Page 1

Protected Terminals | 181

Aprisa XE User Manual

11. Protected Terminals

Monitored Hot Stand By (MHSB)

This section describes configuring the protected terminal in MHSB mode.

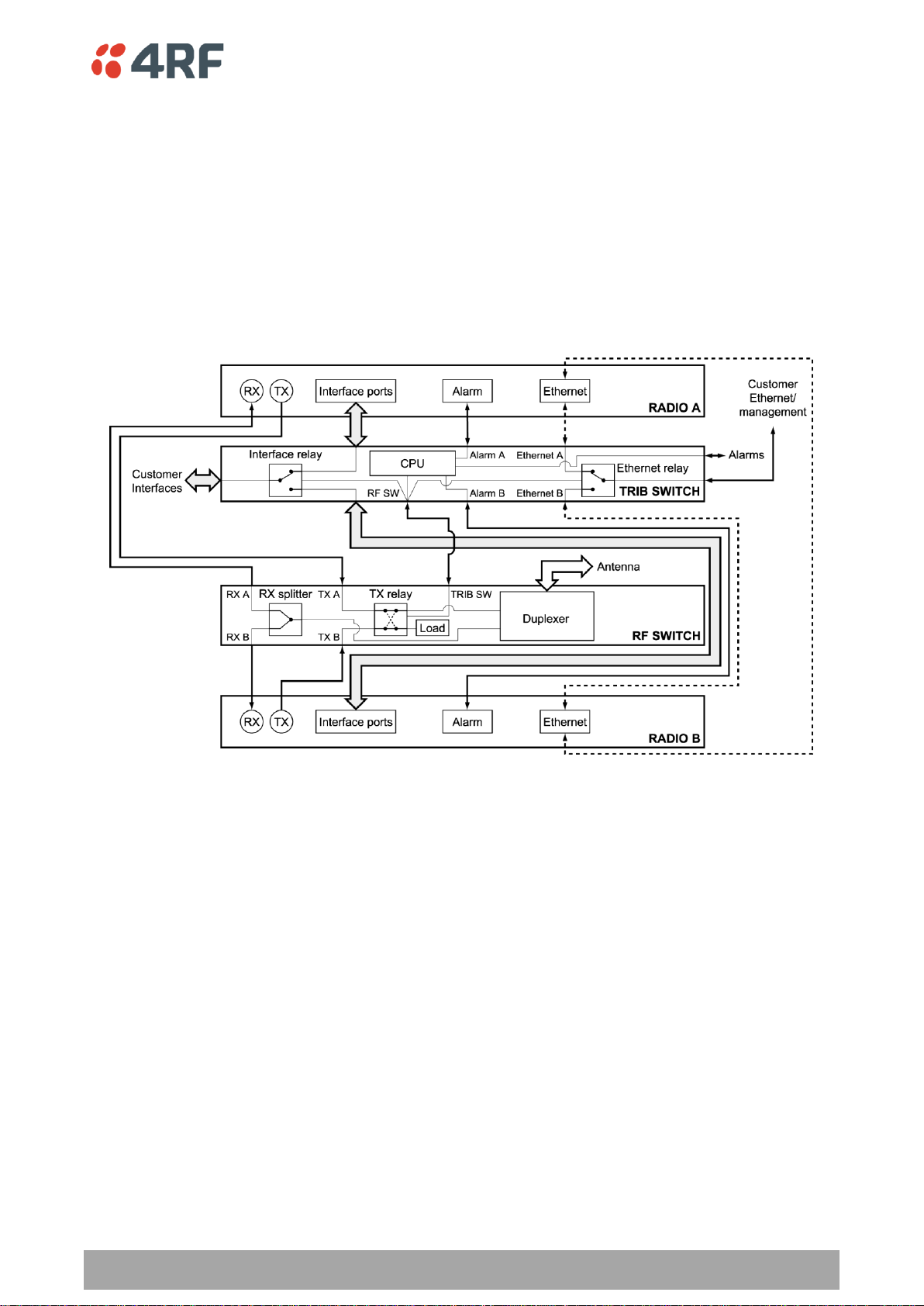

A protected terminal in MHSB mode comprises two radios interconnected using a MHSB switch. This MHSB

switch comprises one RF switch and up to four tributary switches depending on the number of tributaries

requiring switching:

The MHSB switch protect terminals against any single failure in one radio. It also monitors the alarm

output of each radio and switches between radios if major radio link alarms occur. The MHSB switch will

not allow a switch to a faulty radio.

The MHSB switch uses a CPU to monitor the alarm status received from both the connected radios' alarm

ports. When a relevant major radio link alarm is detected on the active radio (that is, transmitter,

receiver, power supply or modem), the CPU switches a bank of relays that switches all the interfaces and

the transmit port from the main radio to a functioning stand-by radio. The stand-by radio now becomes

the active radio.

The MHSB switch has a hysteresis of 30 seconds to prevent switching on short alarm transients.

The tributary switch and the RF switch are both a 19-inch rack-mount 1U high chassis. The MHSB switch

option is available for all Aprisa XE frequency bands.

Page 2

182 | Protected Terminals

Aprisa XE User Manual

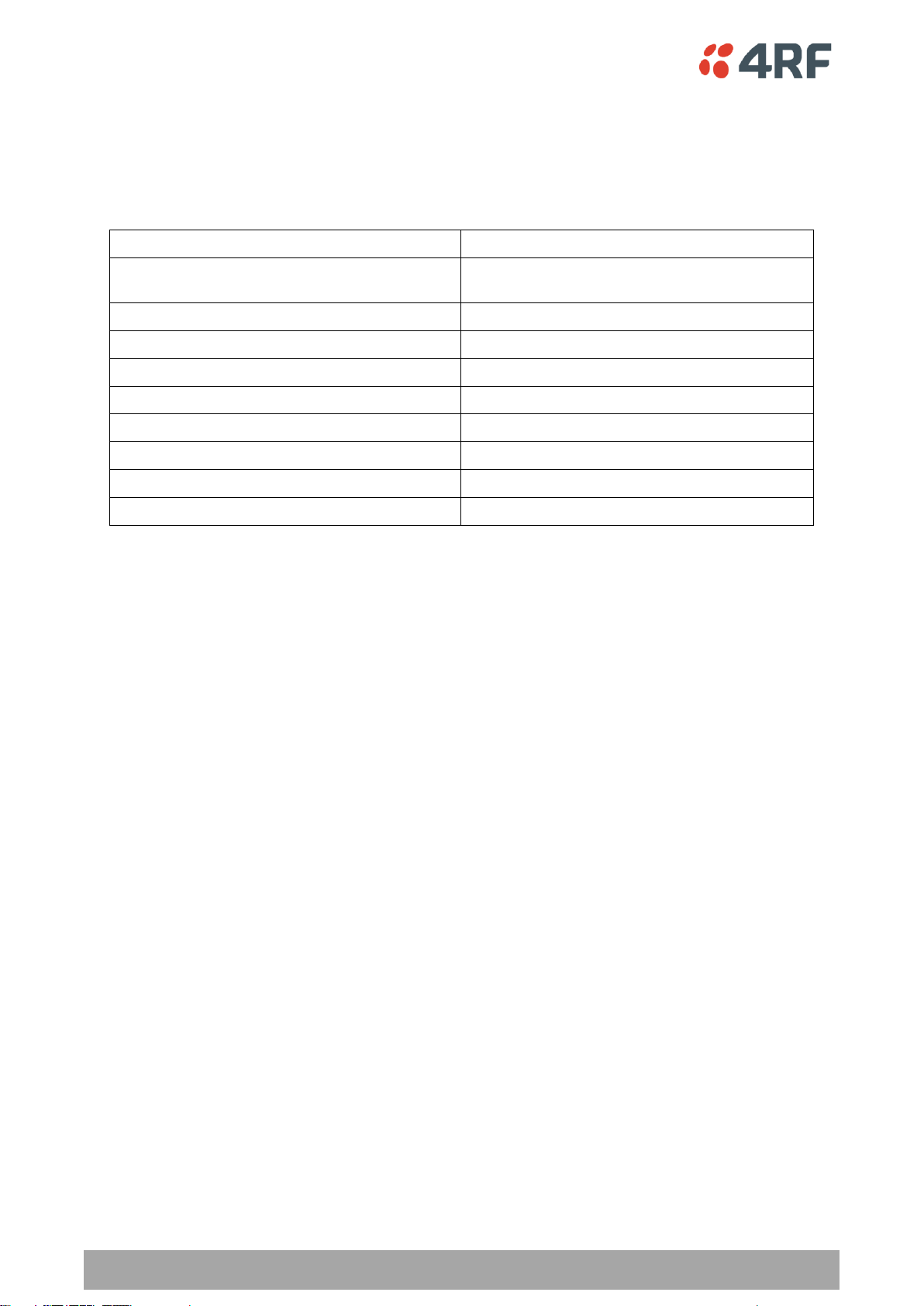

No.

Description

Explanation

1

Power supply input

Input for DC power or AC power

2

Protective earth

M5 terminal intended for connection to an external protective

conductor for protection against electric shock in case of a fault

3

Interface ports

Port for connecting to customer interface equipment

4

Radio A interfaces

These connect to the interface ports on radio A

5

Radio B interfaces

These connect to the interface ports on radio B

6

Console

For factory use only

7

Ethernet

Port for connecting to customer Ethernet network. This port is

also used to set up and manage the radios remotely over an IP

network

8

Radio A Ethernet

Connects to an Ethernet port on radio A

9

Radio B Ethernet

Connects to an Ethernet port on radio B

10

Alarms

Alarm input/output connections for customer equipment

11

Radio A alarms

Connects to the alarm port on radio A

12

Radio B alarms

Connects to the alarm port on radio B

13

RF SW

Provides power and signalling to the RF switch

14

Mode switch

Three-position locking toggle switch to set the MHSB switch into

automatic mode or radio A / radio B test mode

15

LEDs

Mode and status LEDs

Tributary Switch Front Panel

Page 3

Protected Terminals | 183

Aprisa XE User Manual

LED

Colour

Appearance

Explanation

A

Green

Solid

The radio is active and is OK

Green

Flashing

The radio is in standby mode and is OK

Red

Solid

The radio is active and there is a fault

No colour (off)

-

The tributary switch is in 'slave' mode and the

switching is controlled by the master tributary

switch

Red

Flashing

The radio is in standby mode, and there is a fault

B

Green

Solid

The radio is active and is OK

Green

Flashing

The radio is in standby mode and is OK

Red

Solid

The radio is active and there is a fault

No colour (off)

-

The tributary switch is in 'slave' mode and the

switching is controlled by the master tributary

switch

Red

Flashing

The radio is in standby mode, and there is a fault

~

Green

Solid

The tributary protection switch is in 'auto' mode

Green

Flashing

The tributary protection switch is in 'slave' mode

Red

Solid

The tributary protection switch is in 'manual'

mode (A or B)

On

Blue

Solid

Indicates that there is power to the tributary

protection switch

No.

Description

Explanation

1

Radio QMA

QMA connectors for connecting the protected radios

2

Protective earth

M5 terminal intended for connection to an external protective

conductor for protection against electric shock in case of a fault

3

Antenna port

N-type female connector for connection to the antenna feeder

cable. This view shows an internally mounted duplexer. If an

external duplexer is fitted, the antenna port will be on the

external duplexer

4

Slave tributary

switch outputs

Connects to secondary tributary switch for control of additional

interfaces

5

Tributary switch

Connects the RF switch to the tributary switch (the master if

more than one tributary switch is required)

6

LEDs

Status LEDs

Tributary Protection Switch LEDs

RF Switch Front Panel

Page 4

184 | Protected Terminals

Aprisa XE User Manual

LED

Colour

Appearance

Explanation

Tx A

Green

Solid

RF is being received from radio A

Tx B

Green

Solid

RF is being received from radio B

On

Blue

Solid

Indicates that there is power to the RF protection switch

RF Protection Switch LEDs

Slave Tributary Switches

Each tributary switch protects up to eight ports. Up to three slave tributary switches may be added to a

MHSB terminal to protect up to 32 ports. Each slave tributary switch is interconnected by means of the

slave tributary switch ports on the RF switch, as shown below.

Note: A tributary switch that is operating as a slave (rather than a master) has a RJ-45 V.24 loopback

connector plugged into the console port. If the connector is missing, contact Customer Support.

Alternatively, you can make this connector. Follow the standard pinouts for a V.24 RJ-45 connection (see

‘QV24 Interface connections’ on page 273).

Page 5

Protected Terminals | 185

Aprisa XE User Manual

MHSB Cabling

The two radios are interconnected as follows:

CAUTION: Do not connect Transmit to Receive or Receive to Transmit as this may damage the radio or the

MHSB switch.

Cables supplied with MHSB

The following cables are supplied with a MHSB terminal:

Ethernet interface: RJ-45 ports standard TIA-568A patch cables .

Alarm interface: RJ-45 ports standard TIA-568A patch cables.

RF ports: two QMA male patch cables are supplied.

MHSB Power Supply

See ‘DC Power Supply’ on page 37 and ‘AC Power Supply’ on page 40.

Page 6

186 | Protected Terminals

Aprisa XE User Manual

Configuring the Radios for Protected Mode

The MHSB switch does not require any special software. However, the radios connected to the MHSB

switch must be configured to work with the MHSB switch. This sets the alarm outputs and inputs to

function in MHSB mode.

You must configure the interfaces of both radios connected to the MHSB switch identically. To perform

this, you can either connect directly to the radio or use the test mode of the MHSB switch.

MHSB Terminal IP Addresses

Before configuring the link, you must ensure that the two independent links have correctly configured IP

address details.

All four radios in the protected link must be on the same subnet.

Example of MHSB IP addressing

Page 7

Protected Terminals | 187

Aprisa XE User Manual

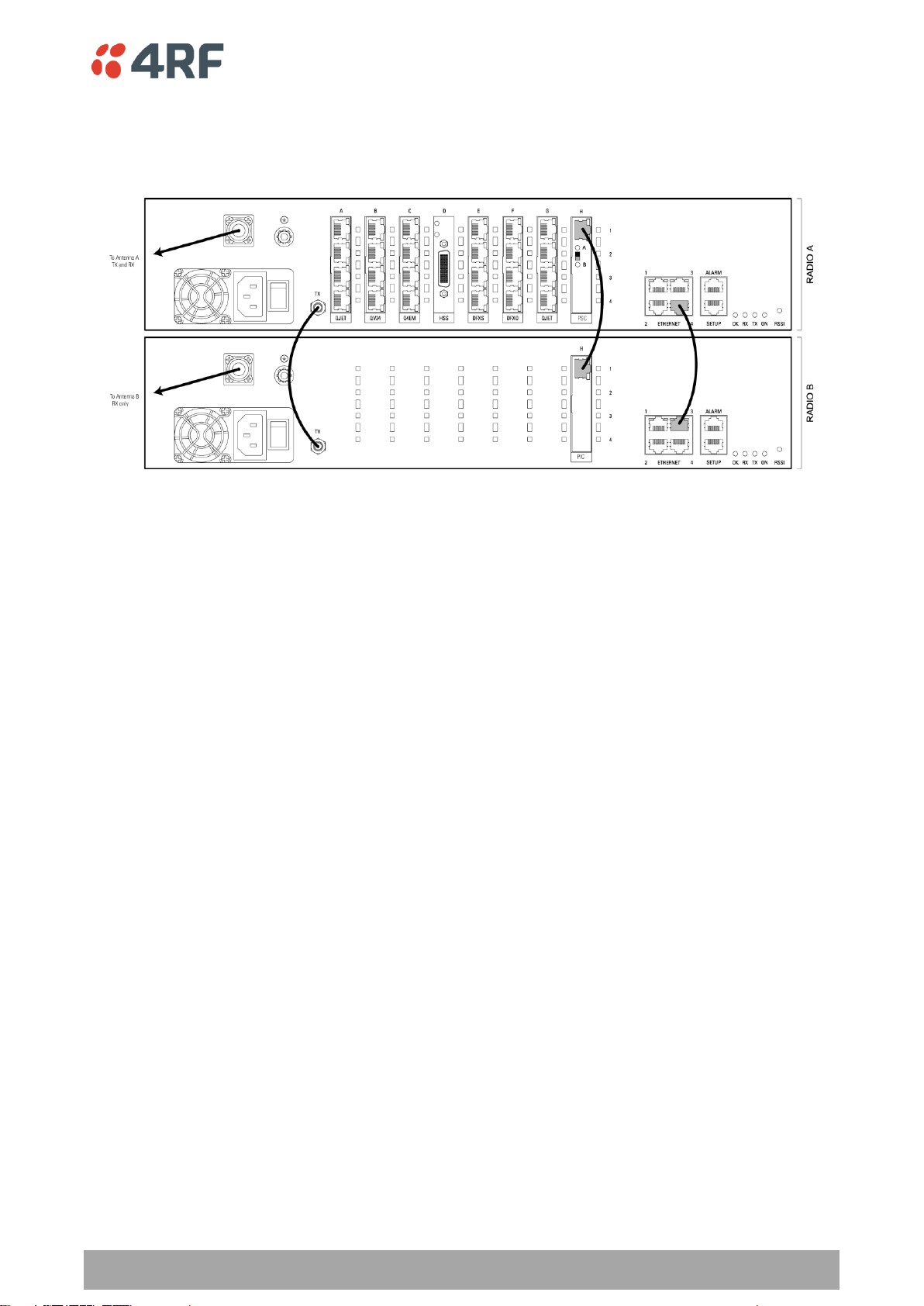

Mounting the MHSB Radios and Switches

Once the IP addresses are correctly configured, it is important to connect the A and B radios' Ethernet and

Alarm ports correctly. In general, mount radio A above the MHSB switch and radio B below the MHSB

switch:

There is an Ethernet connection between any of the four Ethernet ports on each radio and the Ethernet

port on the Tributary switch. There is also a connection between radio A and radio B, which ensures

Ethernet traffic is maintained if a radio loses power.

The Ethernet port on the protection switch can be connected to an Ethernet hub or switch to allow

multiple connections.

Important: The management Ethernet capacity on each of the four radios in the protected terminal must

be identical for remote communications to work and there should only be one IP connection to the

management network (via the tributary switch Ethernet port).

Page 8

188 | Protected Terminals

Aprisa XE User Manual

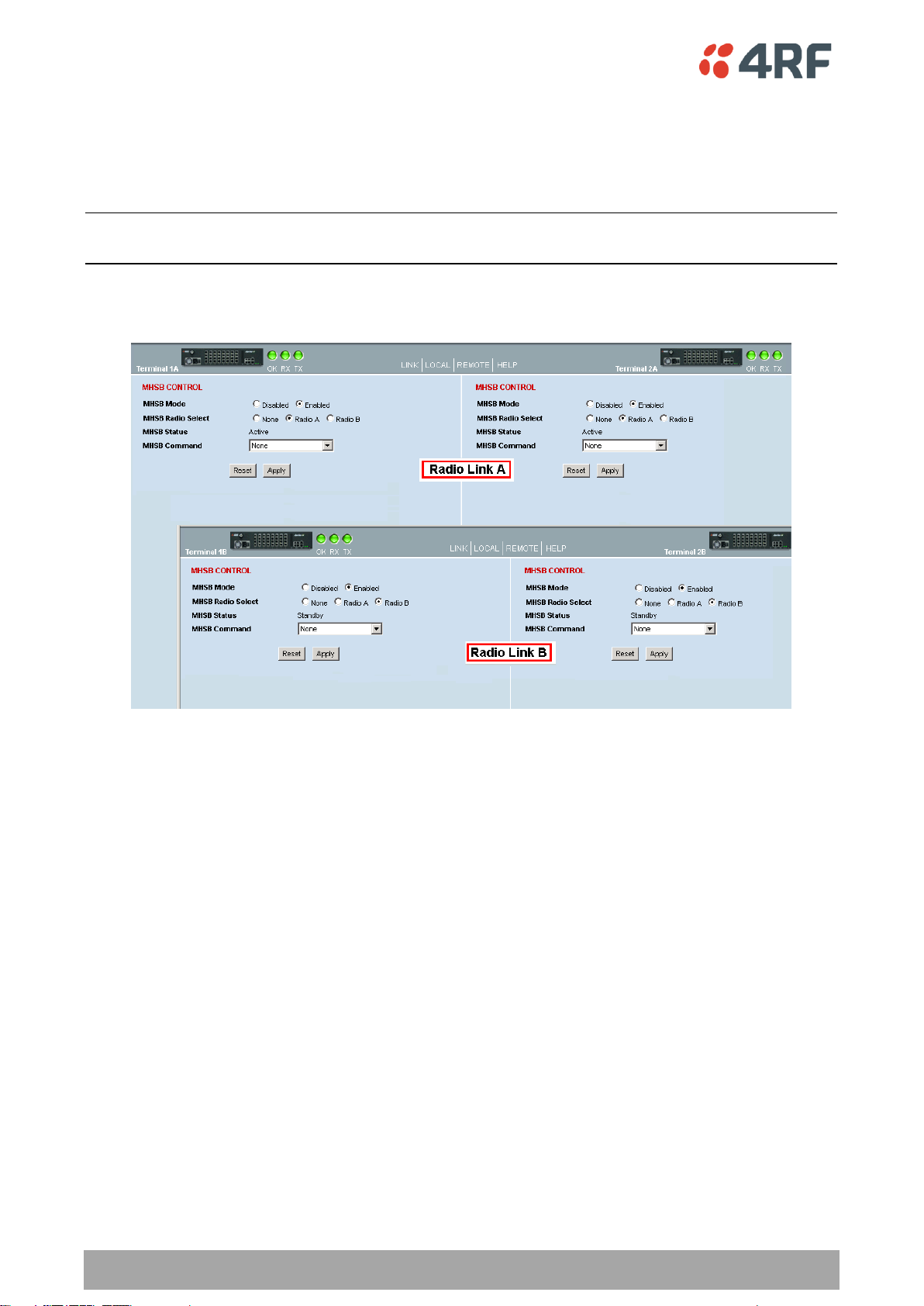

Configuring the Terminals for MHSB

It is recommended that you configure the local and remote A side first, then the local and remote B side.

Both the local A and B radios must be configured identically, and both the remote A and B radios must be

configured identically.

Tip: As illustrated below, you may find it helpful to have two browser sessions running simultaneously.

You can then easily see both the A and B sides of the protected link.

To configure MHSB operation:

1. Select Link > Maintenance > MHSB.

2. Enable MHSB mode.

3. Select whether the radio is A or B.

Ensure that the radio connected to the A side of the protection switch (normally above the MHSB

switch) is set to Radio A and the radio connected to the B side of the protection switch (normally

below the MHSB switch) is set to Radio B.

In the event of a power outage, the radios will switch over to the A side of the protection switch when

the power is restored. The A side is also the default active side.

4. When you have made your changes, click Apply to apply changes or Reset to restore the previous

configuration.

5. Repeat steps 2 to 4 for the other side of the protected link.

Page 9

Protected Terminals | 189

Aprisa XE User Manual

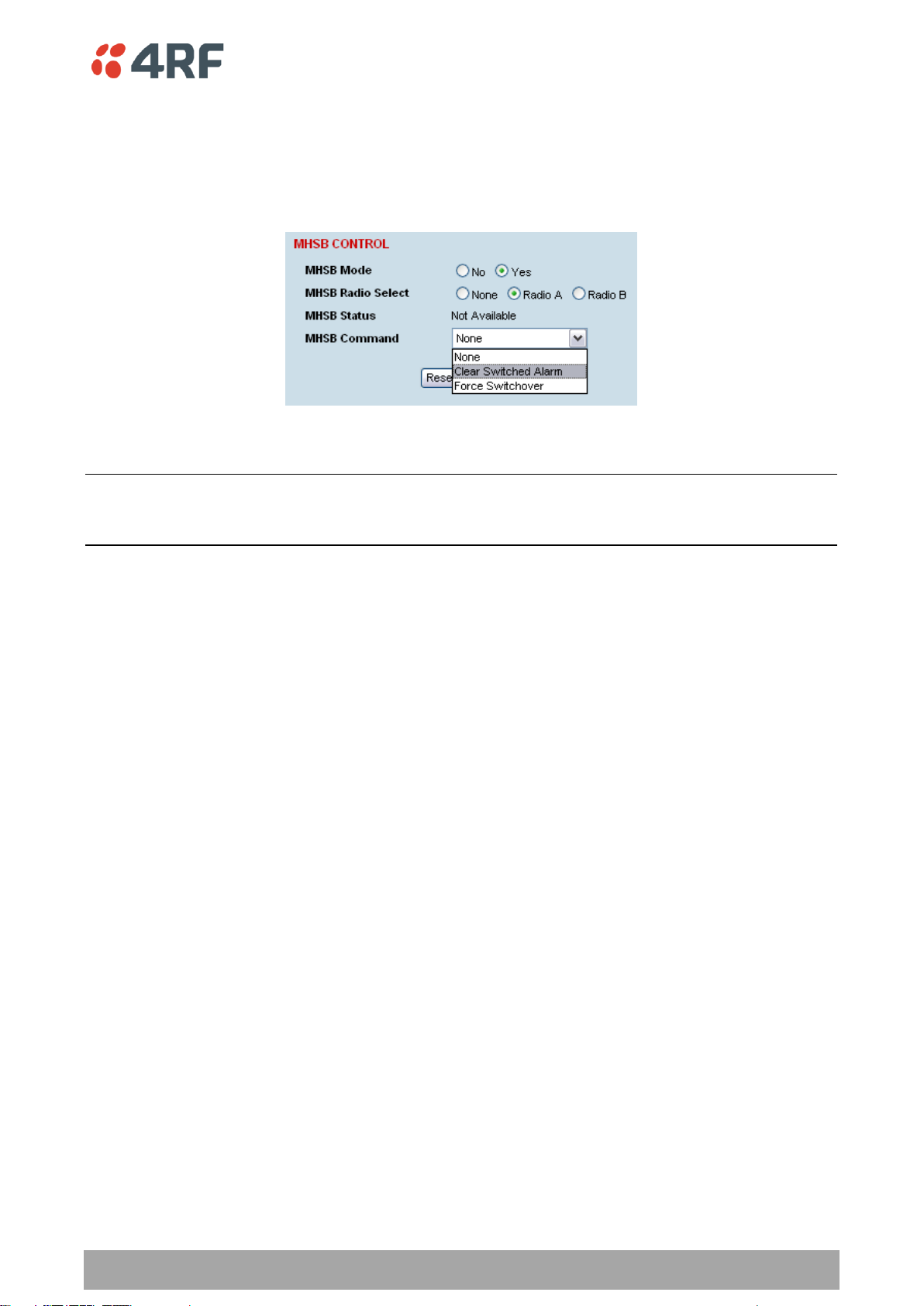

Clearing MHSB Alarms

If a switchover event occurs, the OK LED on the front panel and on the Terminal status and menu bar in

SuperVisor changes to amber.

1. Select Clear Switched Alarm from the MHSB Command drop-down list.

2. Click Apply to apply changes or Reset to reset the page.

Note: When MHSB mode is enabled, external alarm input 2 is used by the protection system to carry

alarms from the protection switch to the radio. In MHSB mode, therefore, only external alarm input 1 is

available for user alarms.

Page 10

190 | Protected Terminals

Aprisa XE User Manual

Hitless Space Diversity (HSD)

HSD provides hitless RF receive path protection and hot standby transmitter redundancy. It is typically

deployed for paths where high path availability is required.

An Aprisa XE hitless space diversity terminal comprises two radio terminals, radio A and radio B.

Radio A is the primary radio which is fitted with the interface cards and connects to antenna A.

Antenna A always carries the transmitted signal and the received signal for Radio A.

Radio B is the secondary radio the receiver of which connects to antenna B. The transmitter in this radio is

the standby transmitter.

In the event of a radio A active transmitter failure, radio B transmitter becomes active.

Antenna B only carries the received signal for Radio B. This antenna is physically separated on the tower

by a pre-determined distance from Antenna A.

As both radios have a receive path, traffic from the path with the best received bit error rate is routed to

the customer interfaces in radio A.

In an HSD terminal, a HSD Protection Switch Card (PSC) is always fitted in slot H in Radio A and a HSD

Protection Interface Card (PIC) is always fitted in slot H in Radio B. The PSC card has a card front switch

which controls the hardware setting of the HSD system Active Radio (Auto Select, Radio A or Radio B).

Customer interfaces are provided on radio A only in interface slots A to G. Interface connections to

Ethernet and the external alarm inputs and outputs are also provided on radio A only.

Page 11

Protected Terminals | 191

Aprisa XE User Manual

HSD Terminal Cabling

The two HSD radios are interconnected as follows:

Cables Supplied with HSD Terminal

The following cables are supplied with a HSD terminal:

RF cable

A 110 mm QMA female to QMA female low loss RF cable is required to interconnect between the TX ports

of both radio A and radio B. This cable carries the radio B transmitter output to the radio A transmitter

switch.

Ethernet Cable

A 200 mm RJ45 to RJ45 Ethernet cable between the Ethernet ports of radio A and radio B. This cable

carries management IP traffic between radio A and radio B.

Traffic Cable

A 200 mm RJ45 to RJ45 Ethernet cable between the PSC and PIC. This cable carries all user traffic

between Radio A and Radio B.

Page 12

192 | Protected Terminals

Aprisa XE User Manual

HSD Terminal IP Addresses

Each radio in the HSD link is assigned a unique IP address. All four radios in the HSD link must be on the

same subnet.

The IP address of the four terminals can only be changed by logging into the relevant radio A or radio B.

When the IP addresses have been setup, an ethernet connection to any of the four radios can access all

four radios in the HSD link. The usual ethernet connection is to the near end Radio A (see ‘IP Addressing of

Terminals’ on page 53).

Example of IP addressing

Page 13

Protected Terminals | 193

Aprisa XE User Manual

Configuring HSD Terminals

To simplify the management and configuration of the HSD terminals, SuperVisor provides four windows

which display the parameters for all four radios, the local and remote, radios A and B. The HSD System

menu item displays the four windows.

When a parameter is changed in the four window mode, the relevant parameter is automatically changed

to the same setting on the corresponding radio e.g. if a radio A modulation type is changed, the radio B

modulation type is also changed to the same setting.

The Local and Remote menus continue to display the parameters for the local and remote radios for the

near end terminal logged into.

The majority of SuperVisor HSD System pages contain the same parameters and controls as the standard

1+0 XE terminal. The main exceptions are the HSD Control page and the HSD Performance Summary page.

Page 14

194 | Protected Terminals

Aprisa XE User Manual

PSC Mode

Switch

Hardware Control Change

Software Control Change

LED A

LED B

LED A

LED B

Radio A

Solid Amber

Off

Flashing Amber

Off

Auto Select

Solid Green

Solid Green

Flashing Amber

Flashing Amber

Radio B

Off

Solid Amber

Off

Flashing Amber

Active Radio

Mode of Operation

Auto Select

(default)

Automatic mode:

The hitless receive will select traffic from the receive path of best

performance

The HSD system will switch to the standby transmitter if the active

transmitter fails (TX failure alarm)

Radio A Only

Manual selection of radio path A only for both the transmitter and

receiver i.e. no automatic switching

Radio B Only

Manual selection of radio path B only for both the transmitter and

receiver i.e. no automatic switching

HSD Active Radio Control

The HSD system ‘Active Radio’ control determines if the selection of Radio A or Radio B is automatic or

manual. This controls both the radio transmitters and receivers.

The Active Radio can be set with the hardware switch on the PSC card front or with the SuperVisor

software control. The last change of hardware / software control determines the state of the HSD system.

The SuperVisor software control will always reflect the state of the HSD system.

After terminal startup or reboot, the state of the PSC mode switch determines the setting used by the

system and the SuperVisor software control is set to reflect the state of the HSD system.

The PSC card has two card front LEDs which indicate the status of the HSD system:

To set the HSD controls:

1. Select HSD System > Maintenance > Control.

2. Set the Active Radio parameter.

Note: There is no timeout for a manual selection of the Active Radio setting (Radio A only or Radio B only)

but a ‘Mode Switch Software Override’ alarm will warn if the software has overwritten the PSC Mode

Switch.

Page 15

Protected Terminals | 195

Aprisa XE User Manual

Parameter Compare Checking

Option

On

(default)

Any mismatch in parameters shown in Terminal Settings

between Radio A and Radio B will generate a Parameter

Mismatch alarm.

Off

No Parameter Mismatch alarm will be generated.

Field

Explanation

Terminal UCEs

The total number of HSD terminal uncorrectable blocks since the last

reset

Terminal Errored

seconds

The total number of HSD terminal operational seconds with errored

traffic since the last reset

Terminal Error free

seconds

The total number of HSD terminal error free operational seconds since

the last reset

Terminal BER

The system will report an estimated HSD terminal Bit Error Rate up to a

maximum of 1 in 1021

Active Transmitter

Dislays the current active transmitter (TxA or TxB)

3. Set the Parameter Compare Checking.

To view the HSD System Performance Summary:

1. Select HSD System > Performance > Summary.

Click Reset Counters to reset the error counters to zero.

Page 16

Page 17

In-Service Commissioning | 197

Aprisa XE User Manual

12. In-Service Commissioning

Before You Start

When you have finished installing the hardware, RF and the traffic interface cabling, the system is ready

to be commissioned. Commissioning the terminal is a simple process and consists of:

1. Powering up the terminals

2. Configuring both the local and remote terminals using SuperVisor

3. Aligning the antennas

4. Synchronizing the terminals

5. Testing the link is operating correctly. As a minimum, conduct the suggested tests to ensure correct

operation. More extensive testing may be required to satisfy the end client or regulatory body

requirements.

6. Connecting up the client or user interfaces

What You Will Need

Appropriately qualified commissioning staff at both ends of the link.

Safety equipment appropriate for the antenna location at both ends of the link.

Communication equipment, that is, mobile phones or two-way radios.

SuperVisor software running on an appropriate laptop, computer, or workstation at one end of the

link.

Tools to facilitate loosening and re-tightening the antenna pan and tilt adjusters.

Predicted receiver input levels and fade margin figures from the radio link budget (You can use

Surveyor (see ‘Path planning’ on page 23) to calculate the RSSI, fade margin, and availability).

Page 18

198 | In-Service Commissioning

Aprisa XE User Manual

WARNING:

Before applying power to a terminal, ensure you have connected the safety

earth and antenna cable.

Red

the antennas are may be significantly mis-aligned with no signal being

received

Amber

the antennas may be roughly aligned with some signal being received

Green

the antennas are well-aligned and adequate signal is being received to create

a reliable path

Red

the transmitter is faulty

Amber

there is a fault in the antenna connection or feeder cable

Green

the transmitter is working normally

Applying Power to the Terminals

Apply power to the terminals at each end of the link.

When power is first applied, all the front panel LEDs will illuminate red for several seconds as the system

initializes.

After the system is initialized, the OK LED on the front panel should illuminate green and if the terminals

are correctly configured, the TX and RX LED should also be illuminated green.

If the RX LED is:

If the TX LED is:

Review the Link Configurations Using SuperVisor

1. Connect a PC, with SuperVisor installed, to both terminals in the link.

2. Log into the link.

3. Select Link > Summary and confirm the following basic information:

Terminal IP address(es)

Terminal TX and RX frequencies

RSSI (dBm)

TX power (dBm)

SNR (dBm)

Note: If the terminals have not already been configured, refer to ‘Configuring the terminal’ on page 69,

‘Configuring the traffic interfaces’ on page 91, and ‘Configuring the traffic cross connections’ on page

145.

Page 19

In-Service Commissioning | 199

Aprisa XE User Manual

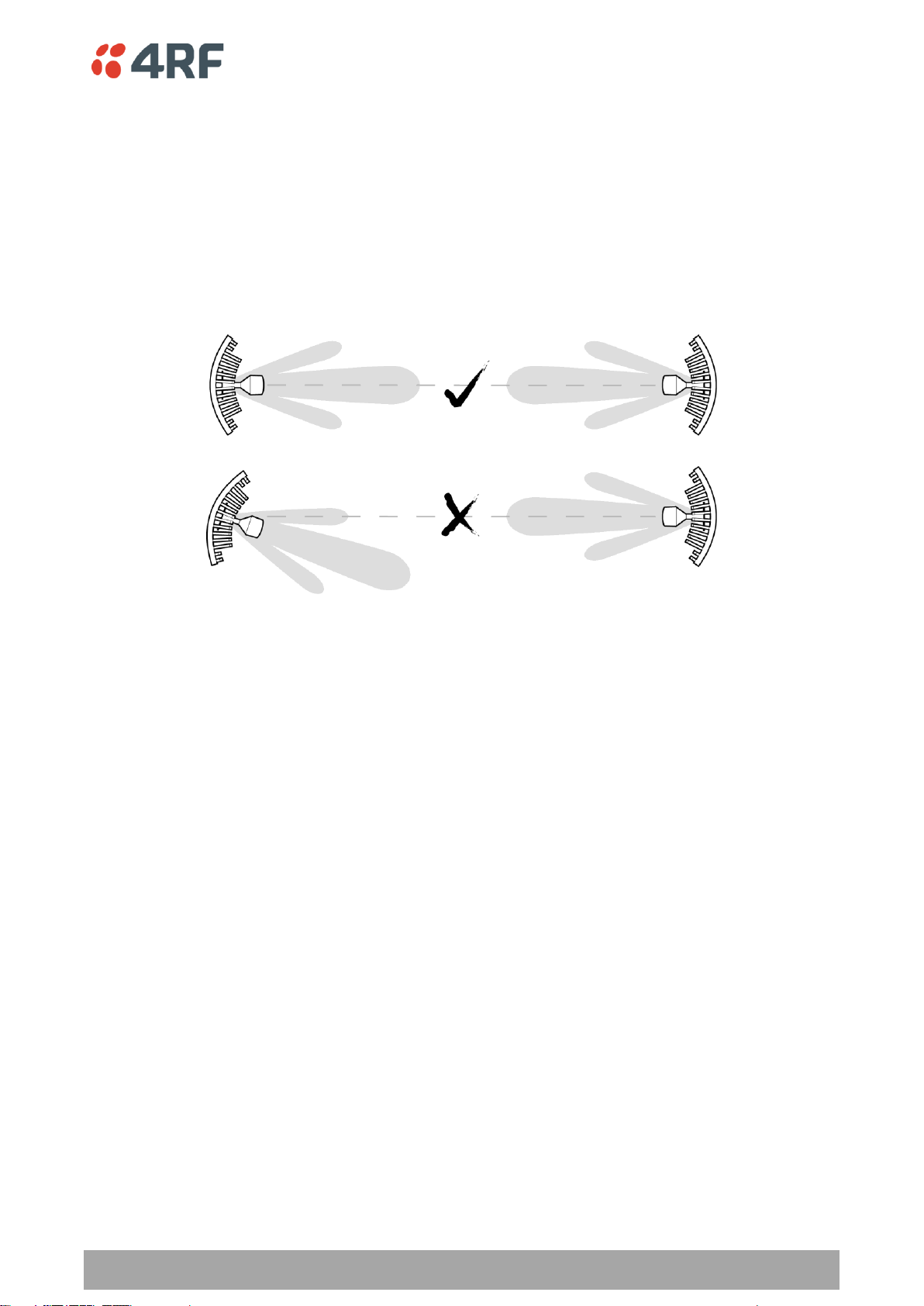

Antenna Alignment

For any point-to-point link, it is important to correctly align the antennas to maximize the signal strength

at both ends of the link. Each antenna must be pointing directly at the corresponding antenna at the

remote site, and they must both be on the same polarization. The antennas are aligned visually, and then

small adjustments are made while the link is operating to maximize the received signal.

Directional antennas have a radiation pattern that is most sensitive in front of the antenna, in line with

the main lobe of the radiation pattern. There are several other lobes (side lobes) that are not as sensitive

as the main lobe in front of the antenna.

For the link to operate reliably, it is important that the main lobes of both antennas are aligned. If any of

the side lobes are aligned to the opposite antenna, the received signal strength of both terminals will be

lower, which could result in fading. If in doubt, check the radiation patterns of the antennas you are

using.

Checking the Antenna Polarization

Check that the polarization of the antennas at each end of the link is the same.

Antenna polarization of grid antennas are normally indicated by an arrow or with ‘H’ and ‘V’ markers

(indicating horizontal and vertical).

On Yagi antennas, ensure the orientation of the elements are the same at each end of the link.

Transmit frequency and power, and antenna polarization would normally be defined by a regulatory body,

and typically licensed to a particular user. Refer to your license details when setting the antenna

polarization.

Page 20

200 | In-Service Commissioning

Aprisa XE User Manual

Visually Aligning Antennas

1. Stand behind the antenna, and move it from side to side until it is pointing directly at the antenna at

the remote site. The remote antenna may be made more visible by using a mirror, strobe light, or

flag.

If the remote end of the link is not visible (due to smoke, haze, or local clutter, etc), align the

antenna by using a magnetic compass. Calculate the bearing using a scale map of the link path.

When setting the antenna on the desired bearing ensure that you use the appropriate true-north to

magnetic-north offset. Also ensure that the compass reading is not affected by standing too close to

metallic objects.

2. Once the antenna is pointing at the remote antenna, tighten the nuts on the U-bolt or antenna clamp

just enough to hold it in position. Leave the nuts loose enough so that small adjustments can still be

made. Check that the antenna is still pointing in the correct direction.

3. Move the antenna up or down until it is pointing directly at the remote site.

4. Tighten the elevation and azimuth adjustment clamps.

5. Mark the position of the antenna clamps so that the antenna can be returned to this rough aim point

easily when accurately aligning the antennas.

6. Repeat steps 1-5 at the opposite site.

Note: Low gain antennas need less adjustment in elevation as they are simply aimed at the horizon. They

should always be panned horizontally to find the peak signal.

Page 21

In-Service Commissioning | 201

Aprisa XE User Manual

Accurately Aligning the Antennas

Once the antennas are visually aligned, accurately align both antennas by carefully making small

adjustments while monitoring the RSSI. This will give the best possible link performance.

Note: Remember that it is important to align the main radiation lobes of the two antennas to each other,

not any side lobes. It may be easier to perform this procedure if you can communicate with someone at

the remote site by telephone, mobile, or two-way radio.

1. Connect a laptop PC running SuperVisor software and power up the terminals at both ends of the link.

Select Link > Performance > Summary so that you can see the RSSI indication for the local terminal.

Alternatively, use the RSSI test point on the front panel together with a multimeter (see ‘Measuring

the RSSI’ on page 202).

2. Move the antenna through a complete sweep horizontally (known as a 'pan') either side of the point

established in the visual alignment process above. Note down the RSSI reading for all the peaks in RSSI

that you discover in the pan.

3. Move the antenna to the position corresponding to the maximum RSSI value obtained during the pan.

Move the antenna horizontally slightly to each side of this maximum to find the two points where the

RSSI drops slightly.

4. Move the antenna halfway between these two points and tighten the clamp.

5. If the antenna has an elevation adjustment, move the antenna through a complete sweep (known as a

'tilt') vertically either side of the point established in the visual alignment process above. Note down

the RSSI reading for all the peaks in RSSI that you discover in the tilt.

6. Move the antenna to the position corresponding to the maximum RSSI value obtained during the tilt.

Move the antenna slightly up and then down from the maximum to find the two points where the RSSI

drops slightly.

7. Move the antenna halfway between these two points and tighten the clamp.

8. Recheck the pan (steps 2-4) and tighten all the clamps firmly.

9. Perform steps 1-8 at the remote site.

Page 22

202 | In-Service Commissioning

Aprisa XE User Manual

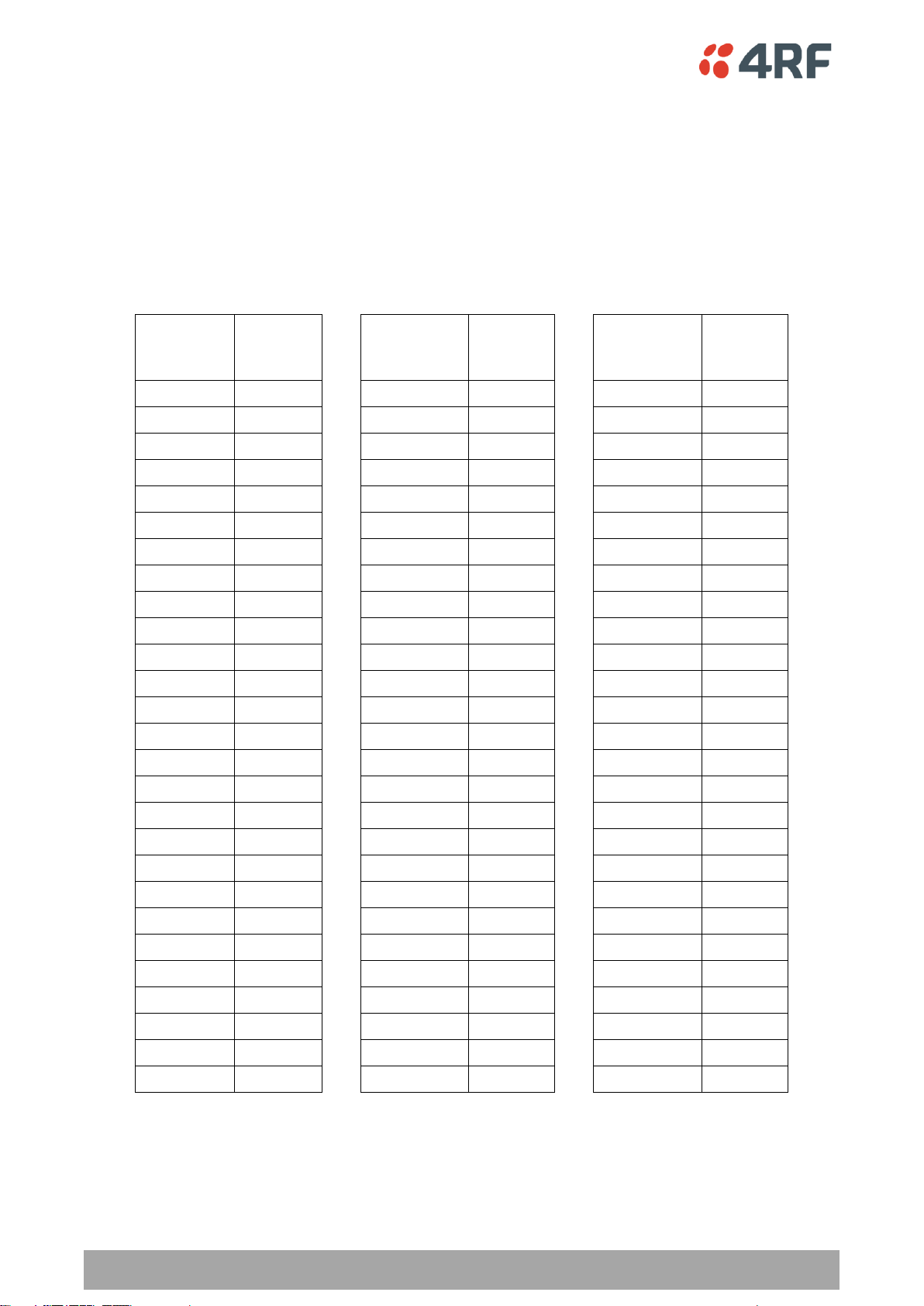

RSSI test

port value

(VDC)

RSSI

reading

(dBm)

RSSI test

port value

(VDC)

RSSI

reading

(dBm)

RSSI test

port value

(VDC)

RSSI

reading

(dBm)

0.000

- 100

0.675

- 73

1.350

- 46

0.025

- 99

0.700

- 72

1.375

- 45

0.050

- 98

0.725

- 71

1.400

- 44

0.075

- 97

0.750

- 70

1.425

- 43

0.100

- 96

0.775

- 69

1.450

- 42

0.125

- 95

0.800

- 68

1.475

- 41

0.150

- 94

0.825

- 67

1.500

- 40

0.175

- 93

0.850

- 66

1.525

- 39

0.200

- 92

0.875

- 65

1.550

- 38

0.225

- 91

0.900

- 64

1.575

- 37

0.250

- 90

0.925

- 63

1.600

- 36

0.275

- 89

0.950

- 62

1.625

- 35

0.300

- 88

0.975

- 61

1.650

- 34

0.325

- 87

1.000

- 60

1.675

- 33

0.350

- 86

1.025

- 59

1.700

- 32

0.375

- 85

1.050

- 58

1.725

- 31

0.400

- 84

1.075

- 57

1.750

- 30

0.425

- 83

1.100

- 56

1.775

- 29

0.450

- 82

1.125

- 55

1.800

- 28

0.475

- 81

1.150

- 54

1.825

- 27

0.500

- 80

1.175

- 53

1.850

- 26

0.525

- 79

1.200

- 52

1.875

- 25

0.550

- 78

1.225

- 51

1.900

- 24

0.575

- 77

1.250

- 50

1.925

- 23

0.600

- 76

1.275

- 49

1.950

- 22

0.625

- 75

1.300

- 48

1.975

- 21

0.650

- 74

1.325

- 47

2.000

- 20

Measuring the RSSI

Measure the RSSI value with a multimeter connected to the RSSI test port on the front of the terminal (see

‘Front panel connections and indicators’ on page 31).

1. Insert the positive probe of the multimeter into the RSSI test port, and clip the negative probe to the

chassis of the terminal (earth).

2. Pan and tilt the antenna until you get the highest VDC reading. The values shown in the table below

relate the measured VDC to the actual received signal level in dBm regardless of bandwidth and

frequency.

Page 23

In-Service Commissioning | 203

Aprisa XE User Manual

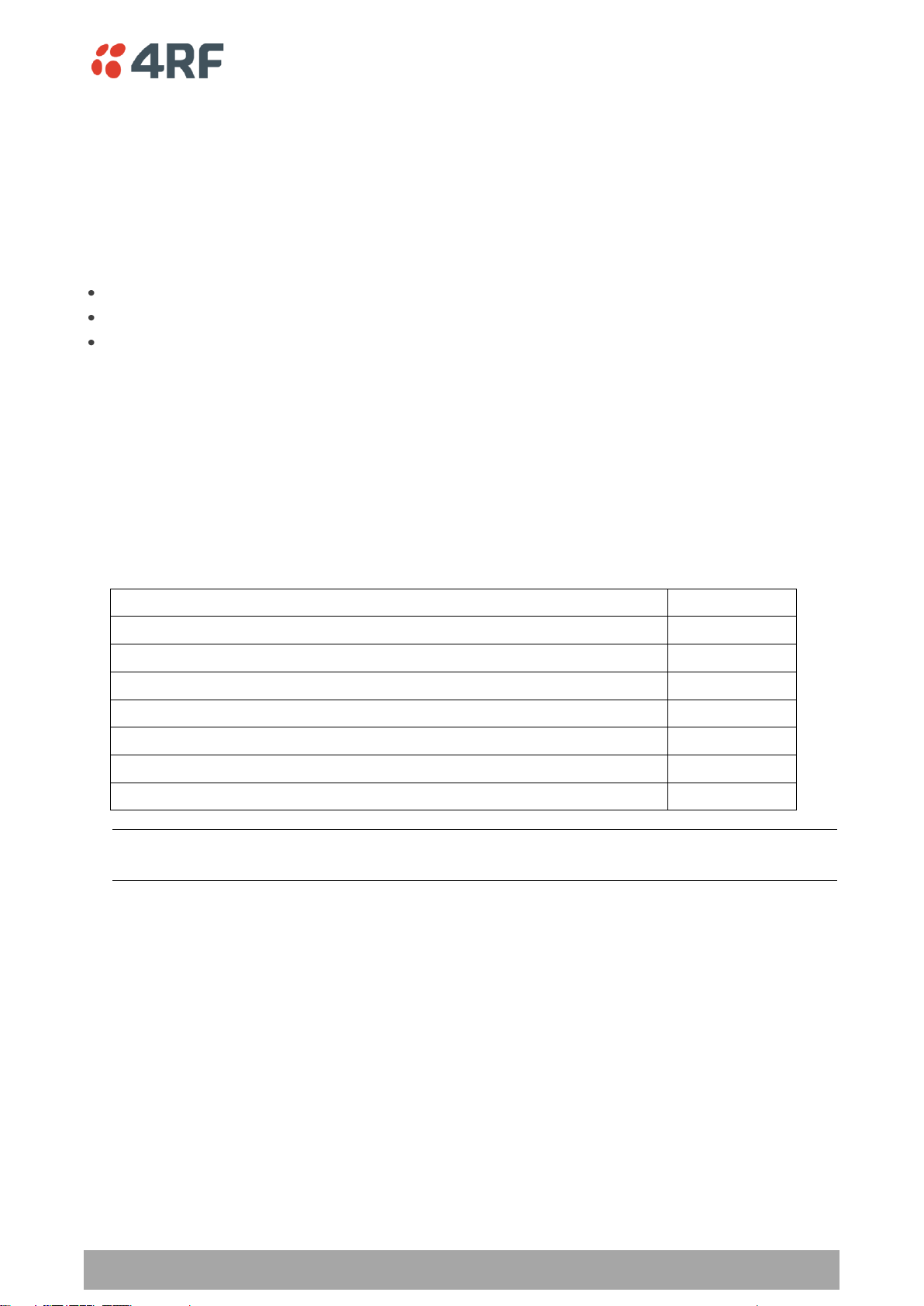

Possible cause

Terminal(s)

Is the terminal operating on the correct frequency?

Local & remote

Is the remote terminal transmit power correct?

Remote

Are all the coaxial connectors tight?

Local & remote

Is the antenna the correct type, that is, gain and frequency of operation?

Local & remote

Is the antenna polarized?

Local & remote

Is the antenna aligned?

Local & remote

Is the path between the terminals obstructed?

Checking Performance

The amount of testing performed on the completed installation will depend on circumstances. Some

customers may need to prove to a local licensing regulatory body that the link complies with the license

provisions. This may require special telecommunications test equipment to complete these tests. Most

customers simply want to confirm that their data traffic is successfully passing over the link, or that the

customer interfaces comply with known quality standard.

However, the most important performance verification checks are:

Receive input level

Fade margin

Long-term BER

Checking the Receive Input Level

The received signal strength at the local terminal is affected by many components in the system and has a

direct relationship with the resulting performance of the link. A link operating with a lower than expected

signal strength is more likely to suffer from degraded performance during fading conditions. The receive

input level of a link is normally symmetrical (that is, similar at both ends).

1. Compare the final RSSI figure obtained after antenna alignment with that calculated for the link.

2. If the RSSI figure is in excess of 3 dB down on the predicted level, recheck and correct problems using

the table below and then recheck the RSSI. Alternatively, recheck the link budget calculations.

Note: If following the above steps does not resolve the situation, contact Customer Support for

assistance.

3. Record the RSSI figure on the commissioning form.

4. Repeat steps 1 to 2 for the other end of the link.

Page 24

204 | In-Service Commissioning

Aprisa XE User Manual

Problem

Terminal

Low receive signal strength (see above table)

Local and Remote

Interfering signals on the same, or very close to, the frequency of the

local terminal receiver.

Local

Intermodulation products that land on the same or very close to the

frequency of the local terminal receiver.

Local or Remote

Operating near the local receiver noise floor

Local

Checking the Fade Margin

The fade margin is affected by many components in the system and is closely related to the received

signal strength. A link operating with a lower than expected fade margin is more likely to suffer from

degraded performance during fading conditions. A reduced fade margin can be due to operating the link

too close to the noise floor, or the presence of external interference. The fade margin of a link can be

asymmetrical (that is, different at each end).

Possible causes of low fade margin are as follows:

To check the fade margin:

1. Confirm (and correct if necessary) the receive input level (see the previous test).

Note: If the receive input level is lower than expected, the fade margin may also be low.

2. Select Link > Performance > Summary and check the current BER of the link in its normal condition is

better than 10-6 (If necessary, clear out any extraneous errors by clicking Reset Counters).

3. Check the signal to noise (S/N) indication on the Link > Performance > Summary page. This shows the

quality of the signal as it is being processed in the modem. It should typically be better than 30 dB. If

it is less than 25 dB, it means that either the RSSI is very low or in-band interference is degrading the

S/N performance.

4. Temporarily reduce the remote site's transmit power using either an external attenuator or SuperVisor

(Remote > Terminal > Basic).

Note: Ideally, the transmit power of the remote site should be reduced by up to 20 dB, which will

require the use of an external 50 ohm coaxial attenuator capable of handling the transmit power

involved. In the absence of an attenuator, reduce the transmit power using SuperVisor.

5. Check and note the current BER of the link in its now faded condition (Again, if necessary, clear out

any extraneous errors (introduced by the power reduction step above) by clicking Reset Counters).

6. Compare the unfaded and faded BER performance of the link (steps 2 and 4). Continue to reduce the

remote transmit power until either the BER drops to 10-6 or the remote transmitter power has been

reduced by 20 dB.

Note: The fade margin of the link is expressed as a number (of dB) that the link can be faded

(transmitter power reduced) without reducing the BER below operating specifications (1 * 10-6 BER). A

20 dB fade margin is adequate for most links.

Page 25

In-Service Commissioning | 205

Aprisa XE User Manual

7. Record the fade margin and SNR results on the commissioning form.

Note: If the transmit power is reduced using SuperVisor rather than an external attenuator, the fade

margin should be recorded as ‘Greater than x dB’ (where x = the power reduction).

8. Restore the remote terminal transmit power to normal.

9. Repeat steps 1 to 7 for the other end of the link.

Note: If following all the guidelines above does not resolve the situation, contact Customer Support

for assistance.

Checking the Long-Term BER

The BER test is a measure of the stability of the complete link. The BER results of a link can be

asymmetrical (that is, different at each end).

1. Select Link > Performance > Summary and check the current BER and error counters of the link. If

necessary, clear out any extraneous errors by selecting Reset Counters.

2. Wait 15 minutes, and check the BER display and error counters again. If there are a small number of

errors and the BER is still better than 1 x 10-9, continue the test for 24 hours. If there are a significant

number of errors, rectify the cause before completing the 24 hour test.

Note: It is normal to conduct the BER test in both directions at the same time, and it is important that

no further work be carried out on the equipment (including the antenna) during this period.

3. The BER after the 24 hour test should typically be better than 1 x 10

-8

.

4. Record the BER results on the commissioning form.

Bit Error Rate Tests

A Bit Error Rate (BER) test can be conducted on the bench, (see ‘Bench Setup’ on page 43).

Attach the BER tester to the interface port(s) of one terminal, and either another BER tester or a loopback

plug to the corresponding interface port of the other terminal.

This BER test can be carried out over the Ethernet, E1 / T1, V.24 or HSS interfaces. It will test the link

quality with regard to user payload data.

CAUTION: Do not apply signals greater than -20 dBm to the antenna as they can damage the receiver. In a

bench setup, there must be 60 - 80 dB at up to 2 GHz of 50 ohm coaxial attenuation (capable of handling

the transmit power) between the terminals’ antenna connectors.

Page 26

206 | In-Service Commissioning

Aprisa XE User Manual

Test

Test equipment required

TX power output measurements (at TX and

duplexer outputs)

Power meter

TX spectrum bandwidth

Spectrum analyzer

TX spectral purity or harmonic outputs

Spectrum analyzer

TX center frequency

Frequency counter or spectrum analyzer

Bulk capacity BER test

BER tester

LAN throughput or errors

LAN tester

G.703 / HDB3 waveforms

Digital oscilloscope

Serial interface BER

BER tester

Audio quality

PCM4 or SINAD test set

Additional Tests

Depending on license requirements or your particular needs, you may need to carry out additional tests,

such as those listed below.

Refer to the relevant test equipment manuals for test details.

Page 27

In-Service Commissioning | 207

Aprisa XE User Manual

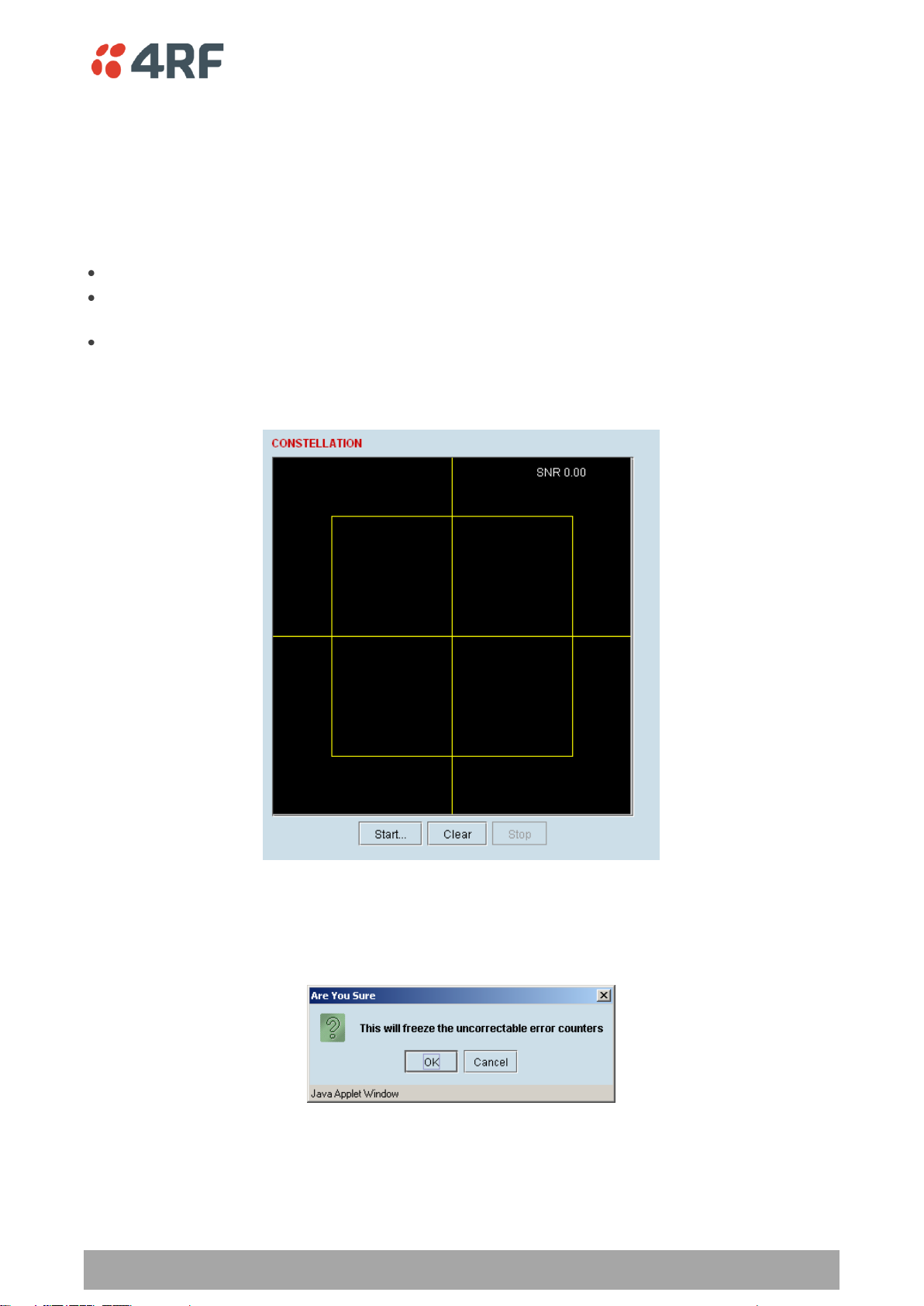

Checking the Link Performance

For a graphical indication of the link performance, you can use the constellation analyzer.

The 'dots' are a graphical indication of the quality of the demodulated signal. Small dots that are close

together indicate a good signal. If the dots become spaced further apart, this indicates that the signal

quality is degrading. This signal quality degradation can be caused by low Rx signal level due to, for

example:

external interference

failure of any of the following: modem, receiver, far end transmitter, an antenna (either end), a

feeder or connector (for example, due to water damage)

path issues such as multipath fading or obstructions

To check the performance of the link using the constellation analyzer:

1. Select Link or Local or Remote > Performance > Constellation.

2. Click Start to start the constellation analyzer.

While the constellation analyzer is running, the terminal will temporarily stop collecting error

performance statistics. If you want to run the constellation analyzer anyway, click OK when you see

this warning message:

3. Click Stop to stop the constellation analyzer.

The terminal automatically resumes collecting error performance statistics.

Page 28

208 | In-Service Commissioning

Aprisa XE User Manual

Field

Explanation

Link Performance

Correctable errors

The total number of correctable blocks since the last reset

Uncorrectable errors

The total number of uncorrectable blocks since the last reset

SNR (dB)

The Signal to Noise Ratio of the link in dB

RSSI (dBm)

The Received Signal Strength Indication at the Rx input in dBm

Errored seconds

The total number of operational seconds with errored traffic since the

last reset

Error free seconds

The total number of error free operational seconds since the last reset

BER

The system will report an estimated Bit Error Rate up to a maximum of

1 in 1021

TX temperature

The measured temperature in the transmitter module in °C

RX temperature

The measured temperature in the receiver module in °C

Ethernet performance

Transmitted packets

The total number of transmitted Ethernet packets

Received packets

The total number of received Ethernet packets

Received packet errors

The total number of packets received with errors

Viewing a Summary of the Link Performance

To view the performance summary for a terminal:

Select Link or Local or Remote > Performance > Summary.

Click Reset Counters to reset the error counters to zero.

Page 29

In-Service Commissioning | 209

Aprisa XE User Manual

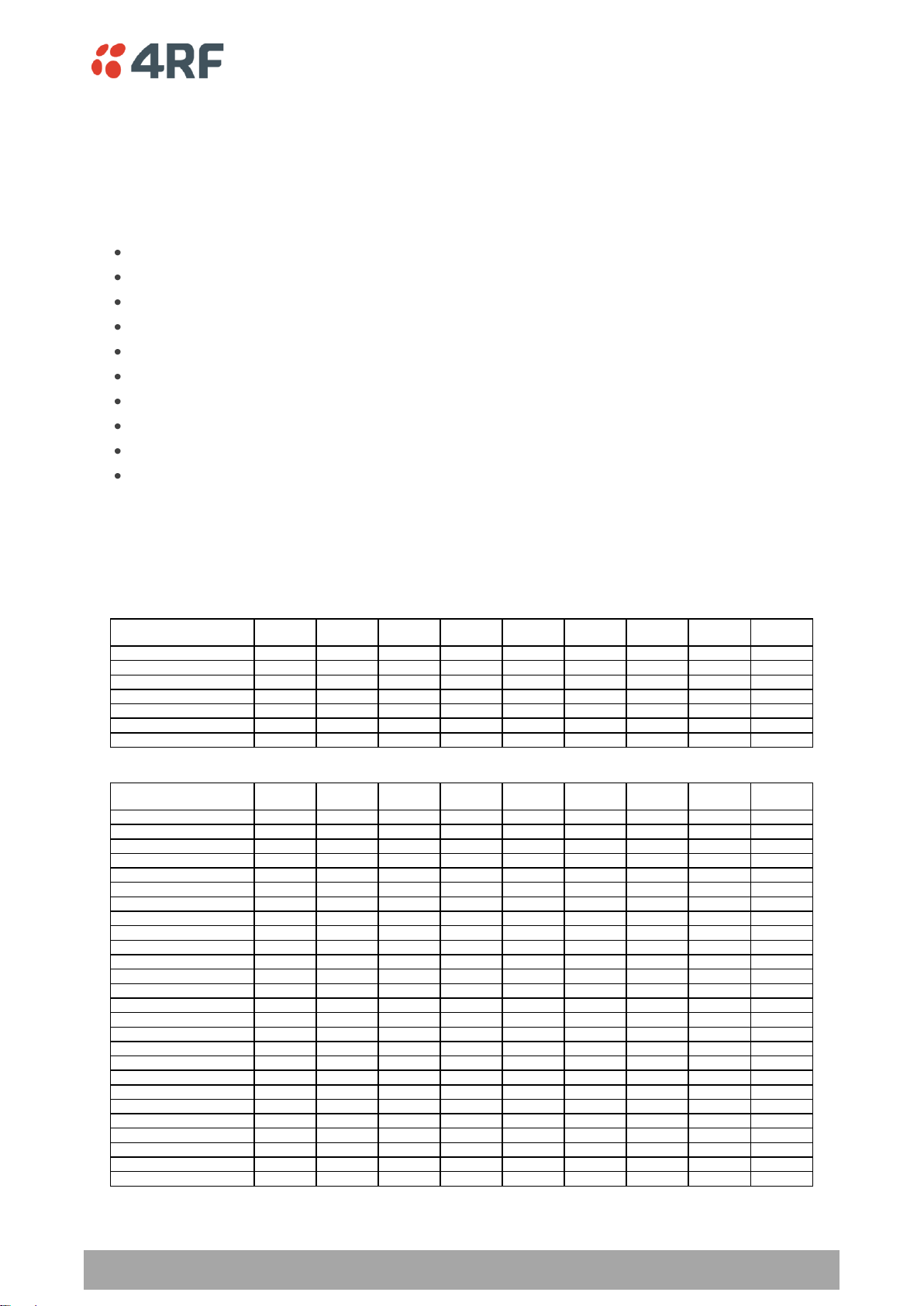

PREVIOUS WEEK

TIME

SNR min

(dB)

SNR avg

(dB)

SNR max

(dB)

RSSI min

(dBm)

RSSI avg

(dBm)

RSSI max

(dBm)

BER UCEs

Tx Temp

(deg C)

Mon Apr 6 09:44:50 2009 35.14 35.26 35.39 -54.00 -54.00 -54.00 3.40E-12 144 50

Mon Apr 6 10:44:50 2009 35.14 35.26 35.40 -54.00 -53.90 -53.90 3.39E-12 144 50

Mon Apr 6 11:44:50 2009 35.14 35.26 35.40 -54.00 -53.90 -53.90 3.38E-12 144 50

Mon Apr 6 12:44:51 2009 15.31 25.77 58.54 -114.00 -77.00 -54.00 1.58E-05 1045 50

Mon Apr 6 13:44:51 2009 22.52 22.75 22.89 -84.10 -83.70 -83.60 6.92E-06 9912 51

Mon Apr 6 14:44:51 2009 16.20 26.05 54.61 -87.10 -77.40 -60.20 9.67E-05 72125 52

…

PREVIOUS HOUR

TIME

SNR min

(dB)

SNR avg

(dB)

SNR max

(dB)

RSSI min

(dBm)

RSSI avg

(dBm)

RSSI max

(dBm)

BER UCEs

Tx Temp

(deg C)

Mon Apr 6 14:11:51 2009 22.52 28.38 22.75 -84.10 -78.19 -83.80 5.89E-06 22821 52

Mon Apr 6 14:12:51 2009 22.55 25.67 22.75 -84.10 -80.89 -83.80 5.86E-06 23369 52

Mon Apr 6 14:13:51 2009 22.50 23.52 22.75 -84.10 -83.07 -83.70 5.84E-06 23847 52

Mon Apr 6 14:14:51 2009 22.50 24.35 22.78 -84.10 -82.23 -83.70 5.81E-06 24338 52

Mon Apr 6 14:15:51 2009 22.54 22.73 22.77 -84.10 -83.86 -83.80 5.78E-06 24855 52

Mon Apr 6 14:16:51 2009 22.52 26.67 22.75 -84.10 -79.90 -83.80 5.75E-06 25374 52

Mon Apr 6 14:17:51 2009 22.48 30.19 22.79 -84.10 -76.38 -83.70 5.73E-06 25918 52

Mon Apr 6 14:18:51 2009 22.49 28.87 22.74 -84.10 -77.68 -83.80 5.71E-06 26473 52

Mon Apr 6 14:19:51 2009 22.48 30.65 22.74 -84.10 -75.94 -83.80 5.68E-06 27007 52

Mon Apr 6 14:20:51 2009 22.50 29.99 22.75 -84.00 -76.59 -83.80 5.66E-06 27561 52

Mon Apr 6 14:21:51 2009 22.61 29.78 22.76 -84.00 -76.82 -83.80 5.64E-06 28167 52

Mon Apr 6 14:22:51 2009 22.46 25.70 22.74 -84.10 -80.86 -83.90 5.62E-06 28717 52

Mon Apr 6 14:23:51 2009 22.46 26.96 22.75 -84.10 -79.61 -83.80 5.59E-06 29237 52

Mon Apr 6 14:24:51 2009 22.47 24.71 22.75 -84.10 -81.86 -83.80 5.57E-06 29776 52

Mon Apr 6 14:25:51 2009 22.48 30.19 22.73 -84.10 -76.36 -83.80 5.55E-06 30368 52

Mon Apr 6 14:26:51 2009 22.49 25.97 22.75 -84.20 -80.61 -83.80 5.53E-06 30942 52

Mon Apr 6 14:27:51 2009 16.20 22.94 54.61 -87.10 -83.76 -83.90 7.30E-06 71751 52

Mon Apr 6 14:28:51 2009 16.23 26.84 49.90 -87.00 -73.31 -60.30 6.67E-03 72125 52

Mon Apr 6 14:29:51 2009 35.10 40.60 35.24 -60.50 -54.96 -60.30 1.70E-03 72125 52

Mon Apr 6 14:30:51 2009 35.08 39.17 35.28 -60.50 -56.40 -60.30 9.13E-04 72125 52

Mon Apr 6 14:31:51 2009 35.07 36.63 35.26 -60.50 -58.95 -60.20 6.11E-04 72125 52

Mon Apr 6 14:32:51 2009 35.06 36.68 35.24 -60.60 -58.90 -60.30 4.52E-04 72125 52

Mon Apr 6 14:33:51 2009 35.06 35.34 35.25 -60.60 -60.24 -60.30 3.56E-04 72125 52

Mon Apr 6 14:34:51 2009 35.09 36.28 35.24 -60.50 -59.28 -60.30 2.92E-04 72125 52

Mon Apr 6 14:35:51 2009 35.07 42.56 35.28 -60.60 -53.03 -60.30 2.46E-04 72125 52

…

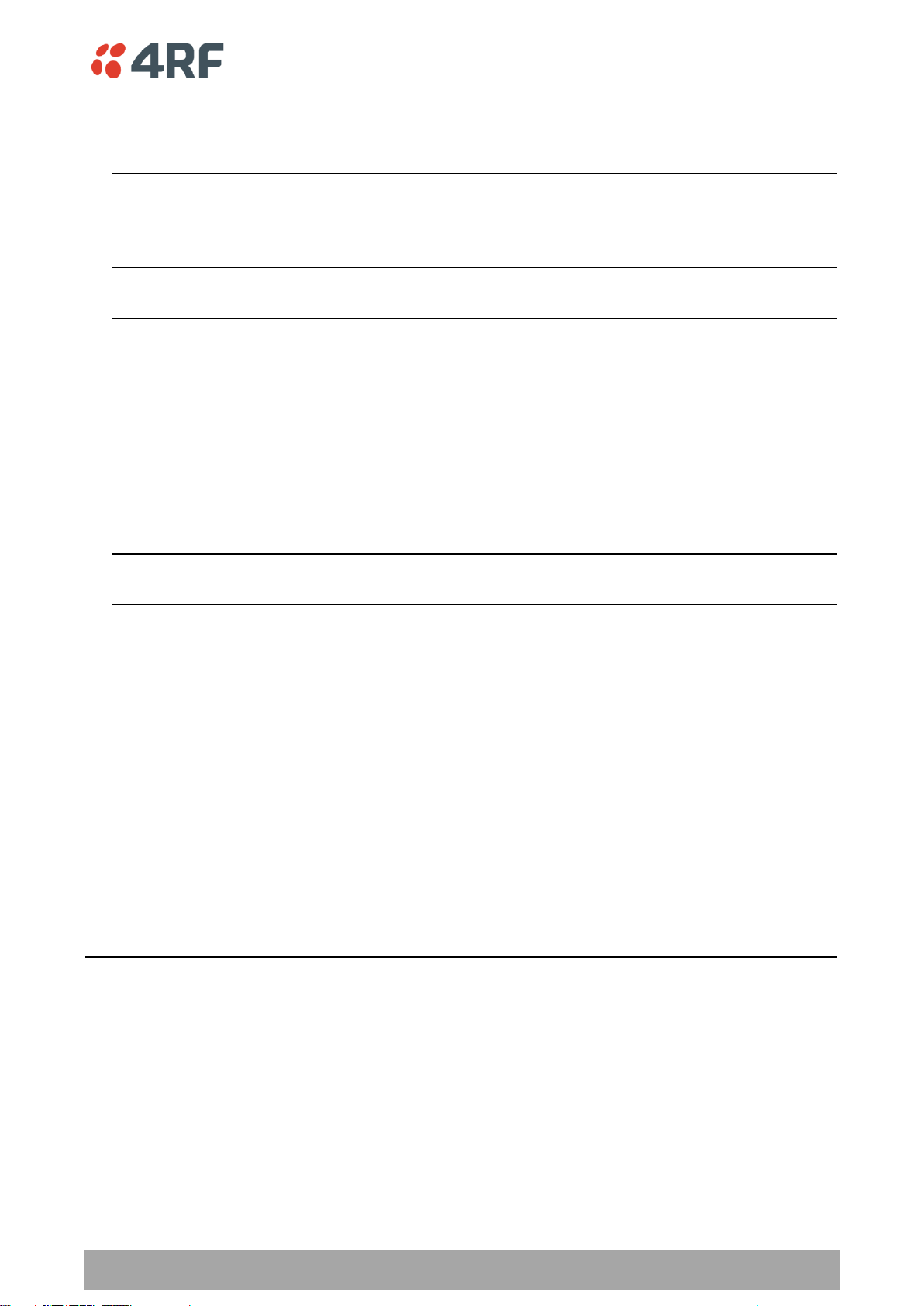

Saving the History of the Link Performance

Link performance history data is stored in a rolling buffer which can be saved as a *.cvs file (default

filename is savedPerformanceHistory.csv). The maximum history data buffer is 1 week of 1 hour records

and the last hour is displayed in minute records.

The parameters saved are:

Date / Time

SNR (minimum over period)

SNR (average over period)

SNR (maximum over period)

RSSI (minimum over period)

RSSI (average over period)

RSSI (maximum over period)

BER (value at end of period)

UCEs count (value at end of period)

Transmitter temperature (value at end of period)

To save the history of the link performance for a terminal:

Select Local > Performance > Save History.

Example of file (simulated fade data):

Page 30

210 | In-Service Commissioning

Aprisa XE User Manual

To save the alarm history from the Remote terminal, login to the Remote terminal and Select Local >

Alarms > Save History.

Page 31

In-Service Commissioning | 211

Aprisa XE User Manual

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

SNR avg (dB)

Aprisa XE Link Performance

-70.00

-60.00

-50.00

-40.00

-30.00

-20.00

-10.00

0.00

Mon Apr 6 14:11:51 2009

Mon Apr 6 14:12:51 2009

Mon Apr 6 14:13:51 2009

Mon Apr 6 14:14:51 2009

Mon Apr 6 14:15:51 2009

Mon Apr 6 14:16:51 2009

Mon Apr 6 14:17:51 2009

Mon Apr 6 14:18:51 2009

Mon Apr 6 14:19:51 2009

Mon Apr 6 14:20:51 2009

Mon Apr 6 14:21:51 2009

Mon Apr 6 14:22:51 2009

Mon Apr 6 14:23:51 2009

Mon Apr 6 14:24:51 2009

Mon Apr 6 14:25:51 2009

Mon Apr 6 14:26:51 2009

Mon Apr 6 14:27:51 2009

Mon Apr 6 14:28:51 2009

Mon Apr 6 14:29:51 2009

Mon Apr 6 14:30:51 2009

Mon Apr 6 14:31:51 2009

Mon Apr 6 14:32:51 2009

Mon Apr 6 14:33:51 2009

Mon Apr 6 14:34:51 2009

Mon Apr 6 14:35:51 2009

RSSI avg (dBm)

Aprisa XE Link Performance

To create an Excel chart of the link performance for a terminal:

1. Open the *.csv file with Excel.

2. Select the ‘Time’ column and the column you wish to graph e.g. ‘SNR avg (dB)’ or ‘RSSI avg (dBm)’

3. Select ‘Insert Chart’ from the Excel menu.

Graph of Date / Time vs the average SNR

Graph of Date / Time vs the average RSSI

To clear the history of the link performance for a terminal:

Select Link or Local or Remote > Performance > Clear History.

Page 32

Page 33

Maintenance | 213

Aprisa XE User Manual

Item

What to check or look for

Equipment shelter environment

Water leaks

Room temperature

Excessive vibration

Vermin damage

Terminal mounting

Firmly mounted

Antenna cable connections

Tight and dry

Antenna cable and its supports

Not loose or suffering from ultra-violet degradation

Antenna and its mounting hardware

Not loose, rusty or damaged

Safety earth

Connections tight

Cabling intact

DC system

Connections tight

Voltage in normal limits

Batteries (if installed)

Connections tight

Electrolyte levels normal

13. Maintenance

There are no user-serviceable components within the terminal.

All hardware maintenance must be completed by 4RF or an authorized service centre.

Do not attempt to carry out repairs to any boards or parts.

Return all faulty terminals to 4RF or an authorized service centre.

For more information on maintenance and training, please contact Customer Services.

CAUTION: Electro Static Discharge (ESD) can damage or destroy the sensitive electrical components in the

terminal.

Routine Maintenance

Every six or twelve months, for both ends of the link, you should record the RSSI and SNR levels as well as

checking the following:

Page 34

214 | Maintenance

Aprisa XE User Manual

Software status

Function

Standard Software

Release

The software status indicates ‘Standard Software Release’ if the

following system software files have not been changed since the last

TFTP Upgrade.

Kernel image file

Software image file

Firmware image files

Configuration files

Modified Software

Release

The software status indicates ‘Modified Software Release’ if the system

software files have been changed since the last TFTP Upgrade.

This could be caused by:

an image file which has been uploaded to the terminal since the

last TFTP upgrade which is not part of that upgrade.

an image file which was part of the last TFTP upgrade but was

subsequently deleted.

Terminal Upgrades

You can upgrade all software for both terminals remotely (through a management network), which

eliminates the need to physically visit either end of the link.

A terminal is upgraded by accessing a running TFTP server (see ‘TFTP Upgrade Process’ on page 221). All

the required files are uploaded from the TFTP server into the terminal and then activated following a

terminal reboot.

System files can be manually uploaded (see ‘Uploading System Files’ on page 226‘).

Inventory File

Software release 8.2.10 and all future software releases, contains an inventory file (similar to a manifest

file) which is used to validate the software files in the terminal.

To view the Software Status of the terminal:

Select Link, Local or Remote > Summary

Upgrade Prerequisites

To minimize disruption of link traffic and prevent your terminals from being rendered inoperative, please

follow the procedures described in this section together with any additional information or instructions

supplied with the upgrade package.

Before upgrading the terminal, ensure that you have saved the configuration file (see ‘Saving the

terminal's configuration’ on page 89) as well as the cross connection configuration (see ‘Saving cross

connection configurations’ on page 155).

The Remote terminal upgrade process will be faster if the bandwidth allocated to the management

ethernet capacity is maximized.

The terminal software must be identical at both ends of the link.

At the end of the terminal upgrade process, the versions of image files (kernel software, and firmware)

that were in use before the upgrade are still in the terminal. You can restore them, if required, by editing

the image tables and reactivating the old files (see ‘Changing the Status of an Image ’ on page 232).

IMPORTANT NOTE: Ensure you are logged into the Near end terminal as Admin before you start an

upgrade.

Page 35

Maintenance | 215

Aprisa XE User Manual

Software Upgrade Process

Unzip and save the following folders to your hard drive:

8.6.77 Software

tftpd32.exe

The following steps are required for the software upgrade process:

1. Identify the correct TFTP upgrade type (see ‘Identifying the Correct TFTP Upgrade Type’ on page

217).

2. If the terminals are operating software prior to 8.3.40:

Upload the Root File System (see ‘Uploading the Root File System’ on page 216)

Upload the Motherboard Images (see ‘Uploading the Motherboard Images’ on page 216).

Reboot the terminal.

3. Go through the steps of the TFTP upgrade process (see ‘TFTP Upgrade Process’ on page 221).

4. Upgrade for new FXO/FXS and modem images

5. Reboot the terminal.

6. Clear the Java and web browser caches (see ‘Step 7: Clear the Java and web browser caches’ on

page 223).

If the TFTP upload process fails, an ‘Upload Fail’ alarm is raised. If the TFTP upload process fails due to a

power failure, the alarm is raised upon power recovery.

Page 36

216 | Maintenance

Aprisa XE User Manual

Motherboard Type

Image Files Required

Rev C

C-fpga_E1-0-7-0.img (Motherboard 1

C-fpga_E2-0-5-3.img (Motherboard 2)

Rev D

C-fpga_E1-1-7-3.img (Motherboard 1

C-fpga_E2-1-5-4.img (Motherboard 2)

Uploading the Root File System

Note: Uploading of image files can only be performed to the local terminal i.e. not via the link to the

remote terminal.

1. Logon to the local terminal as admin.

2. Go to SuperVisor > Local > Maintenance > Upload > Software.

3. Browse to the 8.6.77 Software folder and select ‘C-CC-R-8_6_7.img’.

4. Click Upload and wait for the upload status to display Succeeded.

5. Activate the ‘C-CC-R-8_6_7.img’ with SuperVisor Local > Maintenance > Image Table (see ‘Changing

the Status of an Image File’ on page 232).

Uploading the Motherboard Images

The E1 and E2 motherboard images do not update as part of the TFTP upgrade.

Check if the correct motherboard images are loaded with SuperVisor Local > Maintenance > Image Table.

Example: Radio on V8.4.60 with a Rev C motherboard.

The Motherboard Firmware images for this software version are:

If the motherboard image files are not correct, upload the relevant image files.

Note: Uploading of image files can only be performed to the local terminal i.e. not via the link to the

remote terminal.

1. Logon to the local terminal as admin

2. Go to SuperVisor > Local > Maintenance > Upload > Firmware.

3. Browse to the 8.6.77 Software folder and select ‘C-fpga_Ex-x-x-x.img’.

4. Click Upload and wait for the upload status to display Succeeded.

5. Activate the ‘C-fpga_Ex-x-x-x.img’ with SuperVisor Local > Maintenance > Image Table (see ‘Changing

the Status of an Image File’ on page 232).

Page 37

Maintenance | 217

Aprisa XE User Manual

Identifying the Correct TFTP Upgrade Type

The correct TFTP upgrade type will depend on both the Bootloader Version and the Software Version

Type.

Aprisa XE terminals running the older bootloader software (bootloader version 0) have a limitation on the

number of software images that can be loaded simultaneously into a terminal.

Identifying the Bootloader Version

Determine which bootloader version your terminal is running by using the SuperVisor menu item

Maintenance > Support Summary and look for the ‘Bootloader Version’ number:

(1) If your terminal is running bootloader version 1 or greater, use the TFTP full upgrade process.

(2) If your terminal is running bootloader version 0 and running a software version prior to 7.0.6,

use the TFTP partial upgrade process.

(3) If your terminal is running bootloader version 0 and running a software version 7.0.6 or later,

use the TFTP standard upgrade process.

(4) HSD terminals cannot run with bootloader version 0.

Page 38

218 | Maintenance

Aprisa XE User Manual

8_6_77_E0

The E0 variant supports ETSI (Type 1) 1+0 and MHSB terminals with the same

variants as Aprisa XE software version 8.4.40.

8_6_77_E1

The E1 variant supports ETSI (Type 2) 1+0 and MHSB terminals with the same

variants as Aprisa XE software version 8.4.40 except for the 400 MHz 25 kHz

and 50 kHz which has been replaced with 900 MHz 25 kHz and 50 kHz.

8_6_77_E0h

The E0h variant supports ETSI (Type 1) Hitless Space Diversity (HSD)

terminals with the same variants as Aprisa XE software version 8.4.40.

8_6_77_E1h

The E1 variant supports ETSI (Type 2) Hitless Space Diversity (HSD) terminals

with the same variants as Aprisa XE software version 8.4.40 except for the

400 MHz 25 kHz and 50 kHz which has been replaced with 900 MHz 25 kHz

and 50 kHz.

8_6_77_F0

The F0 variant supports FCC part 90 1+0 and MHSB terminals.

8_6_77_F0h

The F0h variant supports FCC part 90 Hitless Space Diversity (HSD)

terminals.

8_6_77_F1

The F1 variant supports FCC part 101 1+0 and MHSB terminals.

8_6_77_F1h

The F1h variant supports FCC part 101 Hitless Space Diversity (HSD)

terminals.

Identifying the Software Version Type

There are six different software version types; ETSI type 1, ETSI type 1 HSD, ETSI type 2, ETSI type 2 HSD,

FCC Part 101 and FCC Part 90.

To determine which Software Version Type is currently installed on the terminal, take note of the

‘Software Version’ on SuperVisor Summary page. The last three characters indicate the Software Version

Type.

ETSI Compliance Body

FCC Compliance Body

Page 39

Maintenance | 219

Aprisa XE User Manual

Upgrade Version File

Upgrade Type

Software Version Type

8_6_77_E0a

Full TFTP upgrade

ETSI TYPE 1

8_6_77_E0

Standard TFTP upgrade

ETSI TYPE 1

8_6_77_E0h

Standard TFTP upgrade

ETSI TYPE 1 HSD

8_6_77_E0p

Partial TFTP upgrade

ETSI TYPE 1

8_6_77_E1a

Full TFTP upgrade

ETSI TYPE 2

8_6_77_E1

Standard TFTP upgrade

ETSI TYPE 2

8_6_77_E1h

Standard TFTP upgrade

ETSI TYPE 2 HSD

8_6_77_E1p

Partial TFTP upgrade

ETSI TYPE 2

8_6_77_F0a

Full TFTP upgrade

FCC Part 90

8_6_77_F0

Standard TFTP upgrade

FCC Part 90

8_6_77_F1a

Full TFTP upgrade

FCC Part 101

8_6_77_F1

Standard TFTP upgrade

FCC Part 101

Frequency Band

Synthesizer File(to be installed)

Comments

300, 400 MHz

XE_300_400_type_1_synth.cfg

BB synthesizer

300, 400 MHz

XE_300_400_type_2_synth.cfg

E3 synthesizer

300, 400 MHz

XE_300_400_type_3_synth.cfg

5 kHz sythesizer step

600, 700, 800, 900 MHz

XE_600_700_800_900_synth.cfg

1400 MHz

XE_1400_synth.cfg

1400 MHz

XE_1400TCVR_synth.cfg

New transceiver (introduced

April 2012)

1800 MHz

XE_1800_synth.cfg

2000, 2500 MHz

XE_2000_2500_synth.cfg

Upgrade Version Files

The following table defines the purpose of the upgrade version files:

Installing RF Synthesizer Configuration Files

If you are upgrading from a software version prior to 7_1_x, you will need to install new RF synthesizer

files, refer to ‘Configuration Files’ on page 226.

You can then upgrade the terminal using TFTP (see page 221).

Page 40

220 | Maintenance

Aprisa XE User Manual

TFTP Upgrade Process Types

TFTP partial upgrade process

Run the TFTP upgrade process by typing 8_6_77_E0p in the Upgrade Version field.

This will perform a partial upgrade which will delete unnecessary image files that might be taking up

space in the Image Table (which could prevent a standard upgrade succeeding).

Reboot the terminal.

Run a TFTP standard upgrade process on the terminal.

Reboot the terminal again.

TFTP standard upgrade process

This TFTP standard upgrade process excludes FPGA images for the newly introduced revisions of the

Modem, DFXO and DFXS cards.

Run the TFTP upgrade process by typing ‘8_6_77_E0’ in the Upgrade Version field.

If the standard upgrade fails, it may be necessary to make space for the new images by manually deleting

‘Inactive’ firmware image files.

To delete a firmware image file, select the SuperVisor menu item Maintenance > Image Table, select the

firmware image and click on Edit. Set the IMAGE DETAILS Command to ‘Delete’ and click ‘Apply’.

Reboot the terminal.

Additional TFTP upgrade options have been provided to load the new images separately. Run the TFTP

upgrade process using the file:

‘F1_8_6_7’ to load images for the newest DFXO and DFXS cards (rev D).

‘F2_8_6_7’ to load images for all revisions of DFXO and DFXS cards.

‘F3_8_6_7’ to load images for the newest Modem card (rev D).

Reboot the terminal again.

TFTP full upgrade process

Run the TFTP upgrade process for 1+0 and MHSB terminals by typing ‘8_6_77_E0a’ in the Upgrade Version

field.

Run the TFTP upgrade process for HSD terminals by typing ‘8_6_77_E0h’ in the Upgrade Version field.

Reboot the terminal.

Page 41

Maintenance | 221

Aprisa XE User Manual

TFTP Upgrade Process

To upgrade a terminal using the TFTP:

1. Run the TFTP server.

2. Login to the Near end terminal / local terminal (see ‘IP Addressing of Terminals’ on page 53).

3. Run the TFTP upgrade process on the Remote terminal.

4. Reboot the Remote terminal.

5. Run the TFTP upgrade process on the Local terminal.

6. Reboot the Local terminal.

7. Clear the Java and web browser caches.

Step 1: Run the TFTP server

1. Double-click tftpd32.exe (located in the TFTPD directory) from the Aprisa CD supplied with the

product. Leave the TFTPD32 application running until the end of the upgrade process.

2. Click Settings and make sure that both SNTP server and DHCP server are not selected (no tick), and

click OK.

3. Click Browse and navigate to the root directory on the Aprisa CD (for example, D:\) supplied with the

product, then click OK.

4. Note down the IP address of the TFTP server (shown in the Server Interfaces drop-down list in the

TFTPD32 window) as you will need it later.

Page 42

222 | Maintenance

Aprisa XE User Manual

Step 2: Log into the Local terminal

Use SuperVisor to log into the Near end terminal (now the Local terminal) (see ‘IP Addressing of

Terminals’ on page 53) with either 'modify' or 'admin' privileges.

Step 3: Run the TFTP upgrade process on the Remote terminal

1. Select Remote > Maintenance > Upload > TFTP Upgrade.

2. Enter the IP address of the TFTP server.

3. Enter the version number of the software that you are upgrading to as a three digit number separated

by underscores, for example, 8_6_77_E0 for ETSI variants.

4. Click Apply and check the TFTP server for download activity.

The Upgrade Result changes from 'Executing' to either 'Succeeded' or 'Failed'.

Note: This may take several minutes when upgrading the remote terminal.

If the upgrade has failed:

The TFTP server IP address may be set incorrectly

The 'Current Directory' on the TFTP server was not pointing to the location of the upload config file

e.g. 'Rel_8_6_77_E0.cfg' .

There may not be enough free space in the image table to write the file. Inactive images can be

deleted (and the terminal rebooted) to free up space for the new image (see ‘Changing the Status

of an Image File’ on page 232).

Step 4: Reboot the Remote terminal

Reboot the remote terminal before proceeding with the next step of the upgrade process (see ‘Rebooting

the Terminal’ on page 233).

1. Select Remote > Maintenance > Reboot and select [Hard Reboot]

Communications to SuperVisor remote page will fail until the remote terminal reboot has completed.

Page 43

Maintenance | 223

Aprisa XE User Manual

2. Select Java

Step 5: Run the TFTP upgrade process on the Local terminal.

1. Select Local > Maintenance > Upload > TFTP Upgrade.

2. Enter the IP address of the TFTP server (that you noted earlier)

3. Enter the version number of the software (that you are upgrading to) for example, 8_6_77_E0.

4. Click Apply and check the TFTP server for download activity.

The Upgrade Result changes from 'Executing' to either 'Succeeded' or 'Failed'.

Note: This may take several minutes when upgrading the remote terminal.

Step 6: Reboot the Local terminal

Reboot the local terminal before proceeding with the next step of the upgrade process (see ‘Rebooting

the Terminal’ on page 233).

1. Select Local > Maintenance > Reboot and select [Hard Reboot]

2. Log back into the Local terminal when the reboot has completed.

Step 7: Clear the Java and web browser caches

After upgrading the terminal you should clear the Java and web browser caches. The files stored in them

may cause the SuperVisor and Cross Connections applications to display incorrectly.

To clear the Java cache (Windows XP, Java 1.6):

1. Select Start > Control Panel.

3. Click the General tab.

4. In the ‘Temporary Internet Files’, click Settings

5. Click on ‘Delete Files’ (‘Applications and Applets’ and ‘Trace and Log Files’ both ticked) and OK to

confirm.

Page 44

224 | Maintenance

Aprisa XE User Manual

To clear your web browser cache (Mozilla Firefox 1.x and above):

1. Select Tools > Options.

2. Select Privacy and then click Cache.

3. Click Clear to clear the cache, and then click OK to confirm.

Page 45

Maintenance | 225

Aprisa XE User Manual

To clear your web browser cache (Internet Explorer 7.0 and above):

1. Select Tools > Internet Options.

2. On the General tab

3. In Browsing history, click Delete

4. In the ‘Temporary Internet Files’, click Delete Files and Yes to confirm.

Page 46

226 | Maintenance

Aprisa XE User Manual

XE_(frequency bands)_synth.cfg

e.g. XE_300_400_synth.cfg

modem_(version number).cfg

e.g. modem_8_3_1.cfg (ETSI variants)

C-crossconnect_(version number).cfg

e.g. C-crossconnect_8_6_7.cfg

Uploading System Files

System files e.g. configuration files, kernel image files, software image files and firmware image files can

be uploaded manually.

Note: You should only upgrade components that need changing. It is not always necessary, for instance, to

replace kernel or software files when upgrading a single firmware file. If interdependency exists between

file types, this will be made clear in the documentation that accompanied the update package.

Configuration Files

Configuration files (.cfg) are compressed archives containing a script to instruct the terminal on how to

handle the other files in the archive.

Uploading of configuration files can only be performed to the Local Terminal (not via the link to the

Remote Terminal).

RF synthesizer configuration files

The RF synthesizer configuration archive contains files that provide values for the transmitter and receiver

synthesizers to operate across the supported frequency bands.

Synthesizer configuration filenames have the following format:

Modem configuration files

The Modem configuration archive contains files that provide values for the Modem to operate at the

various supported channel sizes and modulation types.

Modem configuration filenames have the following format:

Cross-connect configuration files

The Cross-connect configuration archive contains the Cross Connections application program that can be

launched from within SuperVisor.

Cross-connect configuration filenames have the following format:

Page 47

Maintenance | 227

Aprisa XE User Manual

To upload a configuration file:

1. Select Local > Maintenance > Config Files > Upload Configuration

2. Browse to the location of the file required to be uploaded into the terminal *.cfg.

3. Click on Upload.

The normal response is Succeeded if the file has been loaded correctly.

A response of ‘Failed’ could be caused by:

Not enough temporary space in the filesystem to uncompress the archive and execute the script

A file or directory expected by the script not being present on the filesystem

4. Reboot the terminal using a ‘Hard Reboot’ (see ‘Rebooting the Terminal’ on page 233).

Page 48

228 | Maintenance

Aprisa XE User Manual

Image Files

Image files (.img) are loaded into the terminal and either contains code that is executed by the system

processor, or contain instructions to configure the various programmable logic elements. The image file

types that can be uploaded are:

Kernel image files

Software image files

Firmware image files

Note: The Bootloader image file C-CC-B-(version number).srec and Flash File System image file C-CC-F(version number).img can only be changed in the factory.

Uploading of image files can only be performed to the local terminal (not via the link to the remote

terminal).

To upload and activate an image file:

1. Upload the required image file.

If the Upload Status page show ‘executing’, then ‘writing to flash’, then ‘Succeeded’, then the file has

been written into the image table correctly.

If the Upload Status is ‘Failed’, there may not be enough free space in the image table to write the

file. Inactive images can be deleted (and the terminal rebooted) to free up space for the new image

(see ‘Changing the Status of an Image File’ on page 232).

2. Set the status of the image to ‘activate’ (see ‘Changing the Status of an Image ’ on page 232).

This actually sets the status to ‘Selected’ until after a terminal reboot.

3. Reboot the terminal using a ‘Hard Reboot’ (see ‘Rebooting the Terminal’ on page 233).

This activates the selected image. The image table status will now show ‘Active’.

The previous image file status will now show as ‘Inactive’.

Page 49

Maintenance | 229

Aprisa XE User Manual

C-CC-K-(version number).img

e.g. C-CC-K-6_0_0.img

C-CC-R-(version number).img

e.g. C-CC-R-8_6_7.img

Kernel image files

Kernel image files contain code that forms the basis of the microprocessor’s operating system. There can

only ever be two kernel image files in the image table, the active and the inactive.

Kernel filenames have the following format:

To upload a kernel image file;

1. Select Local > Maintenance > Upload > Kernel

2. Browse to the location of the file required to be uploaded into the terminal *.img.

3. Click on Upload.

4. Activate the image (see ‘Changing the Status of an Image File’ on page 232).

5. Reboot the terminal using a ‘Hard Reboot’ (see ‘Rebooting the Terminal’ on page 233).

Software image files

Software image files contain code that forms the basis of the terminal’s application and management

software (including the Web-based GUI). There can only ever be two software image files in the image

table, the active and the inactive.

Software image filenames have the following format:

To upload a software image file;

1. Select Local > Maintenance > Upload > Software

2. Browse to the location of the file required to be uploaded into the terminal *.img.

3. Click on Upload.

Software image files may take one or two minutes to upload as they can be quite large (≈ 2 Mbytes). The

size of this file has caused some Microsoft Internet Explorer proxy server setups to abort during the

software update process. To avoid this problem, either set the proxy file size limit to 'unlimited' or avoid

the use of the proxy altogether.

4. Activate the image (see ‘Changing the Status of an Image File’ on page 232).

5. Reboot the terminal using a ‘Hard Reboot’ (see ‘Rebooting the Terminal’ on page 233).

Page 50

230 | Maintenance

Aprisa XE User Manual

C-fpga_ff-x-y-z.img

e.g. C-fpga_E5-0-7-3.img

Function Number

Function

E1

Motherboard 1

E2

Motherboard 2

E5

QJET Interface Card

E7

Q4EM Interface Card

E8

DFXO Interface Card

E9

DFXS Interface Card

EA

Modem

EB

QV24 Interface Card

EC

HSS Interface Card

ED

PSC (component of HSD system)

EE

PIC (component of HSD system)

FA

HSD modem

FB

QV24 Sync Interface Card

Firmware image files

Firmware image files contain instructions to configure the various programmable logic elements in the

terminal. There can only ever be two firmware image files for the same HSC version in the image table,

the active and the inactive.

Firmware image filenames have the following format:

where ff indicates the function (motherboard, interface card, etc).

where x indicates the HSC (hardware software compatibility) version.

where y indicates the firmware major revision number

where z indicates the firmware minor revision number

To upload a firmware image file;

1. Select Local > Maintenance > Upload > Firmware

2. Browse to the location of the file required to be uploaded into the terminal *.img.

3. Click on Upload.

4. Activate the image (see ‘Changing the Status of an Image File’ on page 232).

5. Reboot the terminal using a ‘Hard Reboot’ (see ‘Rebooting the Terminal’ on page 233).

Page 51

Maintenance | 231

Aprisa XE User Manual

Heading

Function

Index

A reference number for the image file

Type

The image type ‘Kernel’, ‘Software’ or ‘Firmware’.

Status

The status of the image; 'Active', 'Inactive', ‘Selected’, ‘Current (de-

selected)’

Image Size

The image file size in bytes

Version

The image file name and version details

Viewing the Image Table

To view the image table:

1. Select Link or Local or Remote > Maintenance > Image Table.

The image table shows the following information:

Note: Configuration file details do not appear in the image table.

Page 52

232 | Maintenance

Aprisa XE User Manual

Status

Function

Active

The image is currently being used by the system.

Inactive

The image is not currently being used by the system and could be

deleted.

Selected

The image is not currently being used by the system but has been

activated and will become active following a terminal reboot.

Current (deselected)

The image is currently being used by the system but as another image

has been selected, it will become inactive following a terminal reboot.

Changing the Status of an Image File

To change the status of an image:

1. Select Link or Local or Remote > Maintenance > Image Table.

2. Select the image you wish to change and click Edit.

3. On the Image Details, select the status from the Command drop-down list and click Apply.

Page 53

Maintenance | 233

Aprisa XE User Manual

Reboot Type

Function

None

Does nothing.

Soft Reboot

Reboots the software but does not affect customer traffic.

Hard Reboot

Reboots the entire terminal and affects customer traffic.

This reboot is similar cycling the power off and on.

Reboot Command

Function

None

Does nothing

Reboot Now

Execute the selected reboot now

Timed Reboot

Set the Reboot Time field to execute the selected reboot at a later date

and time.

This feature can be used to schedule the resulting traffic outage for a

time that has least customer impact.

Cancel Reboot

Cancel a timed reboot.

Rebooting the Terminal

The local or remote terminals can be rebooted by SuperVisor.

You can specify a ‘Soft Reboot’ which reboots the terminal without affecting traffic or a ‘Hard Reboot’

which reboots the terminal (similar to power cycling the terminal).

You can specify an immediate reboot or setup a reboot to occur at a predetermined time.

To reboot the terminal:

1. Select Link or Local or Remote > Maintenance > Reboot.

2. Select the Reboot Type field:

3. Select the Reboot Command field:

4. Click Apply to execute the reboot or Reset to restore the previous configuration.

Page 54

234 | Maintenance

Aprisa XE User Manual

Support Summary

The support summary page lists key information about the terminal, for example, serial numbers,

software version, frequencies and so on.

To view the support summary:

Select Link or Local or Remote > Maintenance > Support Summary.

Page 55

Maintenance | 235

Aprisa XE User Manual

Installing Interface Cards

CAUTION: You must power down the terminal before removing or installing interface cards.

Interface cards are initially installed in the factory to the customers’ requirements however, during the

life of the product, additional interface cards may need to be installed.

Unless the terminals are protected (see ‘Protected terminals’ on page 197), installing new interface cards

involves a substantial interruption of traffic across the link. Staff performing this task must have the

appropriate level of education and experience; it should not be attempted by inexperienced personnel.

To install an interface card:

1. Switch off the power to the terminal.

2. Prepare the terminal for new interface cards (see ‘Preparing the Terminal for New Interface Cards’ on

page 236).

3. Install the interface card (see ‘Installing an Interface Card’ on page 238).

4. Power up the terminal.

5. Configure the slot (see ‘Configuring a Slot’ on page 240).

A slot can be configured before installing a new interface card, or after the interface card is installed

and the terminal power cycled.

6. Configure the cross connections. (see ‘Configuring the traffic cross connections’ on page 158)

Page 56

236 | Maintenance

Aprisa XE User Manual

Preparing the Terminal for New Interface Cards

To prepare the terminal for a new interface card:

1. Remove the terminal from service by first switching off the terminal power. For an AC powered