maintenance cost and downtime.

Remote support is also available.

We offer complete measurement solutions

including multiple options for basis weight,

moisture, caliper and coat weight. This allows

the choice for application specific, processoptimized solutions.

Weight

ABB's heritage includes the development of

nucleonic basis weight measurement for the

paper industry. Since that time, our industryleading approach has expanded to include new

technologies for many applications.

• Nucleonic Basis Weight

ABB Basis Weight Measurement provides

unparalleled accuracy and streak resolution for

optimum MD and CD weight control all in a

compact design. The sensors use Krypton

(STLK11) or Strontium (TLS1) isotopic sources,

depending on the application requirements.

Each application-optimized sensor uses

radiation transmission techniques to achieve

laboratory quality accuracy and precision on a

wide range of paper grades. Factory calibration

ensures single, linear measurement range for

long-term accuracy.

• High-Performance Infrared Fiber Weight

(HPIR-FW)

For tissue and non-woven measurement

applications, ABB provides a proven design that

delivers safe and reliable performance to

directly measure fiber weight, moisture and

temperature in a single sensor without

radiological isotopes and the regulations

associated with them.

With these highly precise measurements,

operators can more confidently use MD and CD

controls for reduced variability, faster start-ups

and grade changes while also shifting targets

closer to acceptable quality limits to save on

energy and raw material costs.

Virtual measurements

In addition to our full lineup of physical sensors, ABB offers Virtual Measurements that use machine and process

inputs to produce online calculations of important process variables or product properties.

These measurements can be used to provide:

Online measurements that are not

available from physical sensors (e.g.

strength)

More frequent measurements based on

infrequent physical measurement and

process variables

Virtual Measurements utilize models generated from machine learning technologies to predict an online

measurement, increasing the frequency of the measured paper, pulp or process property. These inferred

measurements are available in informative, user-friendly displays that also include alarms, alerts and performance

indicators. With confidence in the reliability and accuracy, maintenance and operations can take action to reduce

variability and achieve quality, productivity and profitability targets.

Stand-in virtual measurements for physical

sensors when physical sensors are unavailable

Validation measurements for direct

measurements from physical sensors

Page 8

14

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 15

MEASUREMENTS

Moisture

Almost every controllable variable on the paper

machine has an impact on moisture. ABB uses

the latest technologies in order to provide

superior online moisture measurements for

CD and MD control.

• High-Performance Infrared Transmission

(HPIR-T)

ABB’s HPIR-T is the premier moisture and sheet

temperature sensor with an accuracy that helps

maximize control performance to save both

energy and fiber costs. HPIR-T sets a new

standard for precision by increasing speed and

number of measurements; its innovative optical

design doubles the signal-to-noise ratio of the

instrument to provide an industry-leading

moisture measurement rate of 5000 per second.

Robust and inherently stable, it is a consistently

high performer even in severe environments.

HPIR-T is air-cooled, field replaceable, and without

continuously moving parts.

• Microwave

Microwave Moisture Sensors have been

specifically designed for the most challenging

paper web applications; where basis weight and

water weights are high or over a broad range of

temperatures. The unique properties of

microwaves ensure that the moisture

measurement is unaffected by ink residues,

pH, inorganic fillers or colored pigments, which

makes it particularly suitable for applications with

significant recycled content. Measurement output

is robust, stable and insensitive to external

influences.

• High-Performance Infrared Reflection (HPIR-R)

Mid-machine and wet press moisture

measurements help optimize energy, press

loading and quality performance while also

detecting streaks prior to the size press. The

Reflection Moisture sensor provides

papermakers with both process insight and

installation flexibility. The single-sided, noncontacting moisture measurement can be

applied across a wide moisture and location

range; it is usually mounted on an RNP1200,

allowing the sensor to be deployed in tight and/

or hot locations or fabric-backed processes.

Color

High-Performance Color Measurement provides

color, brightness, opacity and whiteness

measurements while scanning over the moving

web. The next-generation sensor incorporates

novel LED technology to make color measurement

faster and more reliable by using a high-speed

spectrophotometer. The sensor works in

conjunction with ABB’s advanced Color Control

to minimize off-spec product and reduce shade

change and start-up times, while helping mills

precisely control color to a target shade.

Caliper

ABB Caliper sensors measure product thickness

and deliver unparalleled accuracy, fast response

time and streak resolution for optimum CD

caliper control and process analysis.

• Glide Technology (GT) Caliper

With patented gliding technology and a low

density, aerodynamic design, GT Caliper glides

smoothly over the sheet to deliver superior

measurement without marking or damaging the

sheet. Caliper options include a light touch

solution for the most delicate processes and

sensing heads optimized to reduce dirt pickup

on grades with high recycle content.

• Optical Caliper

Dual-sided contacting caliper sensors pose

challenges for certain applications. ABB has

developed a new Optical Caliper sensor that is

non-laser based, eliminating measurement

errors caused by light penetration into the

sheet. Instead, the revolutionary technology is

based on the confocal displacement method

that delivers unrivaled accuracy and stability.

Fiber Orientation

The greatest insight into runnability can be

gained when comparing the difference in fiber

orientation between two sides of the sheet. ABB’s

laser-based Fiber Orientation sensor delivers

continuous online, two-sided measurement

providing information on both fiber angle and

ratio. This helps eliminate process problems and

optimize sheet strength and mechanical

conditions faster than relying on lab

measurements alone.

Ash

ABB 2-Component and 3-Component X-Ray

Measurements accurately measure ash weight on

a broad range of applications. These sensors are

highly sensitive to inorganic additives used in the

production of quality paper, such as fillers and

coatings. Pre-calibrated at the factory, these

sensors accurately measure the ash weight of up

to three components simultaneously.

Page 9

16

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 17

MEASUREMENTS

Gloss

Leveraging a measurement principle that

simulates the human eye’s perception of gloss,

Gloss Measurement provides continuous online

measurement in accordance with TAPPI

standards and offers flexibility to meet differing

machine requirements. The compact, totally

enclosed measurement design includes high

intensity LED, which ensures low maintenance

and long-term reliability.

Optical Properties (Optipak)

Coat Weight

Customer requirements and process conditions

require a consultative approach to coat weight

technology selection. ABB offers the expertise and

technology to meet your requirements by offering

multiple options.

• Direct Infrared (IR) Coat Weight

ABB’s IR Coat Weight provides direct

measurement of coating components and

percent moisture at each web surface through

its unique focusing device, detection

capabilities and signal processing of many

infrared wavelengths. This integrated solution

for measurement, process control and

supervision provides great flexibility and

performance; it is designed to overcome

challenges posed by applications such as heavy

grades, simultaneous coating of both sides of

the sheet and limited machine space. Plus, our

AutoCal method processes signals from

multiple online sensors for unprecedented,

optimized measurement.

Choosing the right sensors for your mill

Measurement Best for Benefits

Weight

Nucleonic Basis Weight - STLK-11 High resolution weight measurement for

Nucleonic Basis Weight - TLS-1 Board and pulp grades >1080 gsm up to

HPIR-FW Light tissue and towel grades with virgin

HPIR-T All paper and board grades < 500 gsm High accuracy

Microwave Heavy pulp and board grades, grades

Reflection All grades that require a single sided

Glide Technology (GT) All grades up to 2032 microns (80 mils)

Glide Technology - Light

Touch (LTGT)

Optical High end grades up to 1016 microns

Dry Weight Difference All coated grades Excellent precision and accuracy

X-Ray Difference Lighter coated grades and those with

Direct IR (reflection) Coated board applications with tight

paper and board grades <1080 gsm

4900 gsm - Harsh environments

fiber

Moisture

with very high optical broadband light

absorbers

moisture measurement; particularly good

for heavy grades in hot, mid-machine

locations

Caliper

that can use dual contacting

measurement

Grades up to 2032 microns (80 mils) with

surfaces sensitive to marking

(40 mils)

Coat weight

need for excellent precision and accuracy.

inter-coater space

Excellent process visibility and accuracy

Excellent reliability and broad range

Single sensor for multiple properties.

Lower cost and greater simplicity;

no nuclear source

Ultra-fast measurement

Excellent measurement accuracy in

harsh environments

Excellent precision and accuracy.

Can be installed in tight locations

Excellent precision and accuracy;

reduced maintenance; good performance

with contaminants; lower cost

Excellent precision and accuracy;

reduced maintenance; good

performance with contaminants

Excellent process visibility and

CD performance with minimal

process intrusions

Best resolution and precision

on light coated grades

Excellent precision, good accuracy

with Autocal

The Optical Properties Measurement combines

measurement of three visual paper properties

in one compact package: Formation, Opacity

and Brightness. Continuous and repeatable

measurement of sheet formation online allows

papermakers to capitalize on this dimension of

process visibility while also measuring opacity

and brightness according to TAPPI standards

for substantial economic and quality benefits.

• Dry Weight Difference

ABB’s high signal-to-noise ratio Basis Weight

measurement is combined with our highly

accurate moisture measurements to offer

unparalleled coat weight accuracy.

• X-Ray (Ash) Weight Difference

For lighter grades of paper needing the highest

accuracy and precision, X-ray Difference offers

high measurement sensitivity to coating solids,

combined with low sensitivity to cellulose and

water. ABB’s patented X-ray filtering techniques

eliminate calibration shifts due to coating

composition changes.

Page 10

18

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 19

—

CD actuator systems

Accuracy, precision and speed

CD ACTUATOR SYSTEMS

—

Fast, precise response to dynamic

Slice xP

production and quality challenges

in the cross direction with

advanced control, analytics

and diagnostics from ABB's

CD actuator systems.

Weight xP

ABB's Weight xP suite is designed for better basis

weight or coat weight control and features

advanced electronics and a rugged design that

is both robust and highly reliable. The common

system architecture enables easy installation

and maintenance.

By combining absolute position measurement

with ABB's patented fusion sensor technology,

these actuators deliver unsurpassed precision,

speed and diagnostics.

Benefits of choosing the Weight xP family of

actuators:

• Improved machine performance and runnability

• Increased efficiency with faster grade changes

• Decreased raw material usage

• Reduced rejects and improved quality

Whatever your needs, ABB’s actuators offer the speed and accuracy needed for superior control

Suitable for Weight xP SteamPlus xP Air-Water xP Induction xP Plus

Slice xP Dilution xP Coatweight xP

CD weight

CD moisture

CD caliper

CD fiber

orientation

CD coat weight

CD gloss

Uncoated papers

Coated grades

Uncoated

packaging

Tissue

• •

• • • •

• • •

•

• • • • •

• • • • • •

• • • • •

• • •

ABB pioneered stepper control of headbox slice

spindles in 1985, with close to a thousand

headboxes with ABB actuators in operation. With

Slice xP, weight profile variability is minimized by

the precise positioning of the slice lip for

optimum stock flow adjustments.

Dilution xP

ABB’s Dilution xP actuators have been installed on

consistency profiling headboxes from all leading

suppliers and can be fitted to any type of dilution

valve. Weight profile variability is minimized by

accurately adjusting the valve opening to control

the flow of dilution water.

•

•

Coatweight xP

ABB’s Coatweight xP delivers fast, accurate and

reliable coating profile bar positioning. The

actuator ensures an optimum, smooth coating

application through precise positioning of the

coater blade.

SteamPlus xP

ABB SteamPlus xP precisely and efficiently applies

steam close to the sheet surface to minimize

profile variability and reduce dryer section steam

usage. Unique to ABB’s diffuser design is its

ability to keep the steam jets more than 100mm

from the sheet to protect against pulp build up

and blockages. That, coupled with its

maintenance-free T880C actuator design,

proprietary screen slides and integrated cleaning

system means mills benefit from steady

steambox performance without the need for

regular maintenance, improving fiber usage and

paper quality.

Benefits

• Reduces moisture profile variability by up to

80%

• Manage steam usage for 5-10%+ increase in

production and/or 5-10% reduction in energy

costs

• Improved reel build, sheet break recovery and

runnability

• Increased press felt life, sheet strength

properties and sheet surface properties

Air-Water xP

The Air-Water xP is a re-moisturizing system that

delivers excellent sheet absorption due to its

patented atomizer design. By producing

predictable, homogeneous droplets, the actuator

maintains precise flow, impervious to wear or

water pressure variations while being resistant to

plugging.

Benefits

• Up to 80% reduction in profile variability

• Improved reel building and runnability

• Fast recovery at start-up and after grade

changes or process upsets

Induction xP Plus

Workcoil beam

Power module cabinet

Mills will reduce caliper variability with

ABB Induction xP Plus. The system heats the

calender roll by electromagnetic induction, and

the resulting increase in temperature enables

rapid corrections to sheet finishing profiles.

Benefits

• Ensures maximum heating in concentrated

area in the shortest time

• Reduces CD caliper variability by up to 90%

• Delivers up to 80% improvement in recovery

after sheet breaks and start-up

• Enables best sheet finishing for gloss,

smoothness and printability

Page 11

20

Without automatic shade change

Without automatic shade change

Start Finish

Finish

New target

Old target

With automatic shade change

With automatic shade change

Start

0,5

New target

Old target

Percentage

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 21

—

Quality and production process control

Maximizing and replicating quality

QUALITY AND PRODUCTION PROCESS CONTROL

As the linchpin of the QCS, quality and process

controls are highly reliant on all the components

working together.

ABB’s measurement and control packages

operate seamlessly together to improve quality

for pulp, paper, packaging and tissue makers by

reducing variability, improving grade

repeatability and on-grade utilization.

• Weight

• Moisture

• Ash

• Opacity

• Coat weight

• Caliper

Machine Direction Controls

ABB’s Machine Direction (MD) Controls ensure

minimum variability in paper properties while

minimizing fiber and energy consumption using a

model-based control approach. MD Controls not

only allow for the best steady-state disturbance

rejection during cruise operation, but they also

significantly reduce off-spec time during start-up

and sheet break recovery through fast tracking

response.

Ash con trol

Wet-en d level 1

FC

level I

Weight control

SC

level I

Mills also benefit from optimized production with

minimized energy consumption, increased

throughput and improved availability of both

resources and the machine.

With proven availability, built-in performance KPIs

and local support connected to a global network

of extensive papermaking expertise – all of which

can only be found with ABB – mills can achieve

sustained performance.

Features

- Proven robust model-based approach with

intuitive tuning

- Model error filtering maintains true

measurement signal while optimizing

disturbance rejection and actuator energy

consumption

- Integrated operator interfaces

Level I I

Moisture control

PC

level I

PC

level I

• Yankee-Hood

• Crepe r atio

• Single Color

• Dual Color

• UV Brightness

• Advanced Shad e

Change

—

03 & 04

The second grap h

shows on average

how much faster

shade changes take

using A dvance d Shade

Change (ASC) control.

• Machine Direction – Tissue Controls

ABB’s MD Tissue Controls reduce energy

consumption and improve the utilization of

equipment in the most efficient way. Yankee

hood control enables the tissue maker to make

use of the faster dynamic response in hood

temperature, while maintaining steady state

with the less expensive Yankee steam pressure.

This maximizes energy efficiency while

reducing moisture variability and start-up/

grade change response.

• Machine Direction Multivariable Color Control

Papermakers can exceed emerging

requirements on sheet color and shade

uniformity with ABB’s proven Machine Direction

Multivariable Color Control. Designed to

provide optimal control utilization under

changing conditions, Multivariable Color

Control helps mills minimize rejects and

optimize dye usage.

Advanced Shade Control brings the shade to a

new target in conjunction with or independent

of grade changes. This considers both the

spectral aspects of color and dye, as well as

time-domain responses, minimizing off-spec

time.

ABB’s highly-intuitive, color system matrix

automatically calculates the online control for

multiple actuators for desired dye additions.

1

Color deviation

10

0

—

03

20 30 40 50 60

Time (min.)

The crepe-ratio control helps maintain the

required speed difference between Yankee and

reel, optimizing creping performance.

Features

- Hood temperature ratios

- Flexible moisture actuator and mode handling

- Selectable crepe-ratio entry format

Not only does this minimize the difference

between the actual and target shade, but it

also gives confidence to operators to maintain

a control-on state.

Features

- Full spectrum top, bottom or dual-side color

and brightness control

- Brightness control of actuators using

fluorescence or optical brightening agents

- Flexible color kitchen configurations and

control

- Master-slave dye configuration available

- Support for mixed dye pump types

- Shade setup, handling and changes can

be independent of or combined with

grade changes

Statistical distribution of shade change time

20

18

16

—

04

With ASC

14

12

10

8

6

4

2

0

57%

10

20

30 40 50 60 70

Shade change time (minutes)

Without ASC

Page 12

22

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 23

QUALITY AND PRODUCTION PROCESS CONTROL

• Weight

• Moisture

• Caliper

• Fiber orientation

• Coat weight

• Finishing

• Local Va riabilit y

Contro l (automatic

mapping)

—

05 Paper machin e

example, highlighting

the nee d for a

multivariable approach

due to coordination

of multiple act uators

influencing weight,

moistu re, cali per and

fiber orientation

Multivariable Cross Direction Control

For even the most challenging cross-directional

processes, ABB’s Multivariable Cross Direction

(MCD) Control optimizes and balances multiple

paper quality CD profiles, while coordinating the

contributions of multiple sets of CD actuators

within their optimal operational limits.

ABB’s MCD Control not only allows for the best

steady-state or cruise performance, but it also

significantly reduces start-up and sheet break

recovery time while minimizing fiber and energy

consumption. MCD Control can also be

implemented as a standalone or hybrid

companion. It can be configured for third-party

profiles or actuators when required and includes a

vast number of third-party actuator interfaces to

minimize implementation time.

Response modelsSetpoint targets

MCD Control

Actuator

outputs

ABB’s MCD Control is intuitive and simplifies both

the operation and maintenance experience,

resulting in less erroneous operator interactions

and troubleshooting time to maintain control

performance.

Features

- True multivariable high-resolution CD-control

and process modeling

- Integrated operator interfaces

- Advanced spatial modeling and filtering

techniques combined with temporal dynamic

response modeling

- Integrated bump test and modeling

application

- Local variability control (LVC) dynamic

mapping automates and prevents

performance deterioration

Response mappings Profile targets

• Automatic Grad e

Change

• Coordinated Speed

Control

—

06 Gra phs showing

automat ic grade

change performance.

—

07 Performanc e for Wet

End Cont rol is made

visi ble and sustained

with b uilt in, d efault,

and configurable key

performance indices and

dashboard interfaces.

Transition Controls

Whether you would like to gently change grades

within current specifications, or are required

to go off grade in order to reach the new

specifications, ABB's Automatic Grade Change

enables consistency, repeatability and the

minimization of off-spec production while

changing grades. Equally important is the

production rate control. ABB's Coordinated

Speed Change is vital in enabling the system to

make required machine speed changes, while

maintaining sheet properties to specification.

—

06

• Headbox

• Speed optimization

• Stock an d ply load ing

• Consistency

compensation

• Crepe ratio control

• Bulk compensation

• Yankee/h ood control

Dilution

profiler

—

05

Slice

proflier

Steambox

Press

scanner

Optimizing Controls

Finding the operational sweet spot is challenging

when attempted manually. Optimizing controls

identify performance gaps and and consistently

push machine performance to an ideal state

taking quality, production and process constraint

parameters into consideration.

Examples include:

• Speed Optimization Control identifies slack in

steam, stock flow and/or machine speed to help

maximize production rates within established

quality and process constraints

Induction

Size press

scanner

Water

profiler

profiler

Reel

scanner

Measurement

profiles

• Ply Loading takes the individual ply dynamics

into account, allowing the operator to configure

each ply as the grade specification or current

operational conditions require, and ultimately

shaping a unified weight control for optimized

ply distribution

• Consistency Compensation provides flexibility

in determining the actual consistency

measurement to be used (instrument reading,

calculated bias, or lab value) by the Ply Loading

and Dry Stock Flow Control features, minimizing

process upsets before consistency changes

reach the machine

• Ash Control

• White water

consistency

• Broke flow fill er

disturbances

—

07

Wet End Controls

The traditional approach of using retention aids to

control white water consistency is far from optimal

with the ever-changing retention properties of the

base sheet and disturbances to the fiber flow’s

base filler content. This can lead to runnability

issues in dewatering, excessive variability in ash

content and myriad inefficiencies, particularly for

filler and ash-heavy applications.

ABB Wet End Control takes full control of the

short circulation loop to reduce variability and

runnability issues, while decreasing fiber, energy

and chemical usage.

By combining robust and predictive model-based

control techniques to dynamically adjust to

process changes – while simultaneously finding

ways to optimize operational costs within process

constraints – Wet End Control helps mills

maximize productivity and profit.

Page 13

24

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 25

USER INTERFACE

—

User interface

Flexible displays for

local-to-mill-wide visibility

—

08 Contour map

showing conditioned

weight measurement

—

09 MCD ov ervi ew,

selected zone m apping

response highlighted

The QCS user interface provides a comprehensive

set of role-based displays and analytical tools

tailored for both local and remote users as well as

different levels of the organization.

Based on and integrated with the ABB Ability™

System 800xA platform, mills benefit from a

standard but modification-ready QCS display in a

secure, feature-rich environment that meets a

wide range of user requirements.

Operator Interface

The operator interface is purpose-built to give

the operations team an overview of the process

in an easy-to-access and digest layout for swift,

intuitive decision making. Local languages are

fully supported.

It is preconfigured in a best practice layout that

is based on ABB’s extensive system and process

expertise from decades of serving mills

worldwide. An important advantage of this

configuration is the reduction of complexity

for each display to enable faster operation and

decision making while facilitating easier

onboarding and training of new team members.

Information is segmented into process sections

to avoid overwhelming the operator. Navigation

between sections can be customized by user

preference. Users can instantly view and operate

high-resolution measurements, MD and CD

variations, profile contour maps, reel reports,

grade reports, documentation and support tools.

Specifically, the Multivariable Cross Direction

(MCD) overview display includes the controlled

error profile as well as the participating actuator

sets in a profile, zone -based style (figure 09). The

back-end mapping feature associates each zone

response onto the error profile, eliminating time

spent on understanding the actuator profile

response relationship.

All trend data is easy to export to standard

spreadsheets for analysis. Access to real-time

quality control information enables better

process decisions, reducing waste, saving raw

materials and ultimately increasing profitability

and shareholder value.

—

08

More complex information can be made available

to the user to better understand how specific

variables interact, such as how CD actuators or

a PID-controller response will behave. Some

sections include a prediction horizon, enabling

the operator to have awareness of the full

projected response.

—

09

Page 14

26

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 27

USER INTERFACE

—

10 MCD bump test

—

11 Colo r overview display

with p lot

—

12 Mul tivar iable CD

Contro l overv iew display

Engineering Interface

The engineering user-interface is focused on

enabling the maintenance and engineering

teams to provide an efficient environment

to continuously sustain performance. This includes

asset optimization, controls performance, and

modeling and mapping for swift on-site or remote

troubleshooting.

• Controls performance

Efficiently sustaining the performance of

controls is the most important task for all

engineering operations – especially the

modeling and tuning of process controls. For

example, performance indices provide the

engineering user with awareness of control

performance.

• Modeling and mapping

The MCD controls include a suite of

maintenance related displays to easily maintain

modeling and mapping without the need for

any offline tools. The integral bump-test

scheduler and execution module as well as an

easily accessed bump test analysis module

increases speed of analysis (figure 10) . This

simplifies the representation of the active

spatial response model and identified process

mapping.

• Graphics building

Graphics building is accomplished in a very

straightforward way with a complete set of tools

and a palette of pre-configured elements. This

simplifies display building, supports the needs

of power users and allows operator display

maintenance closer to final users. The back-end

xml-based graphics source code is available,

making for simplified upgrades.

—

10

—

13 Onl ine Spectral

Analysis display

—

14 Color measure ment

overview dis play

—

15 Auto matic grade

change display

Diagnostics displays and OSA

Diagnostic displays allow operators, maintenance

and engineering personnel to have access to

diagnostics information both for the QCS system

and the paper machine process. The system status

and a full featured, filterable, sectionable and

shelveable process alarming package is included

with the system.

Scanners and sensors all have associated health

pages and performance reports, assisting shiftbased maintenance to be the first line of response

for urgent troubleshooting as well as preventive

and corrective maintenance. All diagnostics

displays and information can be remotely accessed

with security considerations tailored to the

individual user or company protocol.

Online Spectral Analysis (OSA) is a software tool

for process engineers and skilled operators to view

and detect the spectral contents of sheet quality

variations while a paper machine is running.

It empowers machine operators and process

engineers to detect their product and process

problems in real-time and associate sheet quality

issues with machine problems instantaneously

during production. It also helps to avoid unplanned

machine downtime with the early detection of

process issues.

—

13

—

14

• Grade and shade code handling

Online or offline grade code handling easily

manages both grade codes and grade grouping.

It allows engineering personnel collaboration

with paper making subject matter experts using

a simple import/export functionality. Grade

and shade file maintenance is independently

managed so that similar shade targets can be

maintained across the grade structure.

• Simulation

An included process simulation package allows

for activities such as system validation and

operator training to be accomplished without

the need for a complete system installation and

startup. Training and analysis can be done early

and in a safe environment.

Enterprise-wide visibility

—

11

ABB systems are designed to provide the rich and

meaningful information necessary for best-in-class

decision making as well as for additional use in

Industry 4.0 applications. In addition to making

available all individual data items and summary

reports, all operator and maintenance displays

can be made accessible to remote users with

appropriate security measures and read/write

protection in place.

—

15

ABB also has companion applications available

for external users to analyze and make use of

—

12

this information, including advanced analytic

applications, data aggregation, dashboards, etc.

Page 15

28

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 29

—

System integration

Break down barriers for targeted, cost-effective use of information

—

—

Verti cal and horizontal

system integration

provides the data and

visi bility n eeded to

improve productivity,

quality, asset utilization

and mor e, from a mil l to

enterprise-wide level.

ABB breaks down the information barriers found

in mill and enterprise-wide systems for end-to-end

visualization and the use of analytical techniques

to optimize productivity. Whether it’s bringing

quality and production information to the front

office and business systems, bringing legacy

system interfaces into a modern context, providing

advanced analytics for optimization or building

new production management applications, ABB

has the right solutions.

QCS800xA

ABB Quality Control Solutions are implemented as

a functional extension to the System 800xA control

platform. The Quality Control System (QCS800xA)

can be standalone or work as a totally integrated

component with other ABB solutions.

Business layer

Manufacturing Execution

Operations layer

Automation

layer

Device layer

DCS

These include paper machine drives and field

instrumentation as well as systems for web

inspection, lab management, manufacturing

execution and distributed control.

The systems fully support Edge computing and

localized analytical applications as well as cloud

computing and advanced analytical, enterprisewide solutions.

From relatively simple to extremely complex,

ABB has the experience, capabilities and system

architecture to scale the system to meet individual

needs across the spectrum for automation and

integration with new and existing systems.

ERP

System

QDMS

QCS

Diagnostics Serv ice tools

LMS

Best practices for swift decision making

In papermaking operations, it is important to be

able to trust and act decisively with the wealth of

information available. Because QCS solutions are

implemented within the 800xA platform, the data

is structured in the necessary format with the

rate, method and timing required. ABB's system

is therefore able to fully support analysis and

model-based decision making, regardless if the

data is generated from a physical online sensor, a

virtual measurement, process variables or derived

from an external source. This also includes model

outputs or one in which other algorithms have

been applied to the raw data source.

This logical system architecture coupled with good

data management practices enable us to develop

value-add applications that further benefit the

ultimate users of the information. Some examples

include:

Integration as the foundation of digital

transformation

Even before "Industry 4.0" was formally defined,

ABB had been using a common platform for data

organization, control and user interface for all

of its new products for decades. This means

our solutions have an inherent interconnection

that makes both application implementation

and digital transformation easier. Others are

only beginning to tie fundamentally different

systems together and many lack the experience

to use data in a way that brings real value. With

ABB, you get a wealth of automation, digital, and

industry expertise within everything we do, driving

improved productivity and smarter decision

making.

• Virtual measurements (weight, strength, etc.)

• Sheet break analytics

• Advanced controls (for square point, ash and

retention optimization, etc.)

• Data-based root cause analysis for processes

and systems

• Integrated Manufacturing Execution Systems

• Integrated analytics and artificial intelligence

applications

Page 16

30

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 31

—

ABB Ability™ System 800xA:

Commitment to a common architecture

ABB AB ILITY™ SYSTEM 800XA:COMMITMENT TO A COMMON A RCHITEC TURE

System

servers

Distributed control systems

Motors Standard drives

Motors

Instrumentation

Chemical delivery systems

Standard drives

Collaborative

production

management

enterprise servers

Drive systems

Enterprise clients

Maintenance workplace(s)Engineer workplace(s)Operator workplace(s)

Mill network, Intranet, Internet

Router/firewall

Router/firewall

Connectivity servers

System supported:

Advant, Freelance, Harmony,

Infi90, MOD, Master, SATT

cpmPlus

mil server

Quality control

systems connectivity server

Actuator systems

Quality control systems

Local I/O and remote I/O

Instrumentation

Intelligent Motor

Control Center

and third-party distributed control systems

Page 17

32

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 33

LIFECYCLE MANAGEMENT

—

Performance Services

Enhancing process and equipment

performance

ABB brings mills a new breed of digital services that not only tap into the vast amount of

information available but also leverage the deep industry expertise that enable the

delivery of long-lasting value.

Lab measurements

Energy Management

Chemical Systems

Condition monitoring

Driv es system

QCS Sys tem

—

Performance Services

are ena bled by th e ABB

Abili ty™ plat form to

colle ct data input s

from acr oss the mill and

provide a highl y scalable

and inte grated

solut ions, some of

which are shown he re.

ABB Ability™ Performance Services for pulp and

paper mills provide a way of operating that allows

both ABB and customer personnel to use the

same information and communication technology

backbone for troubleshooting, technical support,

condition and performance monitoring,

optimization, and predictive maintenance.

Critical equipment and processes can be remotely

monitored and optimized by both ABB and

customer experts to improve mill performance.

Advanced data processing and analytical

applications uncover trends, data patterns

and relationships to improve operations.

Data inputs

Production planning and management

Alarm monitoring and predictive analytics

provide both ABB and mill experts with the

necessary information to reduce unplanned

downtime. By enabling collaboration in a

seamless and fast manner, mills can improve

availability, throughput, quality and profitability.

Performance Services are enabled by the ABB

Ability™ platform to provide a highly scalable

and integrated solution. ABB Ability™ connects

ABB and customer experts to actionable data

and predictive analytics in a collaborative

environment.

ABB Ability

Infrastructure

QMS-specific Performance Services

• Scanner and Sensor Performance

QMS

Asset management

Order management

DCS Sys tem

CMMS

Data Historian

MES

ERP

• MD Contr ol Performance

• CD Control Perfo rmance

• Grade Change Control Performance

• Wet End Control Per formance

• Refiner Control Performance

• Blending Control Performance

• Virtual Measurements

• Sheet Break Performance

• Online Sensor Correlation

Additional Performance Services

• Pulp Mill Optimization

• Winder Performance

• Paper Machine Drives Performance

• Pulp Tracking

• Process Target Optimization

• Plant Asset Management

—

Lifecycle management

Protecting your investment

We are committed to maximizing the usable life of our customers’ investment. Our

approach to lifecycle management provides our customers with the confidence that

there is a well-defined support and a path forward for existing ABB solutions.

With the four phases, ABB enables customers

to plan ahead and protect their investment,

minimizing maintenance costs and reducing

downtime.

Before they move to different stages, ABB shares

the lifecycle plan with dates well ahead of the

phase ending. The classic and limited phases are

active for a minimum of 10 years combined.

Active

12 months 12-18 months

Removal from

Released for Sale

Active sales

Pre-announcement

Service agreements

ABB helps customers cut complexity, control

costs and maximize capital with our global

framework agreements for service. By first

assessing your assets and identifying your needs,

we can find the right Pulp and Paper Care package

for your mill.

Evolution and upgrades

ABB has developed several upgrade paths for our

scanners, sensors, actuators and controls. These

upgrades can be done in stages to provide a

smooth transition from old technology to new

systems. This approach not only ensures your

investment is protected but also provides

enhanced performance capabilities that

maximize the value of installed systems and

components.

Remov al from Classi c sales

Pre-announcement and

Last Time Buy no tice

Active

• Product marketed and available for sale

Classic

• Functional replacement available

• Product maintenance phase

Limited

• Product no longer manufactured

• Supported with best practical effort

Obsolete

• Support not available

• No longer available for sale or delivery

Most products are active for seven-to-ten years.

10 years minimum

Classic

Limited

6 months

Obsolete Notice

Manufacturing End

Obsolete

QCS ASM

ABB’s QCS Automation Software Maintenance

(ASM) program fosters proactive system management, providing easier software delivery. It

enables access to the latest QMS software for

continuous enhancements between system

upgrades. This program features a tiered

subscription service: 1) QCS ASM Maintain Plus

for access to updates within the current version

and, 2) QCS ASM Maintain & Evolve to go between

major QCS versions.

Spares

ABB's lifecycle support policy is to make every

effort to supply original, high-quality spare parts

for at least 10 years after the active lifecycle

phase. To further support that commitment, ABB

offers several services, including selfassessments, that are designed to optimize your

on-site spares and minimize risk of downtime.

Page 18

34

ABB ABILITY™ QUALITY MANAGEMENT SOLUTIONS FOR PULP AND PAPER 35

—

Why choose ABB for your quality

management needs?

Leading-edge online measurement and control

performance from the category creator.

WHY CHOOSE ABB FOR YOUR QUALITY MANAGEMENT NEEDS?

More efficient working methods;

information flow improves

productivity

Operational flexibility

throughout the grade

structure

Increased (measurable)

production through

minimal variation

High equipment availability and

improved machine runability

brings clear productivity gains

Better process insight improves

product repeatability

Proven minimum

lifecycle cost

Page 19

Take control of your quality

For any quality challenge your mill is

facing, ABB's solutions provide insight

into your sheet properties to better

control and optimize processes.

For more information, please

visit our website:

abb.com/pulpandpaper

or email:

Se-pulpandpaper@abb.com

—

ABB Ltd. Finnabair Industrial Park

Dundalk, Co. Louth, Ireland

Tel: +353 42 9385100

—

ABB Engineering Ltd. S.P. Building, No. 5, Lane 369

Chuangye Road Kangqiao Town, Pudong District

Shanghai, 201319, P. R. of China

Tel: +86 21 6105 6777

—

ABB Inc. 579 Executive Campus Drive

Westerville, Ohio 43082, USA

Tel: +1 614 818 6300

abb.com/pulpandpaper

© Copyr ight 2023 ABB. All r ights reser ved.

Specifications subject to change without notice.

3BUS00513 2

Loading...

Loading...